Electrical discharge grinding device for semiconducting ceramic rotating surface with tracking-electrode

A rotary surface and grinding technology, applied in the field of electrical processing devices for engineering ceramic materials, can solve problems such as changes, affecting the smooth progress of processing, and changes in pulse discharge energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

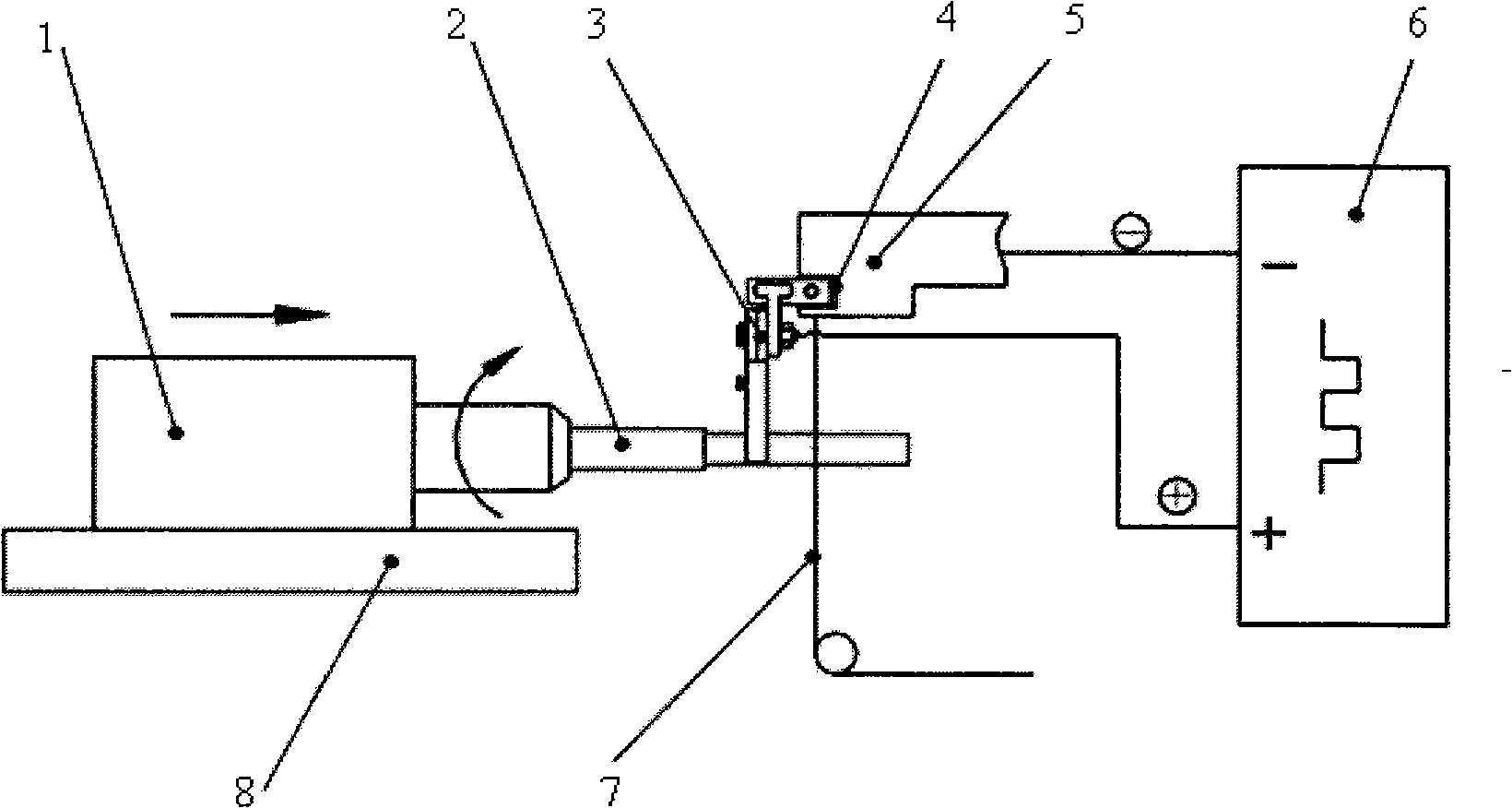

[0017] see figure 1 , The tracking electrode device 3 is fixed on the wire frame 5 of the wire cutting machine when in use. In order to ensure the insulation between the clamp body and the wire frame, an insulating rubber pad 4 is added between the clamp body and the wire frame. The workpiece 2 is clamped on the spindle turning device 1, and the tracking electrode device clamps the workpiece. The positive pole of the pulse power supply 6 is connected to the tracking electrode device, and the negative pole is connected with the electrode wire 7 through the conductive column of the machine tool. The workpiece rotates under the drive of the spindle rotary device, and the worktable 8 drives the spindle rotary device to feed along the axial direction of the workpiece together with the workpiece. As the processing progresses, the worktable advances step by step. From the perspective of the moving workpiece, the tracking electrode device realizes synchronous tracking movement relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com