Patents

Literature

180results about How to "Increase ion concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

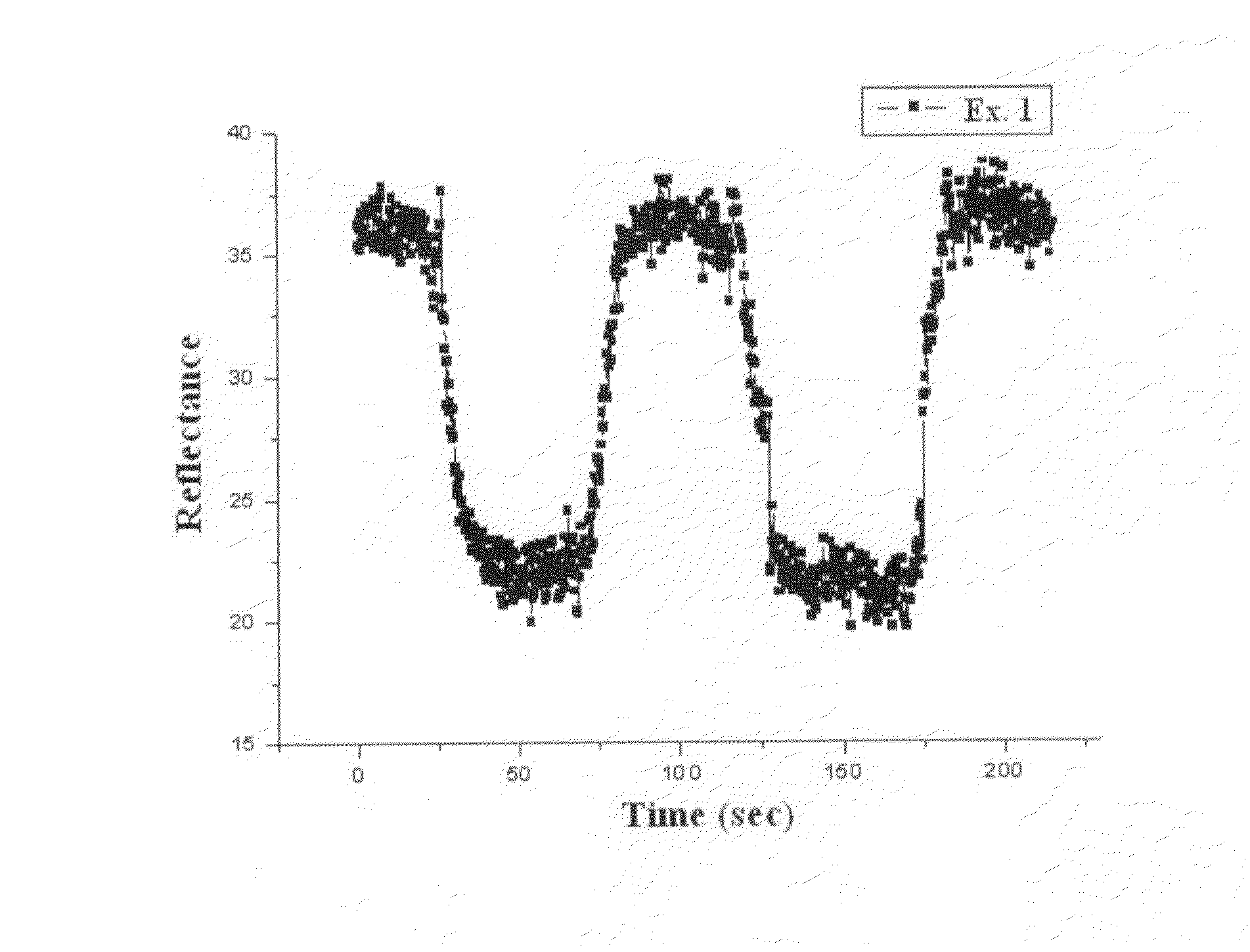

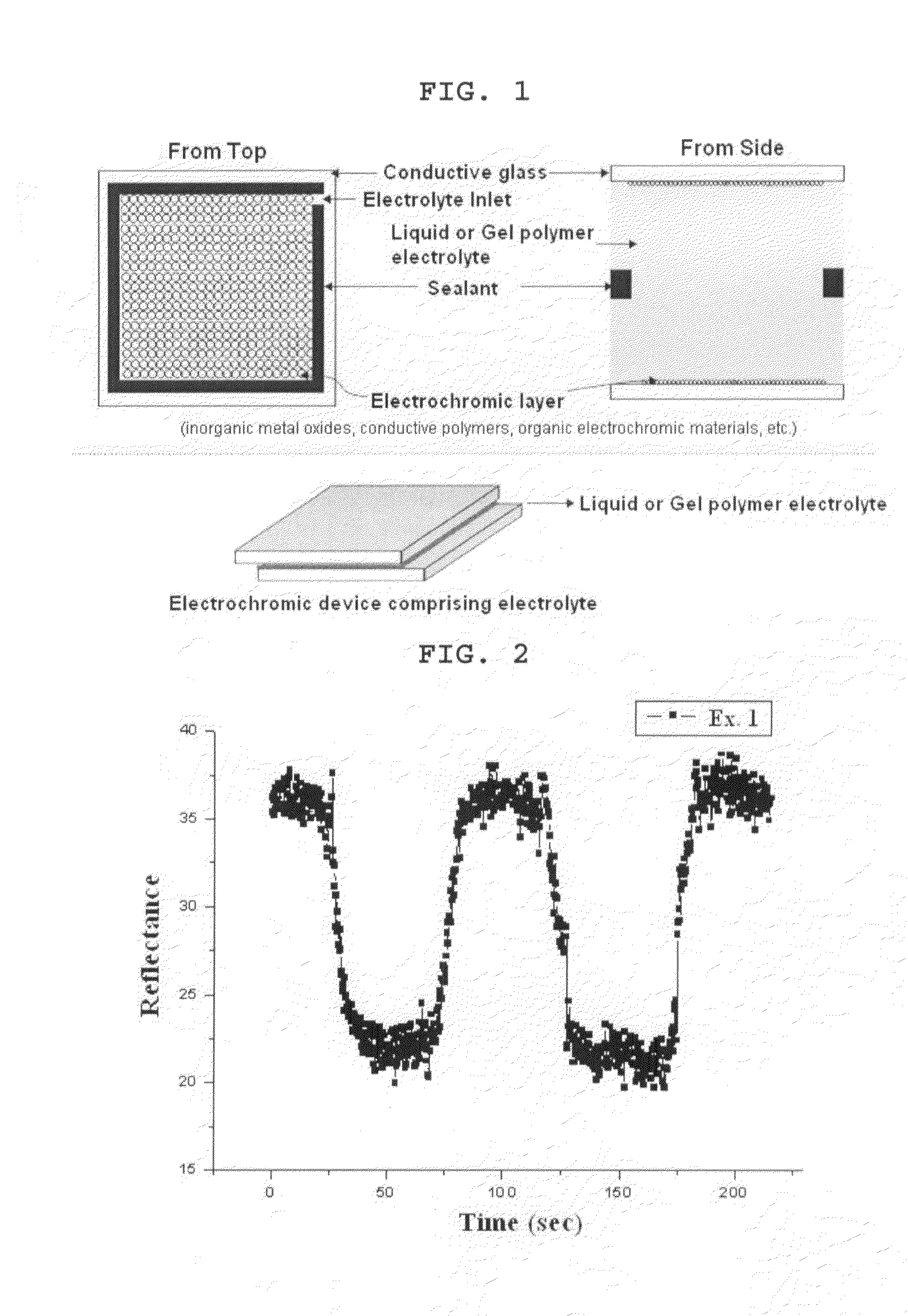

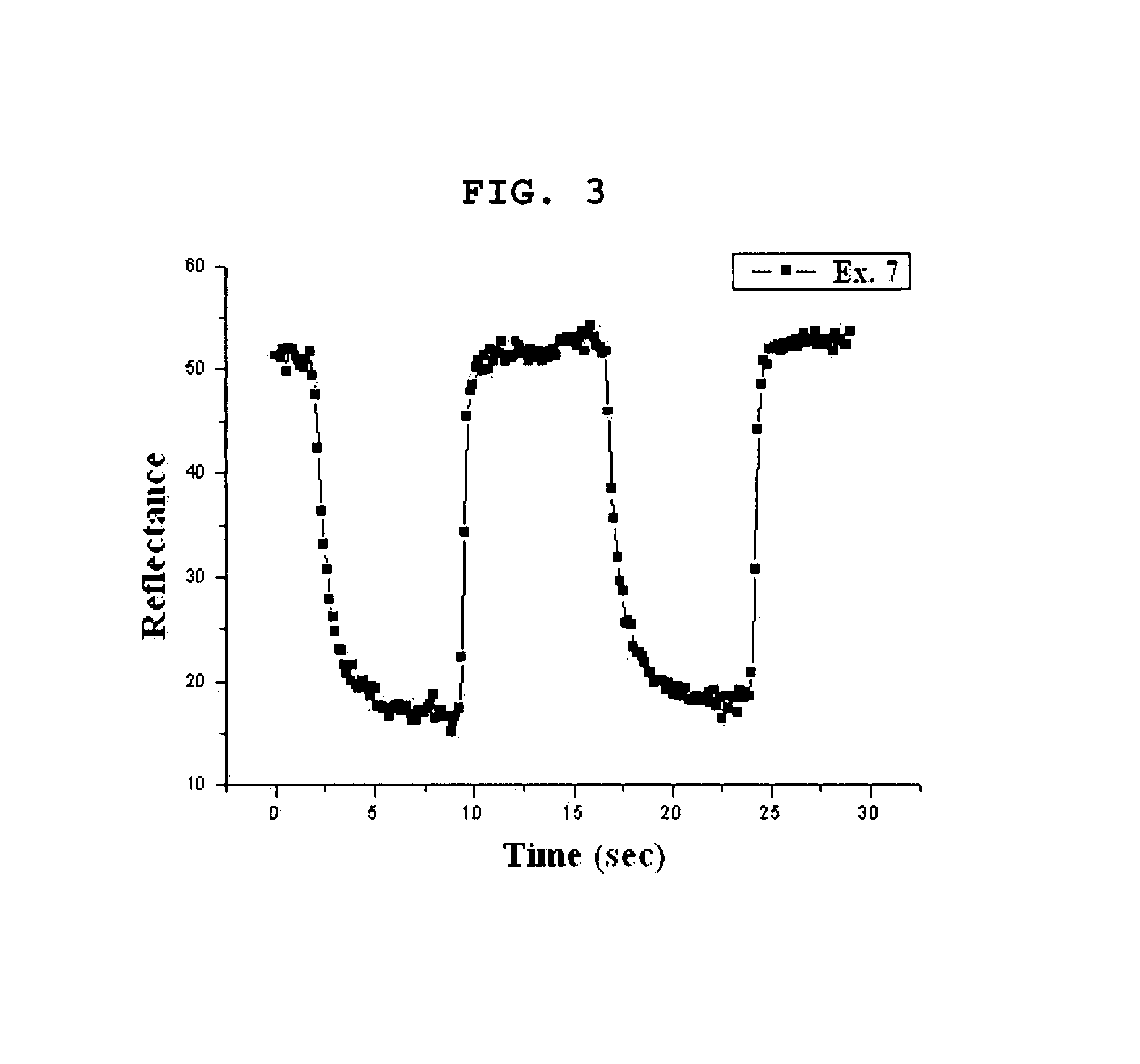

Gel polymer electrolyte containing ionic liquid and electrochromic device using the same

ActiveUS7411716B2Solve the real problemIncrease chanceLapping machinesTenebresent compositionsStructural deformationPolymer electrolytes

