Patents

Literature

114results about How to "Constant resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

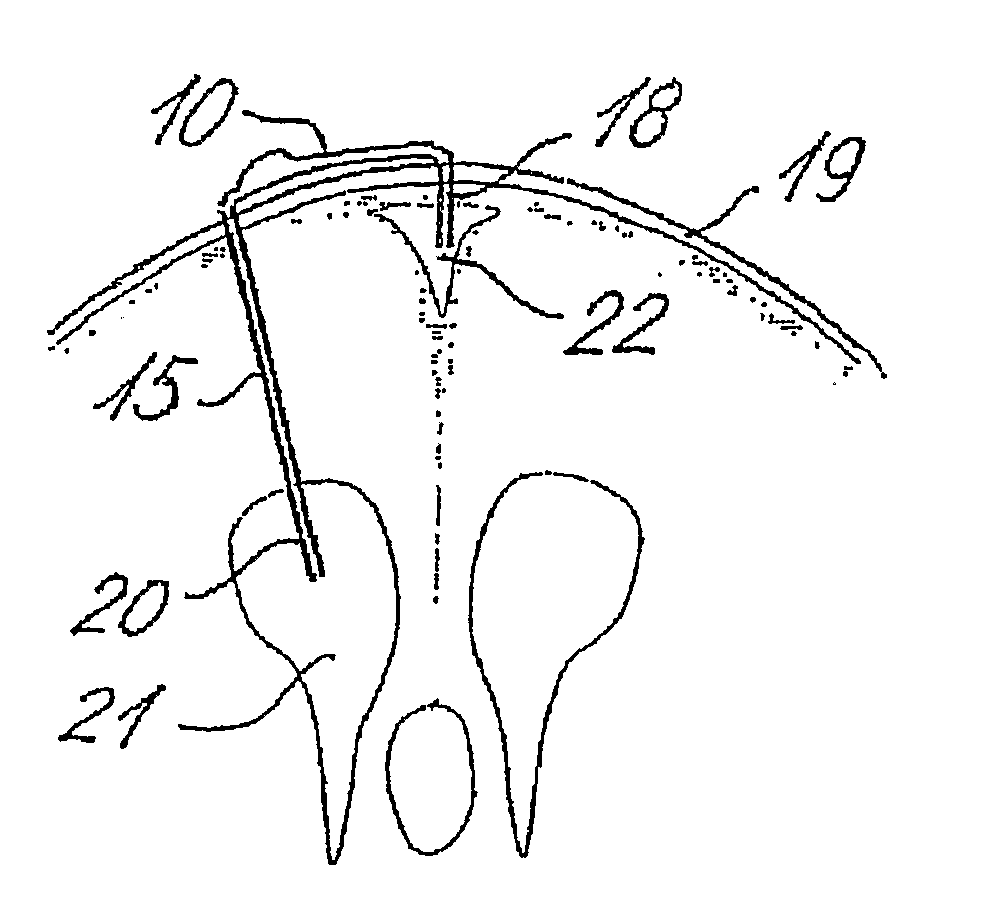

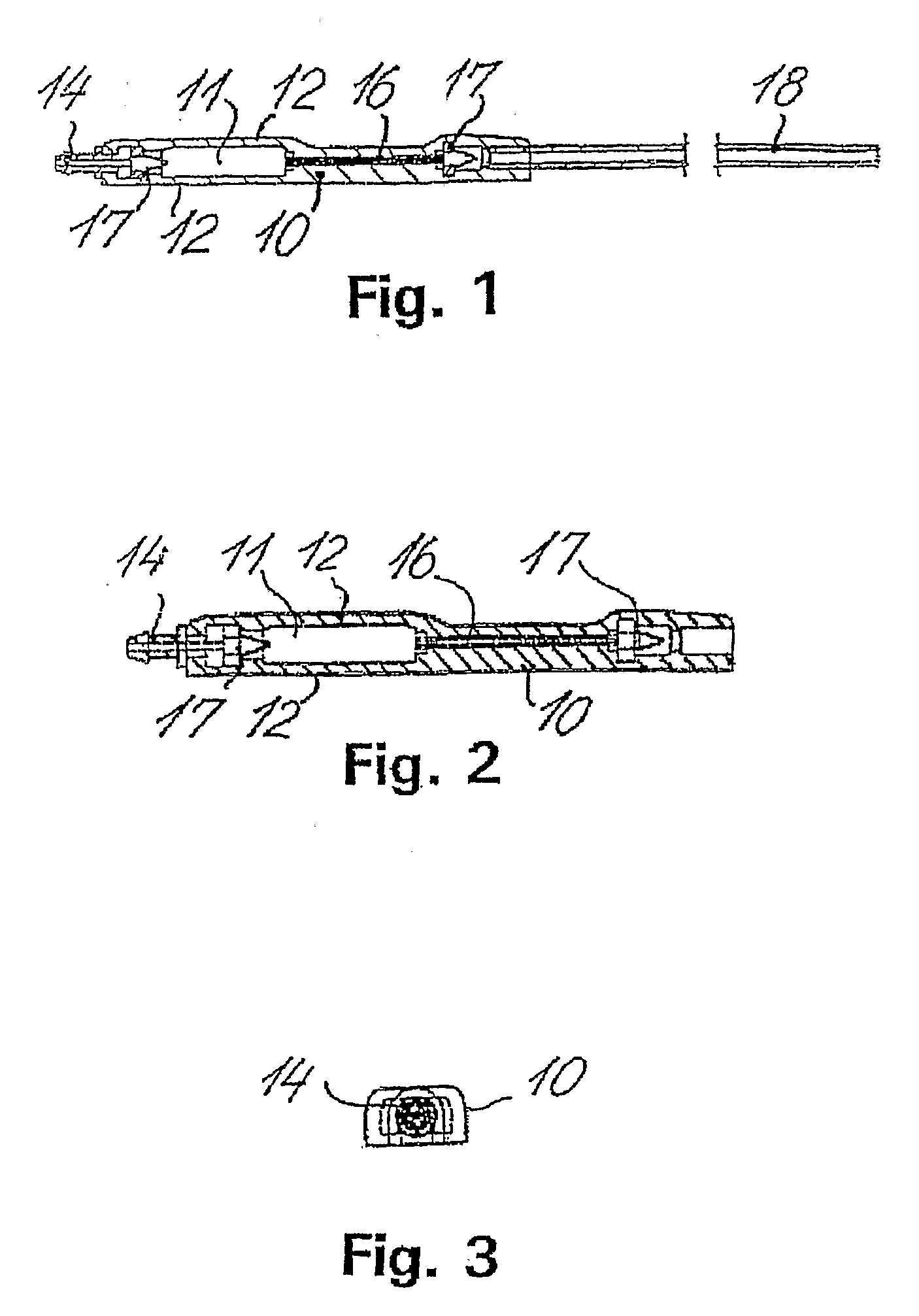

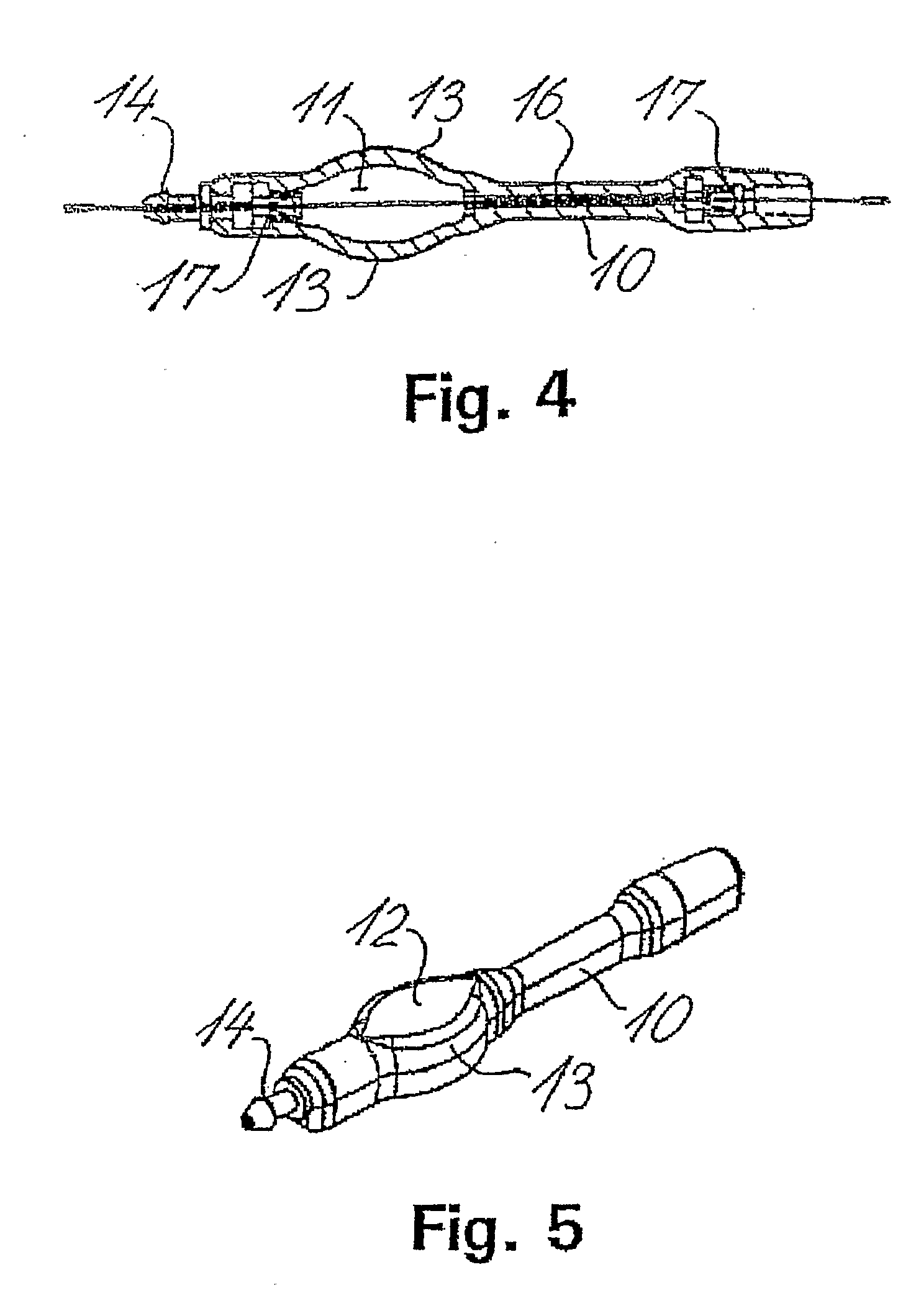

Shunt system with coating and flow restricting component exerting a passive and essentially constant resistance to outflow

InactiveUS20070112291A1Reduce as muchReduce infectionWound drainsFlow monitorsCsf shuntBrain Ventricle

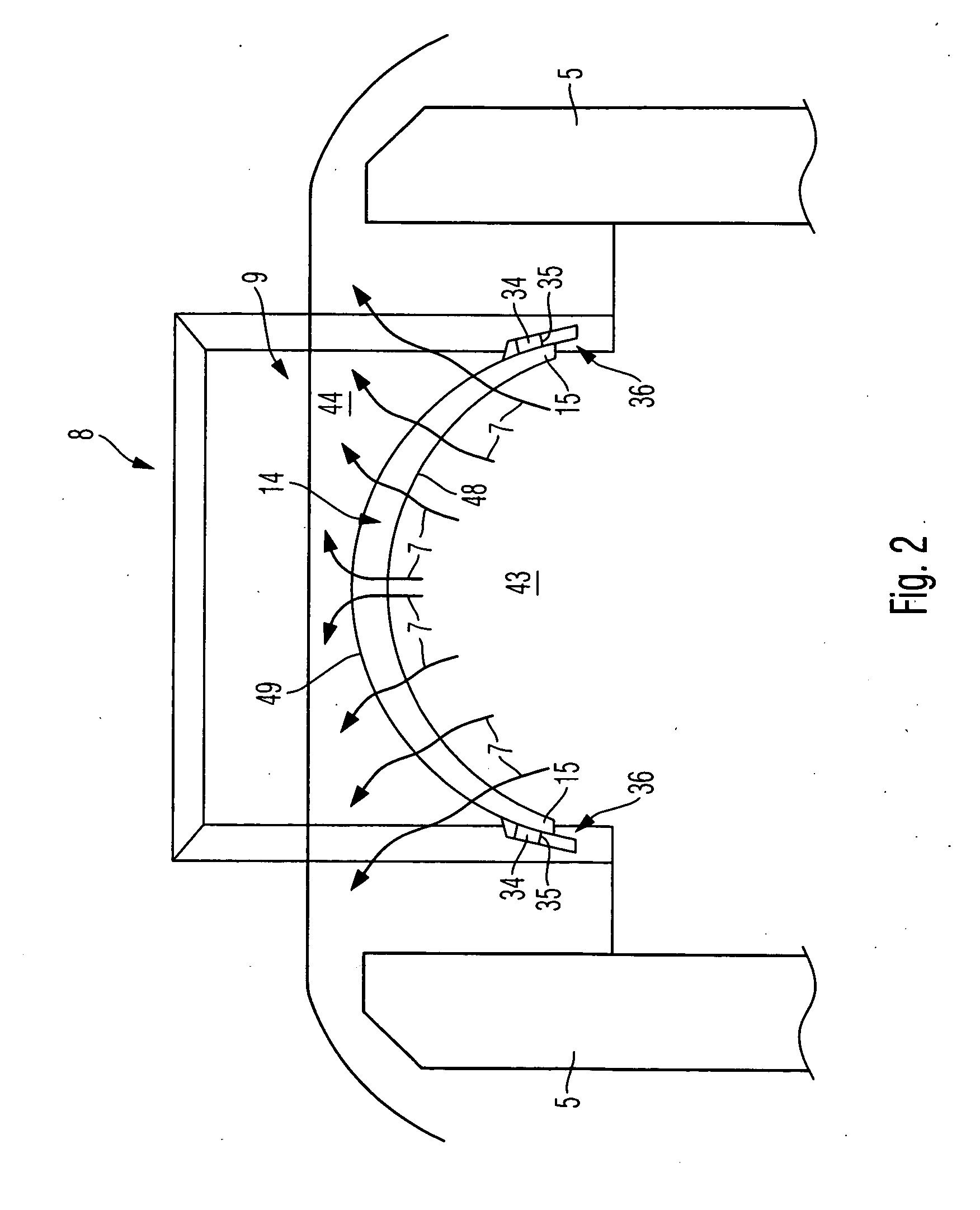

The present invention relates to an improved cerebrospinal fluid shunt system comprising a coating covering at least part of the system and a flow restricting component exerting a passive and essentially constant resistance to flow. The present invention also relates to methods for implanting different catheters of a cerebrospinal fluid shunt system into a brain ventricle and the sinus system, respectively, of an individual. The present invention further relates to methods for shunting cerebrospinal fluid from a brain ventricle to the sinus system of an individual.

Owner:SINU SHUNT

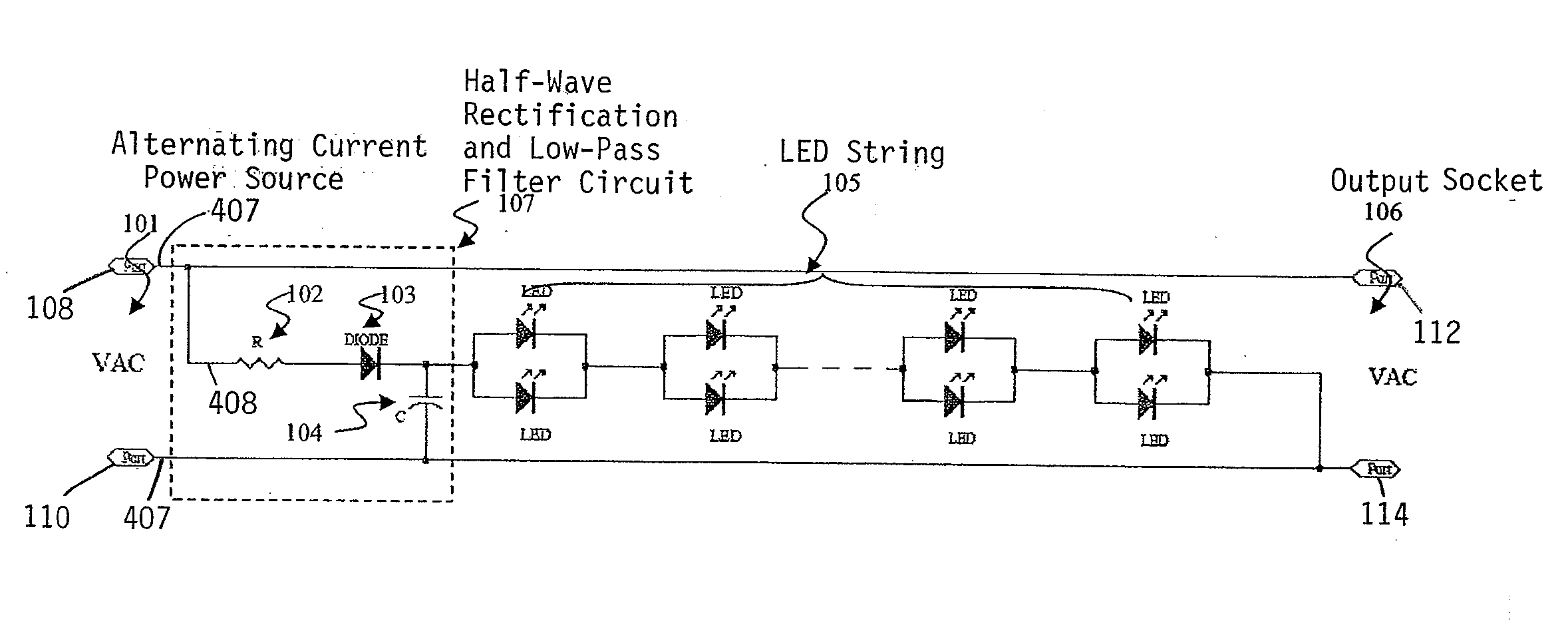

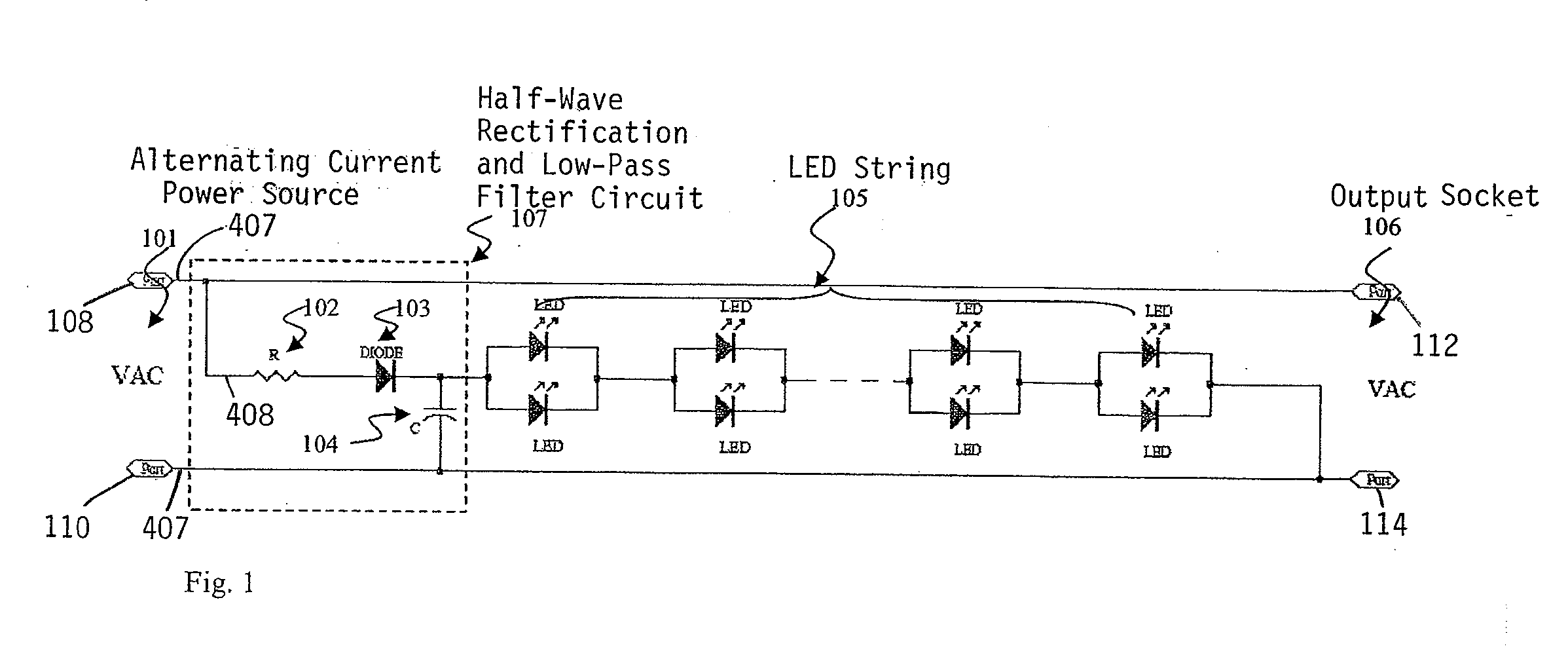

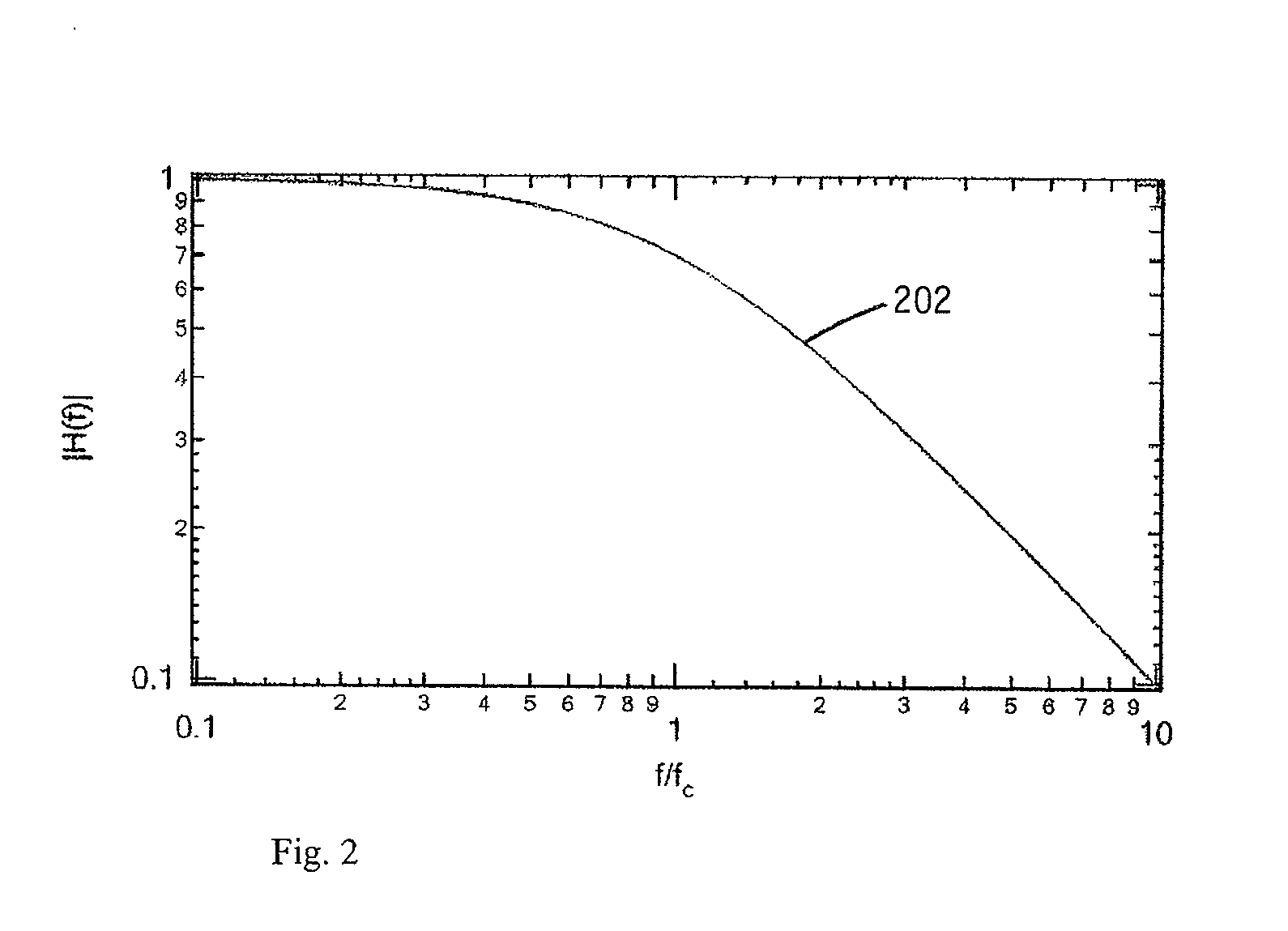

Half-wave rectification circuit with a low-pass filter for LED light strings

ActiveUS20080224623A1Effective resistanceConstant resistanceDischarge tube incandescent screensElectric discharge tubesLow-pass filterBand-pass filter

Disclosed is a low cost LED string circuit design that uses an inexpensive half-wave rectification and low-pass filter circuit that is designed to produce minimal flicker in the LED string that is connected to the circuit. The components of the half-wave rectification and low-pass filter circuit are selected in accordance with design principles that prevent glittering and flickering of the LED string. The circuit components of the half-wave rectification and low-pass filter circuit can be embedded in an outlet plug or as a separate independent unit between an AC power plug and the LED string.

Owner:SANTAS BEST

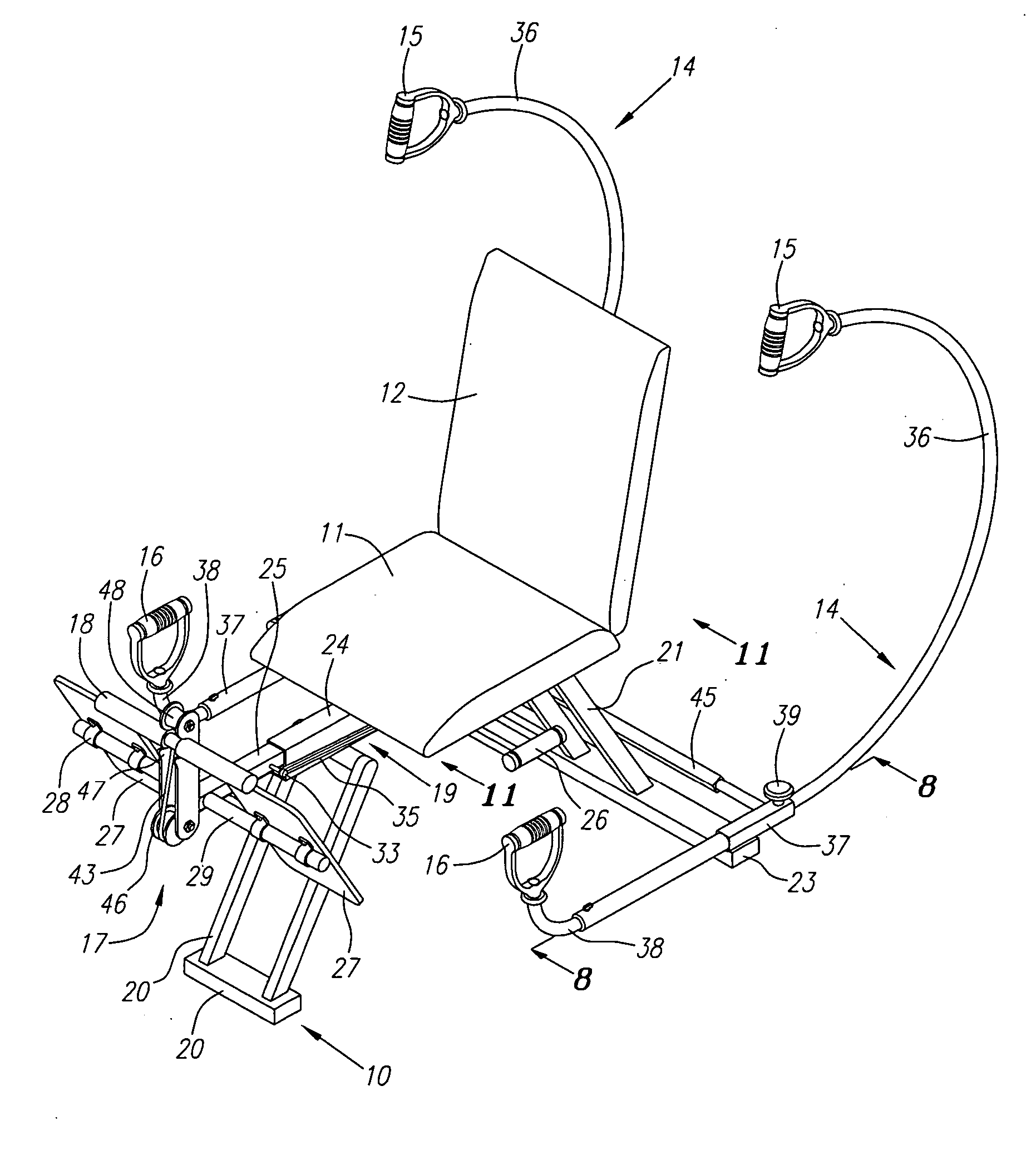

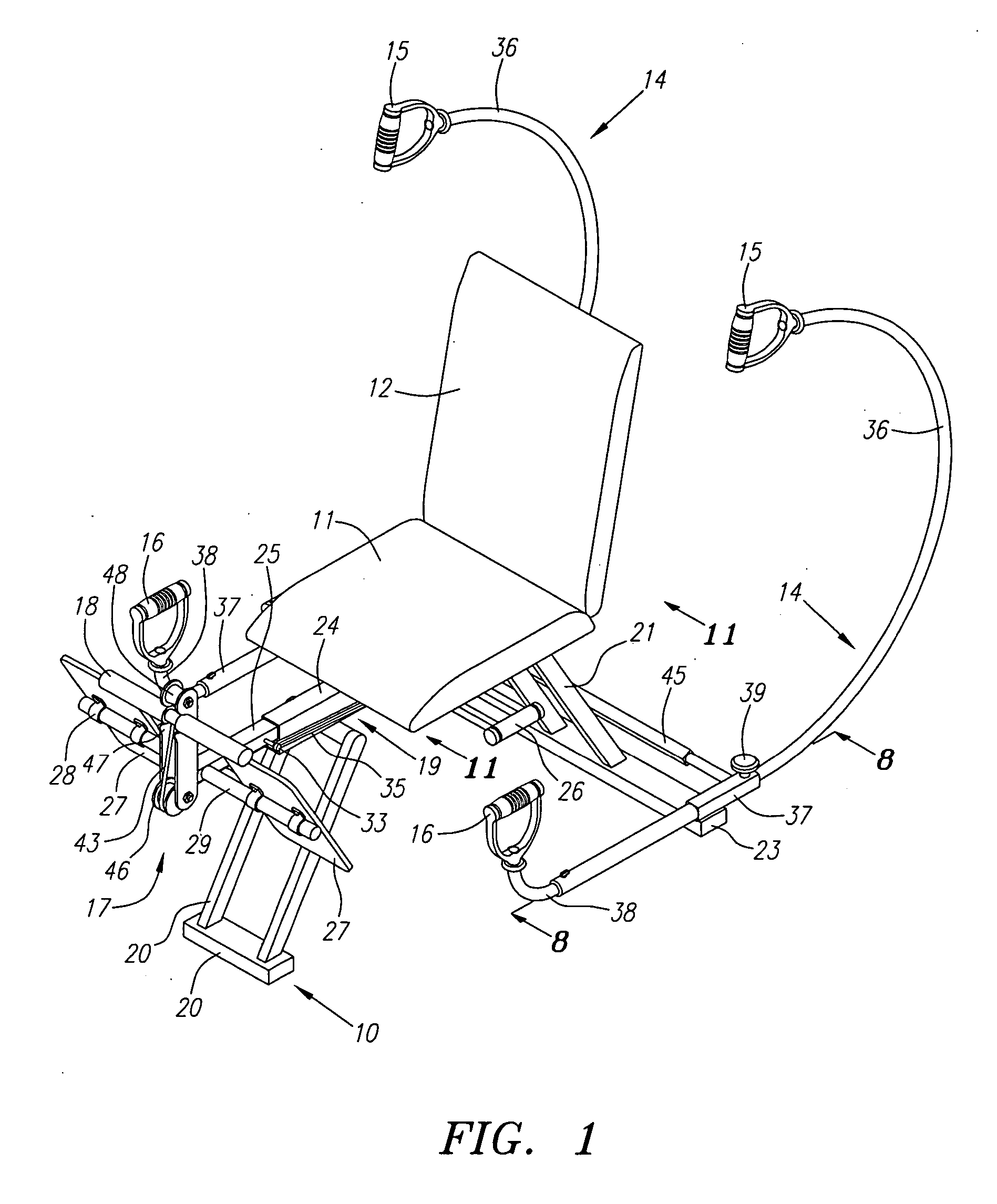

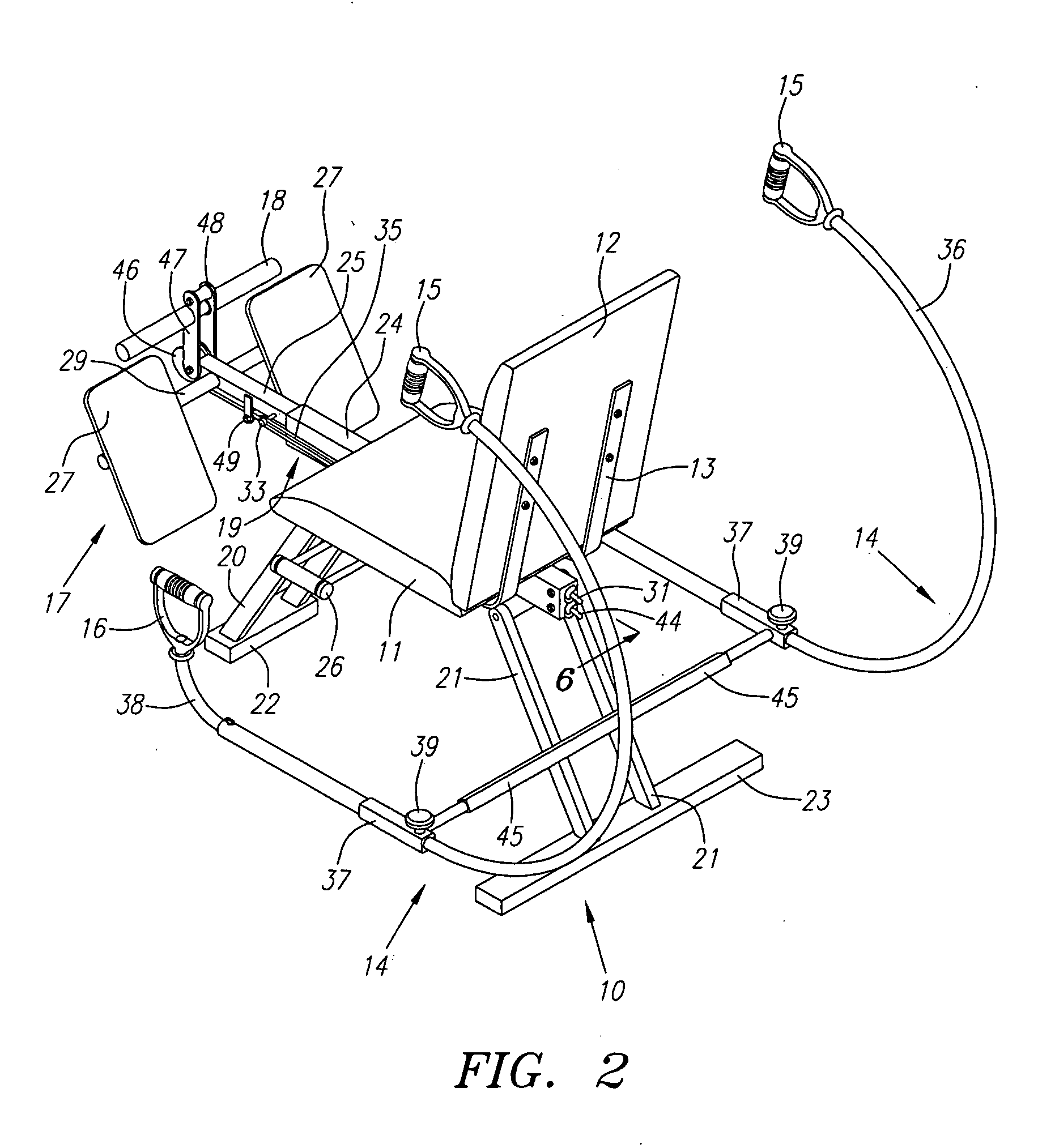

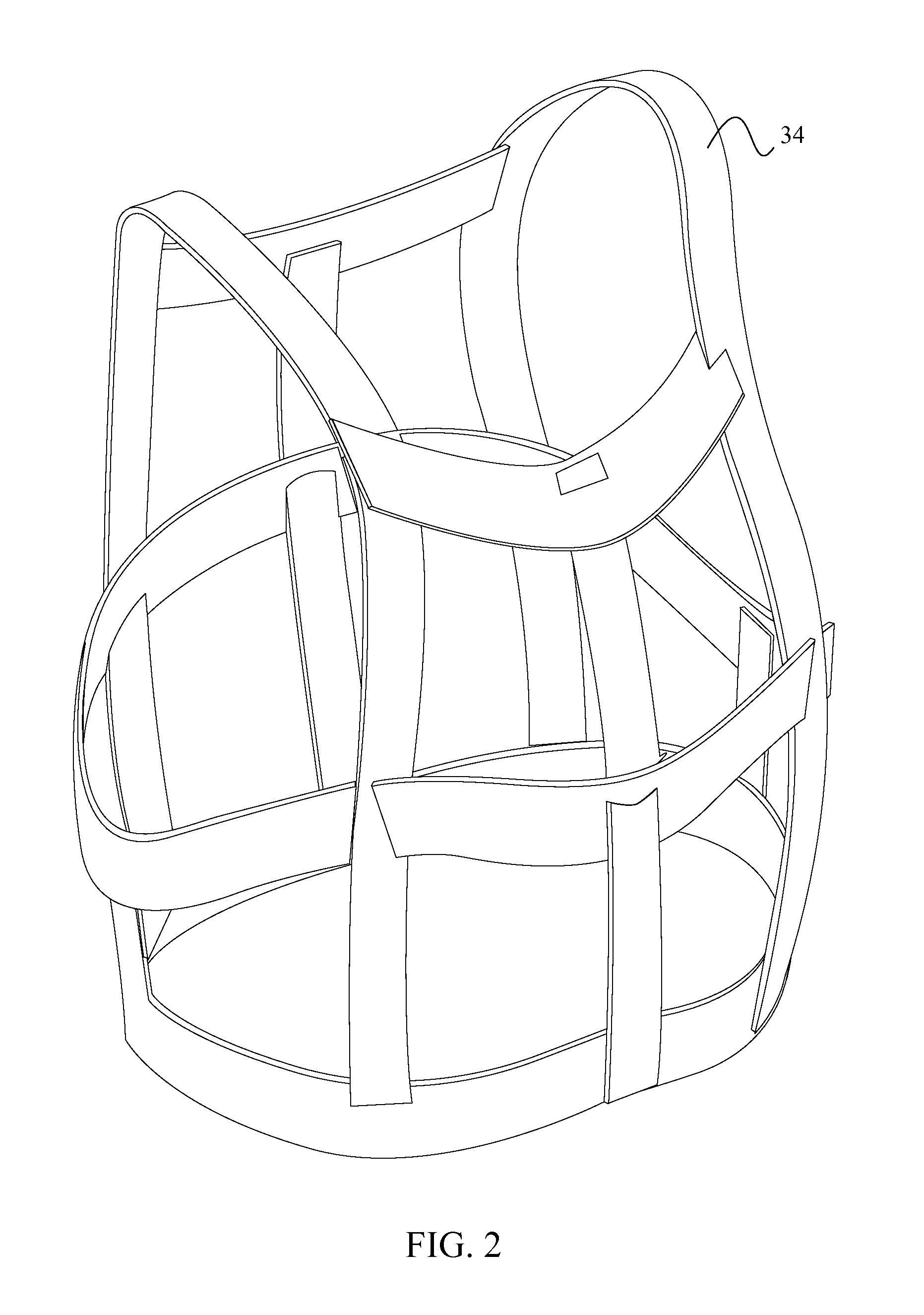

Multi-purpose exercise device

InactiveUS20060025289A1Increase lateral distanceHigh level of operation efficiencyResilient force resistorsSpace saving gamesMuscle groupEngineering

An exercise device capable of simultaneously exercising a plurality of muscle groups, which includes an exercise chair mounted to a base, the exercise chair having a pivotally-resistant seat back. The exercise device further includes large, curvilinear conduits through which pass adjustably-resistant elastic bands with grips fixedly attached to the elastic bands proximate the upper and lower ends of the curvilinear conduits, which curvilinear conduits are laterally spaced, one on each side of the exercise chair. The exercise device further includes a resistive foot platform positioned at the front end of the base, which resistive foot platform is moveably engaged with the exercise chair. The exercise device further includes a resistive seated-row grip positioned at the front end of the base that permits cardiovascular exercise.

