Weight-optimized stiffener and sealing structure for direct liquid cooling module

A reinforcement and weight technology, applied in the direction of cooling/ventilation/heating transformation, electrical components, semiconductor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

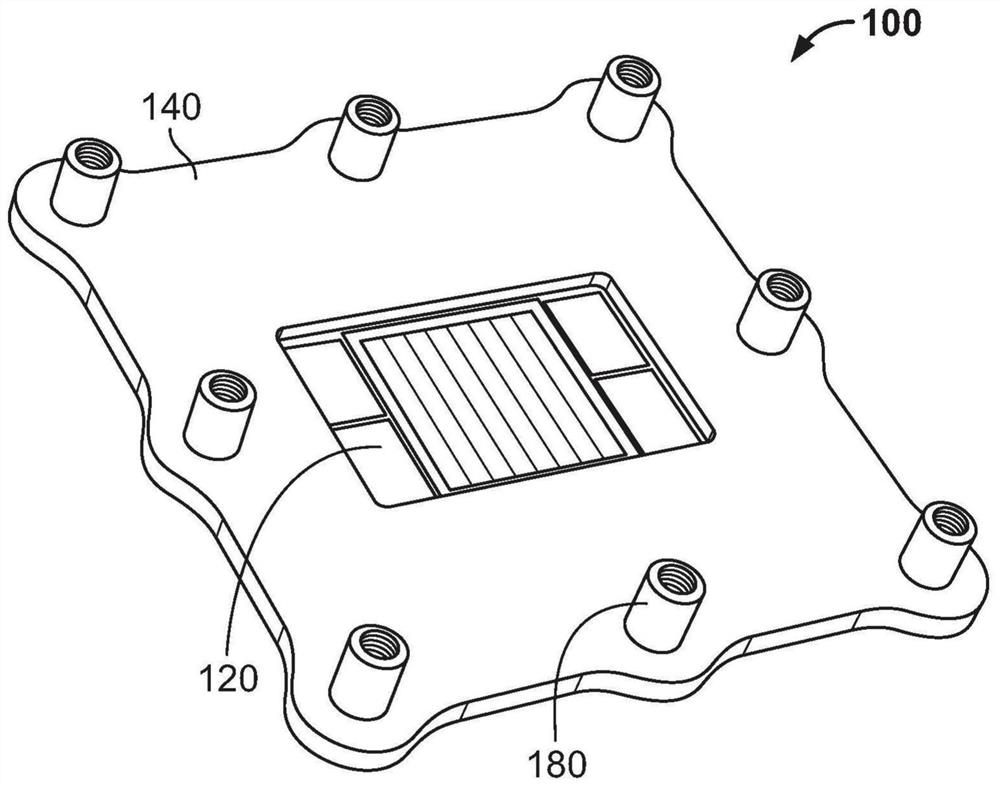

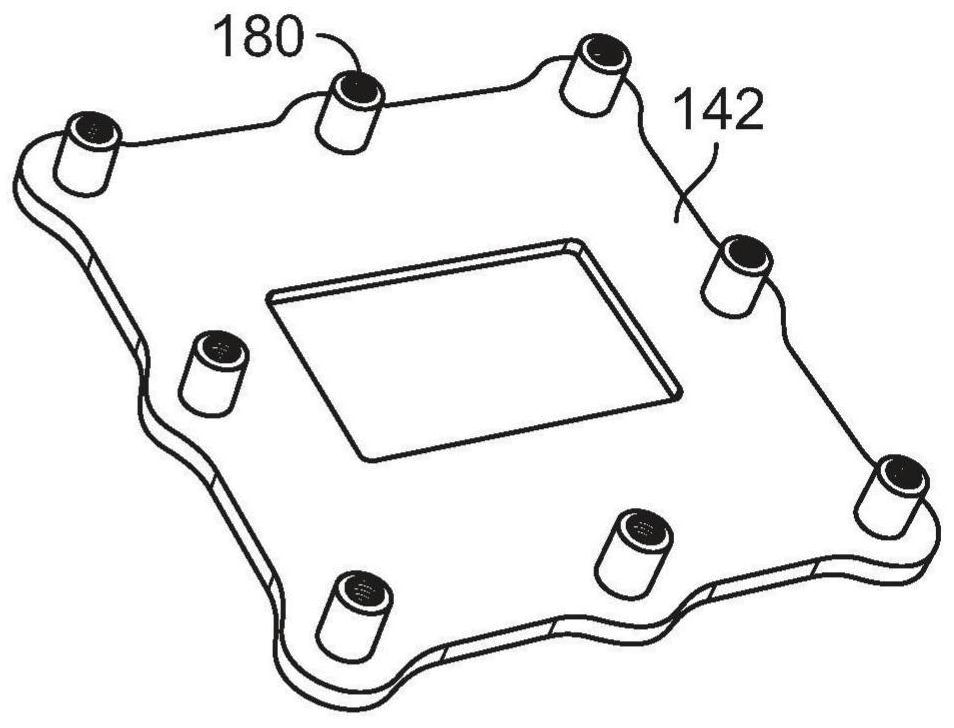

[0023] figure 1 is a perspective view of a packaged subassembly 100 of a semiconductor device including a substrate 1200 bonded to a stiffener 140 with fasteners or threaded hardware 18 mounted to the stiffener.

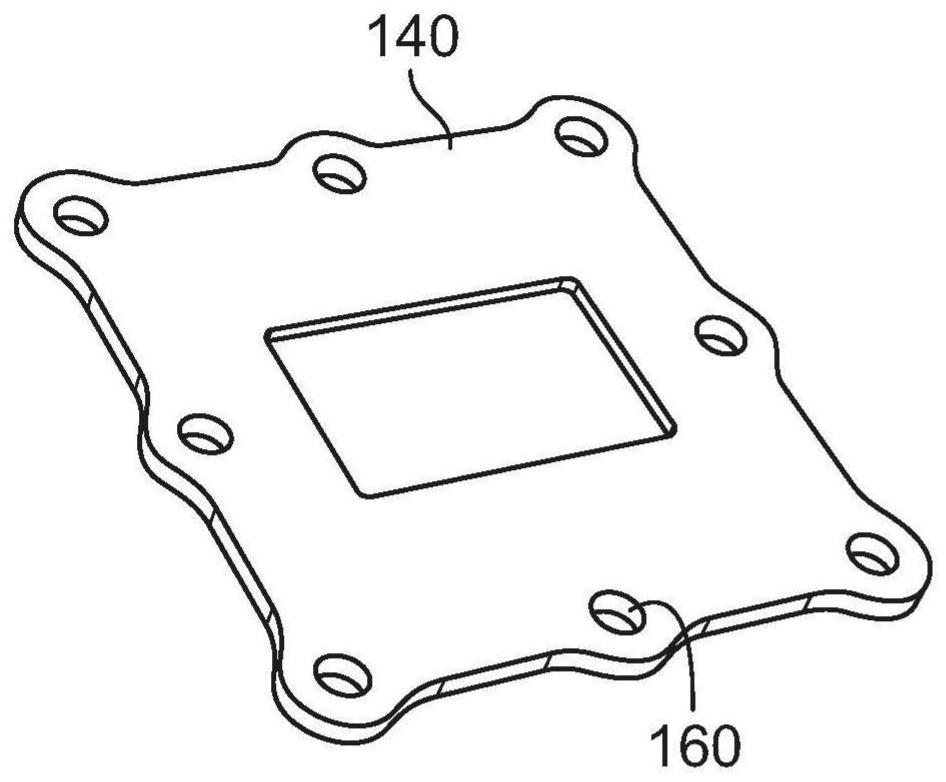

[0024] The stiffener 140 has a top surface, a bottom surface, and a hole passing through the top surface and the bottom surface. The holes may be generally centered relative to the outer perimeter of the stiffener 140, although in other examples the location of the holes may be adjusted. For example, the size, shape, and location of the holes may be tailored based on the circuitry that the underlying substrate 120 is to expose through the holes.

[0025] Substrate 120 may be coupled to the bottom surface of the reinforcement, such as by adhesive or other bonding technique. A portion of the reinforcement 140 may cover a portion of the substrate 120 when the substrate is coupled to the bottom surface of the reinforcement. For example, the substrate may include circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com