Owner:LG ENERGY SOLUTION LTD

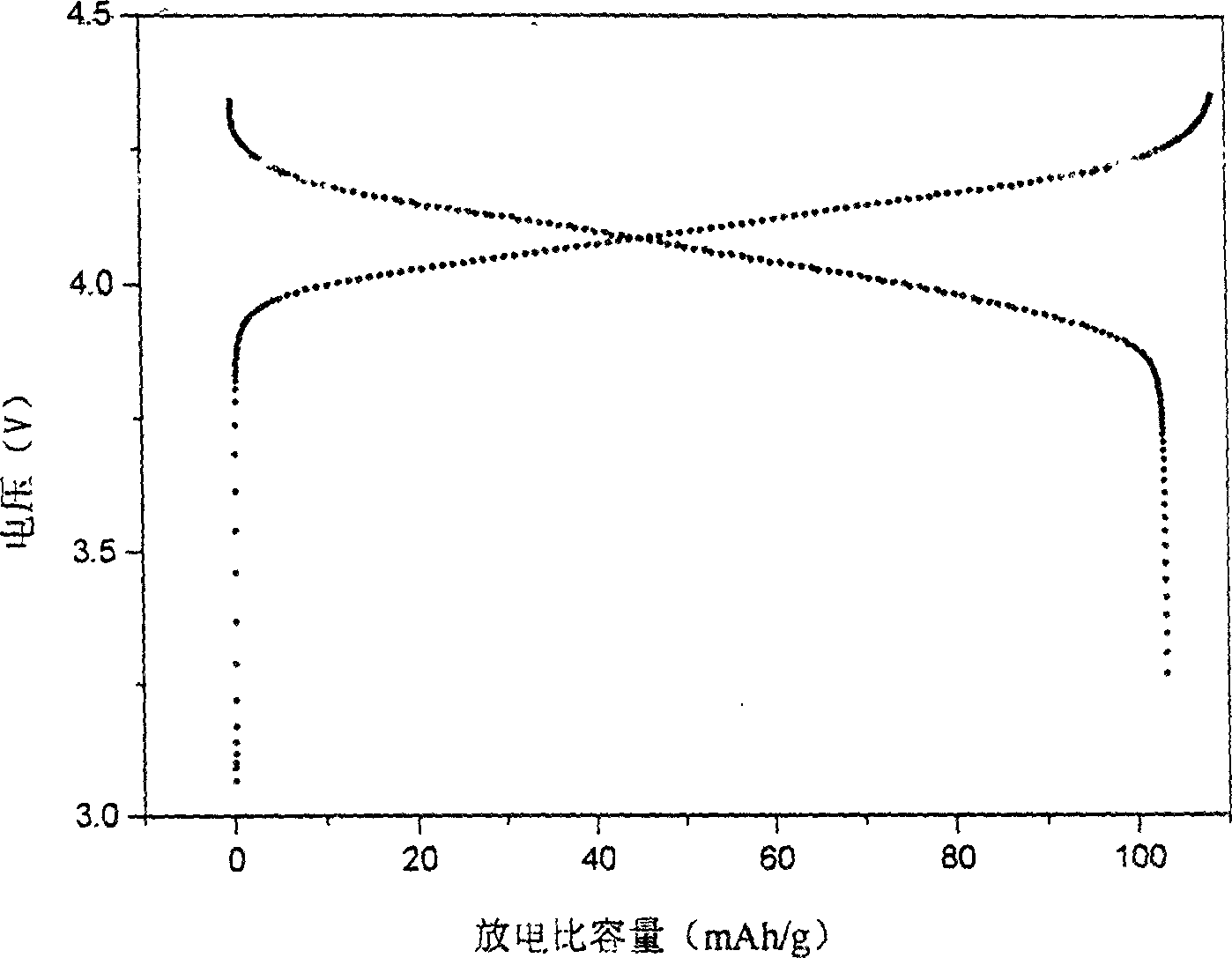

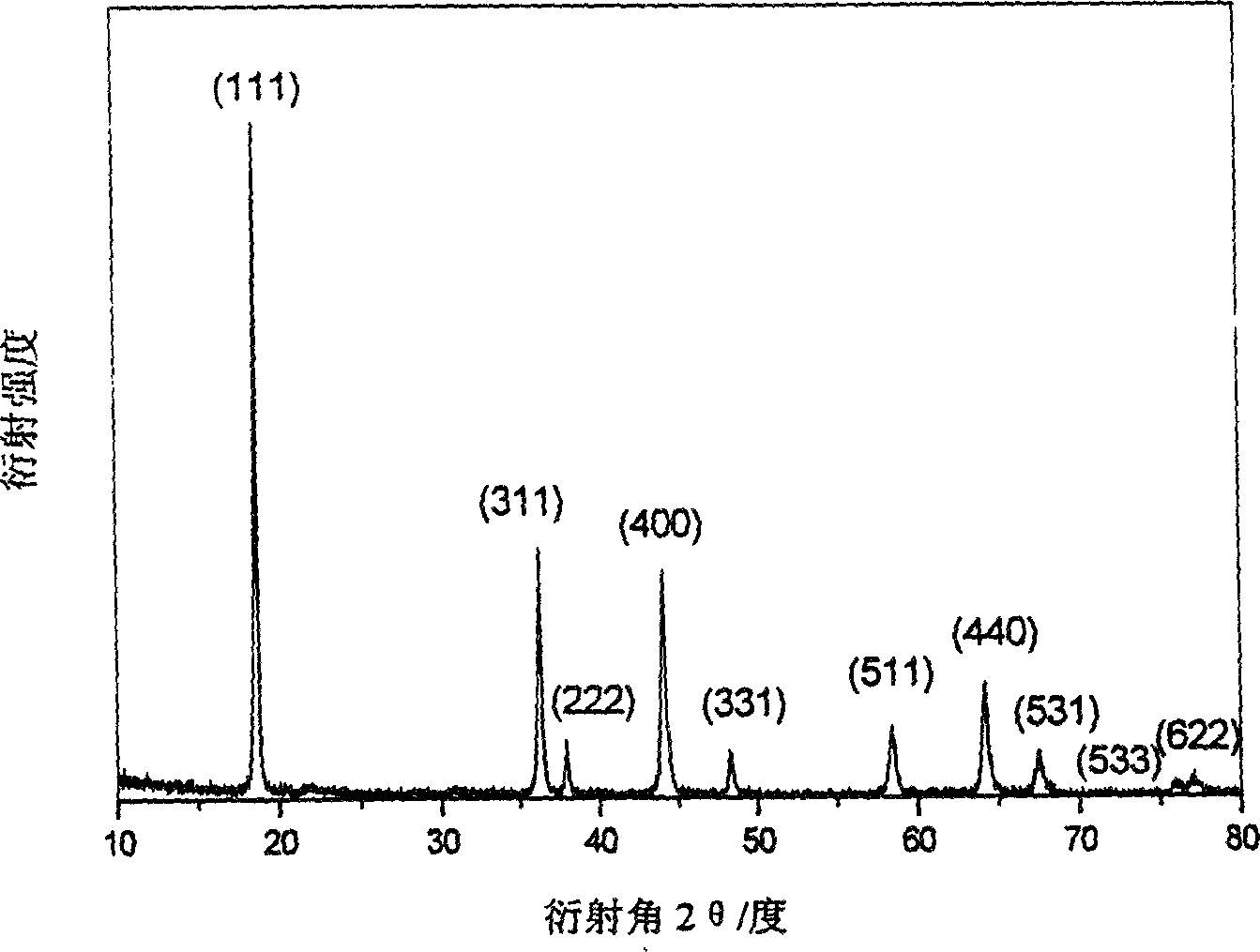

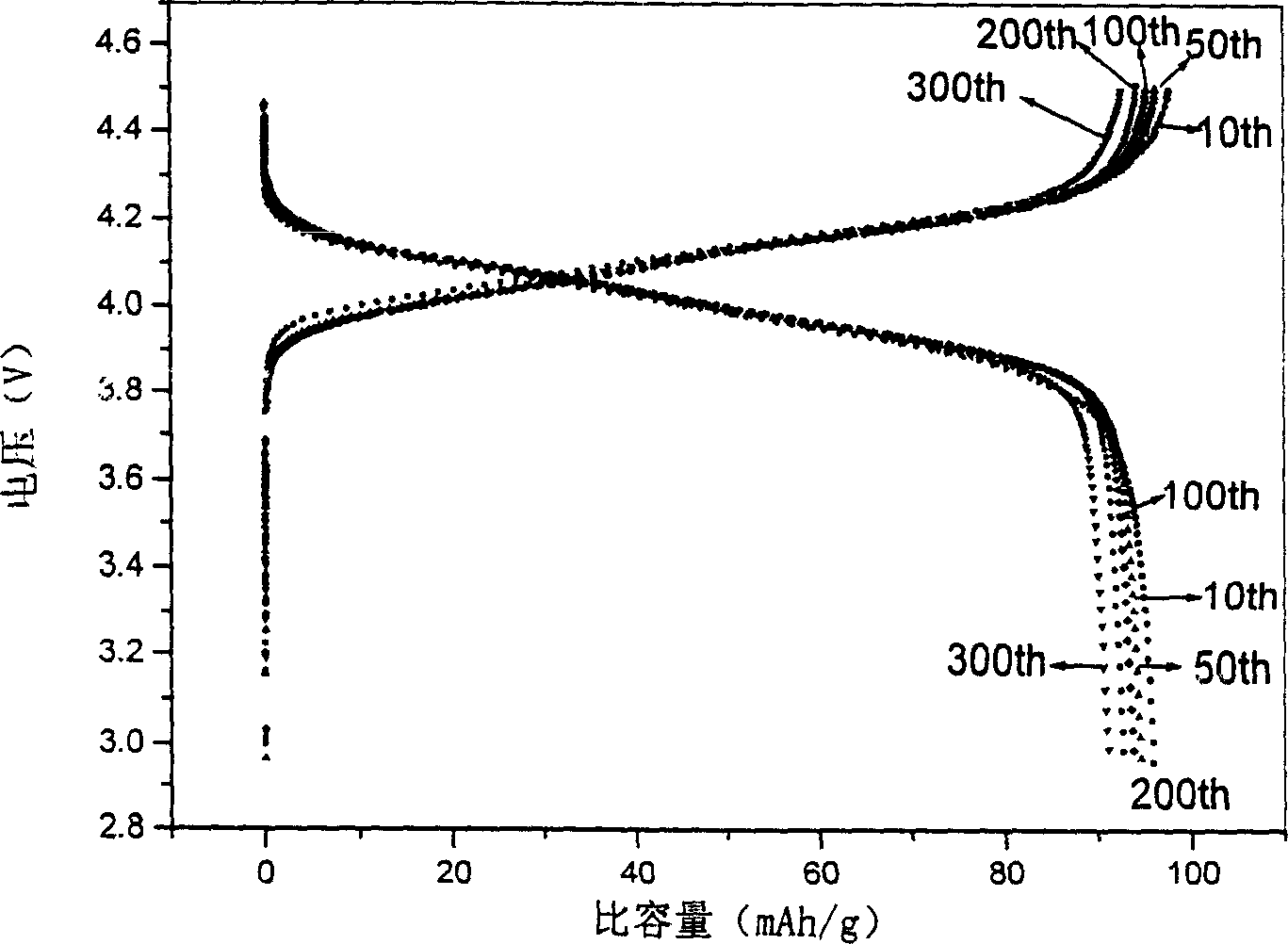

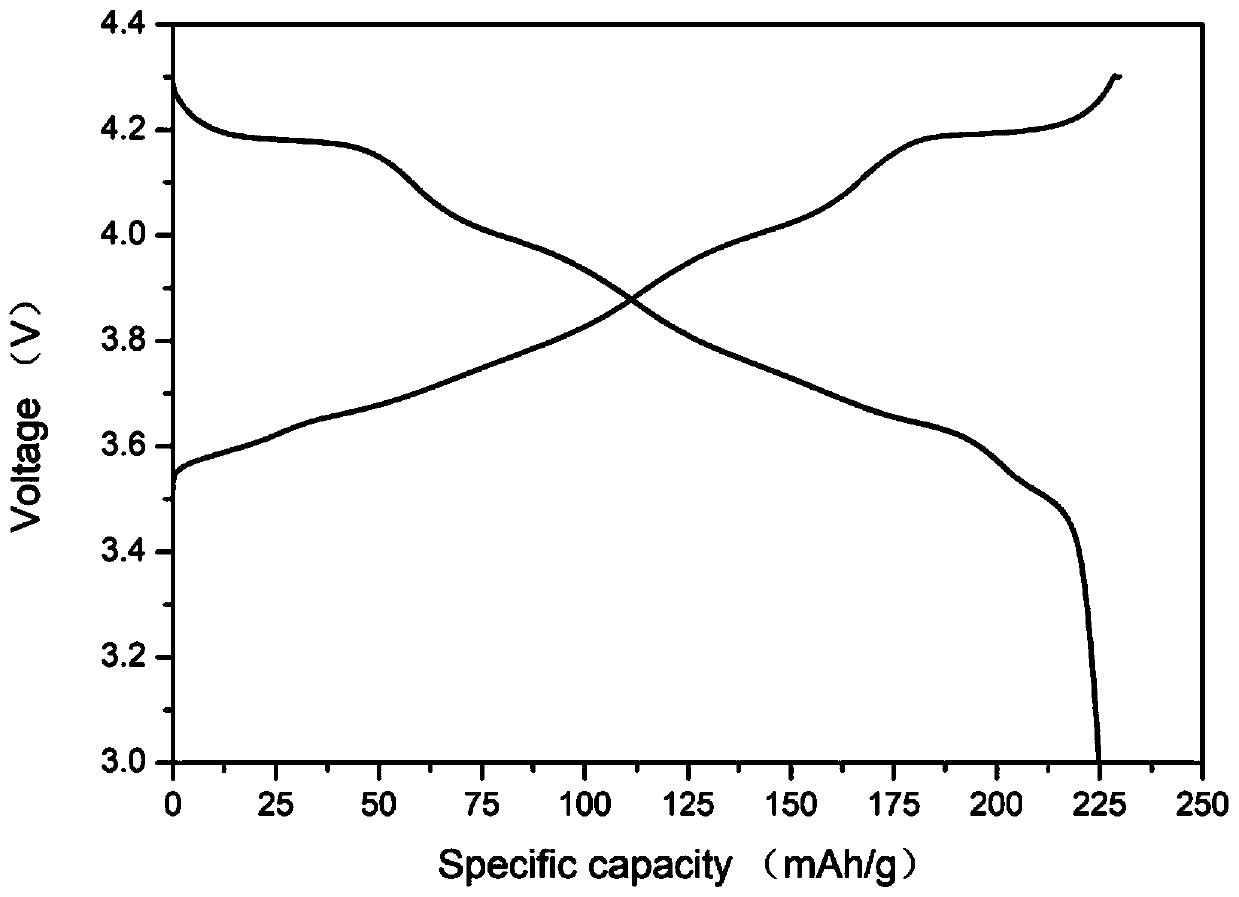

A positive electrode material for lithium secondary cell, and preparation and usage thereof

InactiveCN1595687AIncrease energy densityGood charge and discharge cycle performanceElectrode manufacturing processesIron compoundsLithiumManganese

The invention relates to positive electrode material of a lithium secondary battery, which can combine with electrolyte solution or solid electrolyte, and negative electrode active material to form lithium secondary battery. Its characteristics are: the positive electrode material of lithium secondary battery is LiMn2-zMzO4 (0<=z<=0.5.), M is chosen from Li, Mg, Co, Ni, Fe, Al, Sr, Cr, Ga, Cu and Zn. The manufacturing method for positive electrode material of the lithium 1 secondary battery, includes preparation of usher containing Mn; decorate to the covering of usher particle containing Mn; mix with lithium salt and prepare particle; sintering and other steps. By decoration of the surface of particle to usher of positive electrode containing Mn or active material itself, state of material or apparent condition of material can be changed and its capacity of powerful charge and discharge, cycle performance and thermal stability can be raised. The invention has notable advantages including low cost, capacity of powerful charge and discharge, super-long cycle performance, excellent safety, super-long circulation property and resistance to overcharge.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

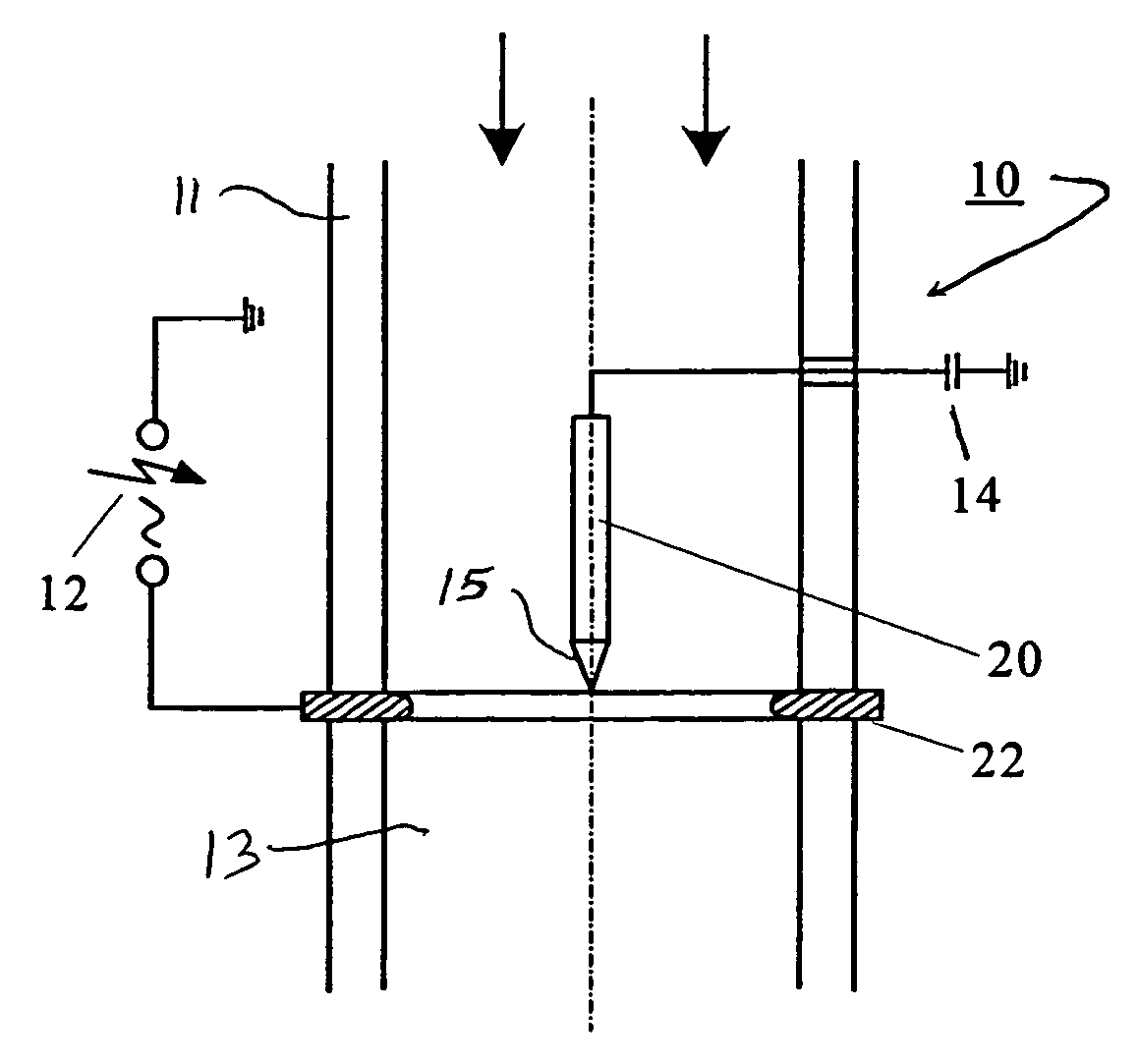

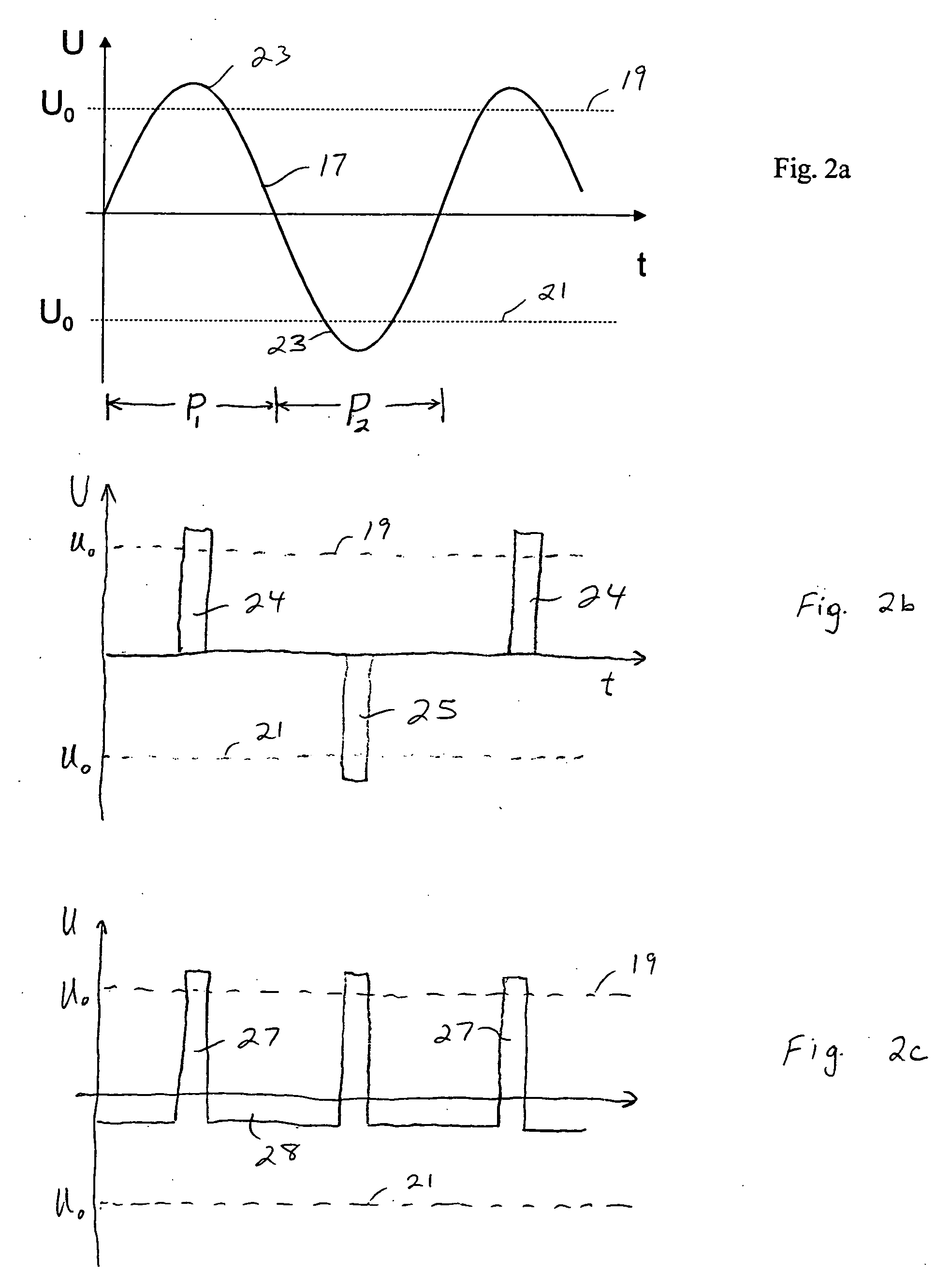

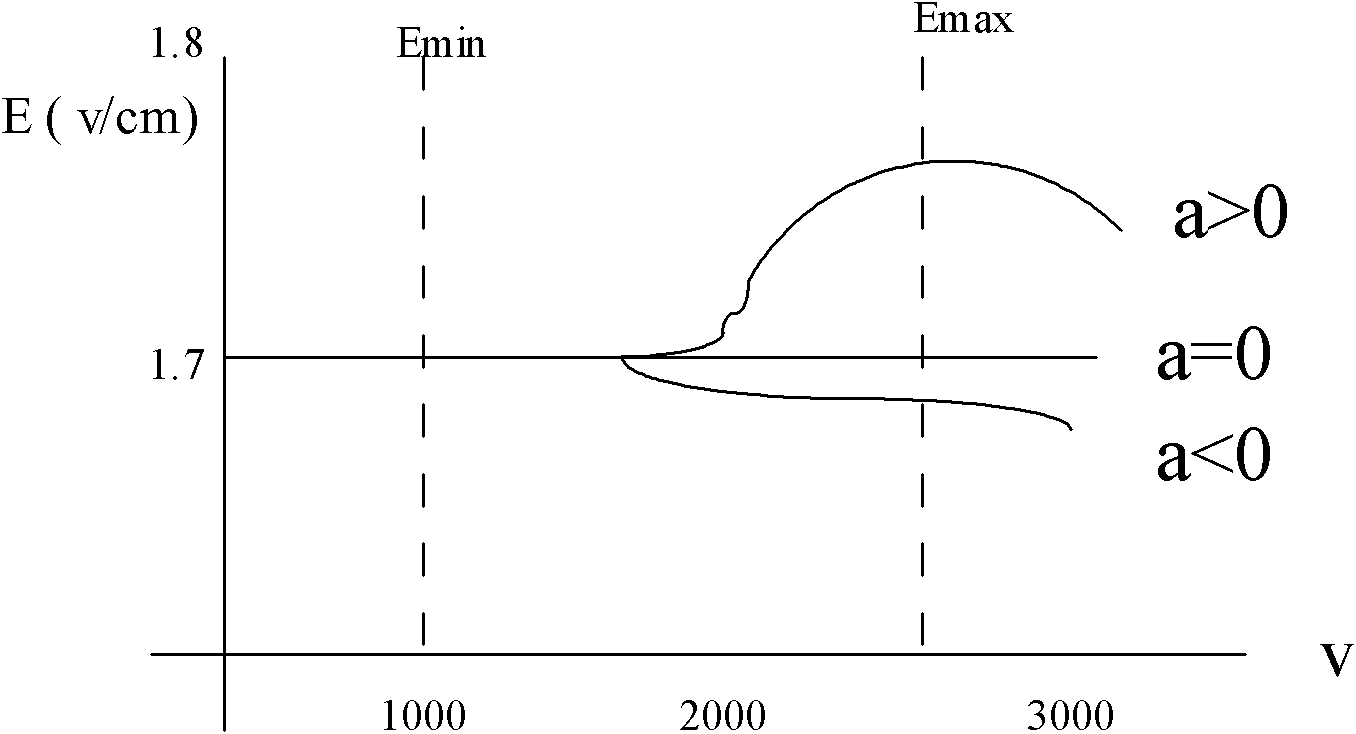

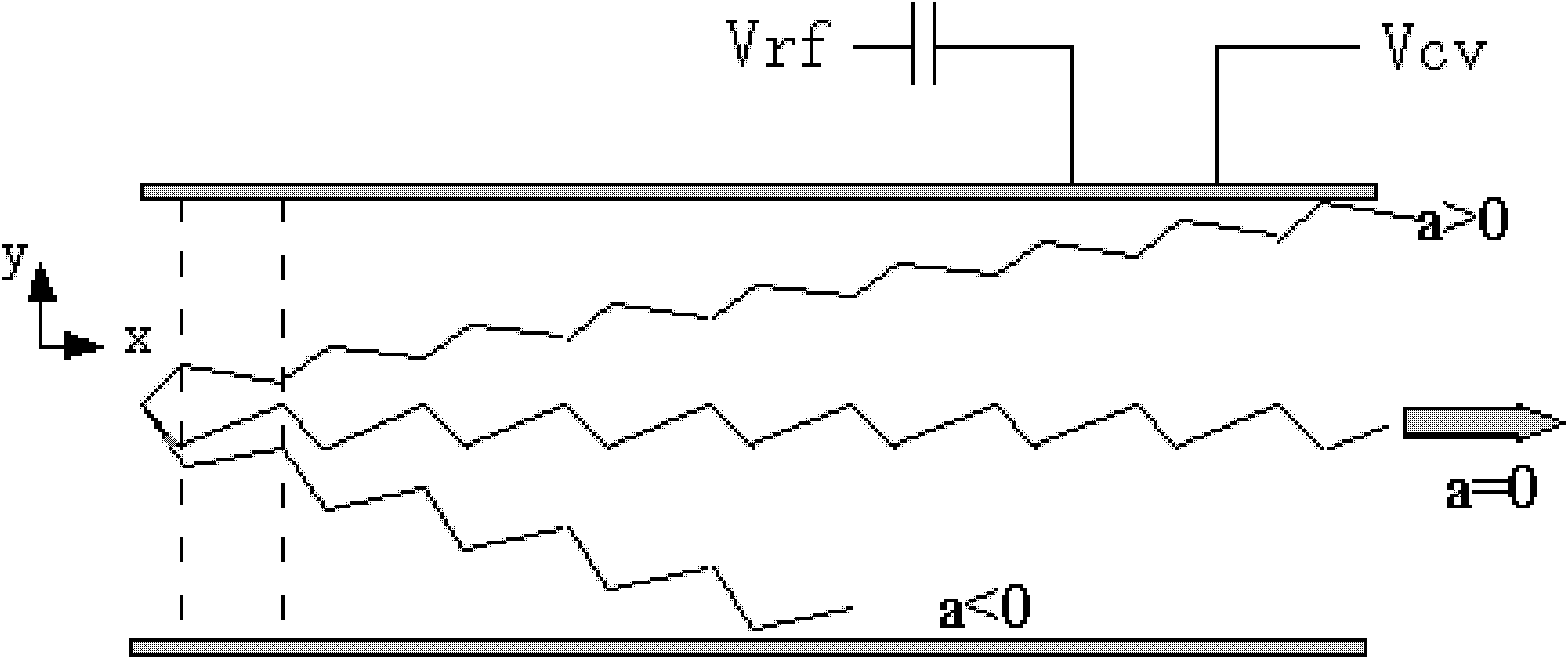

Aerosol charge altering device

InactiveUS20050083633A1Increase ion concentrationEasy to produceElectric heatingEmergency protective arrangement detailsVoltage regulationCorona discharge

The invention relates to a device for charging or adjusting the charge of gas-borne particles into a defined charge distribution under utilization of corona discharge in the aerosol space. In addition to an appropriate geometry of the charger and the electrodes, the voltage waveform and the voltage regulation are of great significance for the result. The application further relates to a method for operating the device.