Owner:WALLACH MARK

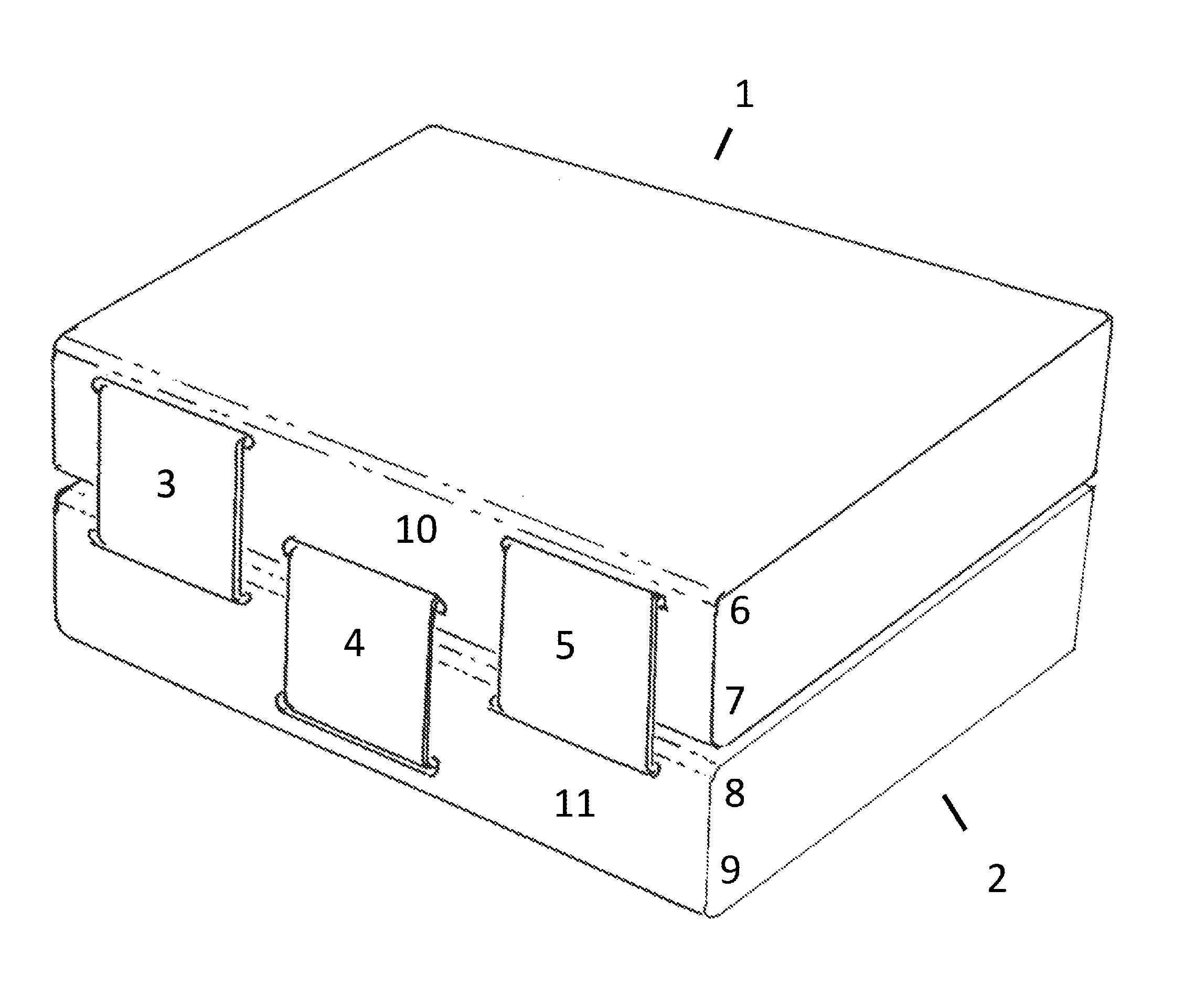

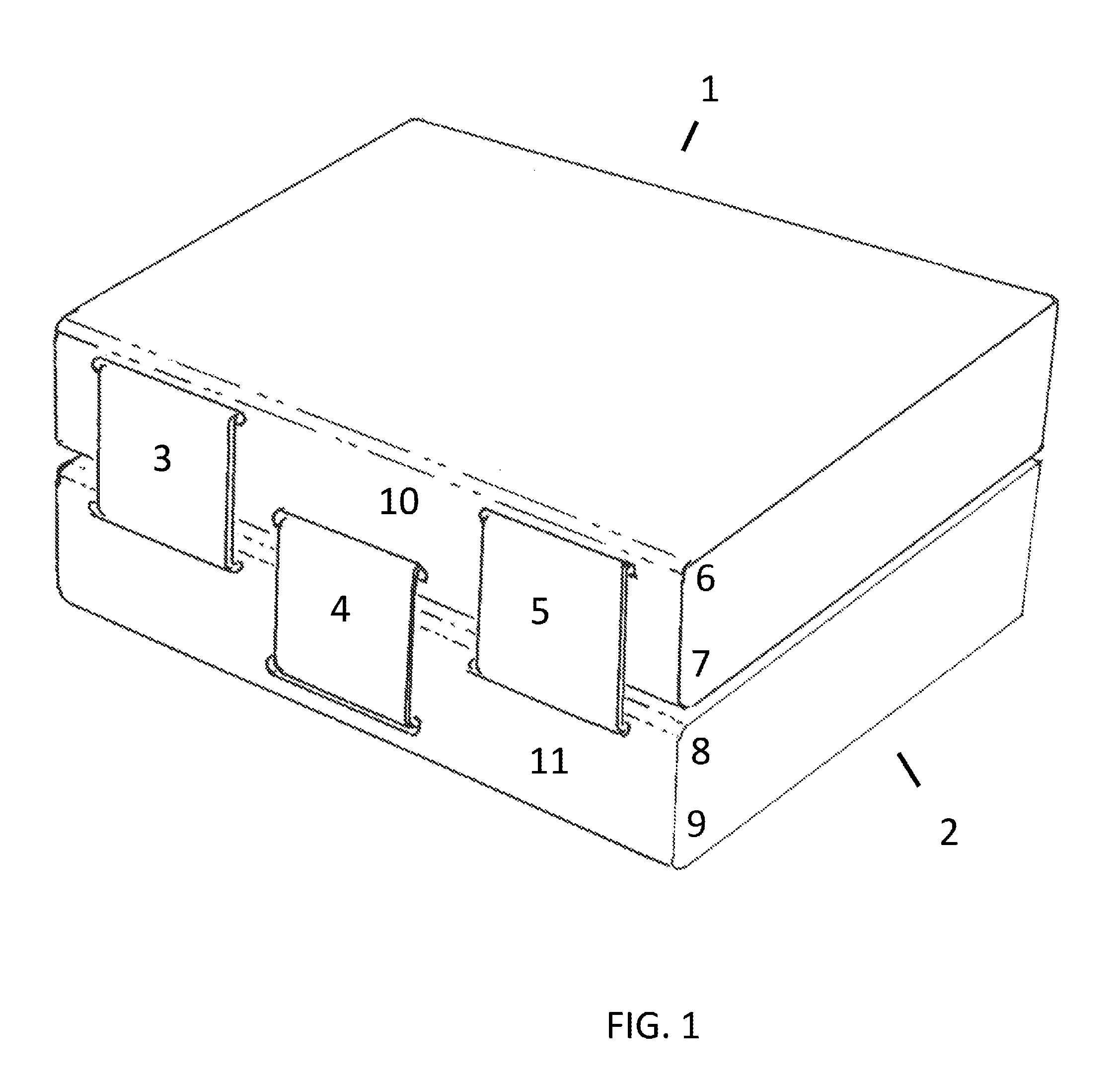

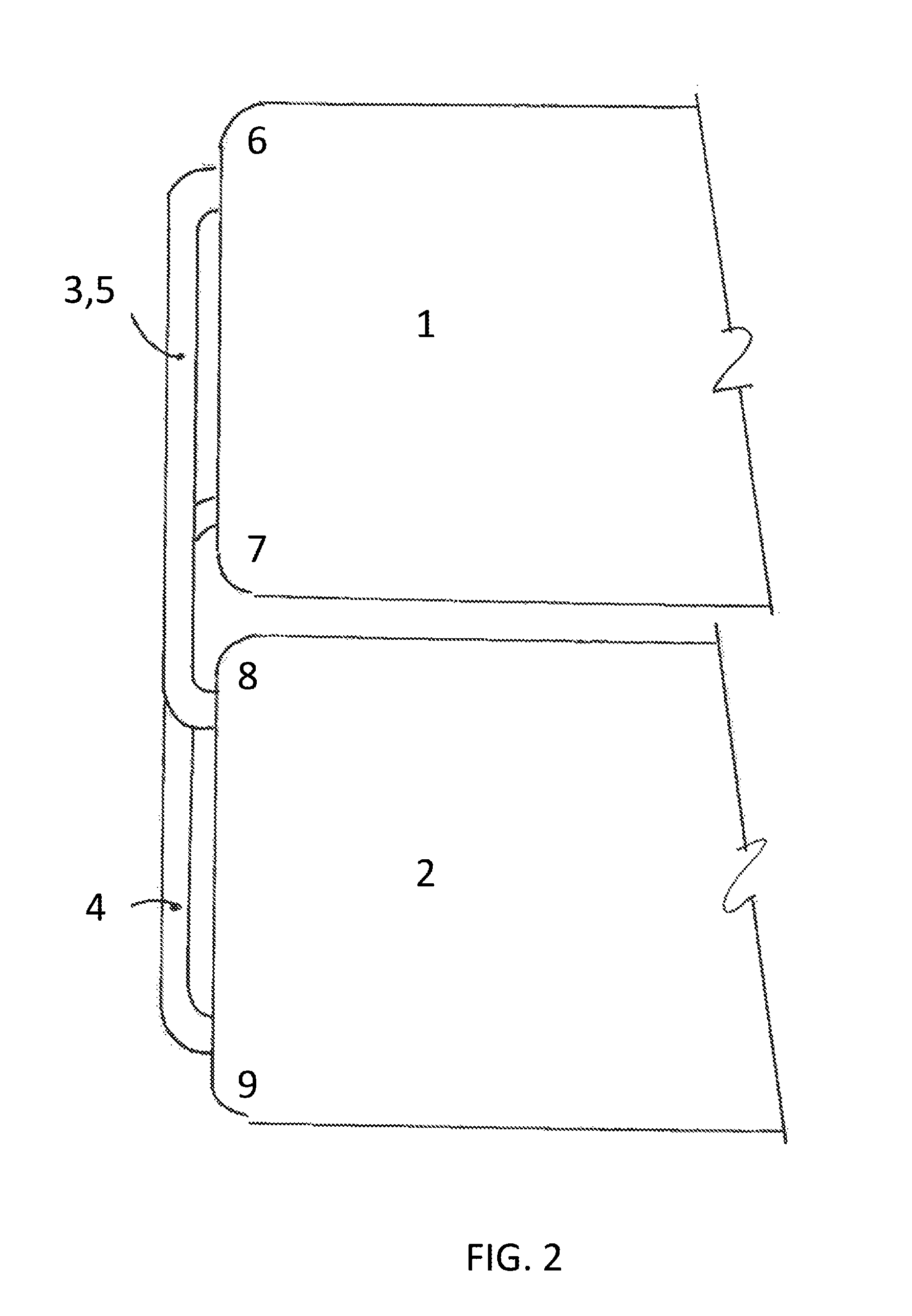

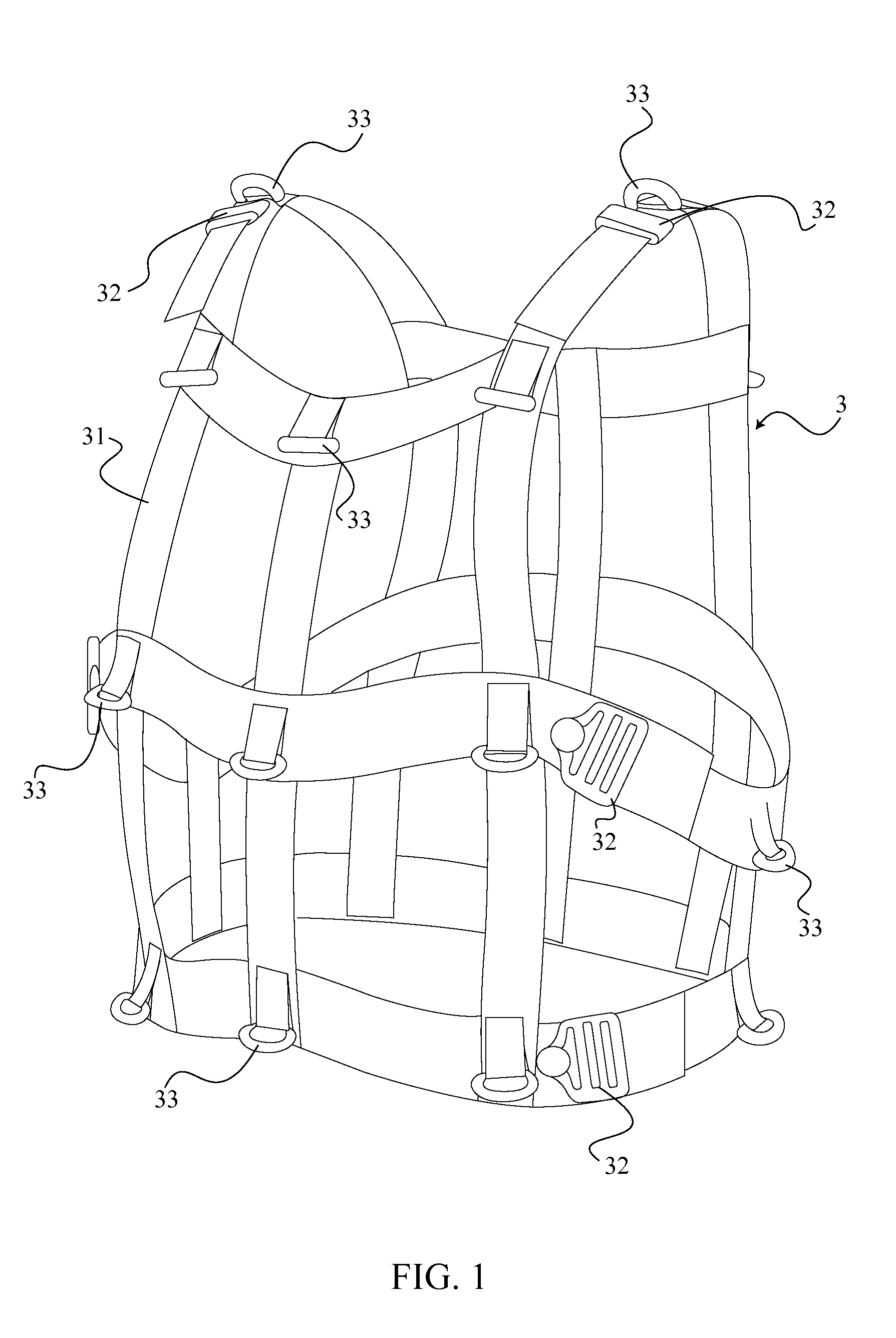

Hinged dual panel electronic device

ActiveUS8826495B2Constant resistanceDigital data processing detailsPinless hingesMechanical engineeringEngineering

A electronic device includes a first housing body with a first hinged end, a first free end, and a first fastening surface between the first hinged end and the first free end. A second housing body has a second hinged end, a second free end, and a second fastening surface between the second hinged end and the second free end. A flexible member is fixed to the first fastening surface and passes though the first hinged end and through the second hinged end for connection to a sliding cartridge that is affixed to the second fastening surface. The sliding cartridge provides substantially constant resistance during 360° rotation between the first housing body and the second housing body.

Owner:INTEL CORP

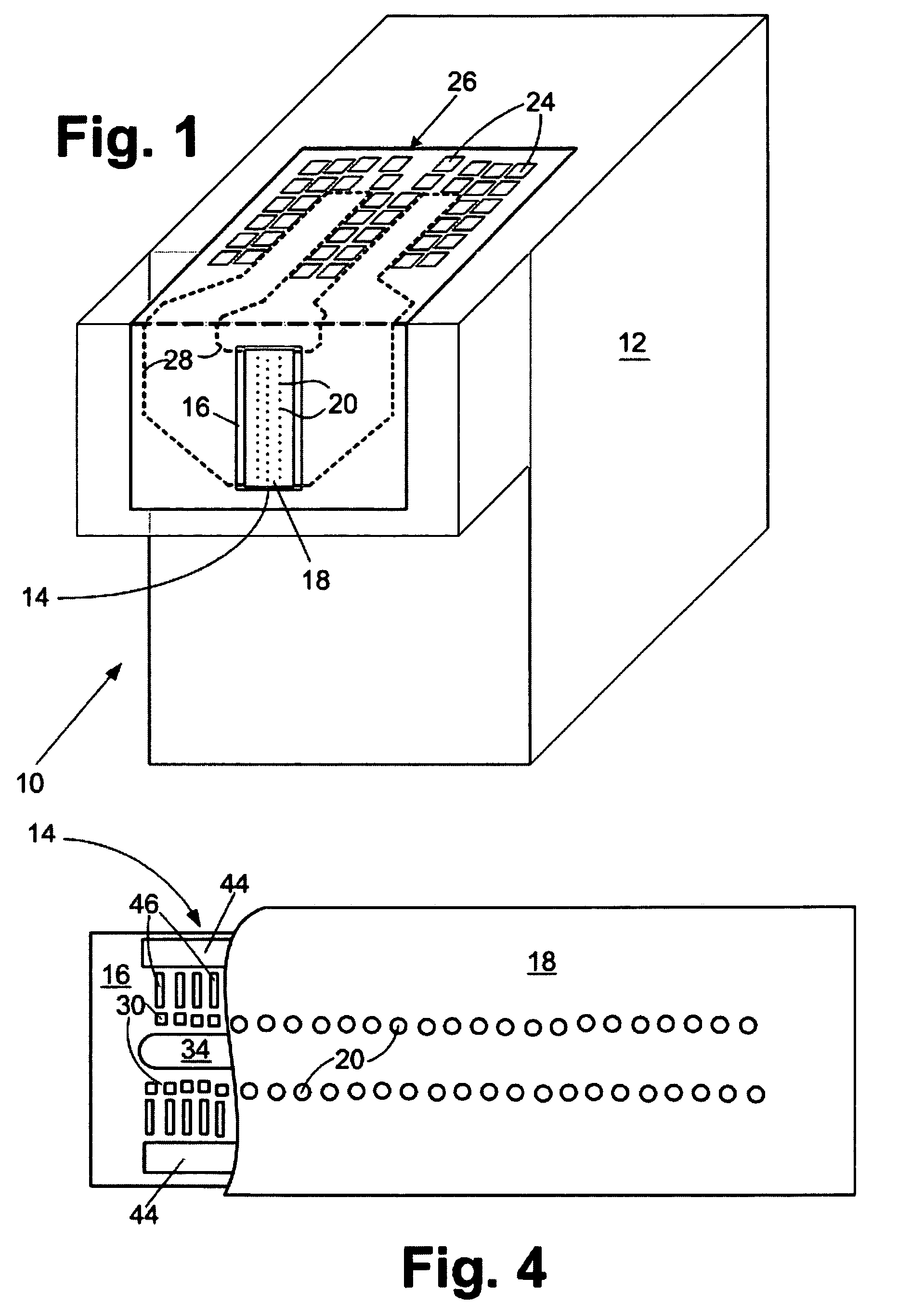

Micro-fluid ejection device having high resistance heater film

A semiconductor substrate for a micro-fluid ejection head. The substrate includes a plurality of fluid ejection actuators disposed on the substrate. Each of the fluid ejection actuators includes a thin heater stack comprising a thin film heater and one or more protective layers adjacent the heater. The thin film heater is made of a tantalum-aluminum-nitride thin film material having a nano-crystalline structure consisting essentially of AlN, TaN, and TaAl alloys, and has a sheet resistance ranging from about 30 to about 100 ohms per square. The thin film material contains from about 30 to about 70 atomic % tantalum, from about 10 to about 40 atomic % aluminum and from about 5 to about 30 atomic % nitrogen.

Owner:SLINGSHOT PRINTING LLC

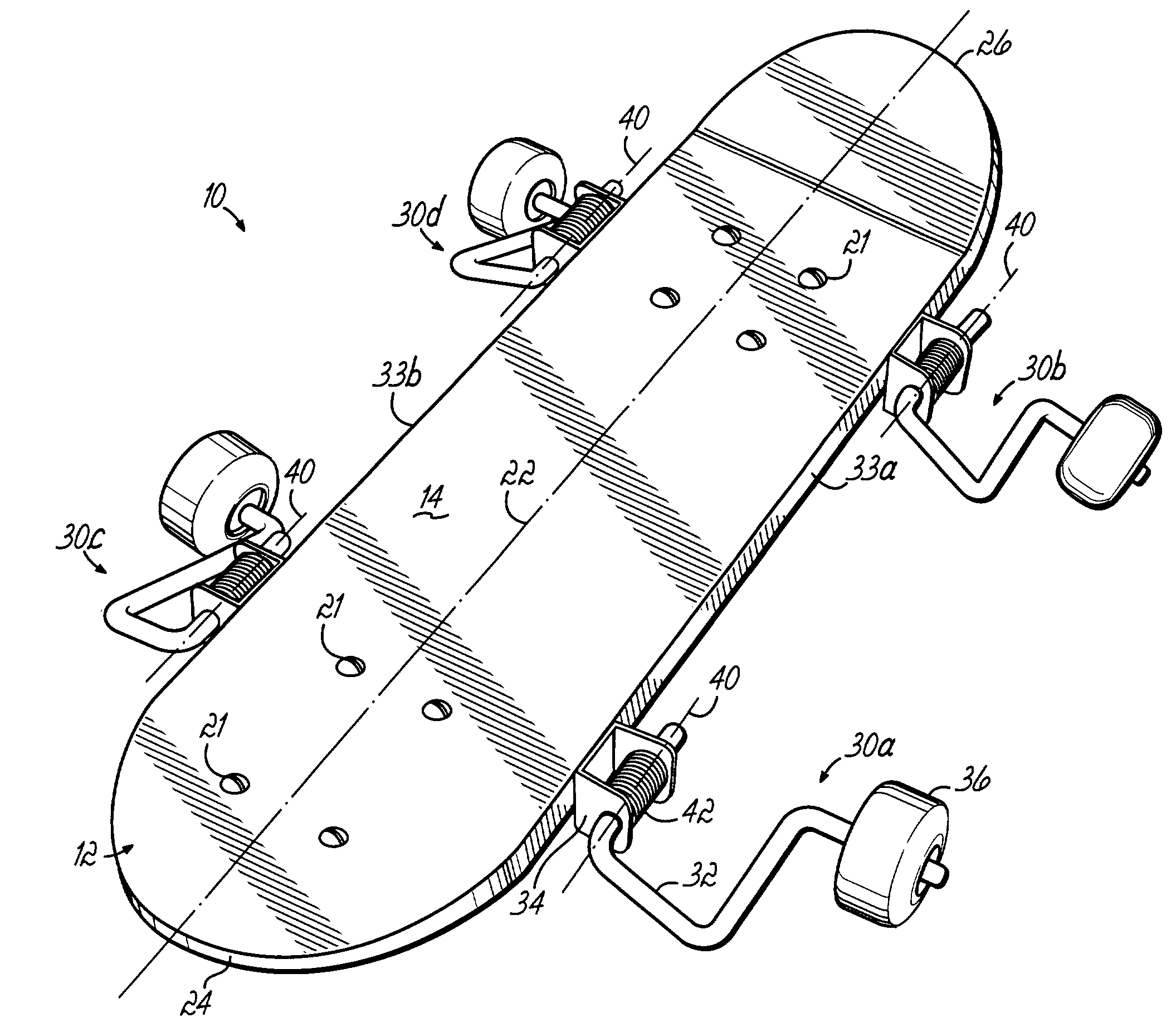

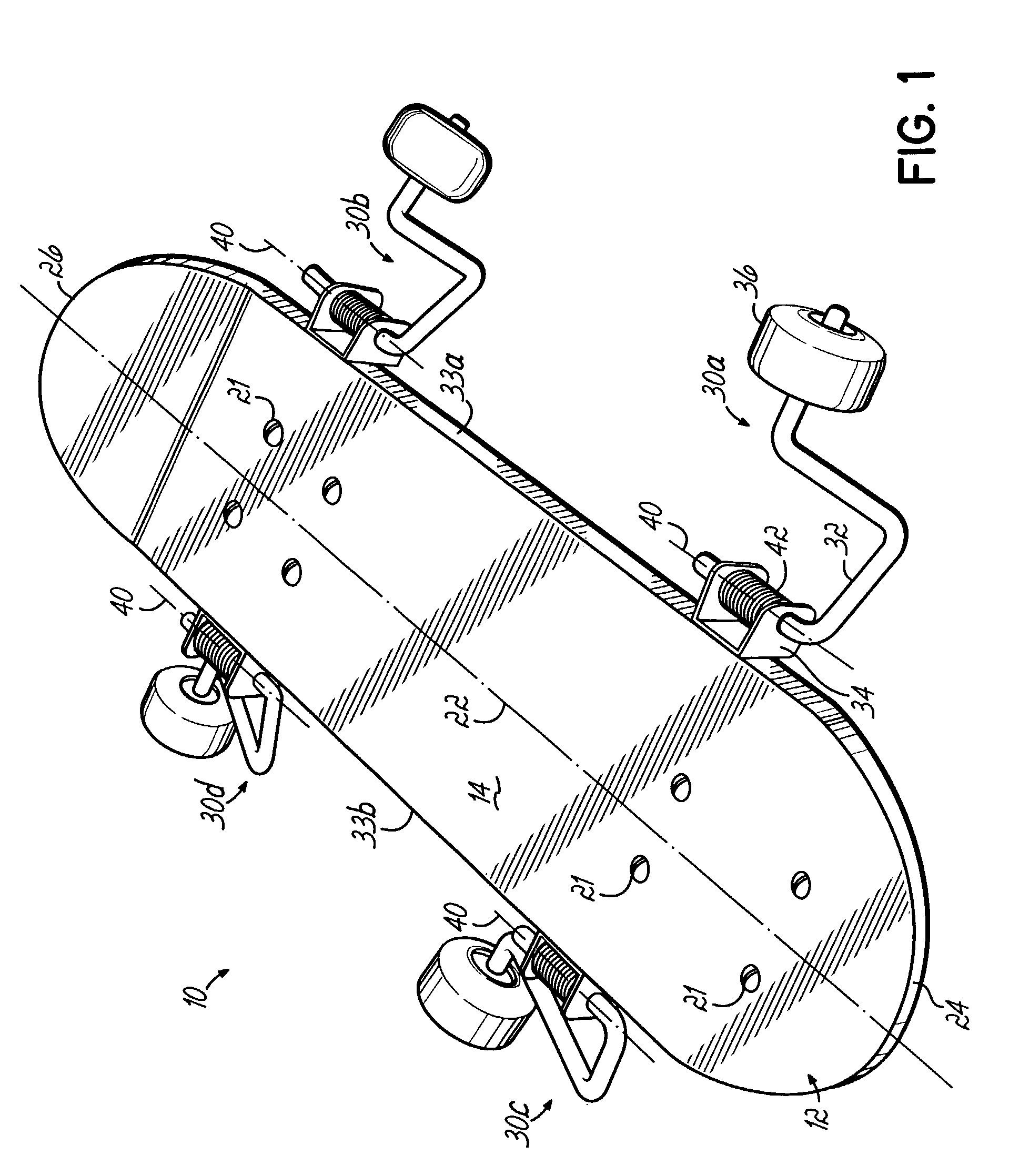

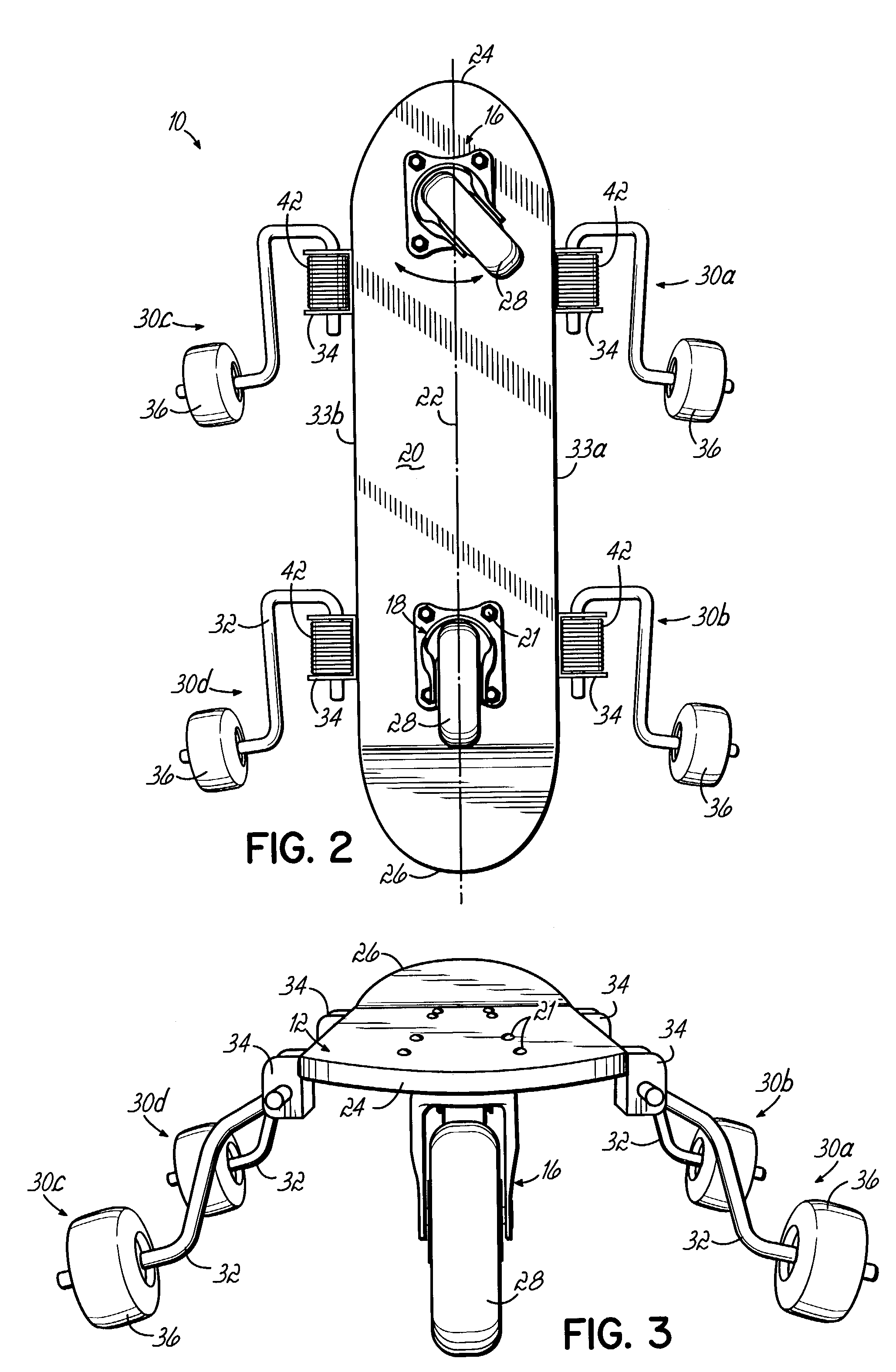

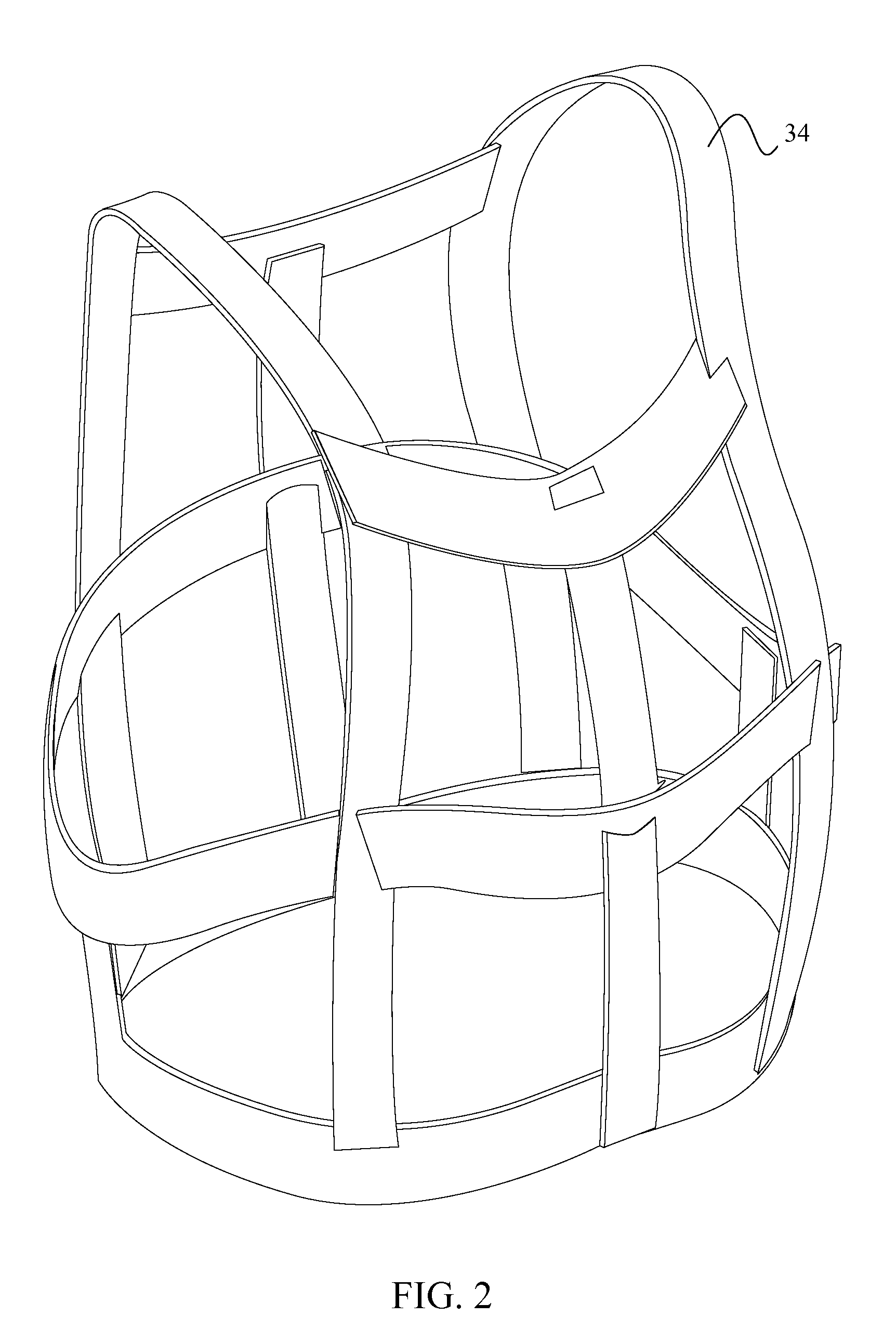

Tandem-wheeled riding device

ActiveUS7000930B2Improve performanceStable maintenanceRider propulsionSkate-boardsEngineeringMechanical engineering

