Patents

Literature

64 results about "Direct liquid cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

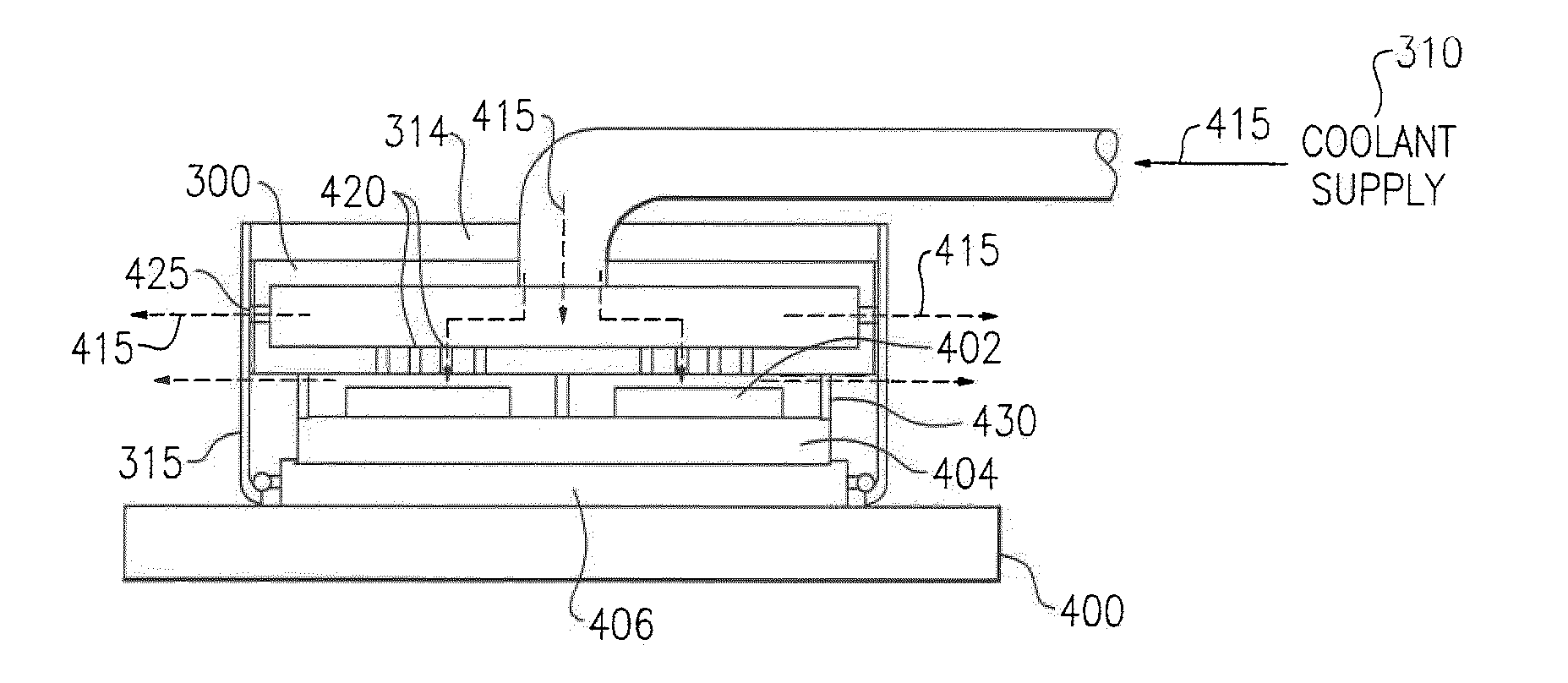

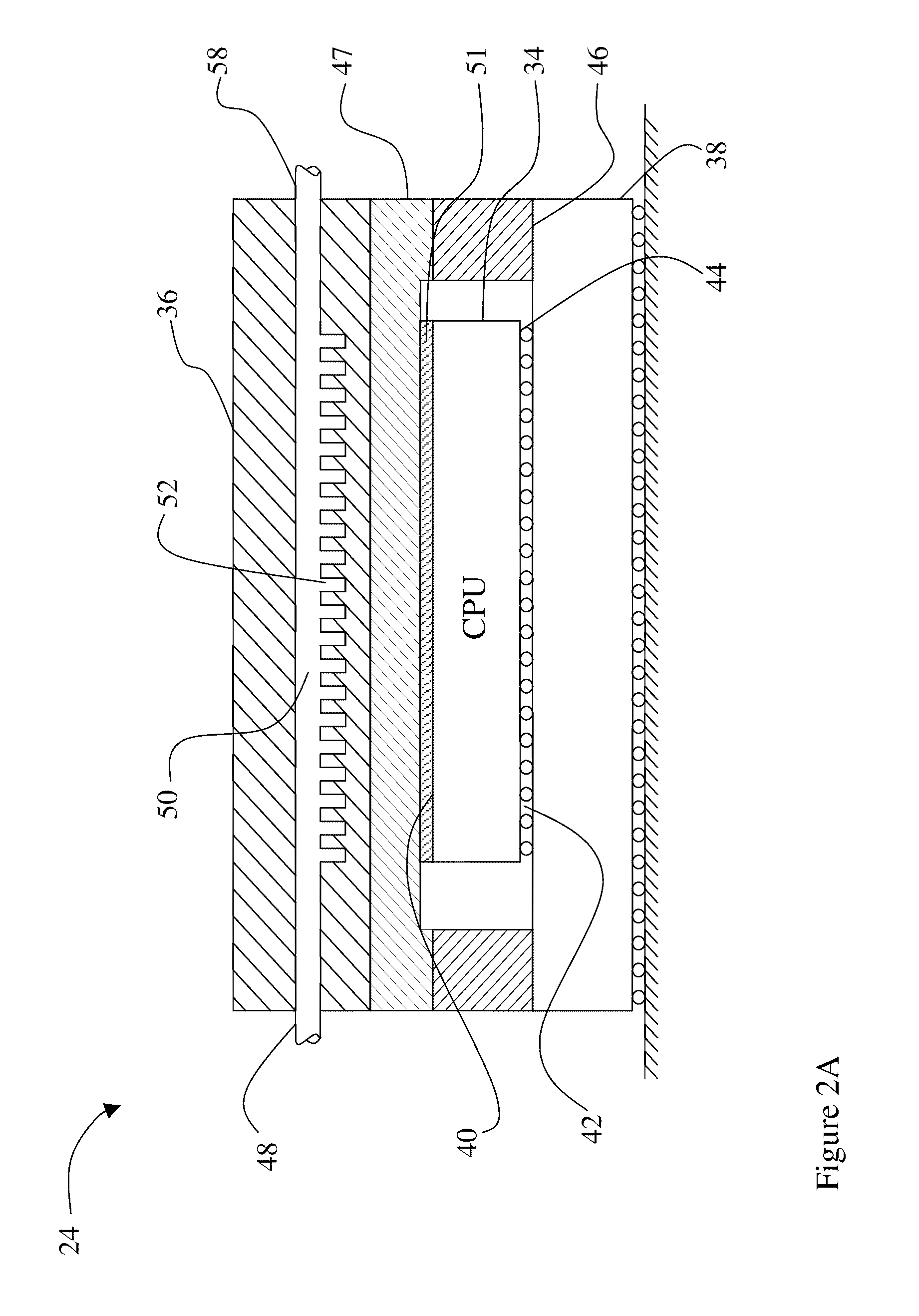

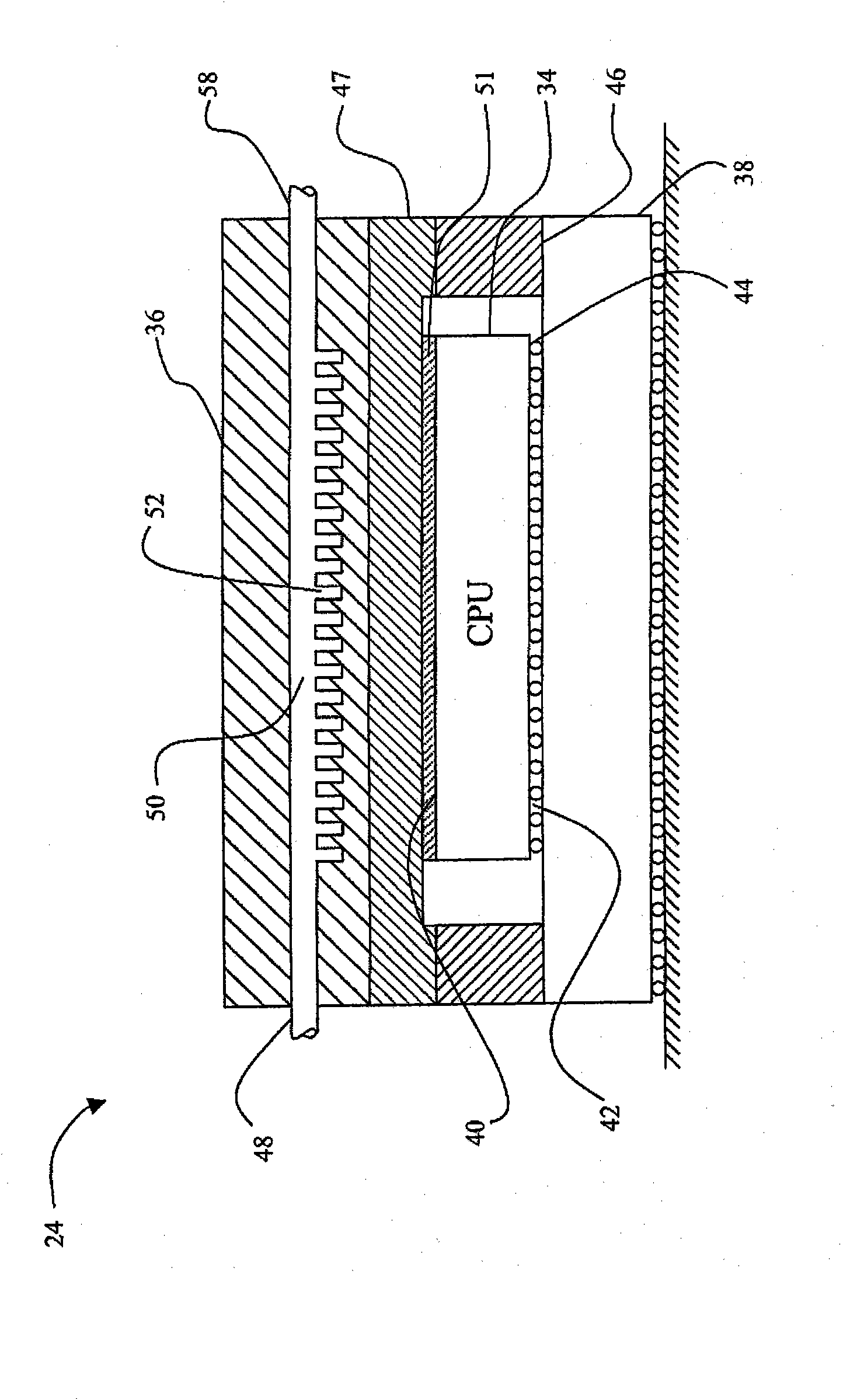

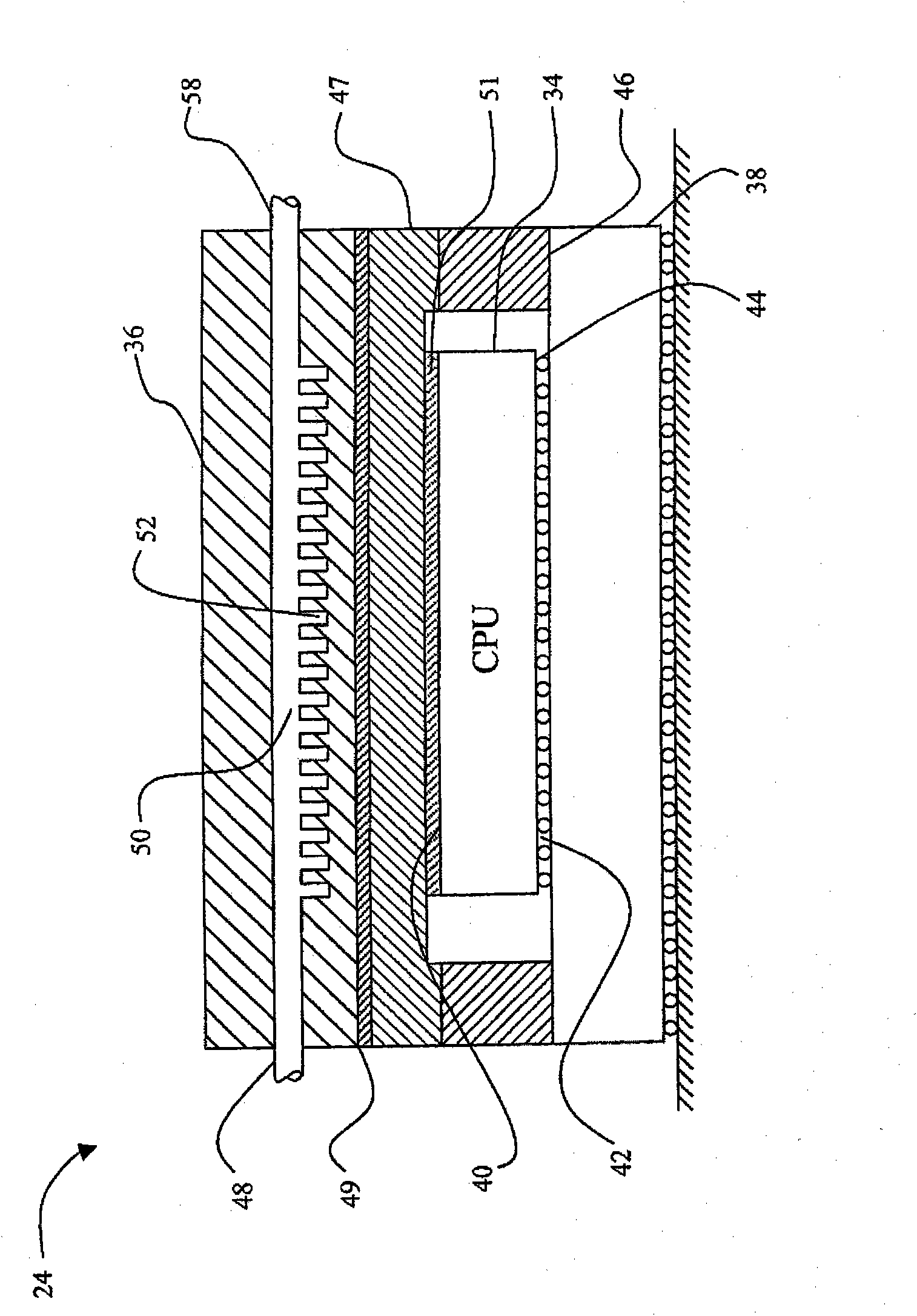

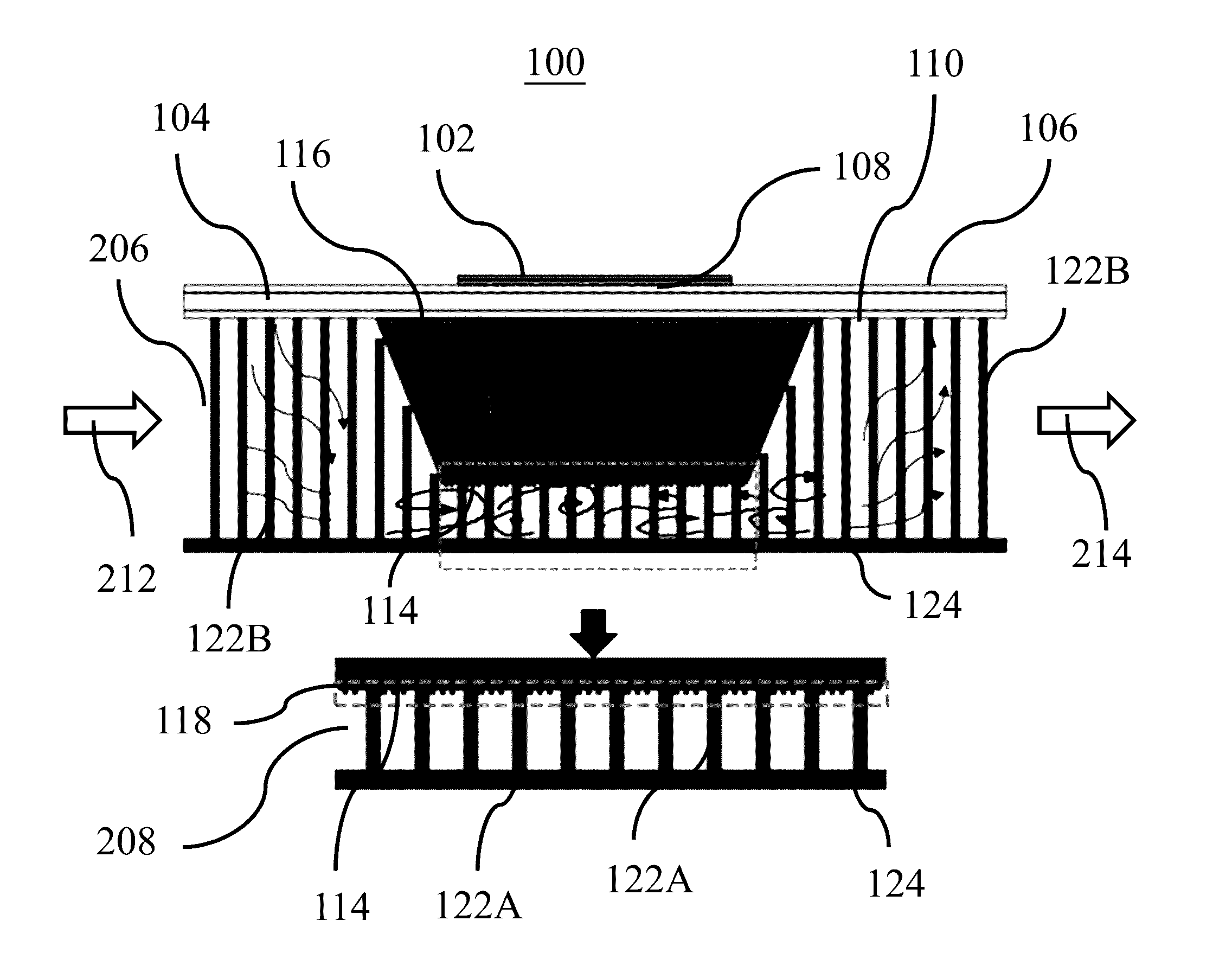

Open flow cold plate for liquid cooled electronic packages

ActiveUS7916483B2Digital data processing detailsSemiconductor/solid-state device detailsCoolant flowDirect liquid cooling

A method and associated assembly is provided for cooling of a computing embodiment having electronic components. The heat generating components are disposed in the vicinity of at least one cold plate providing direct liquid cooling. Coolant is provided to the cold plate which will eventually exit it through one or more ports or orifices placed on the sides or both side and bottom of the cold plate. The placement, size and number of port(s) or orifice(s) can be selectively adjusted to control amount of coolant flow. Effluent flow from the cold plate flows over the remaining immersion cooled components and then exits the liquid tight enclosure which houses the electronic components.

Owner:LENOVO GLOBAL TECH INT LTD

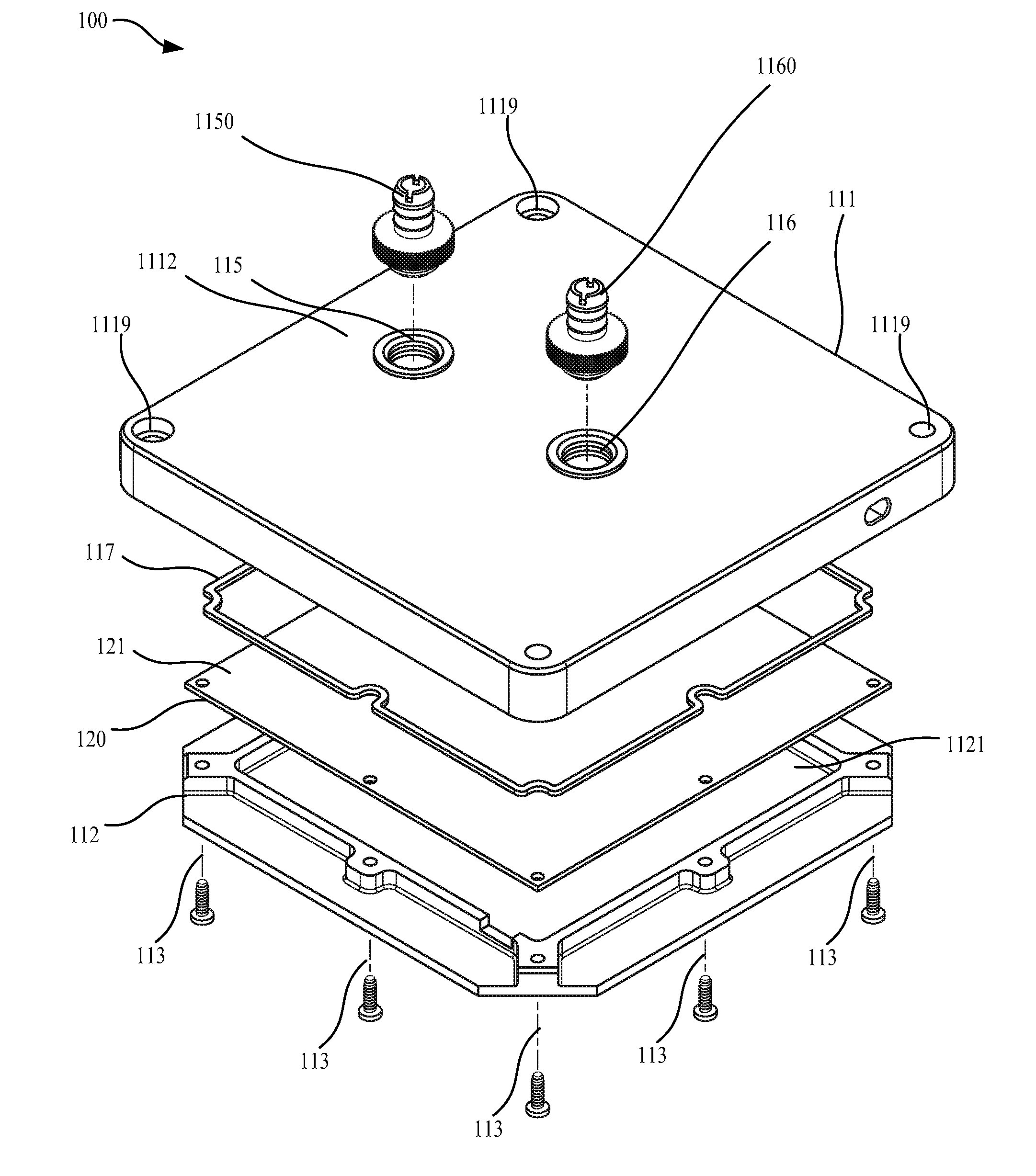

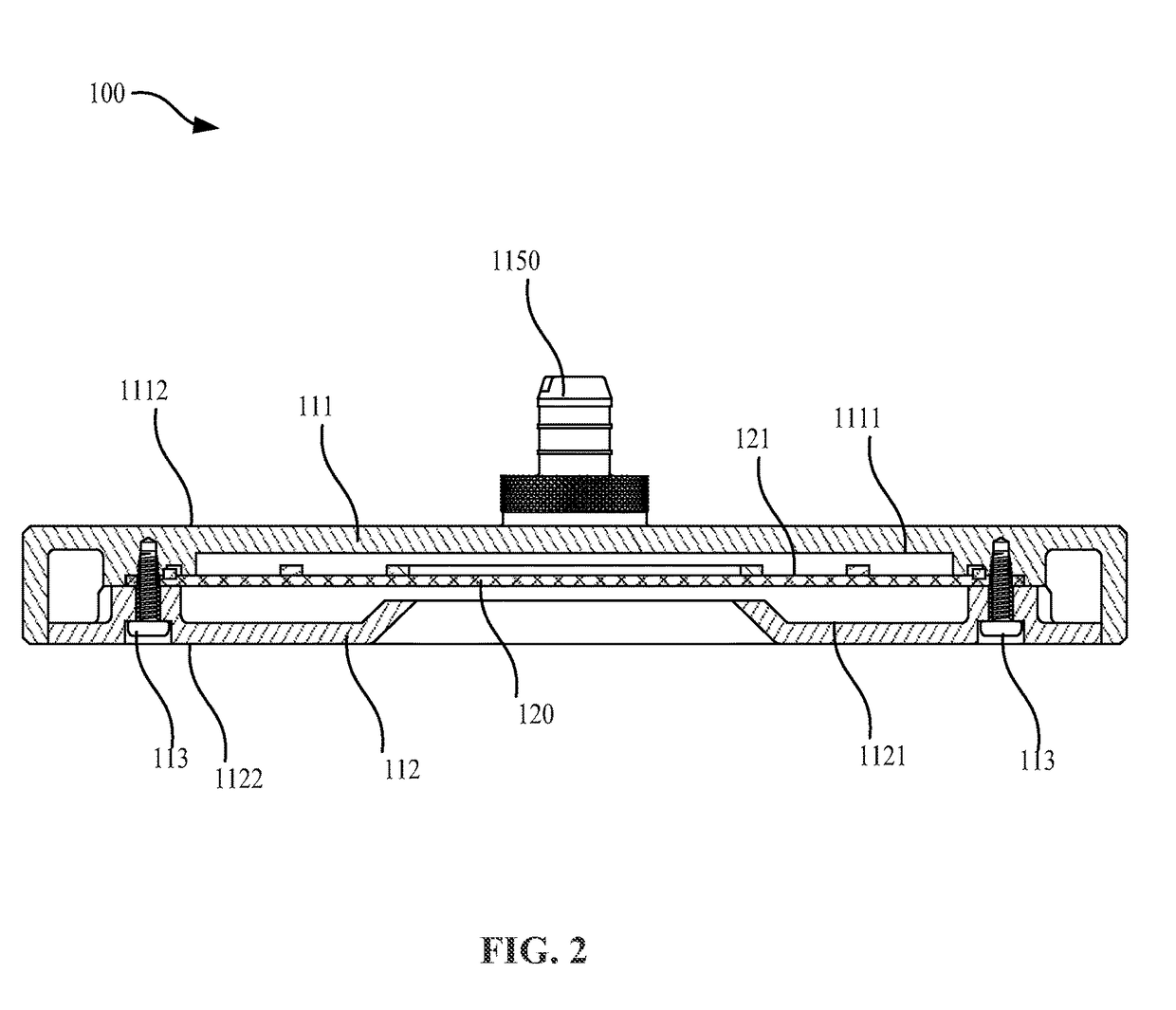

Liquid Cooled Metal Core Printed Circuit Board

ActiveUS20160081178A1Minimize thermal bottleneckReduce in quantityPrinted circuit aspectsPrinted circuit manufactureElectronic systemsNuclear engineering

The present disclosure further contemplates a system and method that cools metal core printed circuit boards by circulating a liquid coolant so that it contacts the base metal of the metal core printed circuit board. In one example the present disclosure contemplates a direct liquid cooled MCPCB system that may include a liquid cavity creating component coupled to the base plate of a MCPCB allowing a liquid coolant to come into contact with the base plate of the MCPCB for cooling of the MCPCB. The direct liquid cooled MCPCB system may minimize thermal bottlenecks between the electrical components and the cooling fluid while reducing the number of components required in previous liquid cooled electronics systems.

