Machine case capable of dissipating heat through method of liquid cooling

A liquid cooling, chassis technology, applied in the direction of cooling/ventilation/heating transformation, can solve the problem of low heat dissipation efficiency of chassis equipment, and achieve the effect of solving low heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

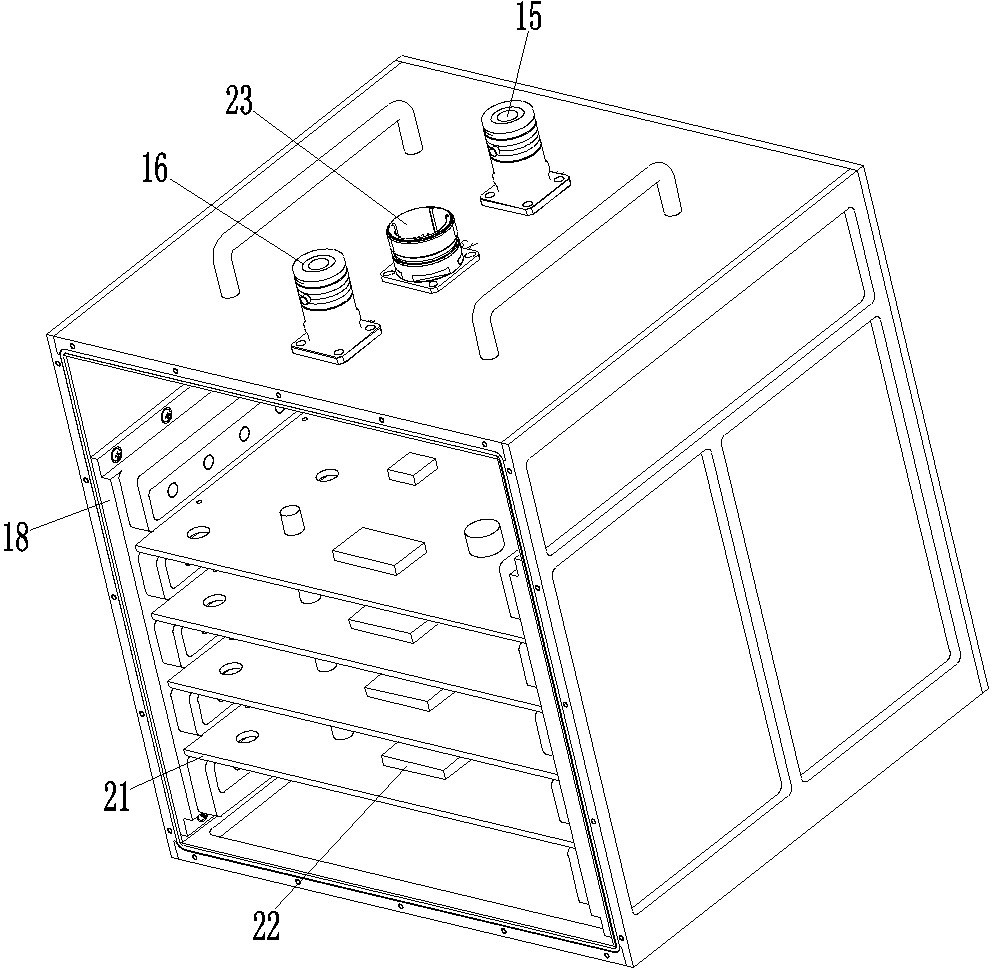

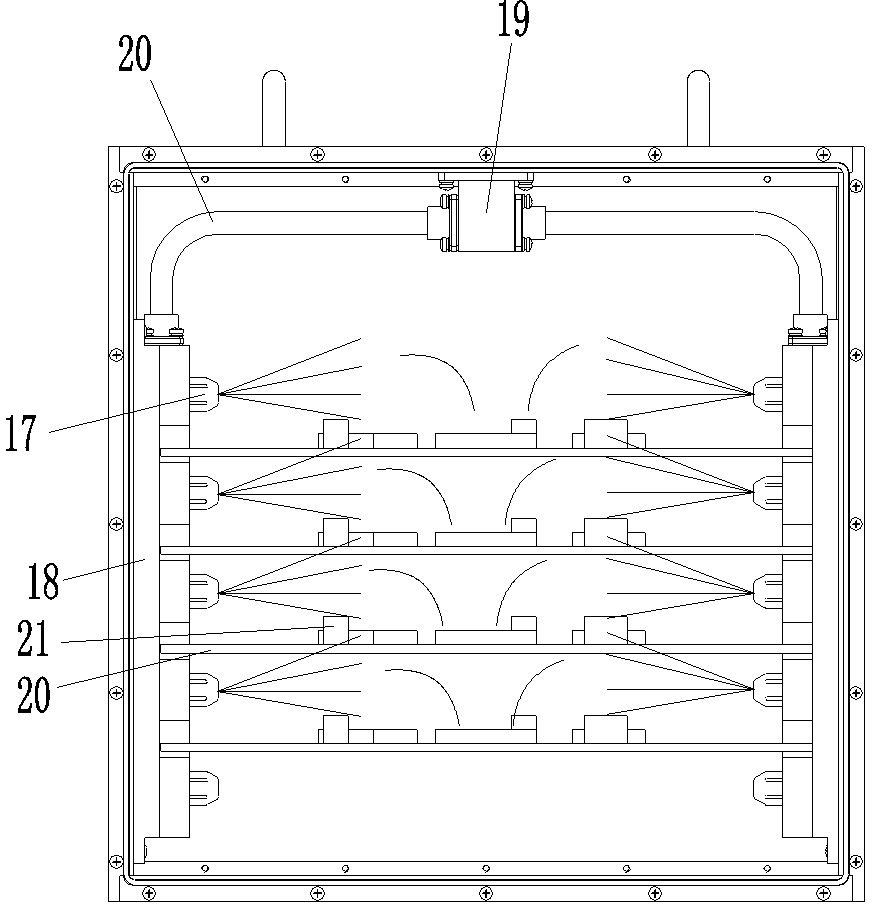

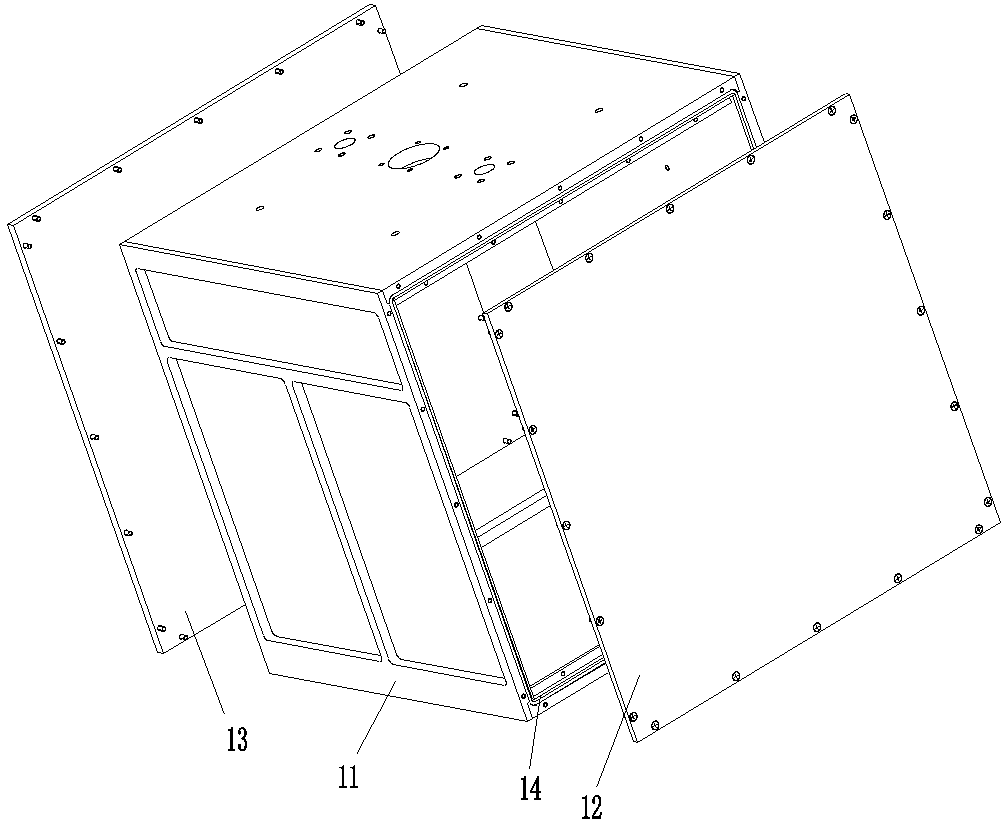

[0018] Examples of liquid cooled thermal enclosures, such as Figure 1-5 As shown, the liquid cooling heat dissipation chassis includes a box body, and electrical components are installed in the box body.

[0019] The box body is a closed box body, which includes a box body frame 11 and a panel assembled on the box body frame, wherein the front panel 12, the rear panel 13 and other panels are split structures, and the two are respectively connected to the box body frame 11. Gasket 14 is arranged to ensure the airtightness of the casing. The upper panel of the box body is provided with a refrigerant inlet and a refrigerant outlet, the refrigerant inlet is provided with an inlet fluid connector 15, and the outlet is provided with an outlet fluid connector 16, and the refrigerant inlet is connected with an atomizing nozzle 17, which is located in the box. In this embodiment, in this embodiment, the atomizing nozzles 17 are divided into two groups, and the two groups of atomizing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com