Owner:SMITH JOHNNIE L

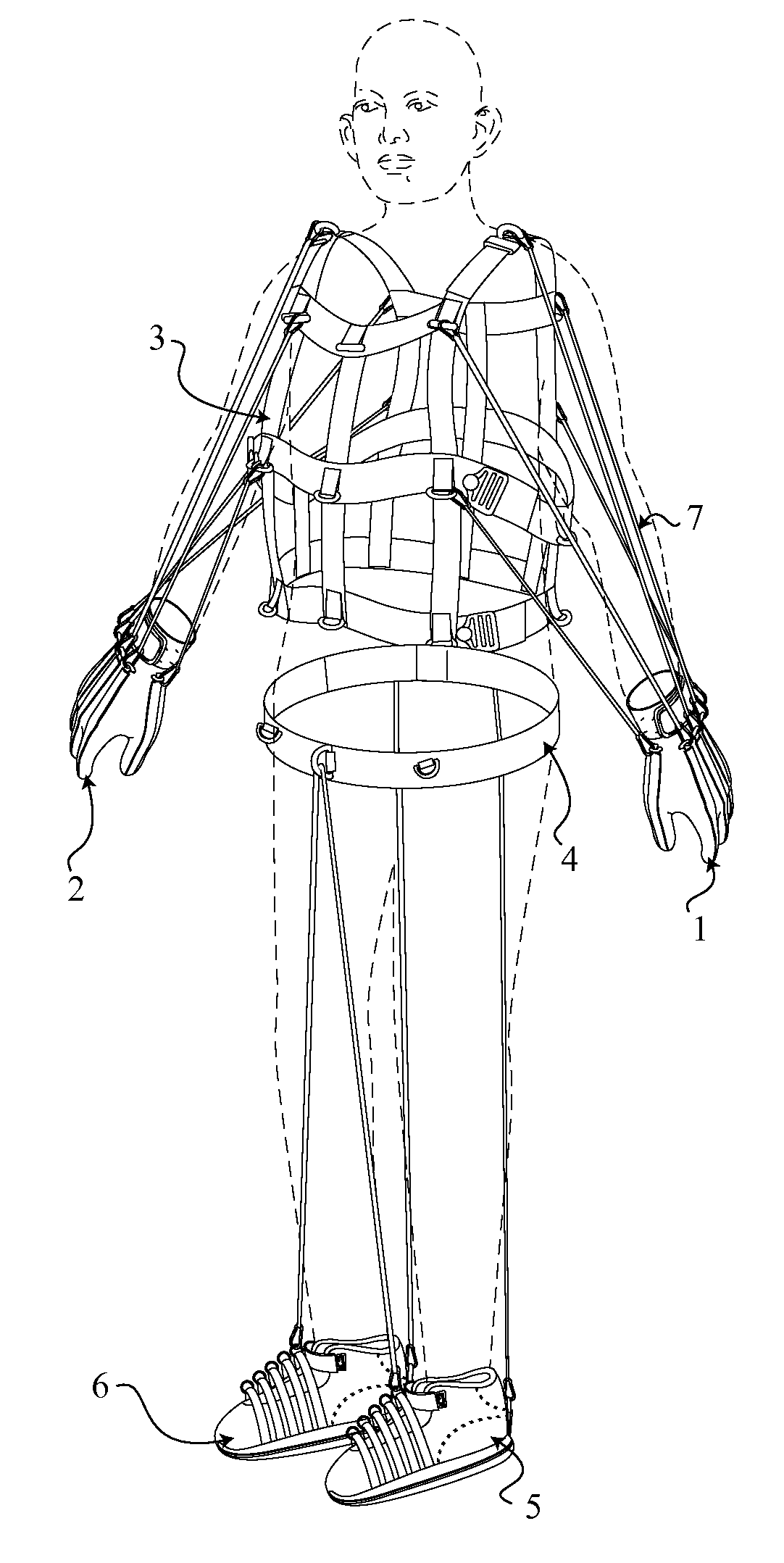

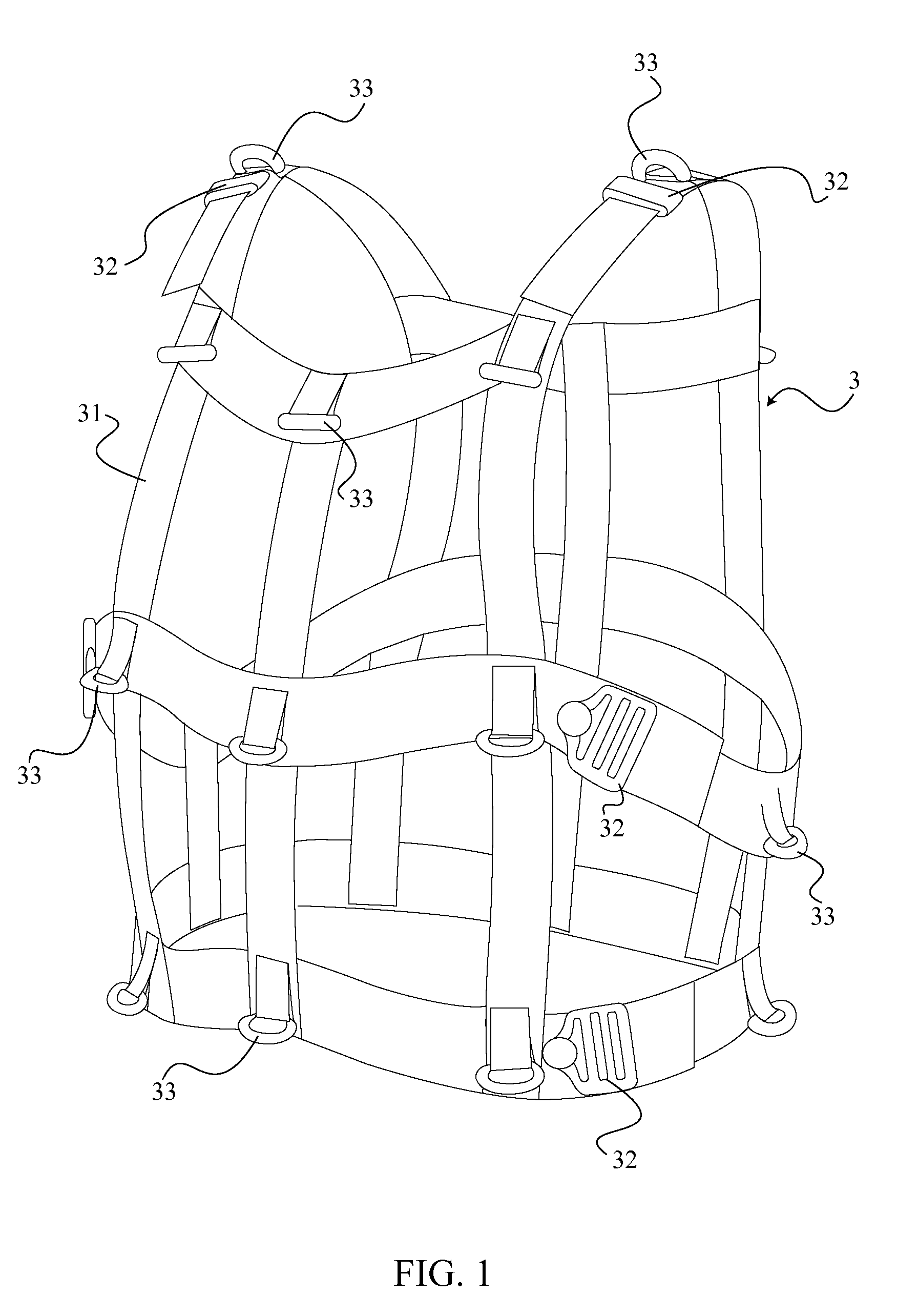

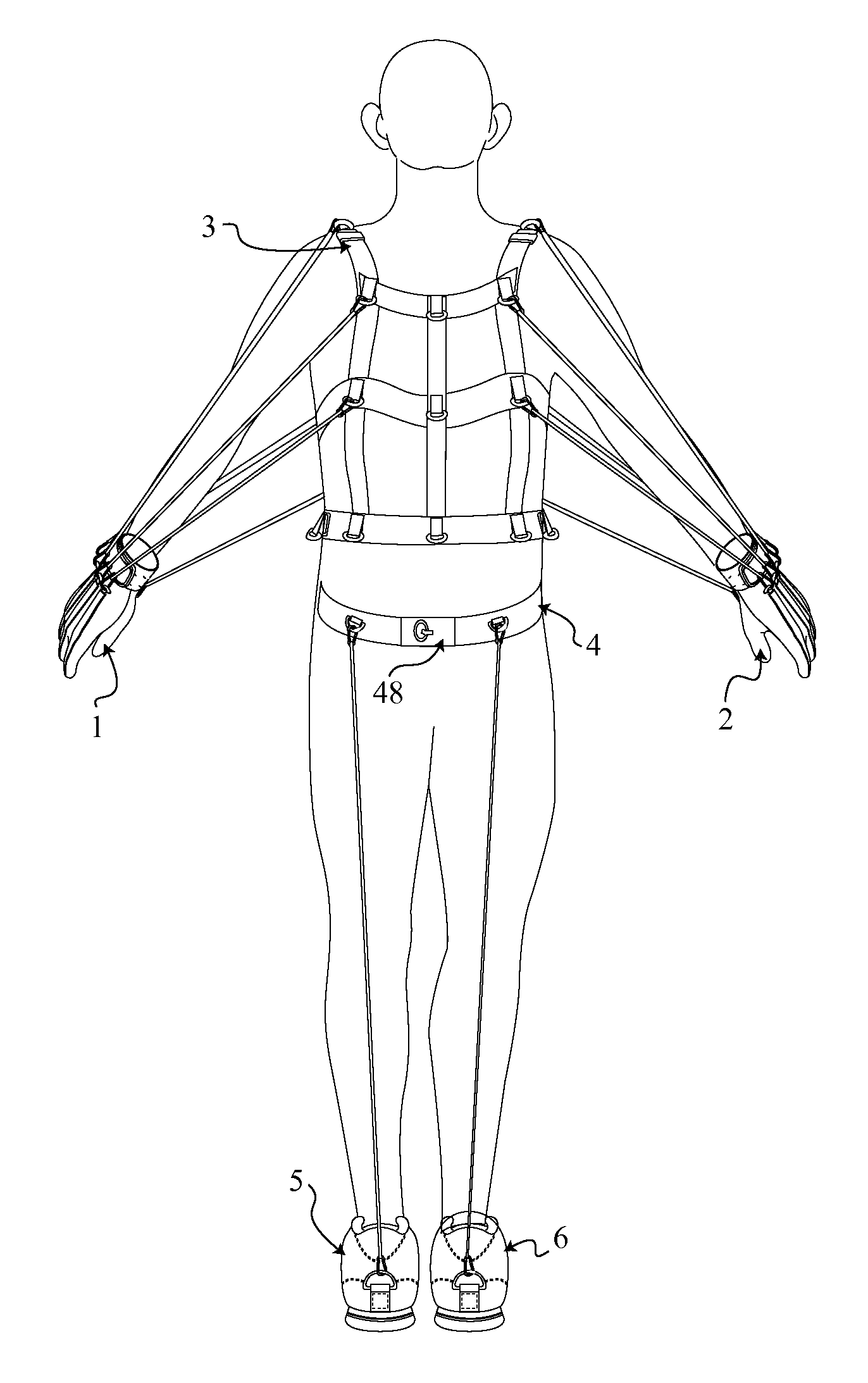

Sports Performance Enhancement System

ActiveUS20120283077A1Maximize qualityMinimize timeResilient force resistorsPerformance enhancementEngineering

A sport performance enhancing system includes a left glove, a right glove, a vest, a belt, a left shoe, a right shoe, and a plurality of resistance bands. The left glove and the right glove each consist at least one D-ring which provide the attachment of the left and right glove with the plurality of resistance bands. The vest also consist a plurality of vest rings that attaches with the plurality of resistance bands, attaching the left and right glove. A plurality of O-rings and a shoe D-ring in the left and right shoe are attached to the plurality of resistance band from one end, and the free end of the plurality of resistance bands attaches with a plurality of vertical rings and a plurality of horizontal rings which are positioned around the belt.

Owner:FUNCTIONWEAR LLC

Hinged Dual Panel Electronic Device

ActiveUS20110291536A1Constant resistancePipe supportsDigital data processing detailsMechanical engineeringEngineering

A electronic device includes a first housing body with a first hinged end, a first free end, and a first fastening surface between the first hinged end and the first free end. A second housing body has a second hinged end, a second free end, and a second fastening surface between the second hinged end and the second free end. A flexible member is fixed to the first fastening surface and passes though the first hinged end and through the second hinged end for connection to a sliding cartridge that is affixed to the second fastening surface. The sliding cartridge provides substantially constant resistance during 360° rotation between the first housing body and the second housing body.

Owner:INTEL CORP

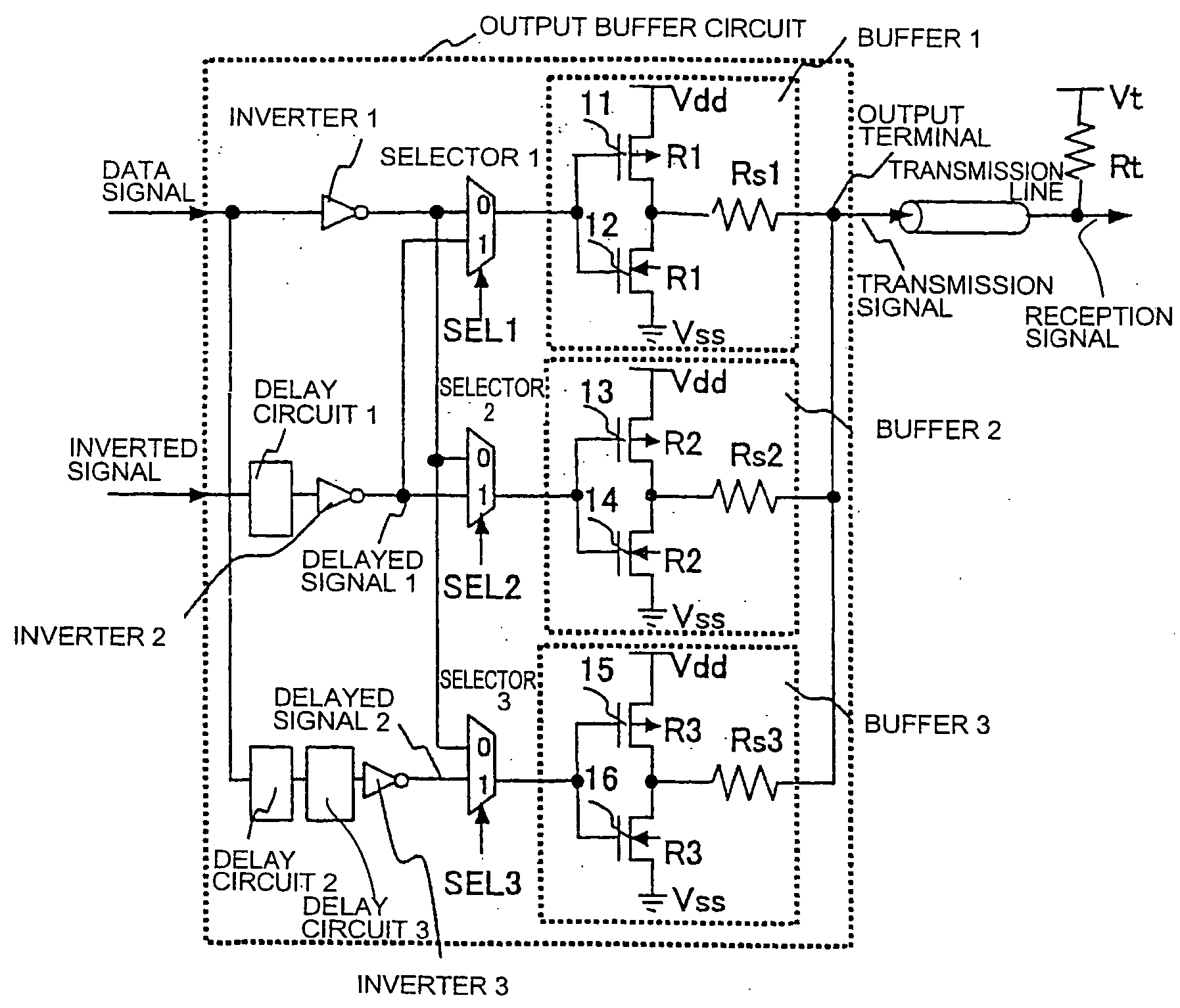

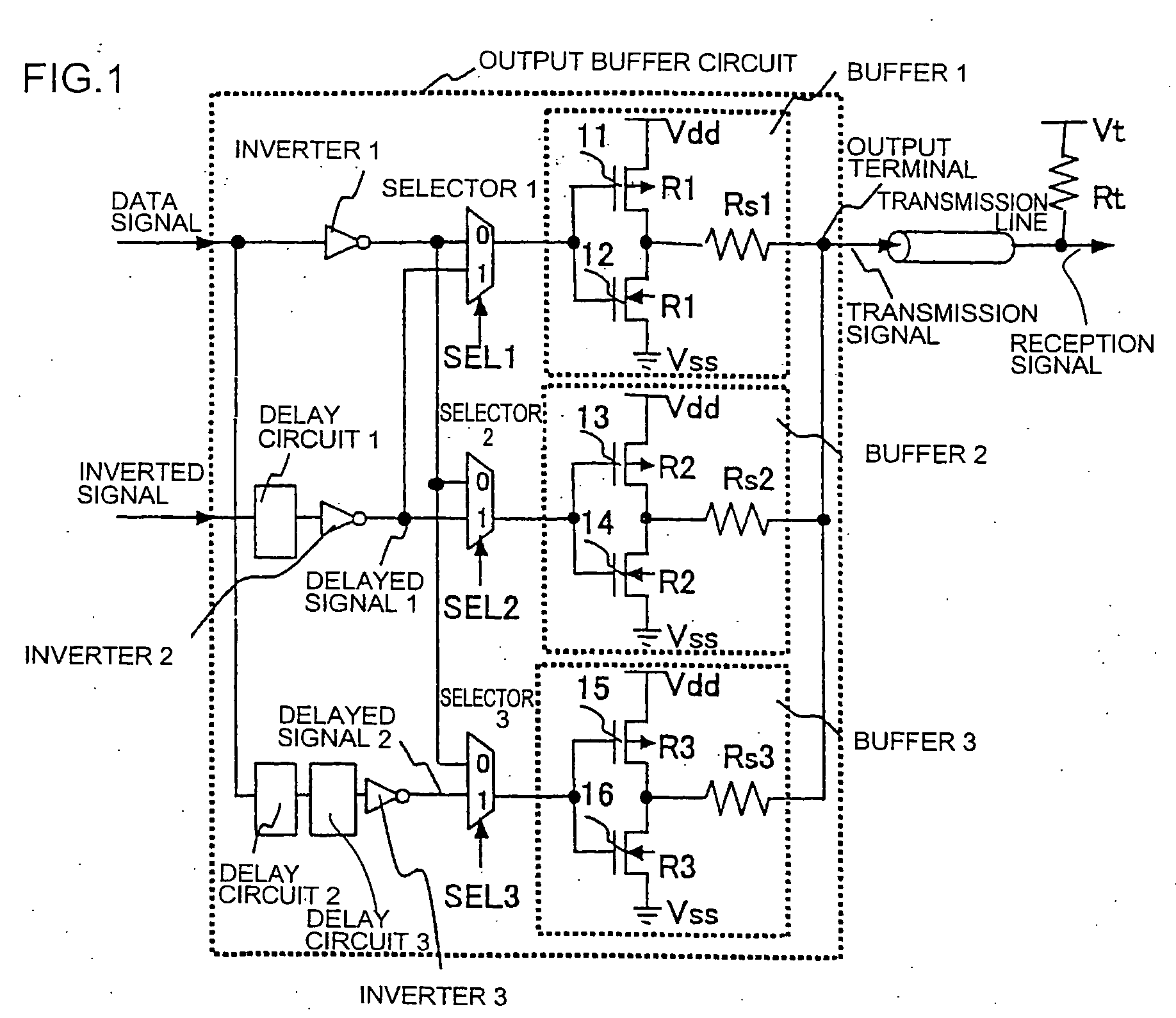

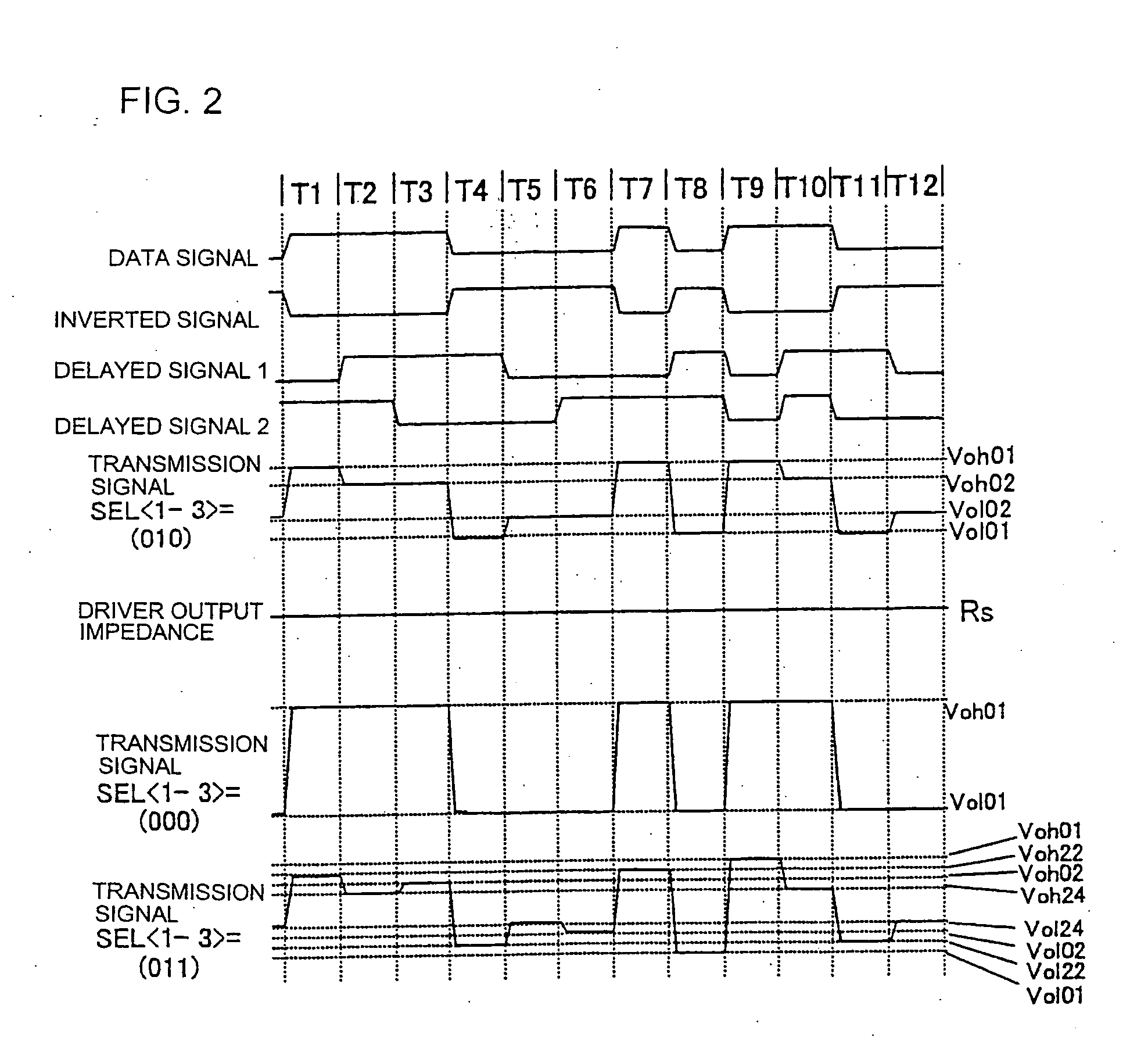

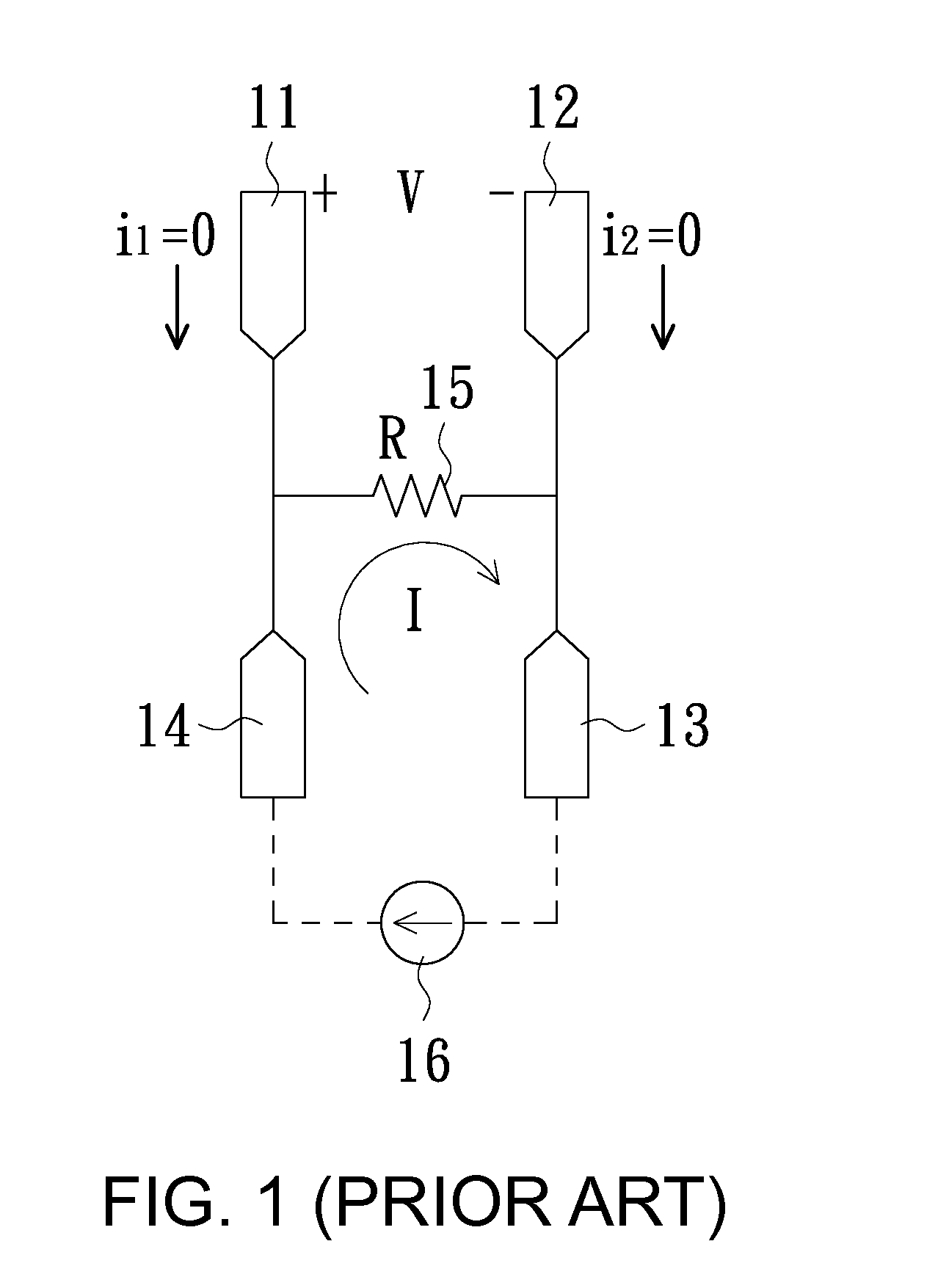

Output Buffer Circuit and Differential Output Buffer Circuit, and Transmission Method

InactiveUS20080265944A1Constant resistanceReduce impactReliability increasing modificationsLogic circuits coupling/interface using field-effect transistorsUltrasound attenuationData signal

In an output buffer circuit including Inverter 1 to Inverter 3, Delay Circuit 1 to Delay Circuit 3 for delaying an input signal for a specific time, Buffer 1 to Buffer 3, and a function for transmitting a logic signal to a transmission path and in accordance with an amount of signal attenuation in the transmission path, creating at a transmission side a waveform including four or more kinds of signal voltages, the preemphasis amount is made variable and the ON resistance Rs of the buffer is made constant. Selector circuit 1 to Selector circuit 3 are situated before the buffers, the inverter, capable of selecting through selector logic a signal to be inputted to the buffer, inverts a data signal, and the preemphasis amount and the number of preemphasis taps are adjusted through a selection signal for the selector logic.