Owner:DONOFRIO NICHOLAS MICHAEL

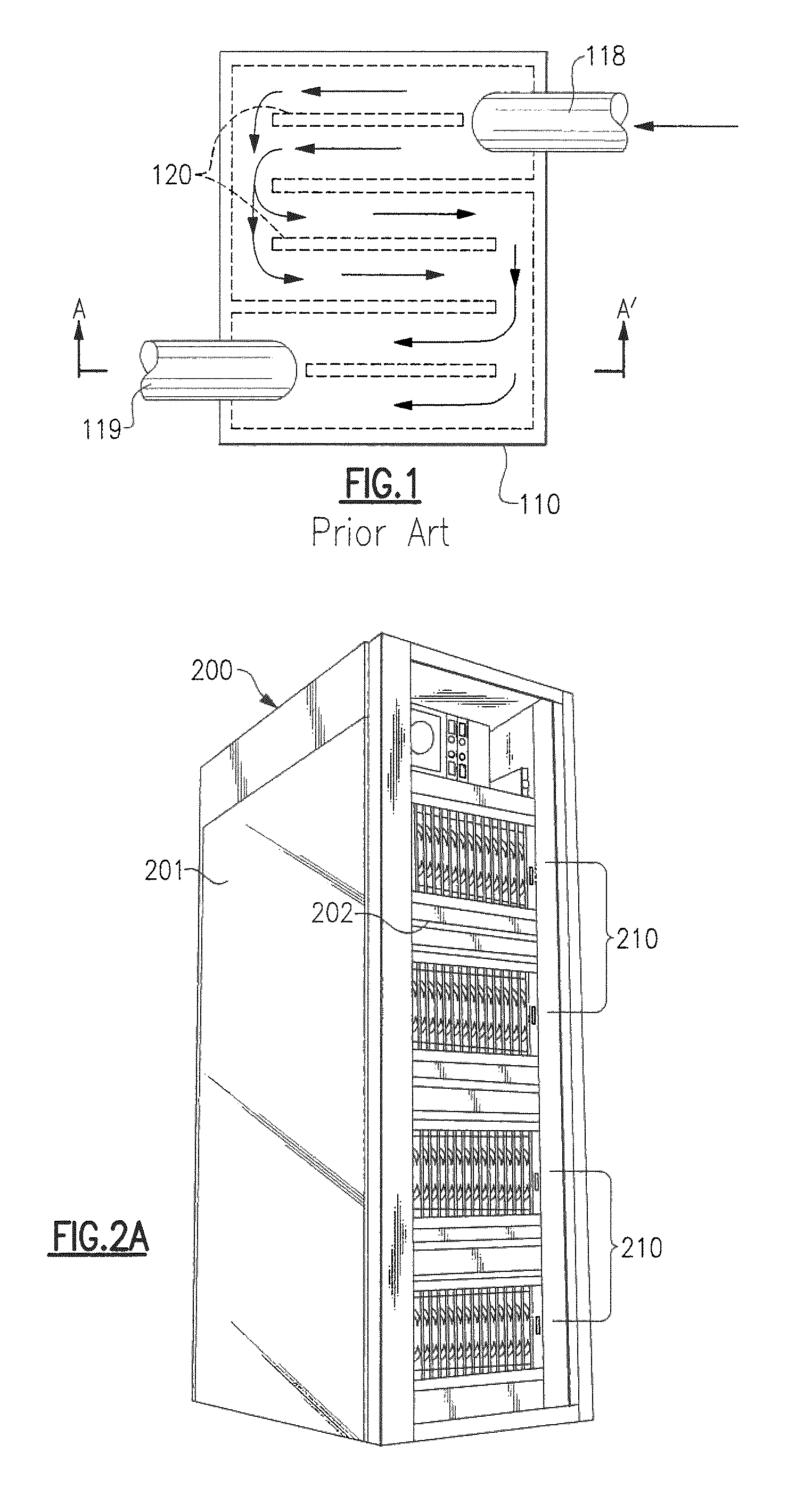

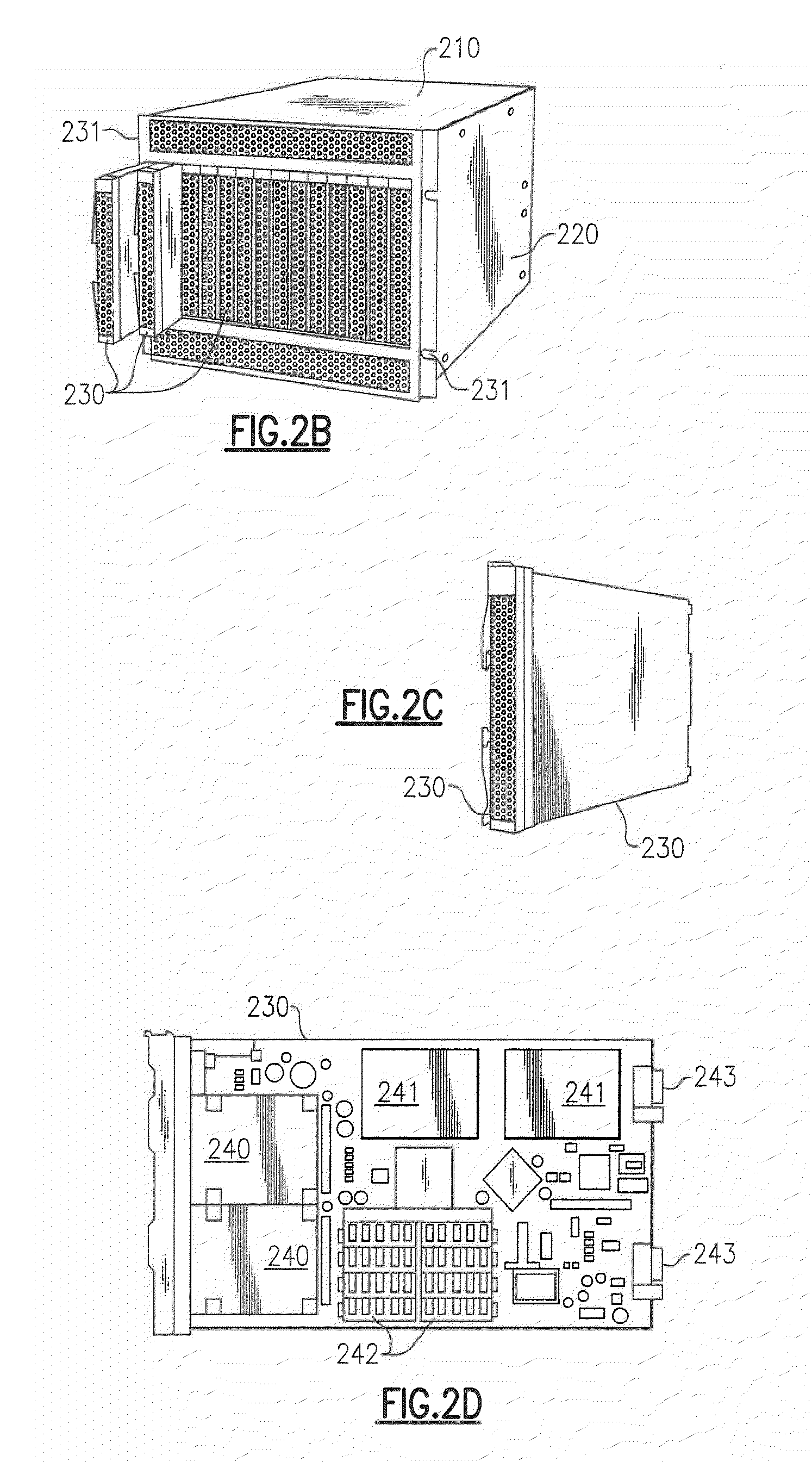

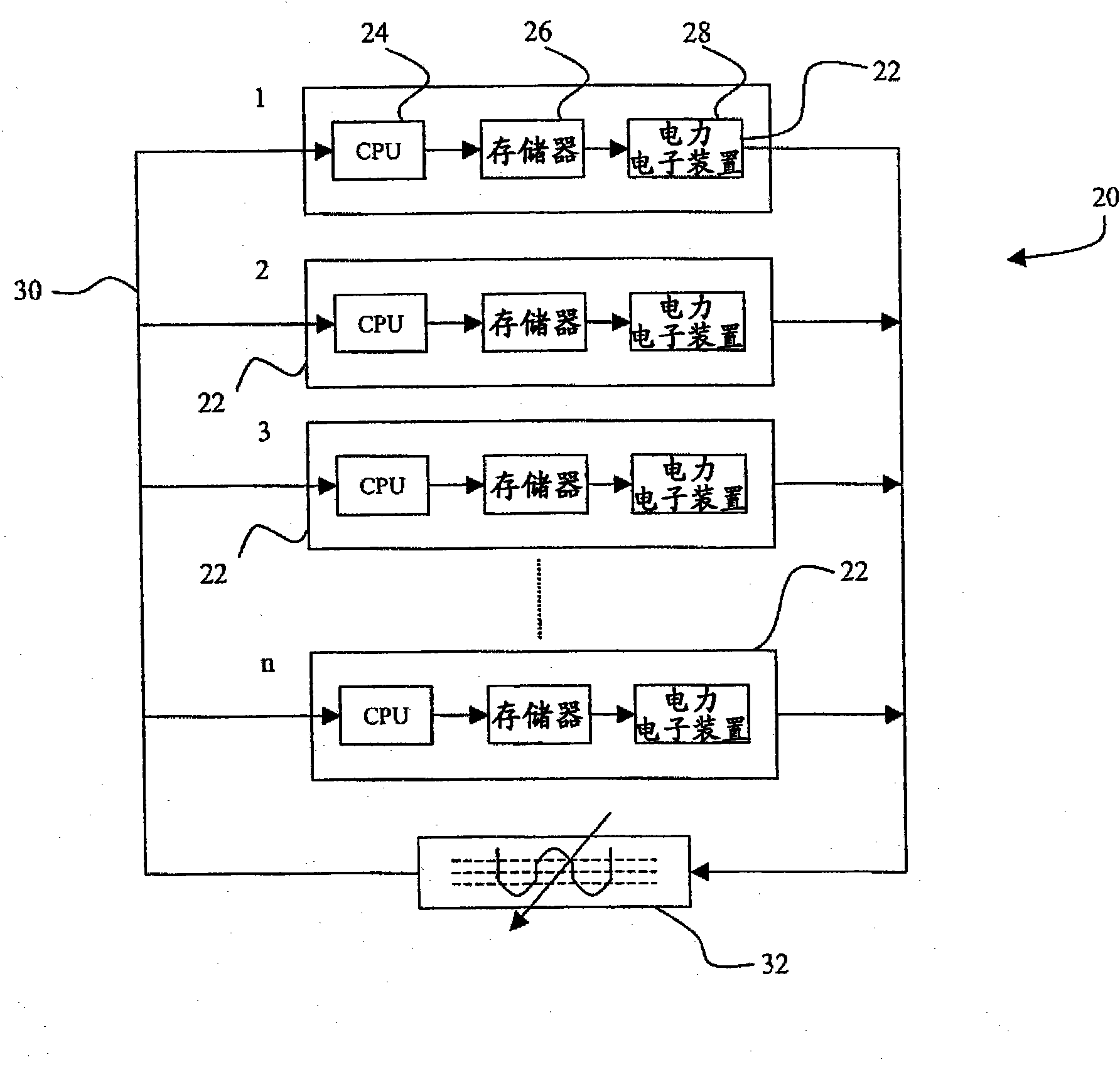

Variable flow computer cooling system for a data center and method of operation

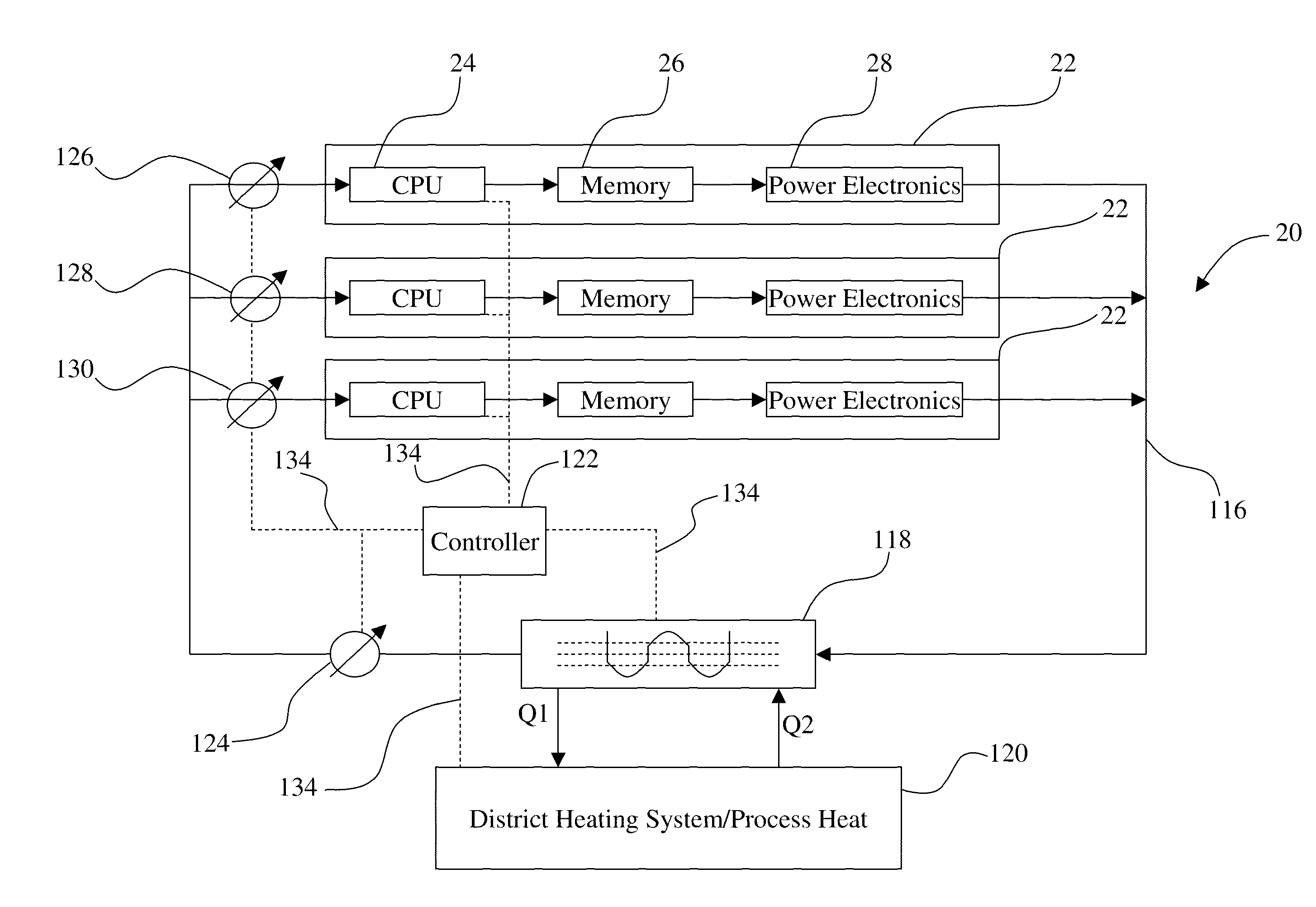

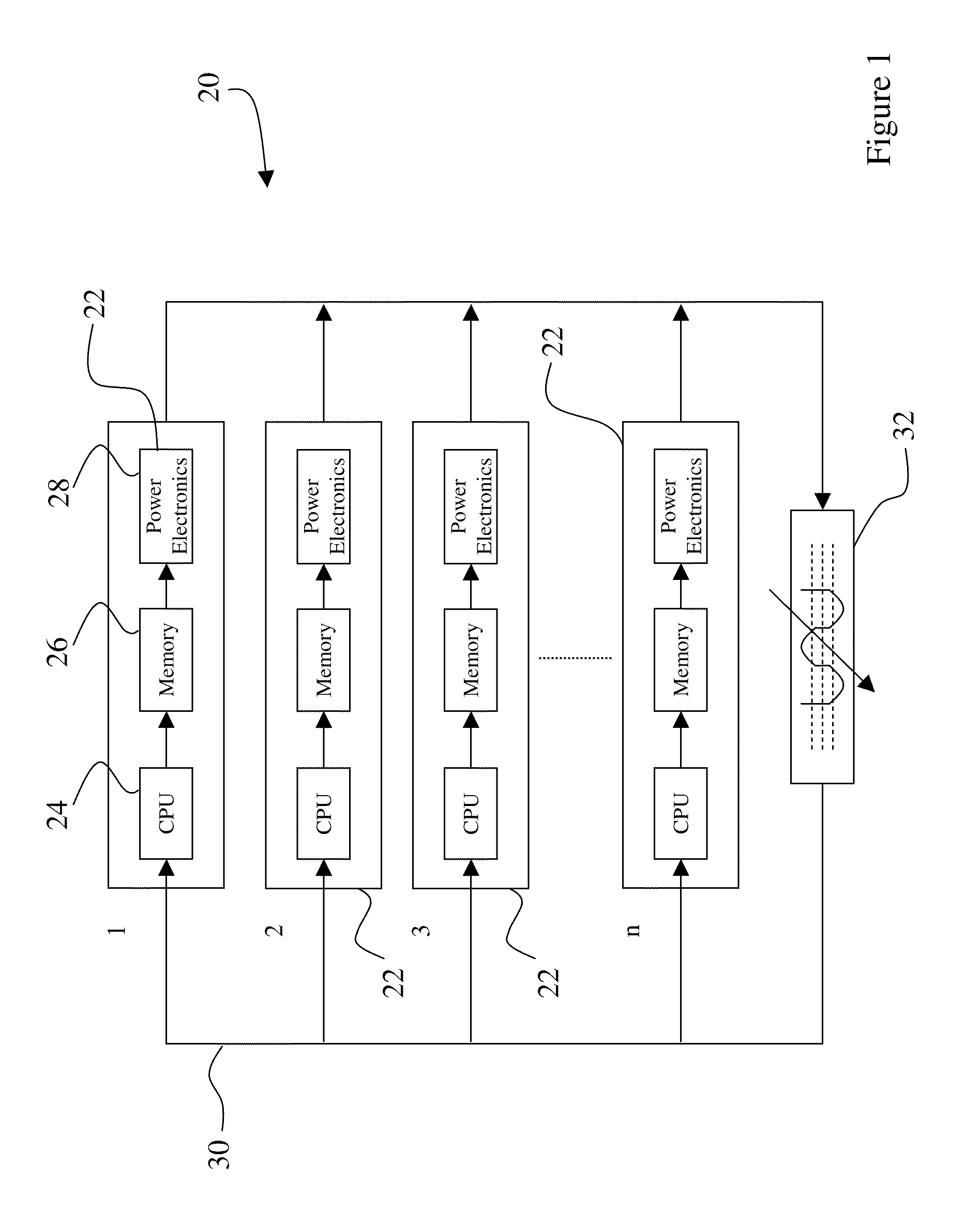

Disclosed herein is a data center having a plurality of liquid cooled computer systems. The computer systems each include a processor coupled with a cold plate that allows direct liquid cooling of the processor. The cold plate is further arranged to provide adapted flow of coolant to different portions of the processor whereby higher temperature regions receive a larger flow rate of coolant. The flow is variably adjusted to reflect different levels of activity. By maximizing the coolant temperature exiting the computer systems, the system may utilize the free cooling temperature of the ambient air and eliminate the need for a chiller. A data center is further provided that is coupled with a district heating system and heat is extracted from the computer systems is used to offset carbon emissions and reduce the total cost of ownership of the data center.

