Full-automatic spraying and drying integrated wire drawing machine

An integrated and fully automatic technology, applied in the direction of dryer, drying, drying gas arrangement, etc., can solve the problems of reducing the quality of wire use, excessive heat, etc., achieve high-efficiency dehumidification and drying treatment, and improve the quality of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

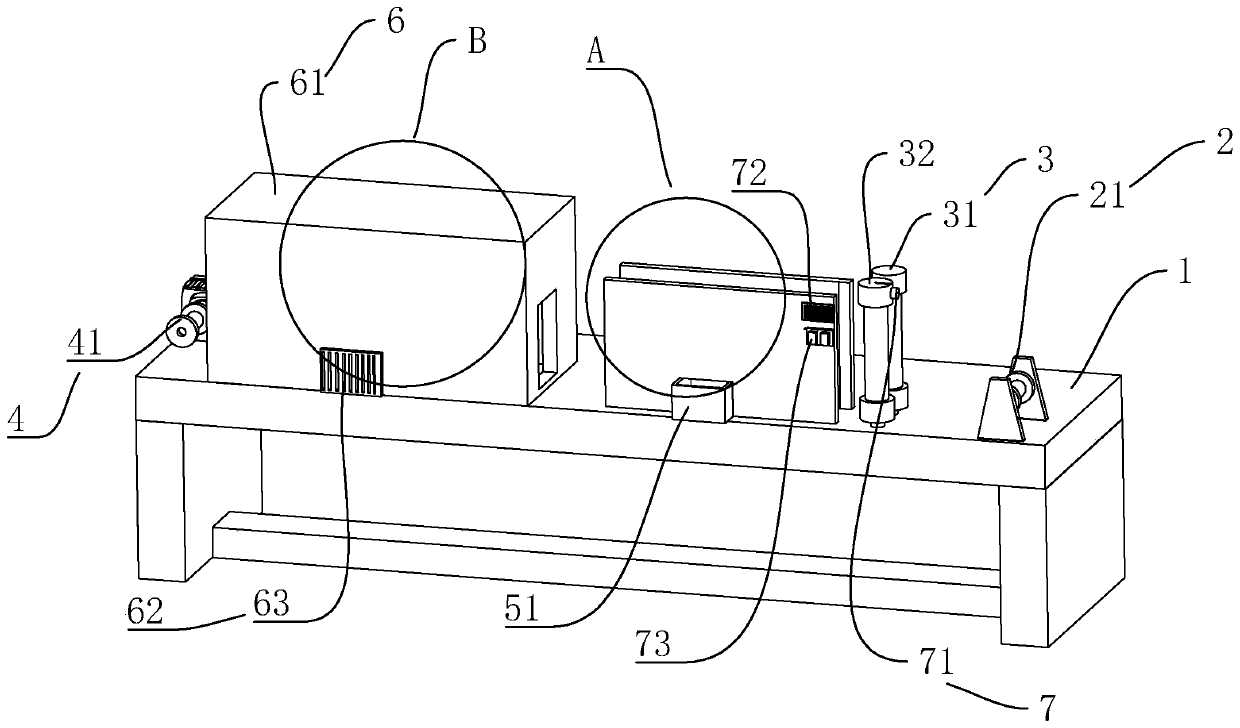

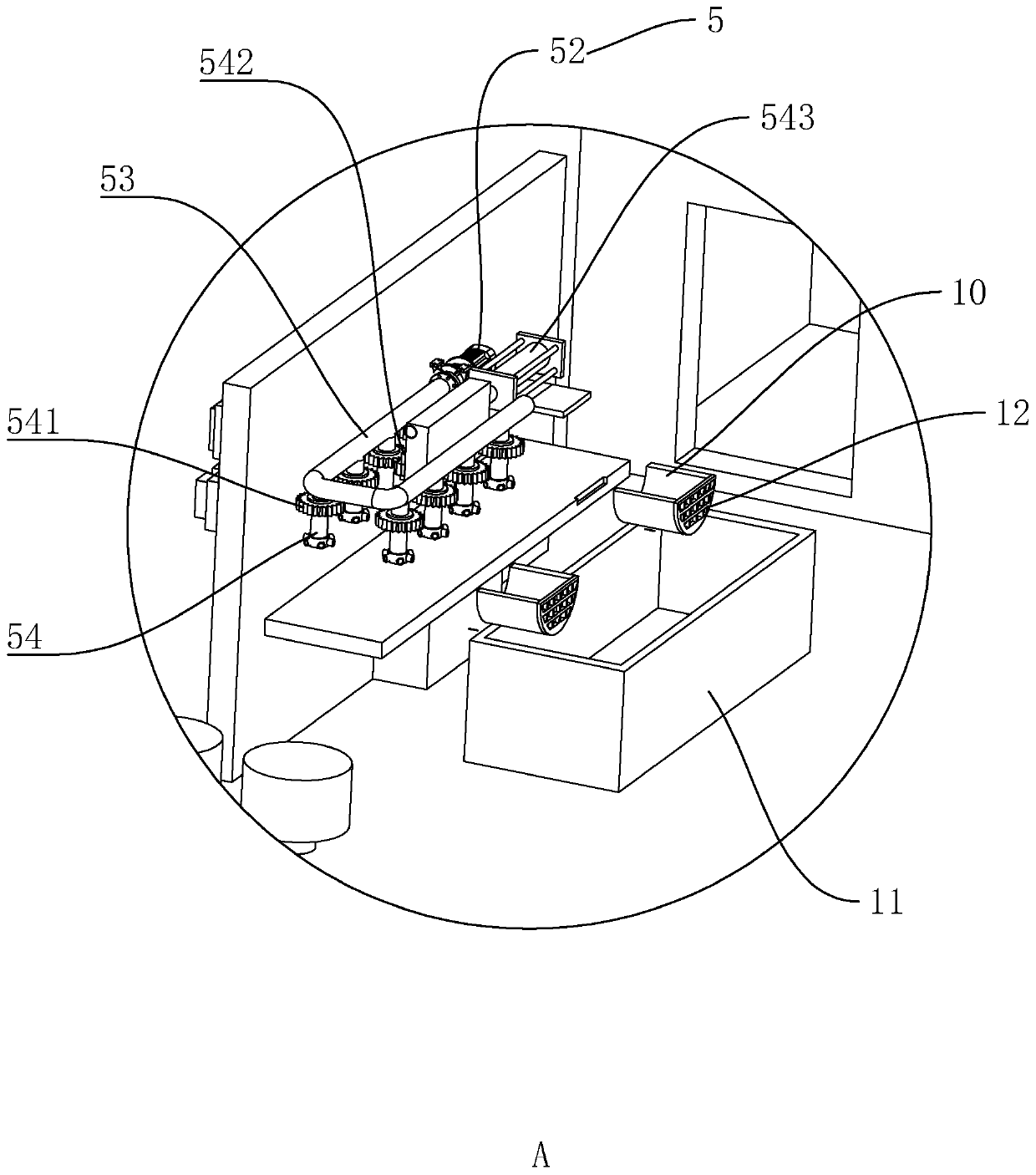