Owner:HITACHI LTD

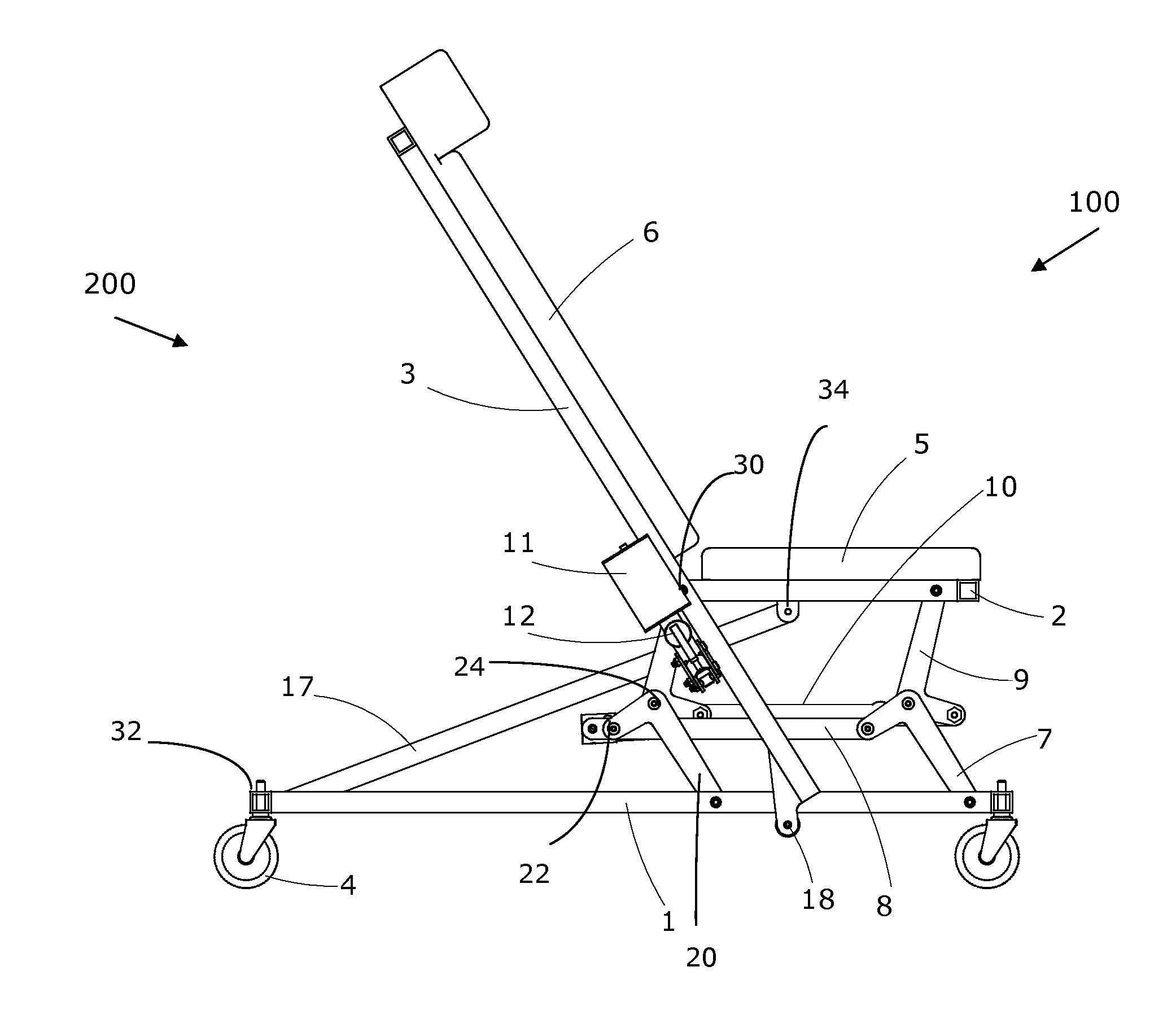

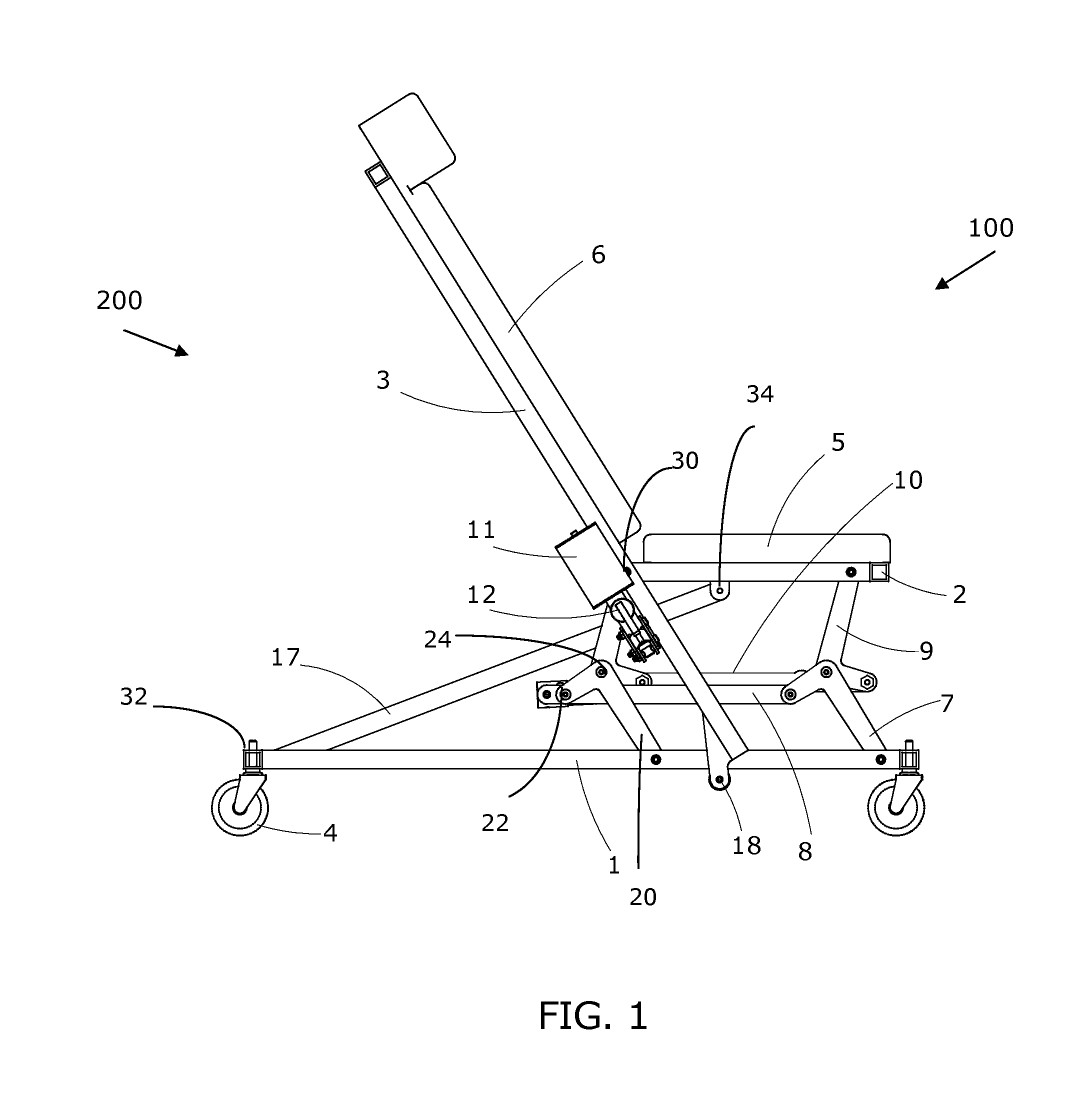

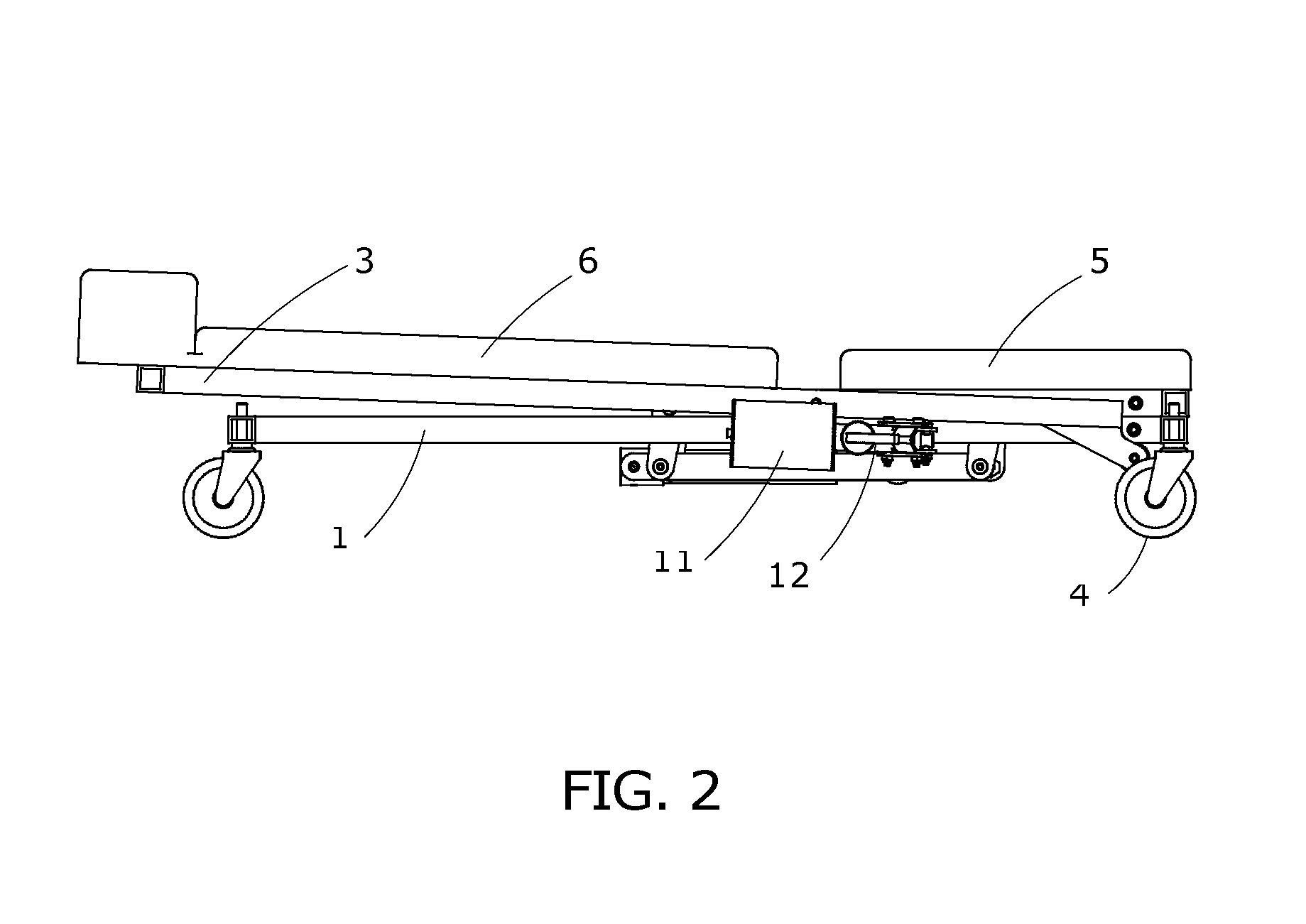

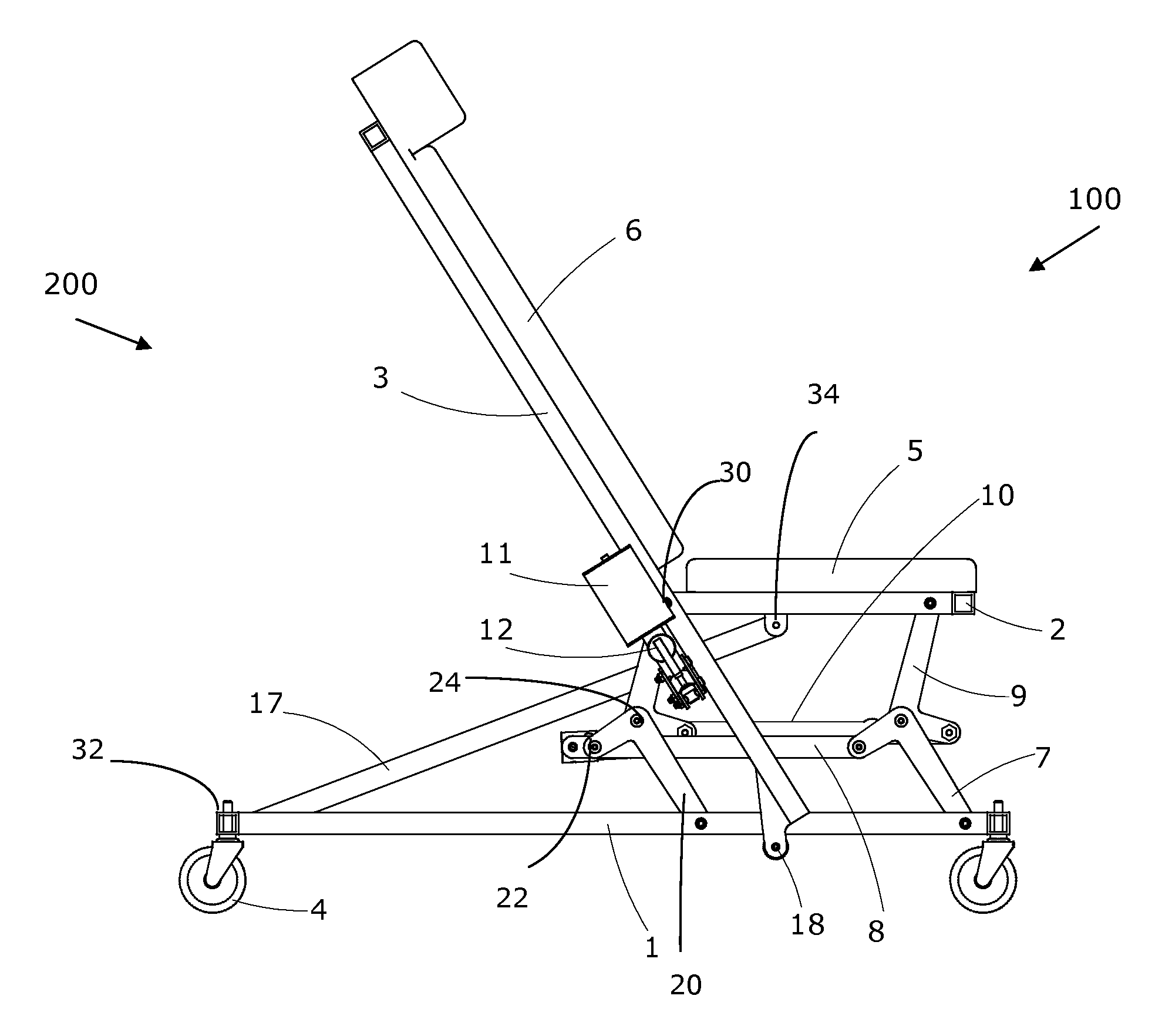

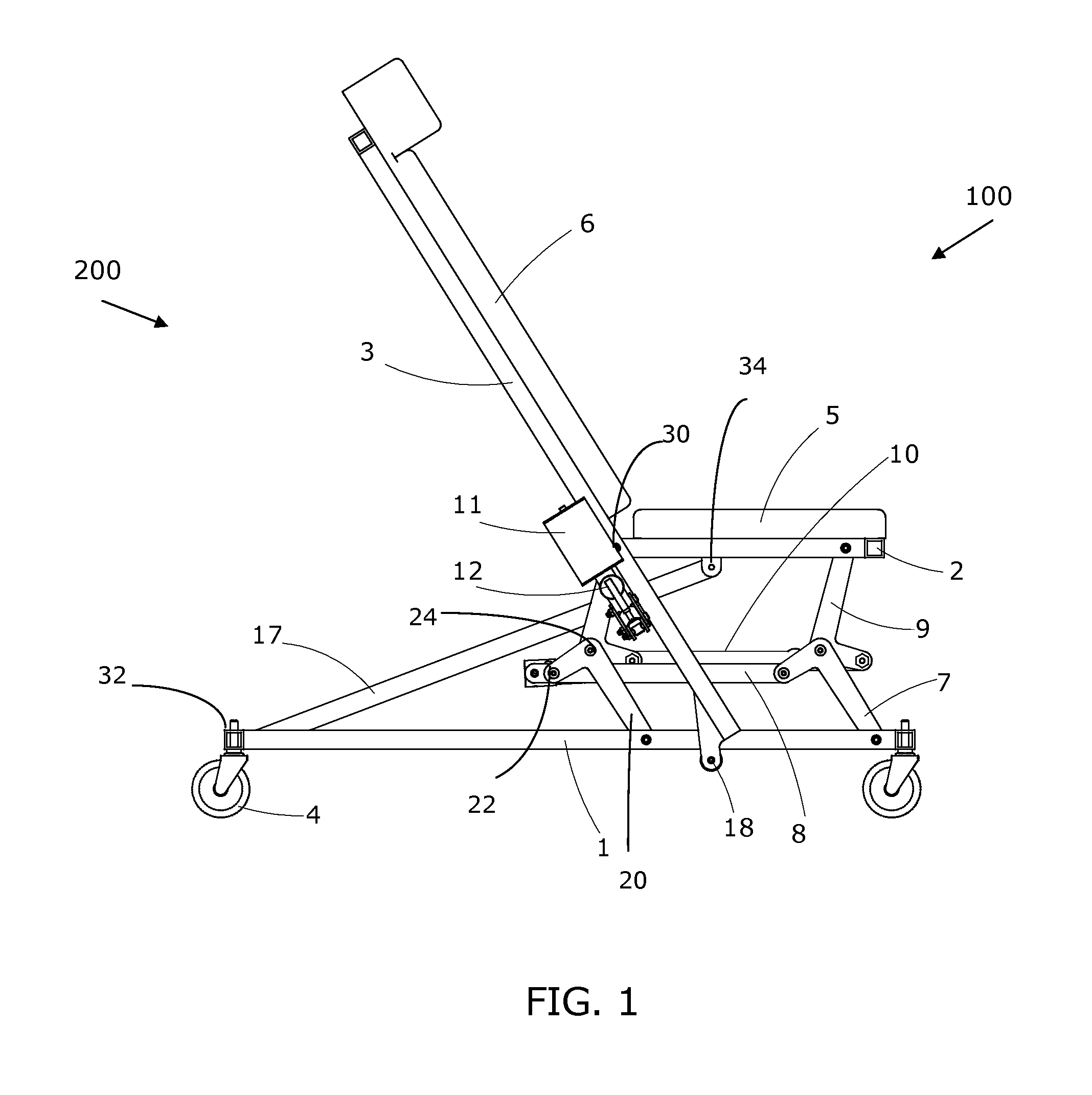

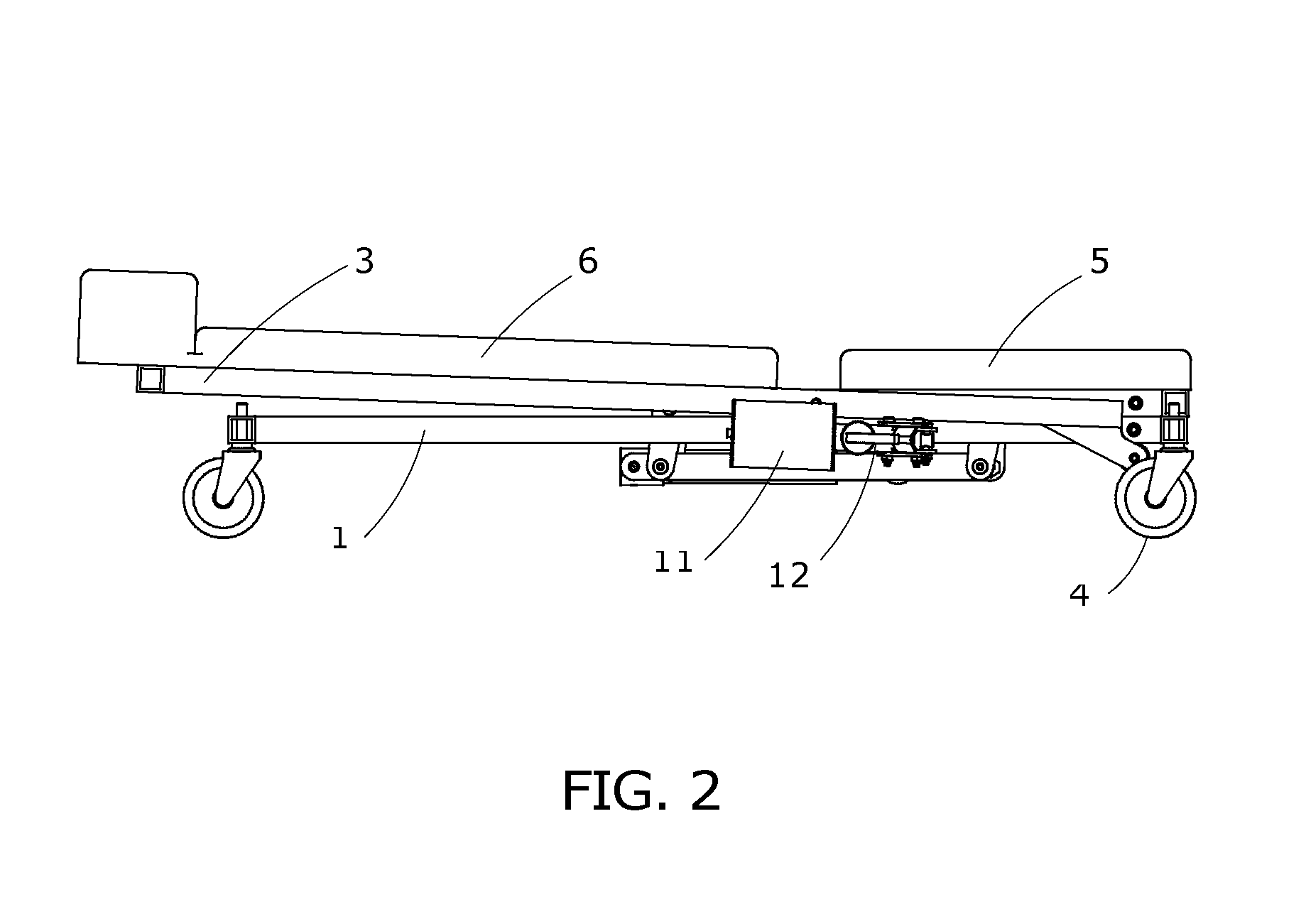

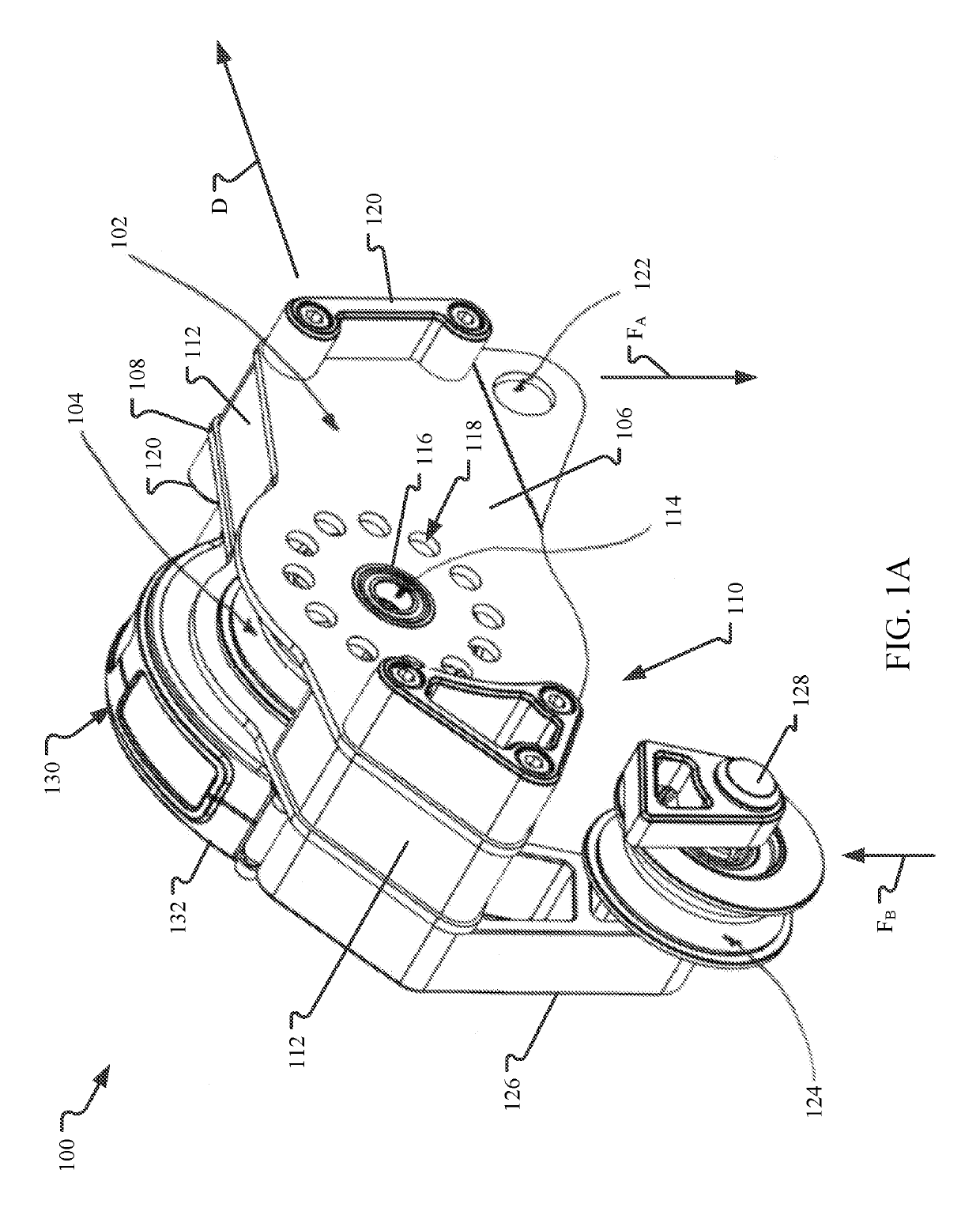

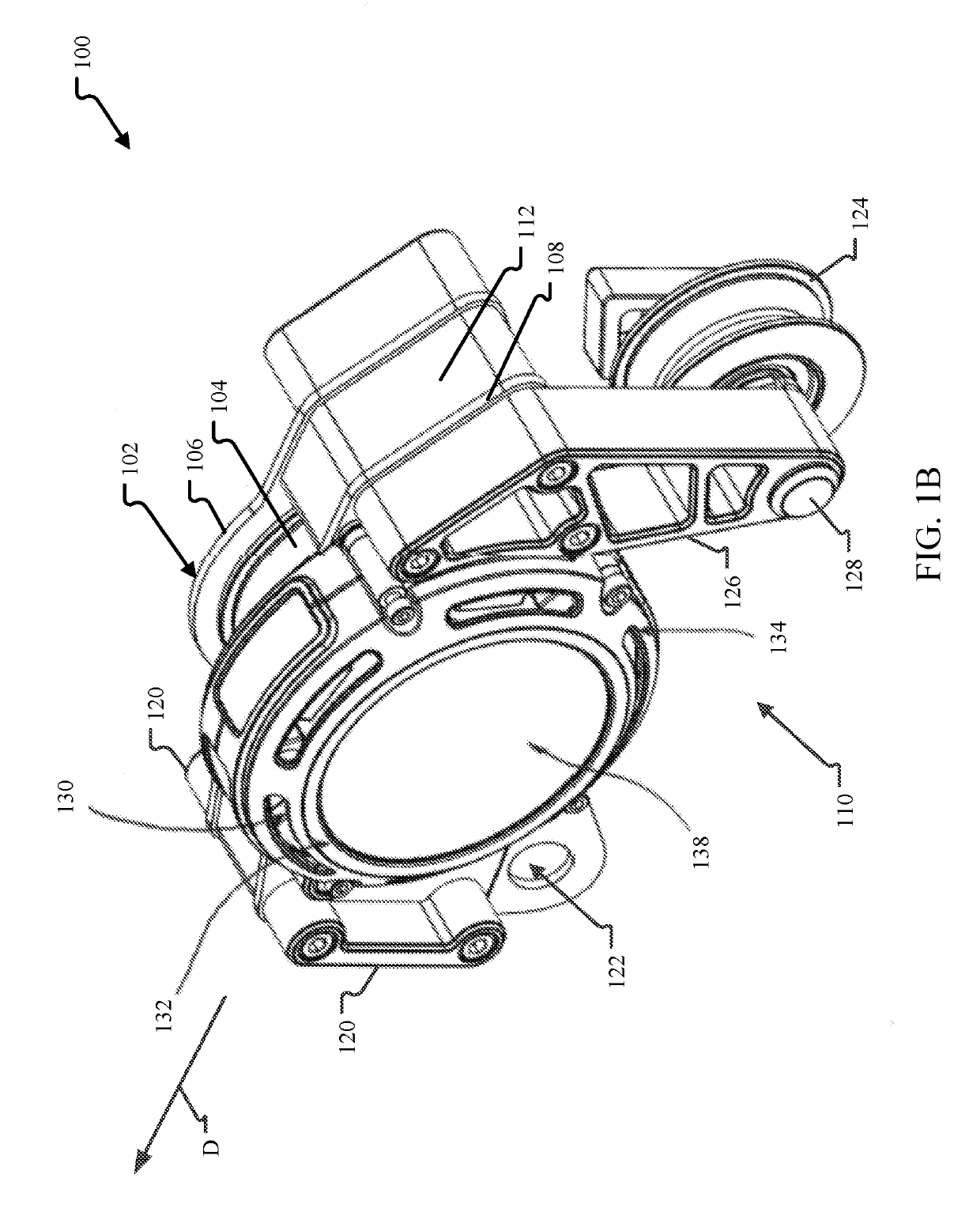

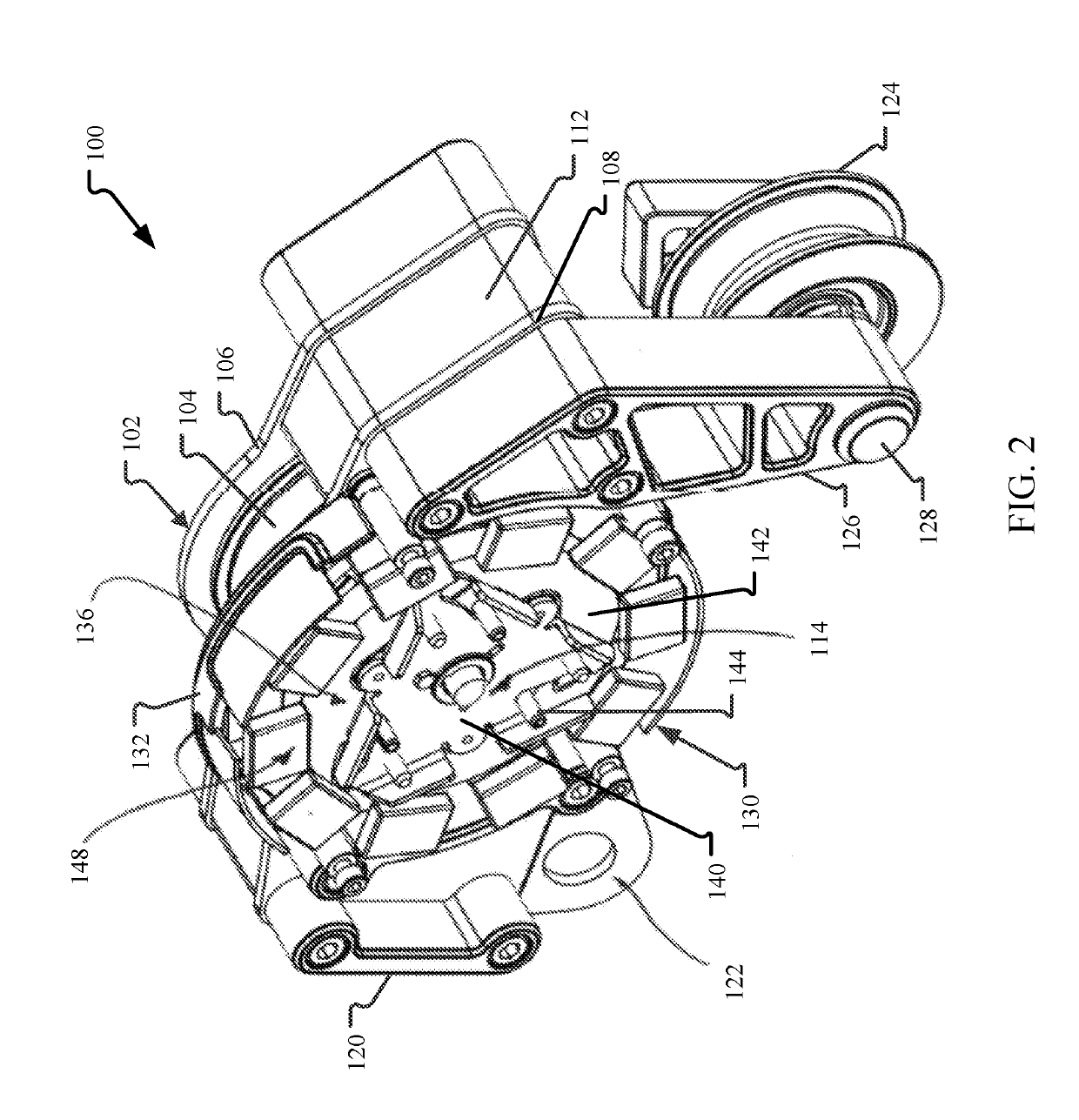

Personal positioning creeper

ActiveUS20140339783A1Smooth shiftingLittle strengthOther workshop equipmentChildren carriages/perambulatorsHydraulic cylinderHydraulic pump

A personal positioning creeper (PPC) for assisting mechanics, technicians and factory workers who need access to various angles and heights on a vehicle, aircraft, factory equipment, etc. The PPC allows the operator to simultaneously maneuver from lying supine near the ground, to moving upward and rotating into a full sitting position without having to dismount the PPC. The PPC comprises: a three member frame system (base, seat, and backrest frame connected together with eight (8) bell cranks and four (4) linkage assemblies), all under the control of a hydraulic system. The hydraulic system comprises: 1) a hydraulic pump with an ergonomically designed pump actuator handle and a release valve; and, 2) a hydraulic cylinder connected to the hydraulic pump, and to the linkage assemblies to rotate the bell cranks. The resistance to the pumping action felt by the operator remains constant regardless of the height of the seat.

Owner:THE EZ CREEPER COMPANY

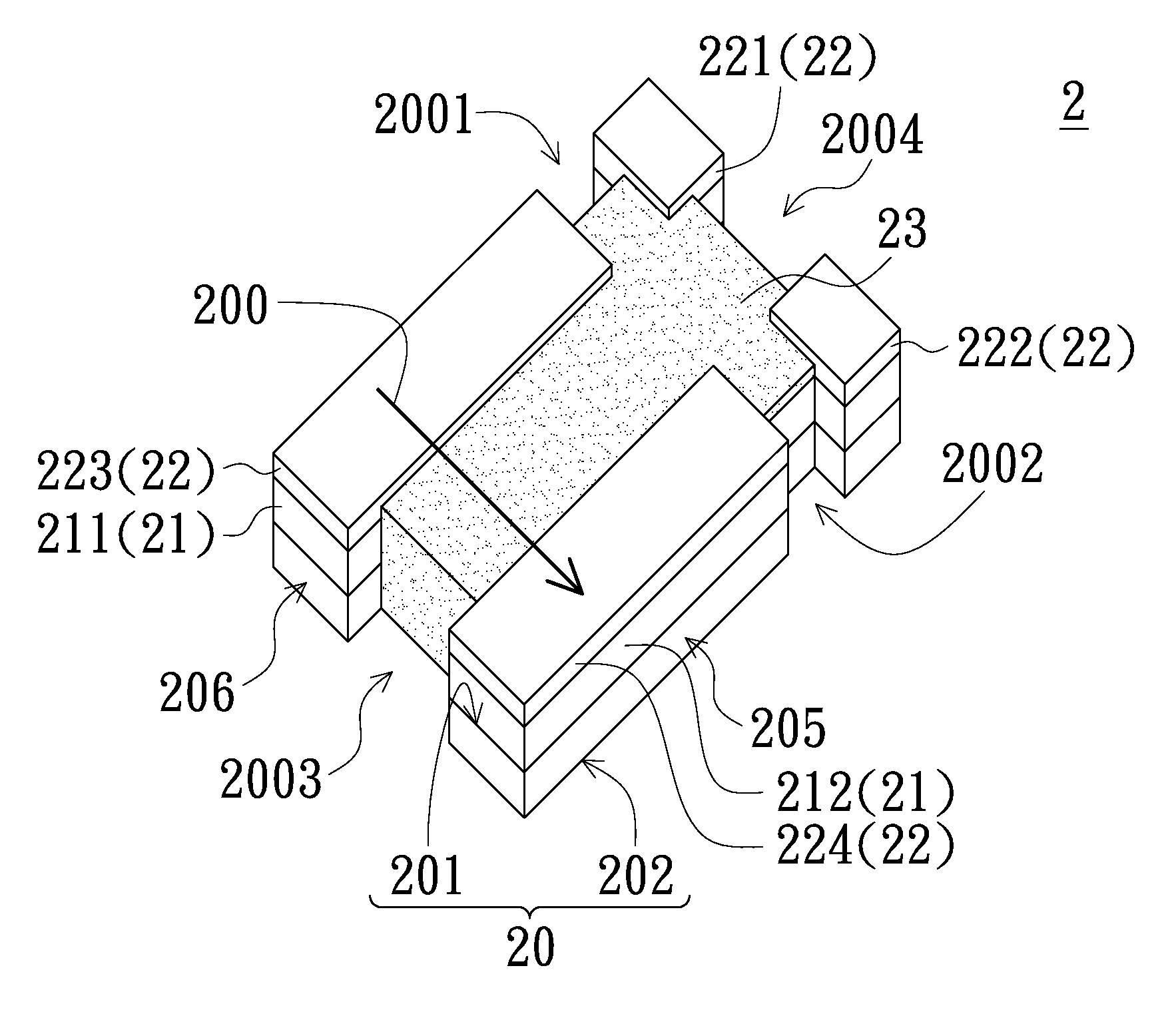

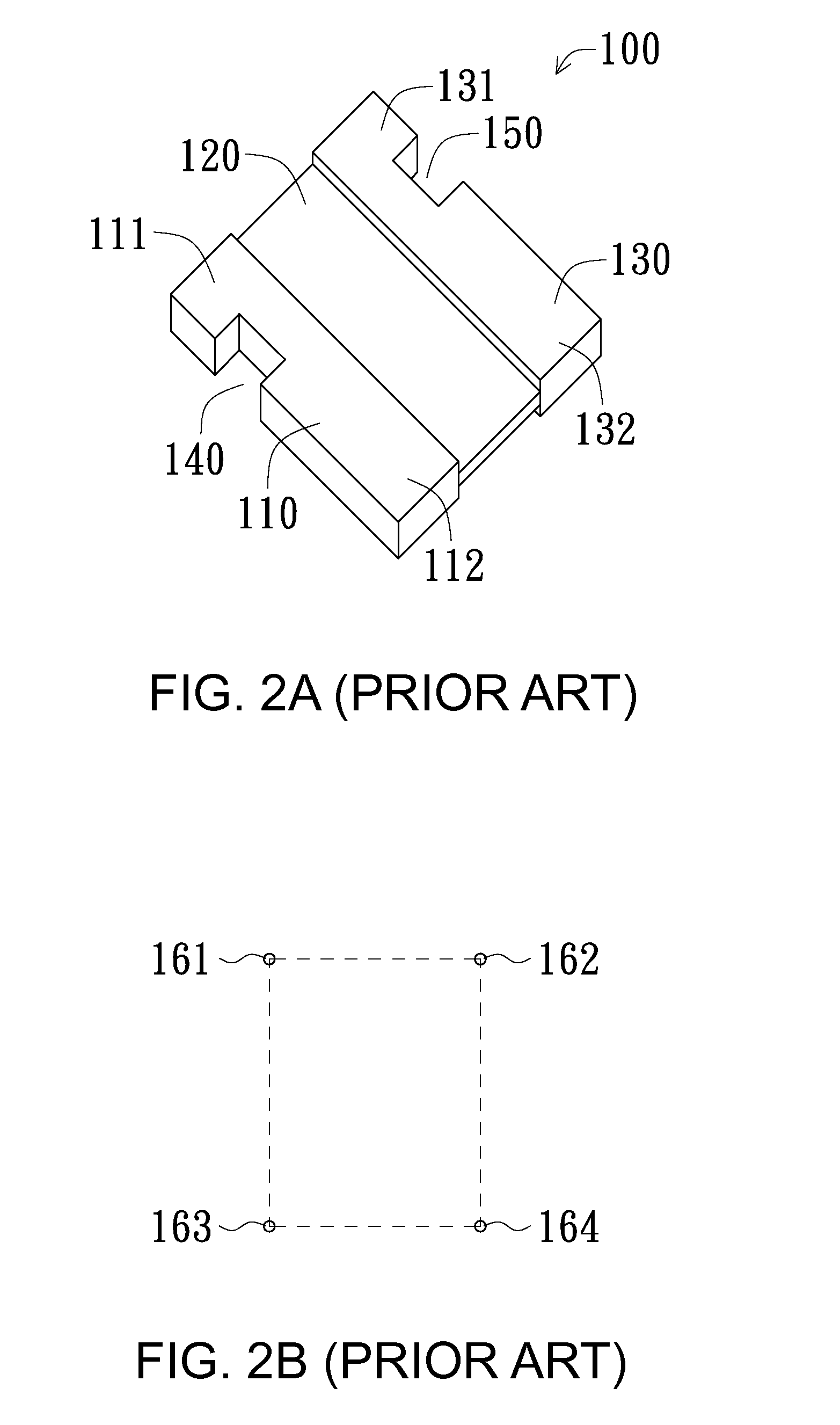

Current sensing resistor

ActiveUS20140266568A1Constant resistanceEliminate the effects ofElectrical measurement instrument detailsCurrent responsive resistorsEngineeringResistor

A resistor device includes a resistor plate having opposite first and second surfaces; a first metal layer including first and second portions which are disposed on the first surface of the resistor plate at opposite first and second sides, respectively; and a second metal layer including a first sensing pad, a second sensing pad, a first current pad and a second current pad, separate from one another, wherein the first sensing pad and the first current pad are disposed on the first portion of the first metal layer and the second sensing pad and the second current pad are disposed on the second portion of the first metal layer. A protective layer is preferably provided, overlying the resistor plate and the first metal layer uncovered by the second metal layer.