Owner:TSI INC

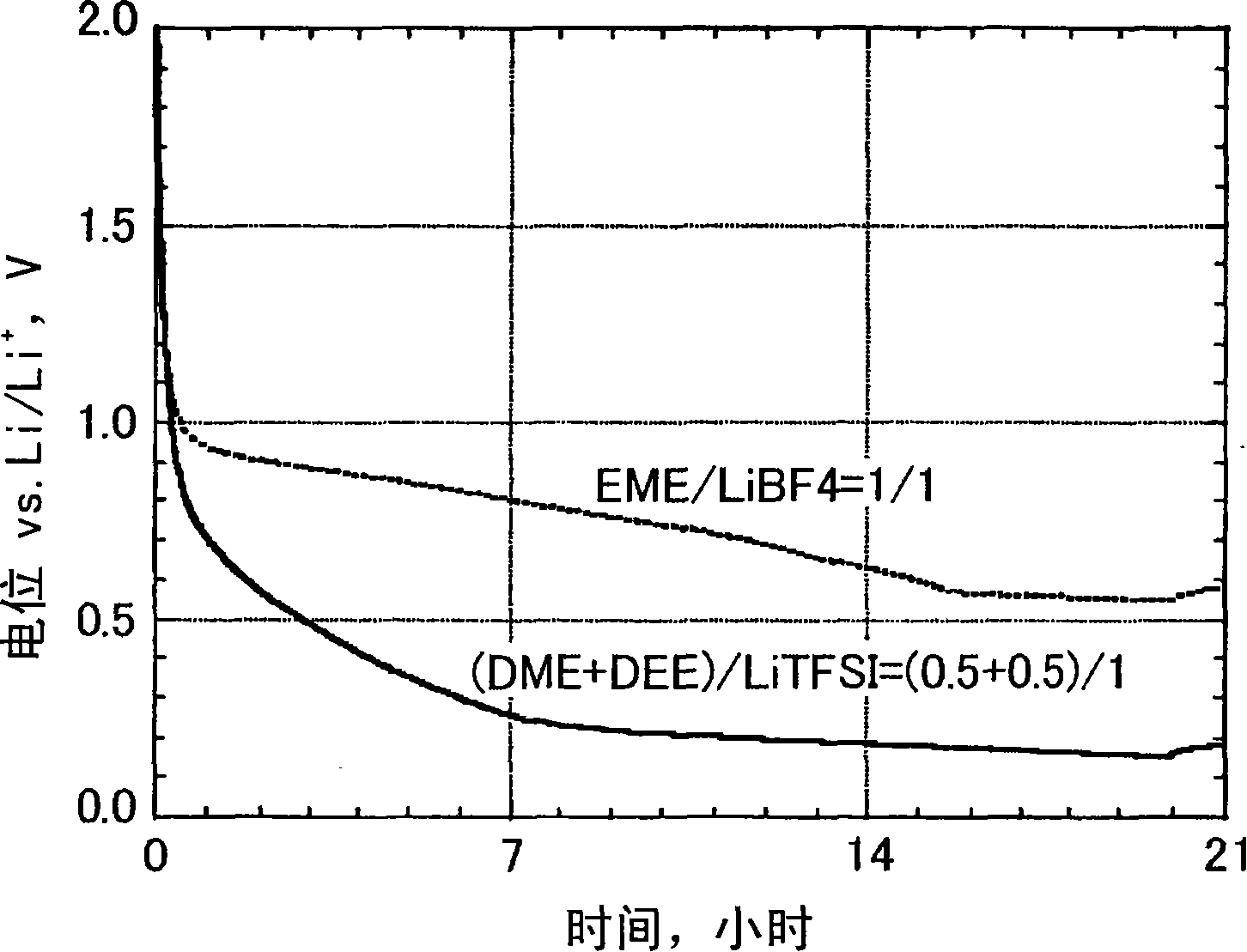

Nonaqueous electrolyte solution, electrochemical energy storage device using same, and nonaqueous electrolyte secondary battery

InactiveCN101164189AImprove stabilityIncrease ion concentrationNon-metal conductorsHybrid capacitor electrolytesLithiumCarbon number

A nonaqueous electrolyte solution being liquid at normal temperature, comprising (A) 1,2-dialkoxyethane represented by Formula: R-O-CH 2 -CH 2 -O-R' (wherein, R and R', which are same or different from each other, independently represent an unsubstituted or fluorine-substituted alkyl group having a carbon number of 3 or less) and (B) lithium bis[trifluoromethanesulfonyl]imide at a molar ratio [(A) / (B)] of 0.75 or more and 2 or less.

Owner:PANASONIC CORP

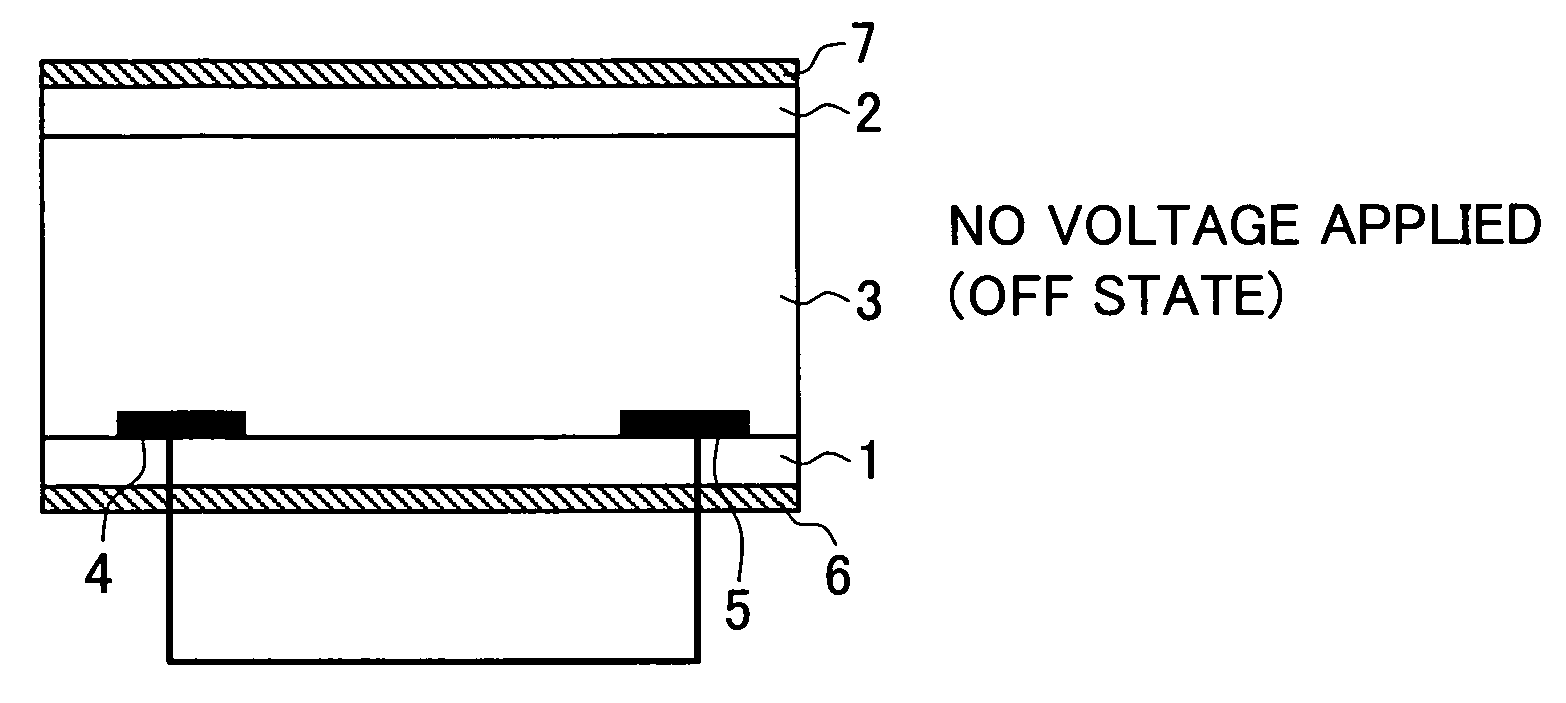

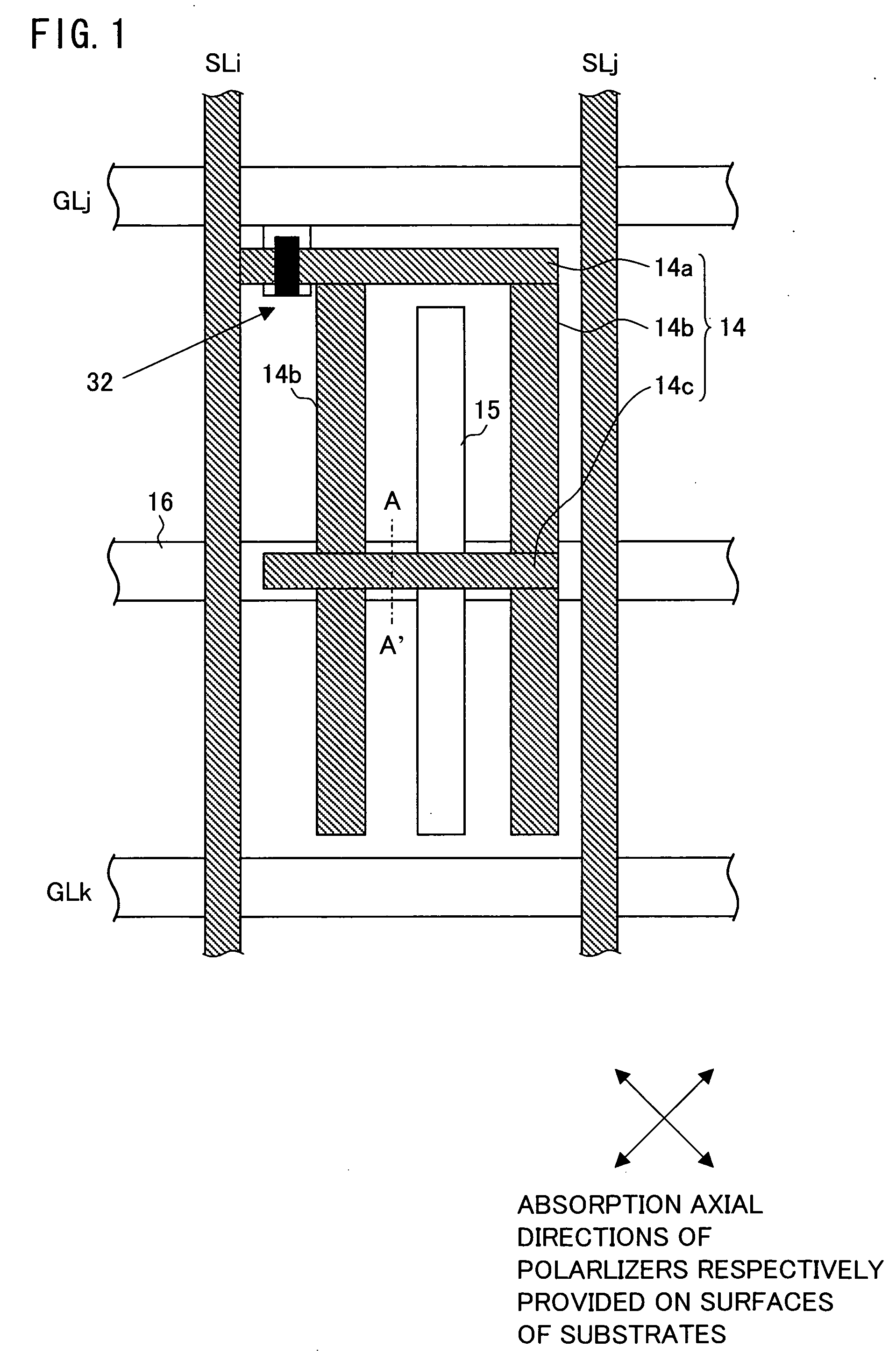

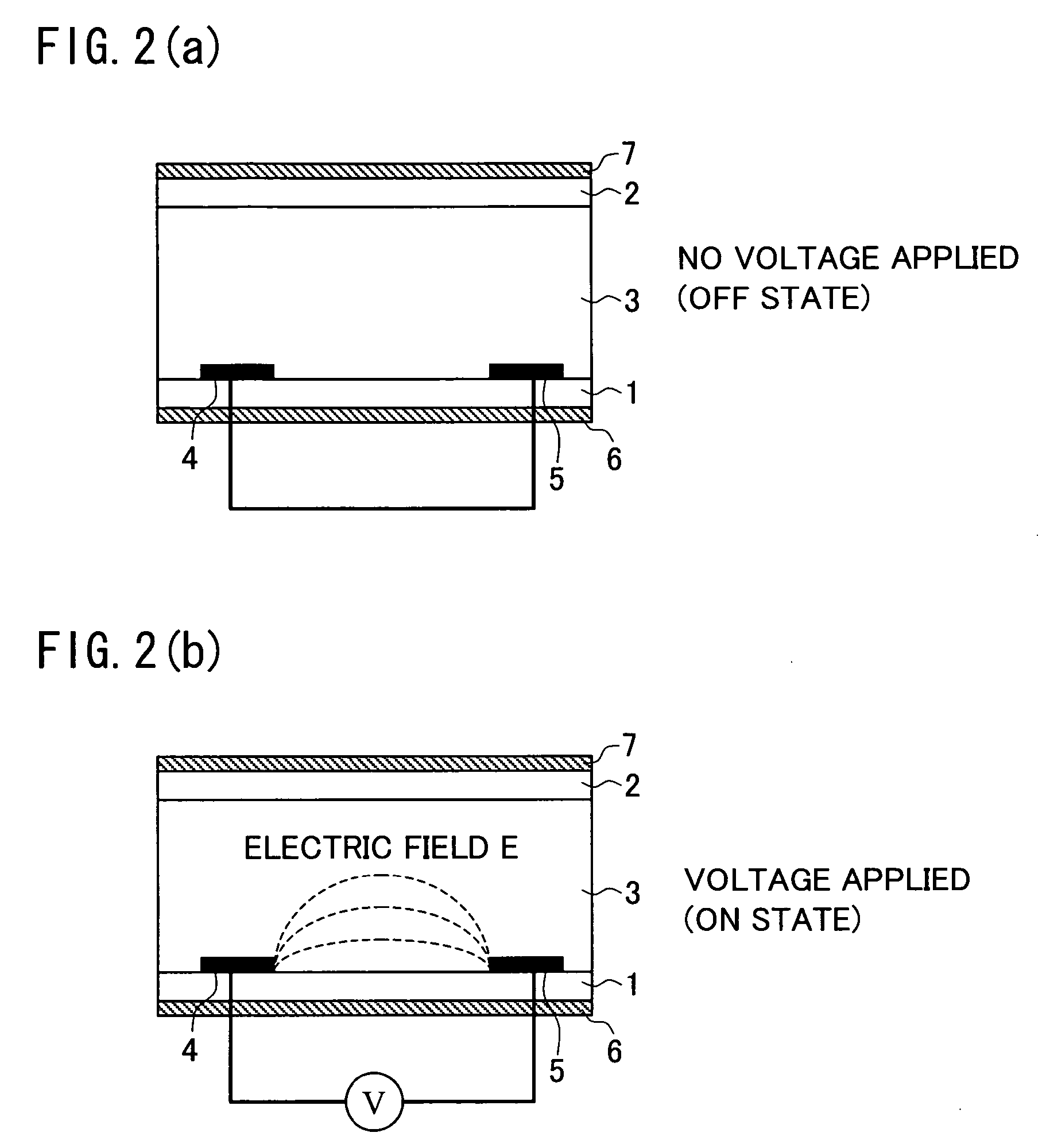

Display element and display apparatus

InactiveUS20050179632A1Reduce degree changeDegree of change is smallStatic indicating devicesNon-linear opticsElectric fieldPhysics

A display element includes: a pair of substrates, at least one of which is transparent; a medium, between the substrates, the medium being changeable in an optical anisotropy magnitude by and according to electric field application; and a region in which a pixel electrode and a counter electrode overlap with each other with an insulating layer therebetween.

Owner:SHARP KK

Composite solid polymer electrolyte film and preparation method and application thereof

InactiveCN109546207AReduce the degree of crystallizationHigh mechanical strengthSolid electrolytesSecondary cellsSlurryElectrochemistry

A composite solid polymer electrolyte film and a preparation method and an application thereof are provided. The preparation method includes the following steps: dissolving a polymer in an organic solvent, and stirring the solution evenly after ultrasonic dispersion; adding lithium salt, nano-ceramic particles, ionic liquid and plasticizer, and stirring the mixed solution evenly to form slurry; applying the slurry to a glass plate to form a liquid film; and drying the liquid film to obtain a composite solid polymer electrolyte film. The composite solid polymer electrolyte film of the inventionhas high room-temperature ionic conductivity and mechanical strength, is prepared through a simple process and can be mass-produced. Moreover, the composite solid polymer electrolyte film of the invention has good electrochemical performance when applied to lithium ion batteries.