Owner:GLOBALFOUNDRIES US INC

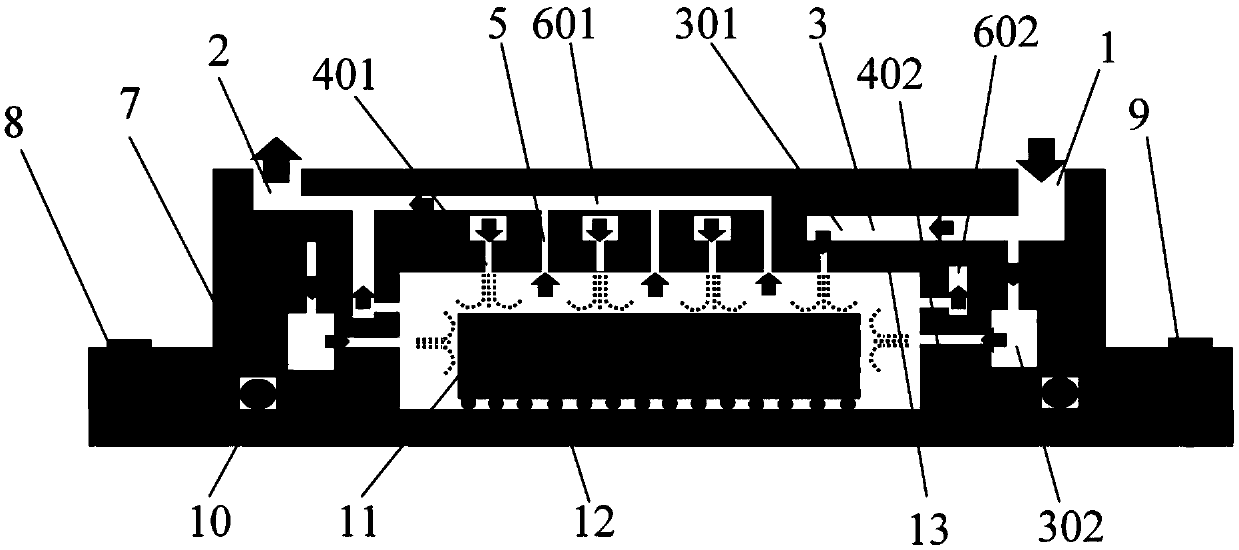

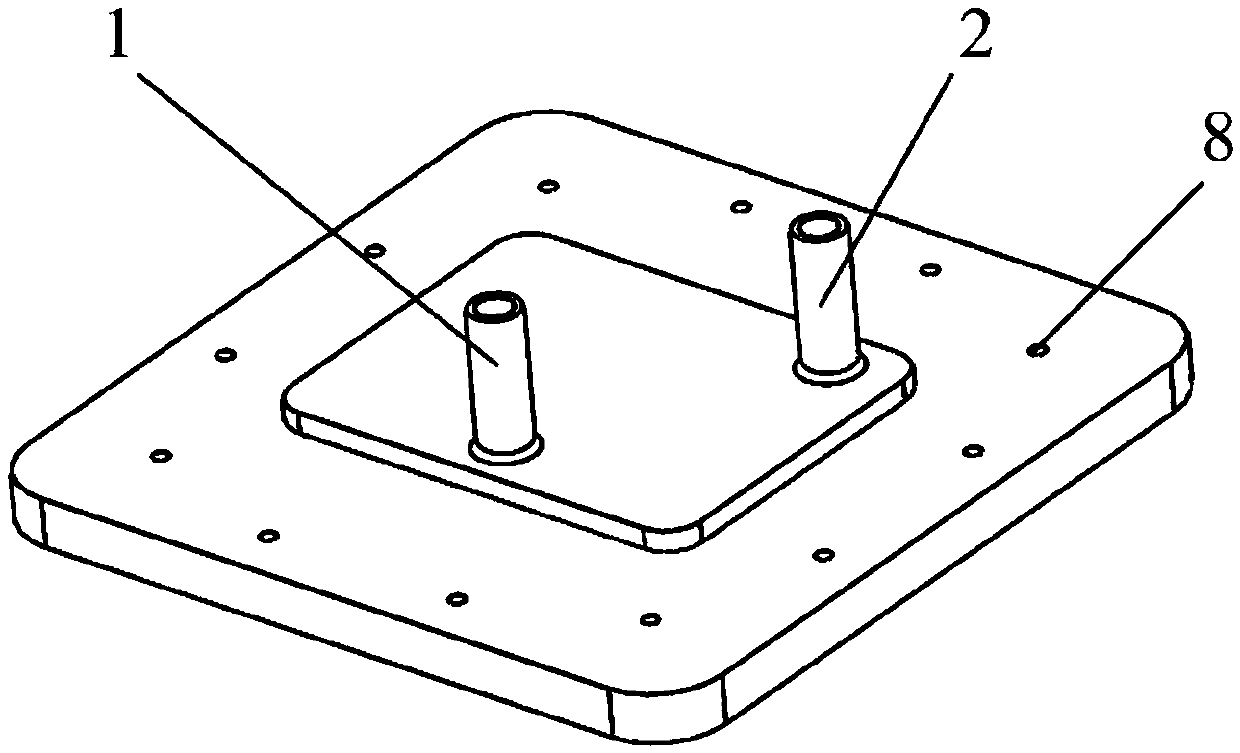

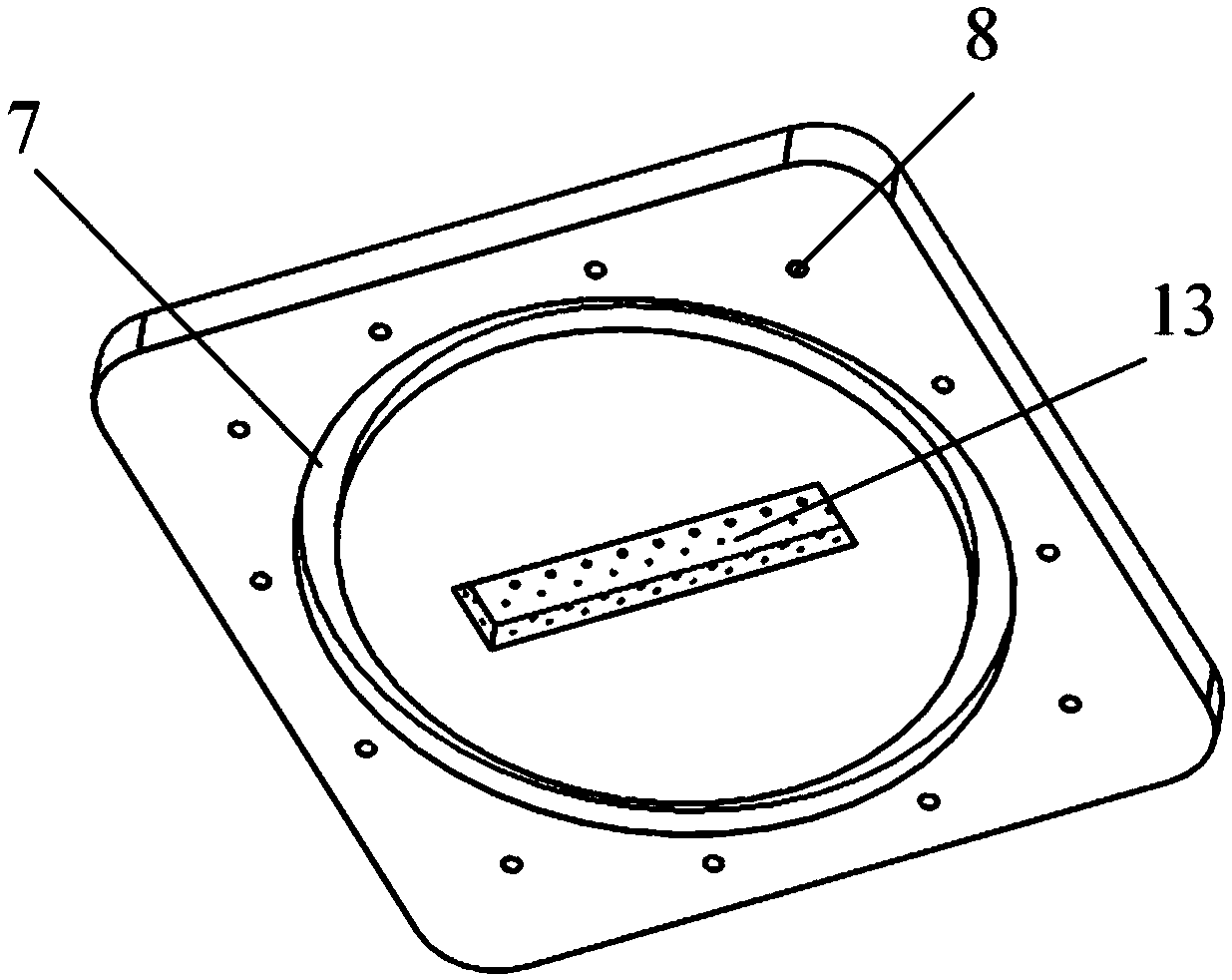

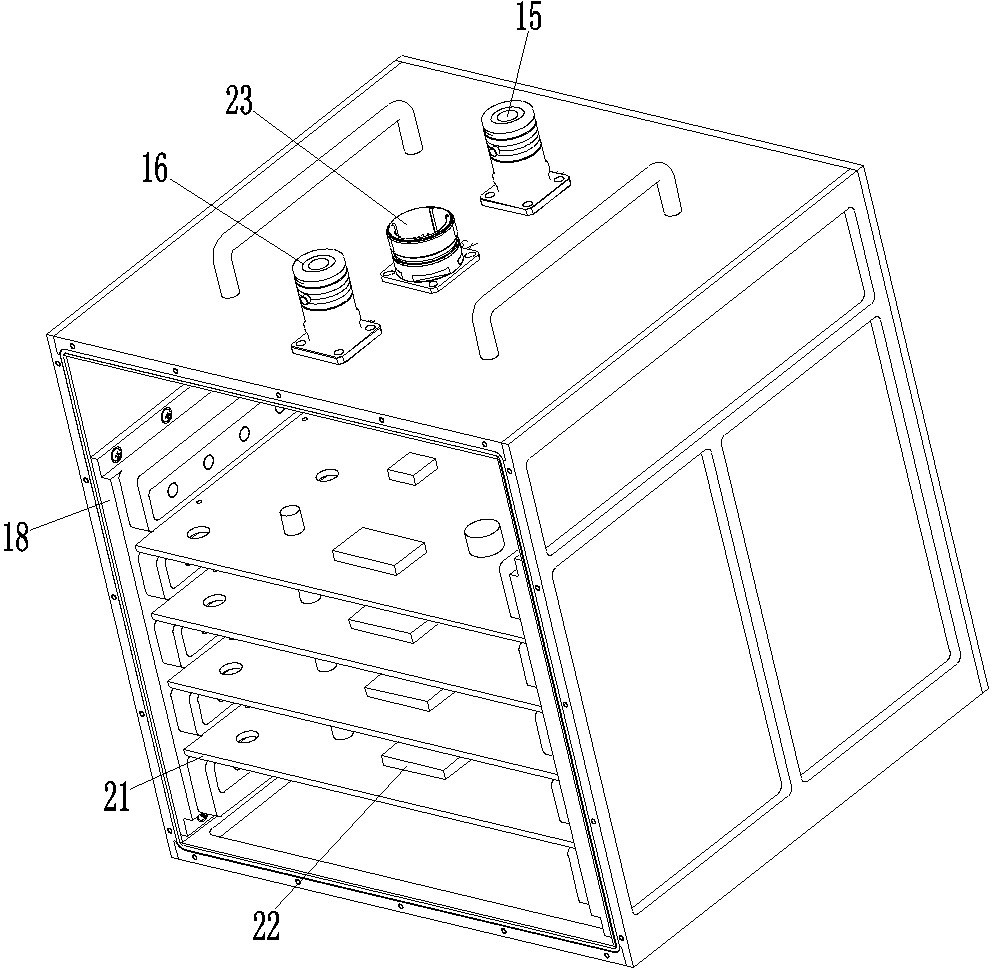

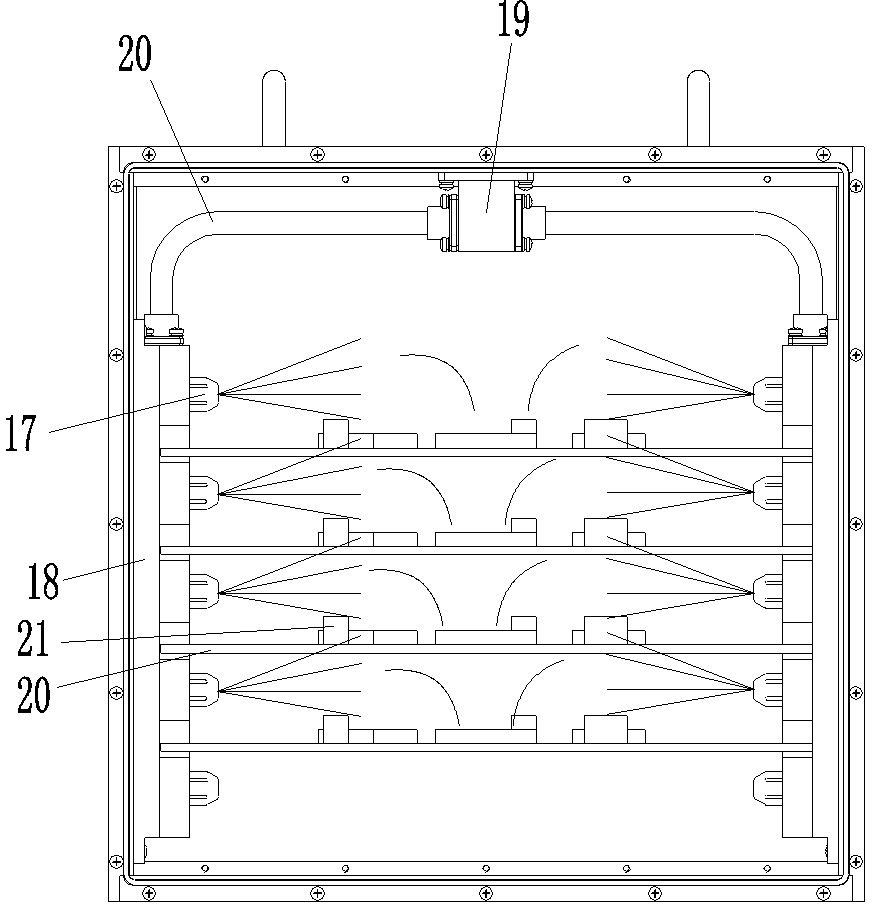

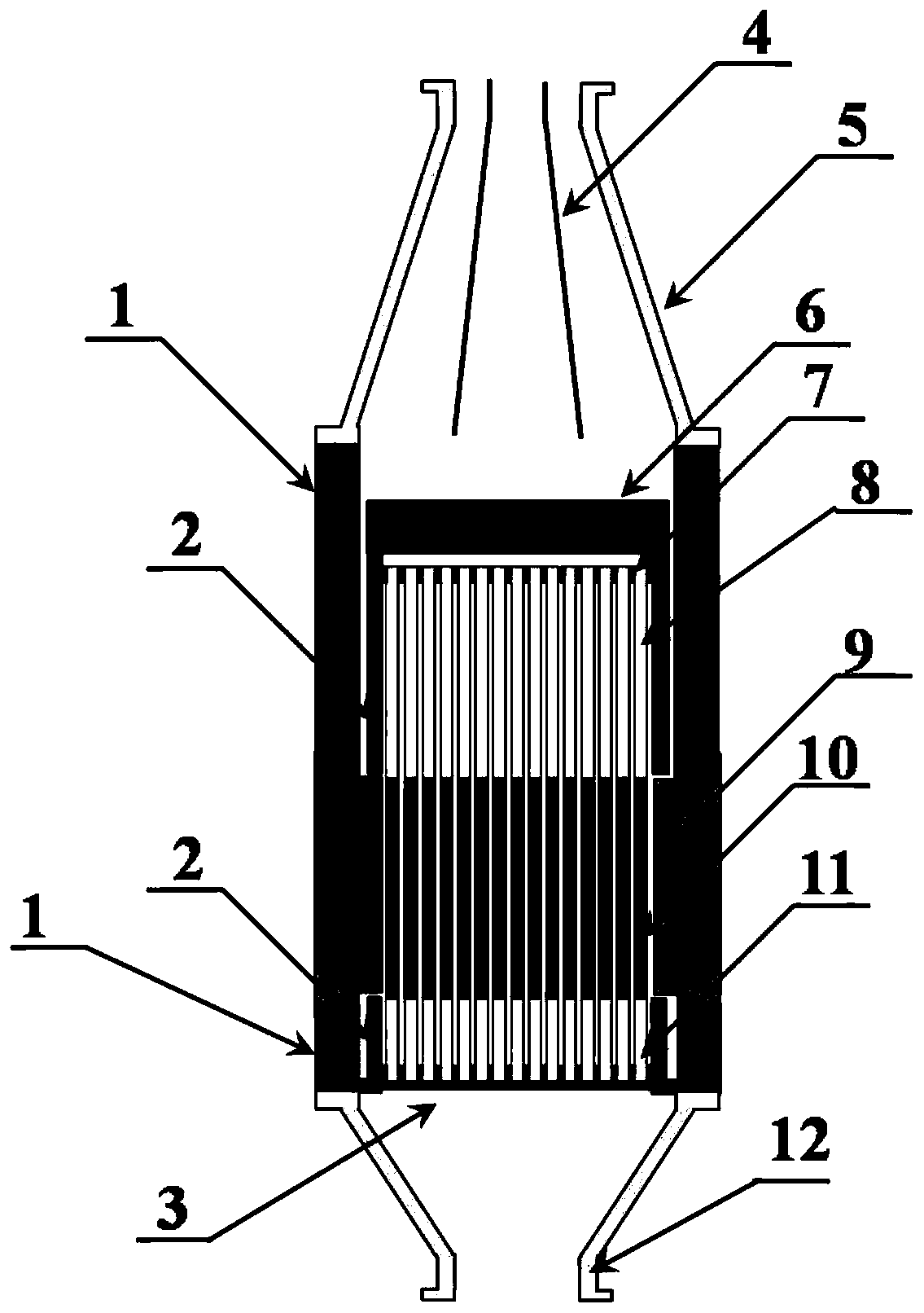

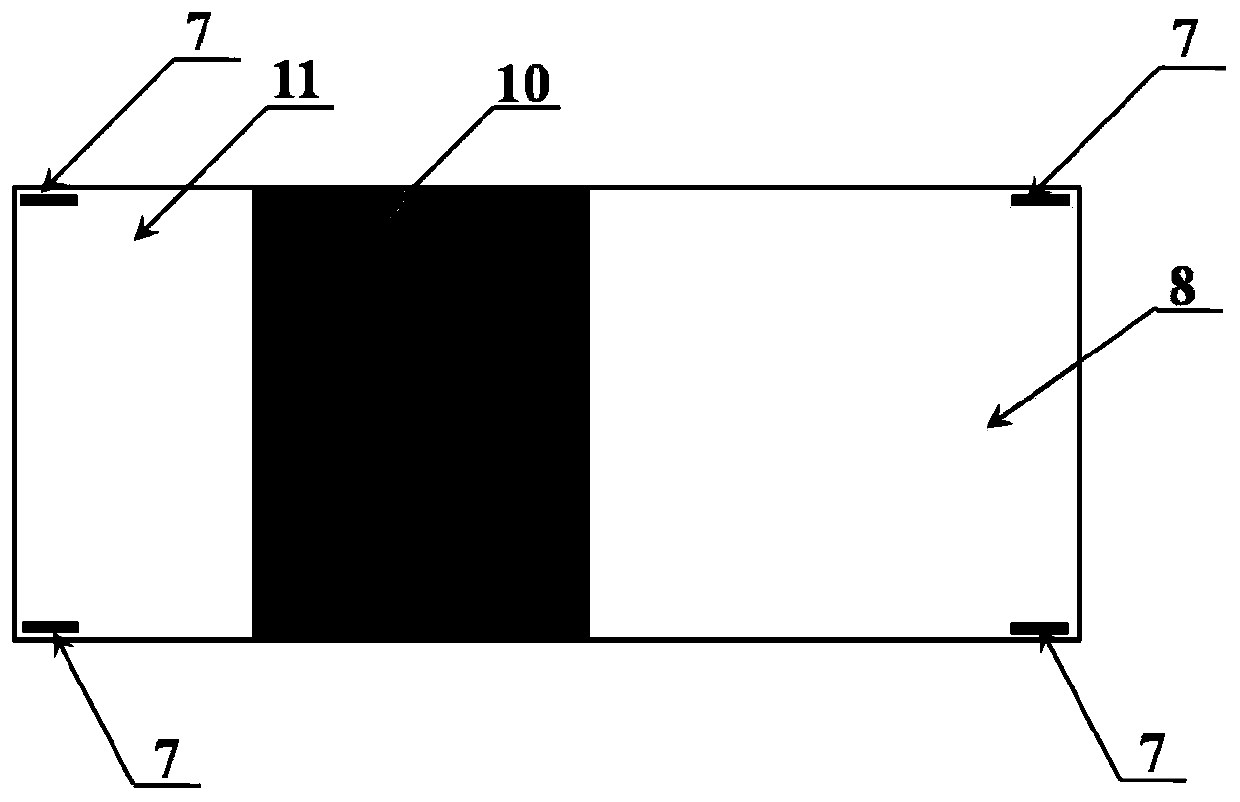

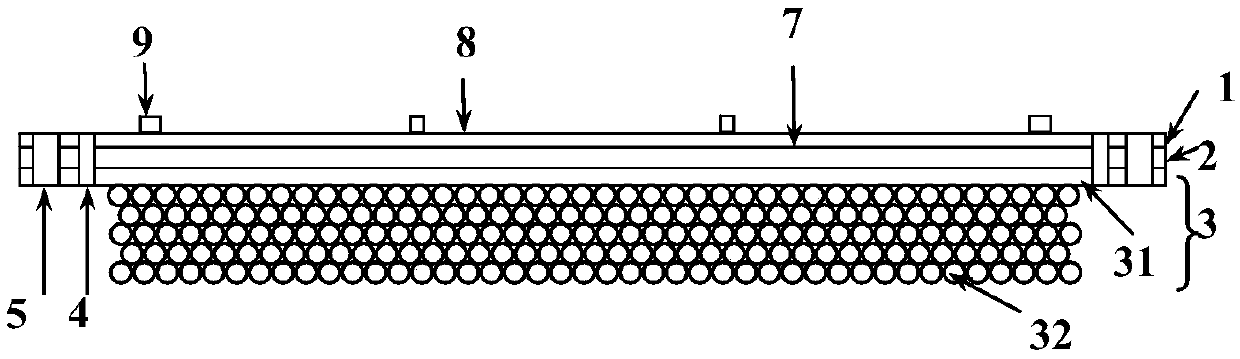

Submerged jet micro-injection direct liquid cooling heat dissipating device

ActiveCN109637987AReduce mutual interferenceThe cooling effect is weakDigital data processing detailsSemiconductor/solid-state device detailsJet flowDirect liquid cooling

The invention belongs to the field of heat dissipation of electronic devices, and discloses a submerged jet micro-injection direct liquid cooling heat dissipating device, wherein the bottom of the heat dissipating device is provided with a first groove to form a sealed space with the circuit board of an object to be cooled, a second groove is arranged in the first groove for placing the object tobe cooled, the coolant enters from the inlet pipe to the nozzle through the liquid separation cavity, and the coolant sprays from the nozzle on the surface of the object to be cooled; the coolant enters from the liquid pumping hole into the outlet pipe through the collecting cavity, and then flows out from the outlet pipe, thereby realizing the collection of the cooling liquid; a plurality of nozzles and a liquid pumping hole are disposed on each surface of the second groove, the liquid pumping hole is arranged on a center line extension line of the connection of the two nozzles, and the liquid pumping hole is higher than the nozzles to avoid interference on the coolant sprayed from adjacent nozzles. Through the invention, the heat dissipation area of the chip is effectively improved, thetemperature of the chip is lowered, and the uniformity of the temperature of the chip is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

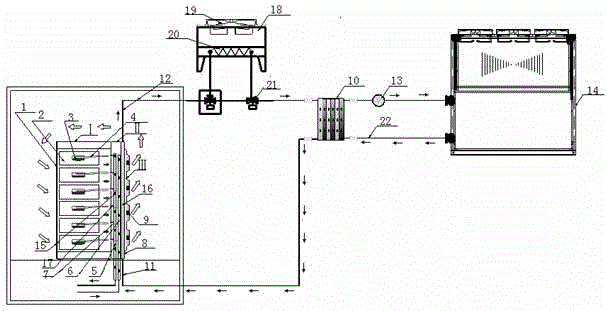

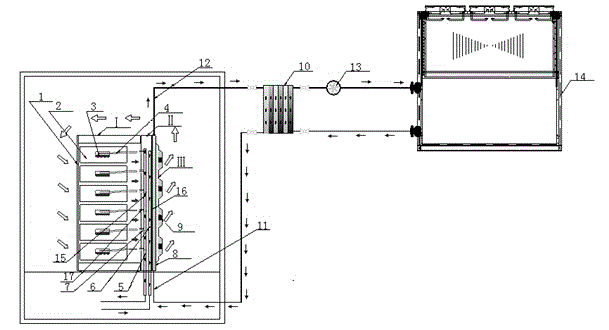

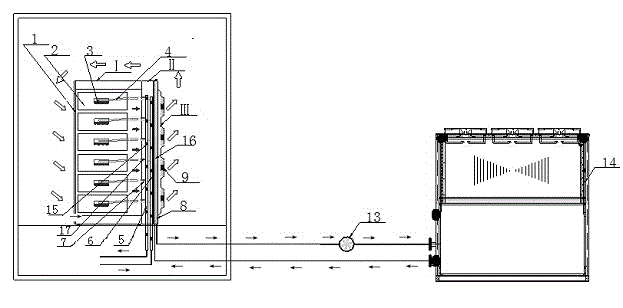

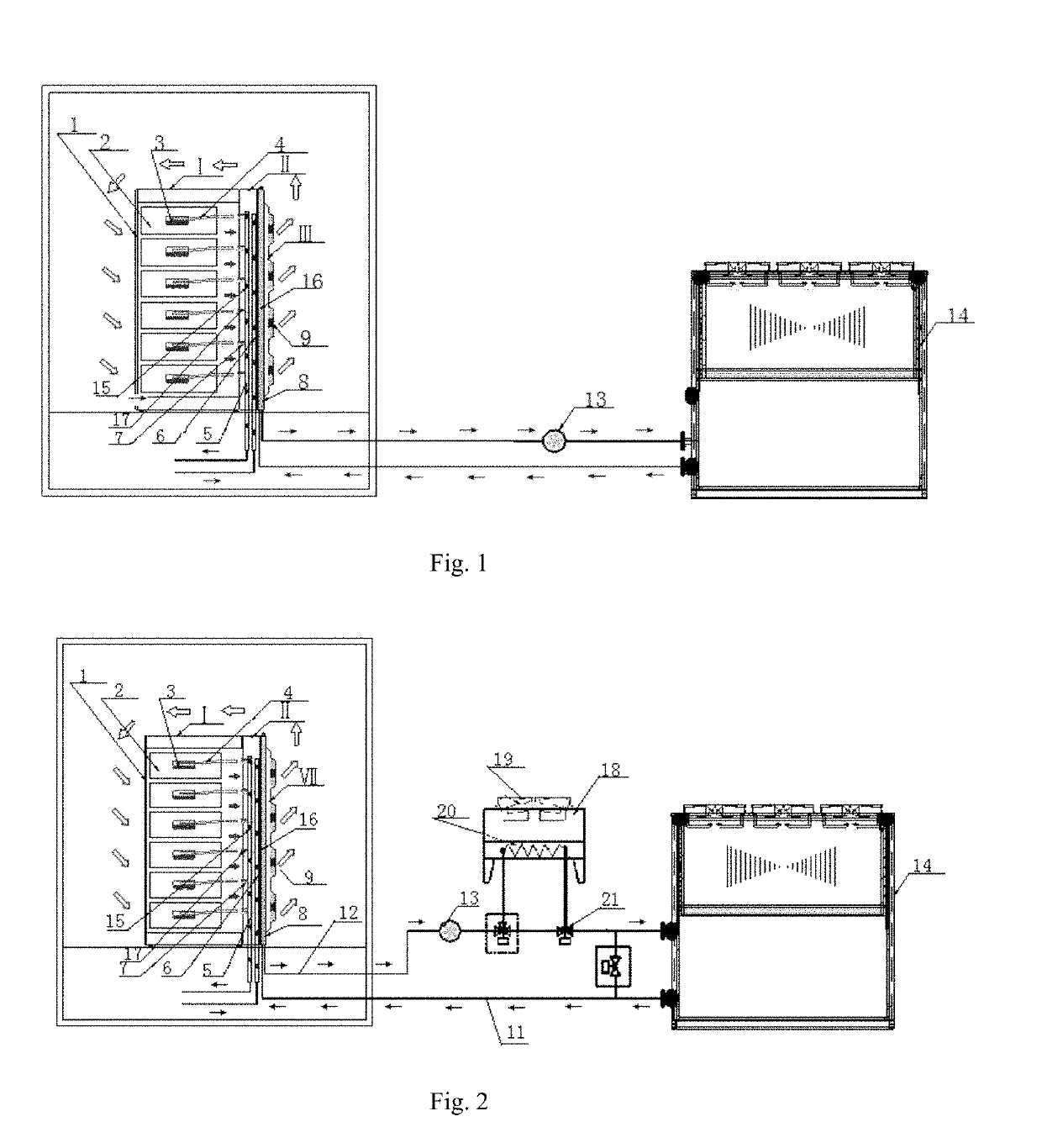

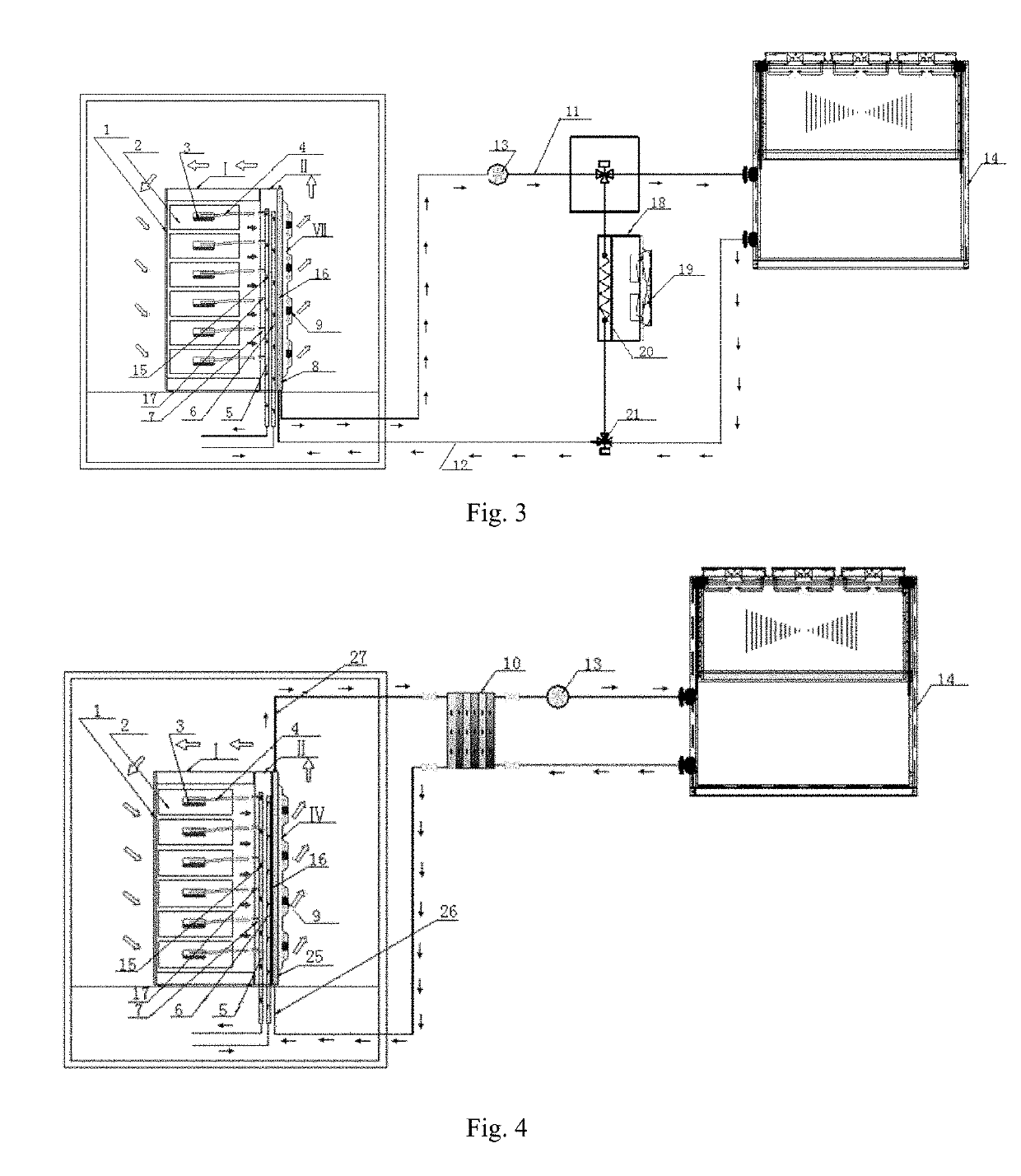

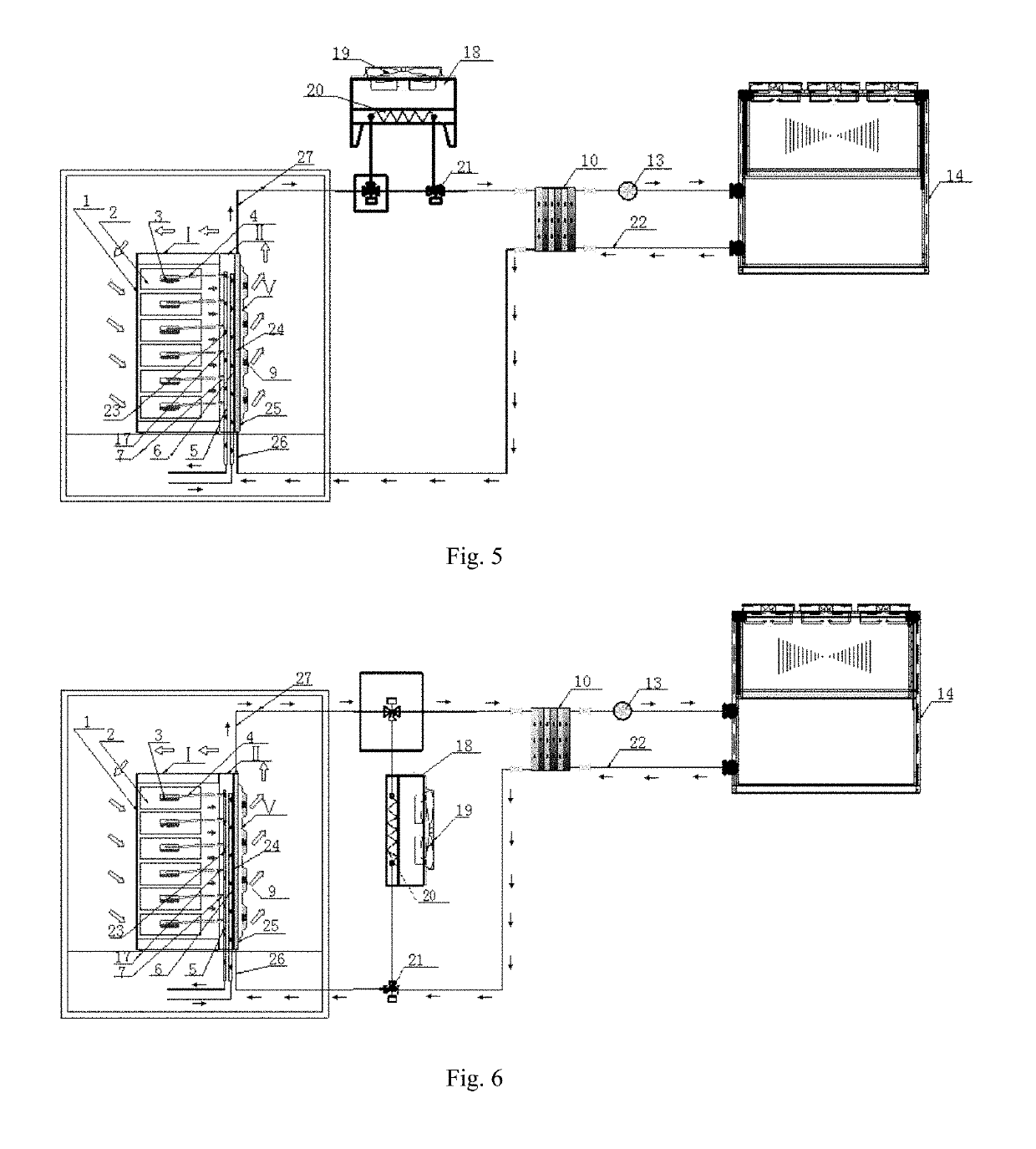

Server radiating system combining air-cooled naturally-cooled heat pipe air-conditioner with liquid-cooled device

ActiveCN104699207AConducive to practical promotionRealize the cooling effectLighting and heating apparatusDigital data processing detailsLow noiseHigh density

The invention discloses a server radiating system combining an air-cooled naturally-cooled heat pipe air-conditioner with a liquid-cooled device. The server radiating system comprises a liquid-cooled server cabinet, the liquid-cooled server cabinet comprises a cabinet body and a plurality of liquid-cooled servers arranged in the cabinet body, the liquid-cooled device is arranged to be used for direct liquid-cooling radiating of the liquid-cooled servers, and the air-cooled naturally-cooled heat pipe air-conditioner is arranged to be used for auxiliary radiating. The server radiating system has the advantages of high-density cooling, high heat exchange efficiency, low energy consumption, capability of overcoming local hot spots, small occupied area, high reliability, low noise and long service life. A standard server cabinet can be applied to the server radiating system.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

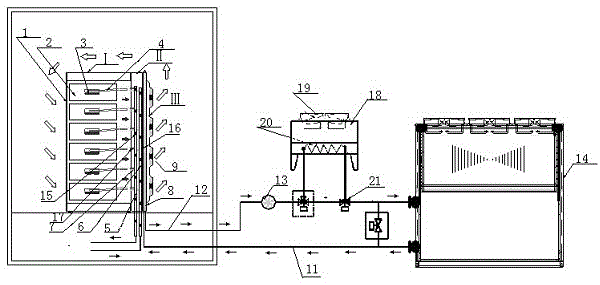

Natural cooling cold water device and liquid cooling device combined server cooling system

ActiveCN104703447AConducive to practical promotionRealize the cooling effectDigital data processing detailsEnergy efficient computingHigh densityDirect liquid cooling

The invention discloses a natural cooling cold water device and liquid cooling device combined server cooling system which comprises a liquid cooling server cabinet. The liquid cooling server cabinet comprises a cabinet body and multiple liquid cooling servers arranged in the cabinet body, is provided with liquid cooling devices for direct liquid cooling and heat dissipation of the liquid cooling servers and is further provided with a natural cooling cold water device for auxiliary heat dissipation. The natural cooling cold water device and liquid cooling device combined server cooling system is capable of performing high-density refrigeration, high in heat exchange efficiency, low in energy consumption, capable of solving local hot points, small in occupied area, high in reliability, small in noise and long in service life.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

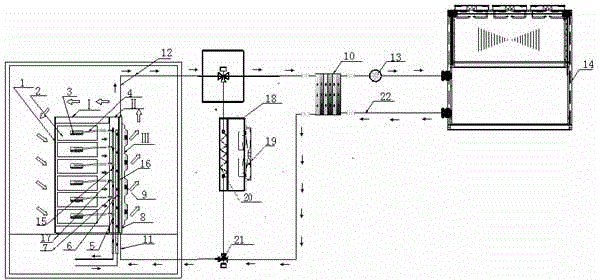

Server cabinet cooling system with combined gate-type heat pipe air-conditioner and liquid cooling device

ActiveCN104703449AConducive to practical promotionRealize the cooling effectCooling/ventilation/heating modificationsDirect liquid coolingEngineering

The invention discloses a server cabinet cooling system with combined gate-type heat pipe air-conditioner and liquid cooling device. The system comprises a liquid-cooled server cabinet; the liquid-cooled server cabinet comprises a cabinet body and a plurality of liquid-cooled servers arranged in the cabinet body; the liquid cooling device is arranged to perform direct liquid cooling heat dissipation on the servers; the gate-type heat pipe air-conditioner is further arranged to realize auxiliary heat dissipation. The server cabinet cooling system is high in cooling density, high in heat exchange efficiency, low in energy consumption, capable of solving local heat spots, small in floor area, high in reliability, low in noise and long in service life. A standard server cabinet can be applied to the system.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

