Reflective plate and method for manufacturing the same and backlight unit and liquid crystal display device having the same

A technology of backlight unit and manufacturing method, which is applied in the direction of optical components, optics, instruments, etc., and can solve problems such as screen light leakage and poor heat dissipation efficiency of the backlight unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

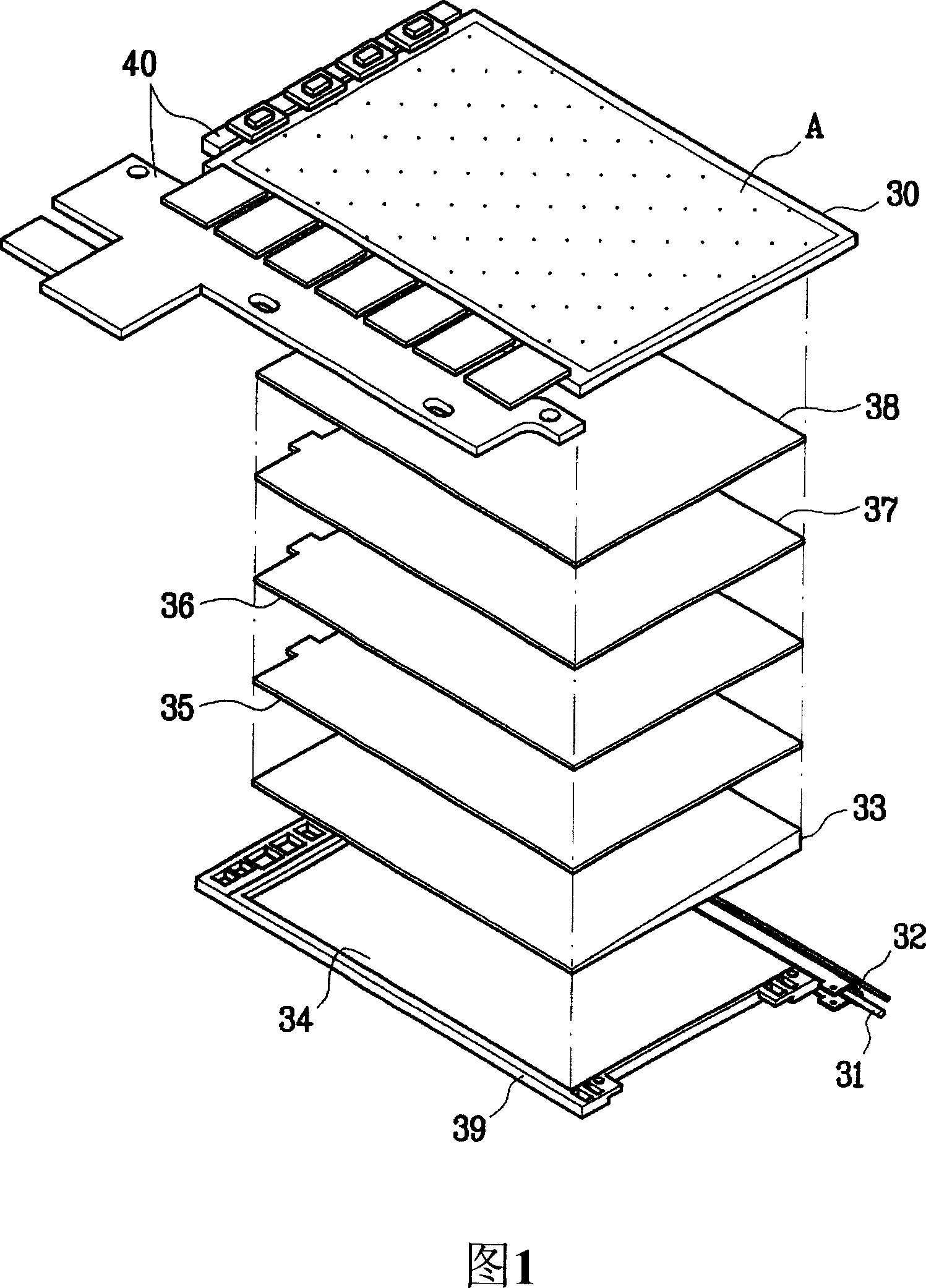

[0047] Preferred embodiments of the present invention will now be described in detail, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0048] 5A to 5C respectively show cross-sectional views of reflective plates according to preferred embodiments of the present invention.

