Graphene wave-absorbing film coating as well as preparation method and application thereof

A technology of wave-absorbing film and graphene, applied in radiation-absorbing coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of high price, long delivery cycle, inability to meet the needs of electronic product production, etc. Interference, high permeability, effect of saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

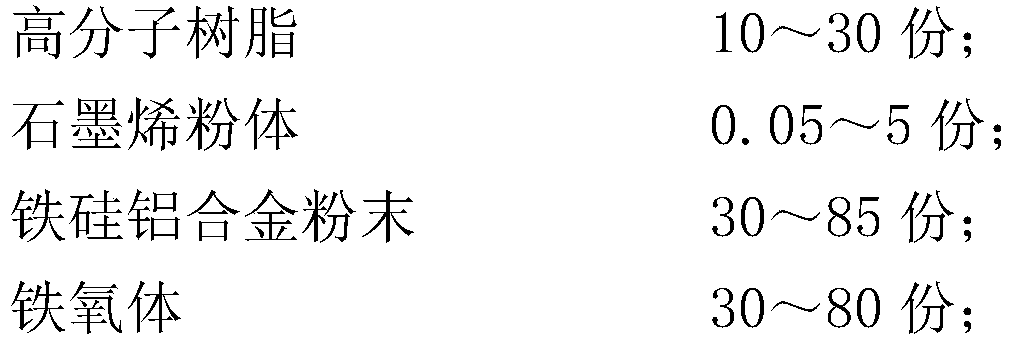

[0045] The present embodiment provides a graphene wave-absorbing film coating, which comprises the following components in parts by weight:

[0046]

[0047]

[0048] Wherein, the polymer resin is water-based acrylic resin, the auxiliary agent includes an anti-settling agent and a pH regulator, and the mass ratio of the two is 2:1, and the anti-settling agent is DISPARLON AQ-633E, which is produced by Japan Kusumoto Chemical Co., Ltd. The pH regulator is American DOW ANGUS AMP-95.

[0049] Its preparation method comprises the following steps:

[0050] S1. Add the polymer resin, graphene powder, sendust powder, ferrite, iron paste, aluminum powder, additives and deionized water into the mixing tank;

[0051] S2. Place the mixing tank on the disperser to stir, and disperse at a high speed of 800r / min for 30min to prepare a graphene wave-absorbing film coating with a pH value of 8.

Embodiment 2

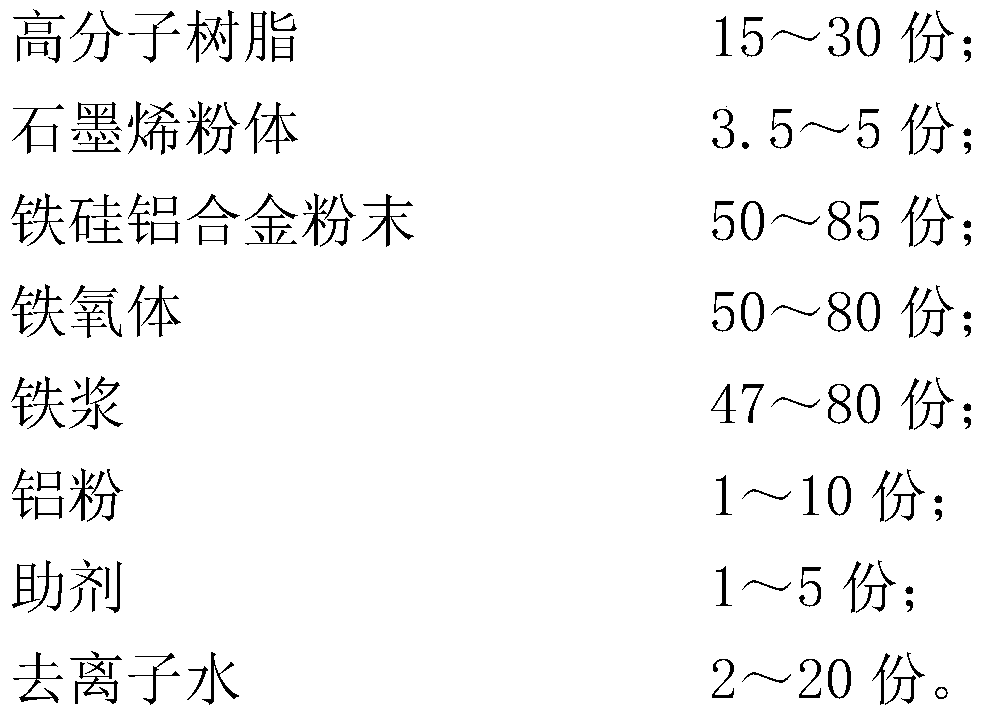

[0053] A graphene wave-absorbing film coating, in parts by weight, comprises the following components:

[0054]

[0055] Wherein, the polymer resin is a water-based PUA resin, and the auxiliary agent includes an anti-settling agent, a wetting agent, a leveling agent and an anti-foaming agent, a compound of an anti-settling agent, a wetting agent, a leveling agent and an anti-foaming agent. The proportioning ratio is 2:1:1:1, and the anti-settling agent is DISPARLON AQ-633E of Japanese Kumben Kasei; the wetting agent is German BASF Hydropalat WE 3220; the leveling agent is German BYK BYK-333; The defoamer mentioned above is Synthron SF 561, which was created in France.

[0056] Its preparation method comprises the following steps:

[0057] S1. Add the polymer resin, graphene powder, sendust powder, ferrite, iron paste, aluminum powder, additives and deionized water into the mixing tank;

[0058] S2. Place the mixing tank on the disperser to stir, and disperse at a high speed...

Embodiment 3

[0060] A graphene wave-absorbing film coating, in parts by weight, comprises the following components:

[0061]

[0062]

[0063] Wherein, the polymer resin is composed of water-based acrylic resin and water-based PUA resin in a mass ratio of 3:1, and the auxiliary agent includes an anti-sedimentation agent, a wetting agent and a pH regulator, and the compounding ratio of the three is 1. :1:1, the anti-sedimentation agent is DISPARLON AQ-633E of Japanese Kumben Kasei, the wetting agent is German BASF Hydropalat WE 3220, and the pH regulator is American DOW ANGUS AMP-95.

[0064] Its preparation method comprises the following steps:

[0065] S1. Add the polymer resin, graphene powder, sendust powder, ferrite, iron paste, aluminum powder, additives and deionized water into the mixing tank;

[0066] S2. Place the mixing tank on a disperser for stirring, and disperse at a high speed of 1000r / min for 27 minutes to prepare a graphene wave-absorbing film coating with a pH valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com