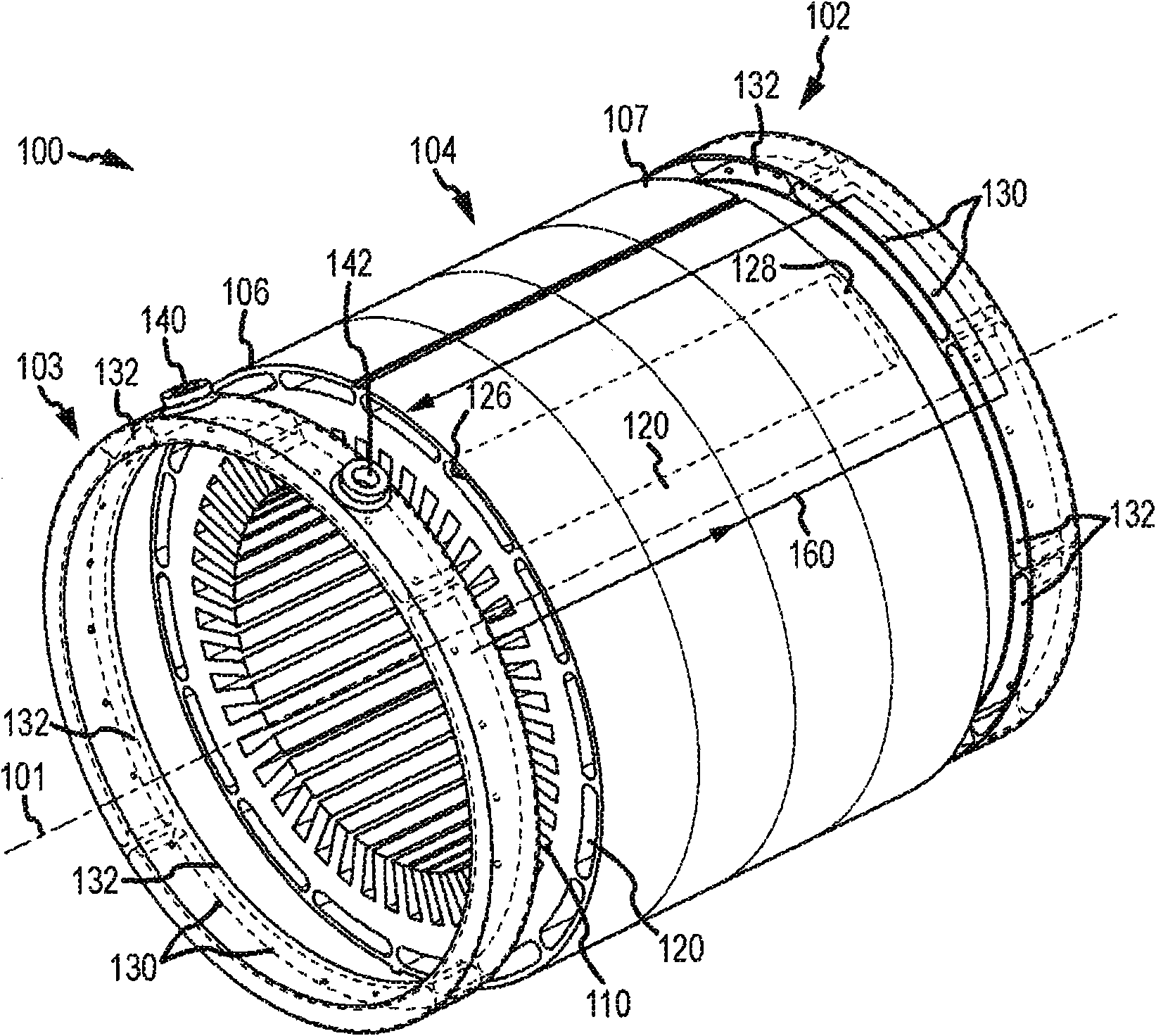

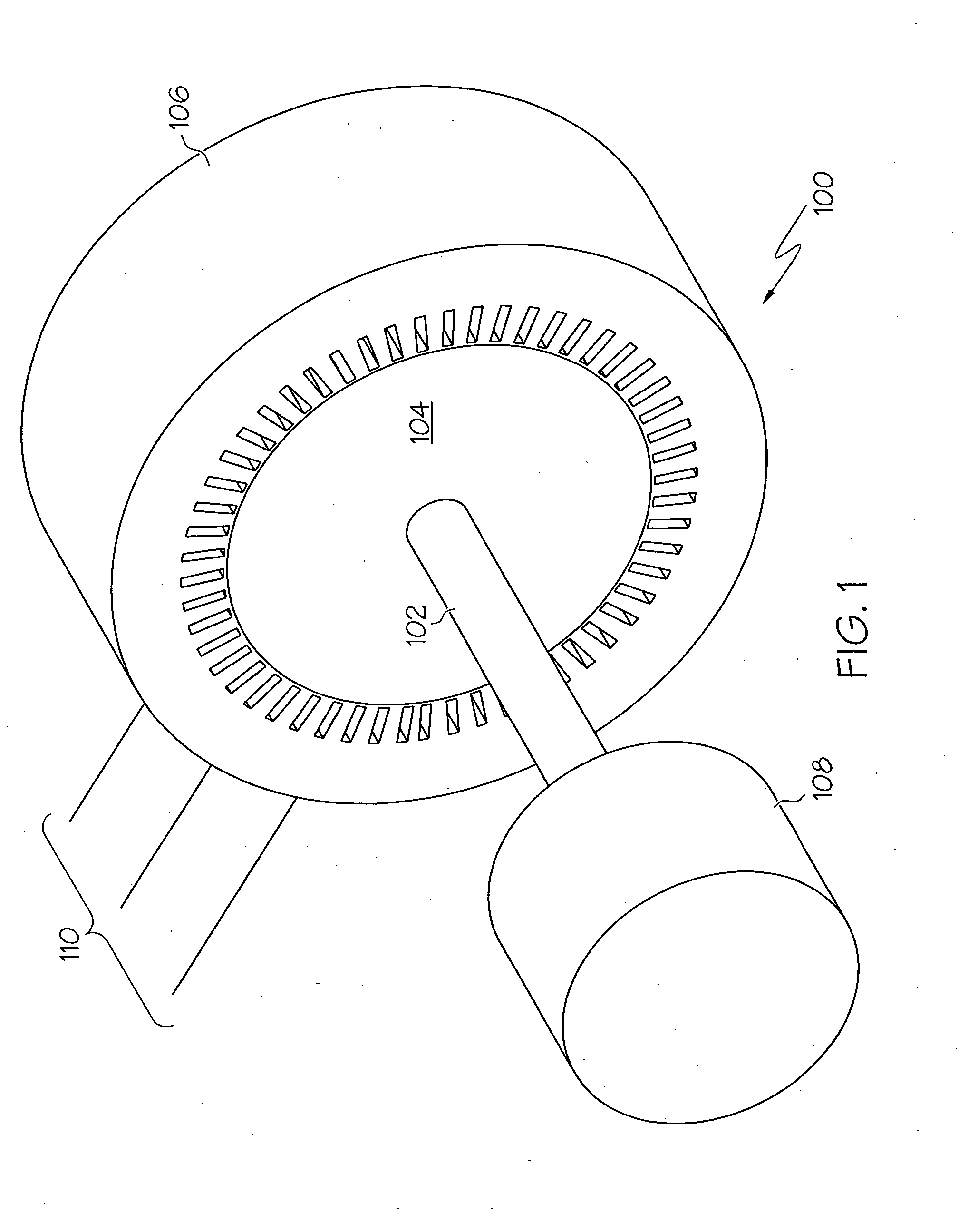

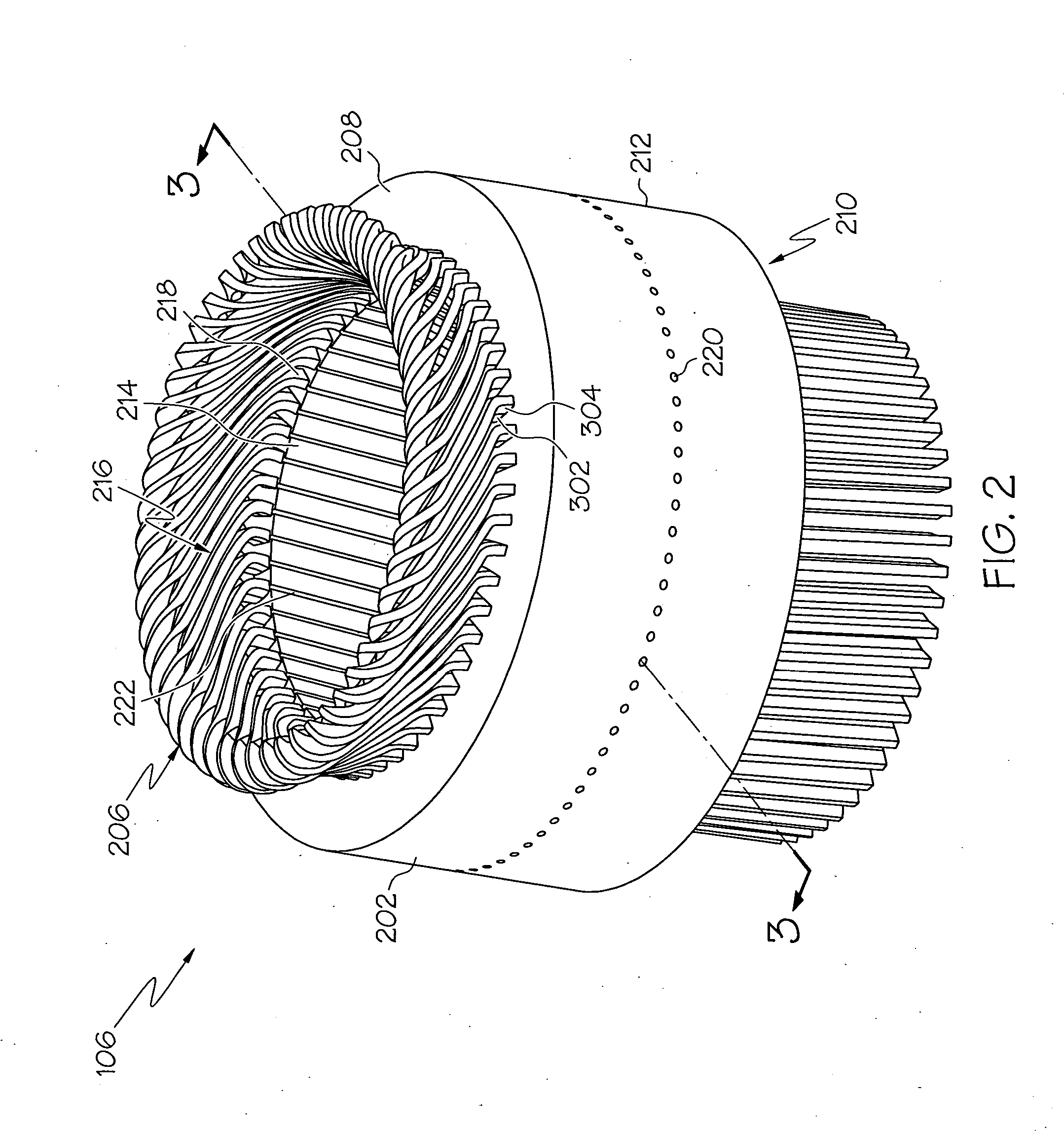

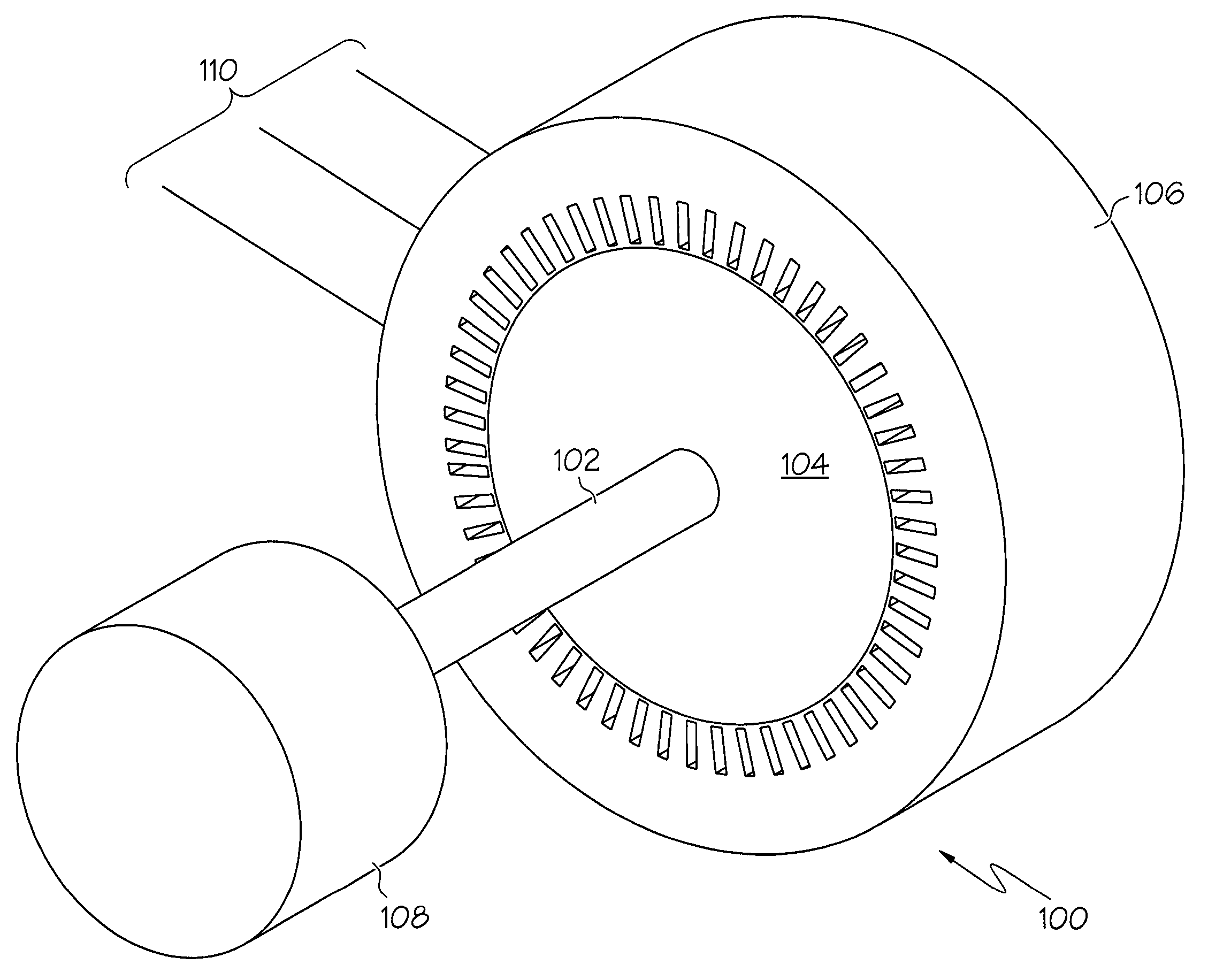

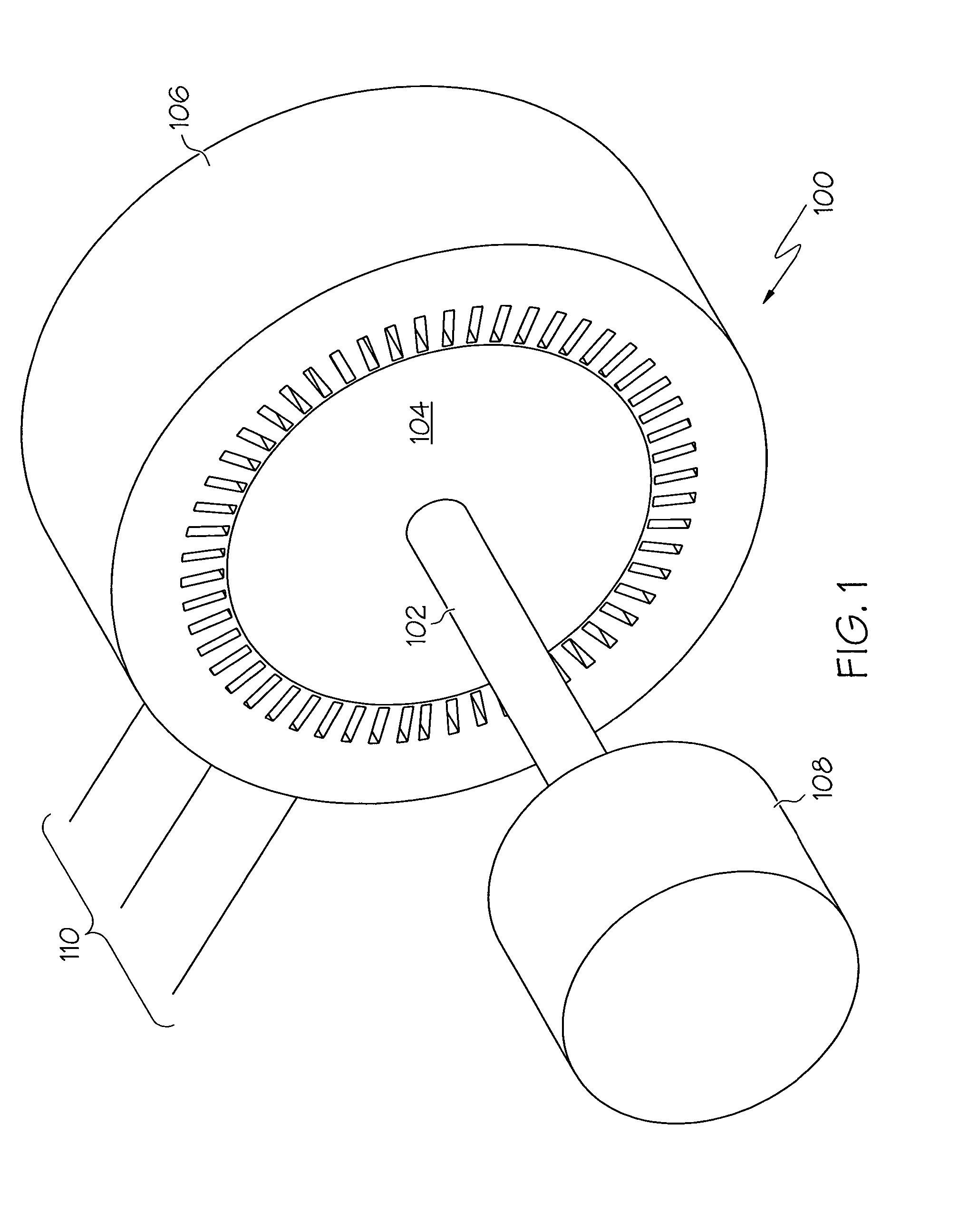

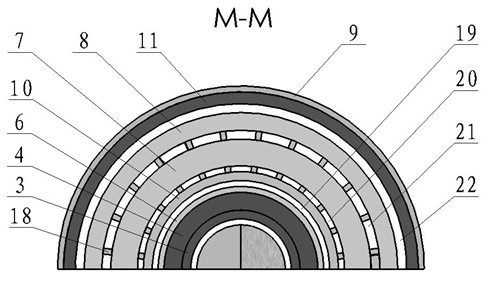

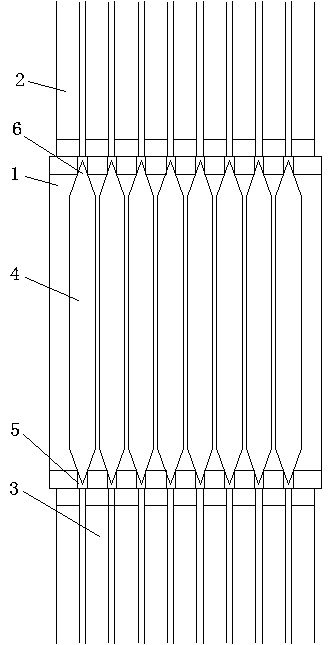

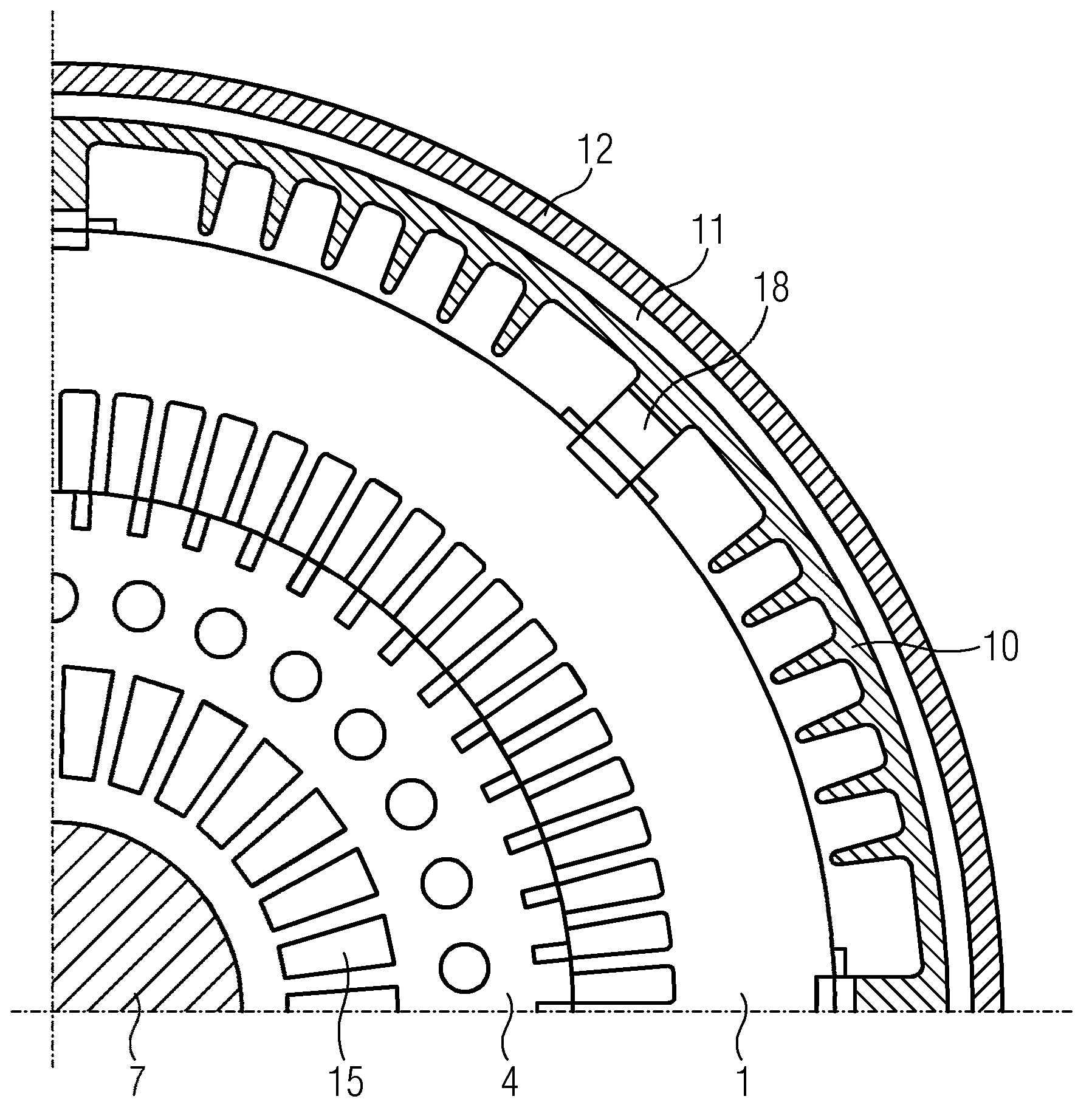

Methods and apparatus for a permanent magnet machine with a direct liquid cooled stator

ActiveCN101877505ASynchronous machinesMagnetic circuit stationary partsDirect liquid coolingConductor Coil

The invention relates to methods and apparatus for a permanent magnet machine with a direct liquid cooled stator. The permanent magnetic machine includes a stator body having a first end, a second end, and a plurality of generally radial slots formed therein for accepting a set of windings having a first set of end-turns at the first end and a second set of end-turns at the second end. The statorbody has a plurality of channels adjacent to the slots and extending from the first end of the stator body to the second end of the stator body, wherein the channels are configured to allow the flow of a cooling fluid therethrough. A plurality of nozzles in fluid communication with the plurality of channels are configured to spray the cooling fluid onto the first and second set of end turns.

Owner:GM GLOBAL TECH OPERATIONS LLC

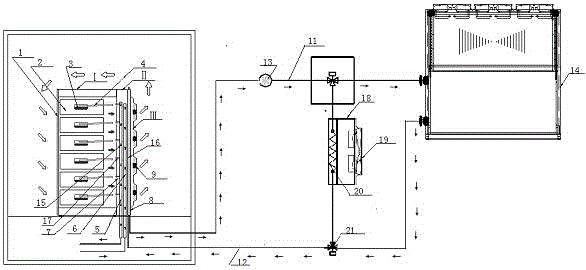

Server cabinet cooling system with combined gate-type cold water heat exchange device and liquid cooling device

ActiveCN104703448AConducive to practical promotionRealize the cooling effectCooling/ventilation/heating modificationsDirect liquid coolingSmall footprint

The invention discloses a server cabinet cooling system with combined gate-type cold water heat exchange device and liquid cooling device. The system comprises a liquid-cooled server cabinet; the liquid-cooled server cabinet comprises a cabinet body and a plurality of liquid-cooled servers arranged in the cabinet body; the liquid cooling device is arranged to perform direct liquid cooling heat dissipation on the servers; the gate-type cold water heat exchange device is further arranged to realize auxiliary heat dissipation. The server cabinet cooling system is high in cooling density, high in heat exchange efficiency, low in energy consumption, capable of solving local heat spots, small in floor area, high in reliability, low in noise and long in service life.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