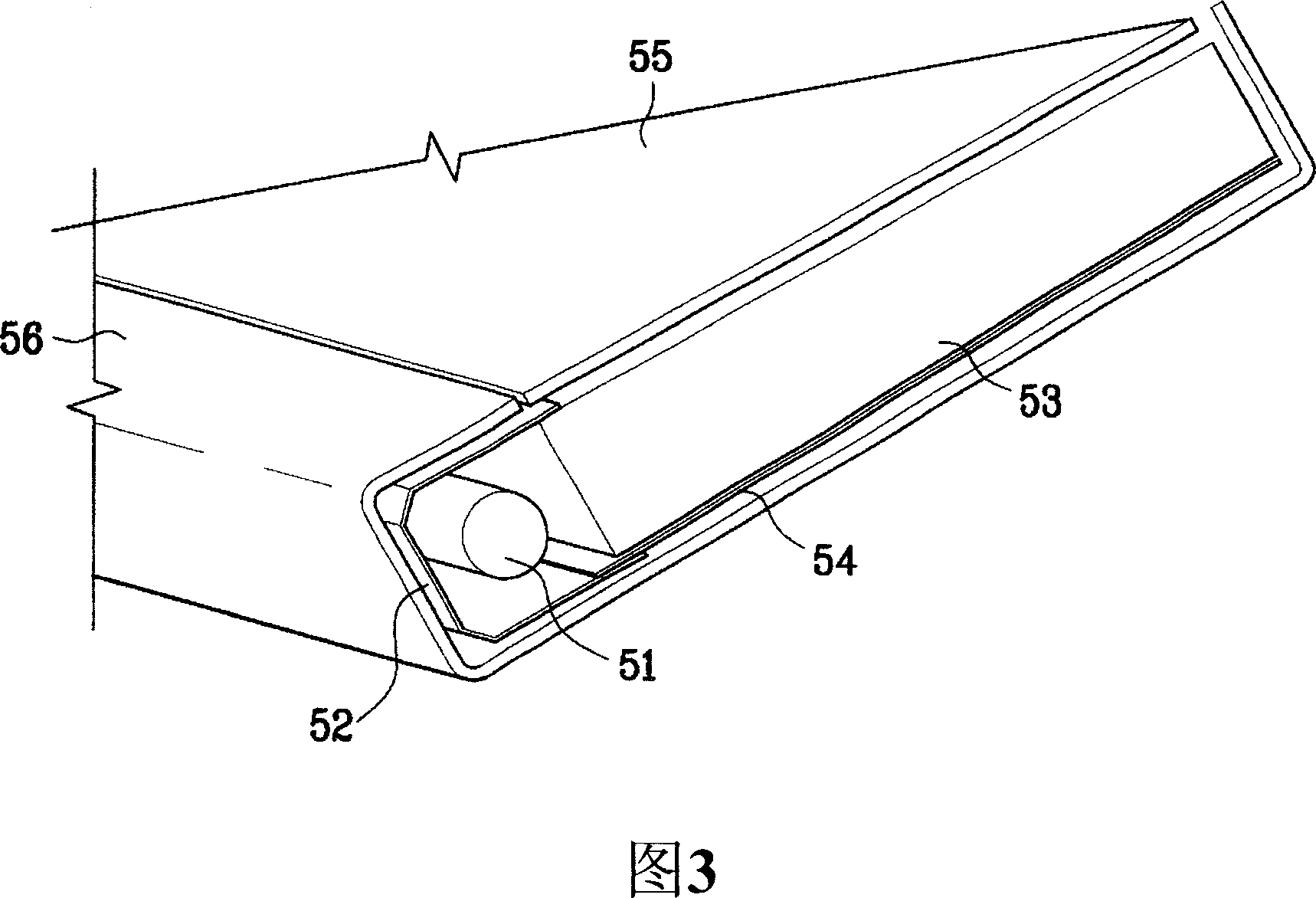

[0049] Referring to FIG. 5A , the reflective plate 500 includes a reflective material 520 on a material 510 with high thermal conductivity.

[0050] The high thermal conductivity material 510 is in the form of flakes, plates or powders, and is at least one of graphite, aluminum, copper, carbon nanotube (CNT), and AlSiC.

[0051] Reflective material 520 is coated with a coating of dispersed material, and is Ag, Al 2 o 3 、TiO 2 , Al, PET (polyester), and at least one of optical fibers.

[0052] Besides, a shielding layer may be disposed under the reflective material 520...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com