Owner:XI AN JIAOTONG UNIV

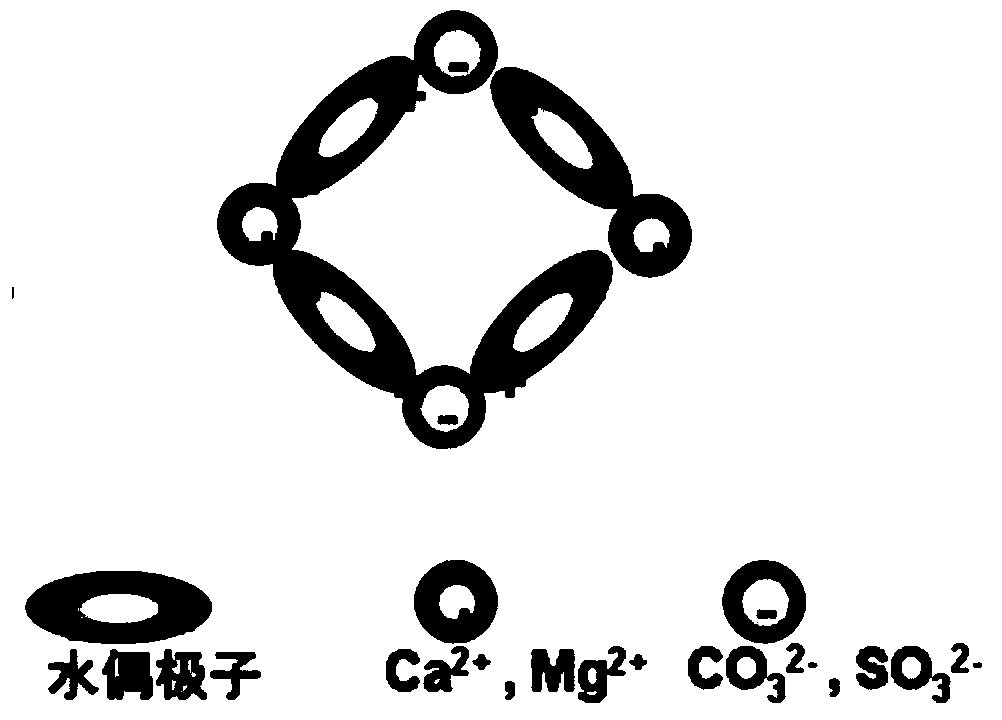

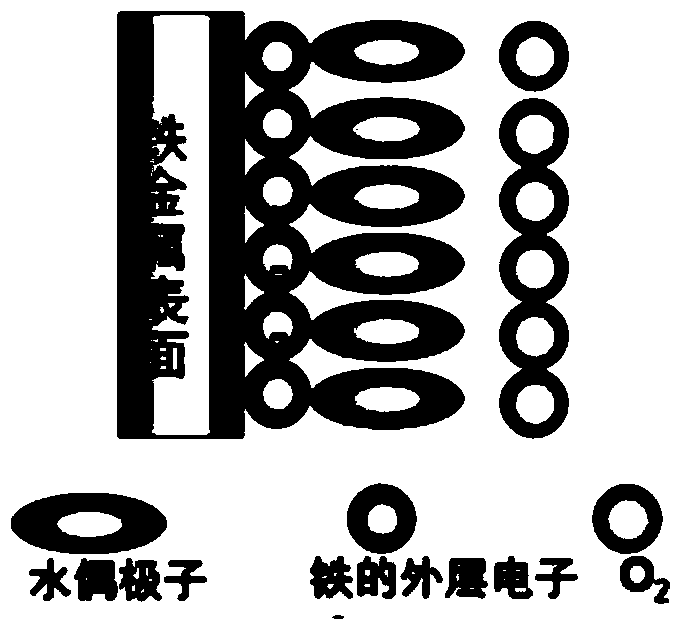

Scale-inhibition copper-based catalyst alloy and preparation method thereof

ActiveCN103805808APrevent scale formationStrong ability to dissolve scaleMetal/metal-oxides/metal-hydroxide catalystsWeak currentElectricity

The invention discloses a scale-inhibition copper-based catalyst alloy and a preparation method thereof. The catalyst alloy comprises the following components in percentage by weight: 40%-70% of Cu, 5%-20% of Ni, 10%-35% of Zn, 5%-30% of Sn, 0.5%-20% of Ag, 0.1%-8% of Fe, 0.01%-2% of Sb and 0.05%-5% of Mn, wherein the components are chemically compounded to form a columnar crystal alloy directionally growing along an S100 crystal axis. The scale-inhibition copper-based catalyst alloy is used for inhibiting the formation of water scale by virtue of an advanced weak-current composite scale-inhibition mechanism on the premise that chemical components of fluid are not changed and has very strong water scale dissolving capacity; the additional maintenance does not need to be carried out in an operation process, the magnetism, the electricity and an additional power supply are not required.

Owner:NANJING CHAOXUSCIENCE&TECH DEV

Method for preparing calcium carbonate powder

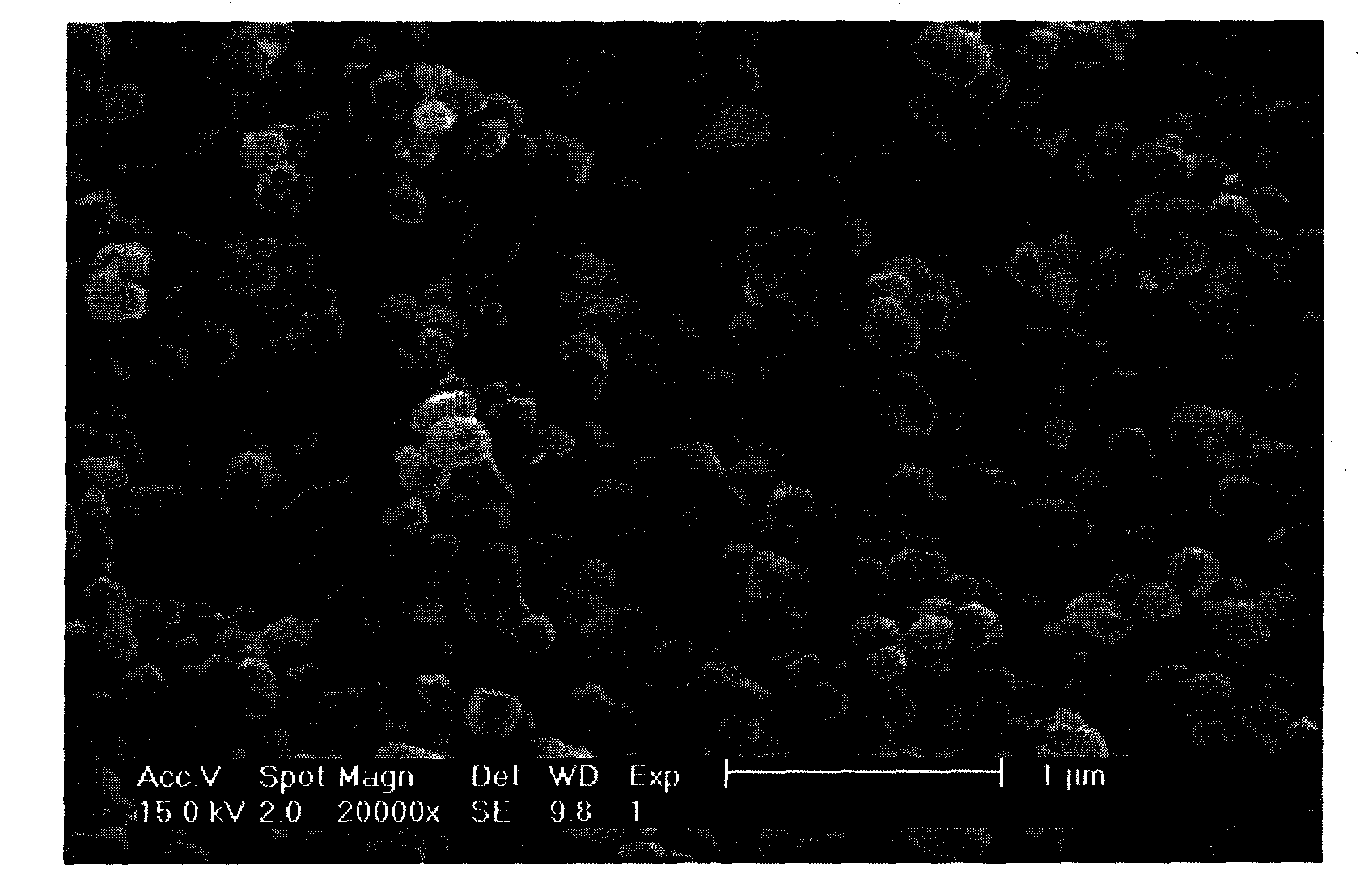

InactiveCN101591033AUniform particlesParticle boostCalcium/strontium/barium carbonatesGranularityRoom temperature

The invention discloses a method for preparing calcium carbonate powder, which comprises the following steps: A, adding an impurity removal agent into calcium chloride solution, heating the mixture until the mixture is boiled for 30+ / -5 minutes while stirring, then standing the mixture for 4+ / -1 hours, and filtering the solution into a reaction kettle when the temperature of the solution is reduced to the room temperature; B, adding sodium hydroxide solution of which the molar ratio is 1.0 to 1.2 into the solution obtained in the step A, and then stirring the mixture circularly; and C, in the stirring state, introducing carbon dioxide into the solution of the step B to perform carbonization reaction, controlling the reaction temperature between 20 and 35 DEG C in the process of the carbonization and stopping the reaction when the pH is equal to between 6 and 7, and finally filtering, washing and drying the prepared calcium carbonate powder. The prepared submicron high-performance superfine calcium carbonate powder has a specific area of 6 to 9 square metes per gram and narrow grain size distribution, and is quite suitable to be applied to high-end MLCC products.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Aluminum alloy rare earth passivating liquid taking chlorine salt as accelerator and use method thereof

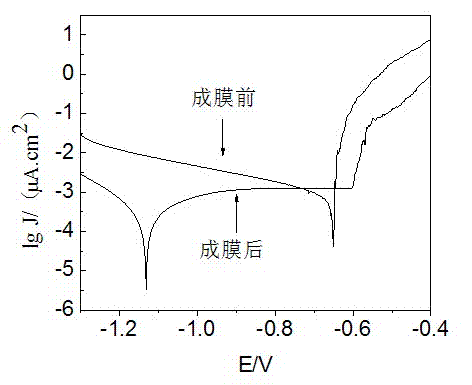

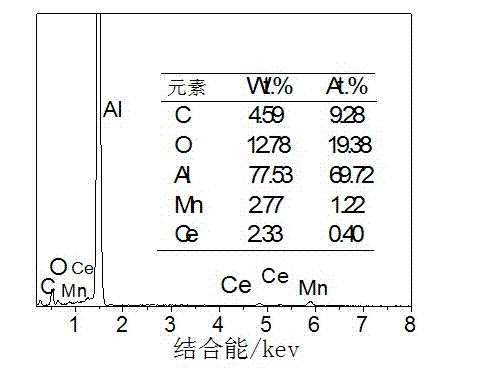

InactiveCN102234800AImprove corrosion resistanceImprove solubilityMetallic material coating processesPhysical chemistryCerium

The invention discloses an aluminum alloy rare earth passivating liquid taking a chlorine salt as an accelerator. The aluminum alloy rare earth passivating liquid can simultaneously meet the requirements of fast film formation and maintain a treatment liquid to be stable for a long term. The rare earth passivating liquid consists of the following components: 5-25g / L of cerium salt, 1-5g / L of oxidant and 0.1-1.5g / L of film-forming accelerator. By addition of the accelerator, aluminum alloy can be filmed at room temperature within 4-15 minutes, and the service life of a rare earth conversion liquid can be maintained so that the rare earth conversion liquid is not precipitated for more than 30 days. According to the invention, an additive is non-toxic and environmentally-friendly, the corrosion resistance of the aluminum alloy subjected to film formation is good, operation is simple, and batch production is easily carried out.

Owner:SOUTH CHINA UNIV OF TECH

Flue gas deep desulfurization and dust removal device and method by use of carbide slag-gypsum method

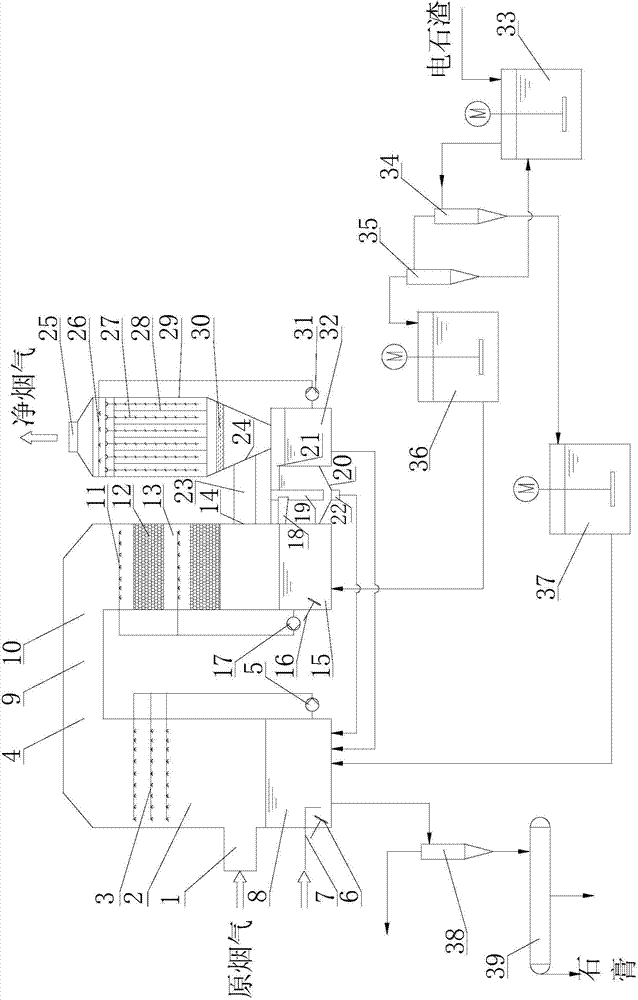

ActiveCN104740992ASignificantly environmentally friendlySignificant comprehensive benefitsDispersed particle separationExternal electric electrostatic seperatorCycloneSlag

The invention discloses a flue gas deep desulfurization and dust removal device and method by use of a carbide slag-gypsum method. The flue gas deep desulfurization and dust removal device comprises a desulfurizing tower, a wet type electric precipitation demister, a sedimentation tank, a dehydration system and a grout preparation system, wherein the two-stage desulfurizing tower is connected with the wet type electric precipitation demister in series, and compared with a traditional double-tower double-circulation desulfurization process, the method has the desulphurization efficiency up to 99% and more, and the occupying space of the desulfurizing tower can be effectively reduced; carbide slag is used as a desulfurizing agent, a method of waste control by waste is utilized, the method is environmentally friendly and has the remarkable economic benefit; two-stage cyclone classification grouting is adopted, and grouts with different specifications can be prepared, while the absorption efficiency of the desulfurizing tower is ensured, a filling layer inside the desulfurizing tower can be prevented from blockage effectively; the wet type electric precipitation demister is combined to further improve the dedusting efficiency, and the device and the method can be used for achieving zero emission of dust such as PM2.5 particularly.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