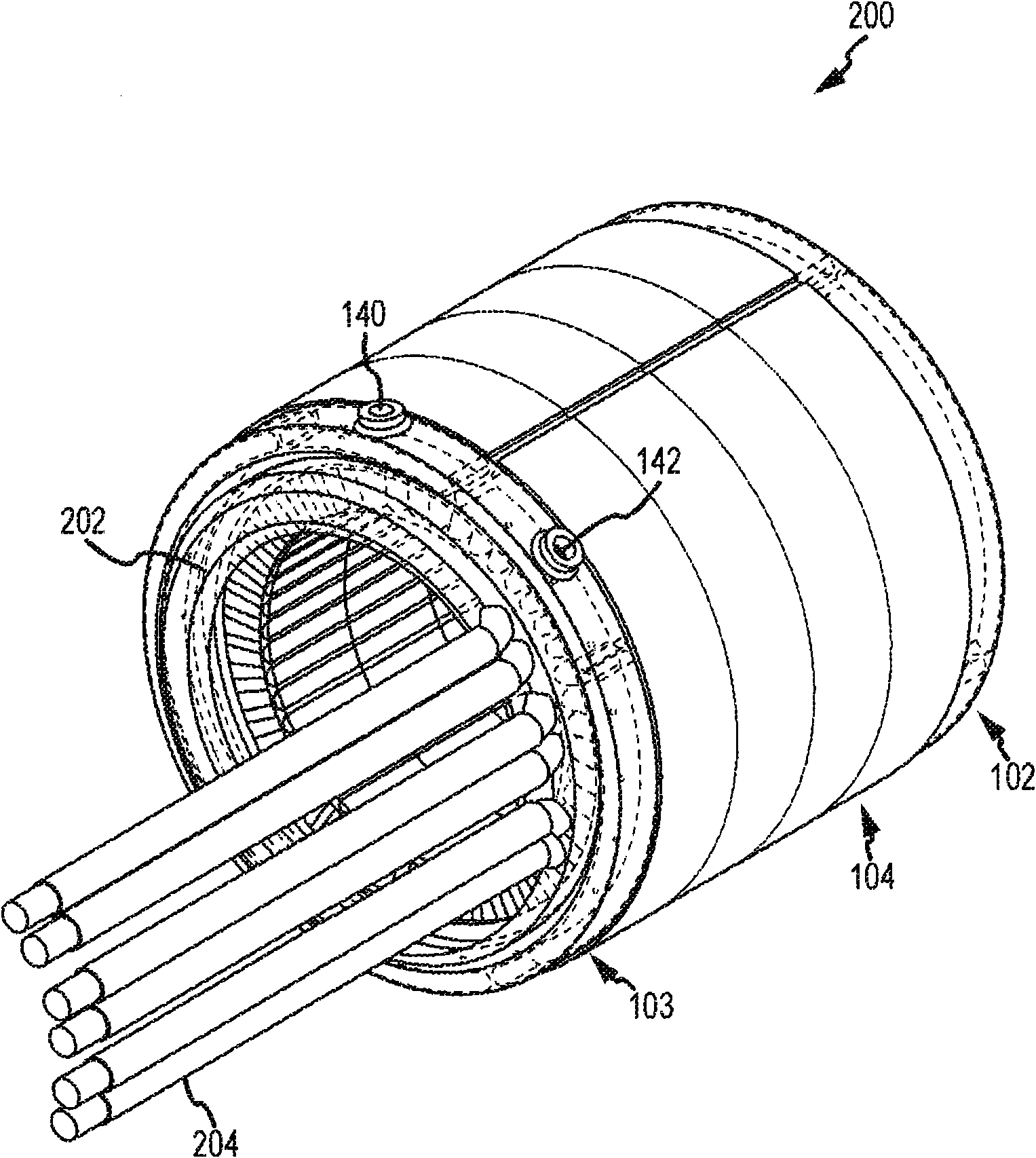

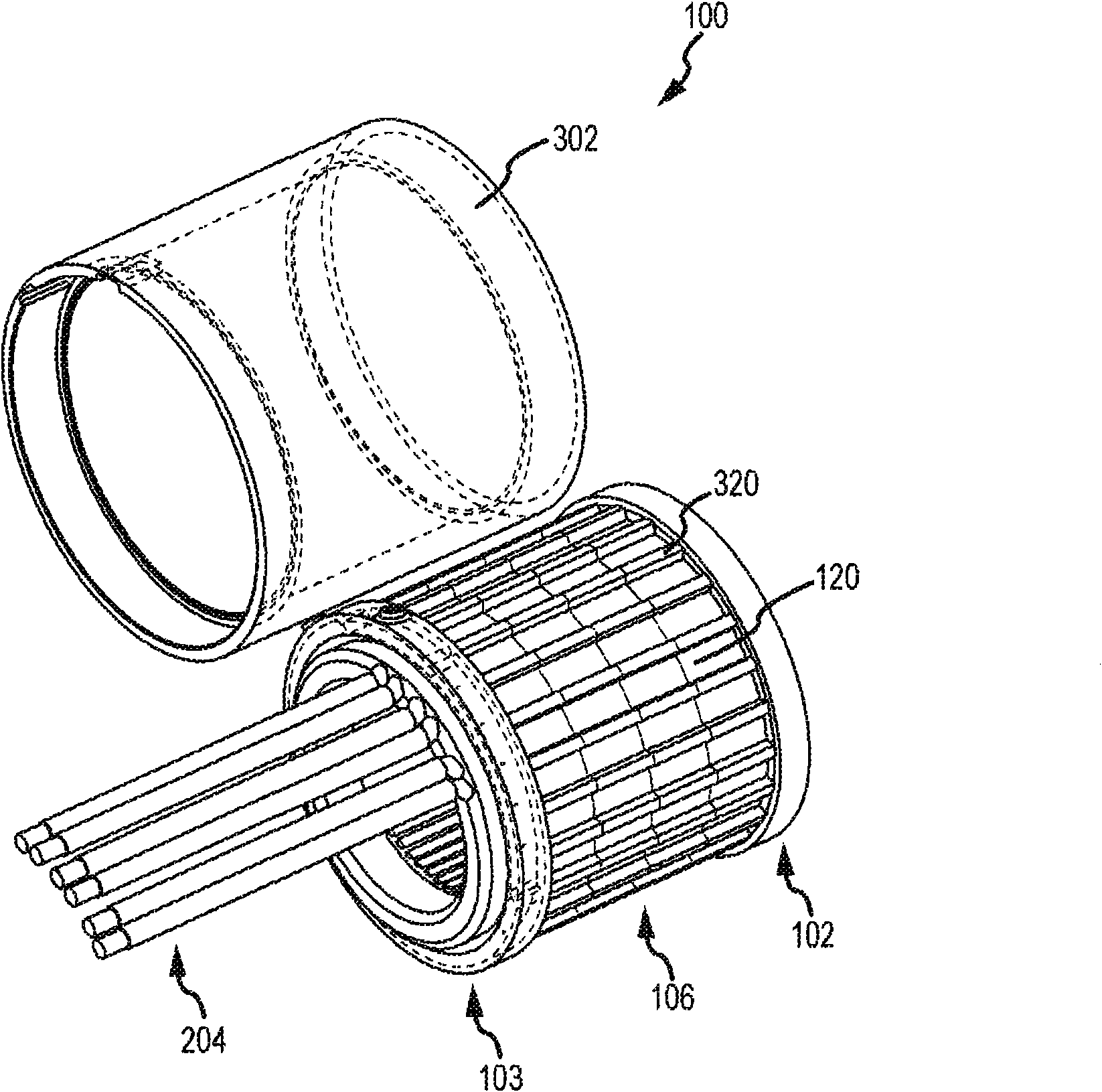

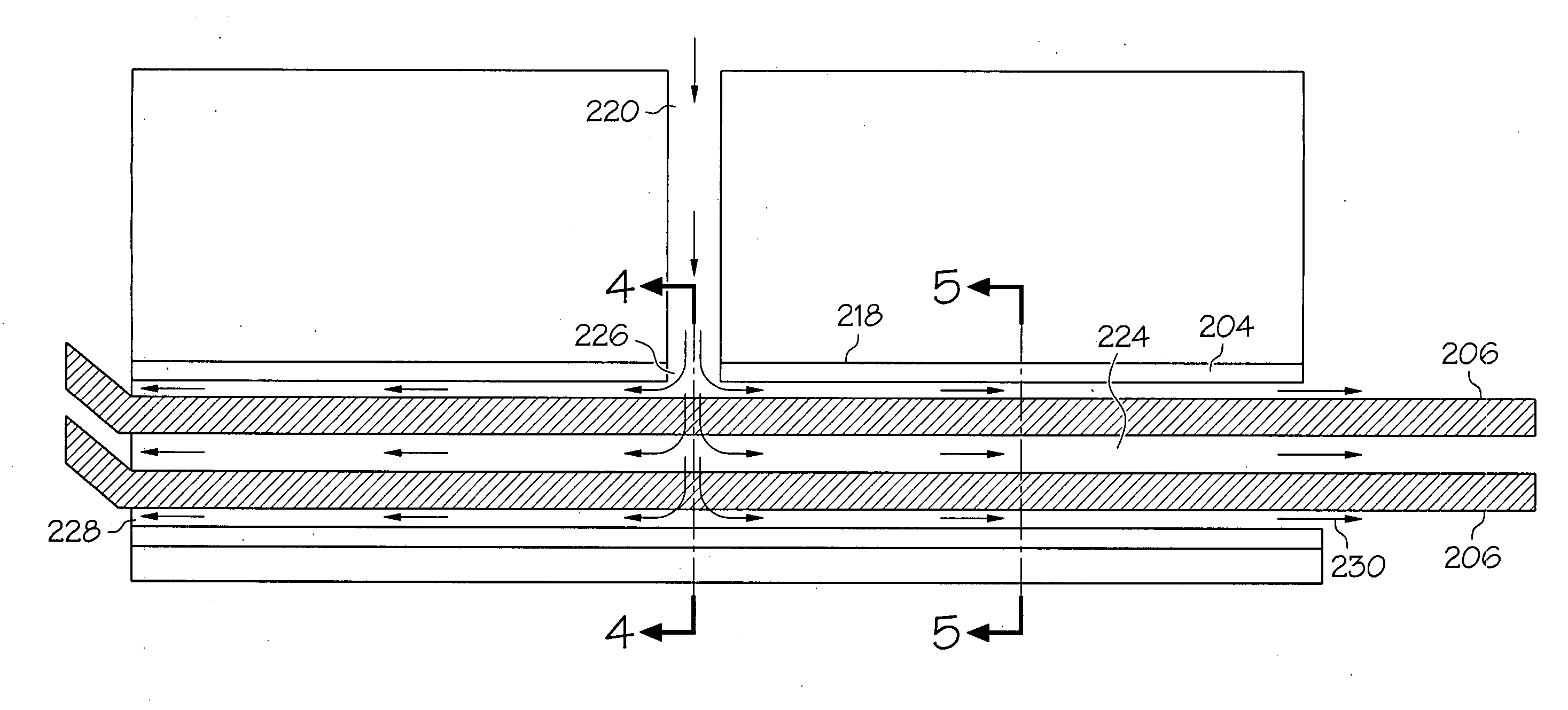

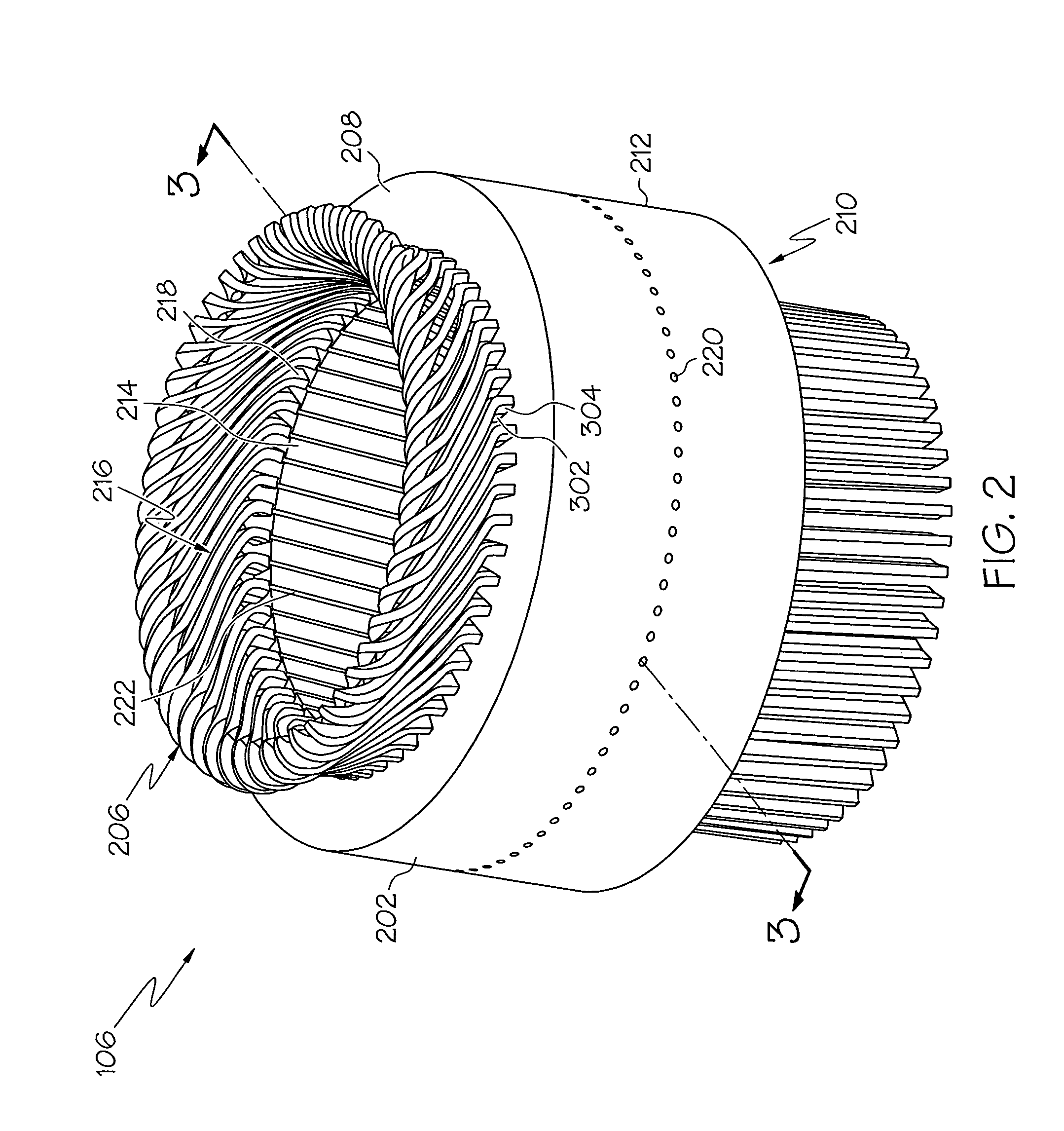

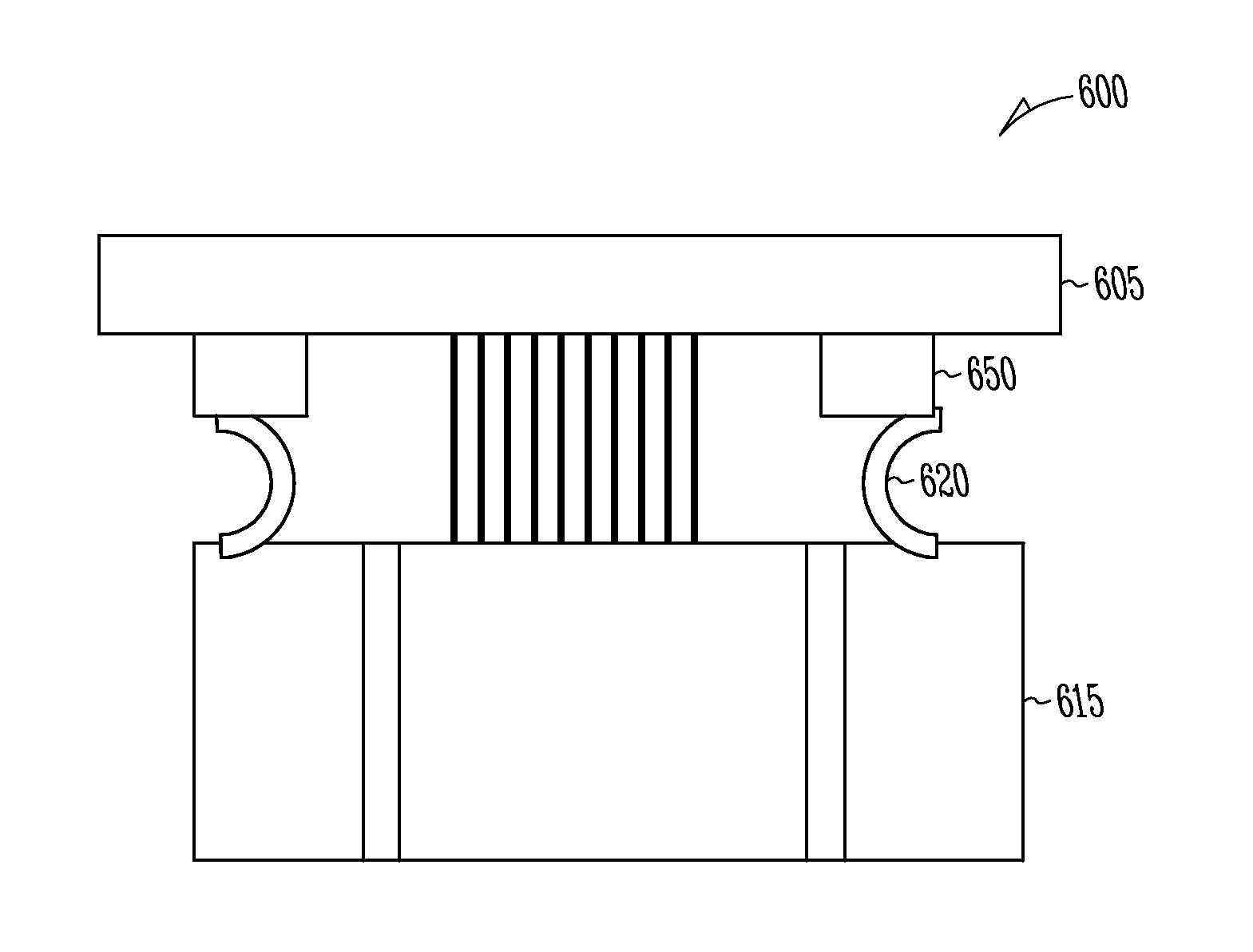

System and method for direct liquid cooling of electric machines

InactiveUS20070138878A1Windings insulation shape/form/constructionCooling/ventillation arrangementElectric machineStator coil

A system is provided for cooling a stator coil of a rotating machine. In one embodiment, and by way of example only, the system includes a stator core, a radial core opening, and a sleeve. The stator core has an axially extending slot formed therein, an outer circumferential surface, and an inner circumferential surface. The radial core opening extends from the stator core outer circumferential surface to the axially extending slot. The sleeve is disposed within the axial slot and configured to surround the stator coil. The sleeve has a cooling fluid supply port formed therein that is aligned with the radial core opening.

Owner:HONEYWELL INT INC

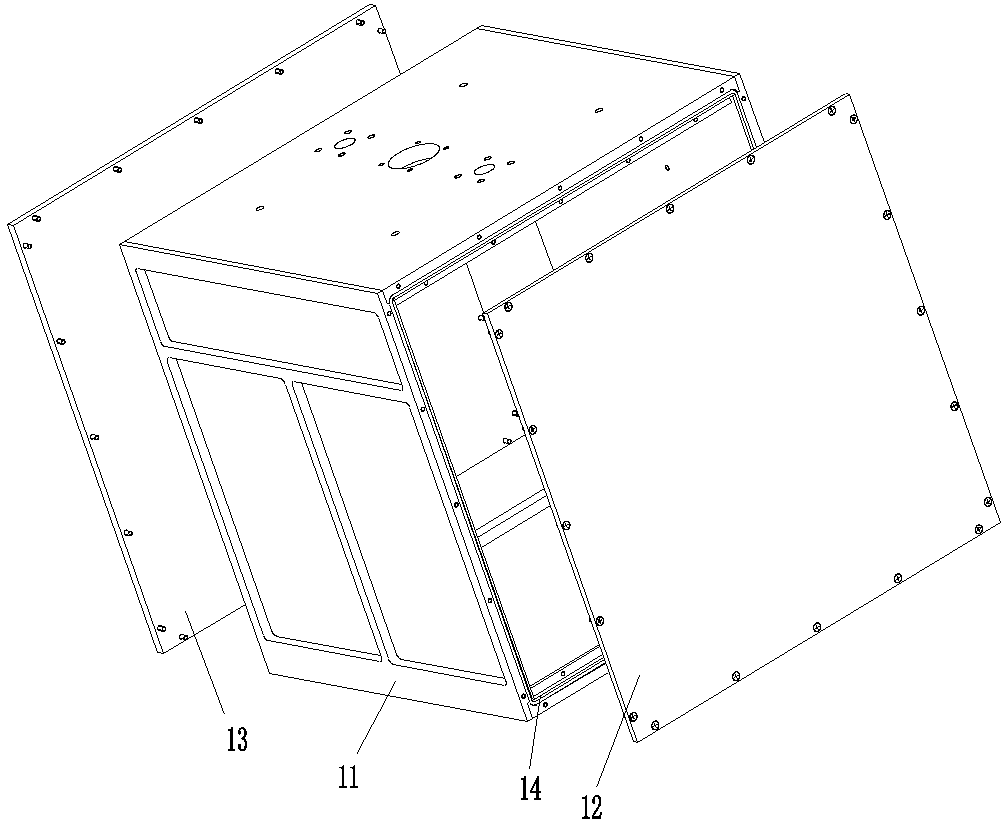

Machine case capable of dissipating heat through method of liquid cooling

InactiveCN104302158AEnables direct liquid coolingSolve the low heat dissipation efficiencyCooling/ventilation/heating modificationsDirect liquid coolingEngineering

The invention relates to the field of electrical cabinets, in particular to a machine case capable of dissipating heat through a method of liquid cooling. The machine case capable of dissipating heat through the method of liquid cooling comprises a case body, wherein electrical elements are installed inside the case body, the case body is airtight and is provided with a refrigerant inlet and a refrigerant outlet, the refrigerant inlet is connected with atomizers, and the atomizers are located inside the case body. When the machine case capable of dissipating heat through the method of liquid cooling is used, cooling liquid entering the case body from the refrigerant inlet is firstly atomized before arriving at the electrical elements, the atomized liquid is still poured on the heating electrical elements as small liquid drops, when making contact with the heating electrical elements, the small liquid drops are instantaneously gasified, and therefore heat dissipated by the electrical elements is taken away. The machine case capable of dissipating heat through the method of liquid cooling realizes direct liquid cooling of the electrical elements, and solves the problem of low heat dissipation efficiency of high heating flux electronic equipment based on the phase change principle.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

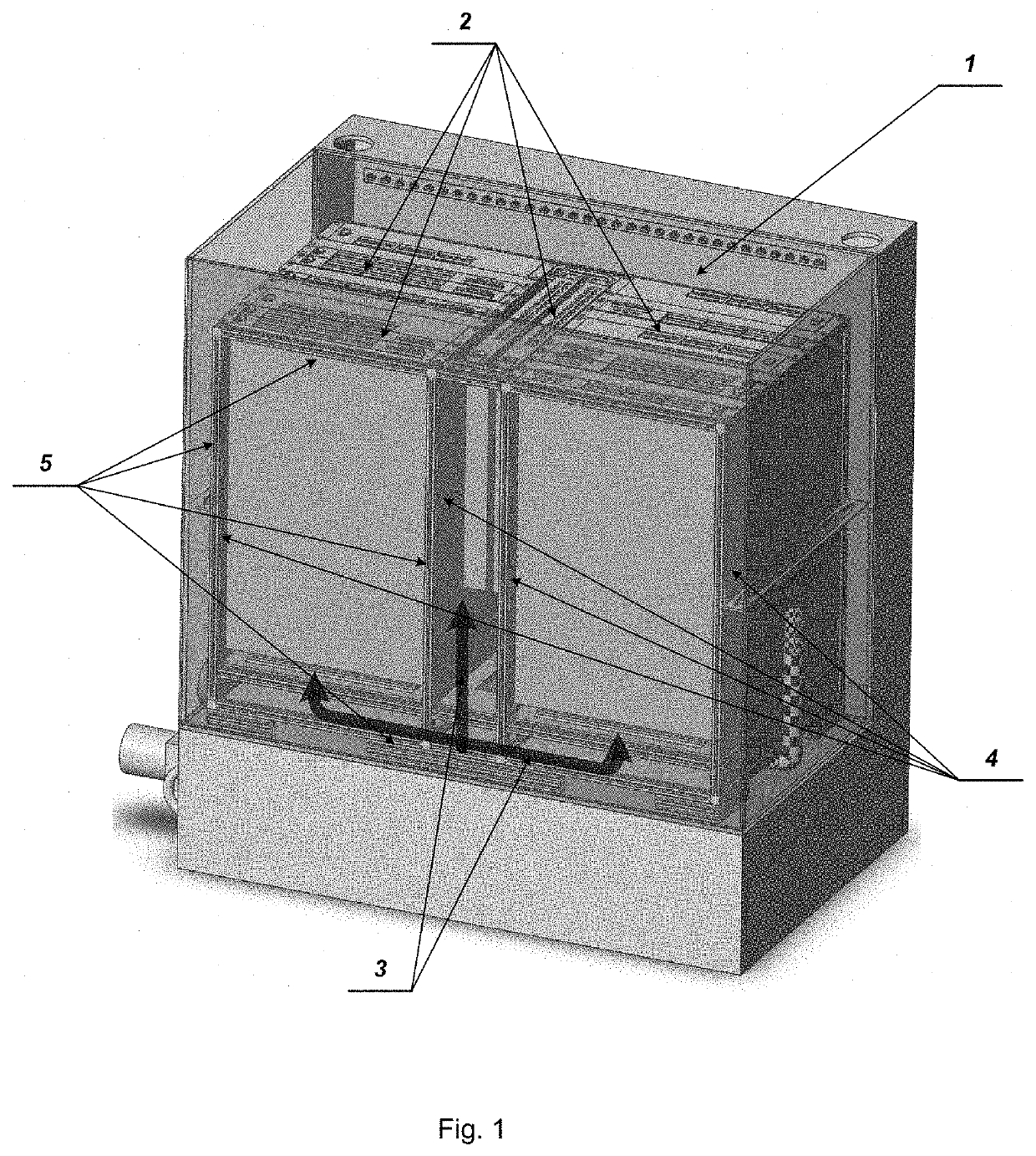

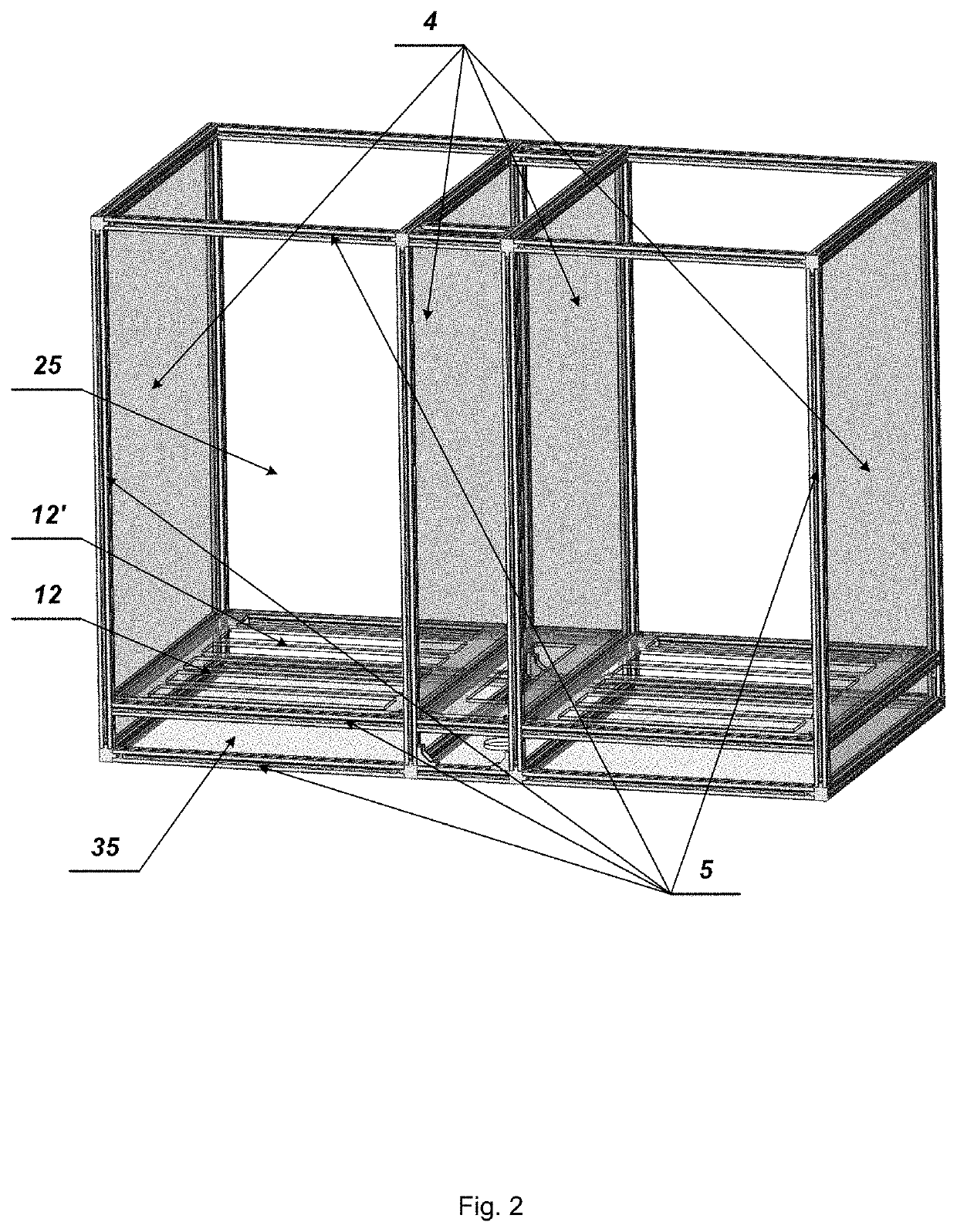

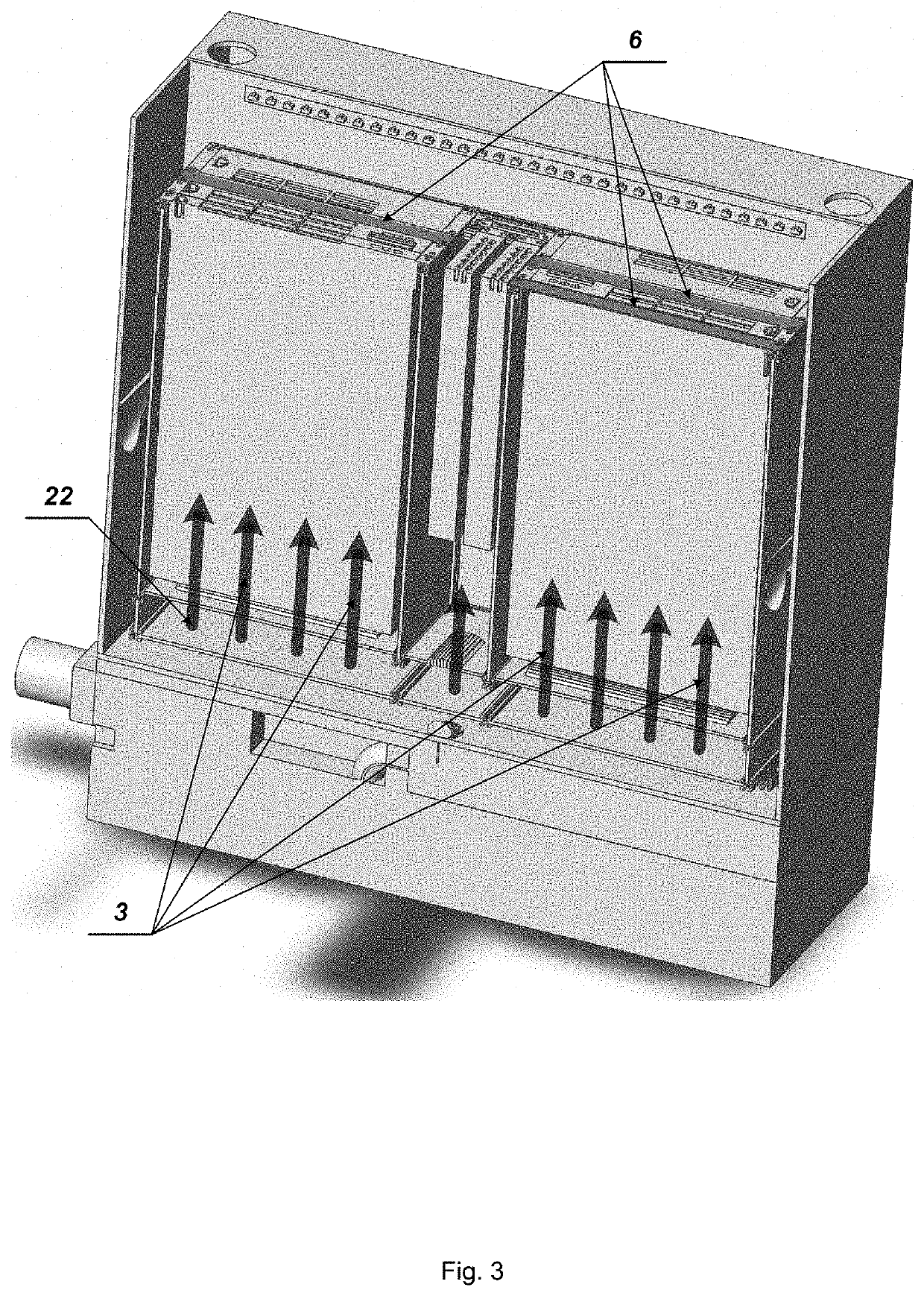

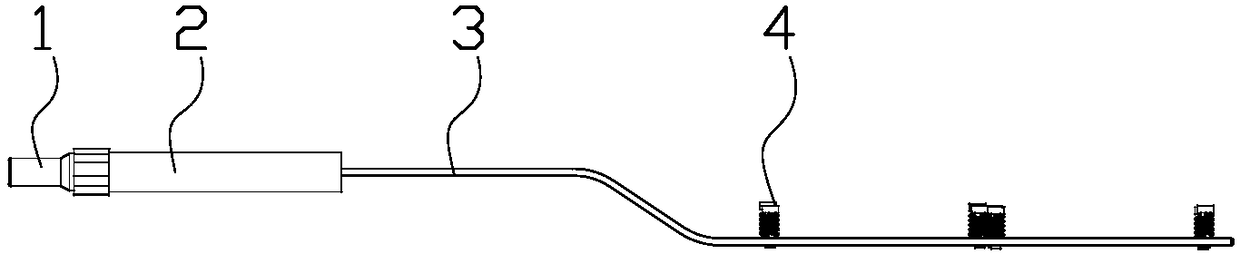

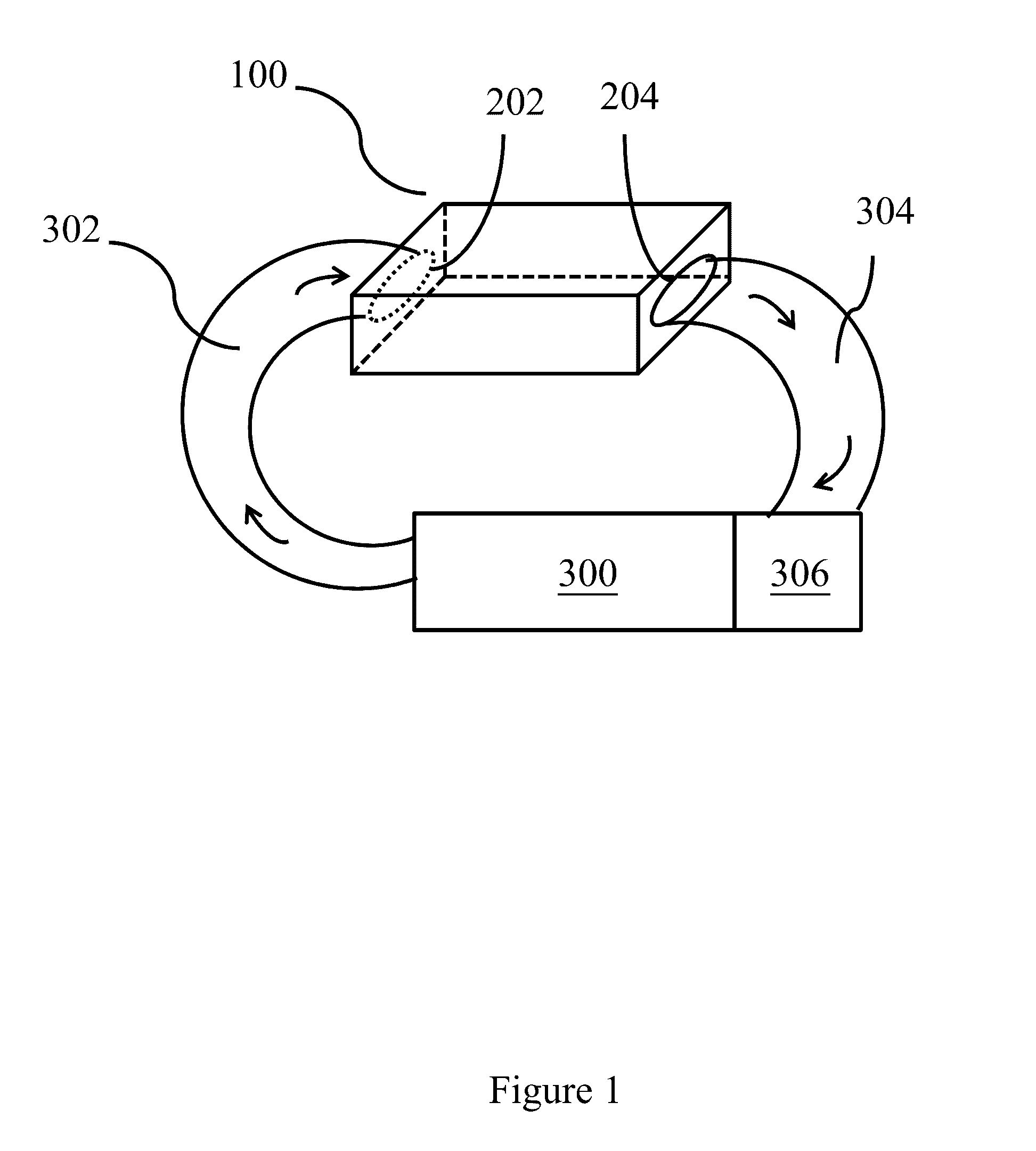

A direct liquid cooling system for cooling of electronic components

ActiveUS20200323108A1Facilitates continuous pumpingServersInstrumental cooling apparatusDirect liquid coolingProcess engineering

The present disclosure is directed to a direct liquid cooling system for cooling of electronic components and configured to maintain a predetermined thermostable environment for the electronic components. The system includes a reservoir and a rack removably placed in the reservoir and securely containing electronic components to be cooled. The system also includes a dielectric coolant which is configured to flow upward in parallel streams between the electronic components and a pump that facilitates continuous pumping of the dielectric coolant thereby forcing the dielectric coolant upwards through the electronic components and overflowing the dielectric coolant within the reservoir. A heat exchanger is also provided and coupled with the reservoir via an outlet pipeline. Additionally, a controller is provided to monitor the temperature of the dielectric coolant and adjust the flow of the coolant.