Owner:CYNTEC

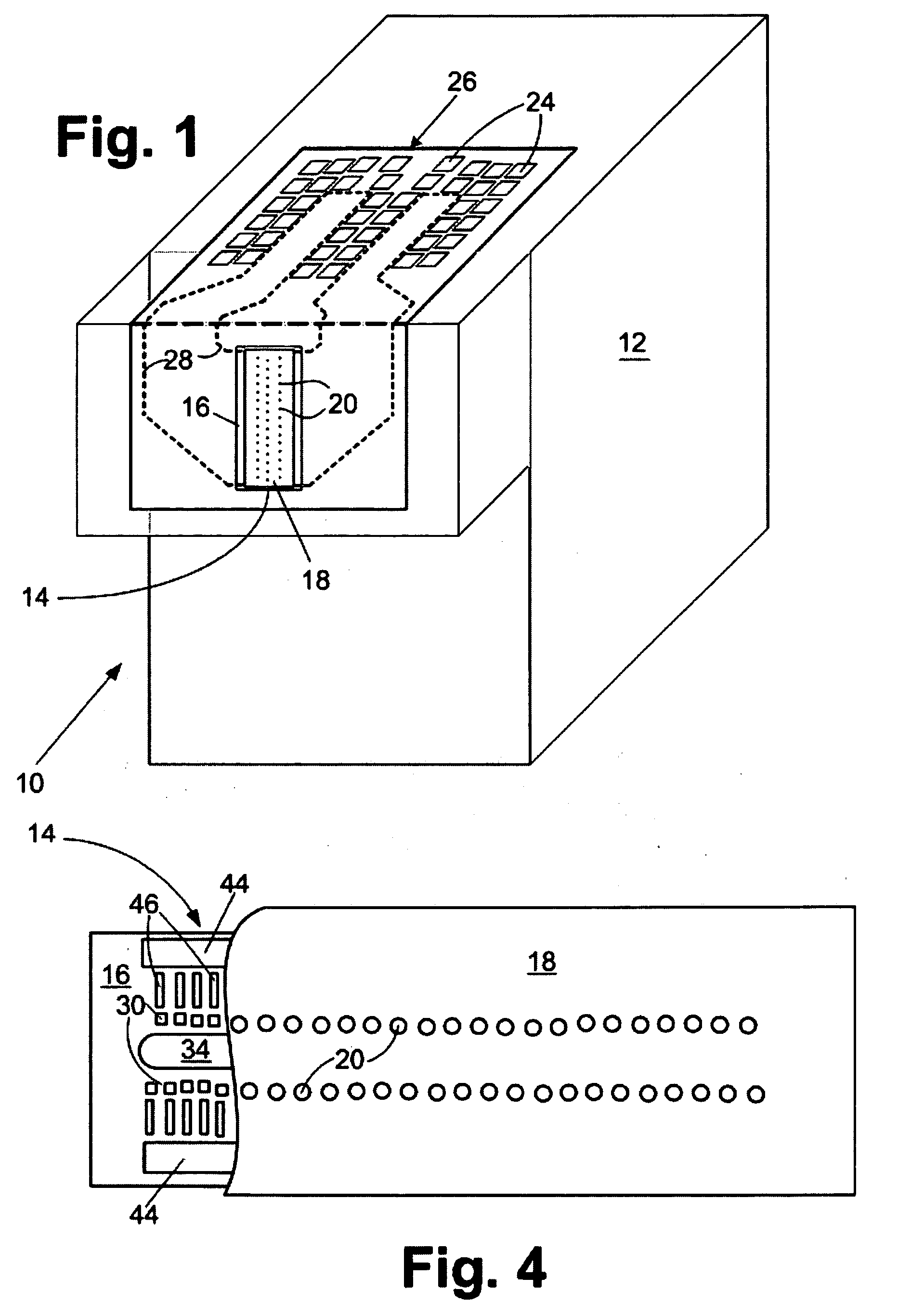

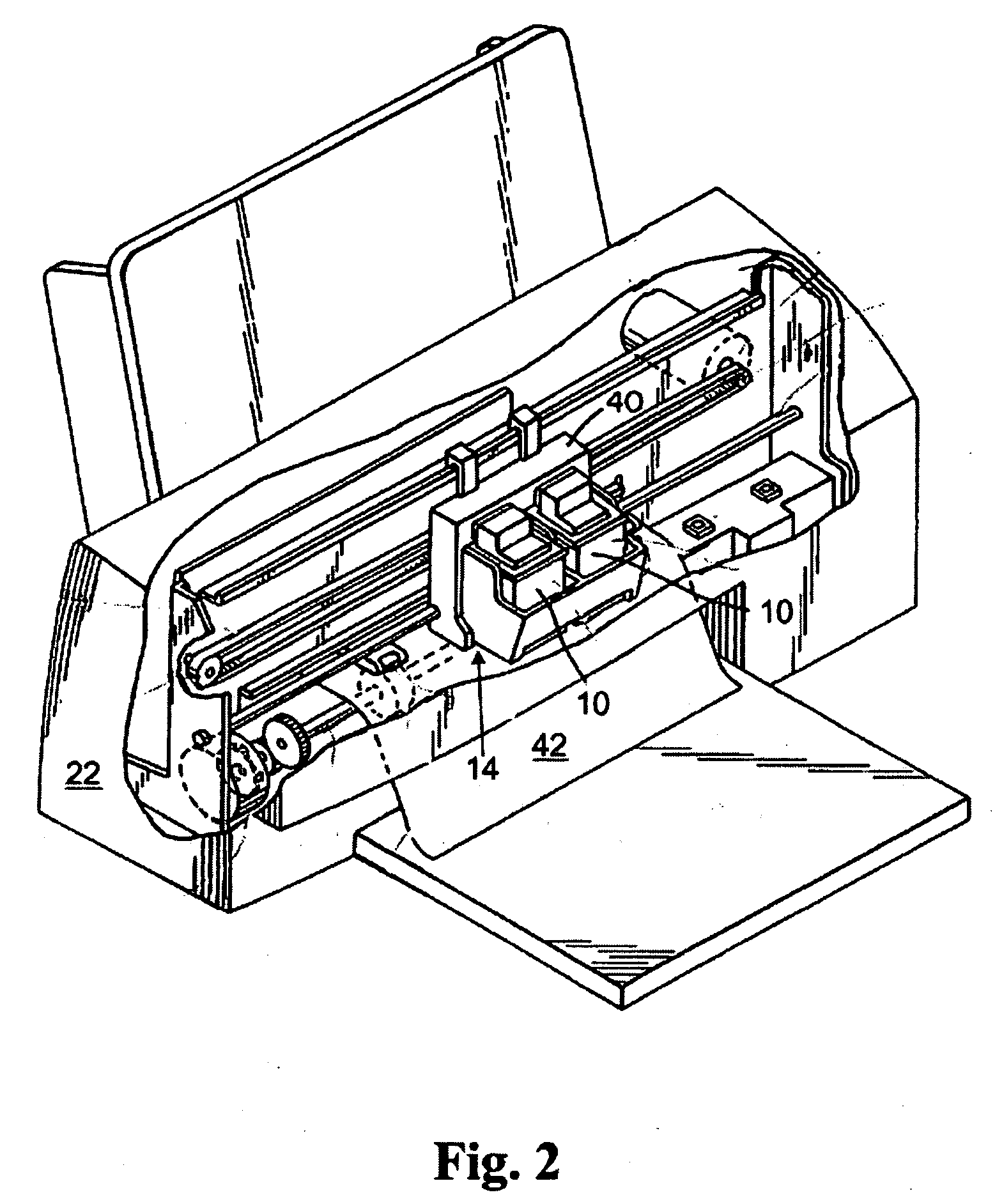

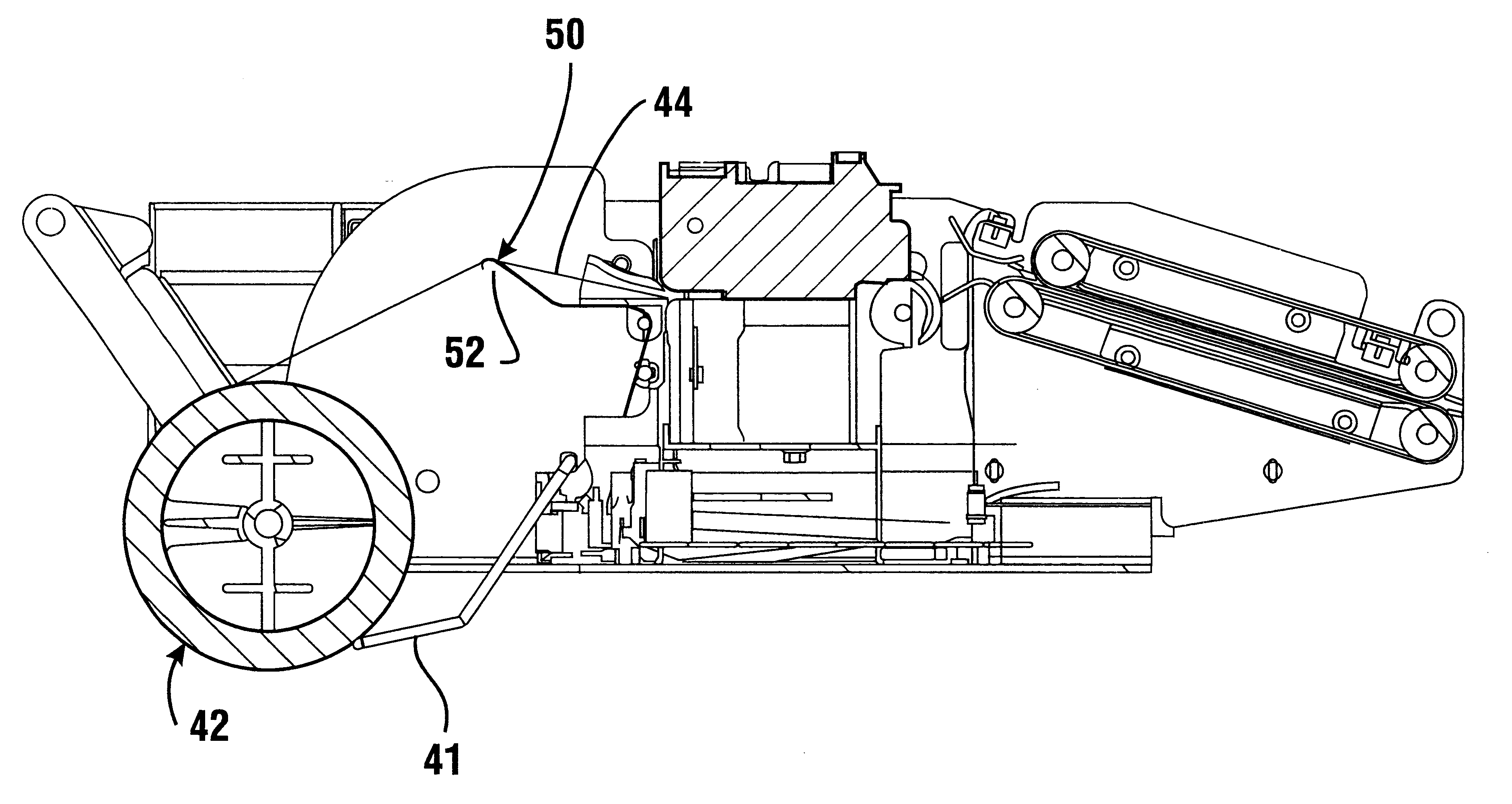

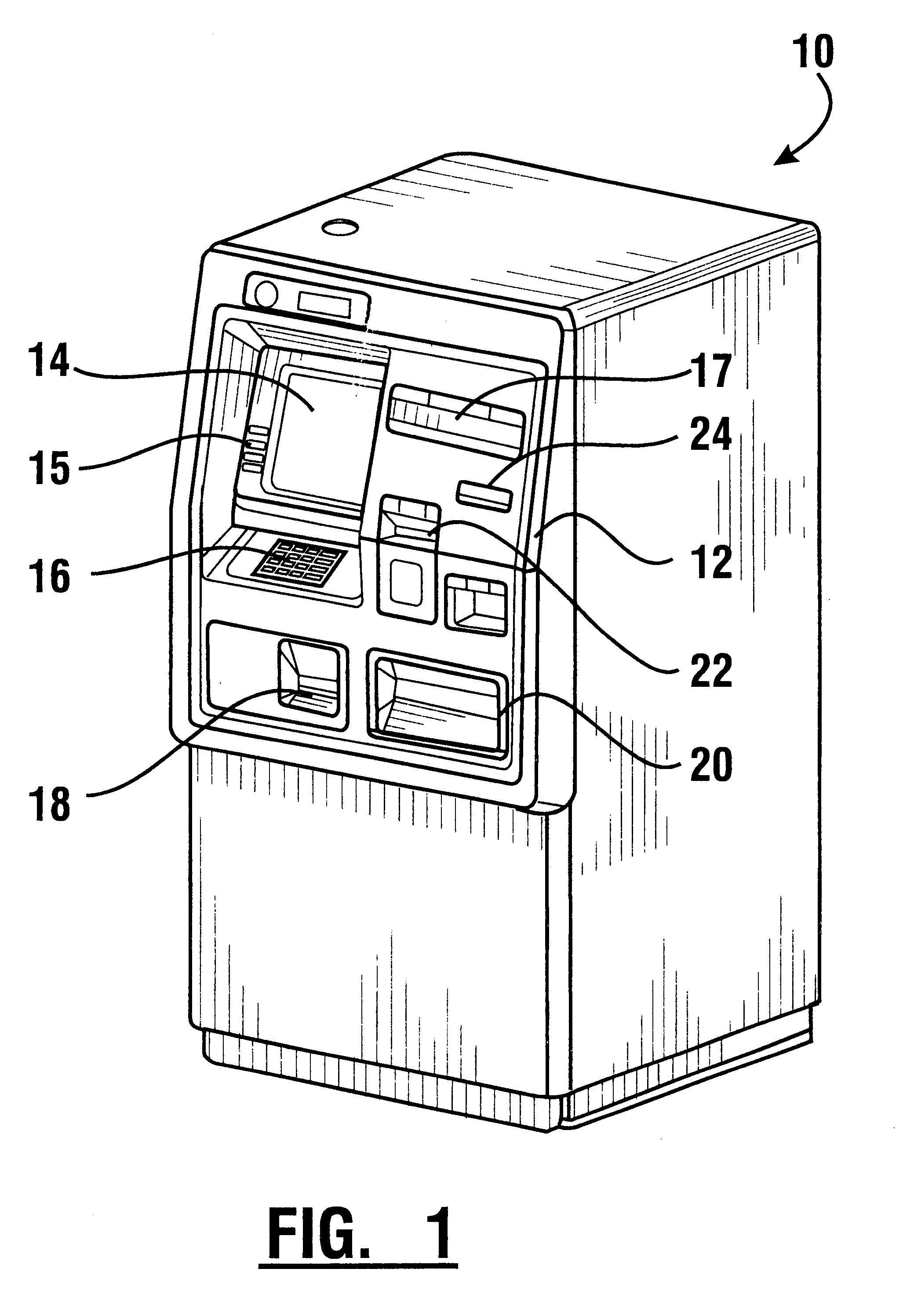

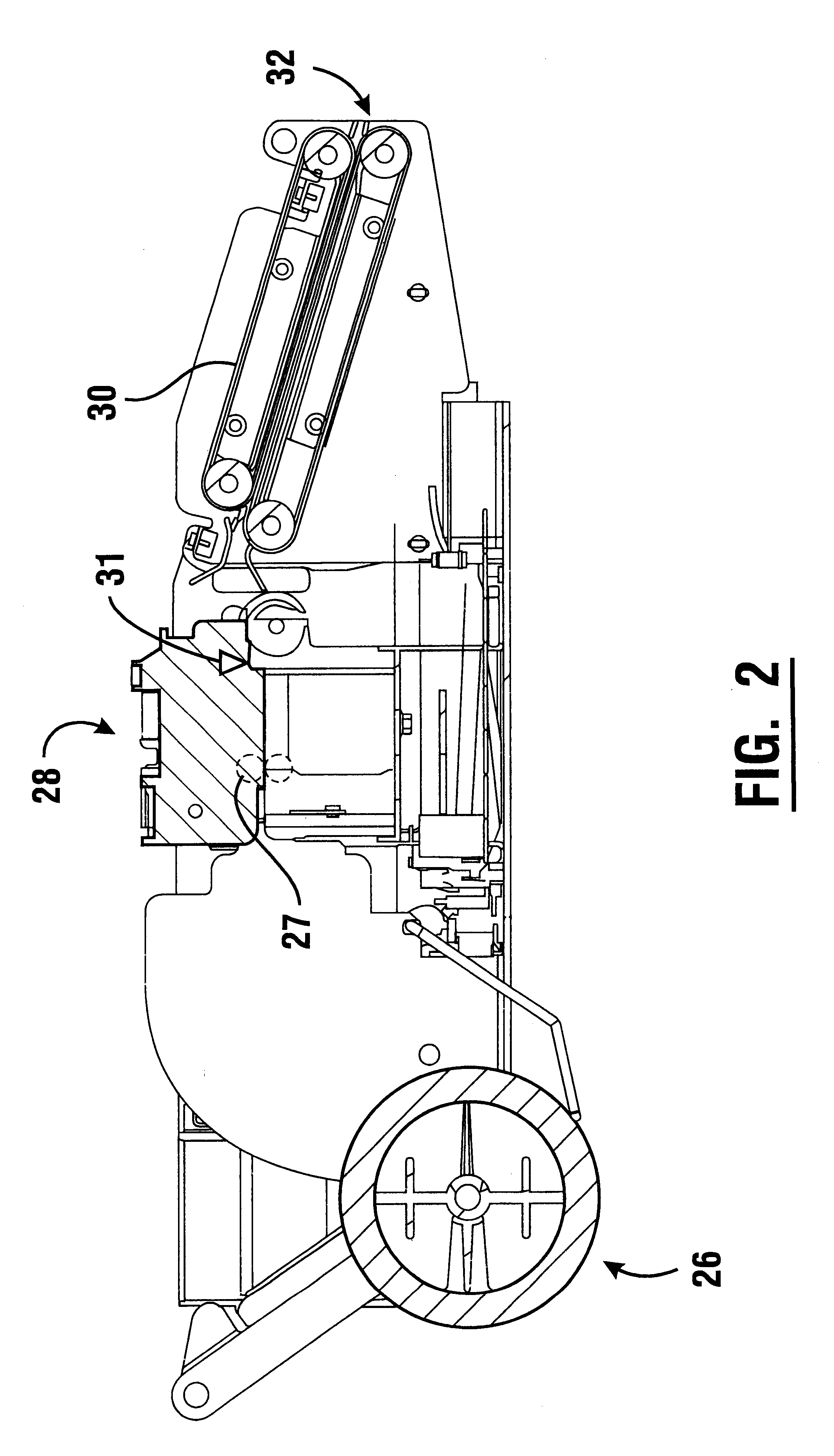

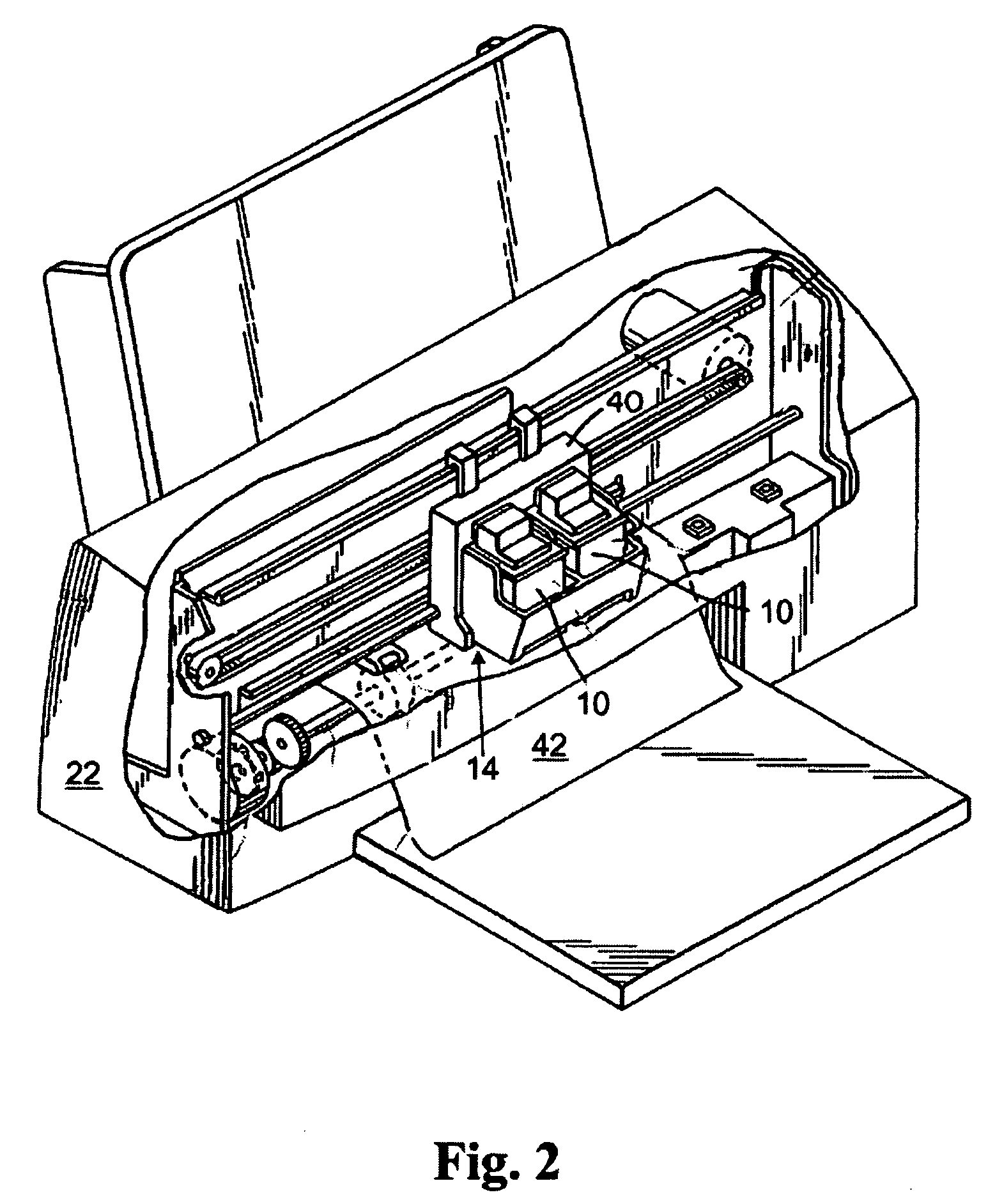

Automated transaction machine printer

InactiveUS6547464B1Constant resistive forceHigh resistance forceAcutation objectsTypewritersDistortionPaper sheet

An automated transaction machine (10) includes a thermal printing apparatus for printing account statements for a user. A paper drive (36) moves a paper web (44) from a paper roll (42) through a printer (40). After indicia is printed on the paper, the paper is cut by a cutter (37) into sheets and delivered to a user by a presenter drive (30). After paper cutting, the paper is moved a short distance in a direction opposed to the direction that the paper normally moves during printing. A paper control device (49) operates to maintain a relatively constant resistance force to movement of the web in the printing direction after the paper has been retracted. The paper control device limits application of resistance forces to below a threshold as well as sudden fluctuation of resistance forces on the paper web which may otherwise cause the paper to slip relative to the drive and cause distortion of printed indicia or damage to the web.

Owner:DIEBOLD NIXDORF

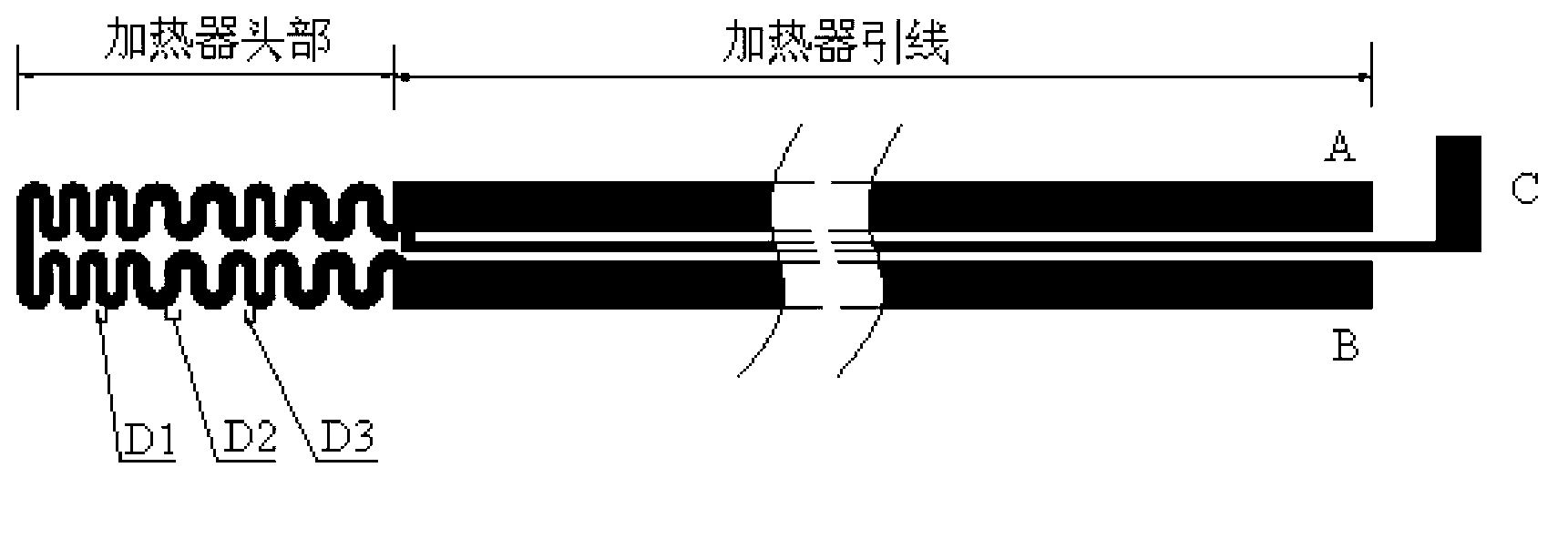

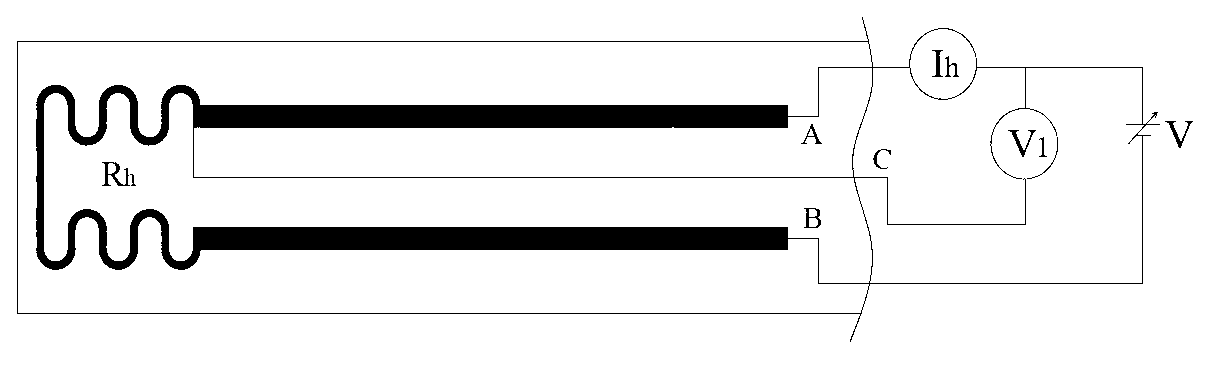

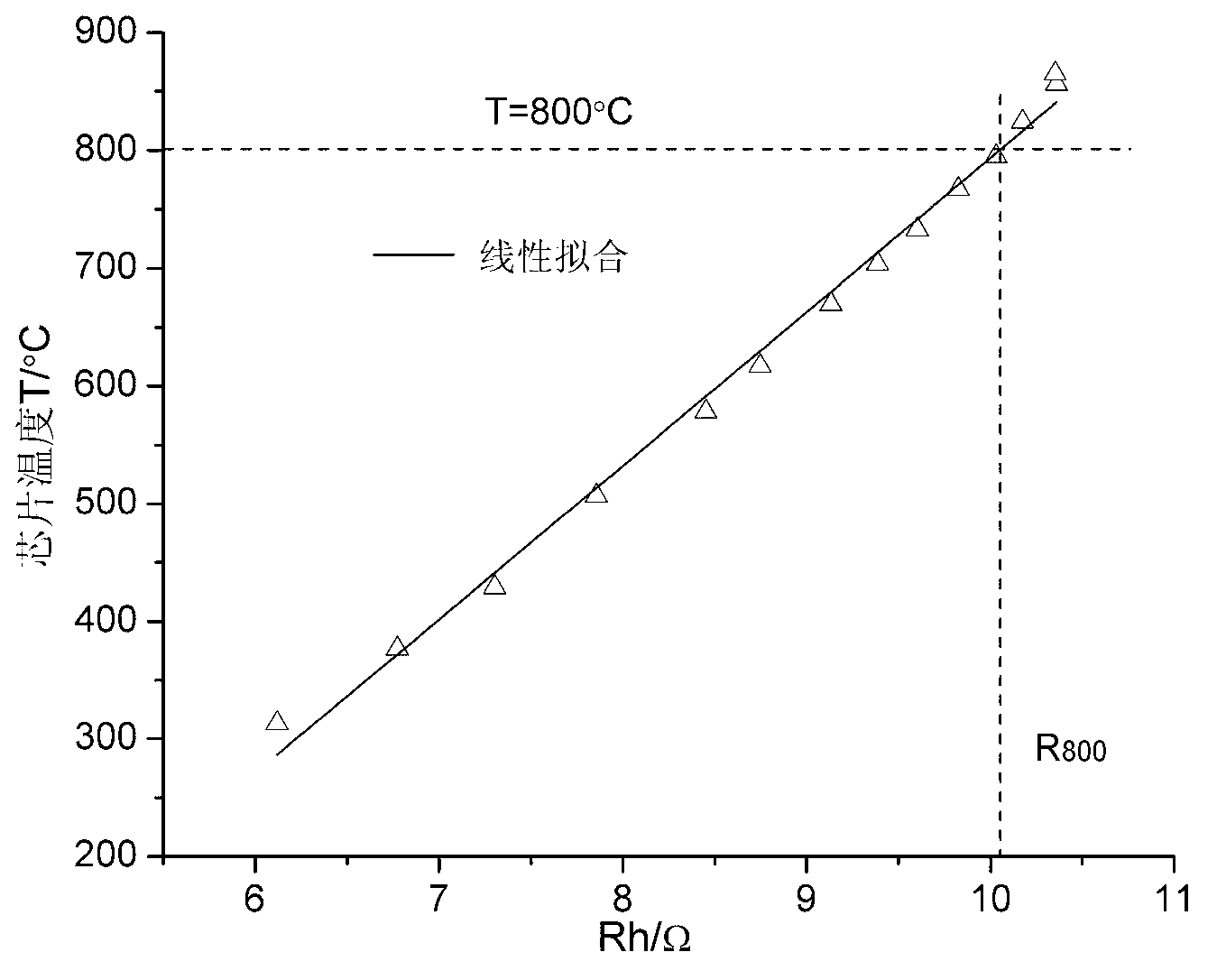

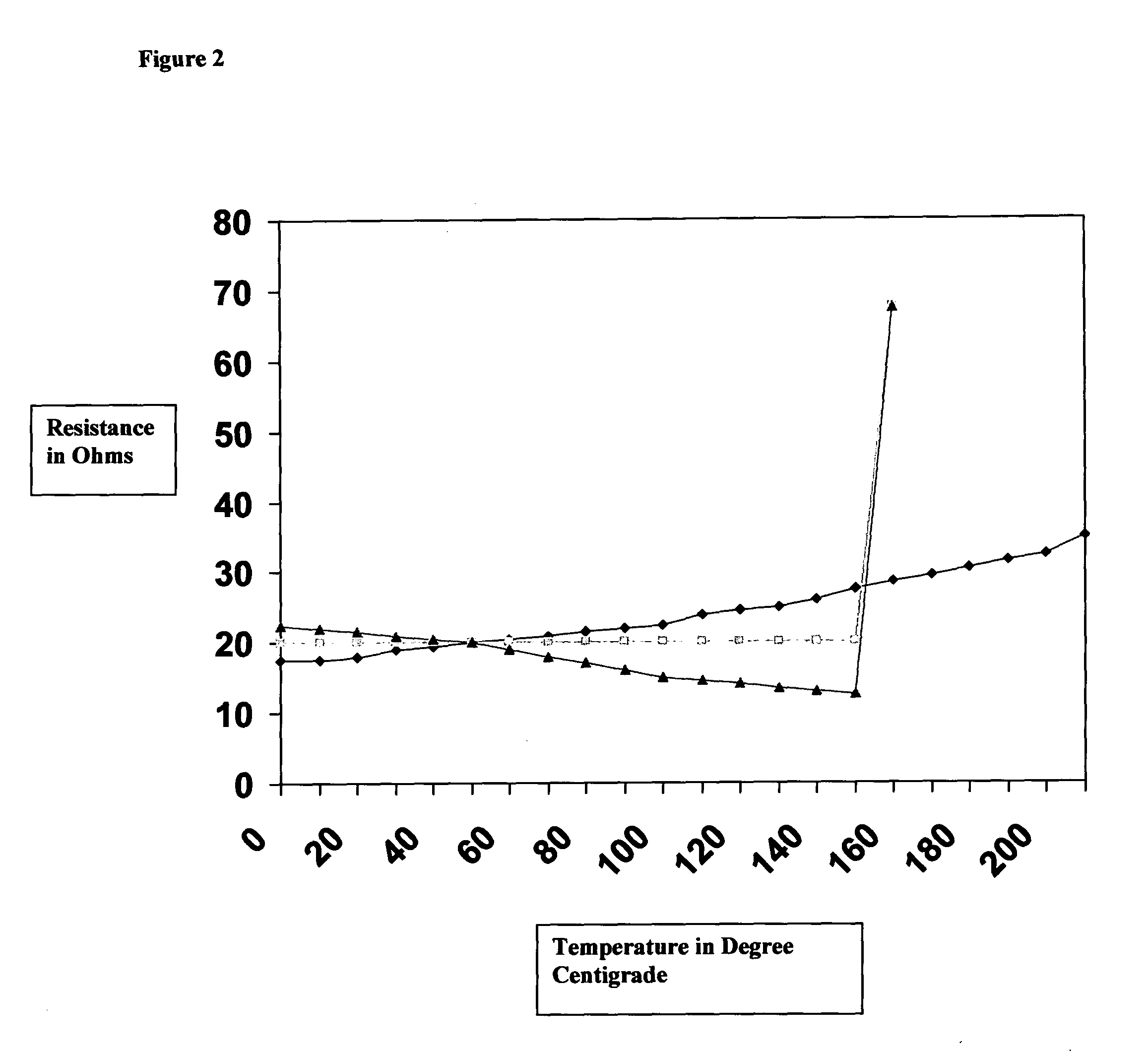

Heating control method for nitrogen oxygen sensor

ActiveCN102798654AConstant resistanceHigh measurement accuracyTemperatue controlMaterial analysis by electric/magnetic meansElectrical resistance and conductanceOxygen sensor

The invention discloses a heating control method for a nitrogen oxygen sensor. The nitrogen oxygen sensor comprises a signal function layer and a heater, wherein the heater is of a three-line type heater structure. The heating method comprises the following specific steps of: a, drawing a graph of a temperature value T of a nitrogen oxygen sensor chip and a head resistance value of the heater; b, when the temperature of the nitrogen oxygen sensor chip is determined to be 800DEG C, determining a resistance calibration value of the heater head to be R 800 and a voltage calibration value of the heater to be V800; and c, adjusting a heating voltage value of the heater for enabling a temperature value of the nitrogen oxygen sensor chip to be maintained at 800DEG C. According to the heating control method disclosed by the invention, the temperature value change of the head of the nitrogen oxygen sensor chip is characterized by adopting the amplitude of the head resistance value of the heater; and a work temperature value of the nitrogen oxygen sensor chip is enabled to be controlled at about 800DEG C by changing voltage values applied to two ends of the heater, and thus the measurement precision of the nitrogen oxygen sensor for NOx is further improved.

Owner:WUXI LONGSHENG TECH

Heat resistant fuel hose

InactiveUS20030188793A1Increase resistanceIncrease costFlexible pipesThin material handlingVulcanizationNitrile rubber

The present invention provides a heat resistant fuel hose comprising a rubber inner pipe with an inner layer and an outer layer in the inner pipe. The inner layer of the inner pipe comprises a hydrogenated acrylonitrile butadiene rubber (H-NBR) that is mixed with zinc oxide (ZnO) and magnesium oxide (MgO) as acid acceptors and is peroxide vulcanized. The outer layer of the inner pipe comprises an epoxy cross-linking type acrylic rubber (ACM) that has been vulcanized bonded to the inner layer of the inner pipe. The inner layer and outer layer of the inner pipe of the heat resistant fuel hose of the present invention are strongly bonded, and the rubber inner pipe has excellent heat resistance.

Owner:SUMITOMO RIKO CO LTD

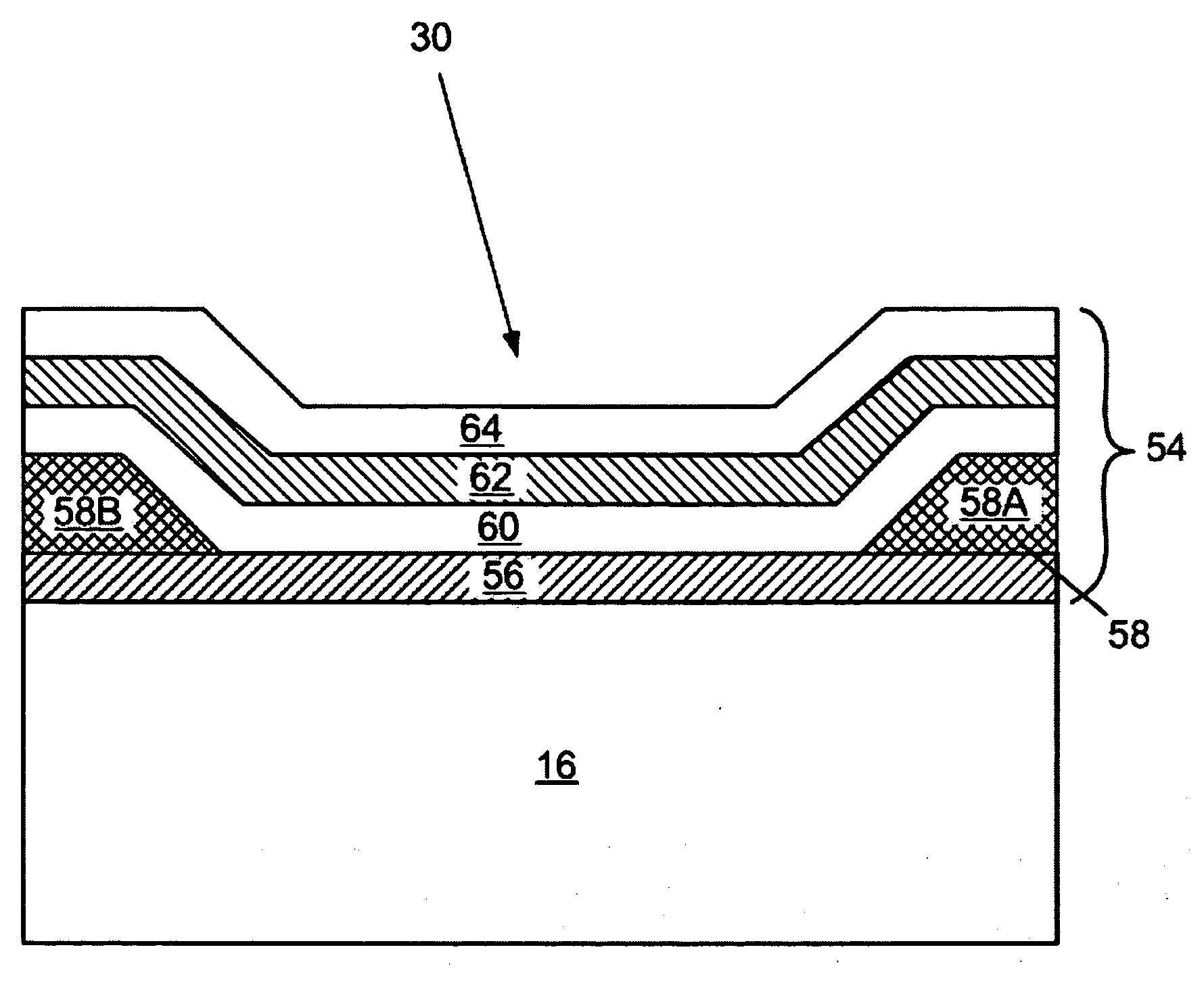

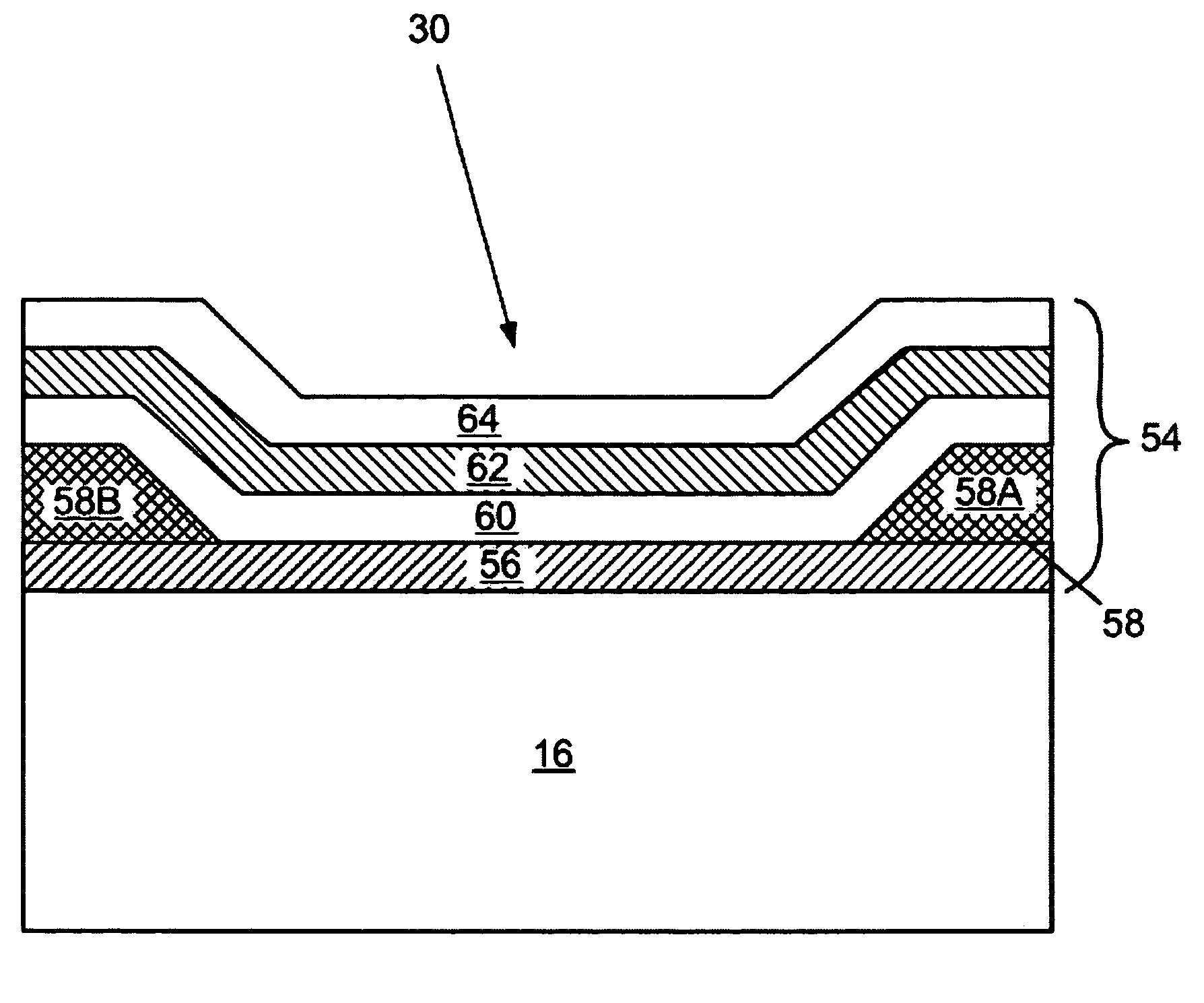

Micro-fluid ejection device having high resistance heater film

A semiconductor substrate for a micro-fluid ejection head. The substrate includes a plurality of fluid ejection actuators disposed on the substrate. Each of the fluid ejection actuators includes a thin heater stack comprising a thin film heater and one or more protective layers adjacent the heater. The thin film heater is made of a tantalum-aluminum-nitride thin film material having a nano-crystalline structure consisting essentially of AlN, TaN, and TaAl alloys, and has a sheet resistance ranging from about 30 to about 100 ohms per square. The thin film material contains from about 30 to about 70 atomic % tantalum, from about 10 to about 40 atomic % aluminum and from about 5 to about 30 atomic % nitrogen.

Owner:SLINGSHOT PRINTING LLC

Sports performance enhancement system

ActiveUS8968166B2Maximize qualityMinimize timeResilient force resistorsPerformance enhancementExercise performance

A sport performance enhancing system includes a left glove, a right glove, a vest, a belt, a left shoe, a right shoe, and a plurality of resistance bands. The left glove and the right glove each consist at least one D-ring which provide the attachment of the left and right glove with the plurality of resistance bands. The vest also consist a plurality of vest rings that attaches with the plurality of resistance bands, attaching the left and right glove. A plurality of O-rings and a shoe D-ring in the left and right shoe are attached to the plurality of resistance band from one end, and the free end of the plurality of resistance bands attaches with a plurality of vertical rings and a plurality of horizontal rings which are positioned around the belt.

