Substrate for IGBT module and encapsulation method for IGBT module

A module packaging and substrate technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of difficulty, hardness, and high cost, and achieve the effect of reducing roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

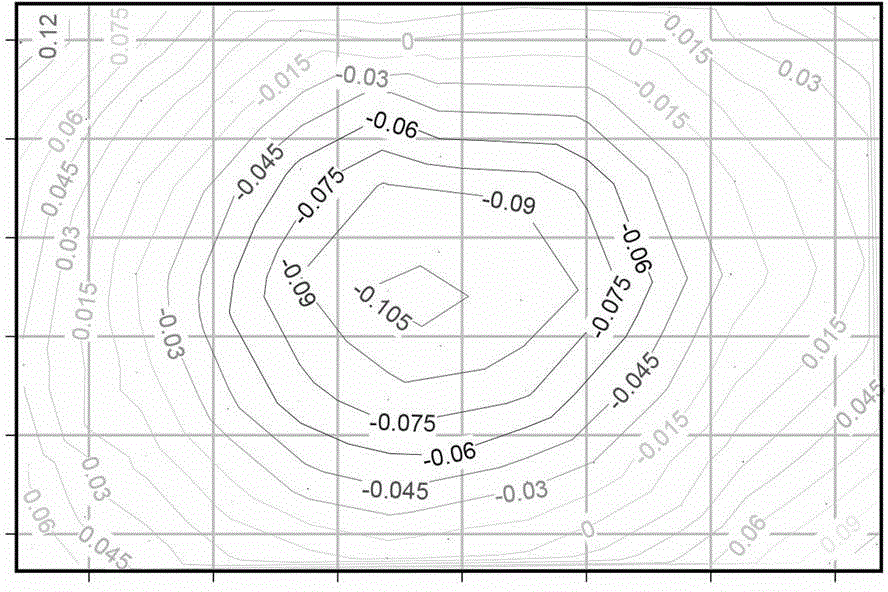

[0029] Such as Figure 6 As shown, a substrate 1 for an IGBT module of the present invention includes an AlSiC layer 2 and an aluminum alloy layer 3 , and the surface of the aluminum alloy layer 3 at the bottom of the AlSiC layer 2 forms a layer to be machined.

[0030] After the IGBT package is completed using the substrate 1 of the present invention, the bottom of the substrate 1 will be recessed inward. At this time, the aluminum alloy layer 3 at the bottom of the substrate 1 is flattened by mechanical processing to eliminate the concave radian (eg, processed by a precision lathe or a precision milling machine). In this way, the removed distance does not exceed the thickness of the aluminum alloy layer 3, and the bottom surface of the substrate 1 of the processed IGBT is a whole plane, which can ensure full contact between the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com