Owner:INPRO TECH LLC

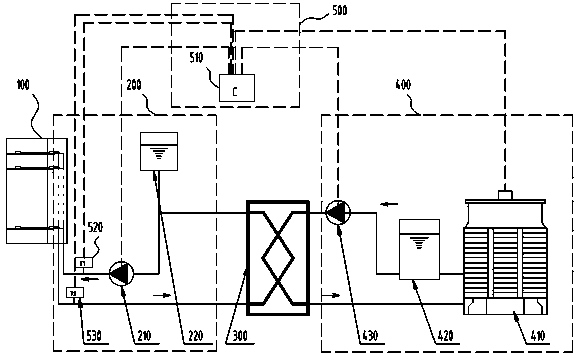

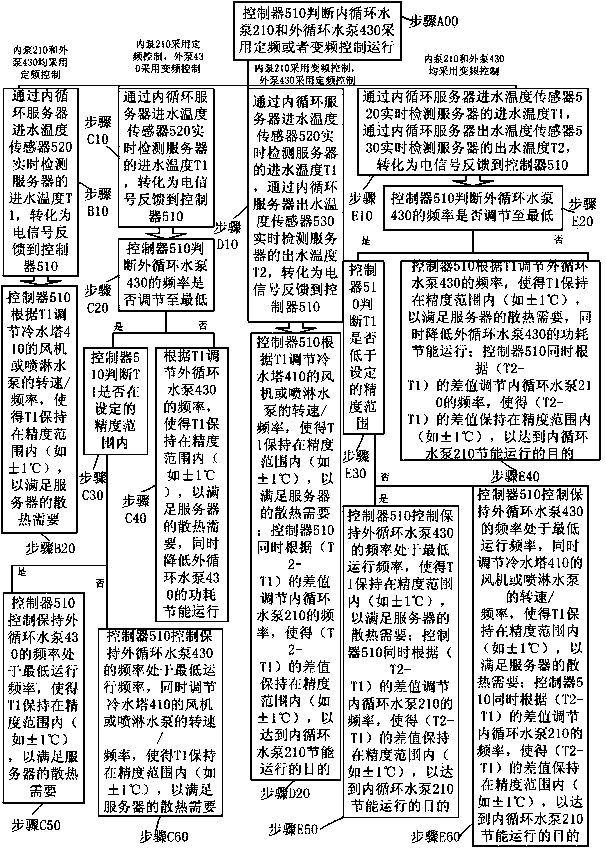

Control method for heat dissipation system of secondary water loop server cabinet

ActiveCN104252187AAvoid enteringAvoid damageTemperature control using electric meansTemperature controlCooling tower

The invention discloses a control method for a heat dissipation system of a secondary water loop server cabinet; heat dissipation is performed by adopting a liquid conduction mode. The heat dissipation system comprises an inner circulating system, an outer circulating system and a control system; firstly, the dissipated heat of a server core component is absorbed by inner circulating loop secondary refrigerant through a server heat pipe assembly, and then, the inner circulating loop secondary refrigerant flows to an intermediate heat exchanger to perform heat exchange with outer circulating flow to dissipate heat; after being absorbed by the outer circulating flow, the heat is dissipated to the external environment through a cooling tower, and therefore a natural heat dissipation process is realized; accurate temperature control and energy-saving running of the heat dissipation system can be realized through the control system. According to the control method disclosed by the invention, without any compressor refrigerating system, fully by a natural cooling mode, the effective heat dissipation of a server is realized, and the energy-saving effect is very obvious; meanwhile, a heat pipe indirect cooling scheme is adopted by a serve chip, so that water cannot directly enter the server; compared with other direct liquid cooling schemes, the heat pipe indirect cooling scheme is capable of enhancing the safety of the server.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

System and method for direct liquid cooling of electric machines

InactiveUS7482725B2Windings insulation shape/form/constructionCooling/ventillation arrangementElectric machineDirect liquid cooling

A system is provided for cooling a stator coil of a rotating machine. In one embodiment, and by way of example only, the system includes a stator core, a radial core opening, and a sleeve. The stator core has an axially extending slot formed therein, an outer circumferential surface, and an inner circumferential surface. The radial core opening extends from the stator core outer circumferential surface to the axially extending slot. The sleeve is disposed within the axial slot and configured to surround the stator coil. The sleeve has a cooling fluid supply port formed therein that is aligned with the radial core opening.

Owner:HONEYWELL INT INC

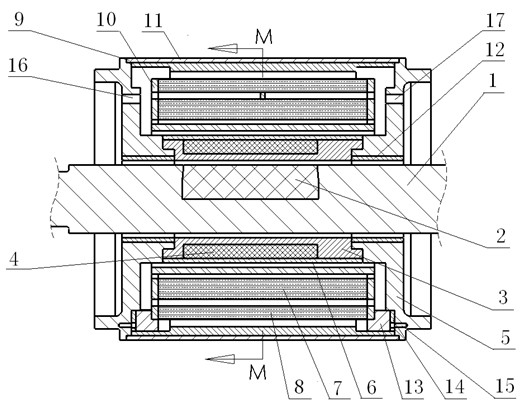

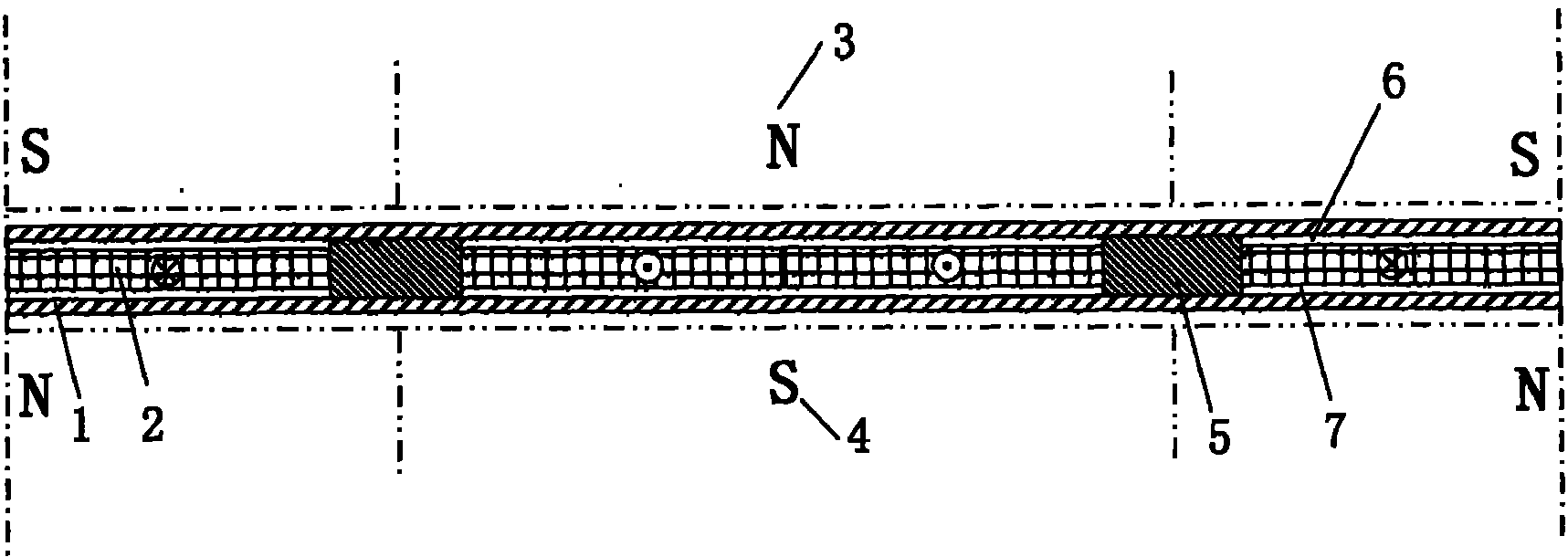

Direct liquid cooling temperature control device of giant magnetostrictive actuator

InactiveCN102427313AImprove thermal efficiencyHigh precisionPiezoelectric/electrostriction/magnetostriction machinesTemperature controlMagnetostrictive actuator

The invention discloses a direct liquid cooling temperature control device of a giant magnetostrictive actuator, which comprises a phase change heat-absorbing layer, a loop frame, inner-layer and outer-layer coils, an outer-layer sleeve, distribution type heat exchange flow channels, a heat insulating material, a claw and an end cover, wherein insulating coolant enters a cavity from an inlet at one side of the end cover, and is in direct contact with the coils infiltrated in multiple layers of distribution type heat exchange flow channels through the distribution type heat exchange flow channels and then flows out from an outlet at the other side of the end cover and carries away the heat after being subjected to heat exchange. Because the coolant directly contacts the coils for cooling and the multiple layers of heat exchange flow channels are designed, compared with the traditional cooling temperature control mode, the direct liquid cooling temperature control device has the advantage of greatly increasing the heat efficiency; and by virtue of the claw type coil frame fixing mode, the conduction of the heat from the coils to a knife bar and the giant magnetostrictive material is basically isolated, and the temperature control precision of the giant magnetostrictive actuator is significantly improved.

Owner:ZHEJIANG UNIV

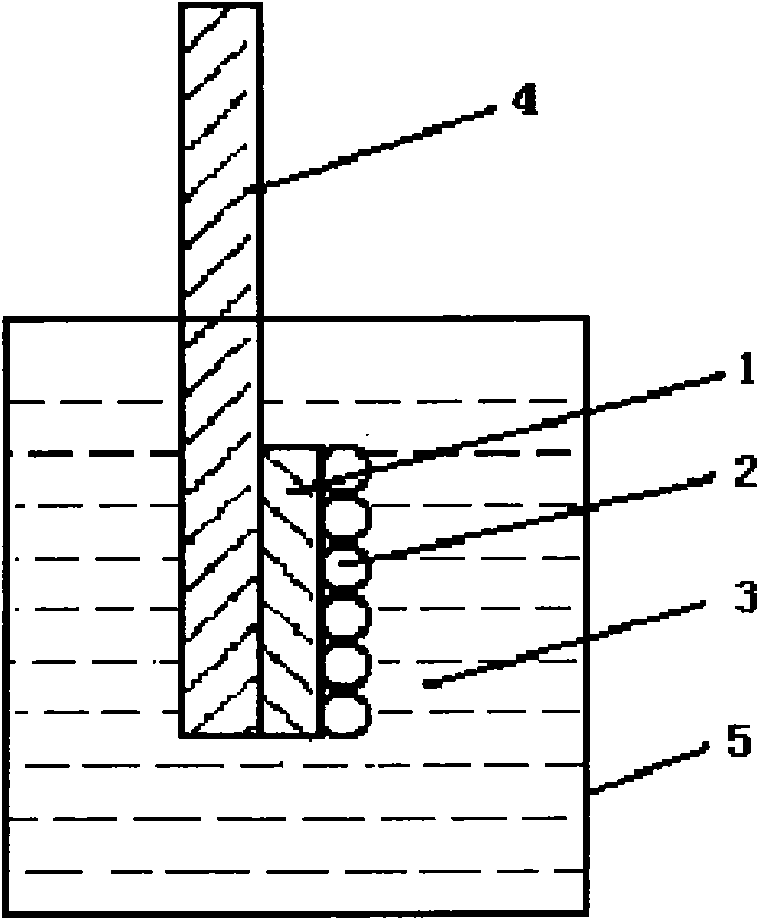

Method for preparing reinforced heat transfer surface of direct liquid cooling chip

InactiveCN101916717ALow equipment requirementsSimple processSemiconductor/solid-state device detailsSolid-state devicesMicrosphereDissolution

The invention discloses a method for preparing a reinforced boiling heat transfer surface of a direct liquid cooling chip, which comprises the following steps of: forming monolayer or multilayer colloid crystal membranes which are arranged regularly with colloid microspheres by an LB membrane method, a self-assembly method or a spin coating method, and taking the membranes as a template; filling the template by utilizing a sol-gel method; and finally removing the template by utilizing a method of calcining or dissolution to prepare the two-dimensional or three-dimensional reinforced boiling heat transfer surface on the surface of the substrate. The reinforced boiling heat transfer surface has the excellent boiling heat transfer performance in a pipeline type natural circulation cooling system, and has the advantages of simple preparation method and low cost.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Server rack heat sink system with combination of liquid cooling device and auxiliary heat sink device

ActiveUS10356949B2Improve cooling efficiencyGood effectModifications using liquid coolingSingle machine energy consumption reductionLow noiseHigh density

A server heat dissipation system is provided, comprising a liquid cooling server cabinet comprising a cabinet body and multiple liquid cooling servers provided inside the cabinet body, wherein it is provided with a liquid cooling device to perform direct liquid cooling to the liquid cooling servers, and with an auxiliary heat dissipation device to perform auxiliary heat dissipation to the liquid cooling servers. The present invention provides high density cooling, high heat exchange efficiency, no local overheating, small space occupied, high reliability, low noise, and long life.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

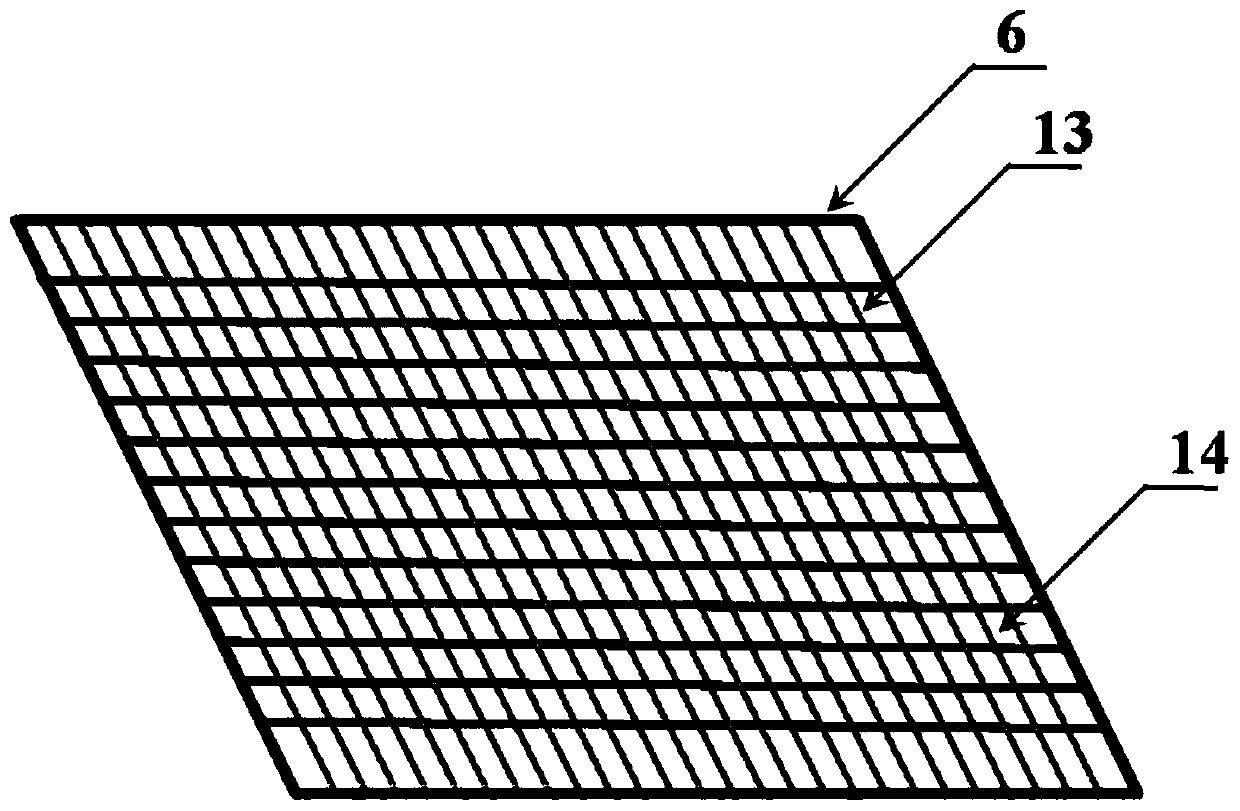

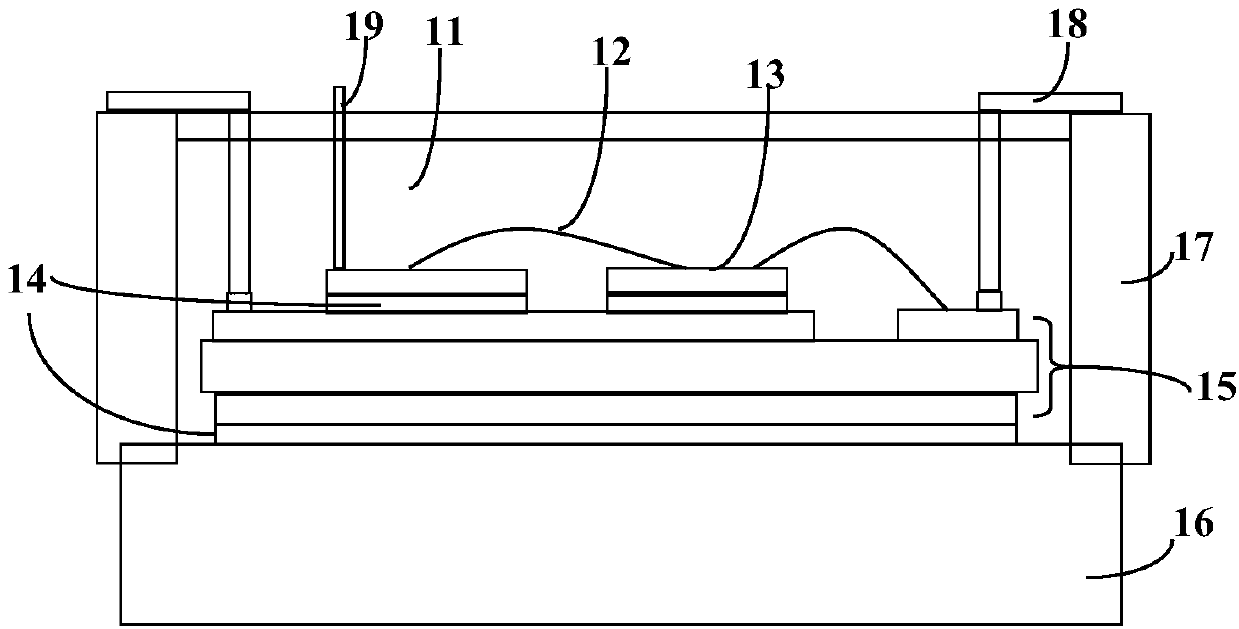

Liquid-cooling type panel aluminum heat pipe radiator and manufacturing method thereof

PendingCN108235653APrecise coolingImprove cooling efficiencyCooling/ventilation/heating modificationsDirect liquid coolingEngineering

The invention relates to a liquid-cooling type panel aluminum heat pipe radiator. The liquid-cooling type panel aluminum heat pipe radiator comprises a liquid cooling plate and a panel aluminum heat pipe, wherein the liquid cooling plate comprises a liquid cooling plate body, a cover body and an accommodating space, wherein the accommodating space is formed by enclosure of the liquid cooling platebody and the cover body, a plurality of separation fins are arranged in the accommodating space, a liquid inlet and a liquid outlet are formed in the liquid cooling plate body, the space between theliquid inlet and the liquid outlet is separated into a plurality of main runners by the separation fins, and the main runners are connected in series in an S manner; and the accommodating space is filled with a cold medium; and insertion holes are formed in a plane side of the liquid cooling plate body. According to the liquid-cooling type panel aluminum heat pipe radiator disclosed by the invention, the accurate heat radiation of heating electronic elements is realized, and the heat radiation efficiency is substantially improved; compared with a direct liquid-cooling type heat radiation manner, the radiator has the advantages that by utilizing an indirect water cooling heat radiation manner, the liquid cooling plate and the panel aluminum heat pipe are respectively sealed, so that the sealing effect is good, the cold medium is unlikely to be leaked, and the stability is good; and compared with a heat radiation structure of a copper water heat pipe type heat exchanging device, the light and convenient panel aluminum heat pipe is adopted.

Owner:SOUTH CHINA UNIV OF TECH +1

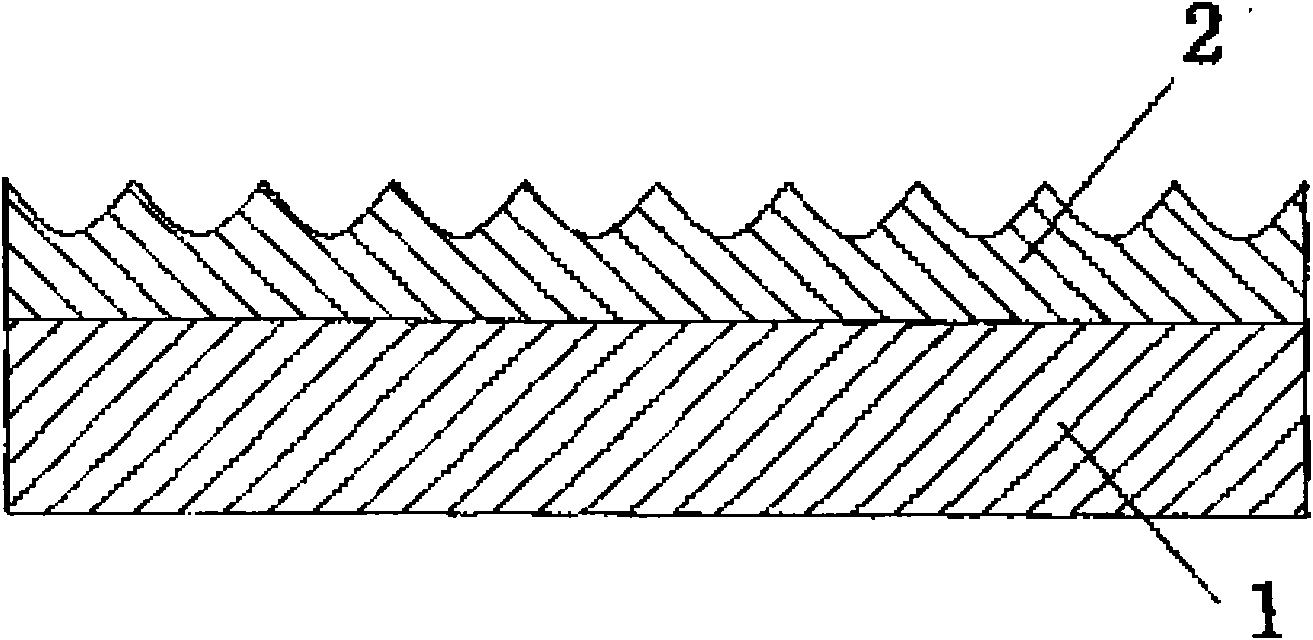

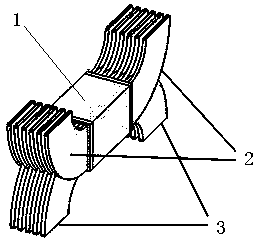

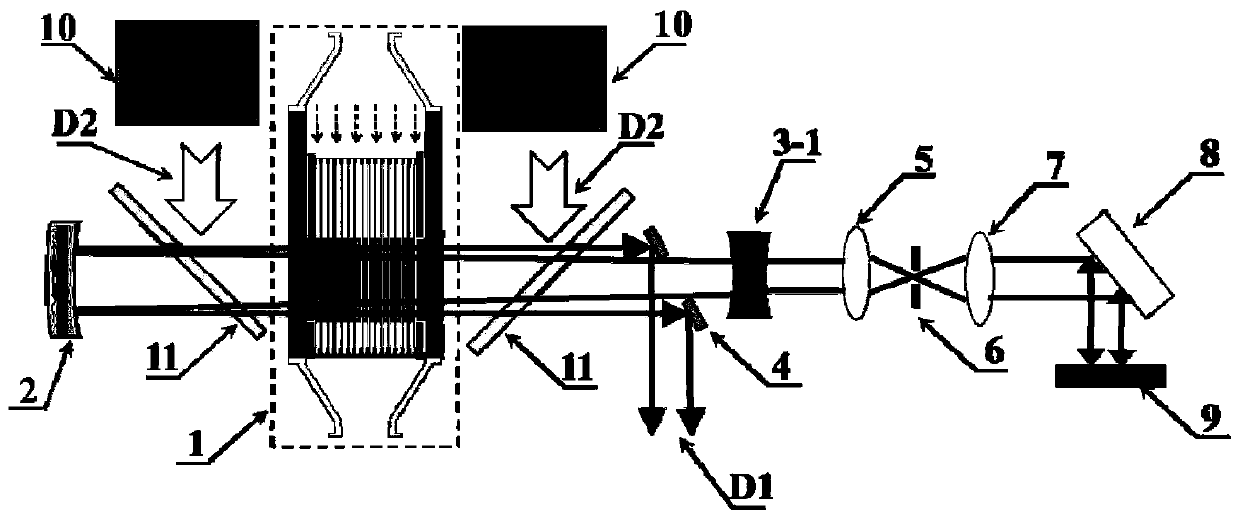

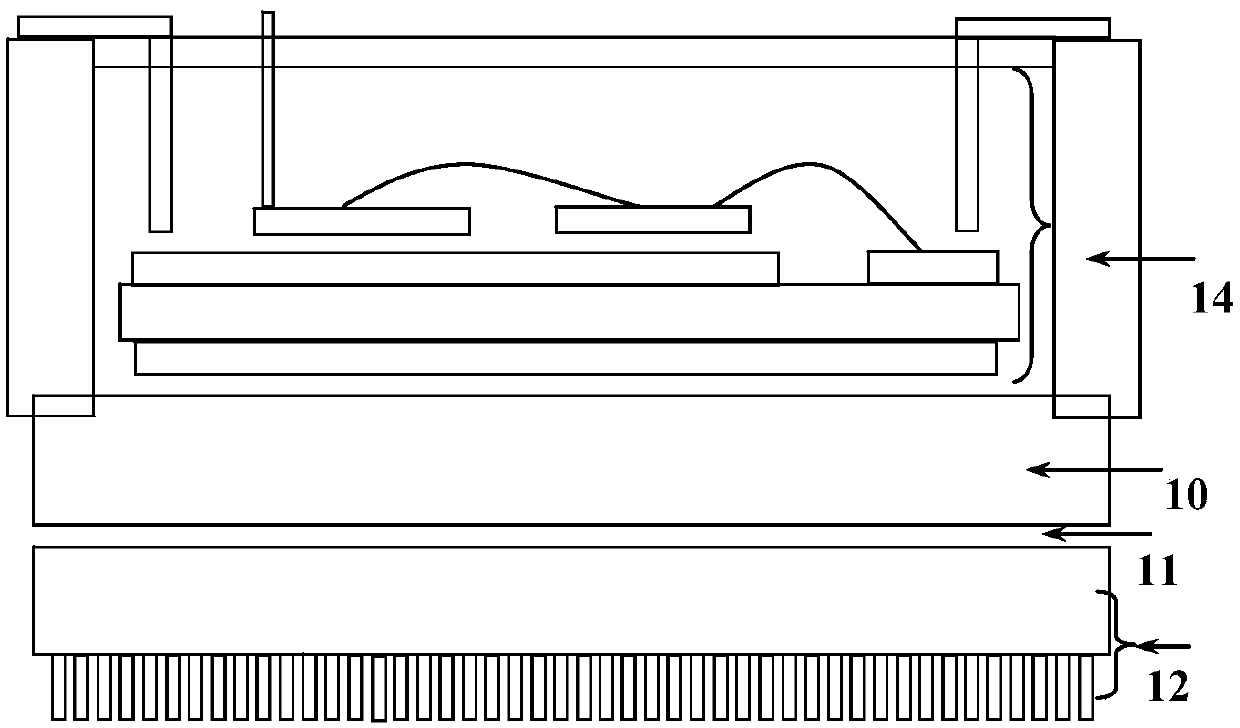

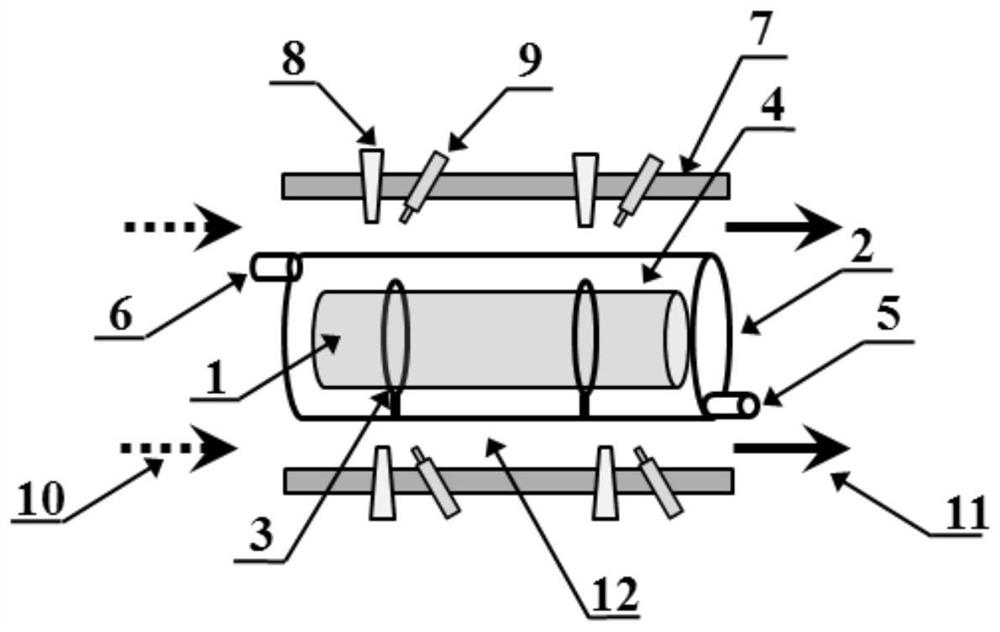

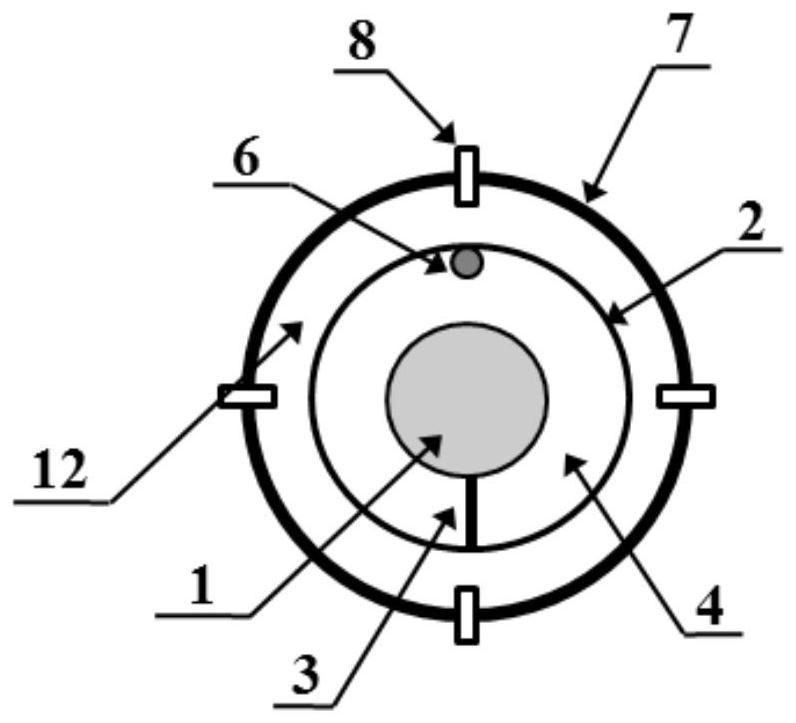

Gain module of tilt aberration self-compensating type direct liquid-cooling thin-disk laser

PendingCN107623245AFlow in the opposite directionIncrease output powerLaser cooling arrangementsDirect liquid coolingComputer module

The present invention provides a gain module of a tilt aberration self-compensating type direct liquid-cooling thin-disk laser. The gain module comprises heat dissipation channels, an adapter, gain plate strips and a packaging shell. The adapter is composed of run-through flow channels and an entity portion, wherein the run-through flow channels and the entity portion are staggered to form the adapter. The heat dissipation channels are divided into a group A of heat dissipation channels and a group B of heat dissipation channels. The group A of heat dissipation channels and the group B of heatdissipation channels are connected with the run-through flow channels of the adapter in opposite directions in a staggered mode. The gain plate strips are fixed between the two run-through flow channels of the adapter. The packaging shell is covered outside the gain plate strips and is fixedly connected with the adapter. According to the invention, two groups of heat dissipation channels are arranged. In this way, the cooling liquid between every two gain plate strips is opposite in flow direction. The aberration can be automatically compensated in the flow direction of the cooling liquid. The output power of the direct liquid-cooling thin-disk laser is improved.