Owner:FUNCTIONWEAR LLC

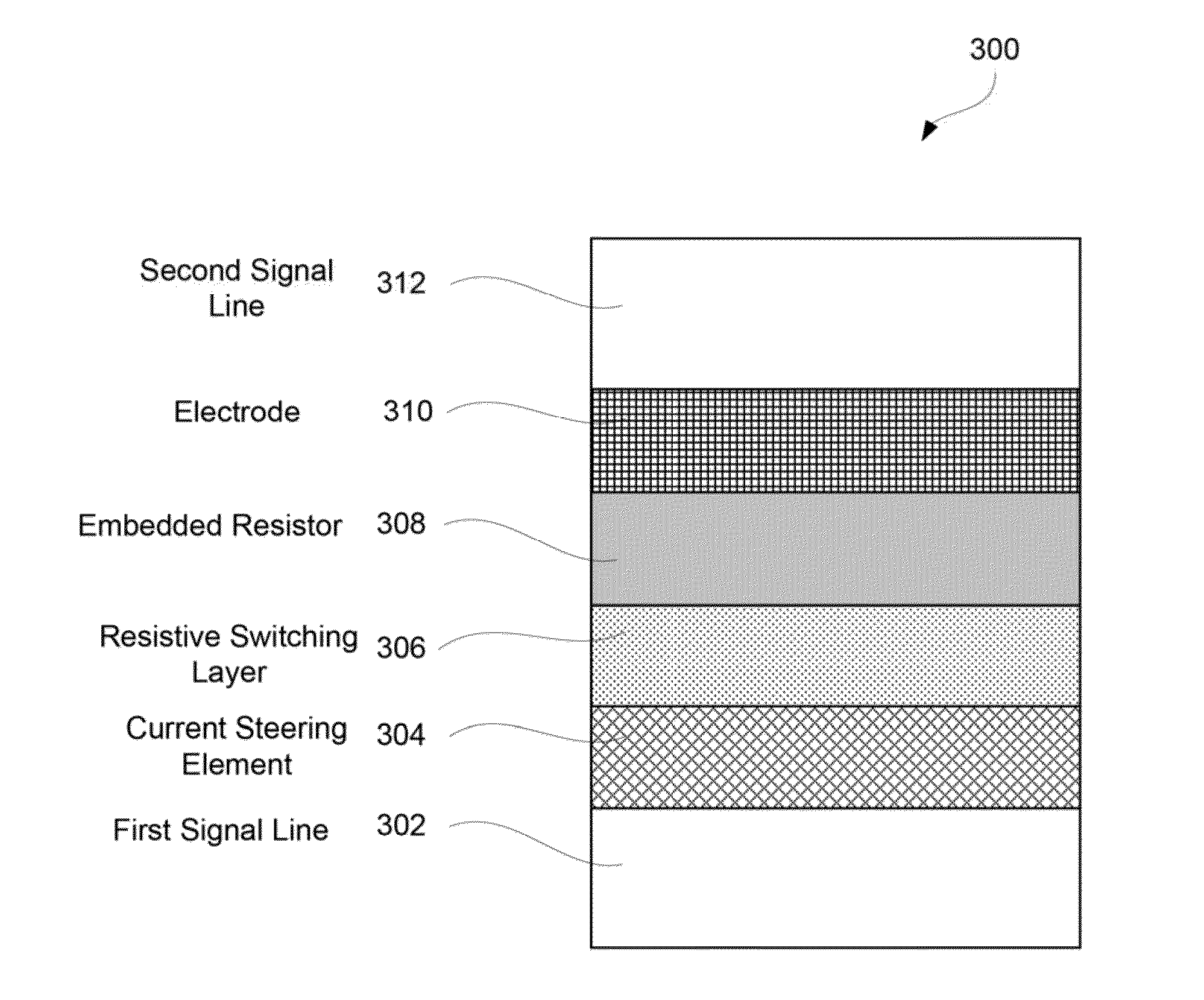

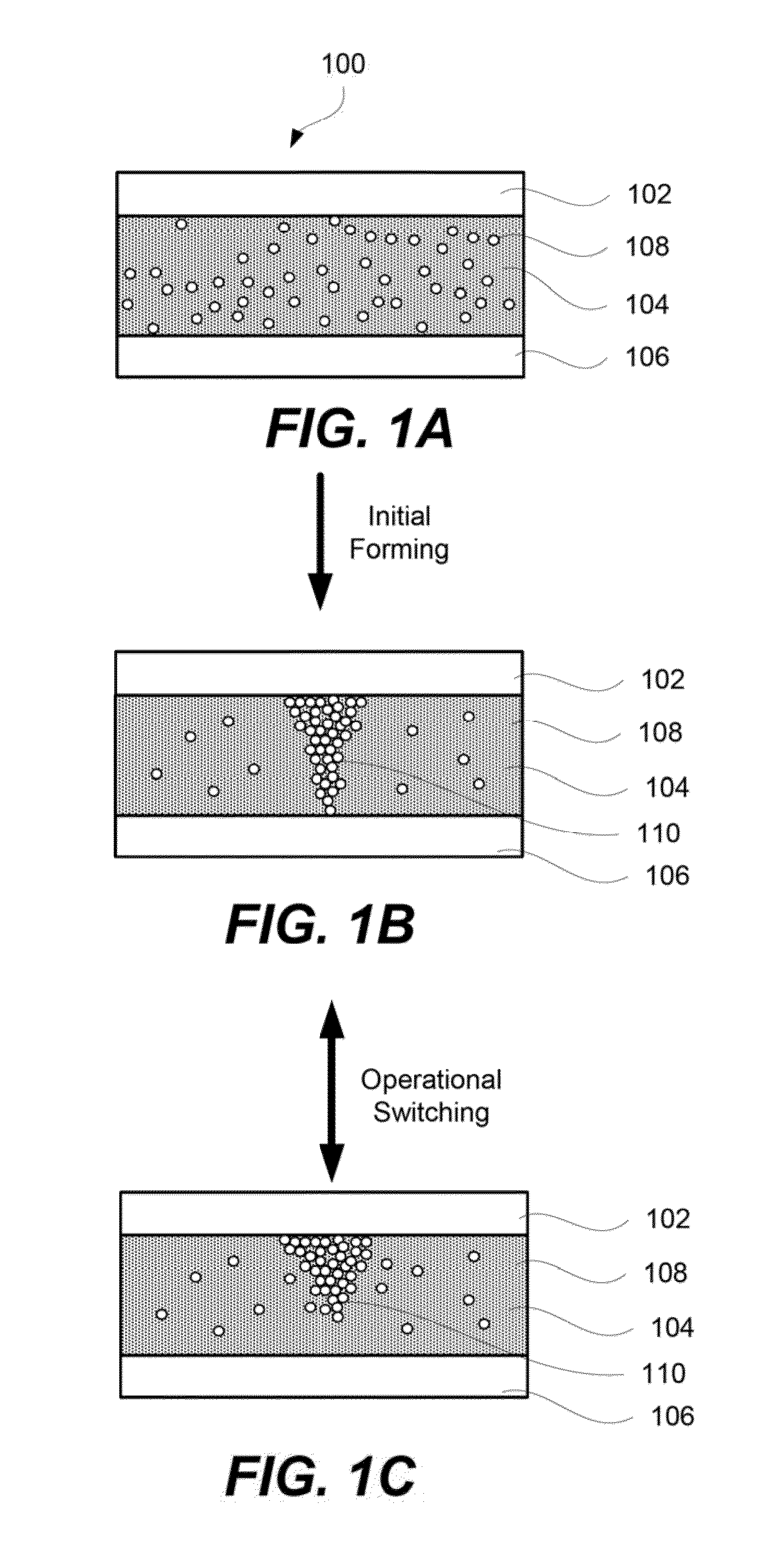

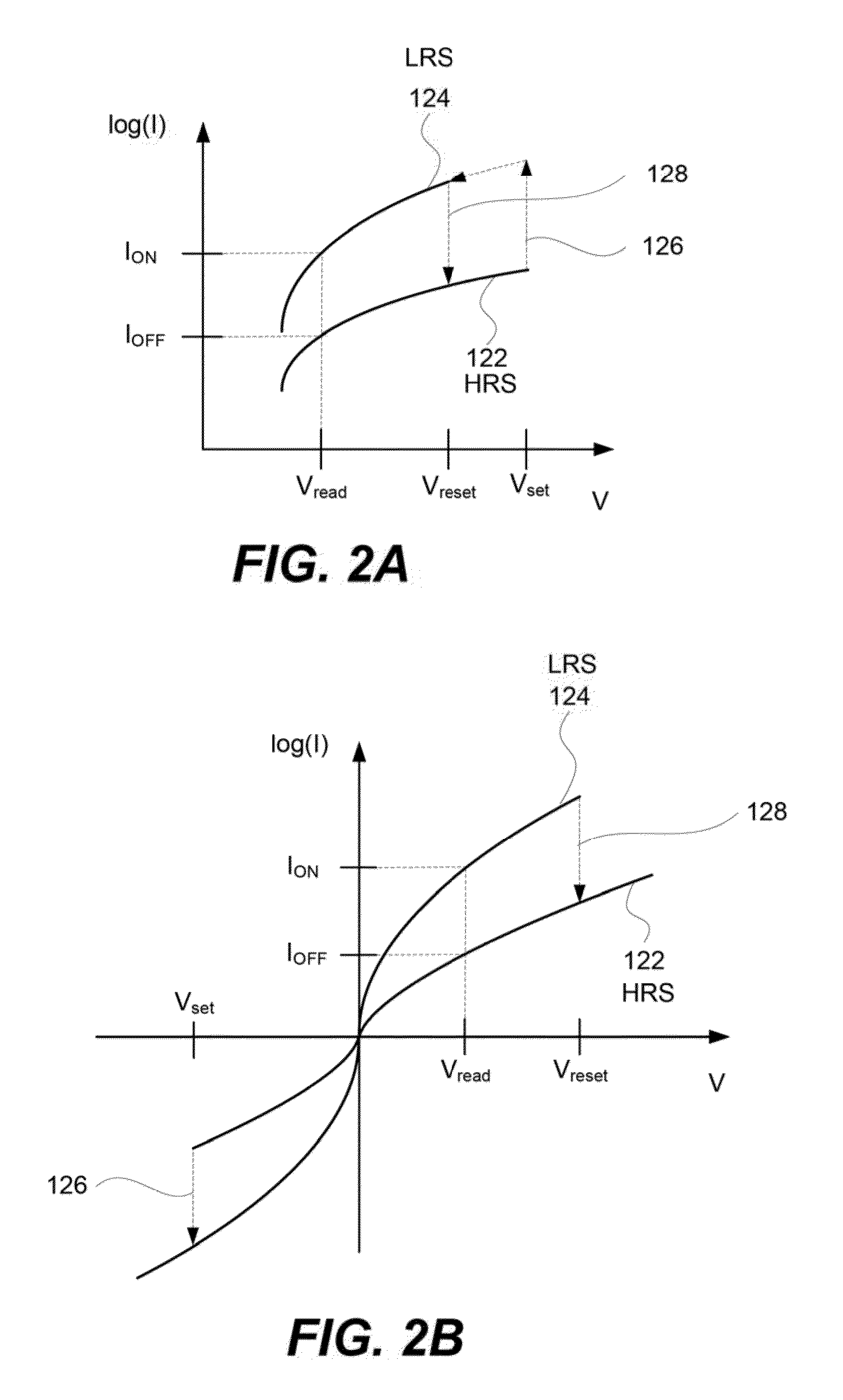

Stacked Bi-layer as the low power switchable RRAM

ActiveUS20150188045A1Constant resistanceSemiconductor/solid-state device manufacturingBulk negative resistance effect devicesMetallic materialsEngineering

Provided are resistive random access memory (ReRAM) cells and methods of fabricating thereof. The resistive switching nonvolatile memory cells may include a first layer disposed. The first layer may be operable as a bottom electrode. The resistive switching nonvolatile memory cells may also include a second layer disposed over the first layer. The second layer may be operable as a resistive switching layer that is configured to switch between a first resistive state and a second resistive state. The resistive switching nonvolatile memory cells may include a third layer disposed over the second layer. The third layer may be operable as a resistive layer that is configured to determine, at least in part, an electrical resistivity of the resistive switching nonvolatile memory element. The third layer may include a semi-metallic material. The resistive switching nonvolatile memory cells may include a fourth layer that may be operable as a top electrode.

Owner:INTERMOLECULAR

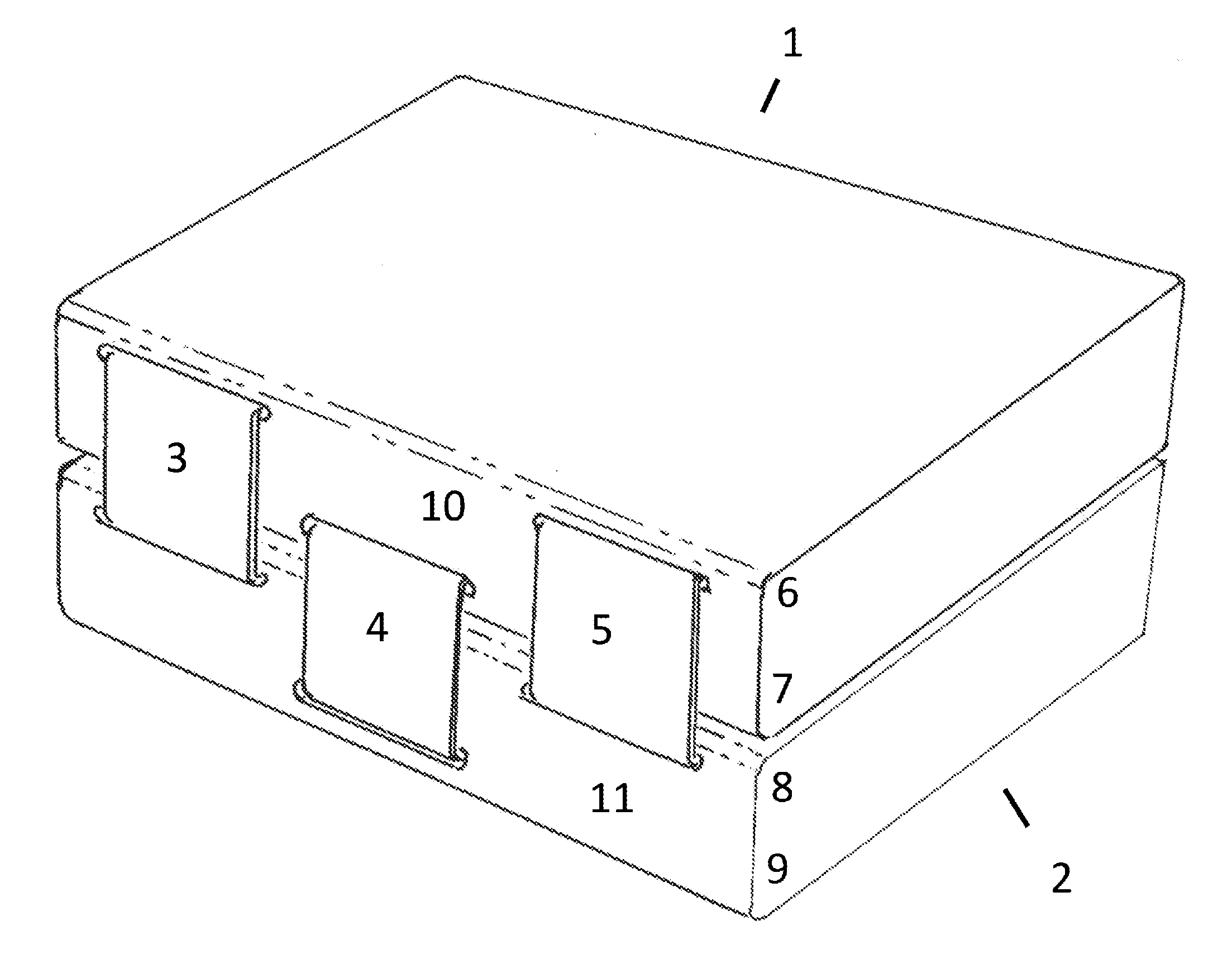

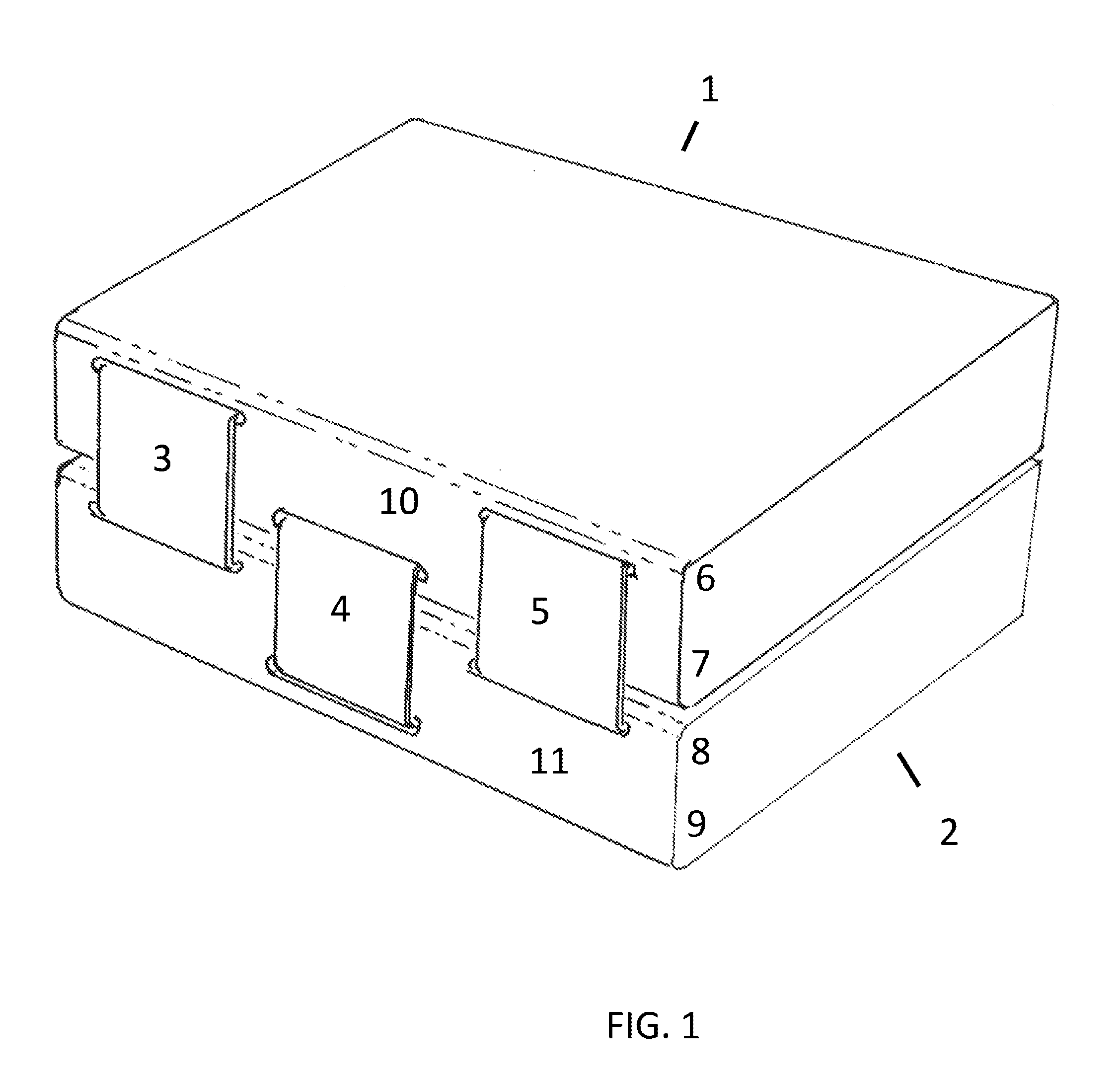

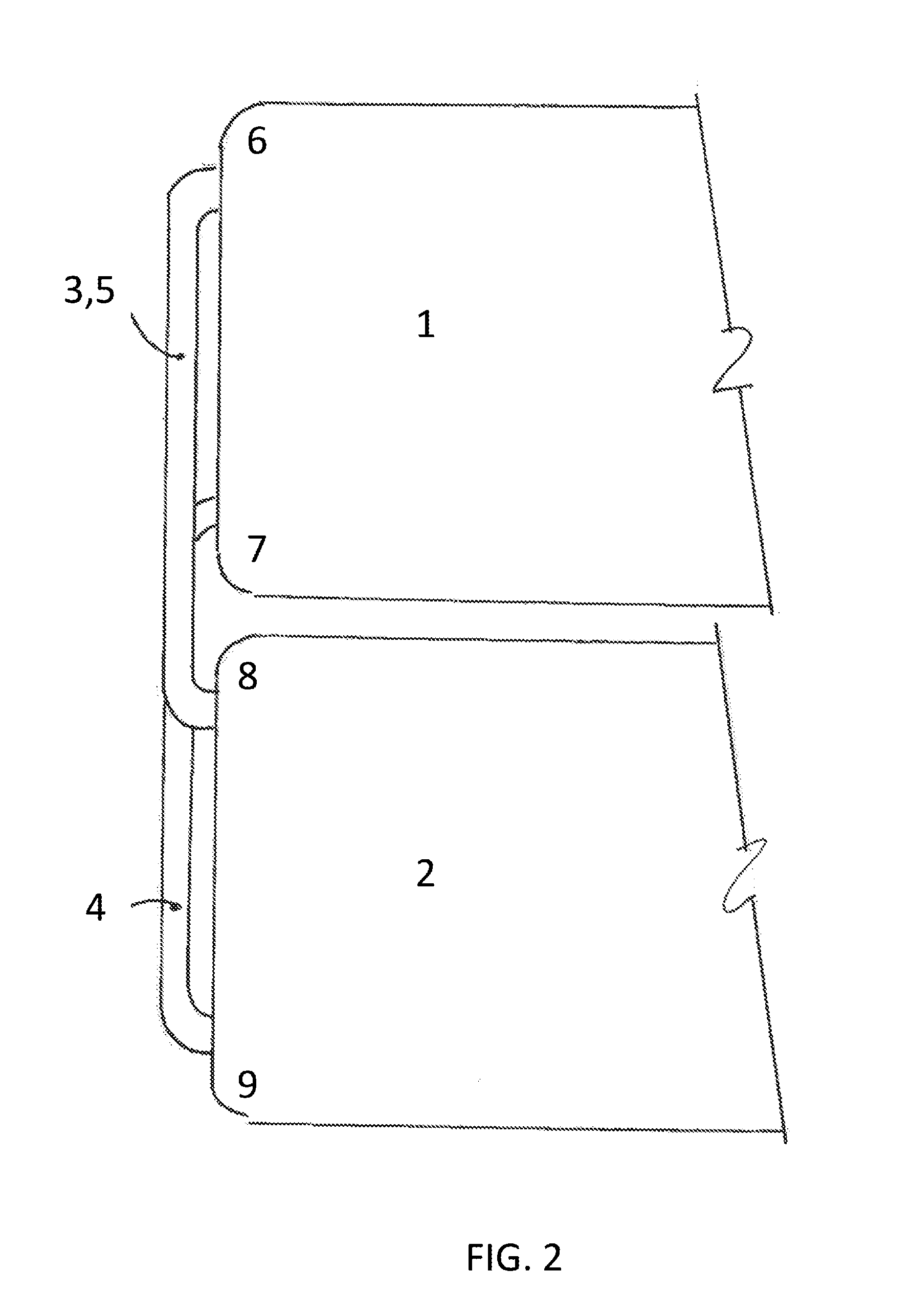

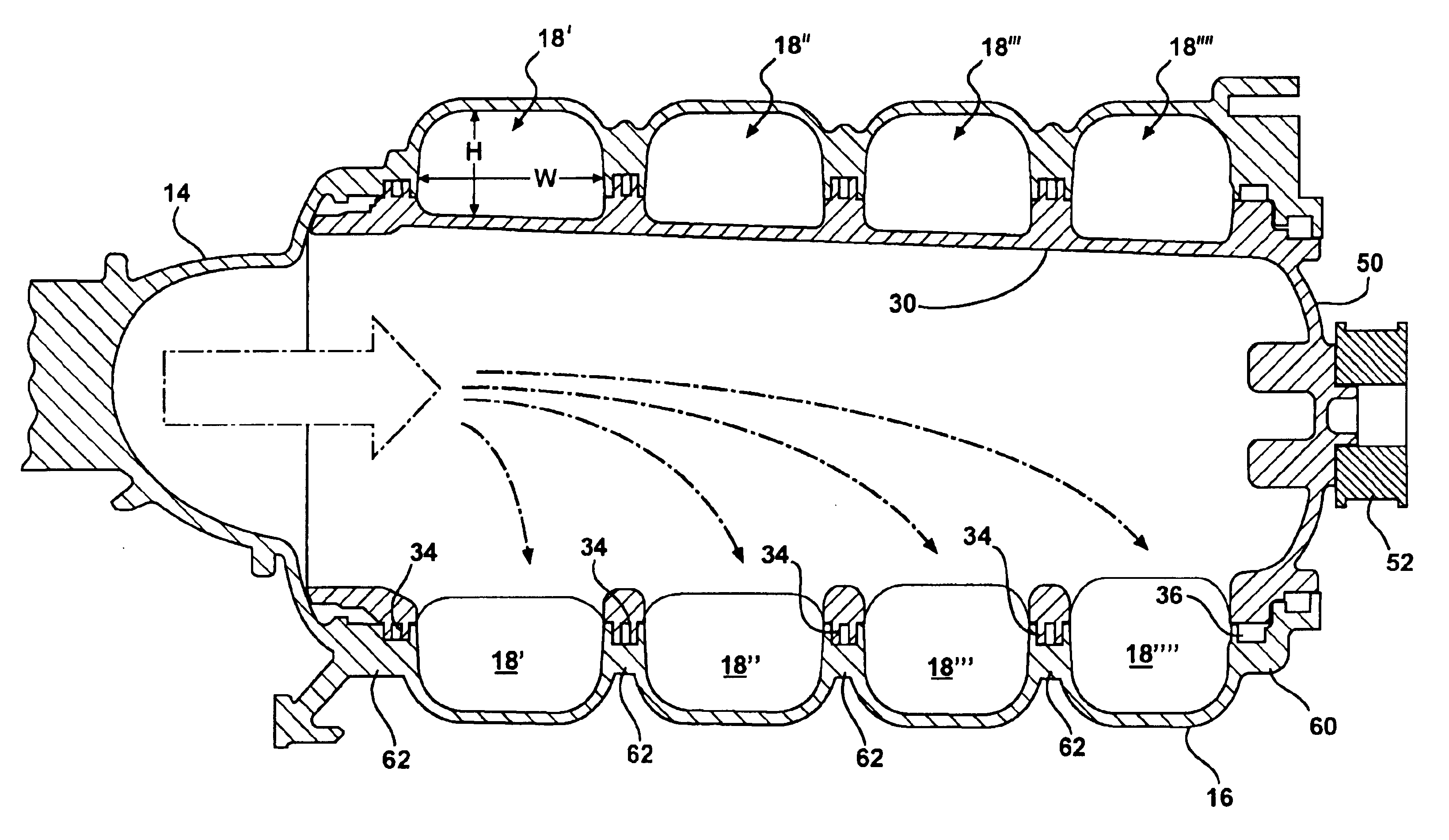

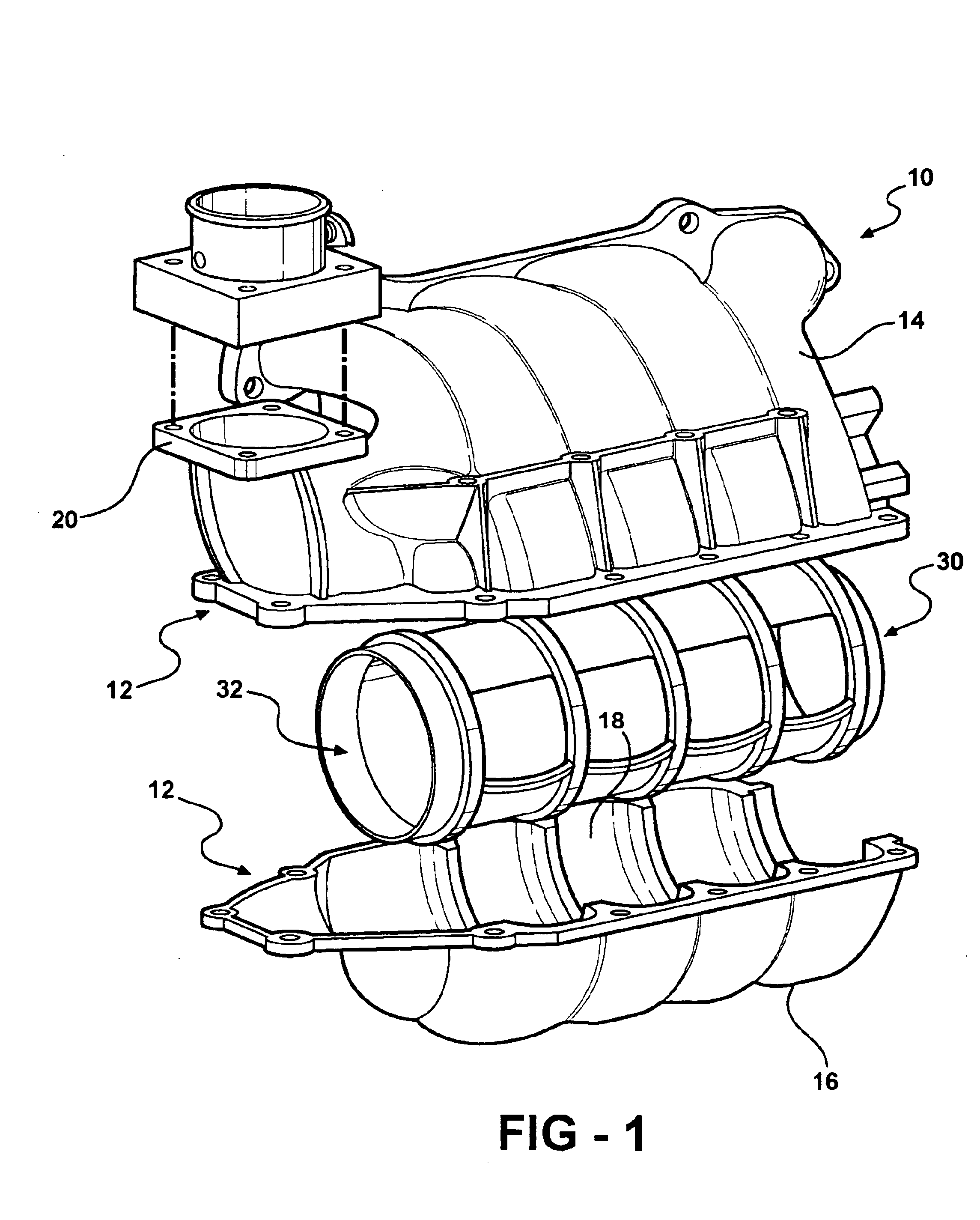

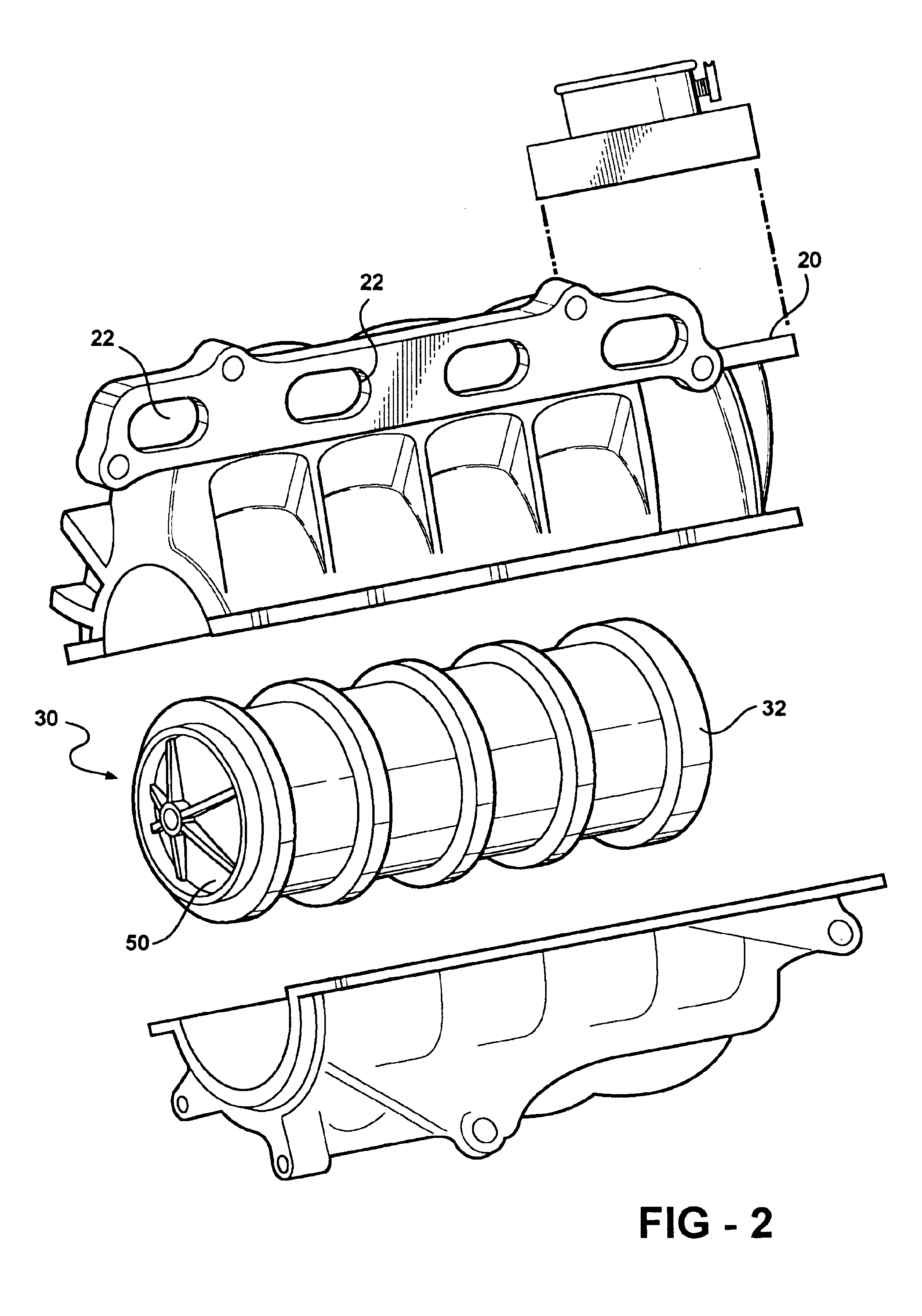

Variable runner length intake manifold

InactiveUS6901898B1Improve performanceConstant resistanceInternal combustion piston enginesAir intakes for fuelExternal combustion engineInlet manifold

The present invention provides a variable runner length intake air manifold operative to optimize the performance of an internal combustion engine over a wide range of engine speeds. The manifold includes a housing formed of upper and lower halves fixedly attached via conventional fastening means. The upper and lower halves define a plurality of runners having constant cross-sectional areas but different cross-sectional shapes. A tapered drum is disposed within the housing and includes one open end and a plurality of openings formed in the outer surface that communicate with corresponding runners of the housing. The tapered drum is rotatably mounted within the housing such that the effective runner length or airflow path of the manifold is made adjustable by varying the angular position of the tapered drum disposed within the housing.

Owner:TOYOTA MOTOR CO LTD

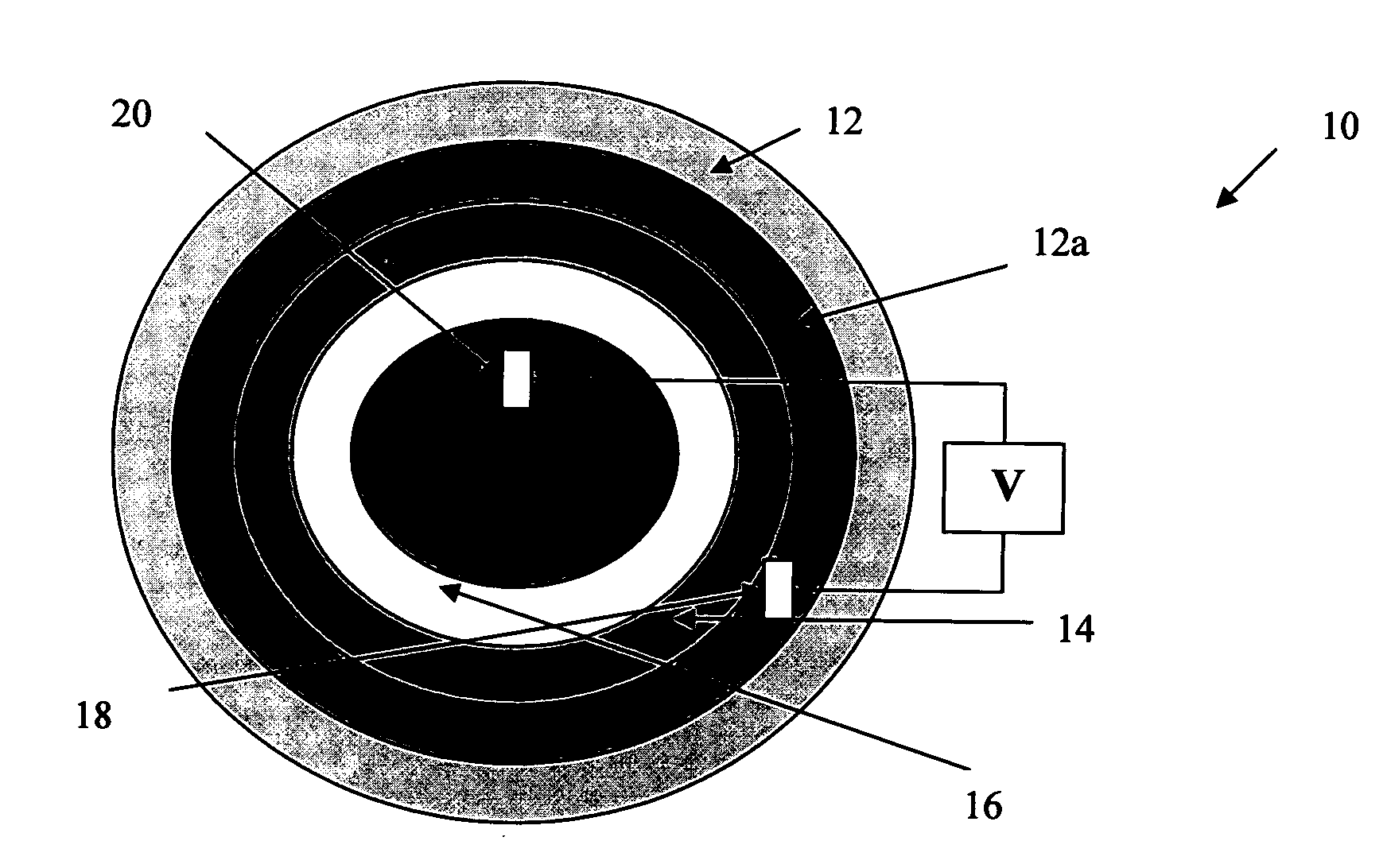

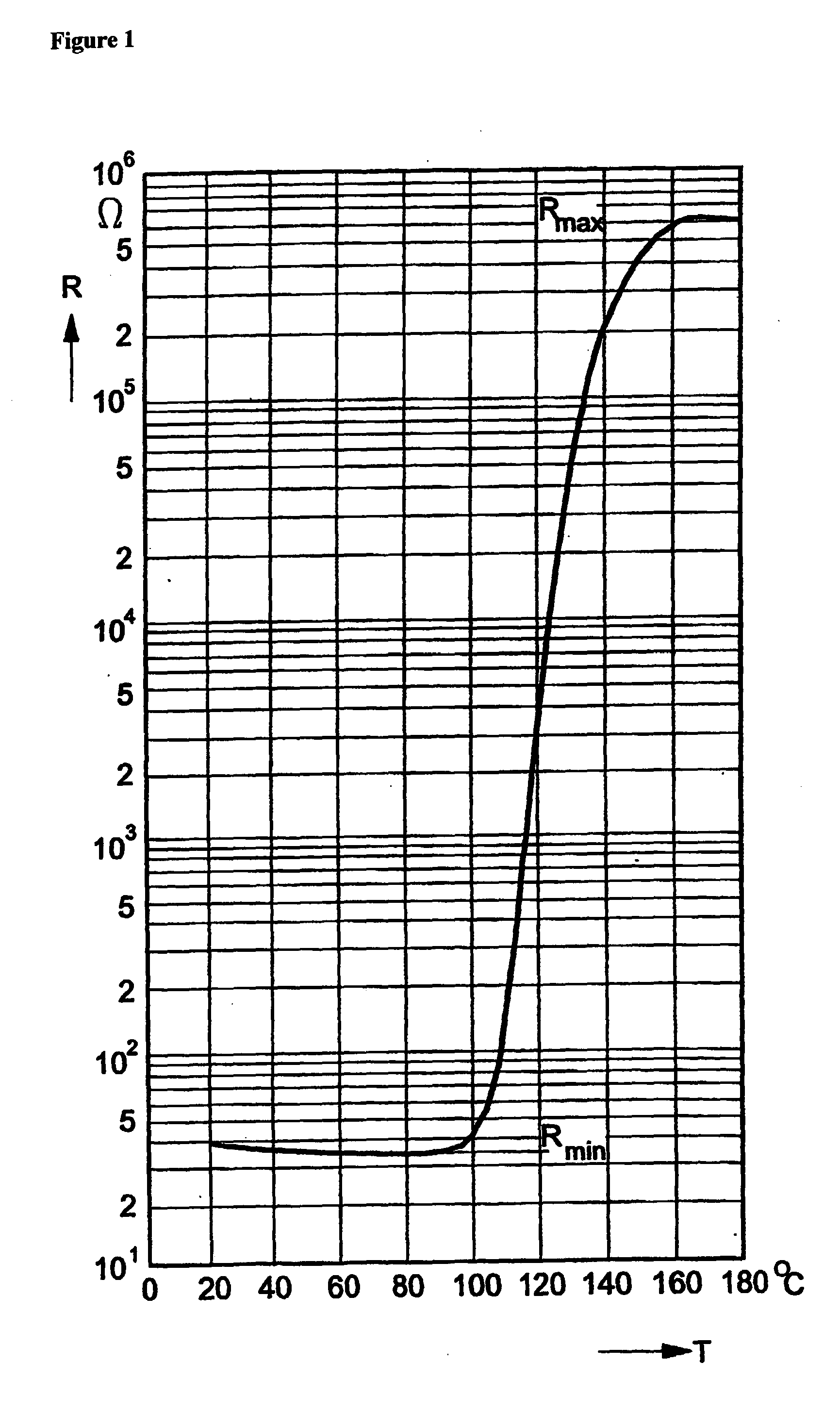

Self-regulating electrical resistance heating element

InactiveUS20100102052A1Small particle size rangeGreat numberNegative temperature coefficient thermistorsOhmic-resistance heating detailsConductive coatingElectrically conductive

The present invention relates to a self-regulating electrical resistance heating element, to an appliance containing same, and to processes for their manufacture. The self regulating electrical resistance heating element (10) comprises a substrate (12) comprising an electrically conductive coating (12a) which serves as a first electrical contact (18) on one side of the composite metal oxide layers. Disposed on said electrically conductive layer (12a) is a first metal oxide (14) which has a positive temperature coefficient of resistance. Overlaying the first metal oxide layer, and in electrical series thereto, is a second metal oxide layer (16) having a negative temperature coefficient of resistance and overlaying this layer is a second electrical contact (20). The second metal oxide layer (16) having a negative temperature coefficient of resistance is applied to the element in a manner which ensures it's resistive characteristics are not altered.

