Method for scratching battery piece by using laser and device thereof

A battery sheet and laser technology, applied in laser welding equipment, circuits, electrical components, etc., can solve problems affecting the power generation efficiency and aesthetics of battery strings and components, and achieve the effect of changing the path of lobes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

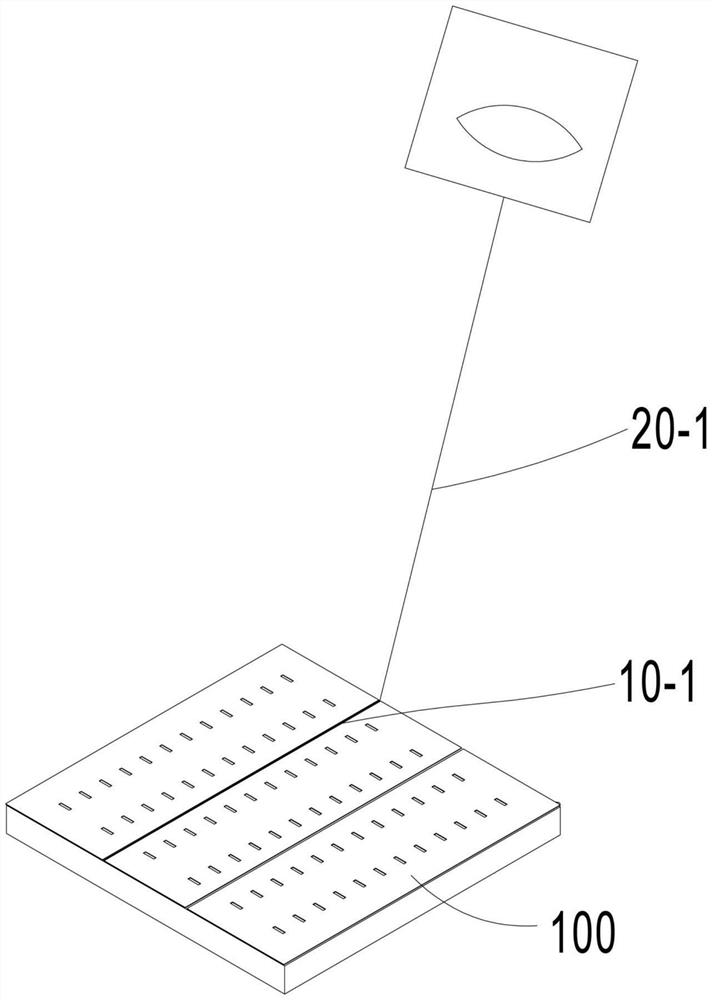

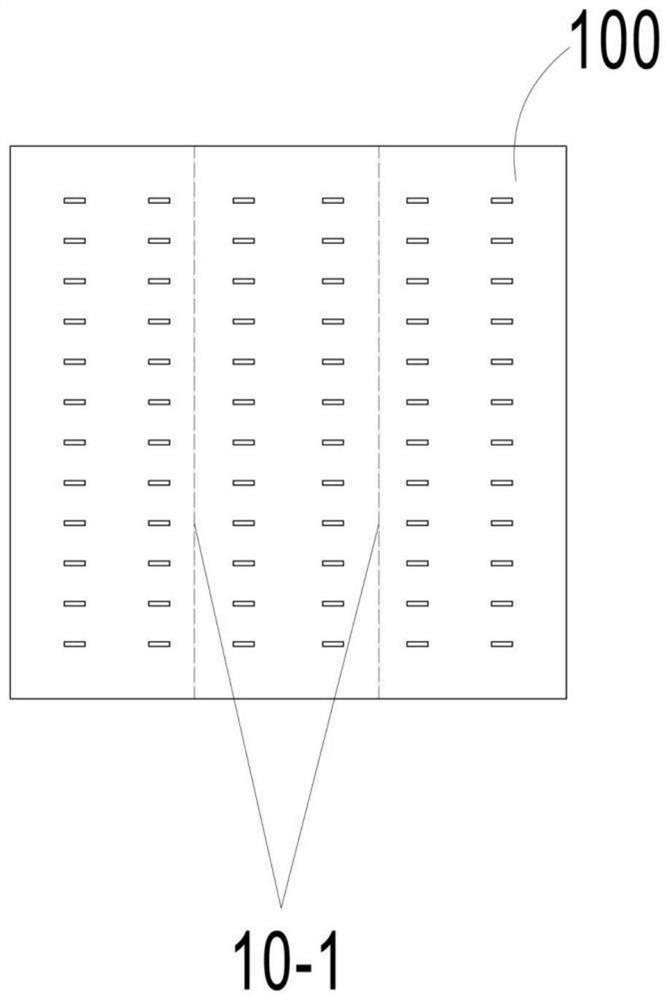

[0032] Combine below Figure 1 to Figure 8 Specific embodiments of the present invention will be described.

[0033] figure 1 and figure 2 The scene where the laser beam acts on the cell is shown in three slices. The ideal split line 10-1 is on the plane of the cell 100 and perpendicular to the