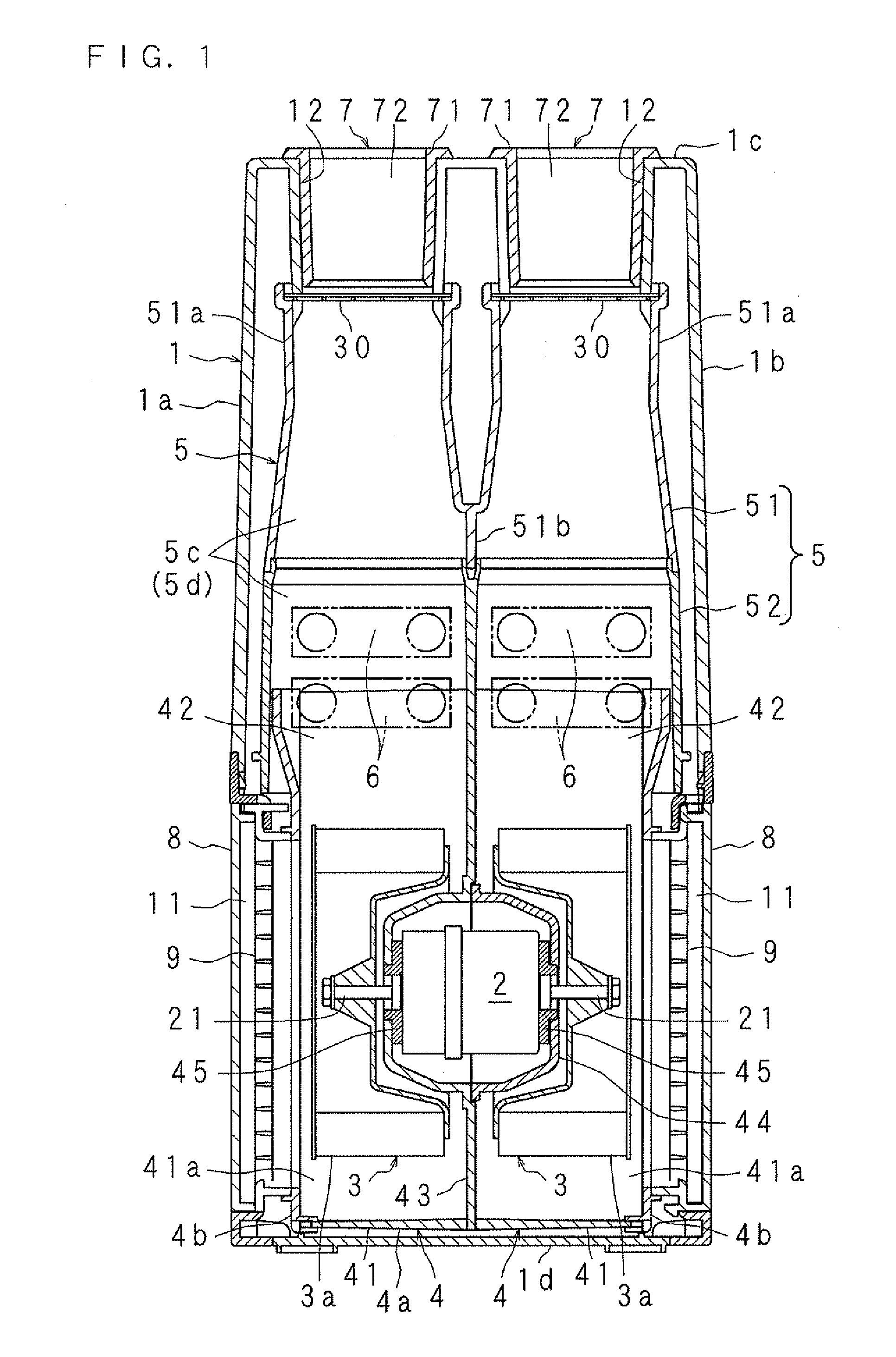

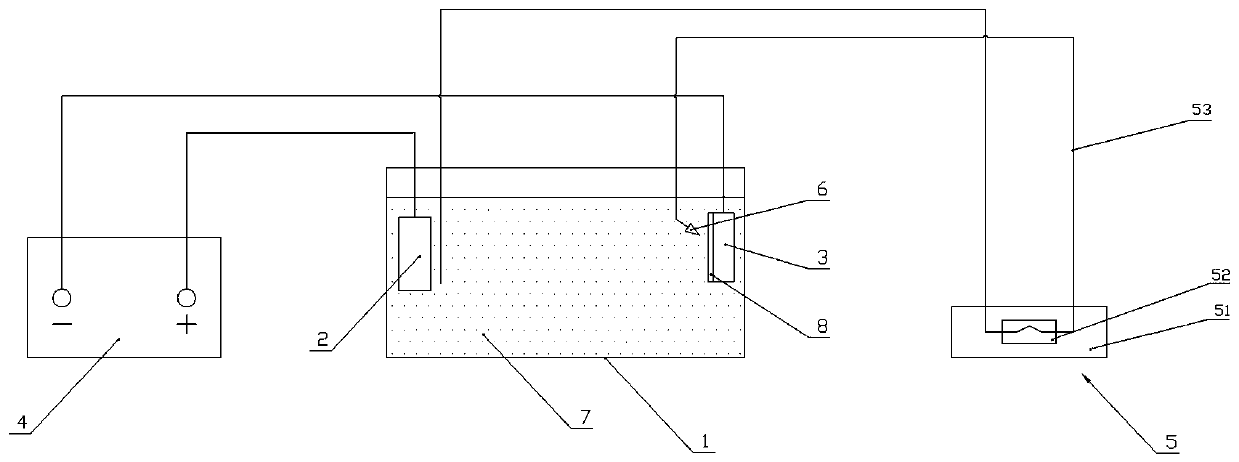

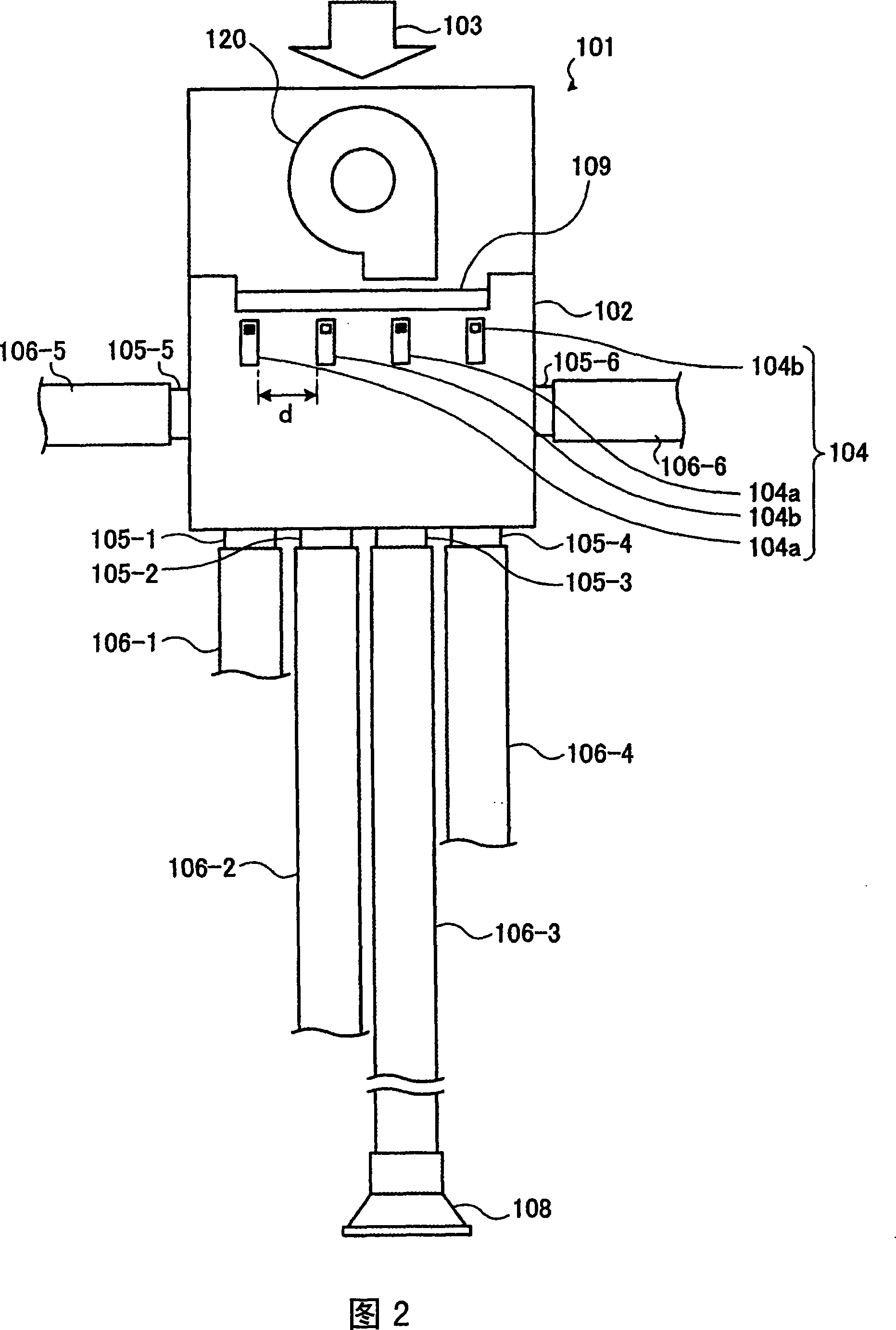

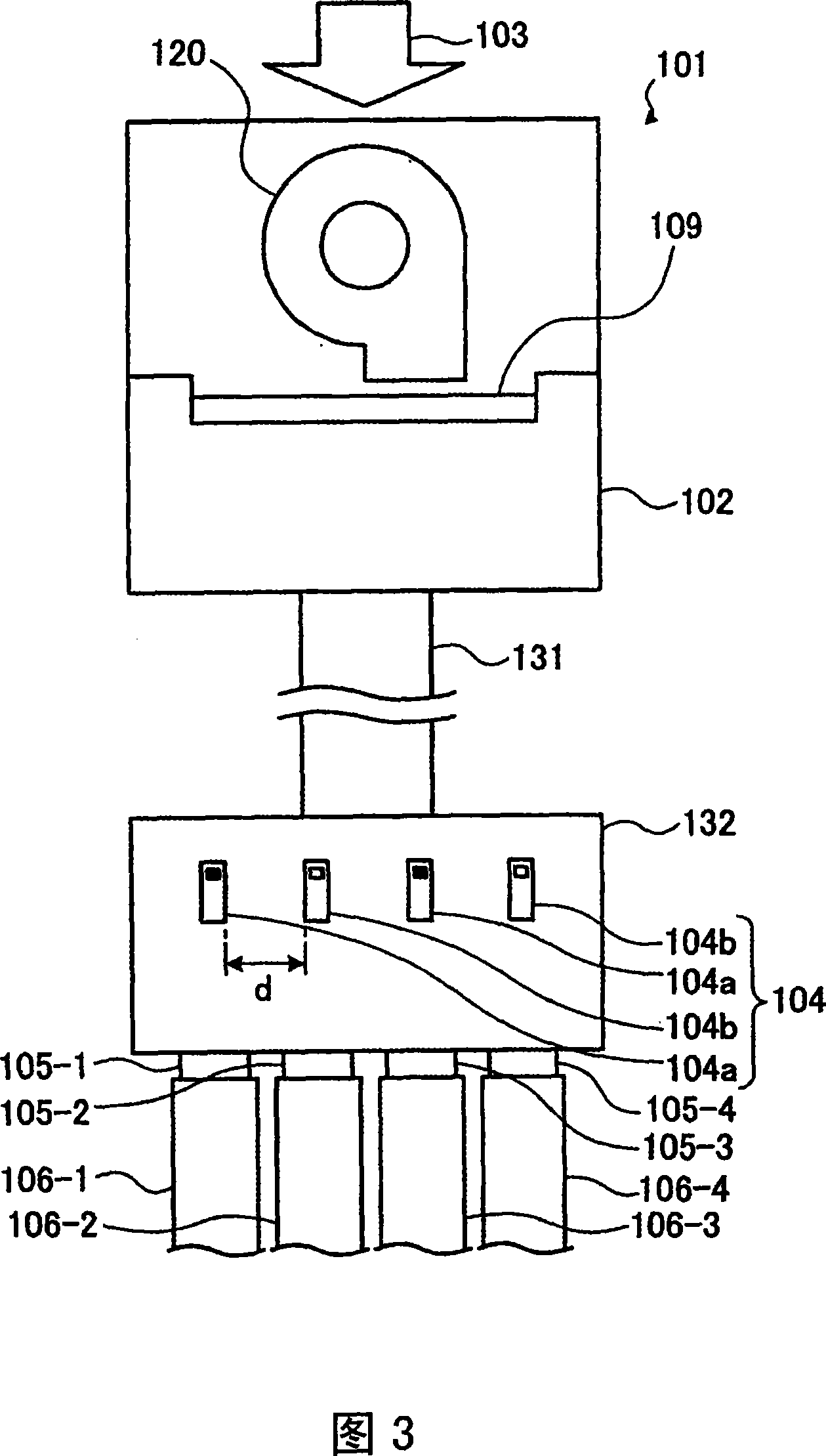

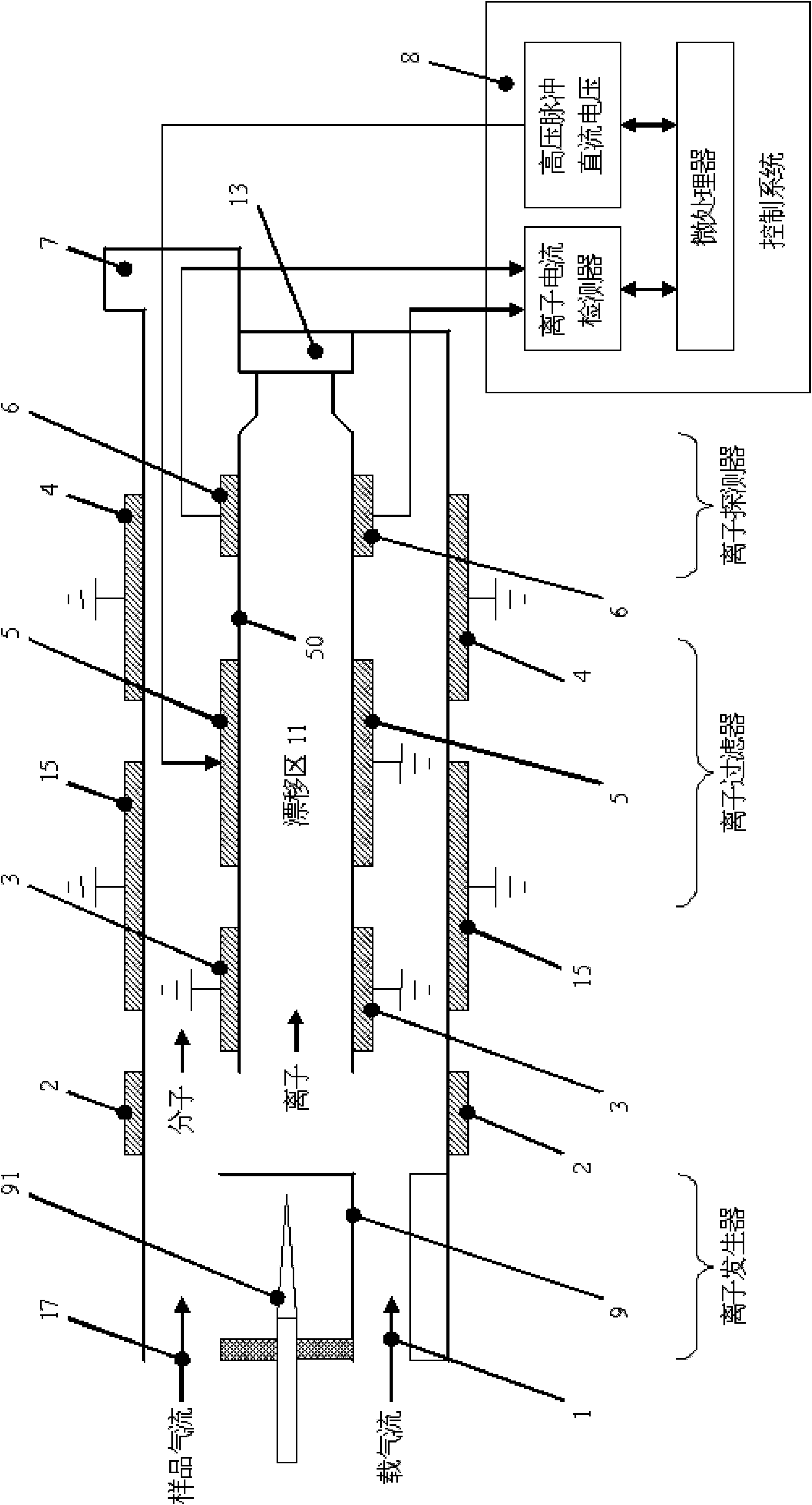

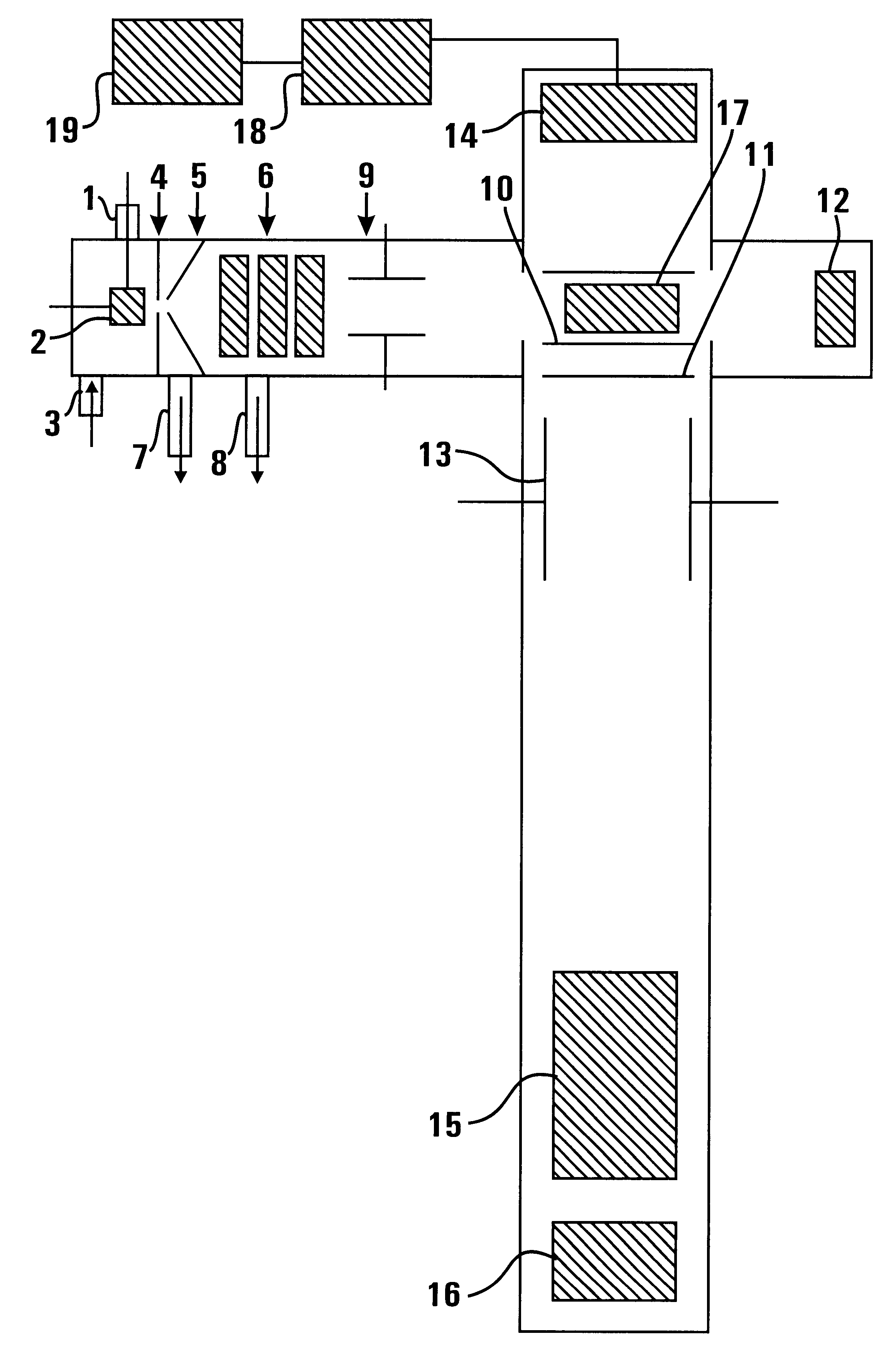

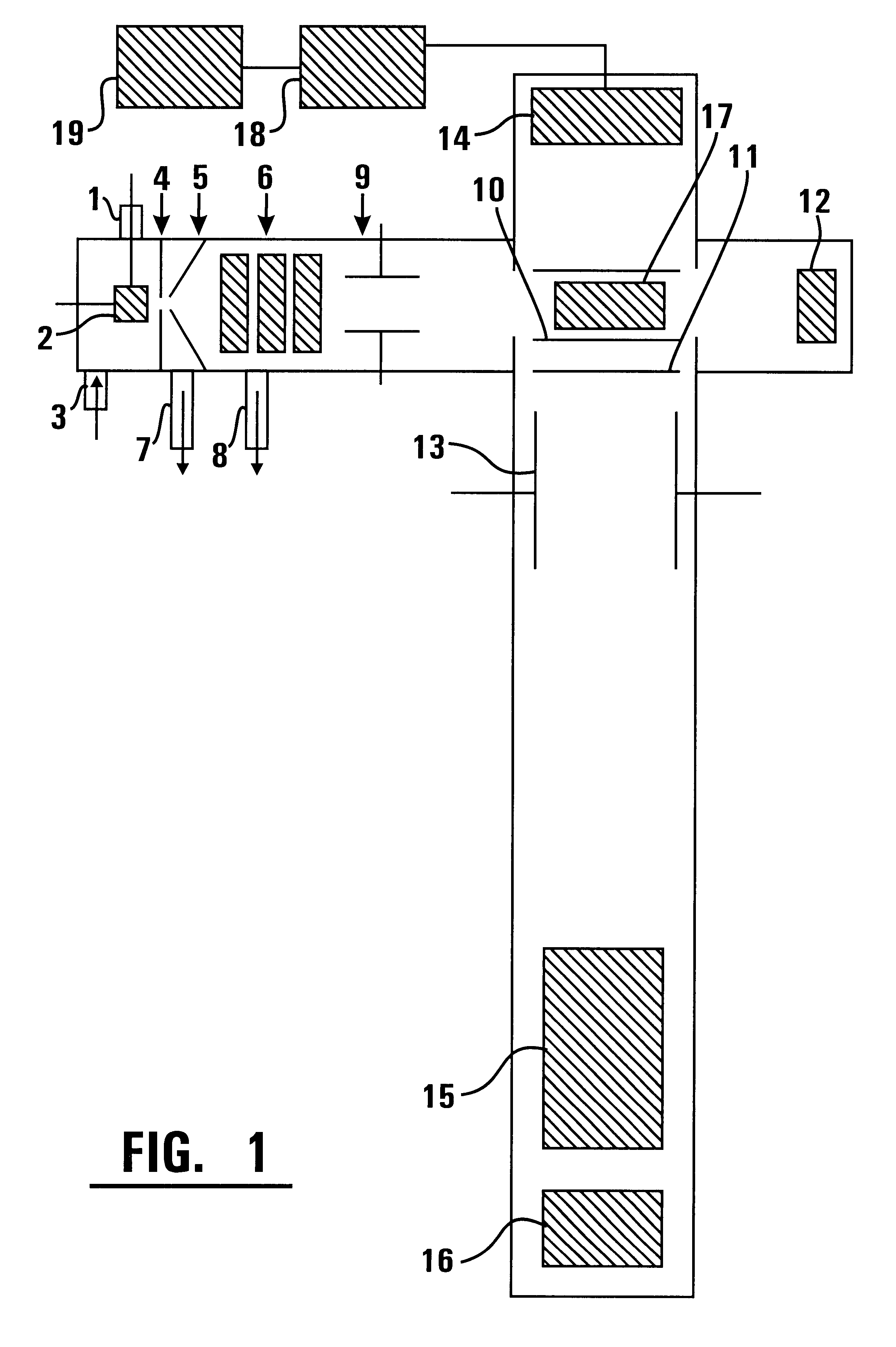

Ion detecting apparatus and ion generating apparatus

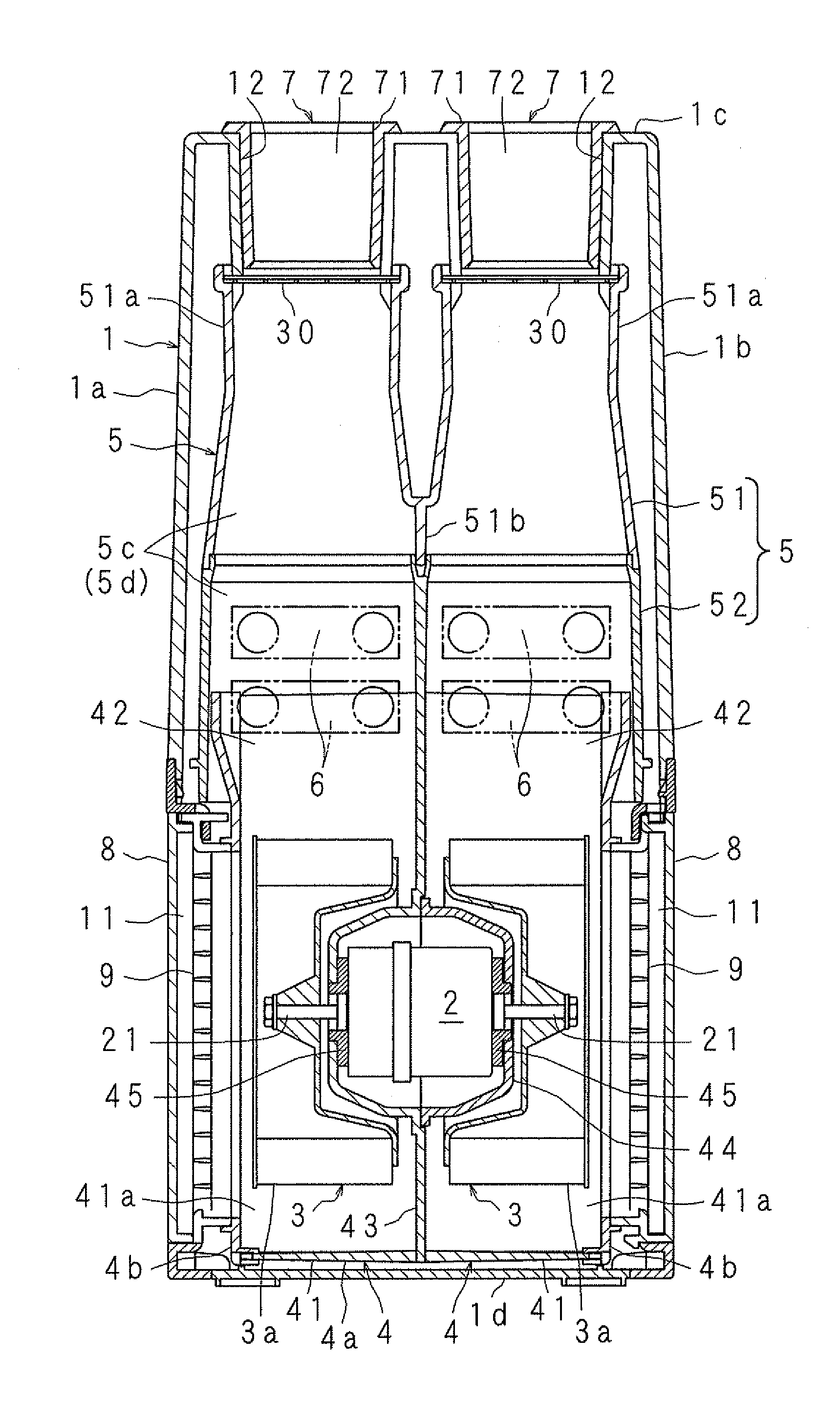

ActiveUS20110155922A1Reduce the possibilityGood effectMechanical apparatusLighting and heating apparatusImpellerEngineering

An air blower including a motor 2 having output shafts 21, 21 on both sides in the axial direction and two impellers 3, 3 mounted on the respective output shafts 21, 21, and two ducts 5, 5 that individually allow passage of the air blown out by rotation of each of the impellers 3, 3 in the same direction and discharge the air to the outside are included. At a part or the whole of each of the ducts 5, 5, a laminar flow section that makes the flowing air laminar flow. An ion generating section is arranged at each laminar flow section so that ions generated by the ion generating section can effectively be included in the air, increasing the ion concentration of ions discharged in a room together with the air.