Owner:2D HEAT LTD

Personal positioning creeper

ActiveUS9193064B2Smooth shiftingLittle strengthOther workshop equipmentHydraulic cylinderHydraulic pump

A personal positioning creeper (PPC) for assisting mechanics, technicians and factory workers who need access to various angles and heights on a vehicle, aircraft, factory equipment, etc. The PPC allows the operator to simultaneously maneuver from lying supine near the ground, to moving upward and rotating into a full sitting position without having to dismount the PPC. The PPC comprises: a three member frame system (base, seat, and backrest frame connected together with eight (8) bell cranks and four (4) linkage assemblies), all under the control of a hydraulic system. The hydraulic system comprises: 1) a hydraulic pump with an ergonomically designed pump actuator handle and a release valve; and, 2) a hydraulic cylinder connected to the hydraulic pump, and to the linkage assemblies to rotate the bell cranks. The resistance to the pumping action felt by the operator remains constant regardless of the height of the seat.

Owner:THE EZ CREEPER COMPANY

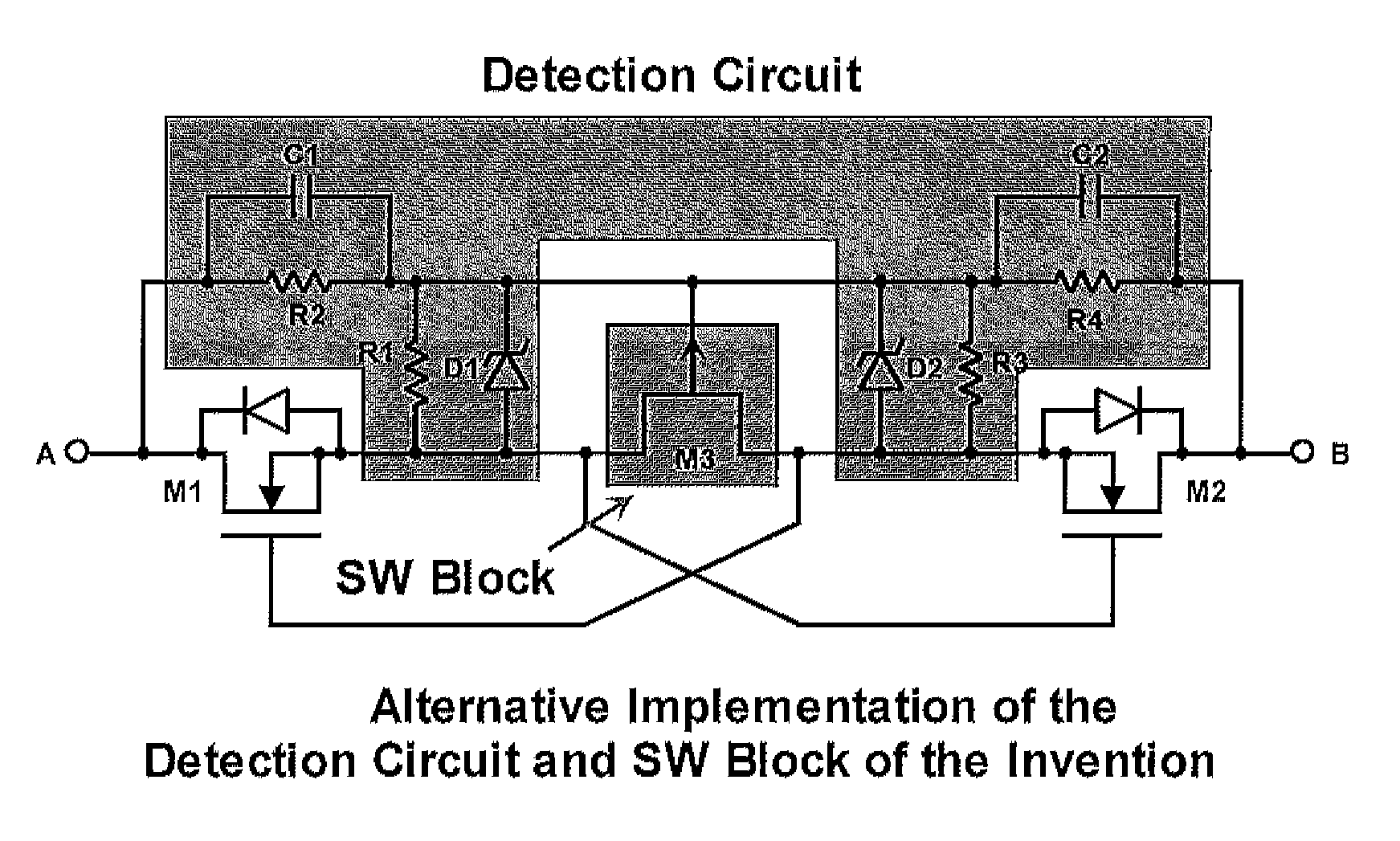

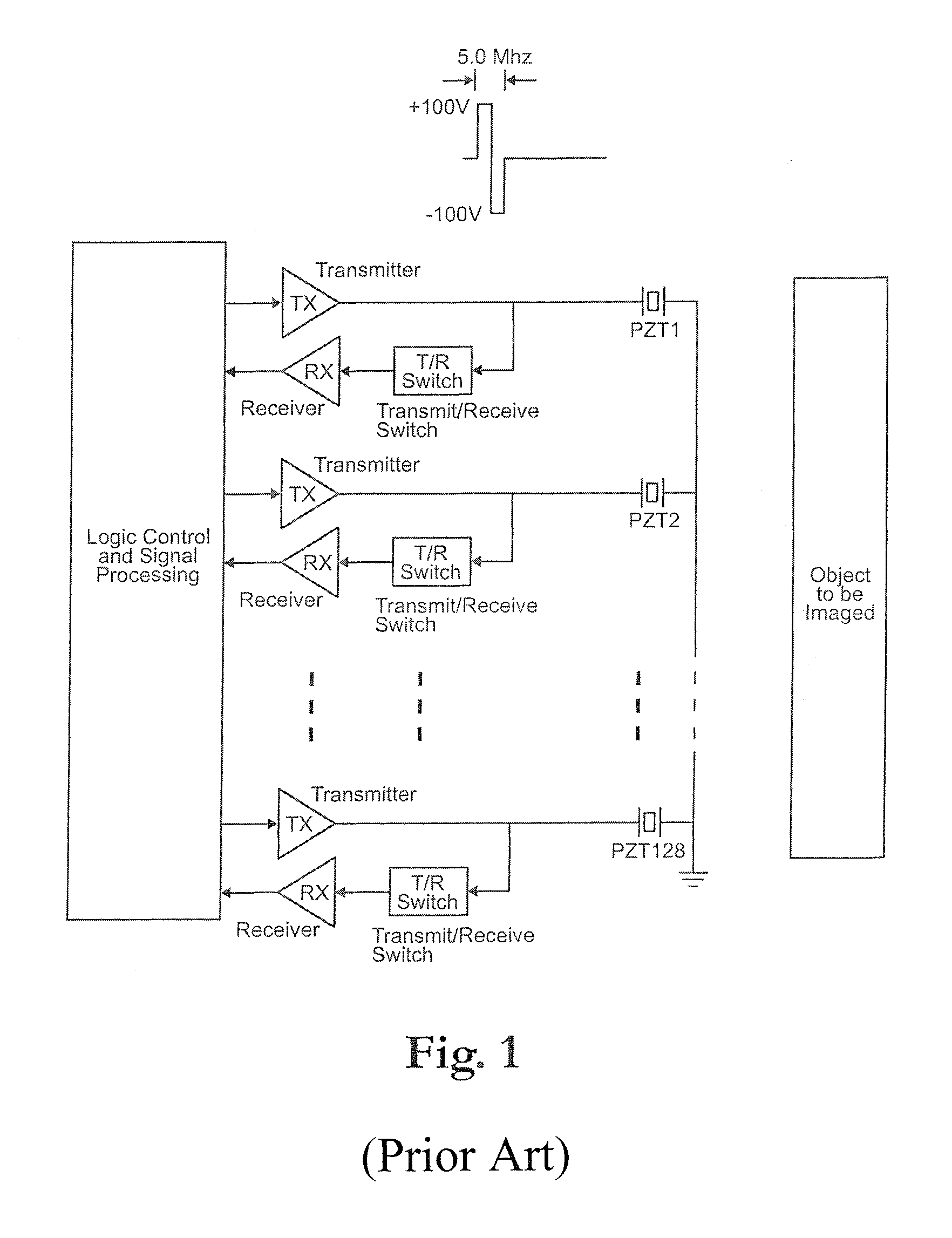

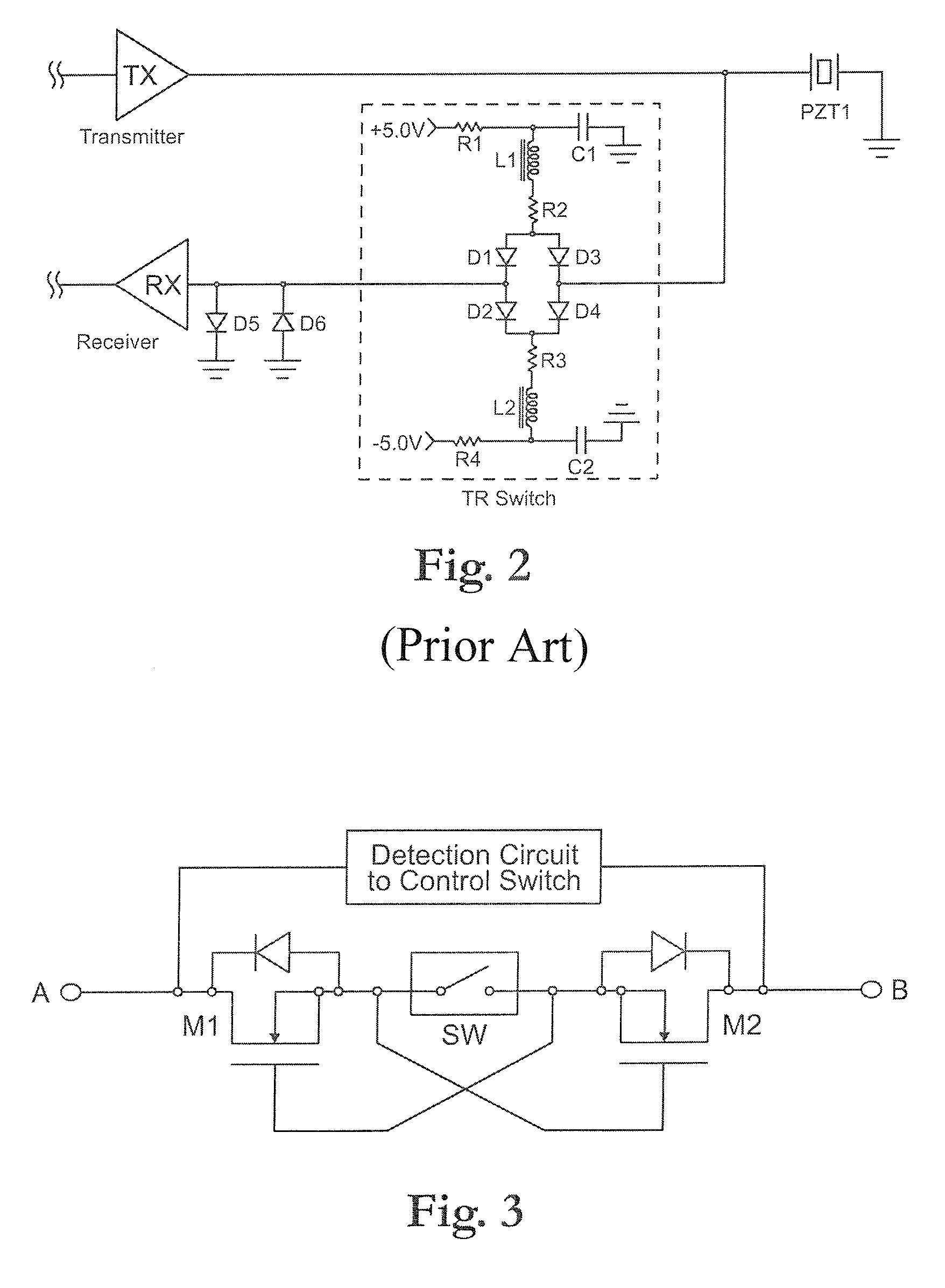

High voltage transmit/receive switch and method therefor

ActiveUS8254073B1Constant resistanceWave based measurement systemsEmergency protective arrangements for limiting excess voltage/currentLow noiseAudio power amplifier

A two terminal transmit receive device passes small analog signals with a constant low resistance value to the input of a low noise, low voltage receiver amplifier and can protect the input against the high voltage transmit signals in ultrasound applications without the aid of any power supplies. The device uses depletion-mode transistors that are normally on to pass small analog signal and a voltage detection circuit that quickly turns off the depletion-mode transistors when the presence of high voltage is detected.

Owner:MICROCHIP TECH INC

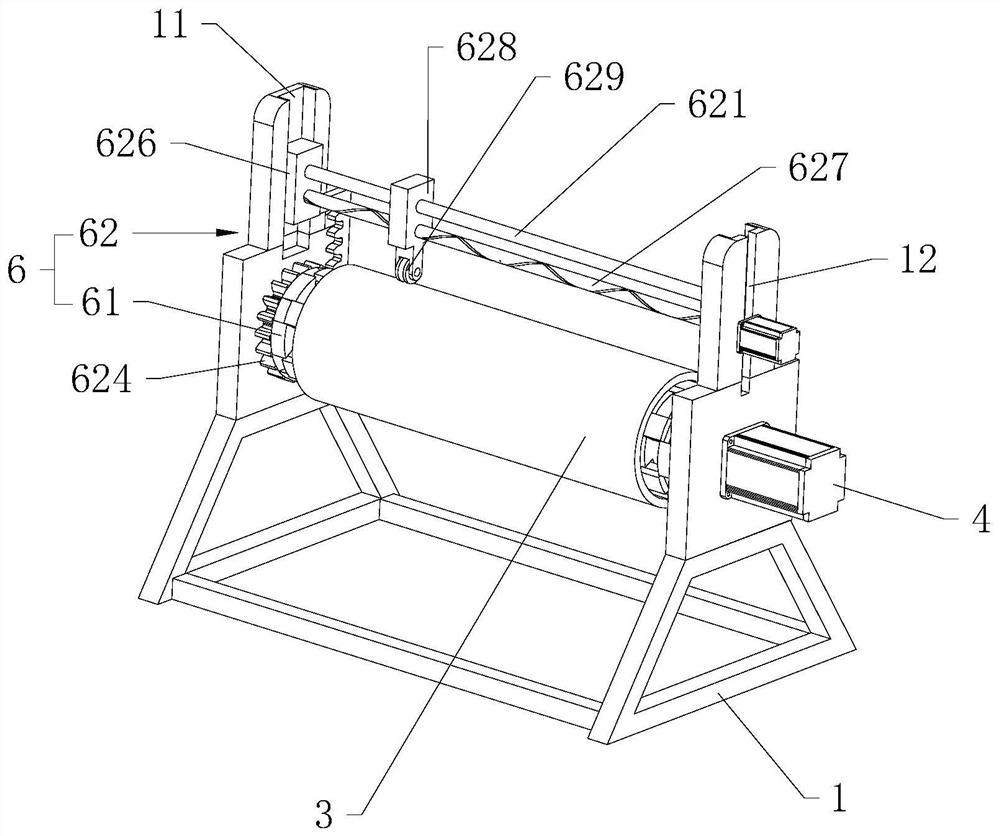

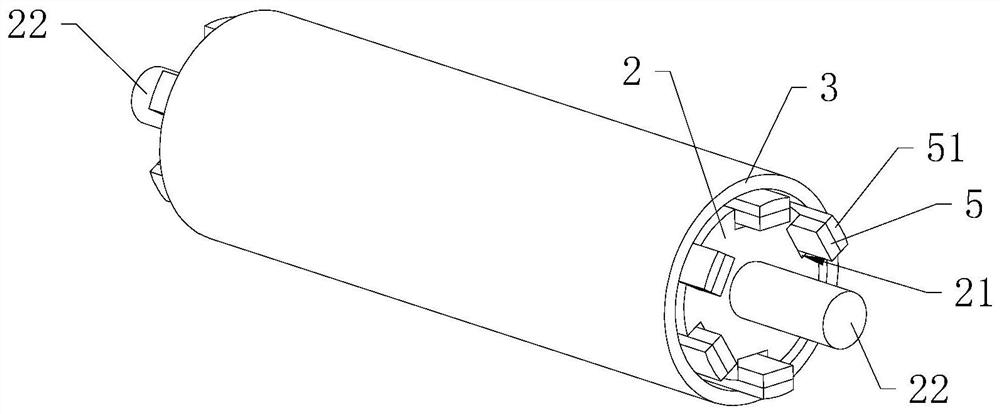

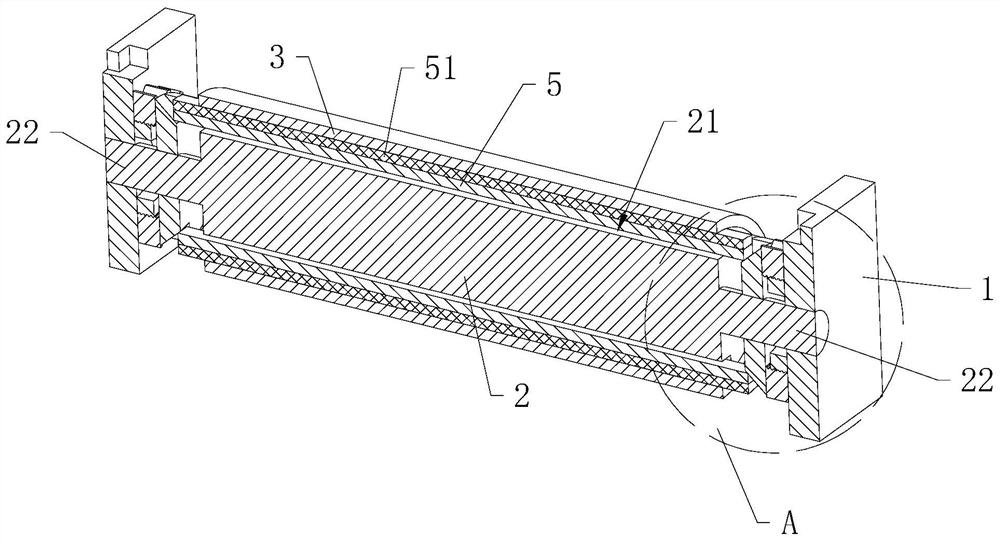

Tubular product rolling device

ActiveCN111620188AAvoid deformationImprove product qualityFilament handlingElectric machineStructural engineering

The invention relates to a tubular product rolling device. The tubular product rolling device comprises a rack, a motor arranged on the rack and a rotating shaft rotatably arranged on the rack. The motor drives the rotating shaft to rotate at a uniform speed, a sleeve is further rotatably connected on the rotating shaft in a sleeving manner, and a friction pair is formed between the inner circumference of the sleeve and the rotating shaft. With a tubular product being rolled, the actual rolling radius of the tubular product is increased gradually, the tubular product blocks rotation of the sleeve, and the sleeve and an elastic part slide relatively, that is, the rotating speed of the sleeve is lower than that of the rotating shaft, so that the rolling linear speed of the tubular product isconstant. The rolling linear speed of the tubular product is equal to an output speed of a first extruder, the tubular product is prevented from being deforming as a result of a too large tensile force, and follow-up normal production is guaranteed, so that a product part is relatively high in production quality.

Owner:台州巨壹塑业有限公司

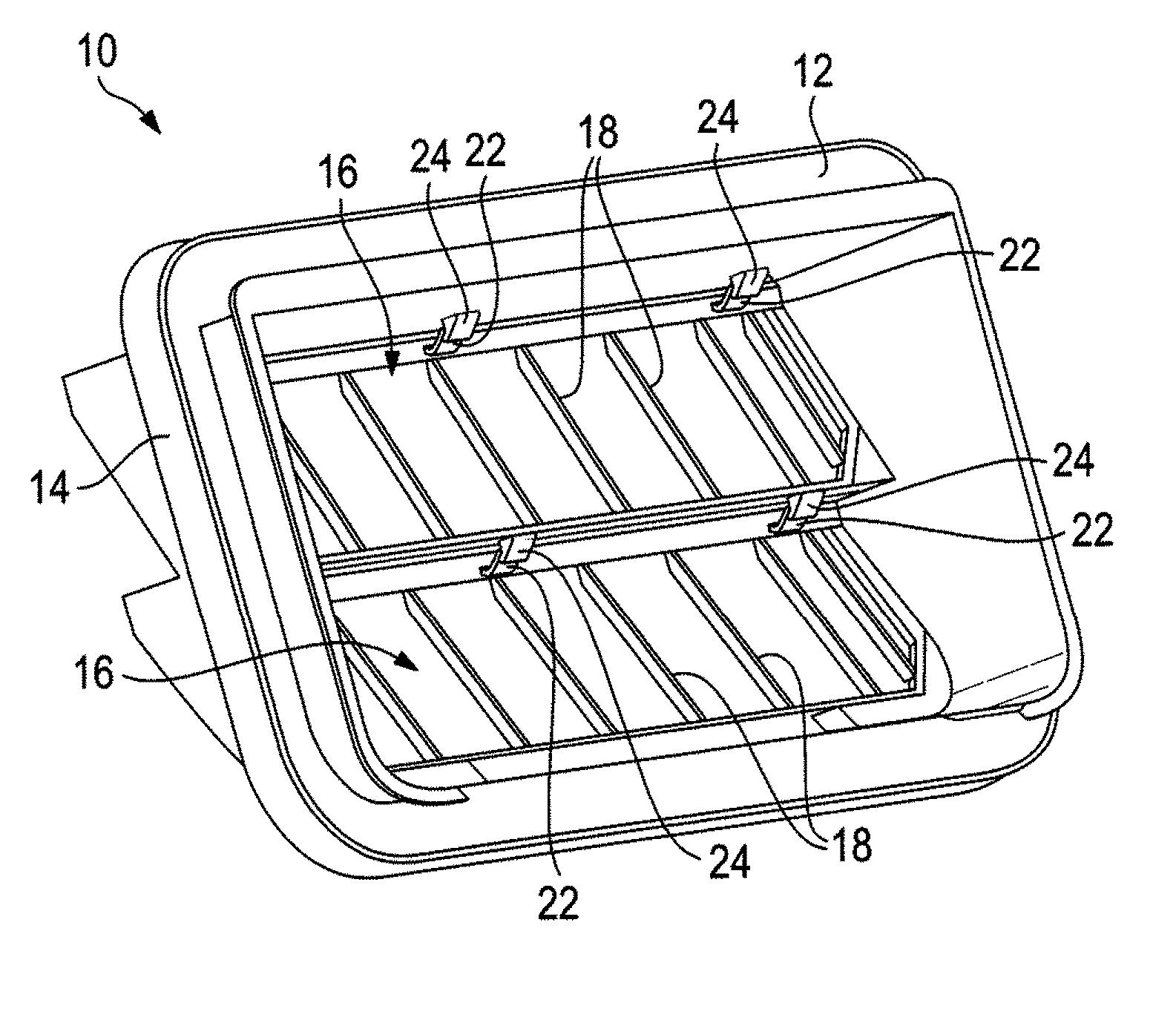

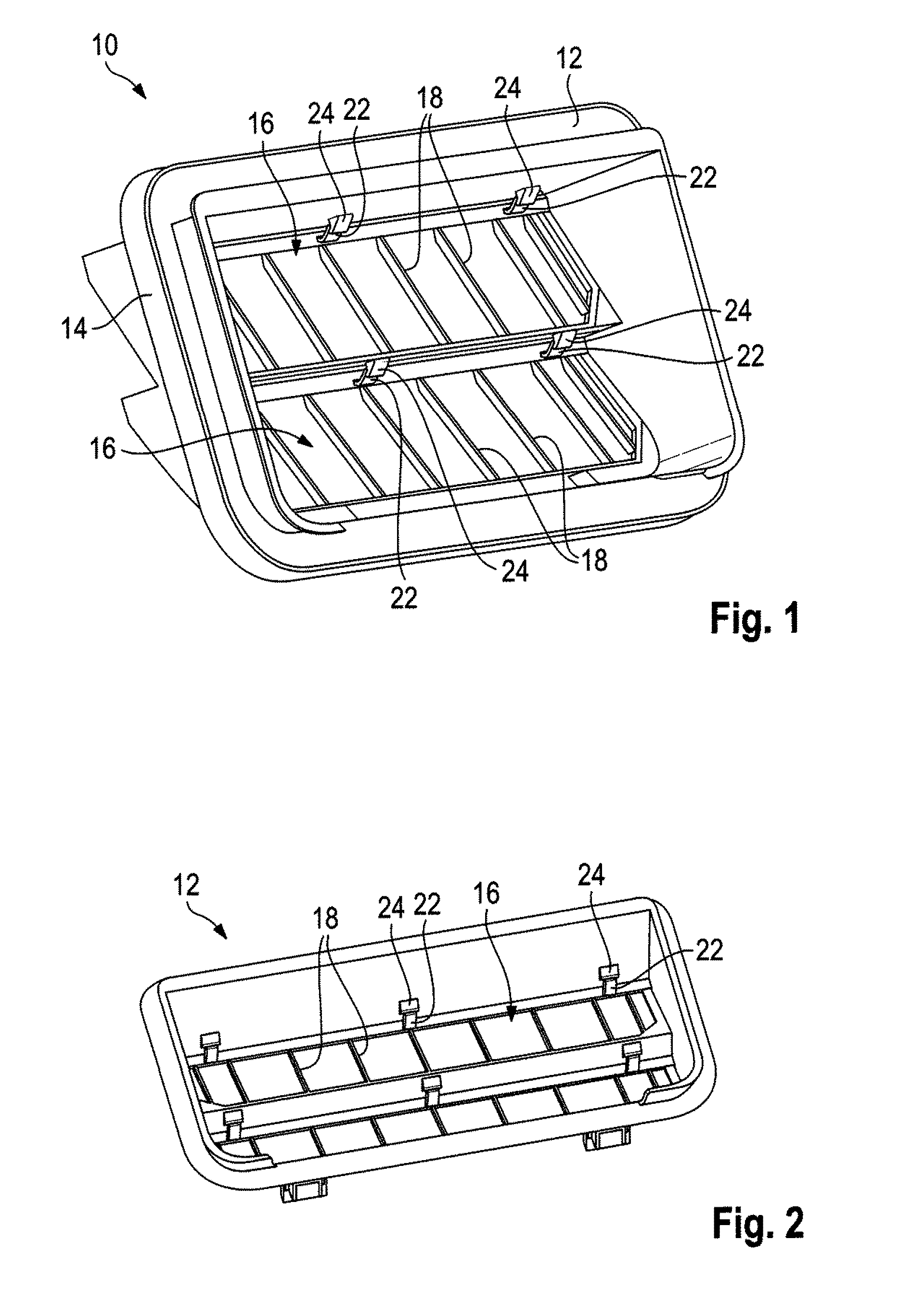

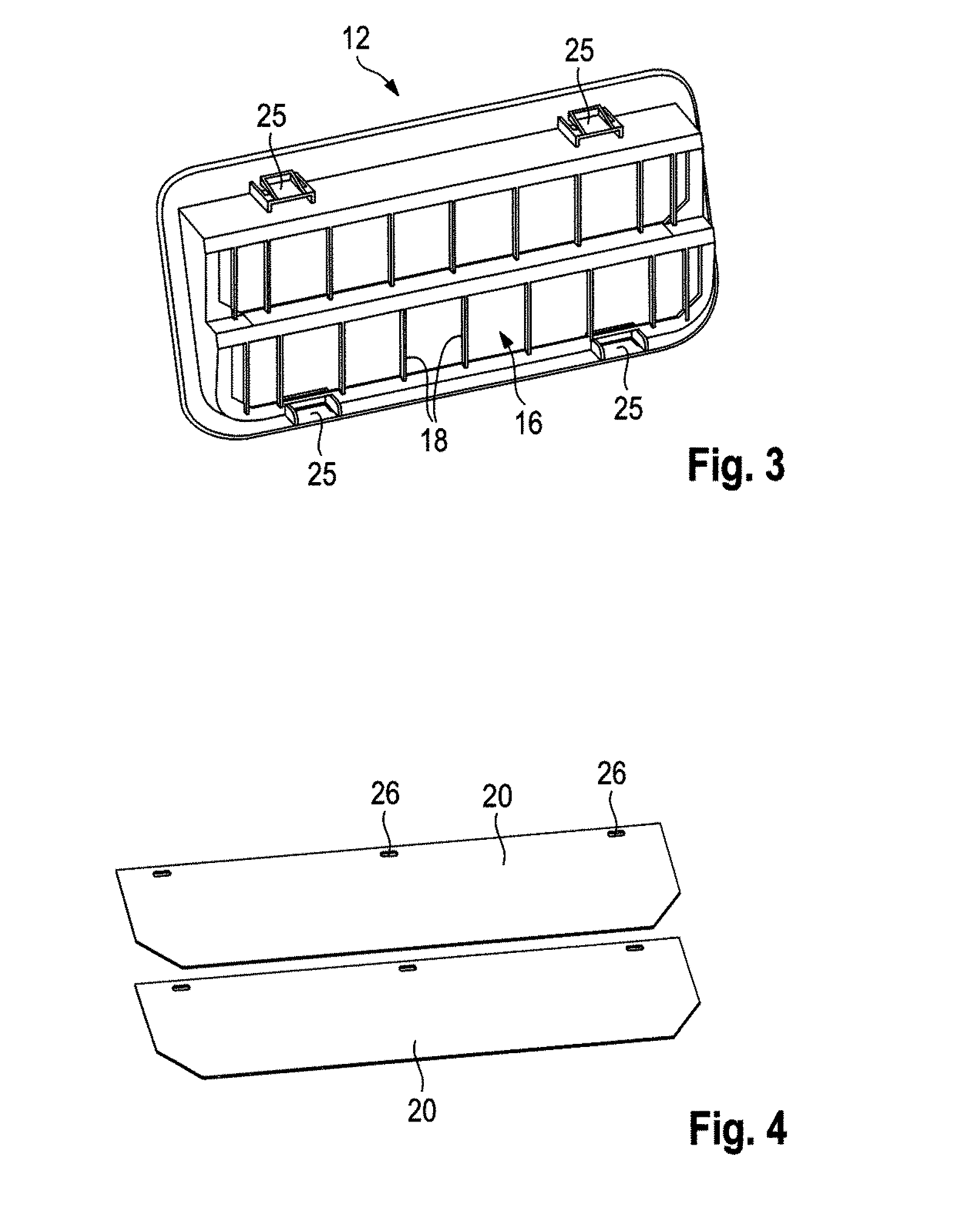

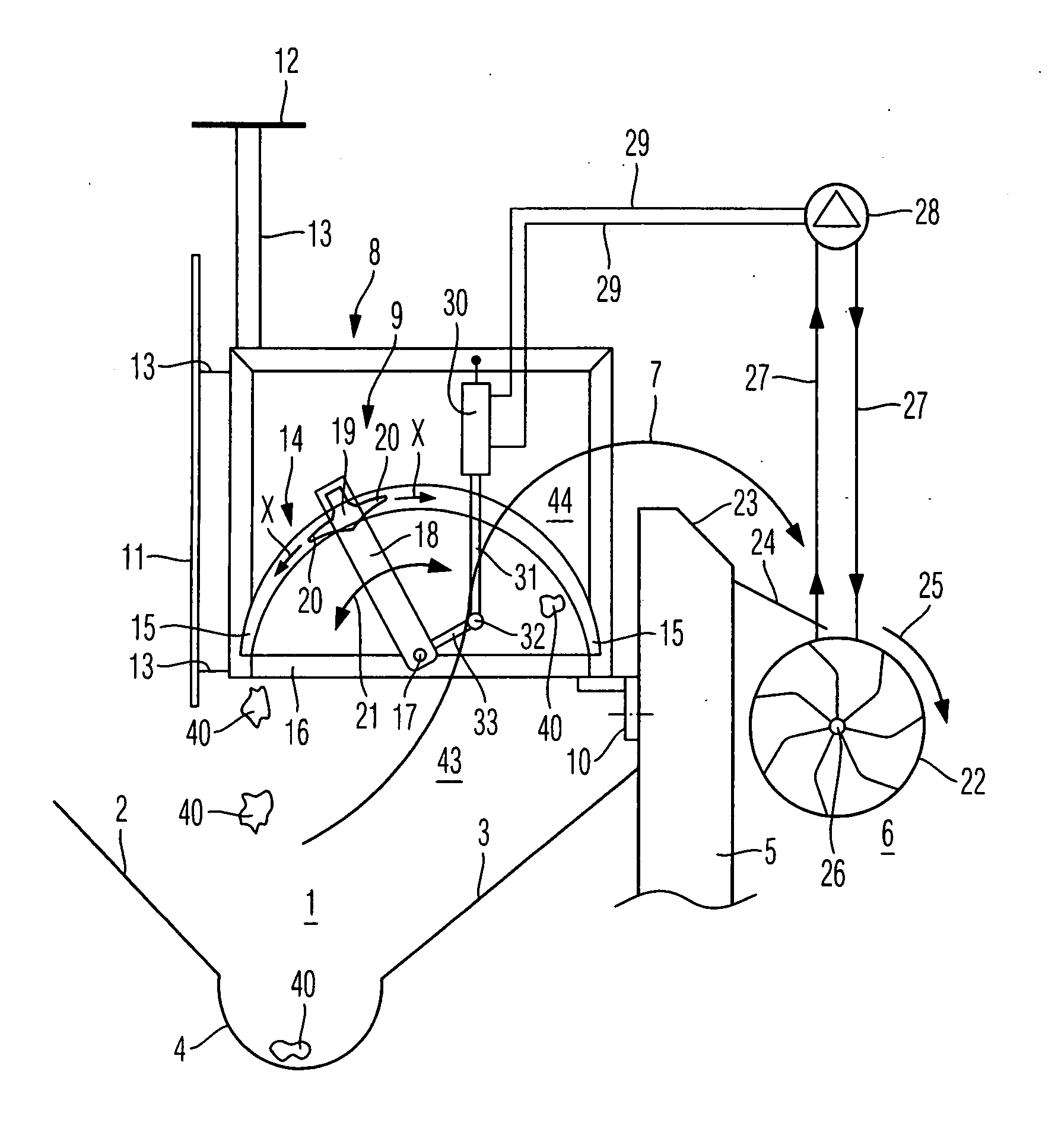

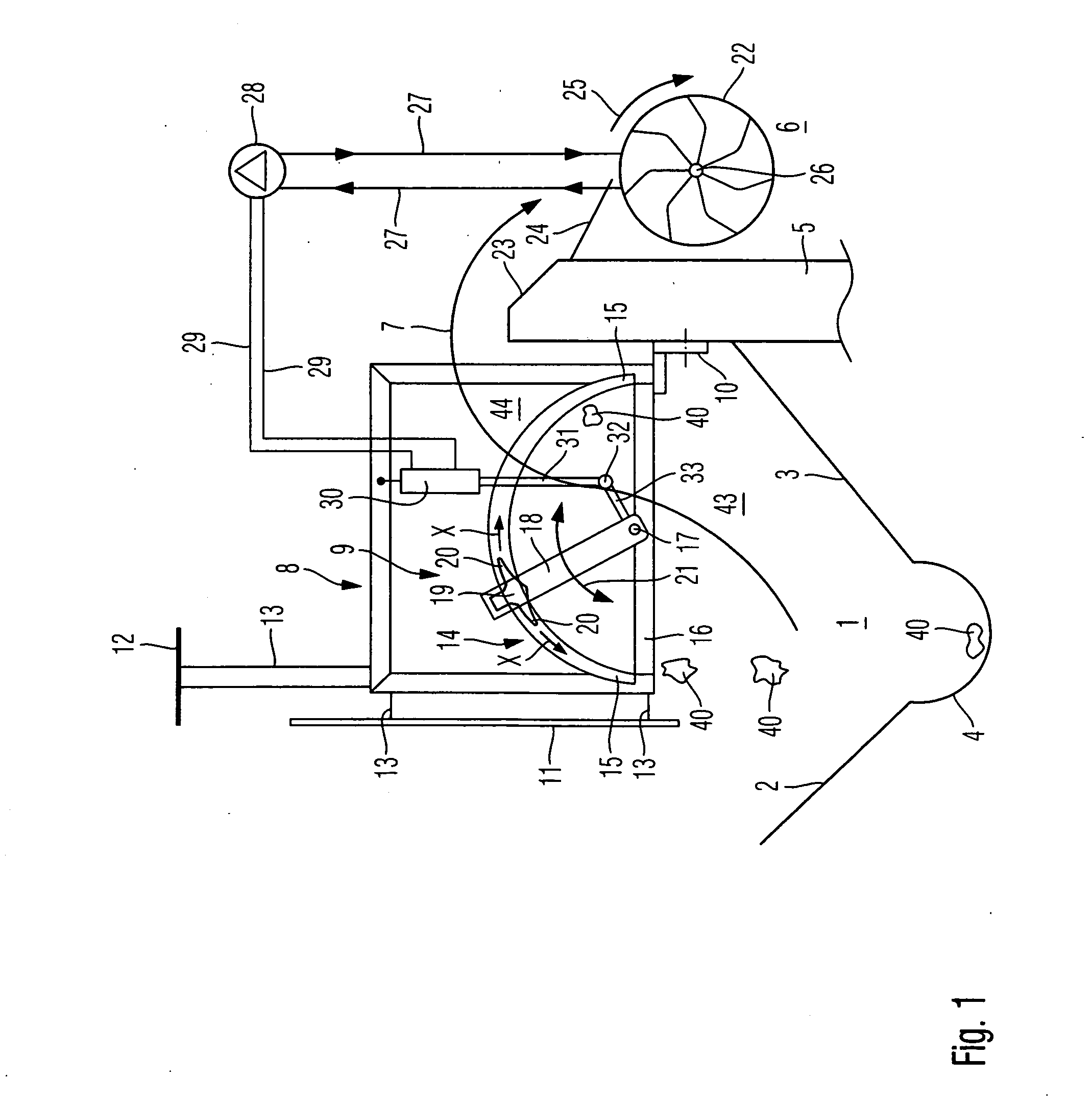

Ventilation device

ActiveUS20110230129A1Fixed securitySimple wayAir-treating devicesVehicle heating/cooling devicesEngineeringPressure difference

Owner:ILLINOIS TOOL WORKS INC

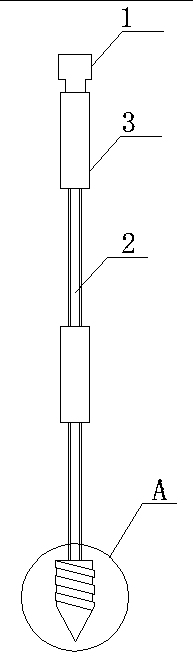

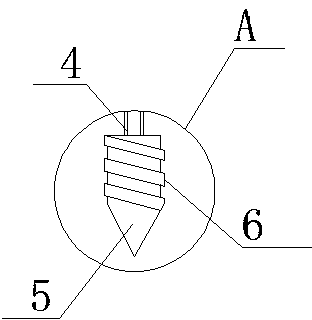

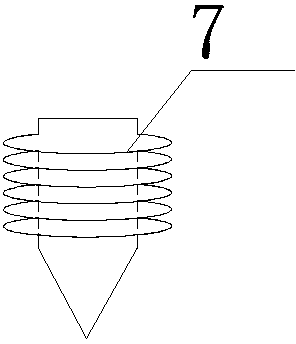

Anti-corrosion and anti-theft grounding electrode

InactiveCN103996909AConvenient and fast entryIncrease the difficulty of extractionConnection contact member materialTowerCopper-clad steel

The invention discloses an anti-corrosion and anti-theft grounding electrode. The anti-corrosion and anti-theft grounding electrode comprises a driving head, grounding rods and connecting rods respectively connected with the driving head and the grounding rods. External threads are arranged at one end of the driving head and the two ends of each grounding rod respectively, and internal threads are arranged at the two ends of each connecting rod. Each grounding rod is a steel core with the surface covered with a copper layer. The end of the lowermost grounding rod is connected with a drill bit. The ratio of the outer diameter of the large end of the drill bit to the outer diameter of each grounding rod is larger than 3, and the surface of the drill bit is spiral or in the shape of a parachute tower. The thickness of each copper layer ranges from 0.3 mm to 0.8 mm, the number of the grounding rods ranges from 1 to 4, and all the grounding rods are connected through the connecting rods. After the grounding electrode is driven into the ground, the gap between the grounding rod bodies and the peripheral soil wall is filled with powdery or mushy resistance reducing agents. Due to the fact that an optimized copper-clad steel technology scheme is adopted for the anti-corrosion and anti-theft grounding electrode and an anti-theft structure convenient to install and detach is adopted for assistance, not only can the anti-corrosion performance and the anti-theft performance be achieved, but also the grounding pass-through performance can be enhanced, and the anti-corrosion and anti-theft grounding electrode has the advantages of being long in service life and high in cost performance ratio.