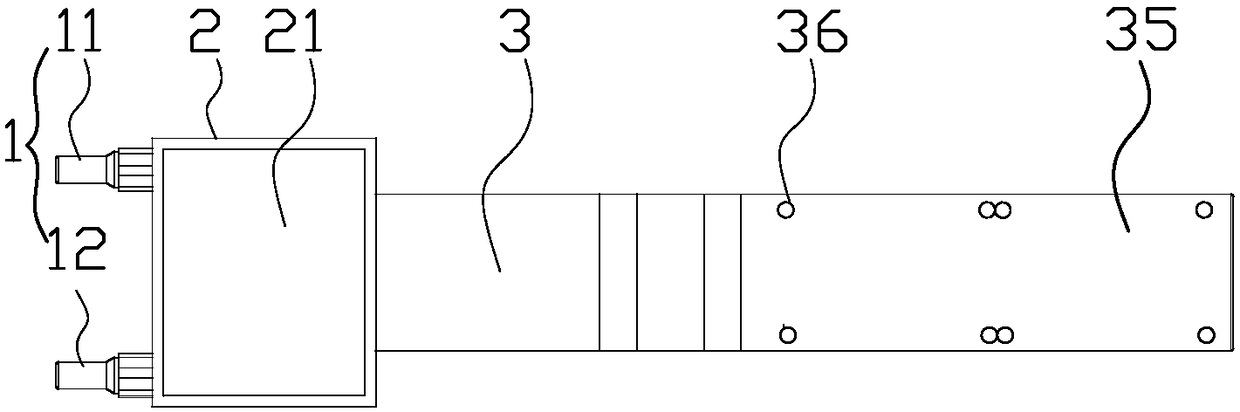

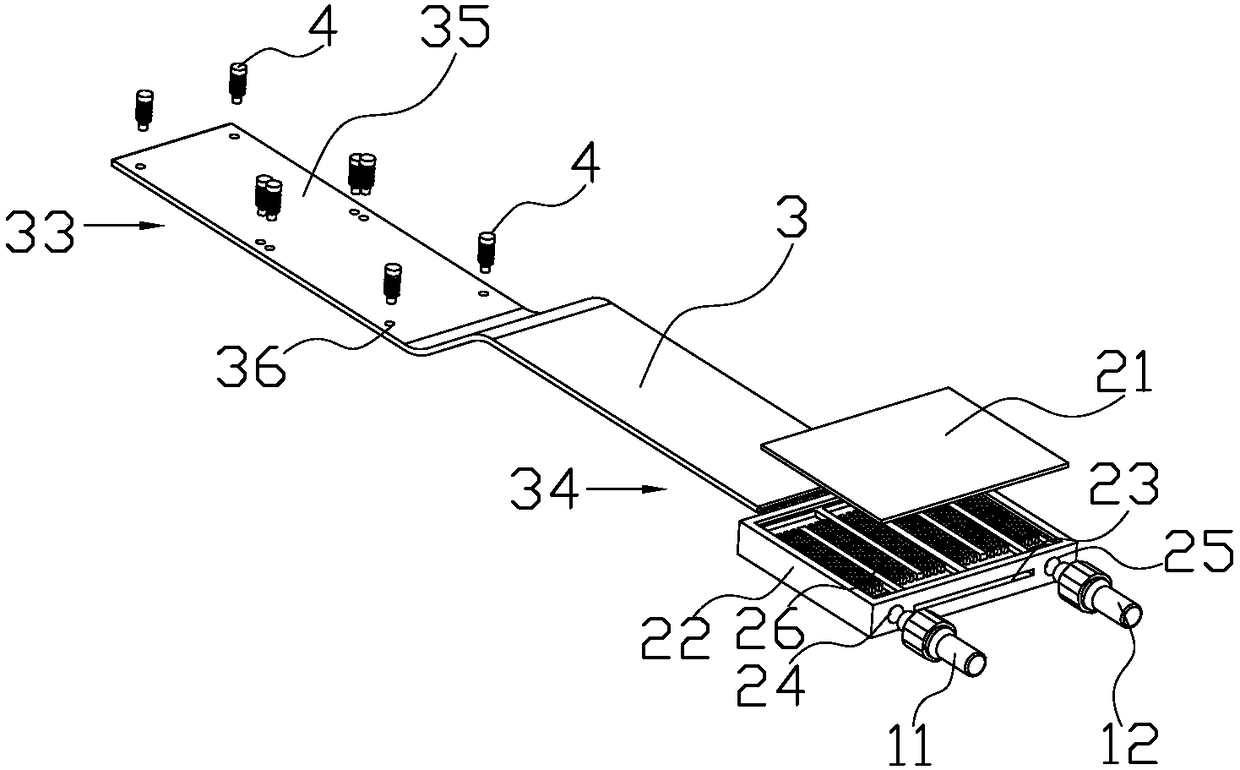

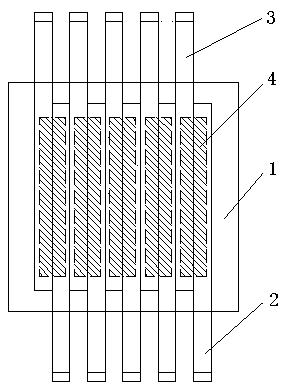

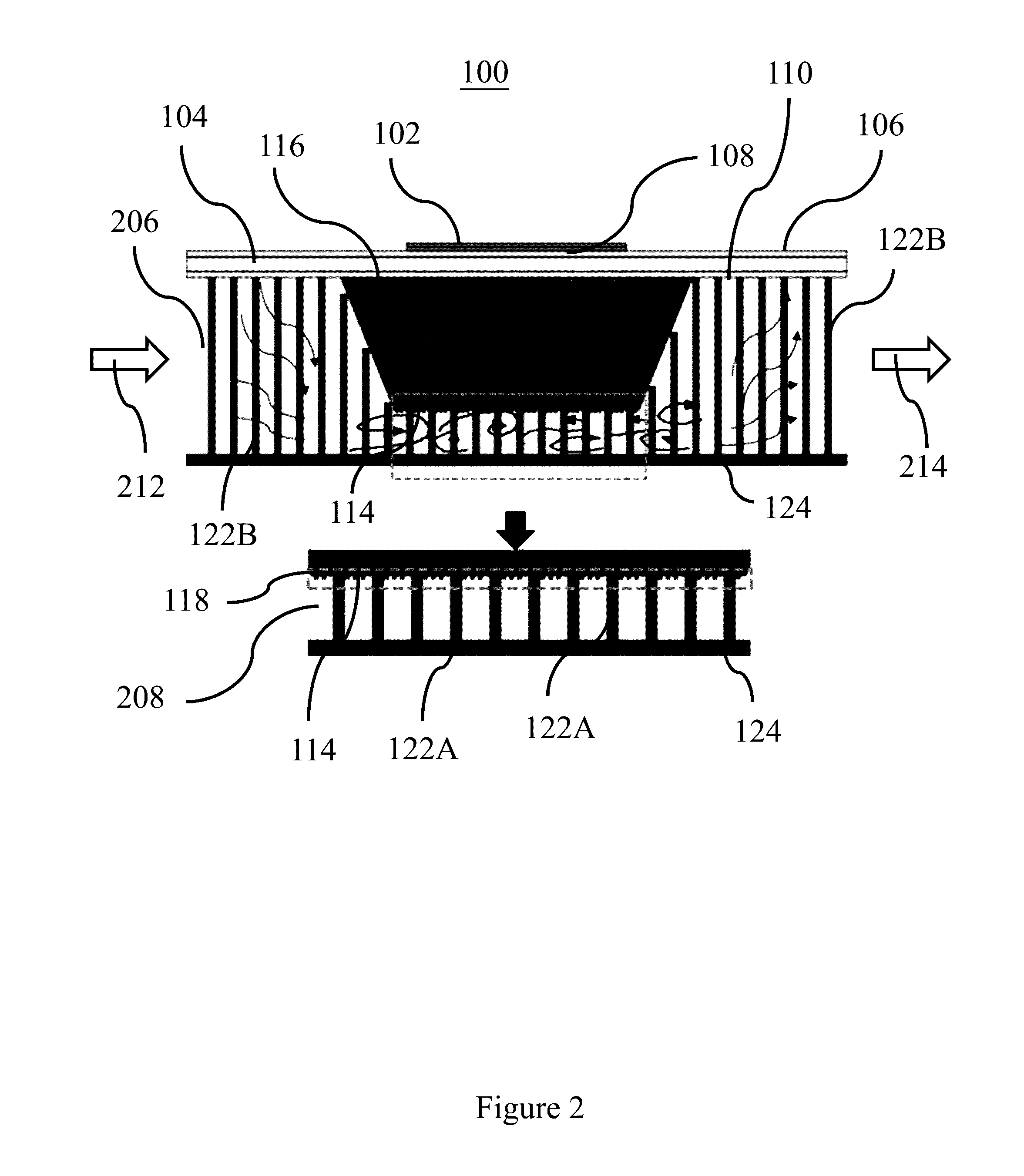

Liquid cooled metal core printed circuit board

ActiveUS9686887B2Minimize thermal bottleneckReduce in quantityPrinted circuit aspectsPrinted circuit manufactureElectronic systemsDirect liquid cooling

The present disclosure further contemplates a system and method that cools metal core printed circuit boards by circulating a liquid coolant so that it contacts the base metal of the metal core printed circuit board. In one example the present disclosure contemplates a direct liquid cooled MCPCB system that may include a liquid cavity creating component coupled to the base plate of a MCPCB allowing a liquid coolant to come into contact with the base plate of the MCPCB for cooling of the MCPCB. The direct liquid cooled MCPCB system may minimize thermal bottlenecks between the electrical components and the cooling fluid while reducing the number of components required in previous liquid cooled electronics systems.

Owner:DONOFRIO NICHOLAS MICHAEL

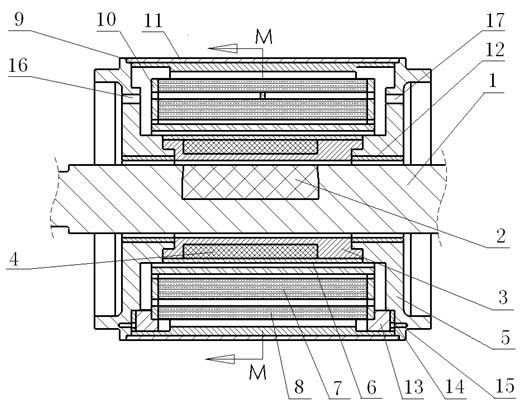

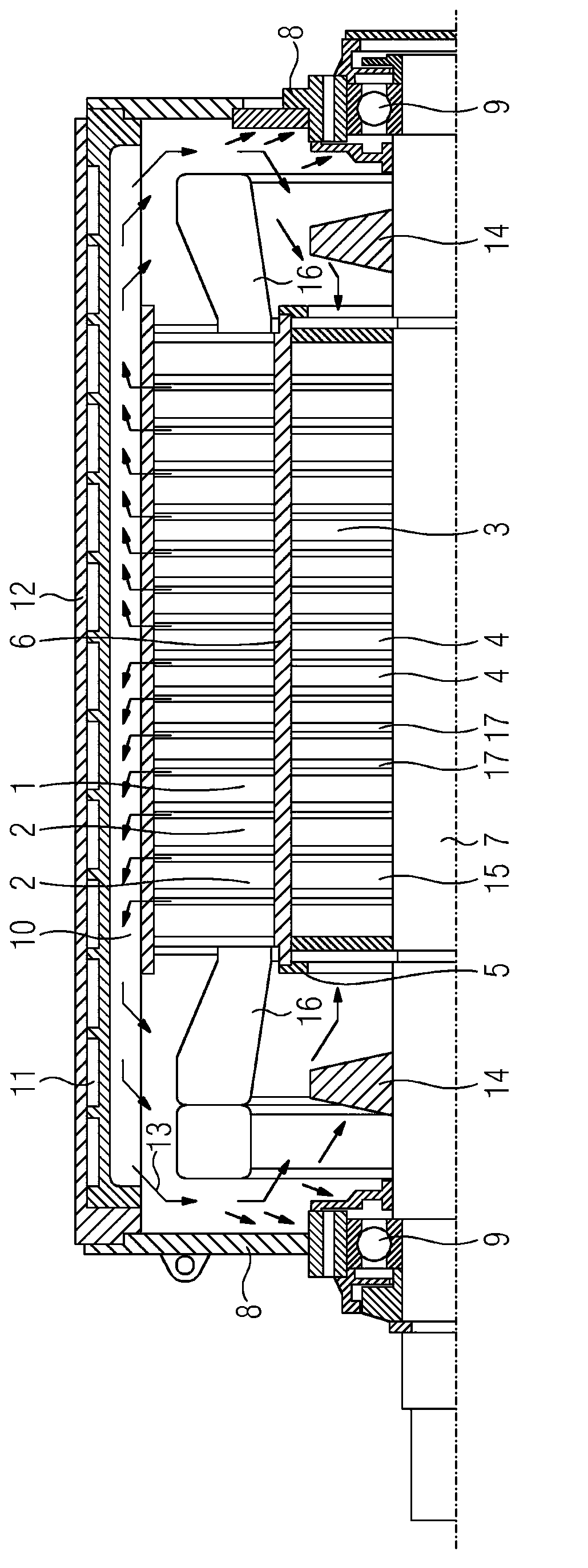

Dynamoelectric machine having air/liquid cooling

InactiveCN102939700AImprove cooling effectLarge heat transfer surfaceWind energy generationMechanical energy handlingWind systemDirect liquid cooling

The invention relates to dynamoelectric machine, in particular a wind generator, comprising a stator (1), which is designed as a laminated core and has a winding system, which forms winding heads (16) on the end faces of the stator (1), and a rotor (3), which is designed as a laminated core and which is connected to a shaft (7) in a rotationally fixed manner, wherein the stator (1) and the rotor (3) are arranged in a housing, wherein the shaft (7) is supported by means of bearings (9), which are arranged in bearing shields (8), wherein the laminated core of the stator (1) and / or rotor (3) has axially extending cooling channels (15), wherein the bearing shields (8) form a closed interior together with the housing, said interior having at least one closed inner cooling circuit, wherein the housing has an outer jacket (12) and an inner jacket (19) facing the stator (1); and arranged at a distance from the outer jacket in some sections, wherein the outer jacket (12) and the inner jacket (19) combined form a cooling jacket (11), in particular a liquid cooling jacket, the axial extension of which equals at least the axial extension of the laminated core of the stator (1).

Owner:SIEMENS AG

Variable flow computer cooling system for a data center and method of operation

ActiveCN101960408ADigital data processing detailsElectrical apparatus contructional detailsData centerEngineering

Owner:GLOBALFOUNDRIES INC

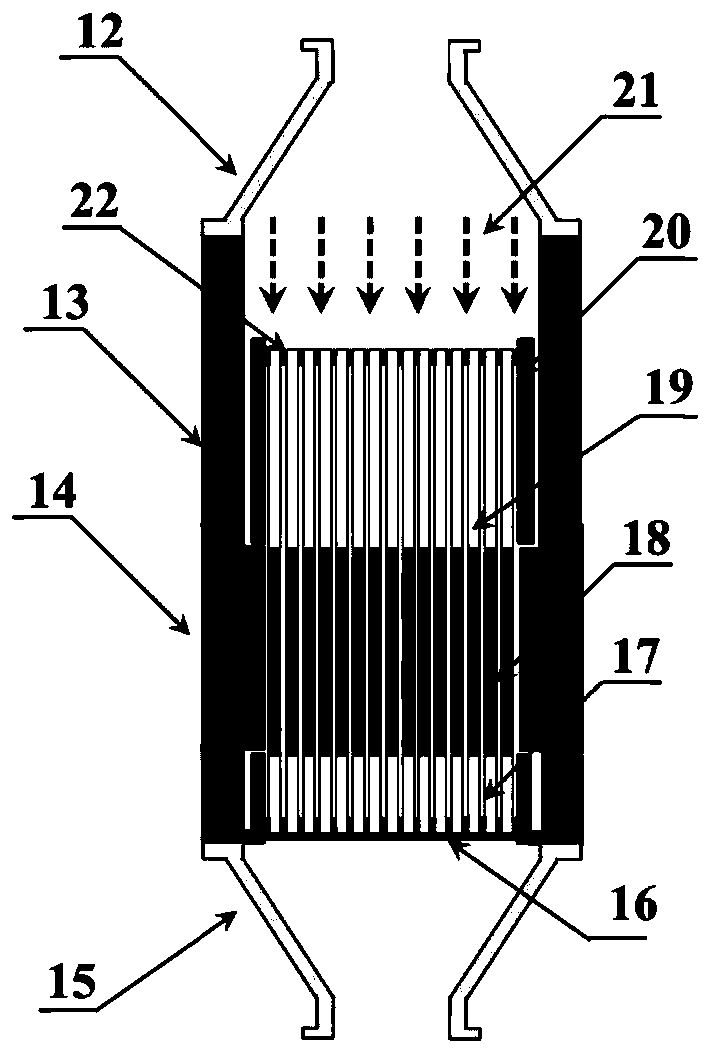

Direct liquid cooling laser gain device based on split type flow channel

ActiveCN111313213AHigh densityImprove cooling effectLaser cooling arrangementsDirect liquid coolingLaser light

The invention discloses a direct liquid cooling laser gain device based on a split type flow channel. The device comprises a device outer frame, a device inner frame, a crystal barrier strip, an incoming flow guide cone, a homogenizing grid, a micro-channel separation strip, a dissipation section crystal, a light transmission window, a laser gain crystal, a recovery section crystal and an outflowcone. Cooling liquid flows into the device outer frame after being shunted by an in-cone flow guide plate in the incoming flow guide cone, and enters the device inner frame after being homogenized bythe homogenizing grid. In a micro-channel of the inner frame, turbulent flow is further dissipated by flowing through a dissipation section crystal area firstly, the speed uniformity of liquid reaching the gain crystal in the spanwise direction is guaranteed, and the liquid flows out of the device inner frame after passing through the recovery section crystal. A small amount of liquid flows out through a gap between the inner frame and the outer frame of the device and is used for cooling the laser light transmission window. All liquid flows out of the device after being converged at the outflow cone. The device is compact and small in structure, and the flow velocity of liquid passing through the gain medium can be uniform.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

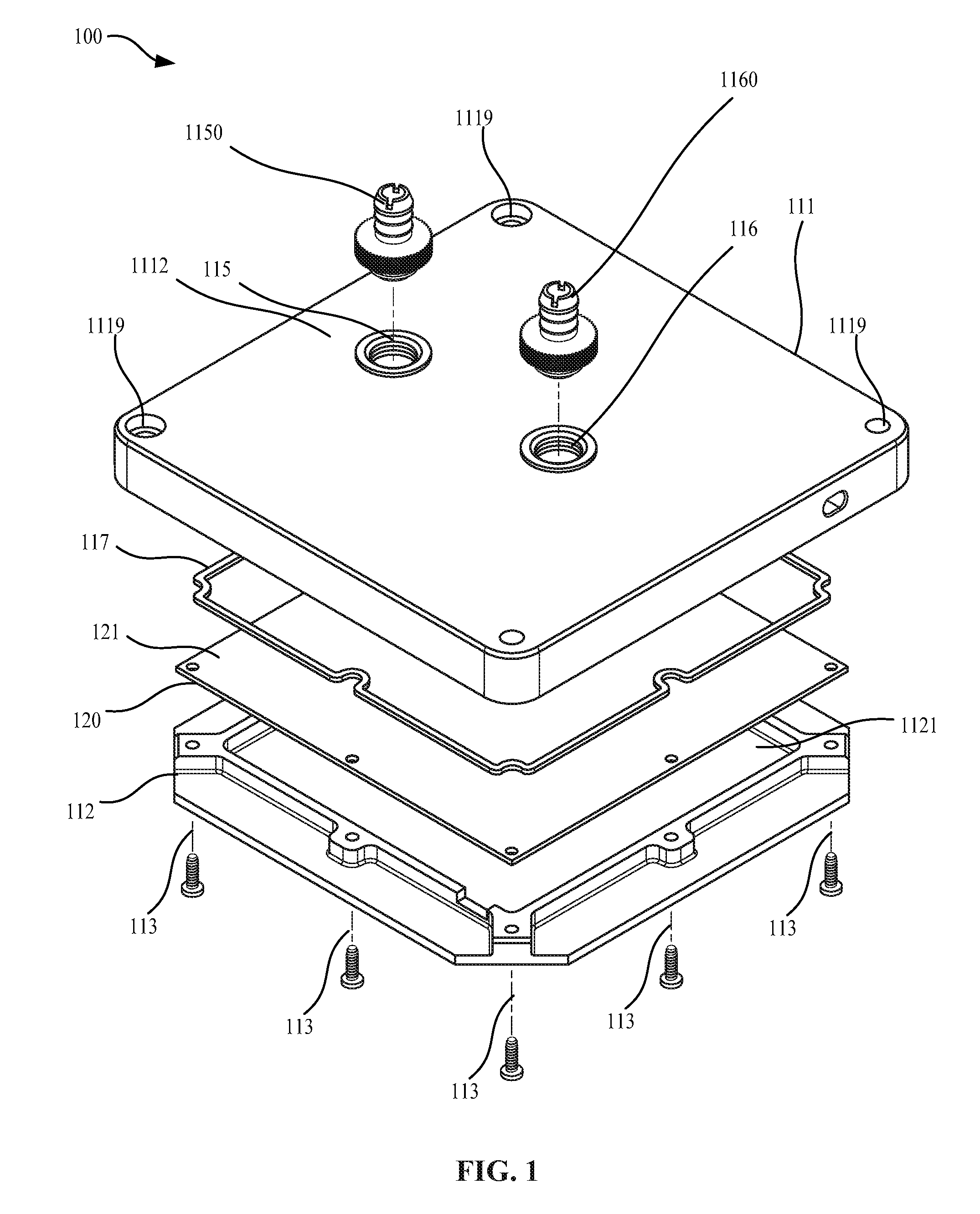

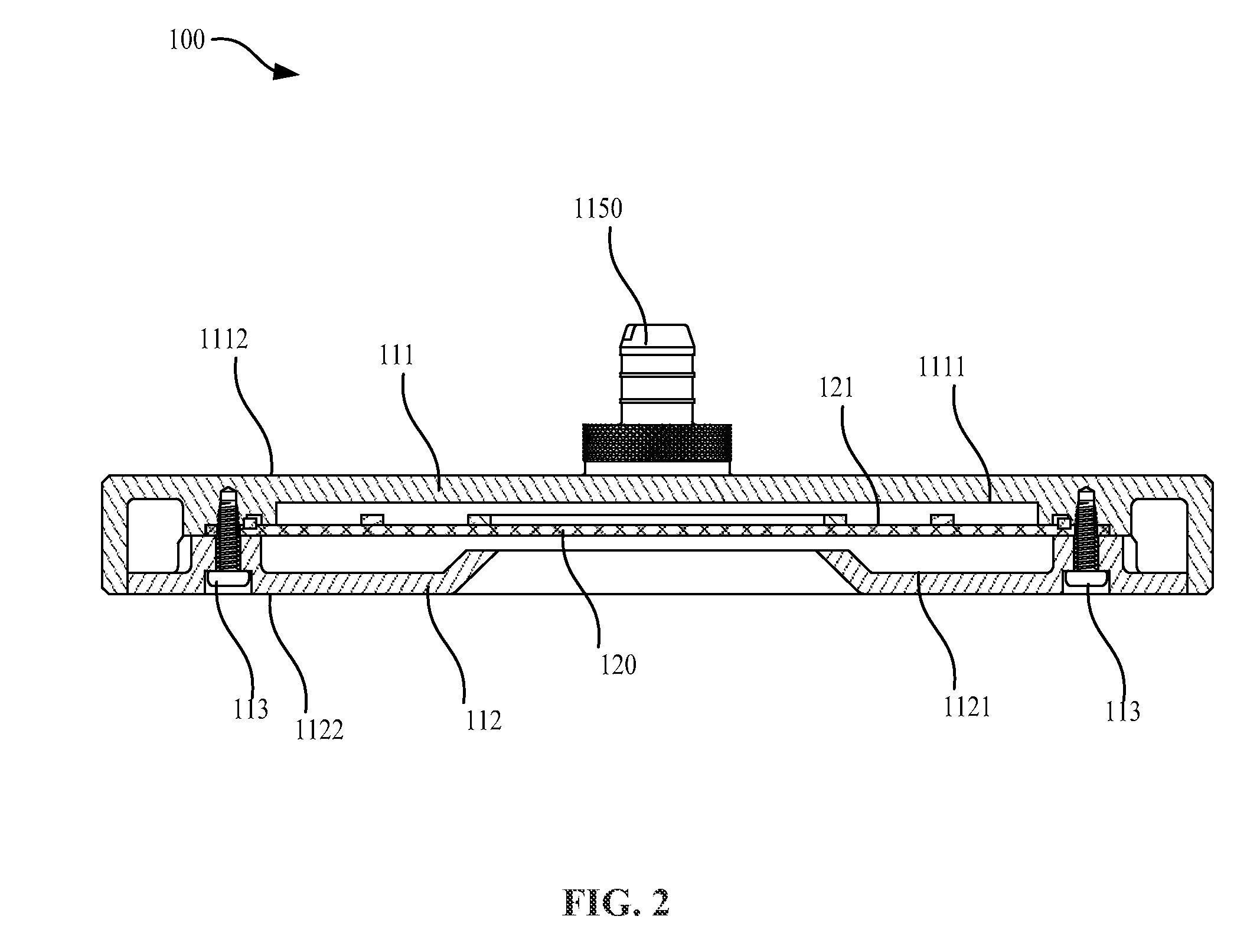

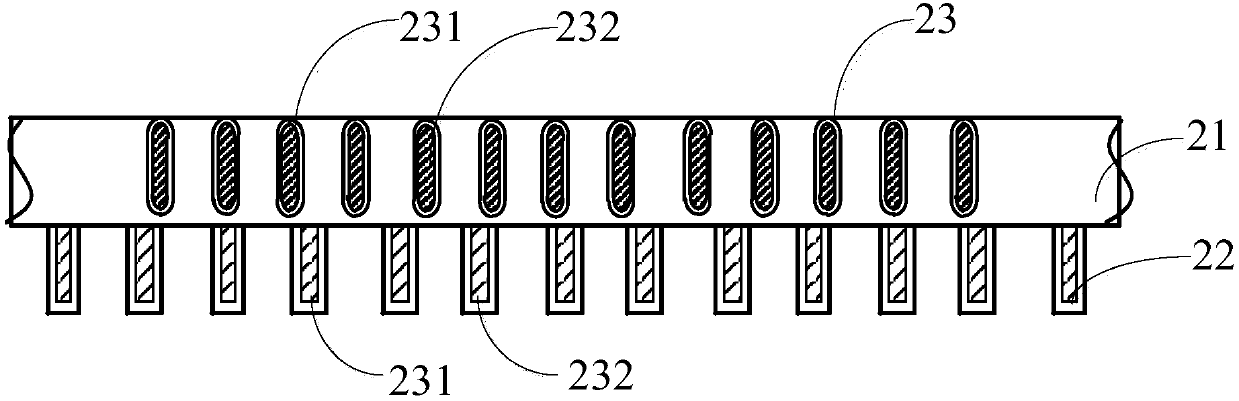

Base plate with integrated heat tubes and module device thereof

ActiveCN105957848AImprove cooling efficiencyEfficient and reliable heat dissipationSemiconductor/solid-state device detailsSolid-state devicesLiquid mediumDirect liquid cooling

The invention discloses a base plate with integrated heat tubes and a module device thereof, wherein the base plate with the integrated heat tubes comprises a base plate main body, direct liquid cooling fins and the integrated heat tubes, the direct liquid cooling fins are arranged at the lower surface of the metal base plate, the base plate main body and the direct liquid cooling fins both are internally provided with the integrated heat tubes, and the integrated heat tubes are internally provided with a low-temperature phase change liquid medium for quickly conducting heat. The base plate with the integrated heat tubes and the module device thereof, provided by the invention, have the integrated heat tubes with high heat dissipation efficiency and the direct liquid cooling fins, perform heat dissipation through the low-temperature phase change liquid medium and an external cooling medium, consequently can eliminate heat conduction silicone grease in a conventional power module, and can realize high-efficiency and reliable heat dissipation for a power module of an electric car.