Owner:SHARP KK

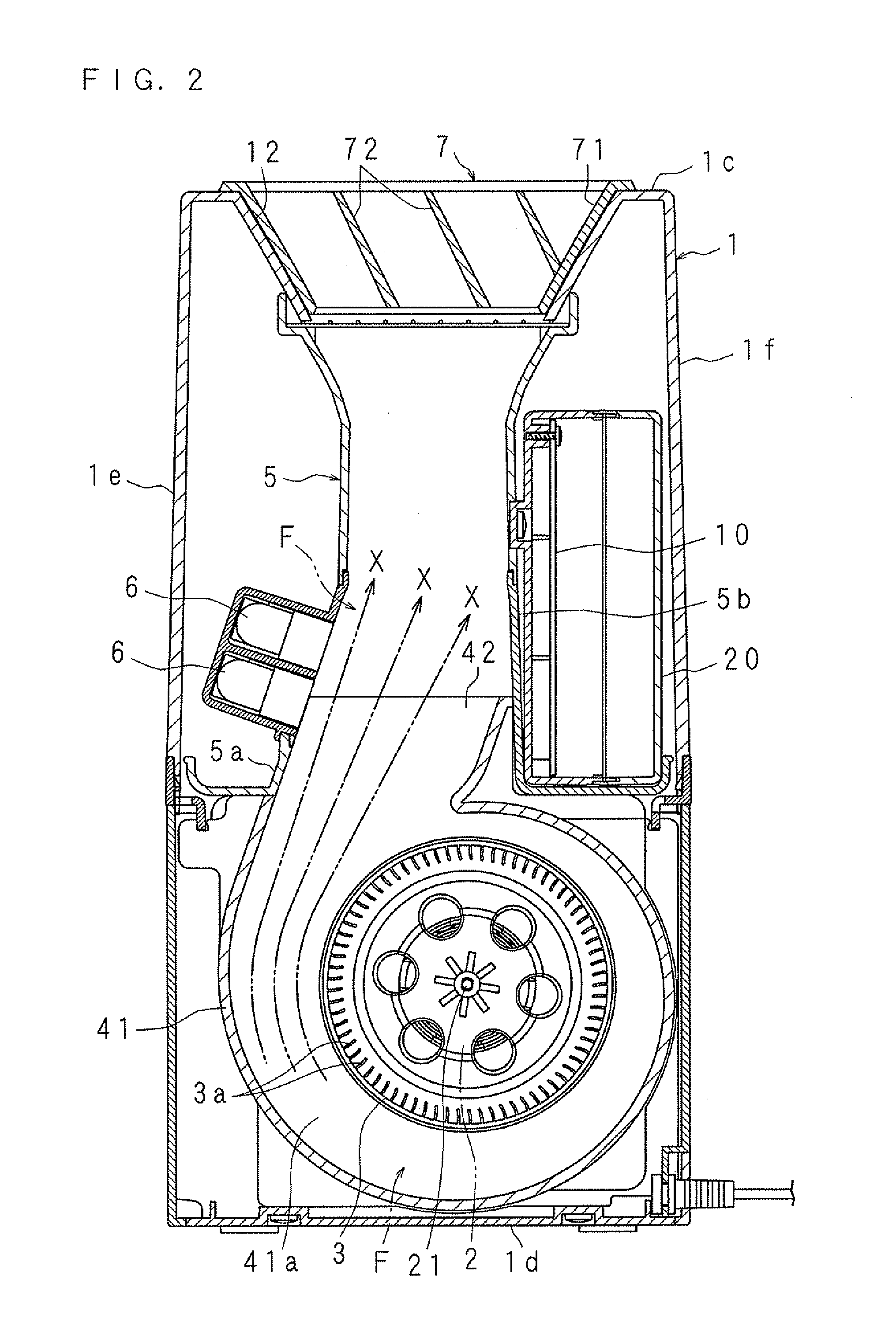

Method for processing quick-frozen fresh lotus

ActiveCN101965860AReduce damage and softenReduce the temperature difference between inside and outsideFruit and vegetables preservationBiotechnologyBrowning

The invention provides quick-frozen fresh lotus processing technology. In the technology, a quick-frozen fresh lotus finished product is obtained by the harvesting of fresh lotus, shelling, stripping, core hollowing, low-temperature vacuum filling, impregnation for pre-cooling, draining, quick-freezing, packaging and cold storage. Due to the adoption of the low-temperature vacuum filling technology to combine pre-cooling, color conservation and anti-freezing processes, the technology inhibits the activity of PPO and POD, prevents the browning of the quick-frozen fresh lotus in the processing and storage, reduces the damage and softening of tissue cells, endows the product with crisp texture and faint scent, improves the ion concentration and osmotic pressure of the cells of the fresh lotus, effectively rises the vitrification transition temperature, promotes the exhaust of air from tissues, reduces the swelling pressure of ice crystals, prevents low-temperature breakage, shortens the processing time, is easy to control, high in operability, less in energy consumption and suitable for the large-scale production of the quick-frozen fresh lotus, and develops a new way for the deep processing of the lotus industry. The product completely keeps the original taste and smell of the fresh lotus, has the faint scent and is convenient to take.

Owner:福建闽江源绿田实业投资发展有限公司

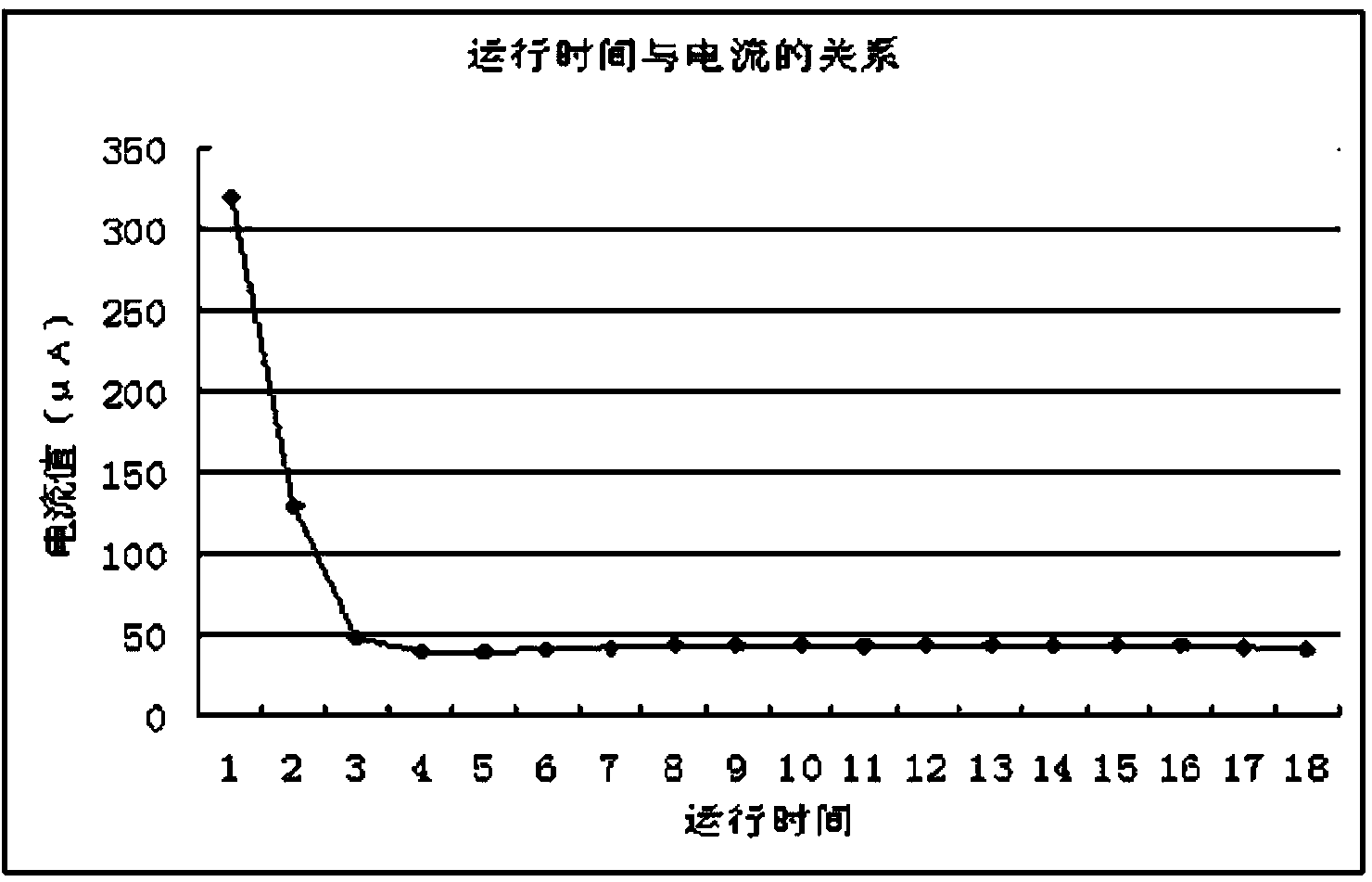

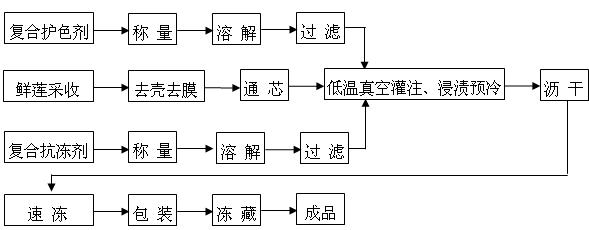

Full-intelligent scale-preventing and scale-removing alloy and preparation method thereof

The invention discloses a fully intelligent anti-scaling and descaling alloy, which comprises the following components by weight percentage: Cu: 40%-70%, Ni: 5%-20%, Zn: 8%-35%, Sn: 5% ‑30%, Ag: 0.5%‑20%, Fe: 0.1%‑8%, Nb: 0.01%‑3%, Mn: 0.05%‑5%, V: 0.01%‑2%, C: 0.01%‑0.5 %, the components are smelted at high temperature to form a columnar crystal alloy that grows oriented along the S110 crystal axis. The activation current of the invention is about 80 μA, and the stabilization time is about 150 minutes, which not only fully meets the engineering application requirements of scale inhibitors, but also increases the activation current by about 60% compared with the existing copper-based catalyst products, and the composition is more reasonable and safe, and the processing cost is also lower. Low.

Owner:NANJING CHAOXUSCIENCE&TECH DEV

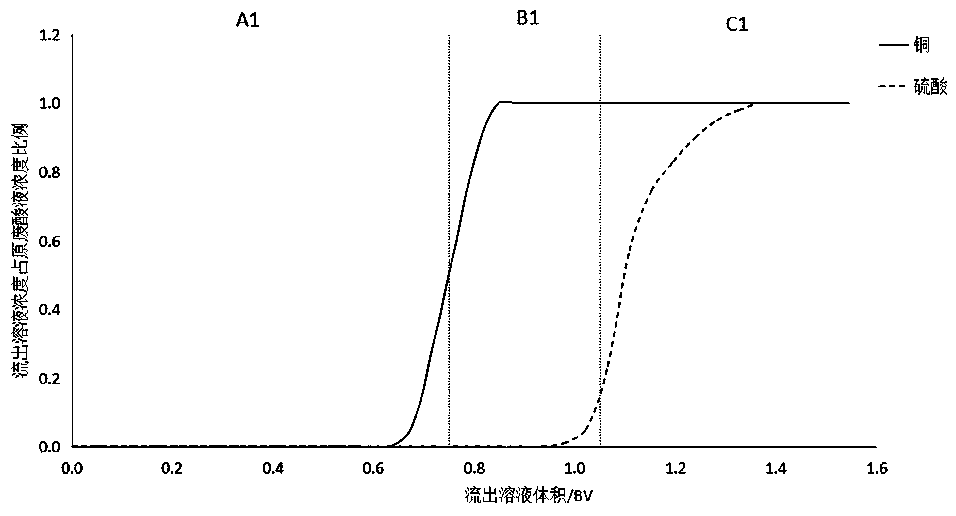

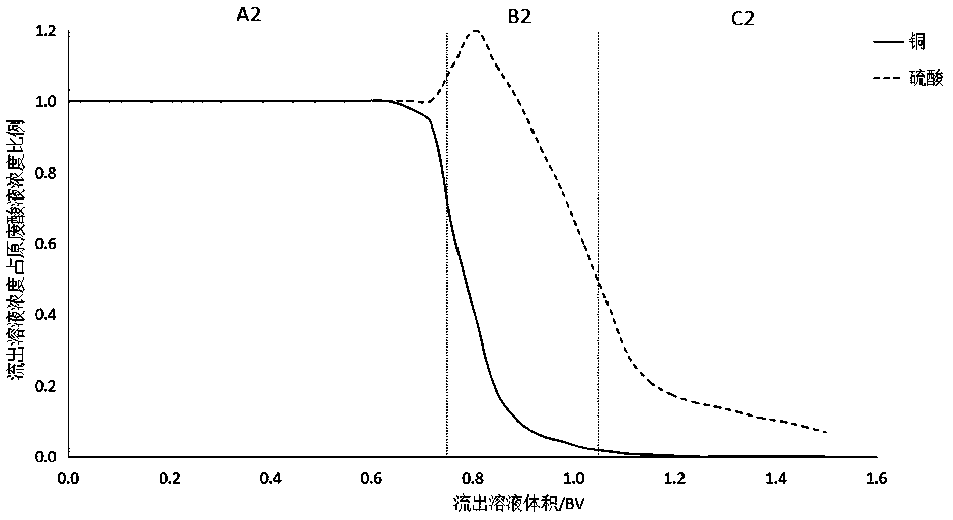

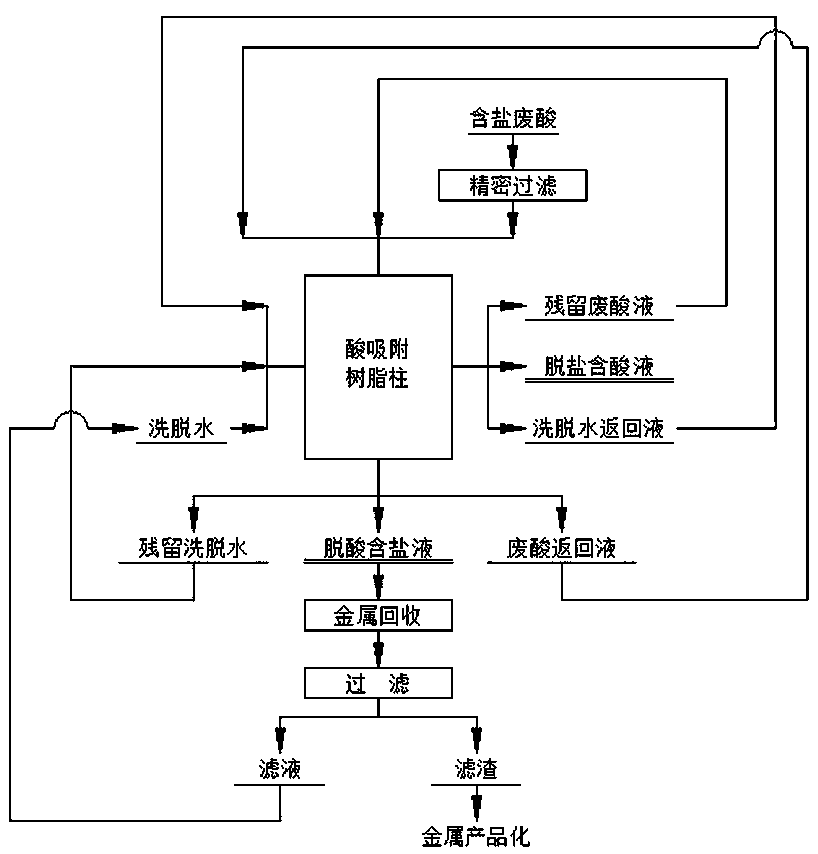

Process for separation of acid and salt in salt-containing waste acid

ActiveCN110902922ALarge amount of processingSeparation effect optimization adjustmentSpecific water treatment objectivesTreatment involving filtrationDesalinationEnvironmental engineering

The invention discloses a process for separation of acid and salt in salt-containing waste acid. The process includes: subjecting salt-containing waste acid to multi-period adsorption-elution treatment by an acid adsorption resin column, during adsorption, passing waste acid return liquid, residual waste acid liquid and a salt-containing waste acid stock solution obtained in a previous period sequentially through acid adsorption resin from the bottom up for acid adsorption, collecting residual elution water, deacidified salt-containing liquid and waste acid return liquid successively, stoppingliquid feeding after the volume meeting the requirement, completely feeding salt-containing waste acid in the first period, during elution, passing elution water return liquid, residual elution waterand elution water obtained in a previous period through acid adsorption resin from top to bottom in sequence for elution, and collecting residual waste acid liquid, desalted acid-containing liquid and elution water return liquid successively, stopping water inflow after the volume meets the requirement, completely feeding elution water in the first period, and performing repetition till completing treatment of the salt-containing waste acid. The process disclosed by the invention can be used for separation of various acids and cations, has good separation effect, is not limited by the heightof the resin column, does not generate volume expansion, and has wide applicability.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