Owner:LUOHE POWER SUPPLY OF HENAN ELECTRIC POWER CORP

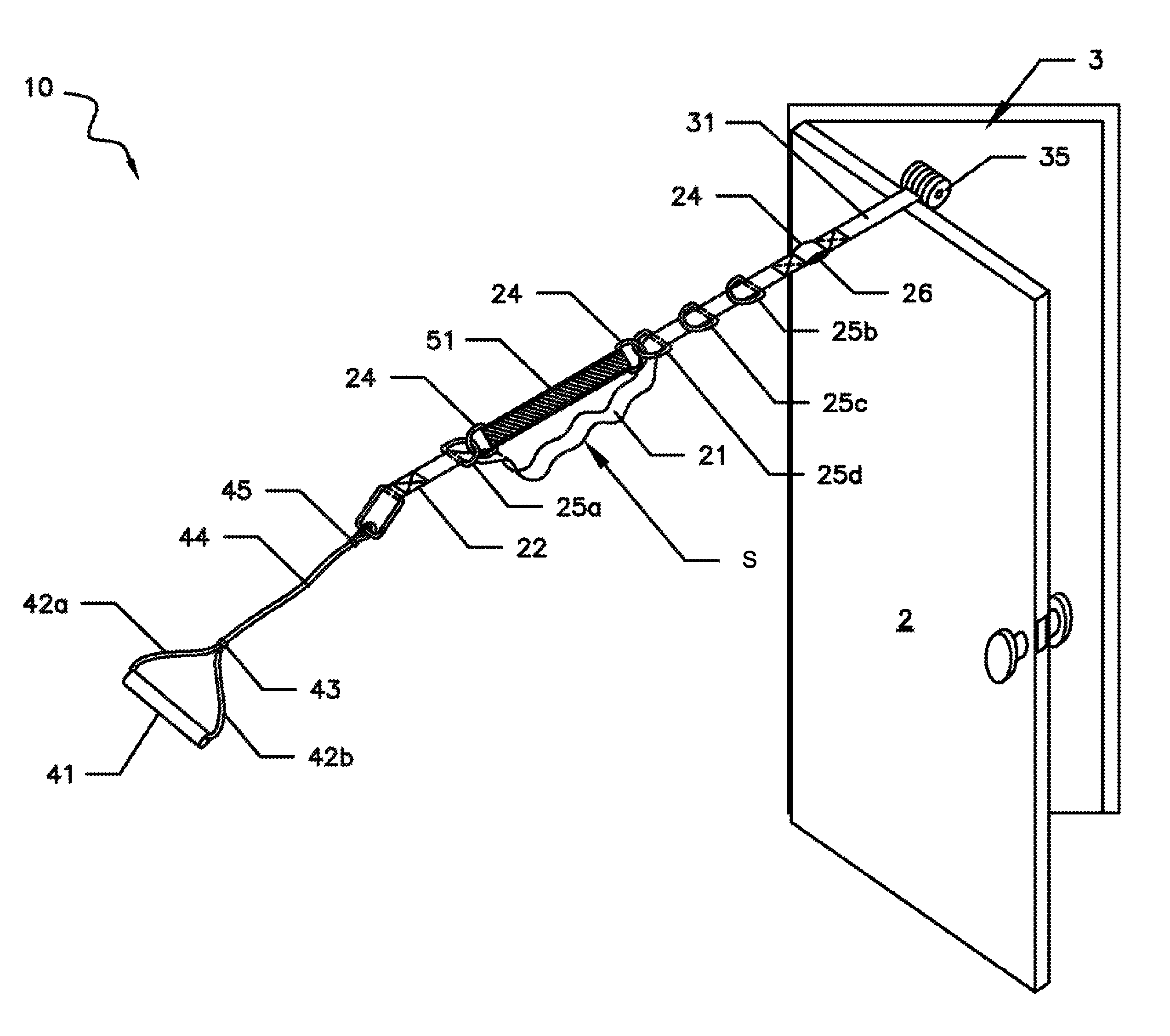

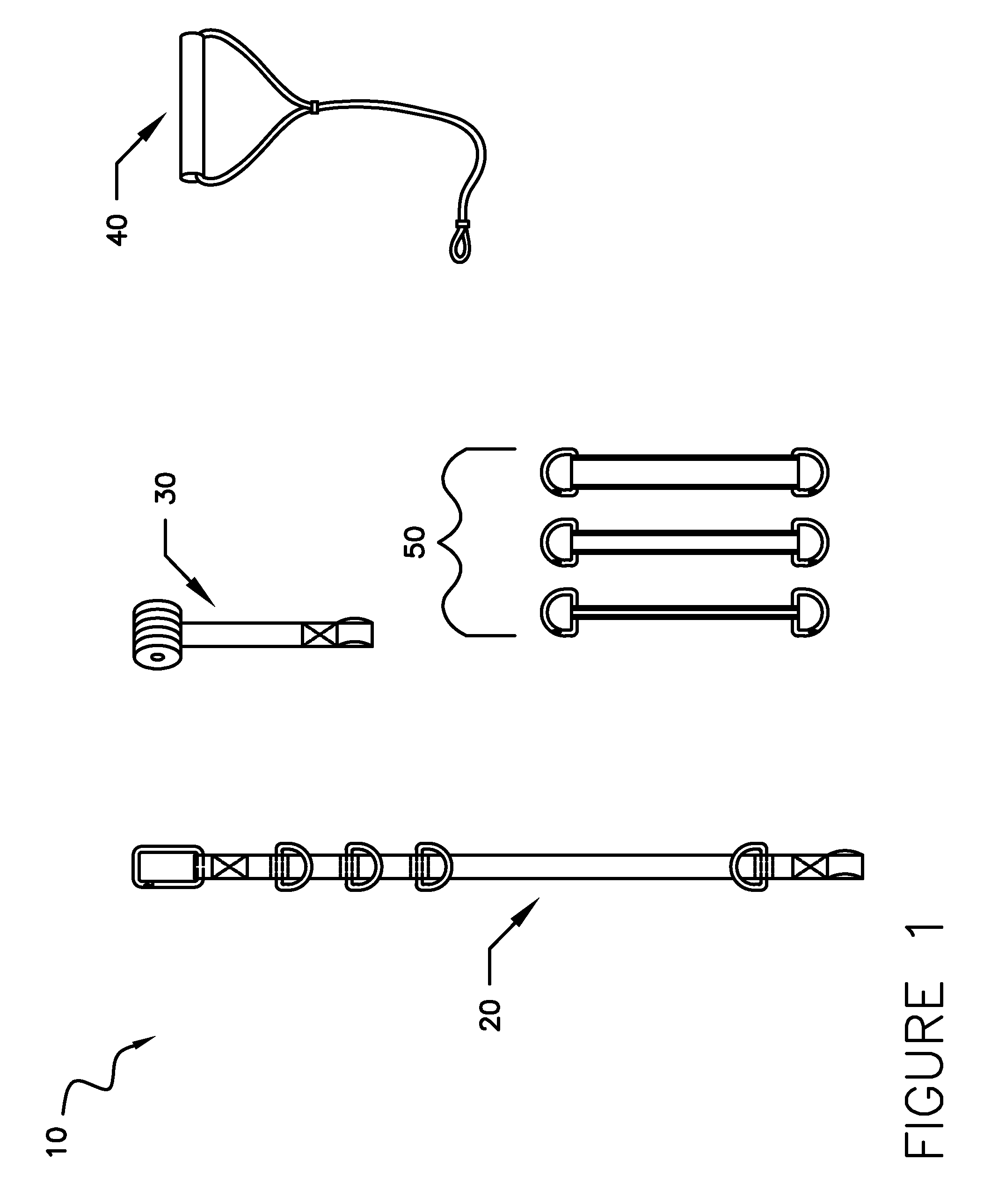

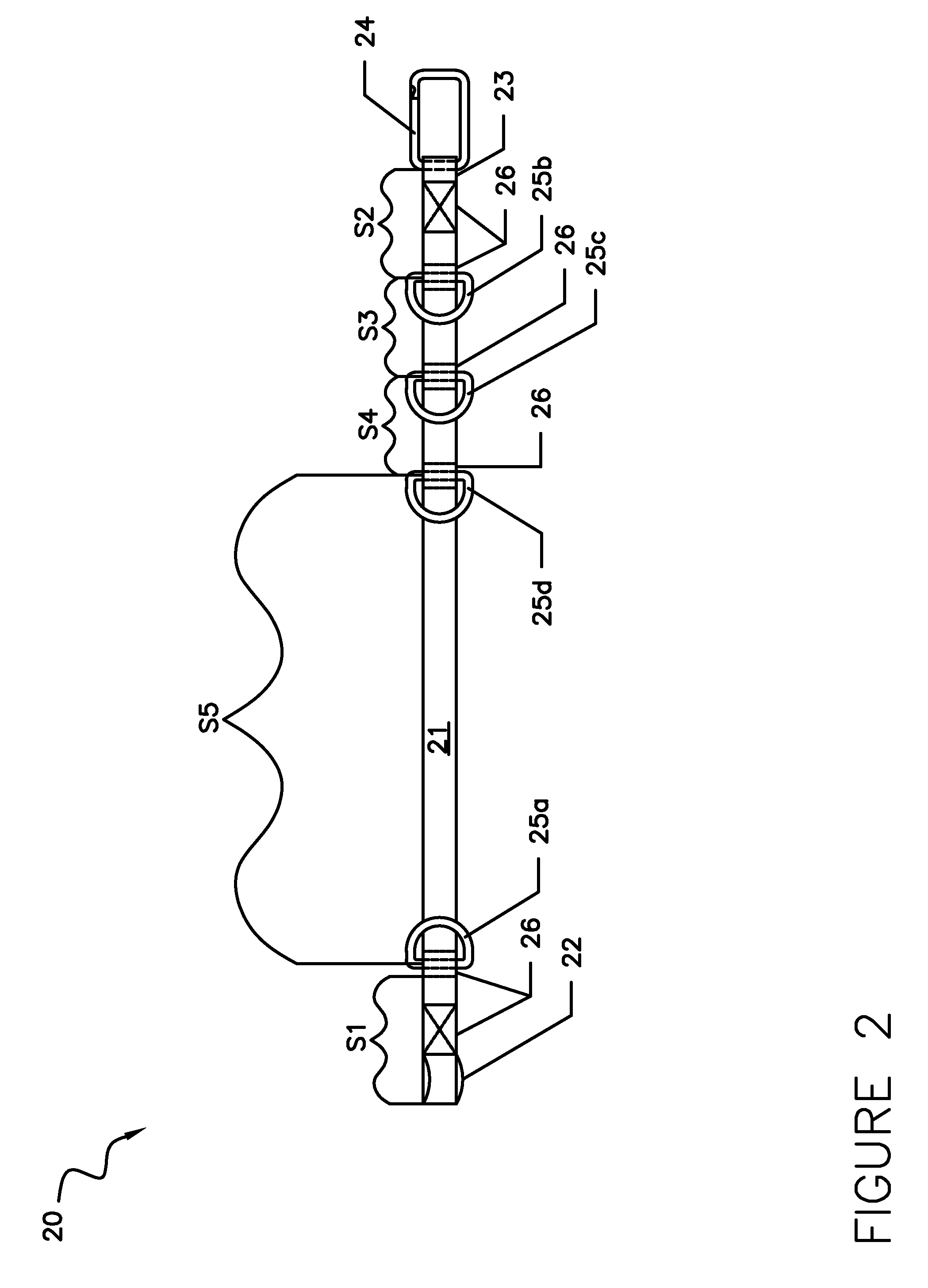

Watersport resistance training device

A watersport resistance training device includes an elongated inelastic strap having an anchor an anchor unit disposed along a first end, and a ski handle assembly disposed along a second end. A plurality of rings is disposed along the middle section of the inelastic strap, and one or more watersport resistance elements are removably connected to at least two of the rings.

Owner:GARNER DAVID KENT +1

Cable and structure traversing trolleys

A trolley includes a housing, at least one sheave rotatably mounted at least partially within the housing, and a braking mechanism. The braking mechanism includes a rotor assembly coupled to the at least one sheave, at least one conductive element, and at least one magnetic element. The rotor assembly is rotatable with the at least one sheave, and when the rotor assembly rotates, the at least one conductive element overlaps with the at least one magnetic element based at least in part on a rotational speed of the rotor assembly.

Owner:TRUBLUE

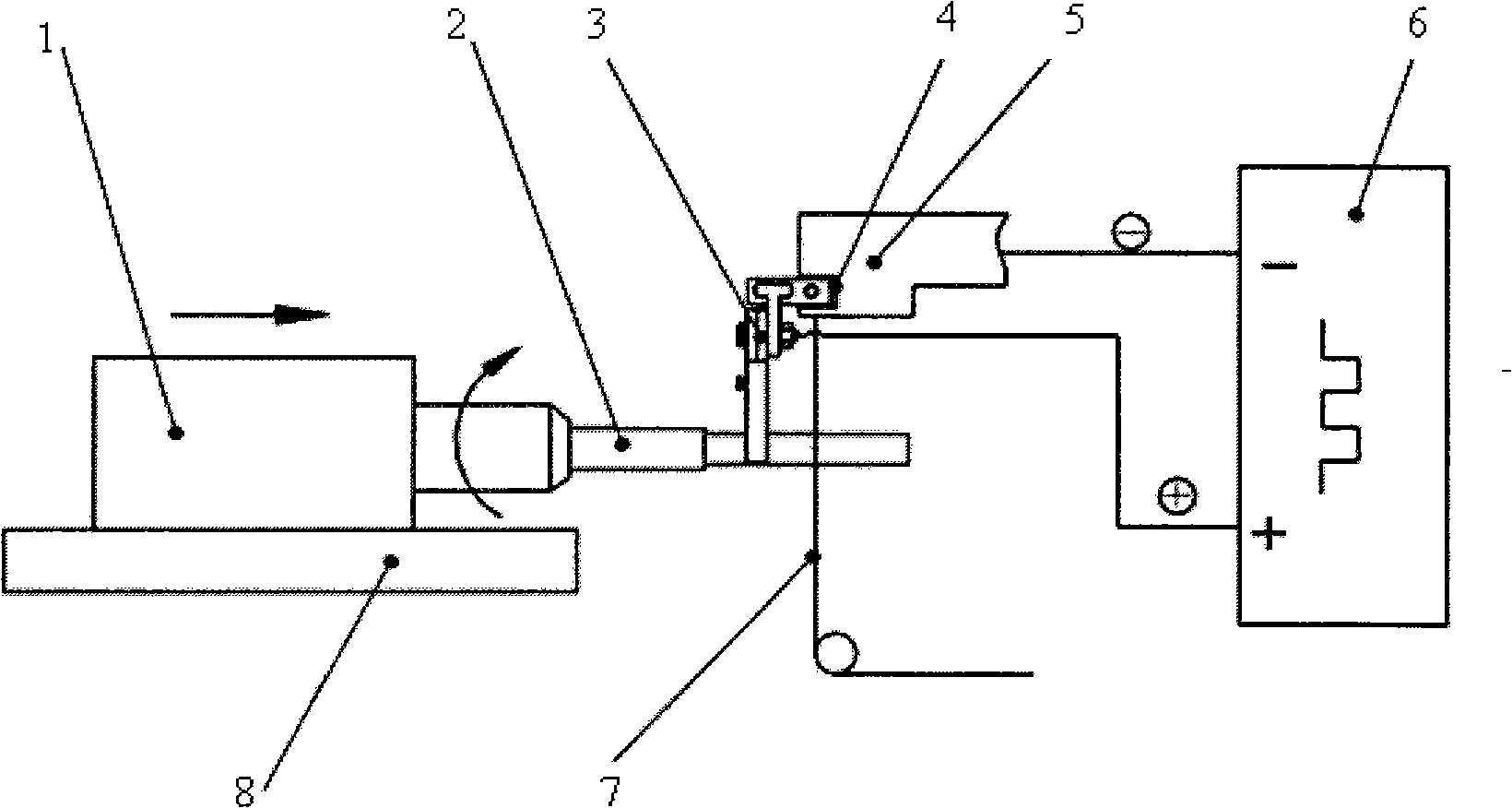

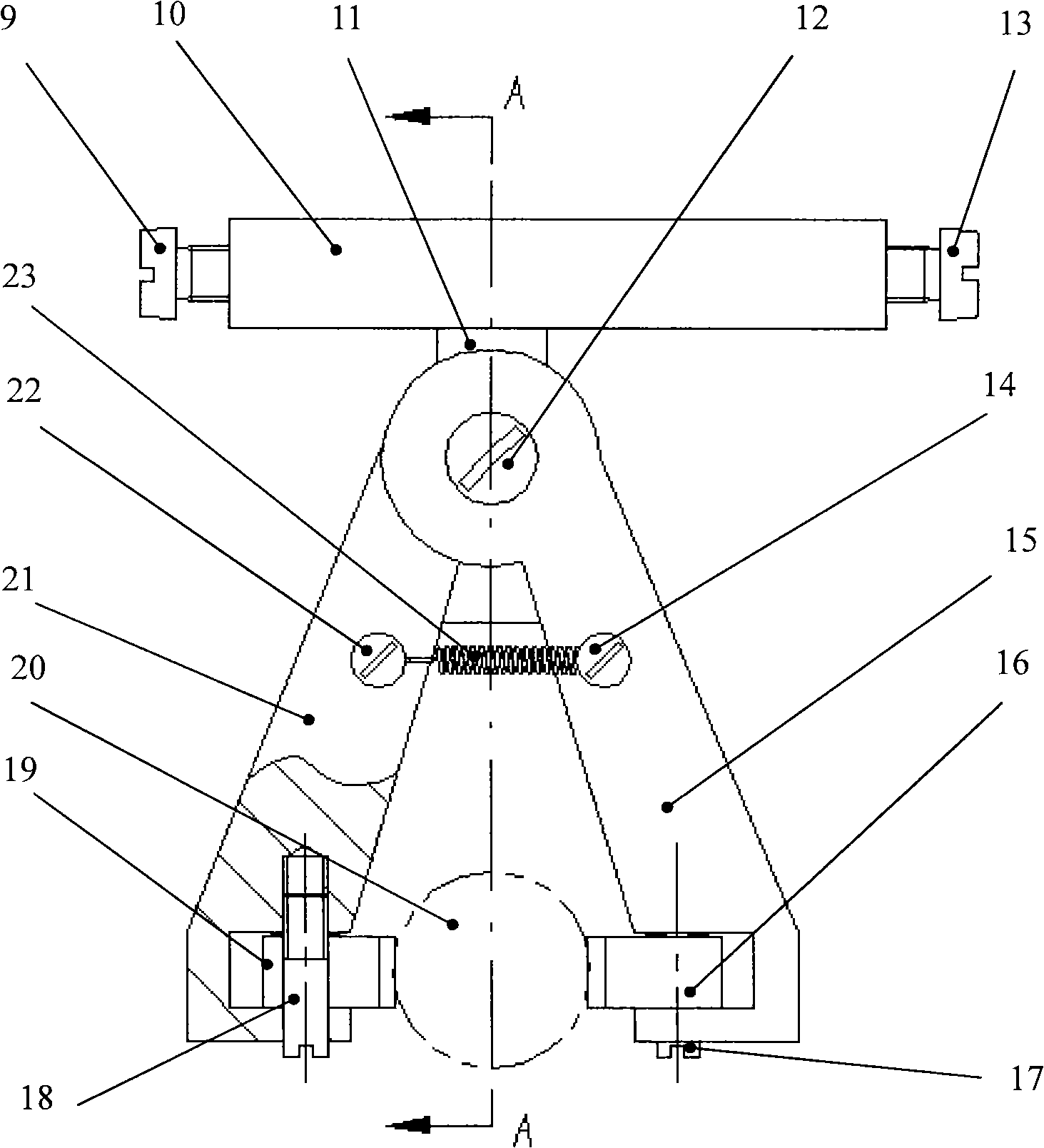

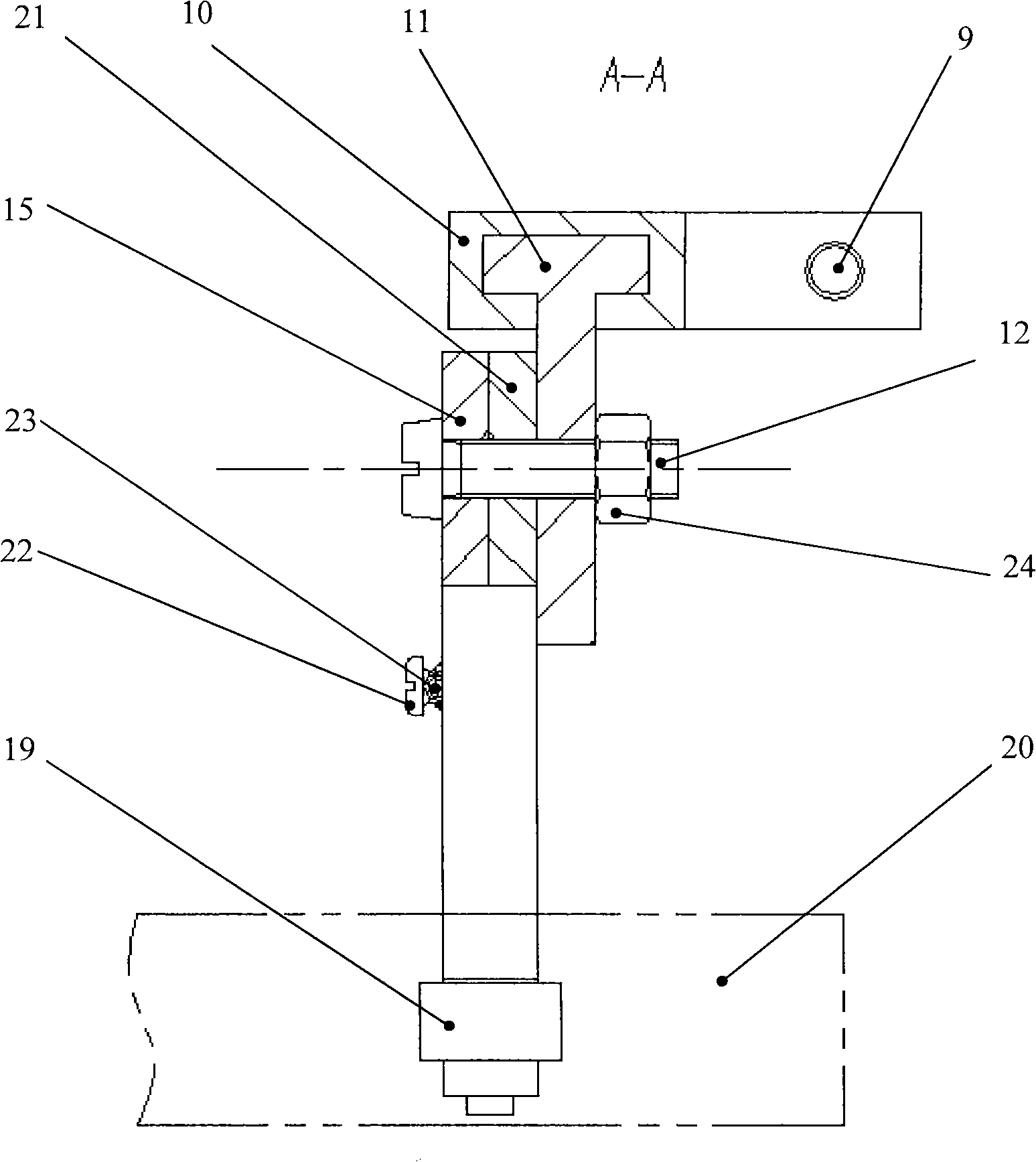

Electrical discharge grinding device for semiconducting ceramic rotating surface with tracking-electrode

The invention relates to an electrical machining device of engineering ceramic materials, in particular to a semiconducting ceramic rotary surface discharge grinding machining device with a tracking electrode. The device aims at eliminating the phenomenon that the resistance of a work piece in a discharge channel is changed along with the change of the electric discharge machining part, thus ensuring the consistency of the pulse discharge energy during the machining process and further ensuring the consistency of the discharge erosion amount and the machining quality. The device connects a cathode of a pulse power supply of a wire cutting machine with an electrode wire, an anode is connected with a ceramic work piece by the self-adaptive variable diameter tracking electrode, the tracking electrode device is utilized to lead the electrodes of the pulse power supply of the wire cutting machine to slide correspondingly to the work piece, thus maintaining the resistance of the work piece between a feeding end and a discharge point constant. The invention changes the machining mode that the electrodes of the original pulse power supply are connected on a work bench, and the power supply is just carried out at the clamping position of the work piece.

Owner:JILIN UNIV

Wastewater screening device

ActiveUS20090272685A1Large forceReduce manufacturing costBarrages/weirsSewerage structuresWastewater

A screening device for wastewater overflow weirs and the like includes a perforate screening member through which wastewater flows from a bottom to top sides thereof, with a frame and a plurality of screening rods arranged in a laterally spaced apart, mutually parallel relationship. The opposite ends of the screening rods are fixedly connected with the frame to capture solids in the wastewater. The screening rods are each configured with narrow portions at the opposite ends.

Owner:STEINHARDT

Vertical injection molding machine

ActiveUS20070224304A1Accurately determineConstant slide resistance to slideAuxillary shaping apparatusFood shapingEngineeringInjection molding machine

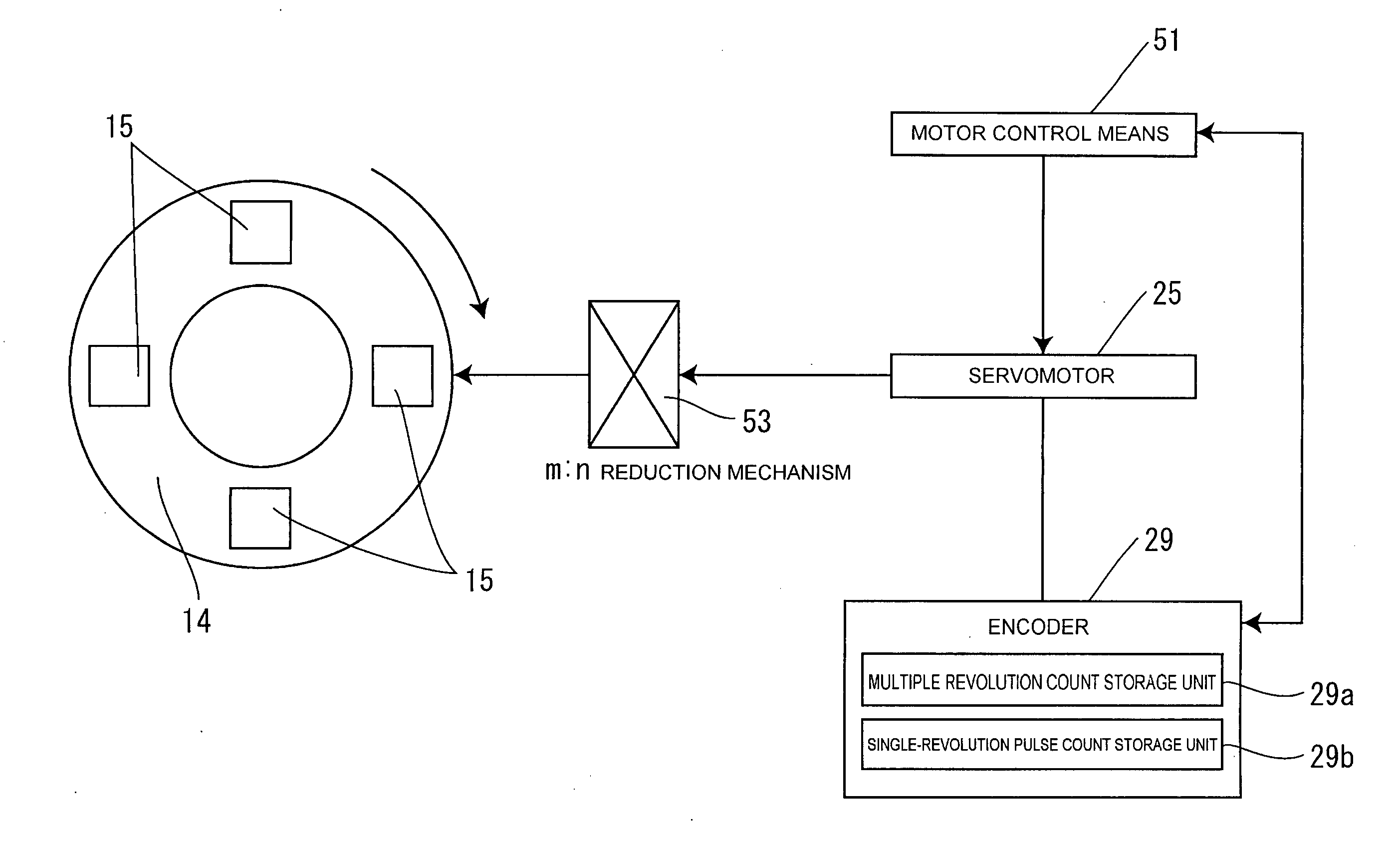

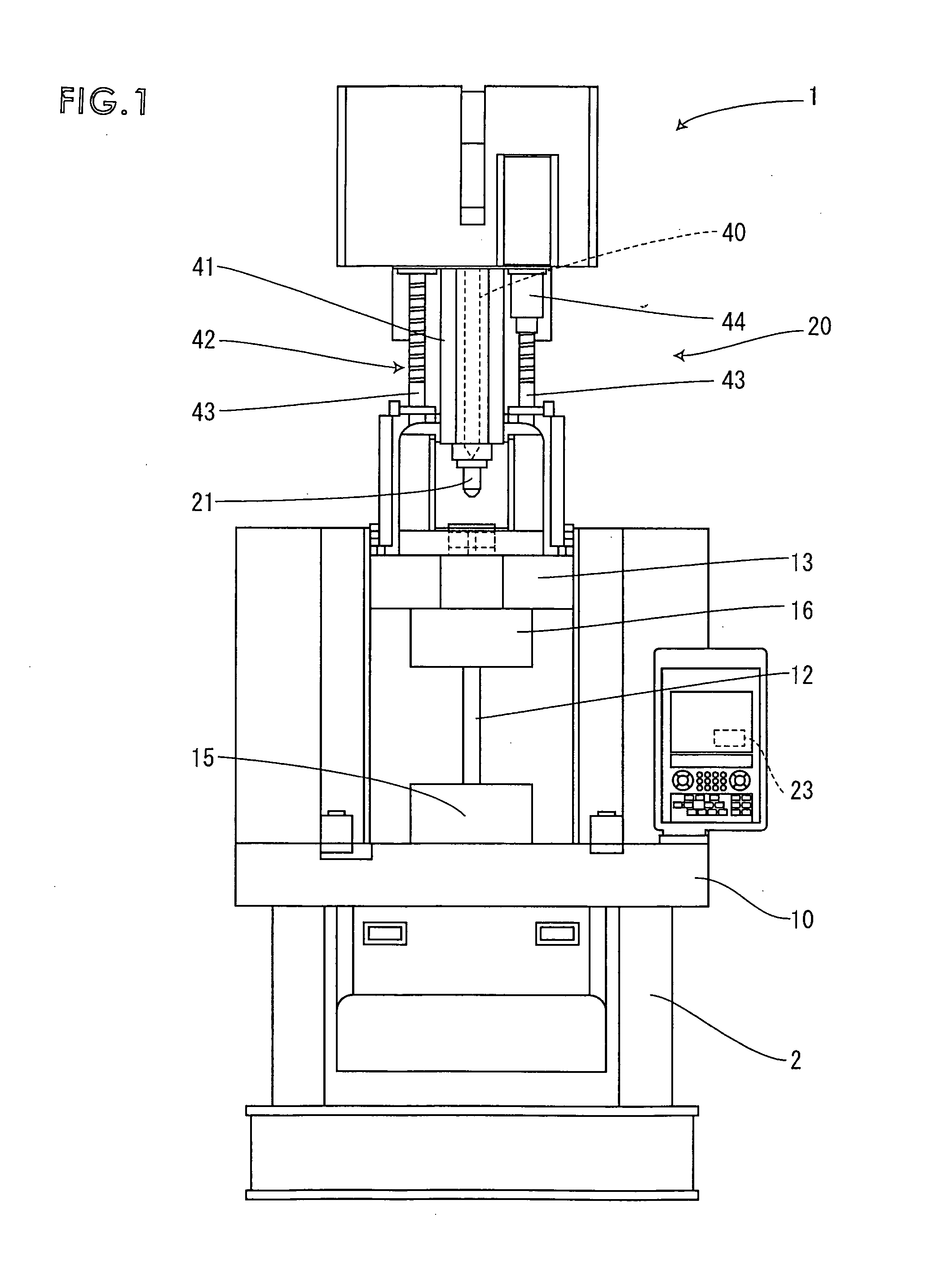

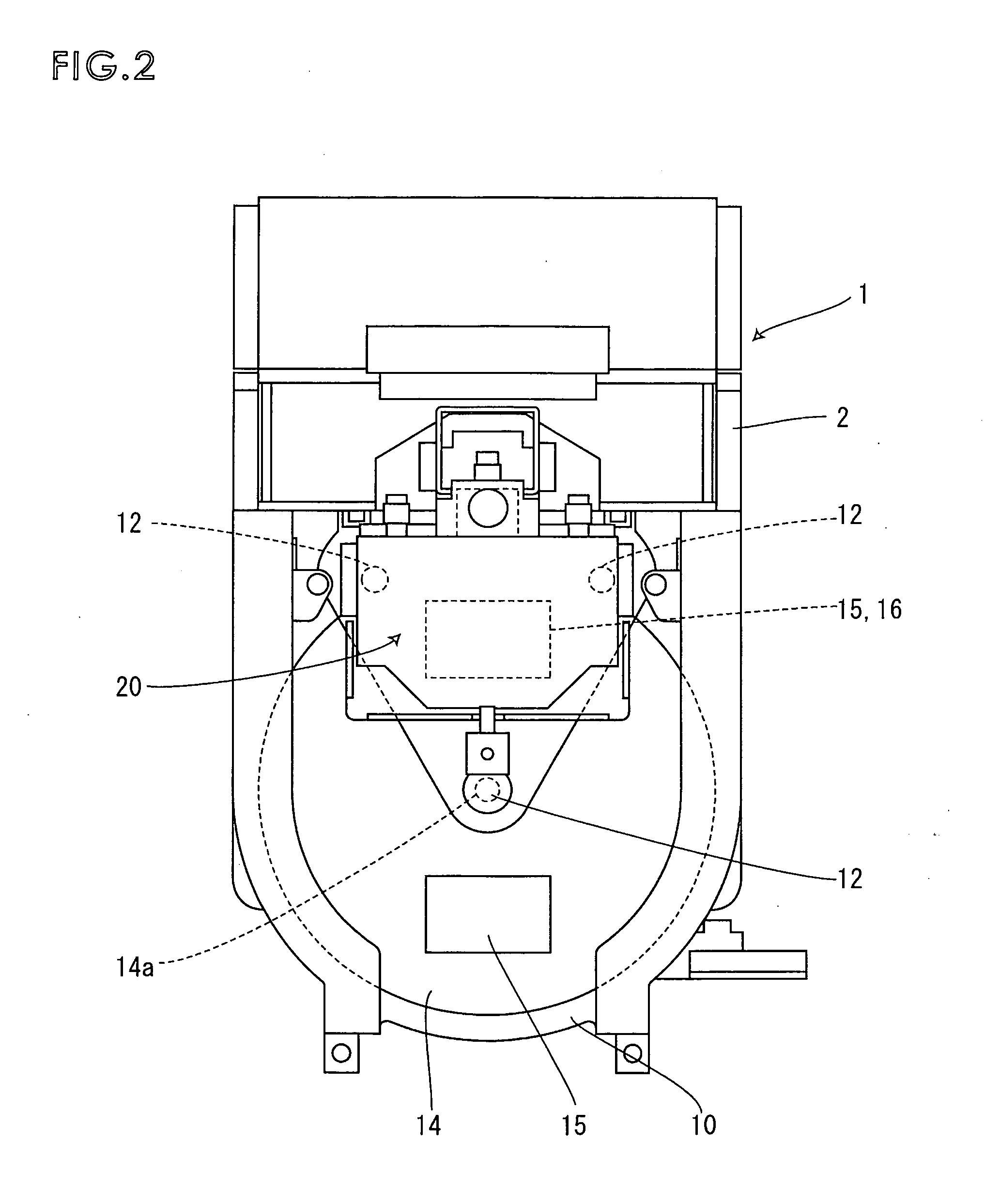

The invention provides a vertical injection molding machine capable of periodically feeding lubricant to sliding portions of the turntable to maintain a substantially constant turntable slide resistance and also capable of determining the position of the repeatedly revolving turntable. During operation of a vertical injection molding machine 1, lubricant is periodically fed from a pump 30 to slide portions S of the revolving turntable 14 so as to maintain the slide resistance of the sliding portions S substantially constant. Further, a motor control means 51 resets the count of pulses output from an encoder 29 at a timing at which the number of revolutions of a servomotor 25 and the number of revolutions of the turntable 14 are integers, so that it is possible to prevent pulse errors from accumulating even when the turntable 14 is revolved many times in the same direction.

Owner:TOYO MACH & METAL CO LTD

Method of vulcanized bonding of heat-resistant rubber

InactiveUS20030187146A1Increase resistanceConstant resistanceFlexible pipesSolid ballsPolymer scienceVulcanization

The present invention provides a method of vulcanized bonding of heat resistant rubber. Vulcanized bonding of a hydrogenated acrylonitrile butadiene rubber (H-NBR) and an acrylic rubber (ACM) comprises a step for mixing zinc oxide (ZnO) and magnesium oxide (MgO) as acid acceptors into non-vulcanized H-NBR; and a step for the peroxide vulcanization of the H-NBR at the same time as the vulcanized bonding of the ACM, which is of an epoxy cross-linking type. Thus, hydrogenated acrylonitrile butadiene rubber (H-NBR) and acrylic rubber (ACM) are vulcanized bonded securely while also providing heat resistance.

Owner:SUMITOMO RIKO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com