Owner:ZHUZHOU CRRC TIMES SEMICON CO LTD

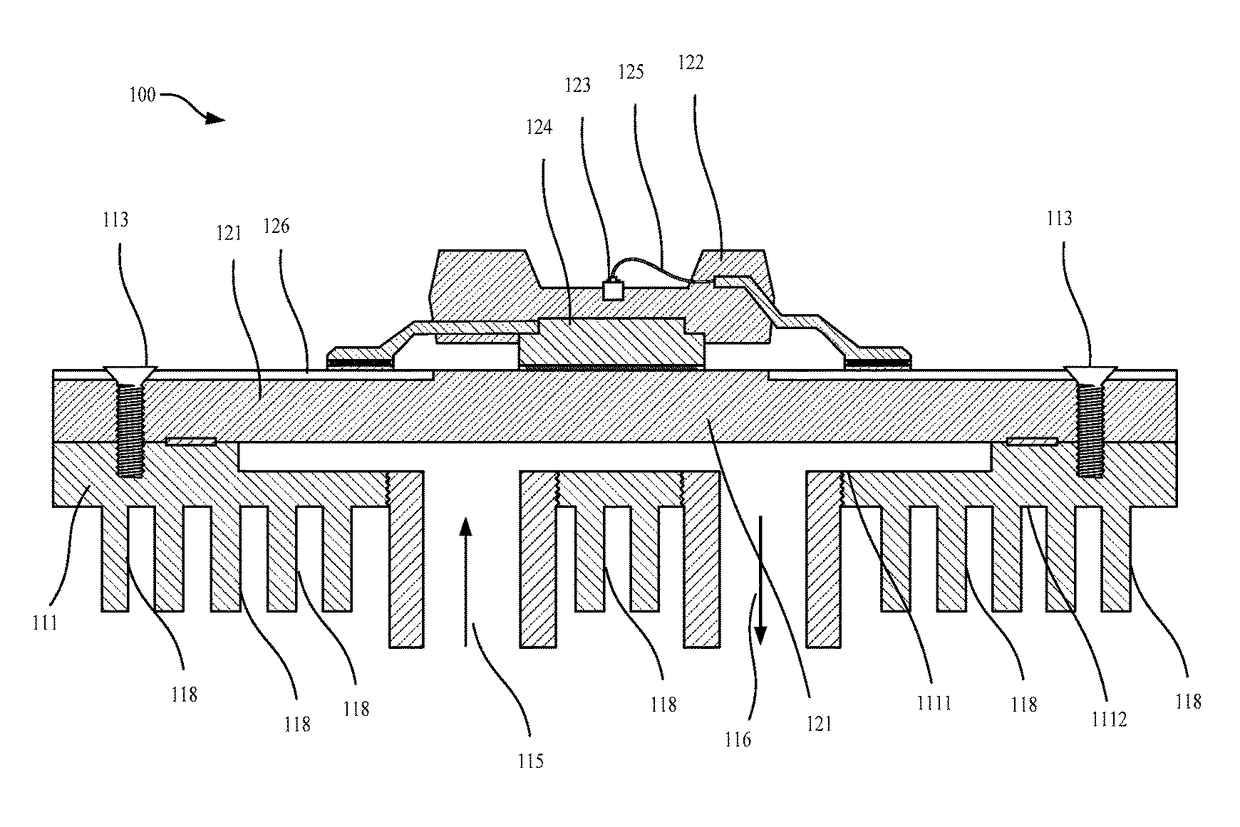

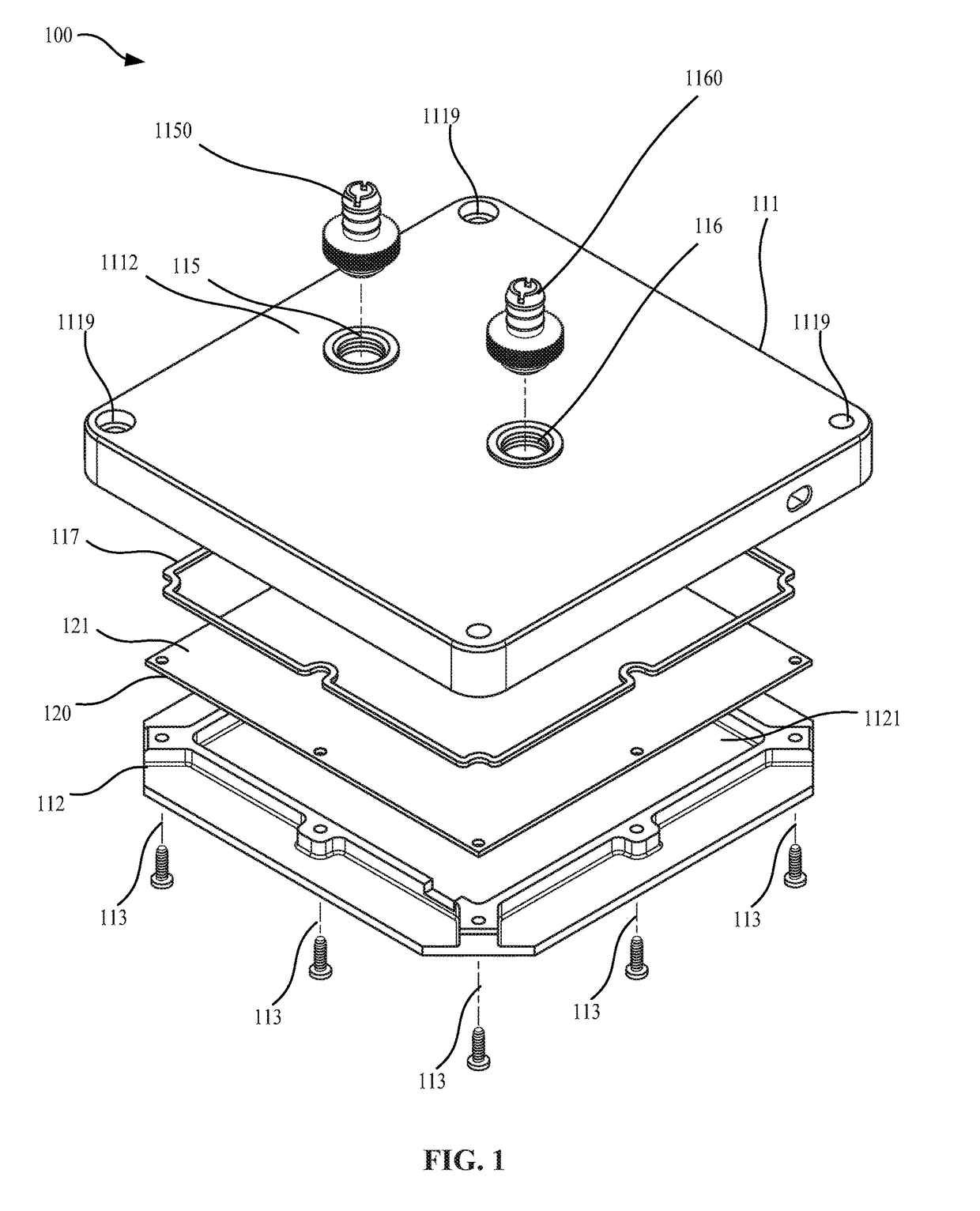

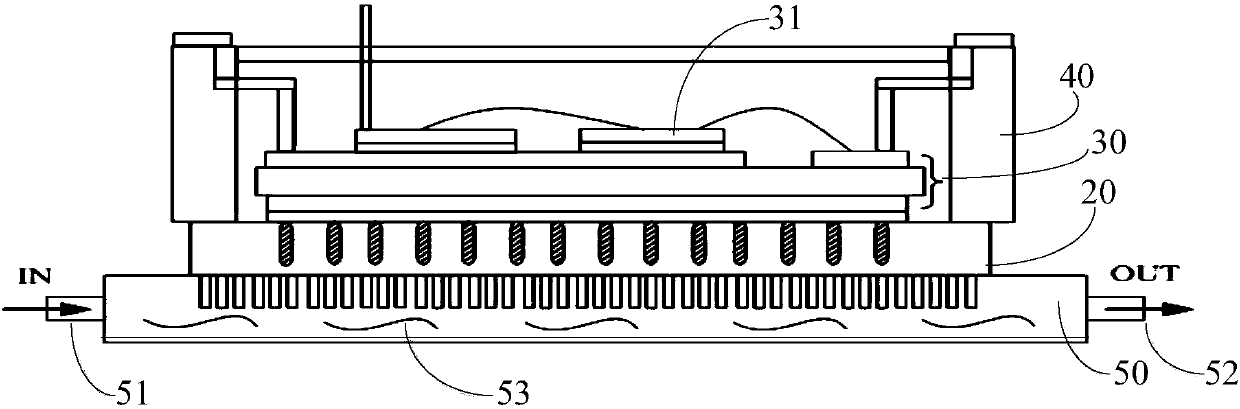

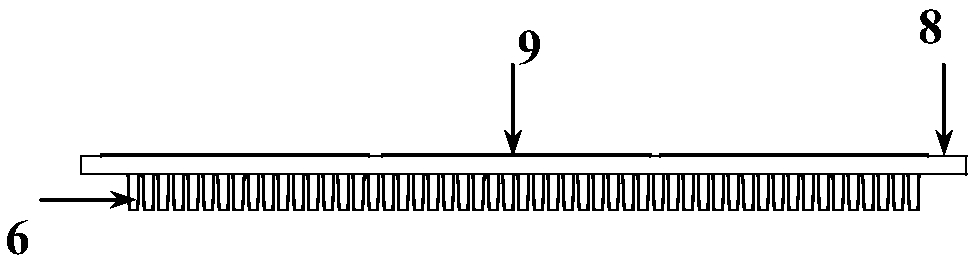

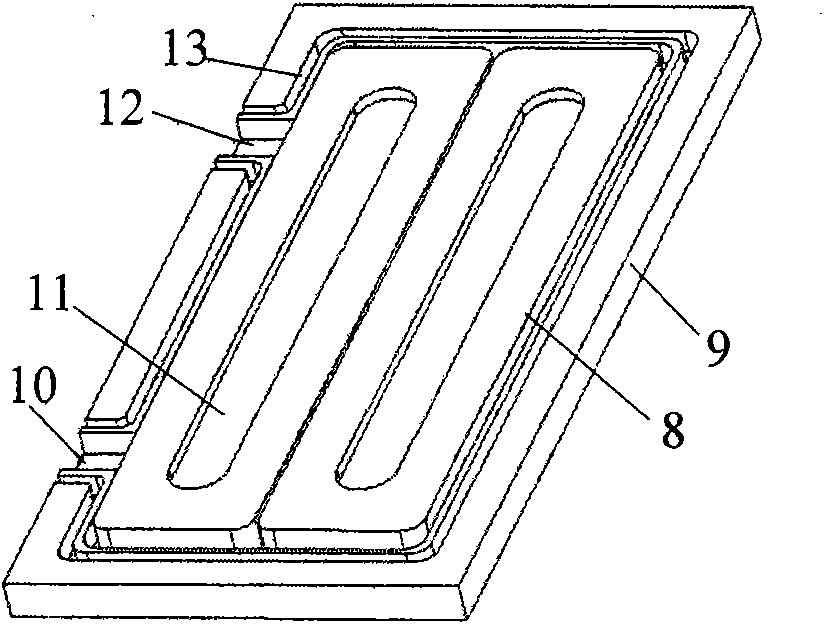

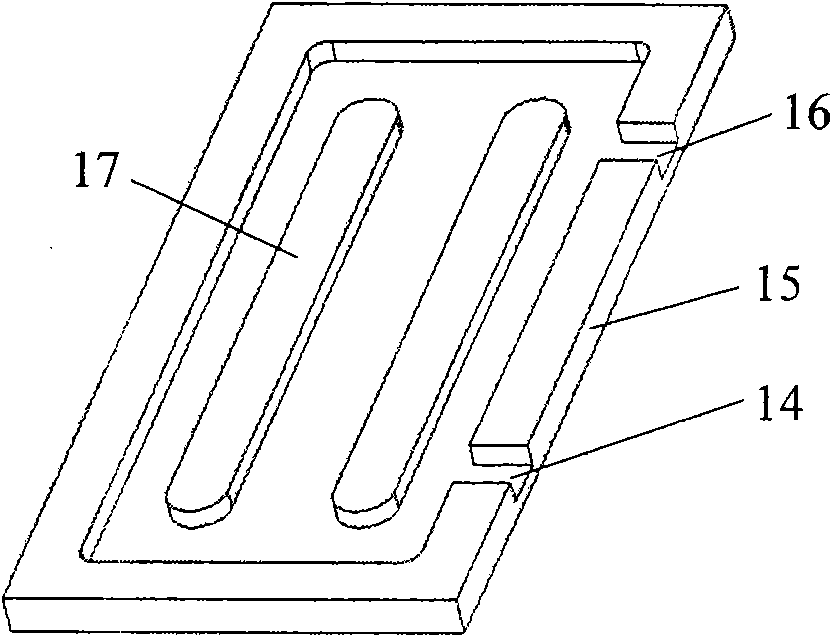

Locally Enhanced Direct Liquid Cooling System for High Power Applications

ActiveUS20170020027A1Increased turbulenceEffective coolingSemiconductor/solid-state device detailsModifications by conduction heat transferDirect liquid coolingEngineering

The present invention discloses a fluid cooling assembly which facilitates turbulent flow inside the assembly so as to achieve better heat dissipating effect. The cooling assembly comprises an enclosed chamber with an inlet and an outlet for fluid to pass through; together with a heat spreader; a plurality of micropillars and a plurality of heat dissipating fins installed inside the assembly. When fluid flows through the chamber, these elements in combination are adapted to create an enhanced turbulent flow upon the fluid so as to effectively dissipate heat from said heat spreader through the fluid.

Owner:HONG KONG APPLIED SCI & TECH RES INST

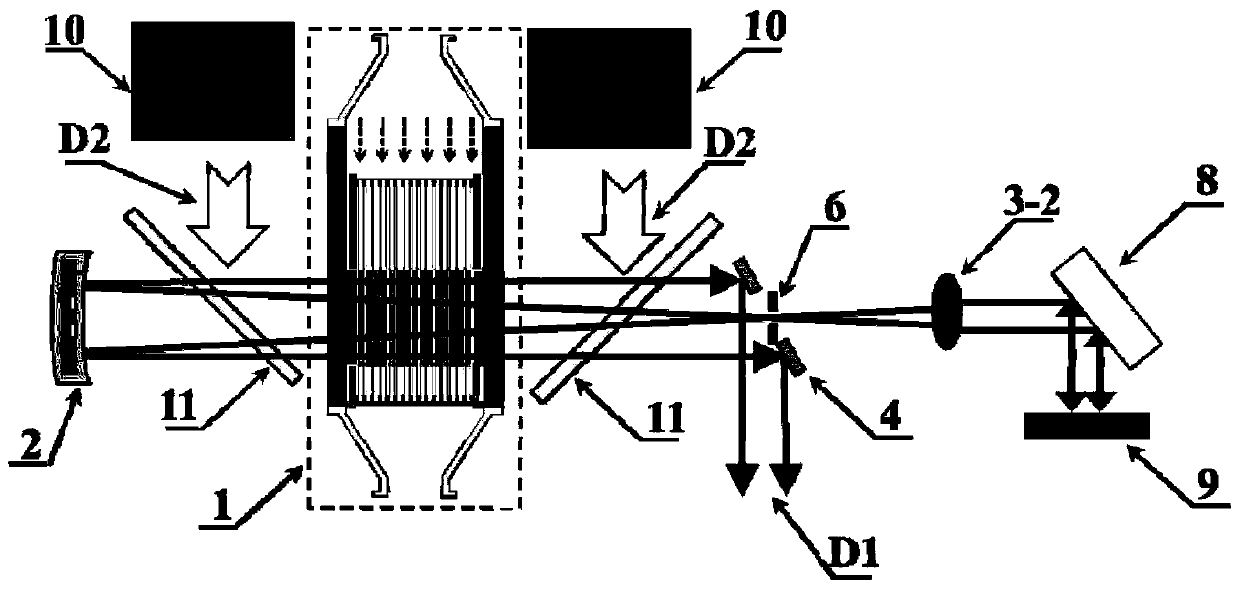

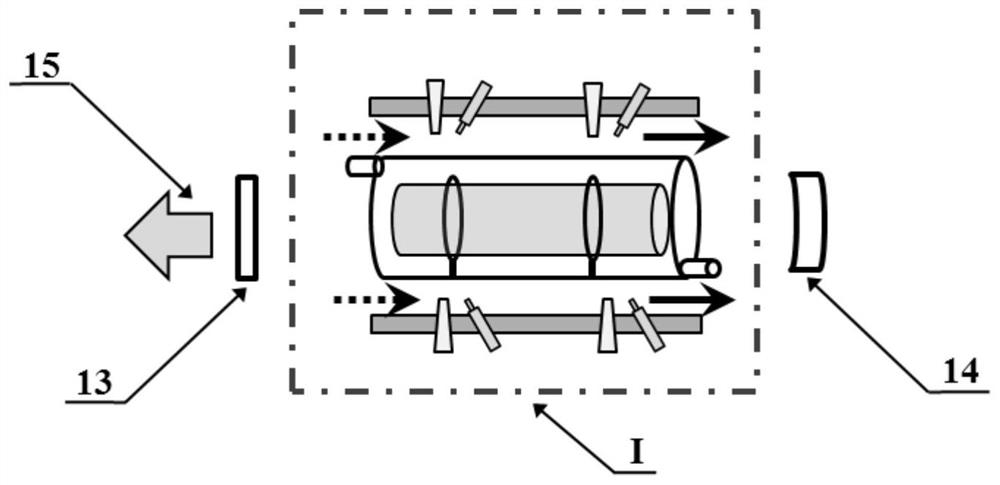

Direct liquid cooling array type sheet unstable resonant cavity capable of suppressing high-order distortion in cavity

ActiveCN111404000AAvoid crosstalkHigh and uniform flow fieldLaser cooling arrangementsResonant cavityGrating

The invention discloses a direct liquid cooling array type sheet unstable resonant cavity capable of suppressing high-order distortion in a cavity. The structure of the direct liquid cooling array type sheet unstable resonant cavity comprises a direct liquid cooling array distributed gain module, a resonant cavity mirror, a 4f phase transmission, a diaphragm, a reflection type volume Bragg gratingand a pumping system. The invention aims to overcome the defect of poor light beam quality caused by more high-order distortion introduced by liquid flow of a direct liquid cooling array type sheet laser device. An unstable cavity structure is innovatively changed, a 4f system is introduced into the cavity, and high-order wavefront distortion suppression is realized in the cavity by adopting a mode of combining a diaphragm and a reflective Bragg grating, so that high-beam-quality laser output is obtained. The laser device not only can effectively solve the problem of solid laser thermal management, but also realizes high-beam-quality laser output, and is a novel high-power laser device.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

Direct cooling heat dissipation substrate and power module thereof

InactiveCN110707054AImprove cooling efficiencyDirect cooling achievedSemiconductor/solid-state device detailsSolid-state devicesDirect liquid coolingEngineering

The invention provides a direct cooling heat dissipation substrate which realizes the direct liquid cooling without needing the contact between a heat conduction silicone grease layer and an externalradiator. The direct cooling heat dissipation substrate comprises an electrical loop layer, an insulating layer and a heat dissipation layer, the heat dissipation layer comprises a direct cooling layer, and the direct cooling layer can perform air cooling or can be directly connected to an external cooling system to realize the direct cooling. The invention also provides a power module prepared from the direct cooling heat dissipation substrate. According to the direct cooling heat dissipation substrate and the power module thereof, a porous metal foam structure is integrated under a metal layer to access to the external cooling system, and the direct cooling is achieved through the external cooling liquid, so that the number of the thermal interfaces of the internal materials of the module is reduced, the thermal resistance of the module is reduced, the heat dissipation performance and reliability of the power module are improved, the rapid and efficient heat dissipation of the powerIGBT module is achieved, the purpose of reducing the weight and size of the module is achieved, and the direct cooling heat dissipation substrate and the module have the advantages of being low in thermal resistance, light in weight and high in reliability.

Owner:ZHUZHOU CRRC TIMES SEMICON CO LTD

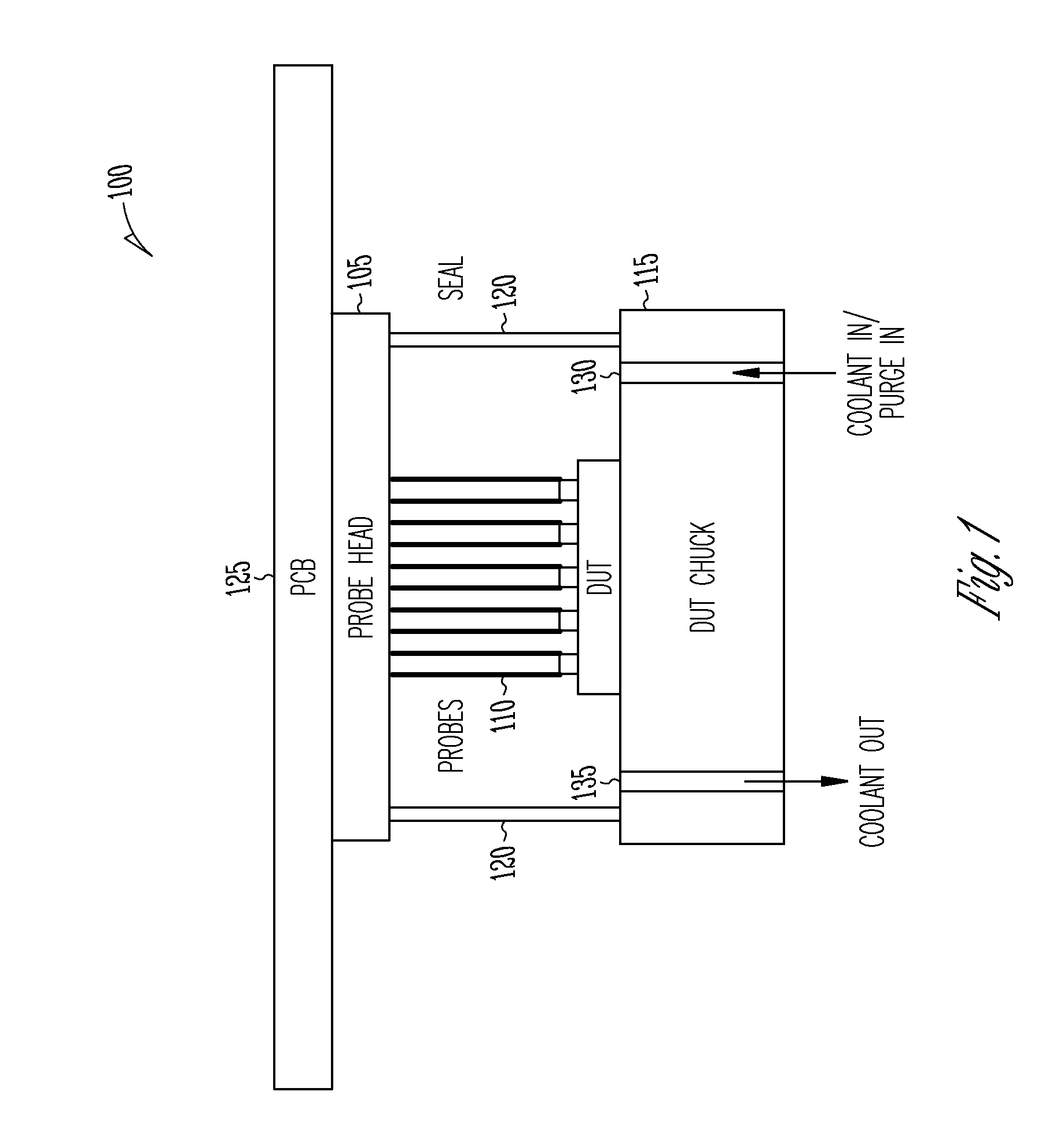

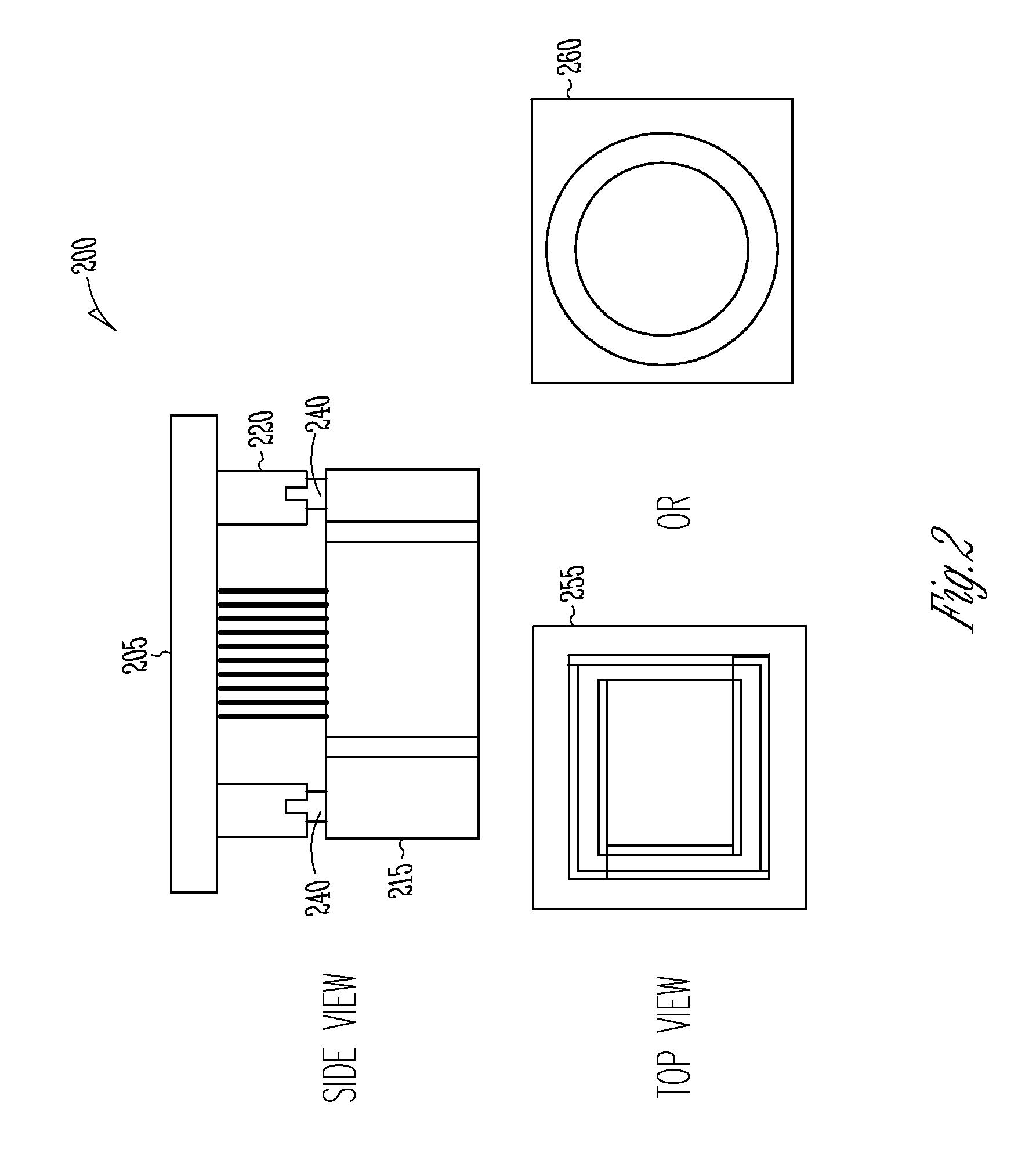

Seal method for direct liquid cooling of probes used at first level interconnect

InactiveUS20140125367A1Semiconductor/solid-state device manufacturingFault location by increasing destruction at faultDirect liquid coolingElectrical contacts

Embodiments of an apparatus and method for providing cooling of probes for testing of integrated circuits are generally described herein. In some embodiments, an apparatus comprises a probe head assembly configured to hold one or more probes that are adapted to provide electrical contact with an integrated circuit device under test (DUT), a DUT chuck adapted to hold the DUT for contact with the probes, a seal arranged between the probe head assembly and the DUT chuck to form a chamber when the seal is in contact with the probe head assembly and the DUT chuck, and a first port and a second port arranged to provide fluid flow into and fluid flow out of the chamber.

Owner:INTEL CORP

Direct liquid cooling high-power laser gain device based on fuel injection pump

ActiveCN112467506AGuaranteed uniformityGuaranteed StrengthActive medium materialLaser cooling arrangementsCombustion chamberEngineering

The invention discloses a direct liquid cooling high-power laser gain device based on a fuel injection pump, which relates to the technical field of high-energy laser. The gain device comprises a gainmedium for acquiring a laser gain, a device inner frame, laser cooling liquid, a cooling liquid inlet, a cooling liquid outlet, a device outer frame, a fuel nozzle for injecting fuel and realizing combustion, an ignition plug, a high-speed airflow inlet, a waste gas exhaust port and a combustion chamber for fuelcombustion. Compared with the prior art, the inner frame and the outer frame of the device are separated, meanwhile, controllable combustion of fuel in the open type combustion cavity can be achieved by designing the proper injection amount, injection angle and ignition time, and the uniformity and strength of optical pumping are guaranteed. On the other hand, the laser gain medium is cooled in a direct liquid cooling mode, effective thermal management is guaranteed, continuous high-power laser output can be achieved, the output laser beam quality is good, and meanwhile the device is compact, small and exquisite and can be used in various application scenes.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

Direct liquid cooling and heat shielding type sandwich-structured motor armature

InactiveCN101969243AConstant resistanceKeep other parameters unchangedWindings conductor shape/form/constructionSports equipmentCooling effect

The invention relates to a direct liquid cooling and heat shielding type sandwich-structured motor armature. A thin box-shaped armature assembly of a motor is formed by arranging pancake-shaped windings into a cavity of a thin sealing box made from electrical insulating, magnetic isolating and thermal insulating materials; and a gap for forced circulation of cooling liquid is formed between two surfaces of an armature winding and cavity walls of the sealing box. Direct liquid cooling is performed on the surfaces of the armature winding, so that heat consumed by copper of the armature winding is fully taken away by the cooling liquid. The direct liquid cooling and heat shielding type sandwich-structured motor armature of the invention has the advantages of avoiding the influence of temperature change on a control system and control precision, ensuring positioning precision of the system, along with compact structure and good cooling effect, and is suitable for high-tech sophisticated sport equipment and special semiconductor electronic equipment.

Owner:SHANGHAI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com