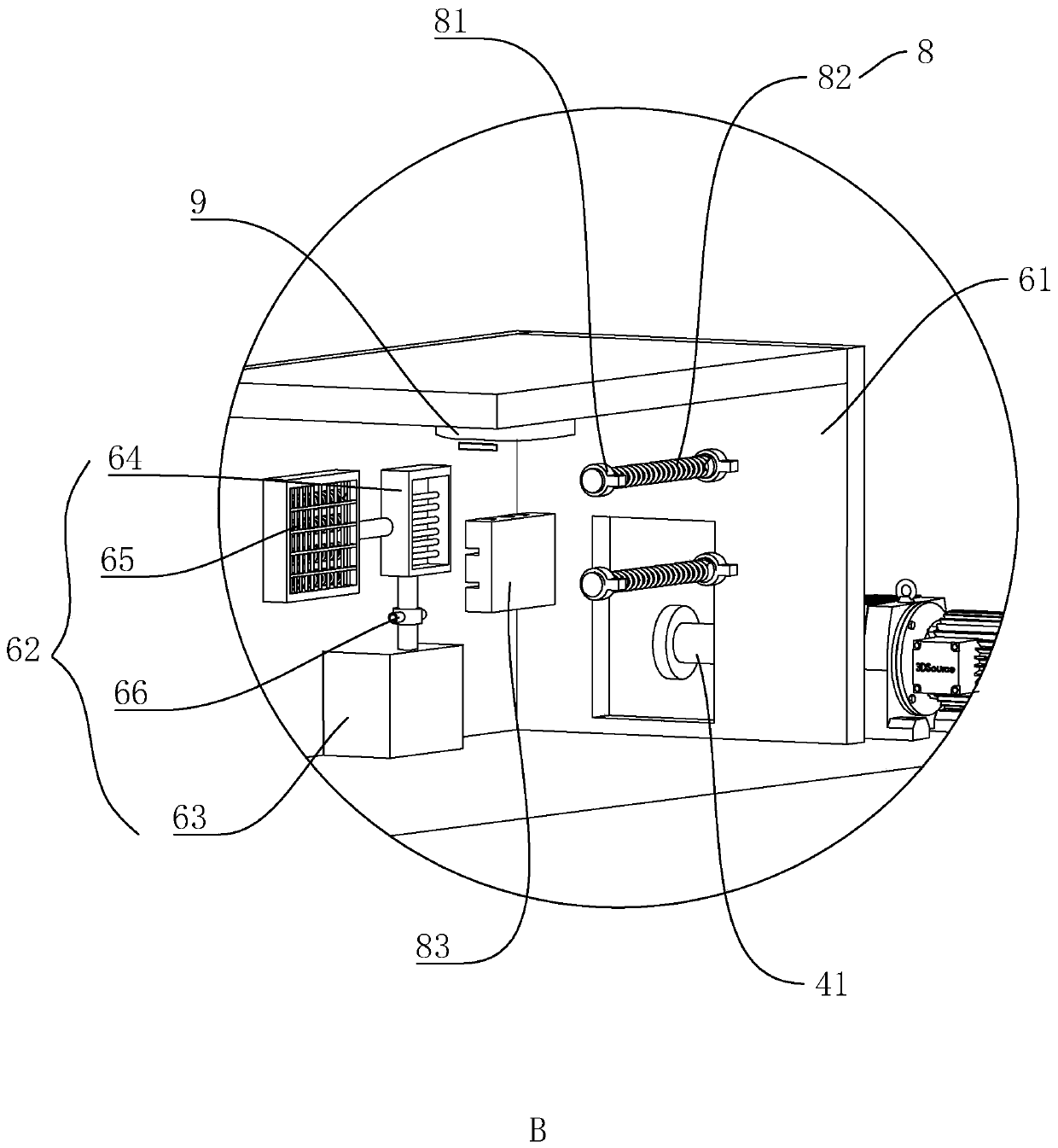

[0026] A fully automatic spray drying integrated wire drawing machine, such as figure 1 , figure 2 and image 3 As shown, including the base 1, the base 1 is provided with a wire-releasing mechanism 2, a wire-drawing mechanism 3 and a wire-receiving mechanism 4 in sequence, and a spray cooling mechanism 5 and a drying and dehumidifying mechanism 6 are arranged between the wire-drawing mechanism 3 and the wire-receiving mechanism 4 The pay-off mechanism 2 is a pay-off roller 21 that is rotatably connected to the base 1, the wire-drawing mechanism 3 is a first pressure roller 31 and a second pressure roller 32 driven by an air cylinder, and the take-up mechanism 4 is a take-up roller 41 driven by a motor. The spray cooling mechanism 5 includes a water storage tank 51 on the base 1, a water pump 52 above the water storage tank 51, a catheter 53 connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com