direction of the grid line of the cell 100, dividing the cell 100 into N equal parts, where N is a natural number greater than or equal to 2;

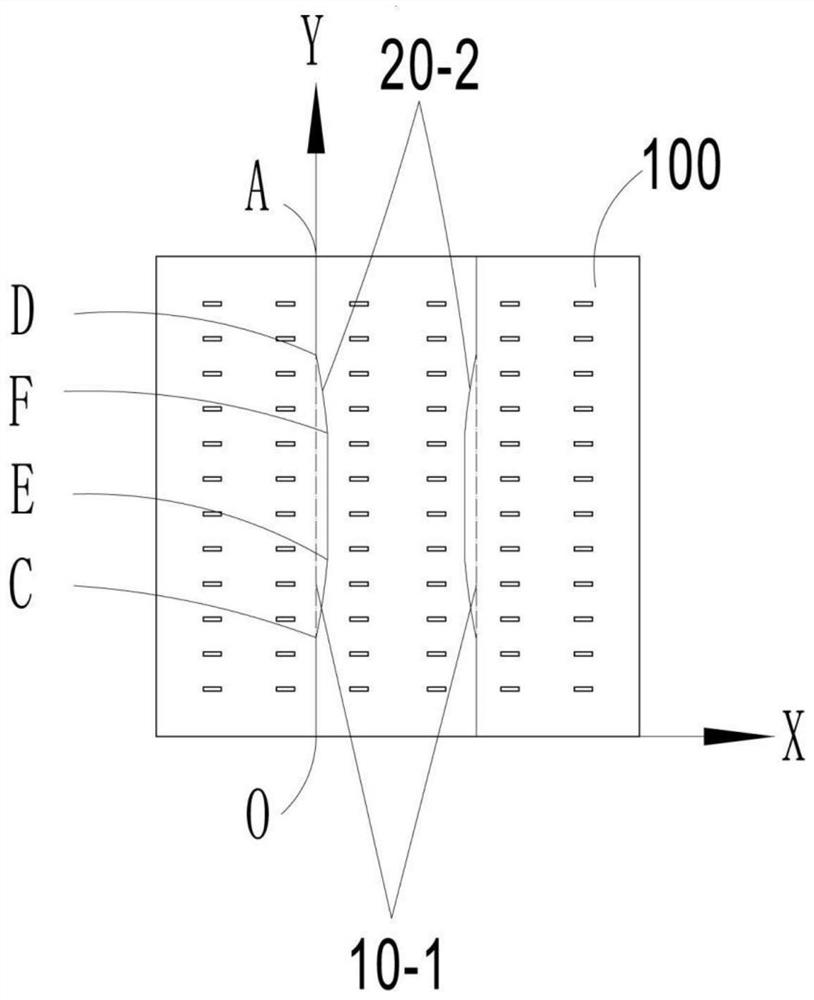

[0034] image 3 It shows that one of the endpoints of any ideal splitting line is taken as the origin, and a coordinate system is established on the plane where the battery sheet 100 is located, with the focus of the laser beam 20-1 at the starting point O of the ideal splitting line 10-1 as the origin, and point O The line connecting point A is the y-axis, and the line passing through the origin and parallel to the grid line of the battery sheet 100 is the x-axis. The trajectory 20-2 is the focus of the laser beam 20-1 on the XY coordinate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com