Direct liquid cooling temperature control device of giant magnetostrictive actuator

A giant magnetostrictive and liquid cooling technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. Problems such as small area and complex selection of inner sleeve materials achieve the effect of improving precision and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

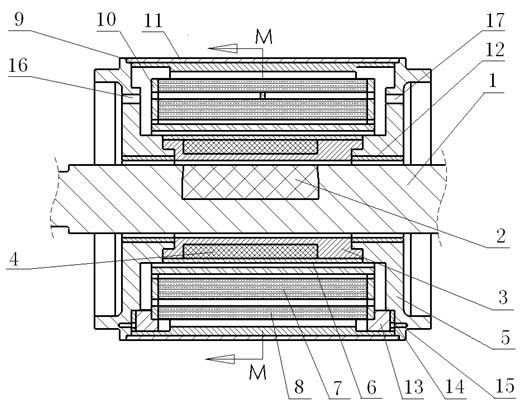

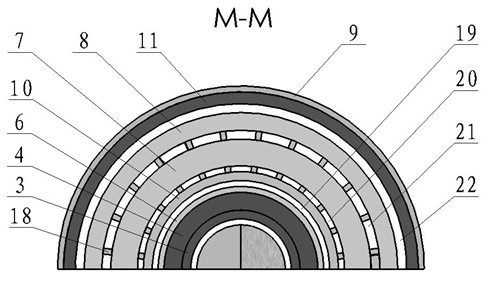

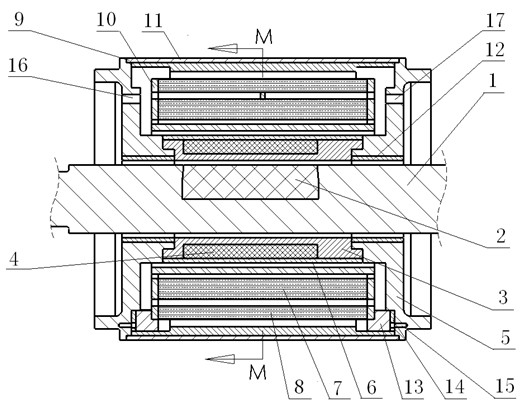

[0014] The present invention will be further described below in conjunction with the accompanying drawings, and the purpose and effect of the present invention will become more obvious.

[0015] Such as figure 1 As shown, the direct liquid cooling temperature control device of the giant magnetostrictive driver of the present invention includes: a phase change material inner bracket 3, a phase change material 4, an end cap 5, a phase change material outer sleeve 6, an inner layer coil 7, an outer layer Coil 8 , outer layer sleeve 9 , coil bobbin 10 , outer layer heat insulating material 11 , inner layer heat insulating material 12 , claw 13 , claw heat insulating pad 14 , stay 18 .

[0016] Wherein, the phase change material outer sleeve 6 is sleeved outside the phase change material inner bracket 3, and an annular cavity is formed between the phase change material outer sleeve 6 and the phase change material inner bracket 3, and the annular cavity is filled with Phase change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com