Direct cooling heat dissipation substrate and power module thereof

A heat-dissipating substrate, direct technology, applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of large volume and weight, disadvantage, etc., achieve efficient heat transfer, reduce overall thermal resistance, and optimize size design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, as long as there is no conflict, each embodiment and each feature in each embodiment of the present invention can be combined with each other, and the formed technical solutions are all within the protection scope of the present invention.

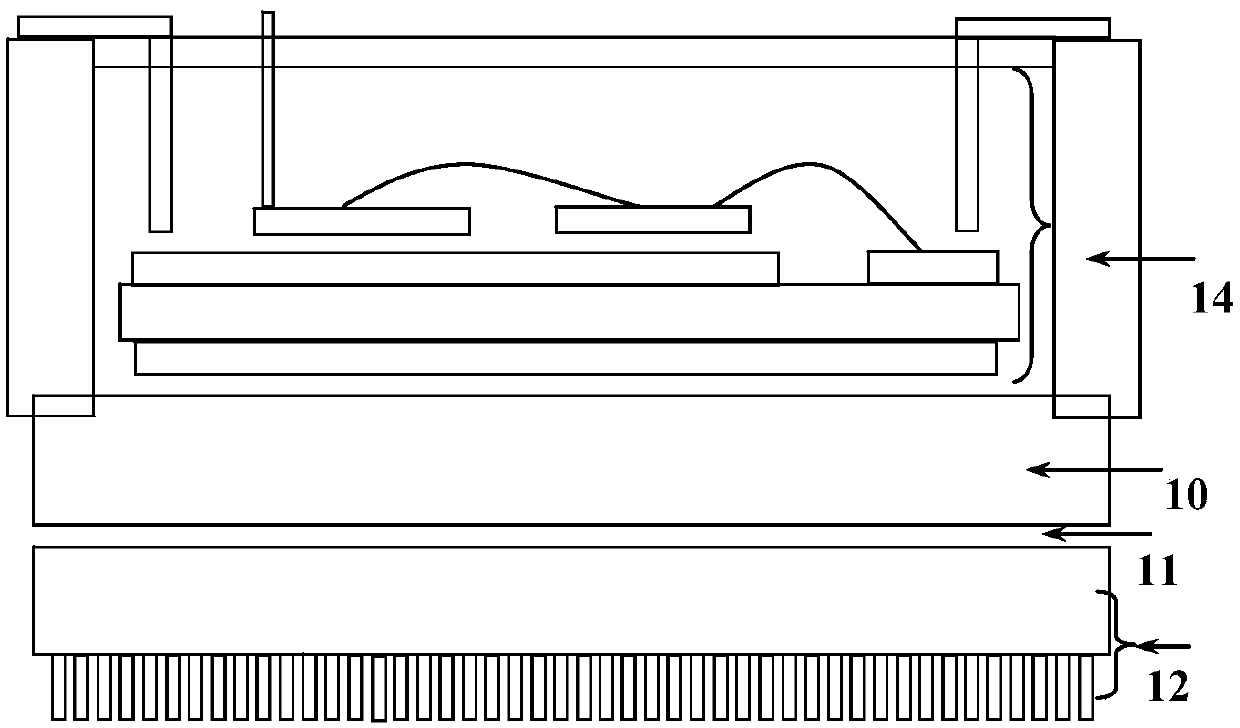

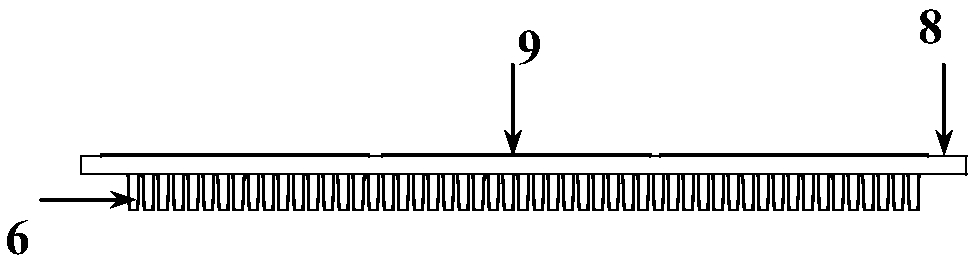

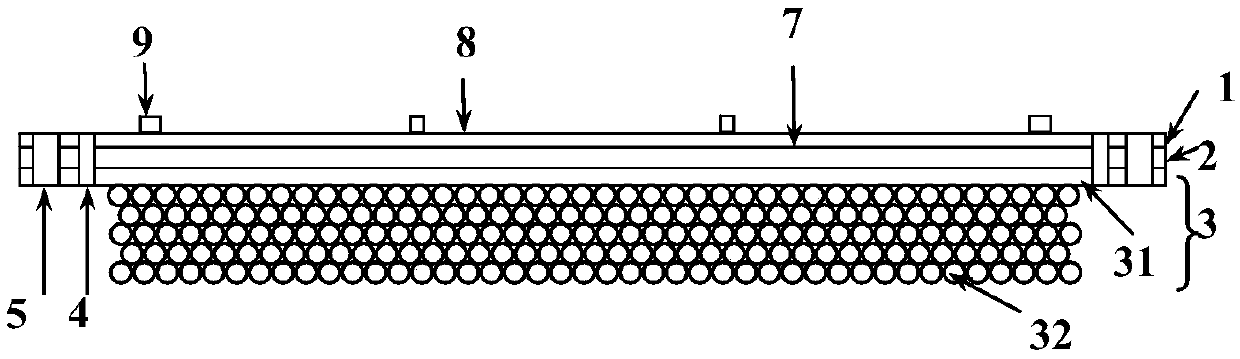

[0035] like image 3 and Figure 4 As shown, the direct cooling and heat dissipation substrate of the present invention includes an electrical circuit layer 1, an insulating layer 2 and a heat dissipation layer 3, and the heat dissipation layer 3 includes a direct cooling layer 32, and the direct cooling layer 32 can be air-cooled or directly connected to the outside Cooling system for direct cooling.

[0036] In one embodiment, the direct cooling layer 32 is a porous metal foam structure.

[0037] In one embodiment, the electrical circuit layer includes an upper metal la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com