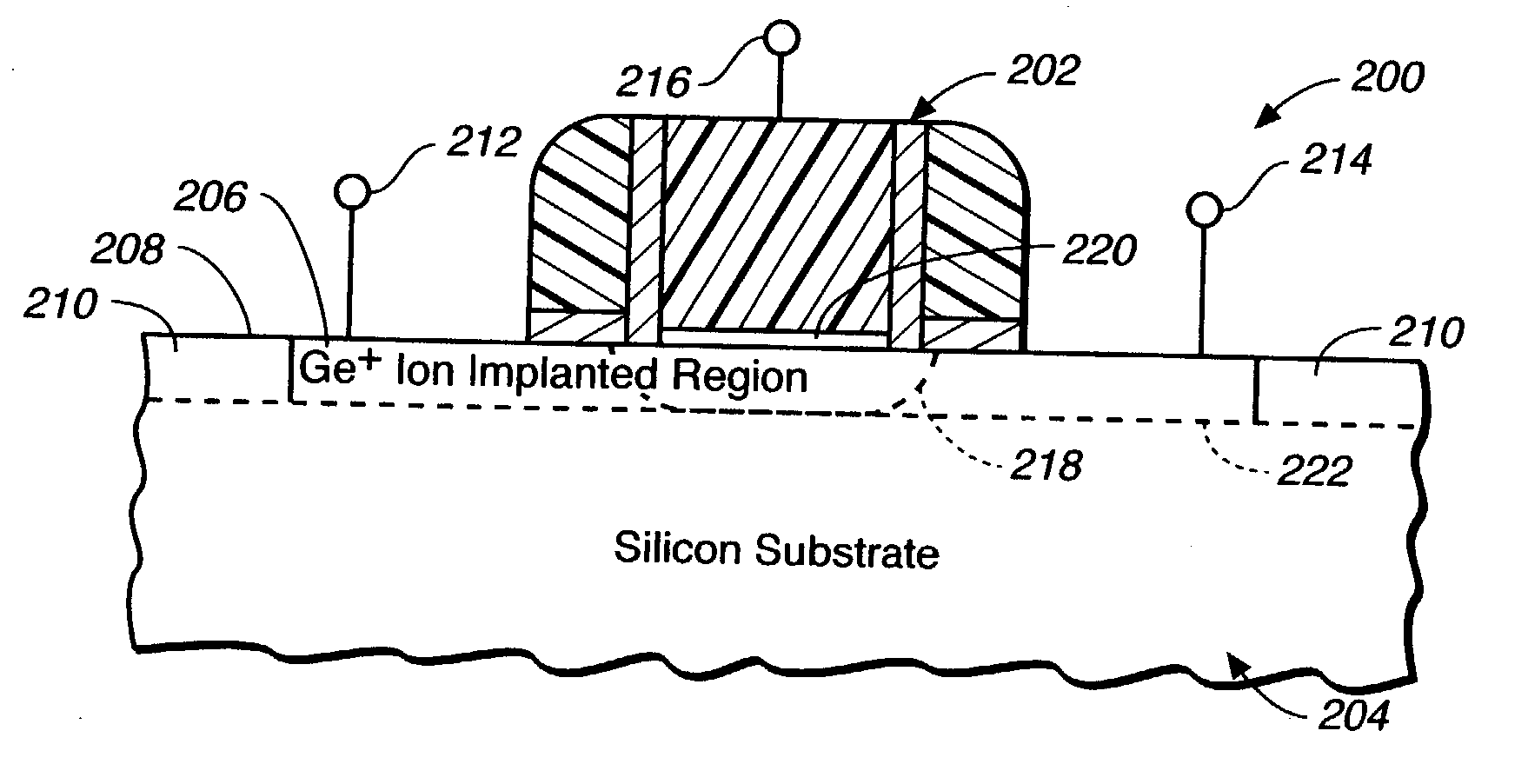

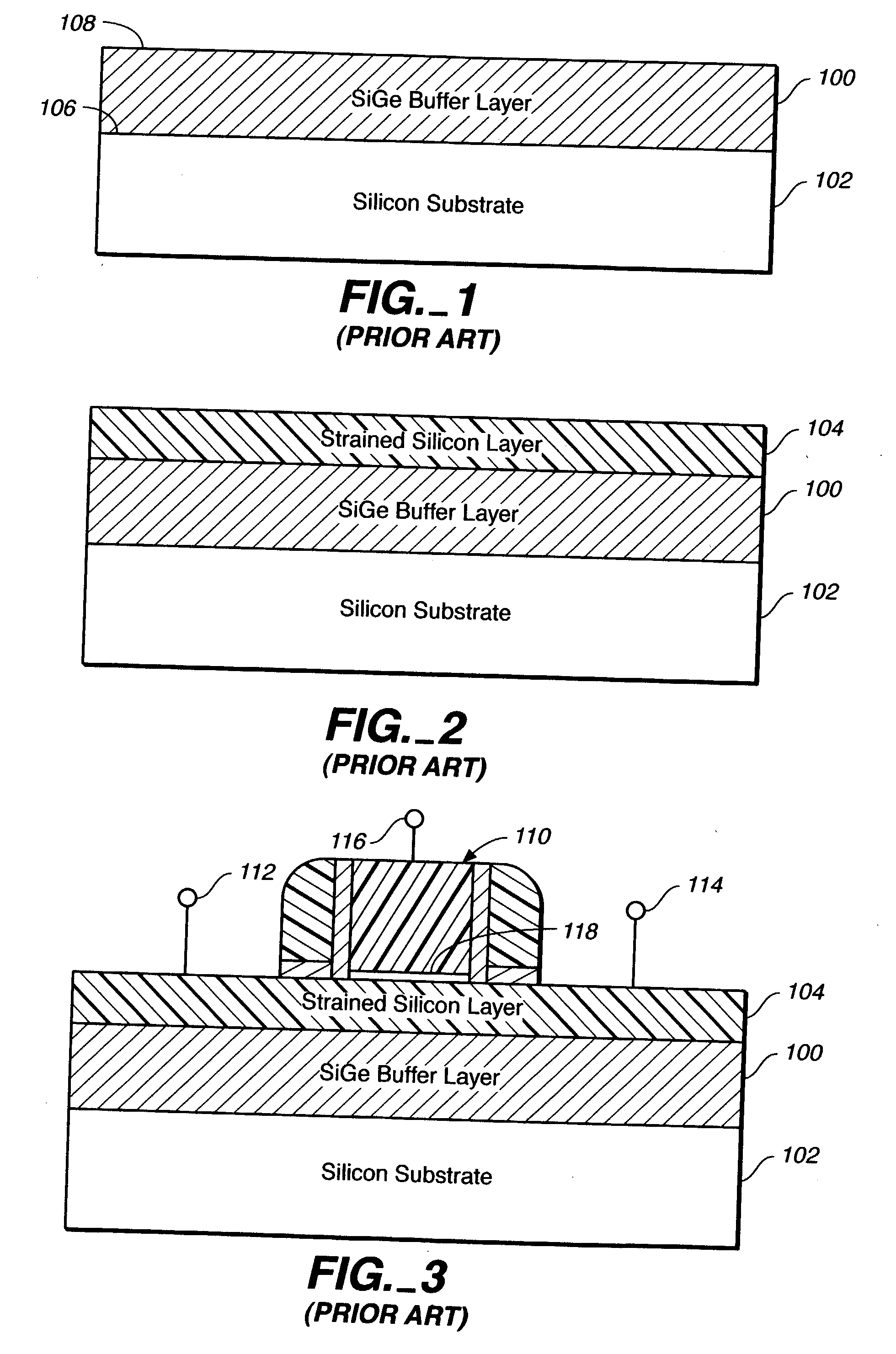

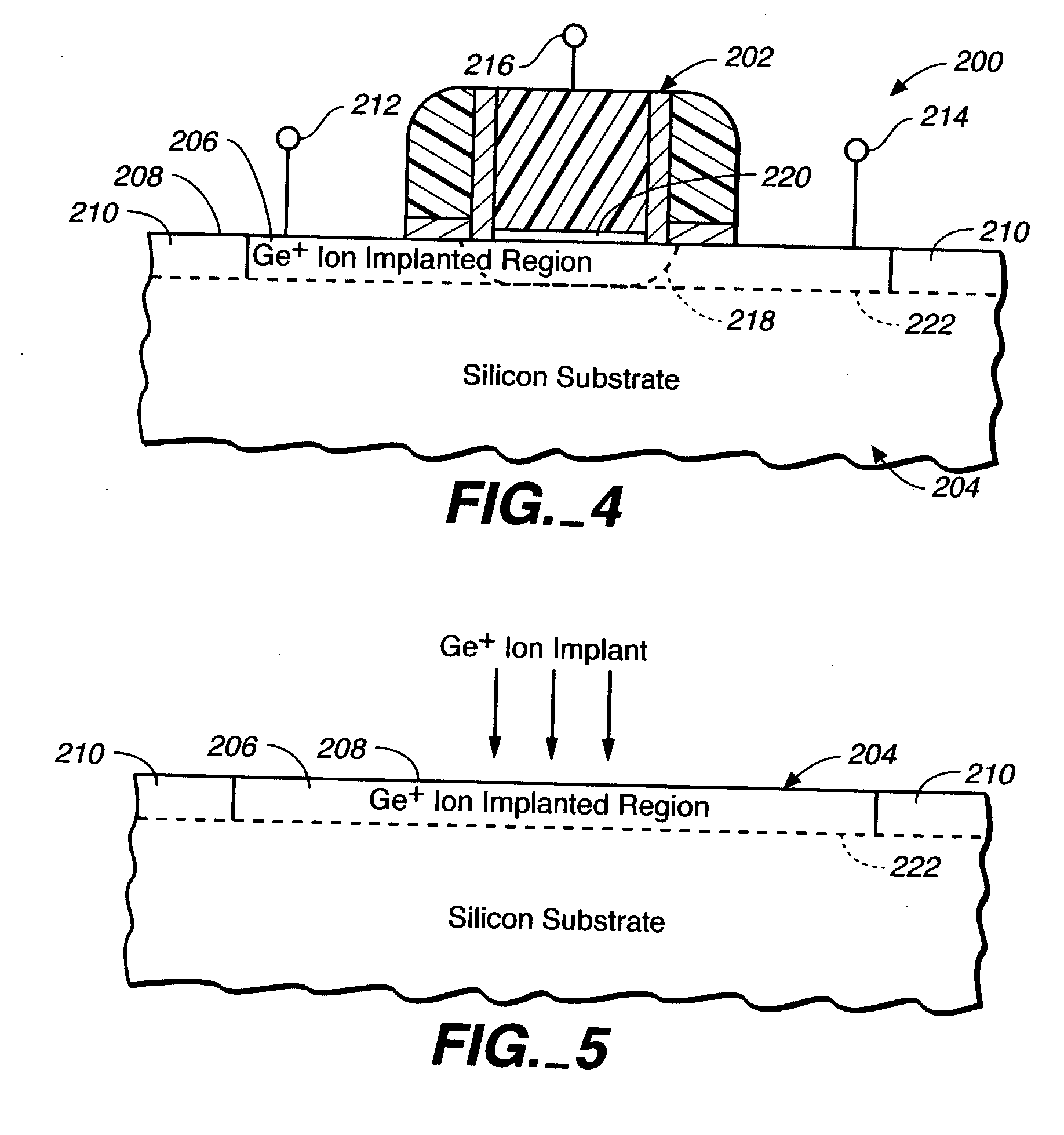

Ion implantation in channel region of CMOS device for enhanced carrier mobility

InactiveUS20040206951A1High carrier mobilityImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesCMOSIntegrated circuit

An integrated circuit (IC) includes a CMOS device with a channel region that has ions implanted therein. The IC preferably incorporates sub-0.1 micron technology in the CMOS device. The implanted ions may preferably be germanium ions. The ion-implanted channel region preferably has a carrier mobility that is greater than that for a region that is not implanted with the ions.

Owner:LSI CORPORATION

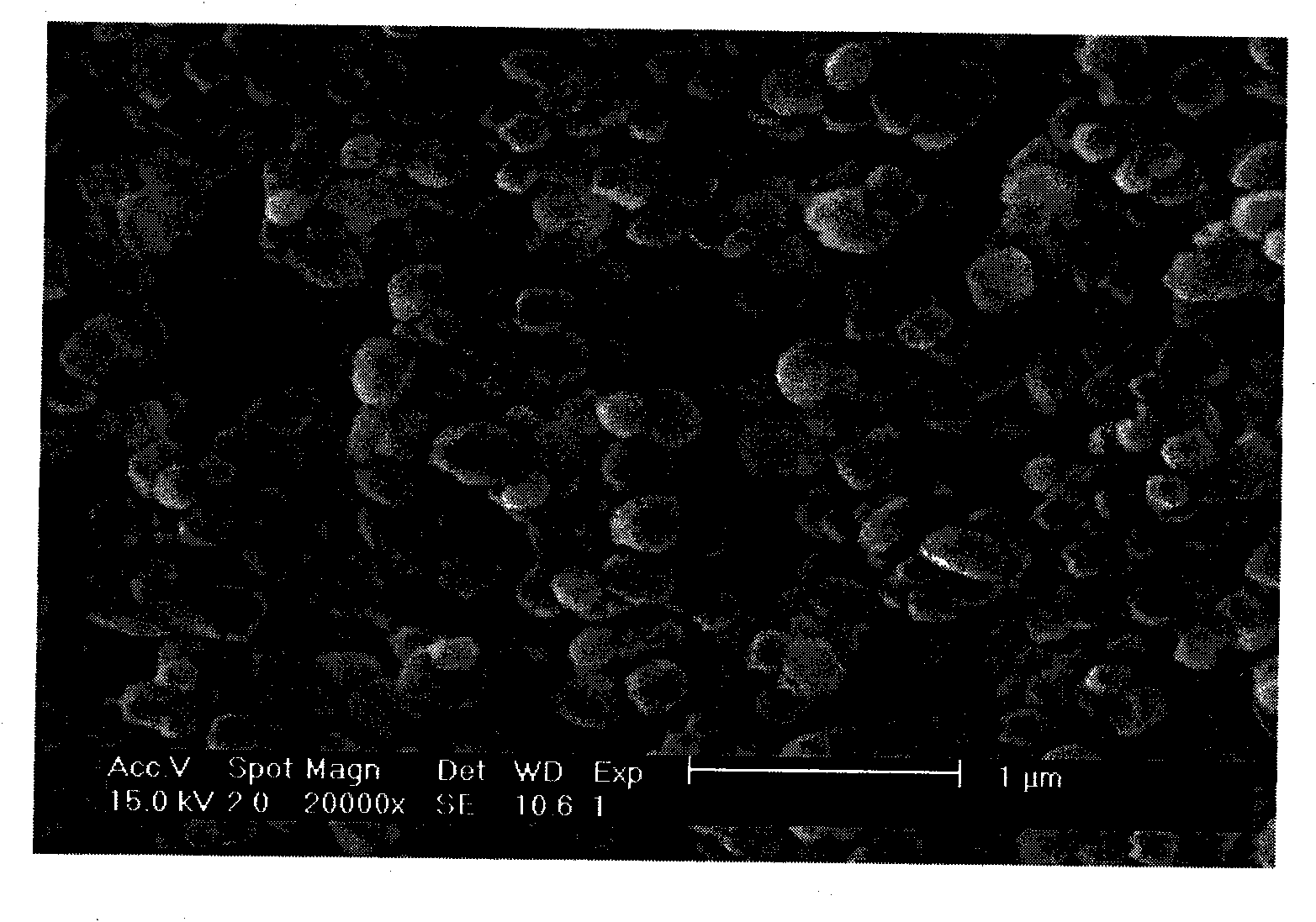

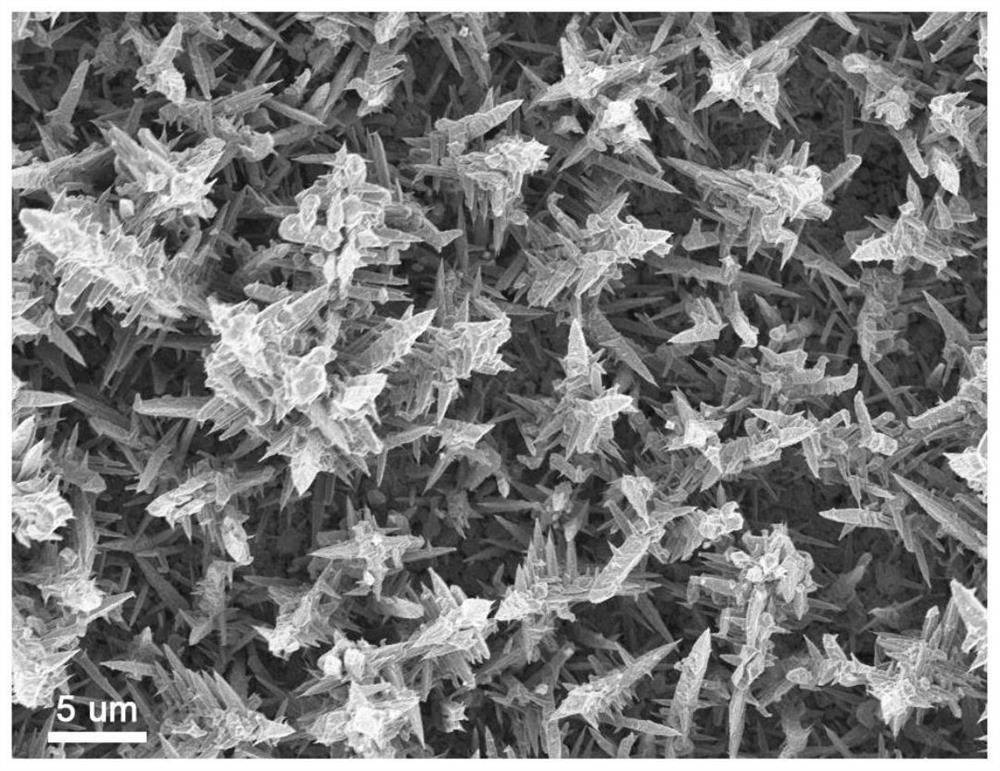

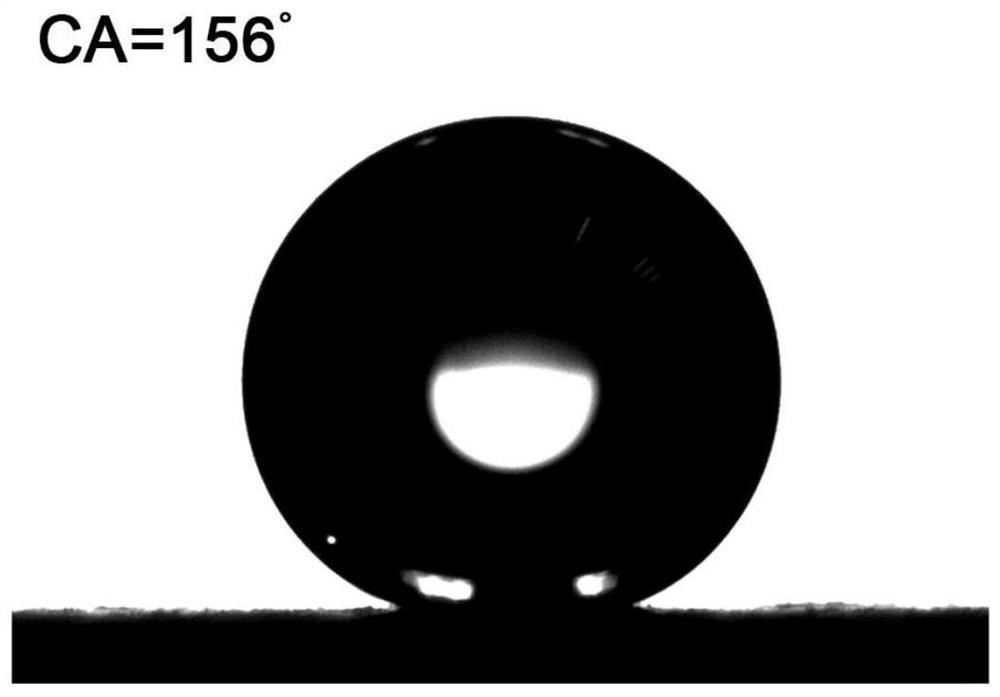

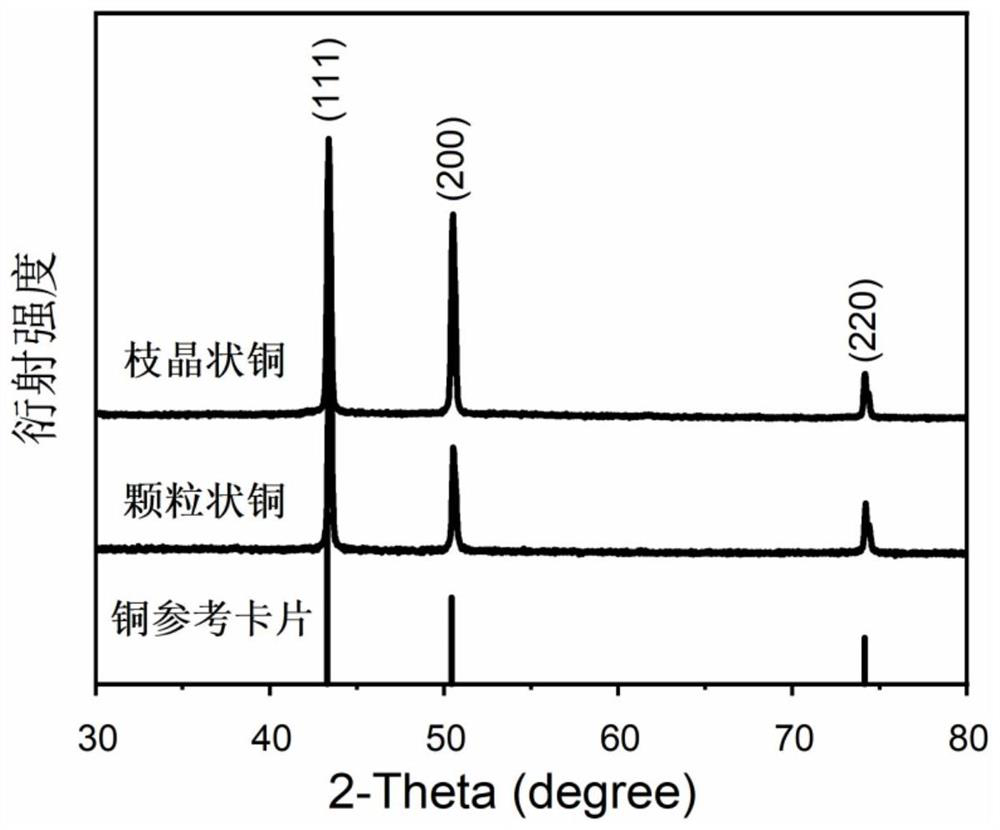

Dendritic copper electrode with hydrophobic surface and preparation method and application thereof

InactiveCN111647909AImprove stabilityAvoid overexposureElectrolytic organic productionElectrodesElectrolytic agentReduction Activity

The invention belongs to the technical field of electrocatalysis, and particularly relates to a dendritic copper electrode with a hydrophobic surface and a preparation method and application thereof.The copper electrode provided by the invention comprises a gas diffusion layer and a copper layer deposited on the surface of the gas diffusion layer, and the microstructure of the copper layer is dendritic. The surface of the copper electrode is composed of regular copper dendrites, so that good hydrophobicity is shown and excessive contact of electrolyte can be effectively prevented, and therebyflooding of the electrode is avoided, and the stability of the electrode is improved; in addition, the dendritic copper can efficiently enrich cations in the electrolyte to form a local high electricfield, so that the carbon-carbon coupling rate is increased, and the electrode shows excellent electro-catalytic CO2 reduction activity.

