Direct liquid cooling and heat shielding type sandwich-structured motor armature

A heat shielding and sandwich technology applied to the shape/style/structure of the winding conductor to ensure positioning accuracy, improve frequency response and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

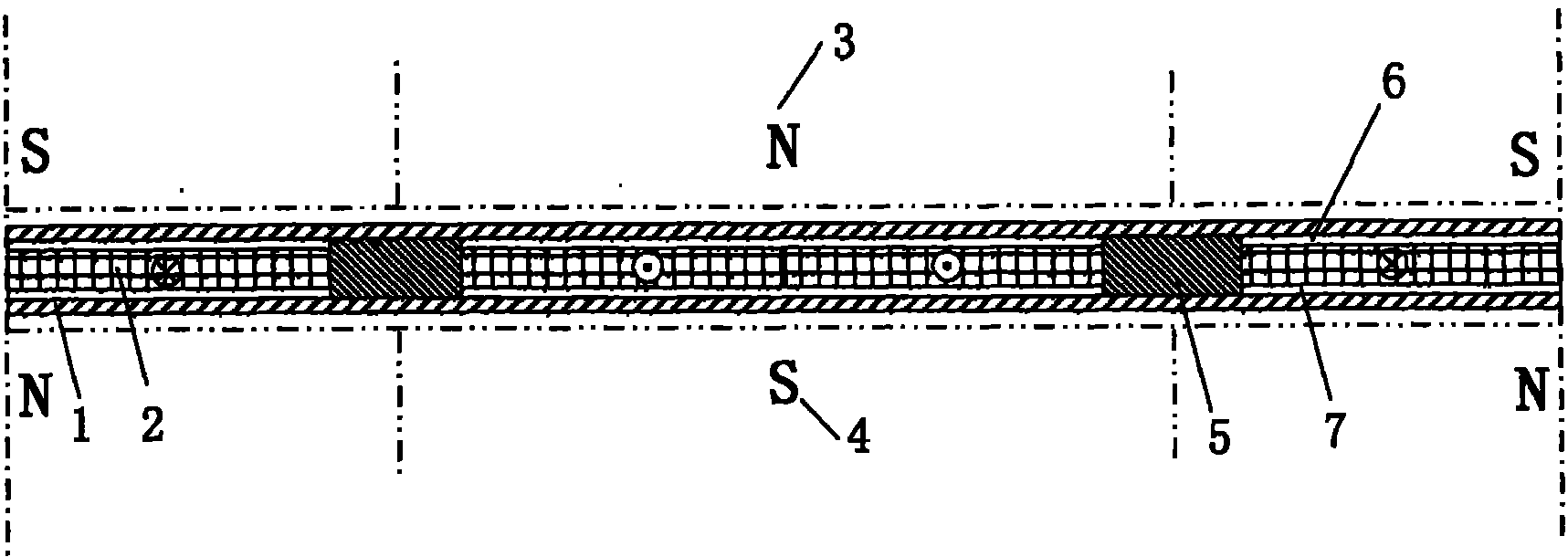

[0024] Embodiment 1: the sandwich structure straight line or planar motor armature of this direct liquid cooling and thermal shielding (a pair of very lower structural sections refer to figure 1 ) includes a thin box-shaped armature assembly composed of a thin sealed box 1 and multiple sets of pancake-shaped armature windings 2 placed in the thin sealed box 1 . There are a plurality of support frames 5 in the sealed box 1 to fix the armature winding 2, and gaps 6, 7 for forced circulation of cooling liquid are formed between the cavity wall of the sealed box 1 and the upper and lower surfaces of the armature winding 2. The upper and lower sides of the thin box-shaped armature assembly are two magnetic pole assemblies 3, 4 respectively.

[0025] A one-pole sandwich structure permanent magnet linear motor consists of upper and lower permanent magnet pole assemblies and a thin box-shaped armature assembly as described above, with a gap for plane movement formed by air bearing tec...

Embodiment 2

[0028] Embodiment 2: The armature of the sandwich structure disc rotating electrical machine with direct liquid cooling and thermal shielding (a pair of extremely lower structural sections developed along the circumference after turning 90 degrees clockwise refer to figure 1 ) contains a thin box-shaped armature assembly consisting of a thin sealed box 1 and multiple sets of pancake-shaped armature windings 2. There are a plurality of support frames 5 in the sealed box 1 to fix the armature windings 2, and on the cavity wall of the sealed box 1 Between the upper and lower surfaces of the armature winding 2, gaps 6, 7 for forced circulation of cooling liquid are formed. The pole assemblies 3, 4 are located on the left and right sides thereof.

[0029] A four-pole sandwich structure permanent disk type rotating electrical machine consists of left and right permanent magnet pole assemblies and a thin box-shaped armature assembly as described above, with bearing support between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com