Liquid-cooling type panel aluminum heat pipe radiator and manufacturing method thereof

A technology of aluminum heat pipe and liquid cold plate, applied in the direction of cooling/ventilation/heating transformation, electrical equipment structural parts, electrical components, etc., can solve problems such as complex manufacturing process, hidden safety hazards, obvious shortcomings, etc., and achieve weight and volume reduction , easy installation and maintenance, and the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

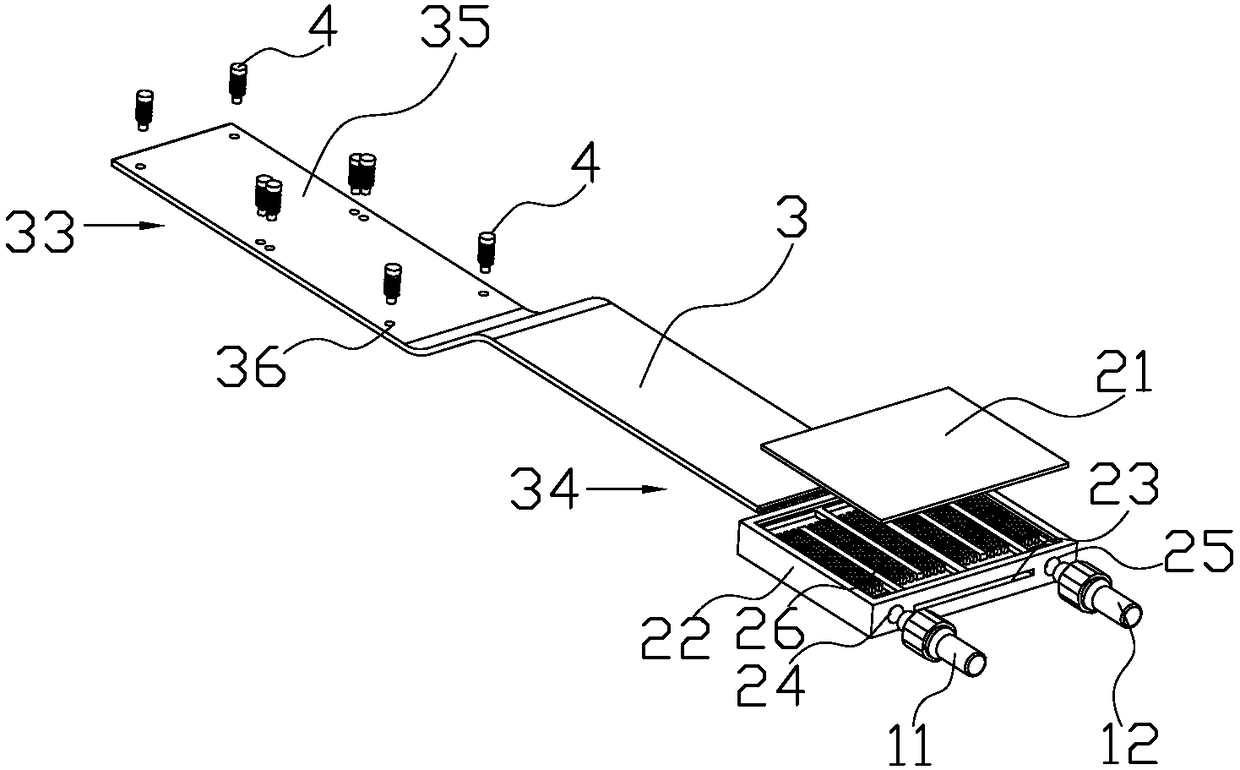

[0062] The main structure of this embodiment is the same as that of the embodiment, and the similarities will not be repeated here. The difference is:

[0063] The several partition fins and the several distribution fins are all arranged on the cover body, and the cover body, the several partition fins and the several distribution fins are all of an integral structure. (not shown in the figure) when the cover is processed, the partition fins and the flow distribution fins are milled on the cover at the same time to form the main channel and the flow distribution channel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com