Owner:UNIV OF SCI & TECH OF CHINA

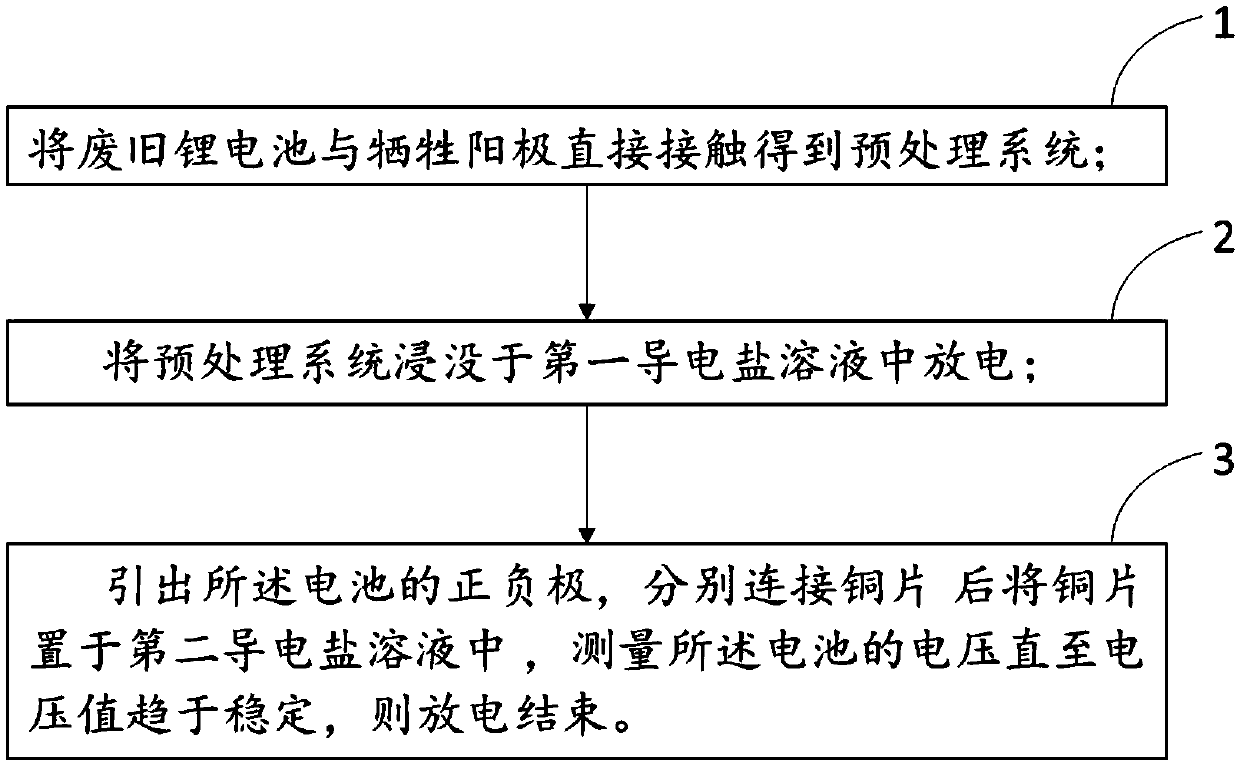

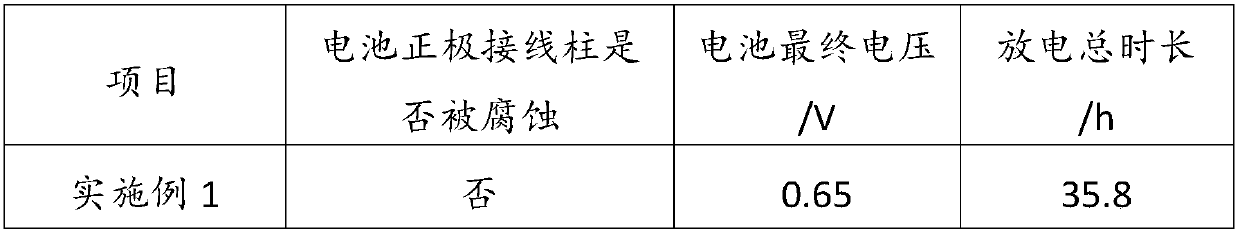

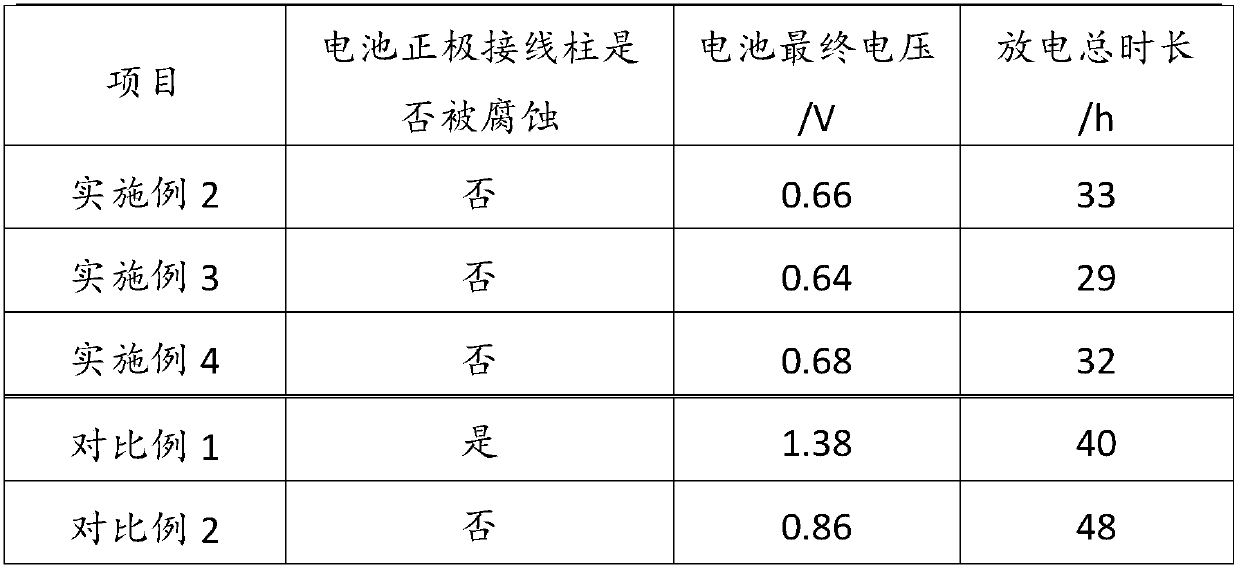

Discharge method of waste lithium battery

InactiveCN110635185ANo corrosionIncrease ion concentrationSecondary cells charging/dischargingElectrical batteryEngineering

The invention provides a discharge method of a waste lithium battery. The discharge method comprises the following steps of: firstly, directly contacting a waste lithium battery with a sacrificial anode to obtain a pretreatment system, immersing the pretreatment system in a conductive salt solution for discharge, and finally, leading out the positive electrode and the negative electrode of the battery, respectively connecting the positive electrode and the negative electrode with copper sheets, putting the copper sheets into the conductive salt solution, measuring the voltage of the battery until the voltage value tends to be stable, and ending discharge. The sacrificial anode can stably exist in a neutral or alkaline solution, the influence of illumination, temperature and the like is small, and the discharge condition is easy to control; the sacrificial anode is preferentially oxidized and dissolved in the discharge process to prevent chlorine from being separated out, so that the problem of electrolyte leakage pollution is effectively solved; moreover, as the sacrificial anode corresponds to the positive ions of the conducting salt, the ion concentration of the conductive salt solution is increased after the sacrificial anode is dissolved, the cyclic utilization of the conductive salt solution can be realized while the discharge rate is increased, and the discharge cost is saved. The method is simple in process, easy to operate and suitable for large-scale application.

Owner:ZHONGTIAN ENERGY STORAGE TECH +3

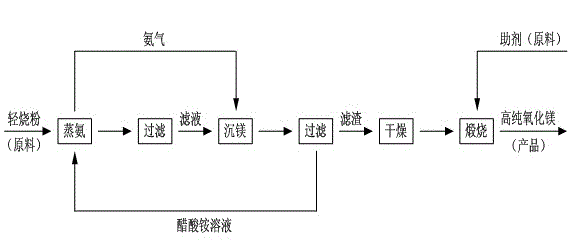

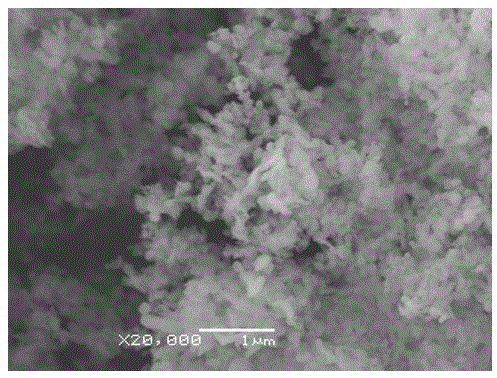

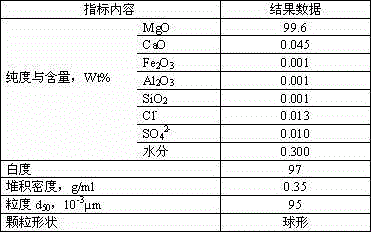

Method for producing high-purity magnesium oxide by using light calcined powder as raw material

A method for producing high-purity magnesium oxide by using light calcined powder as a raw material relates to a production method of magnesium oxide; ammonia gas and ammonia distilled liquid are obtained by the raw material of light calcined powder and an ammonium acetate solution through an ammonia distillation process; the ammonia distilled liquid is filtered to remove solids so as to obtain magnesium salt refined liquid; a magnesium precipitation reaction is performed by the refined liquid and the ammonia gas released in the ammonia distillation process to obtain magnesium hydroxide mother liquor; the magnesium hydroxide mother liquor is filtered to separate magnesium hydroxide filter residues and an ammonium acetate filtrate, and the filter residues are dried to obtain magnesium hydroxide; the dried magnesium hydroxide is calcined with a raw material additive to obtain the high-purity magnesium oxide product whose purity, whiteness, granularity, and bulk density meet requirements. The method produces high-purity magnesium oxide by using light calcined powder as a raw material, realizes ammonia (ammonium) circulation; not only the ammonia distillation time is shortened to less than 1 hour, but also the Mg2+ concentration of the magnesium salt liquid obtained after ammonia distillation is increased to above 2.5 mol / L; production energy consumption per unit product is reduced by 30-50%; the production cost is reduced and the economic benefit is improved.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

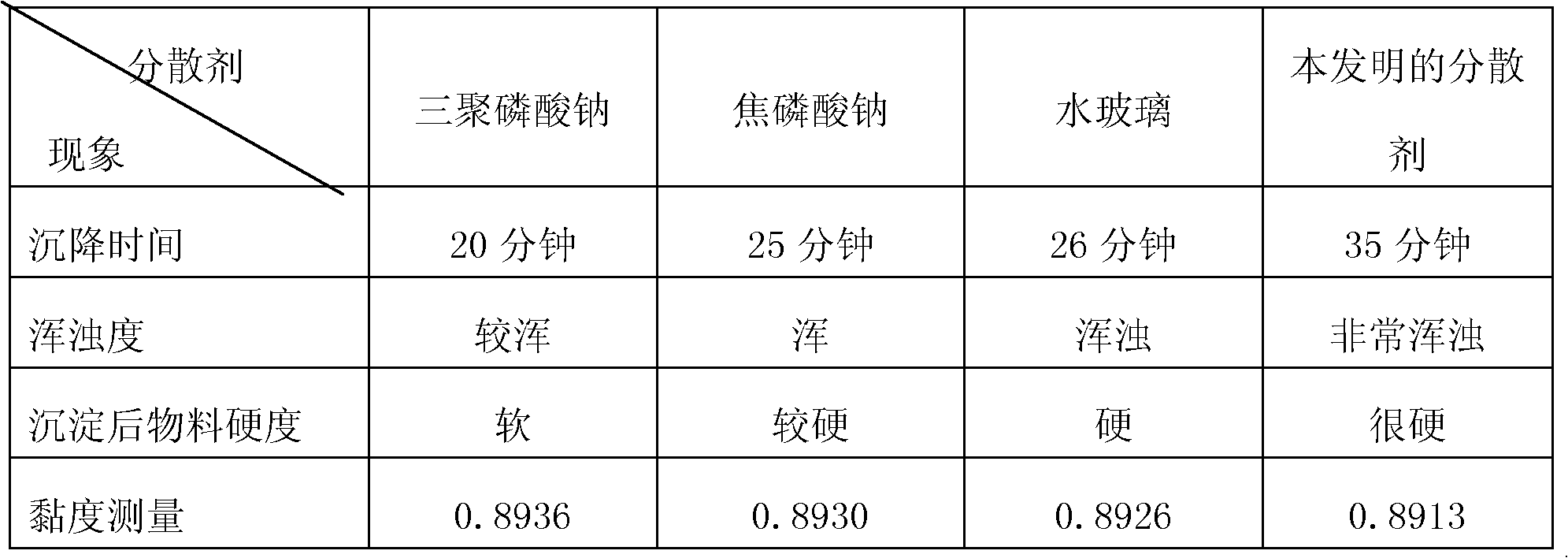

Special dispersant for hydraulic overflow classification for high-purity superfine silicon carbide micro powder for linear cutting and using method

The invention relates to a special dispersant for hydraulic overflow classification for high-purity superfine silicon carbide micro powder for linear cutting and a using method, and belongs to the preparation of high-purity silicon carbide micro powder. The special dispersant is prepared from the following raw materials in percentage by mass: 50 to 70 percent of pure water, 25 percent of tetramethylammonium hydroxide, 15 to 35 percent of aqueous solution, 5 to 20 percent of alkyl alcohol amine, 2 to 10 percent of ethylene diamine tetraacetic acid (EDTA), 0.1 to 2.0 percent of fatty alcohol-polyoxyethylene ether, 0.5 to 3.0 percent of alkylpheol ethoxylate and 0.1 to 3.0 percent of bacteriostatic agent. The invention provides the special dispersant for the hydraulic overflow classification for the high-purity superfine silicon carbide micro powder for the linear cutting and a preparation method and the using method thereof, wherein the special dispersant has the advantages of short hydraulic overflow classification period in the production process of the high-purity superfine silicon carbide micro powder for the linear cutting, high yield, uniform product granularity distribution, difficult agglomeration of granules and capability of meeting the requirement of the linear cutting industry. The special dispersant can remarkably improve the potential of the high-purity superfine silicon carbide micro powder for the linear cutting and reduce the viscosity of slurry so as to remarkably optimize the rheological property of the slurry.

Owner:LINSHUSNTIAN ABRASIVE

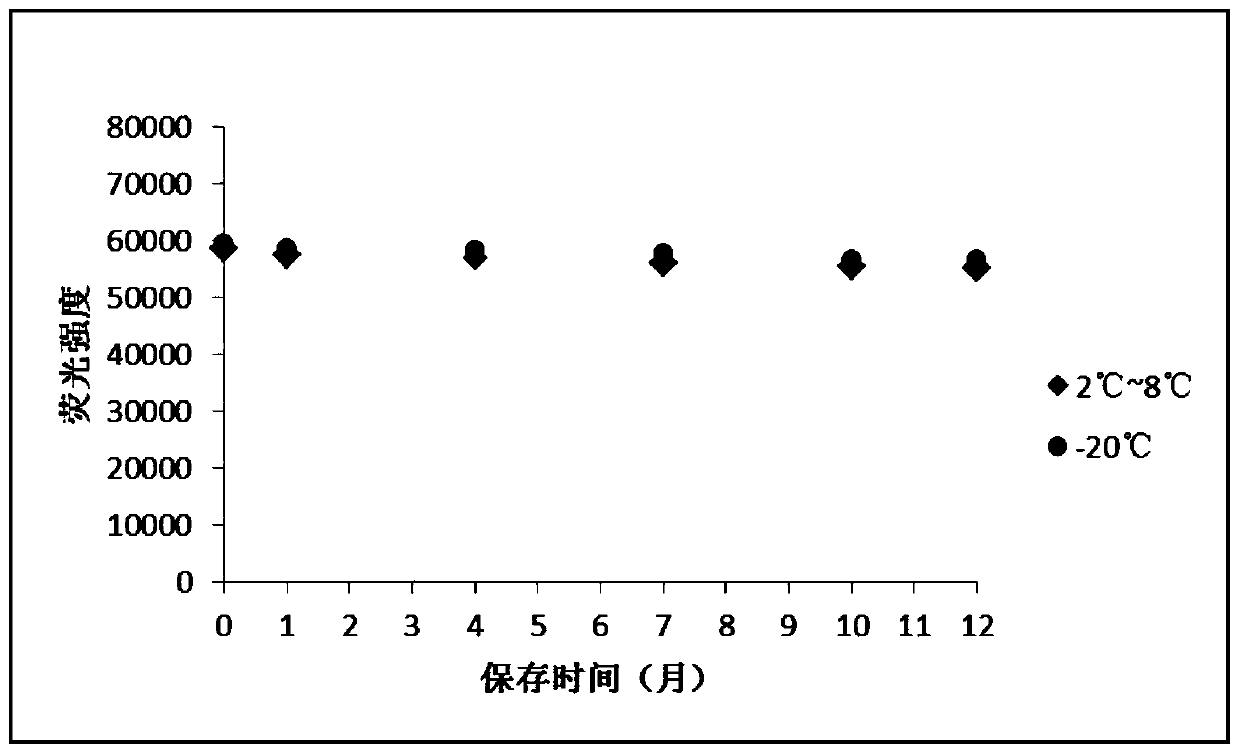

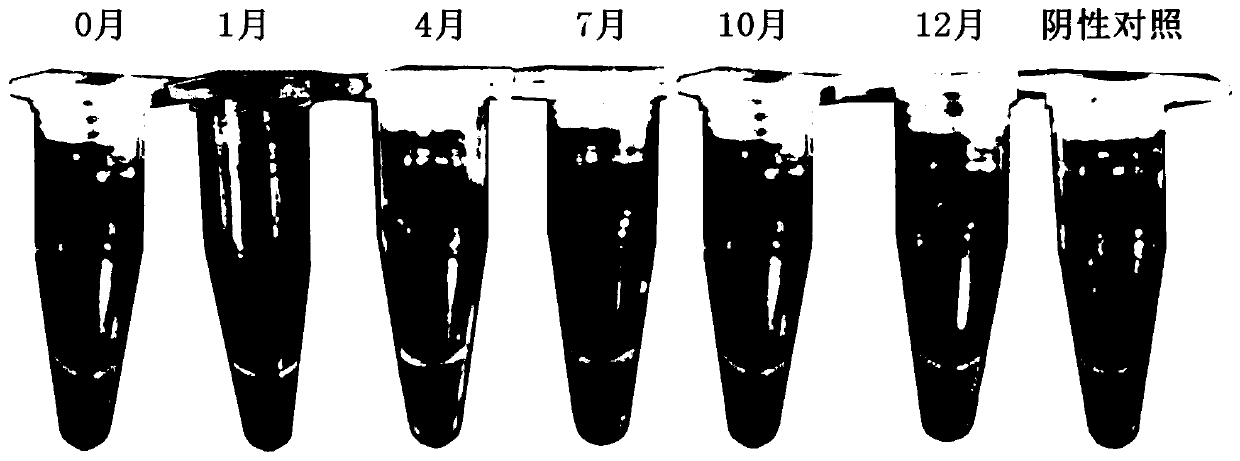

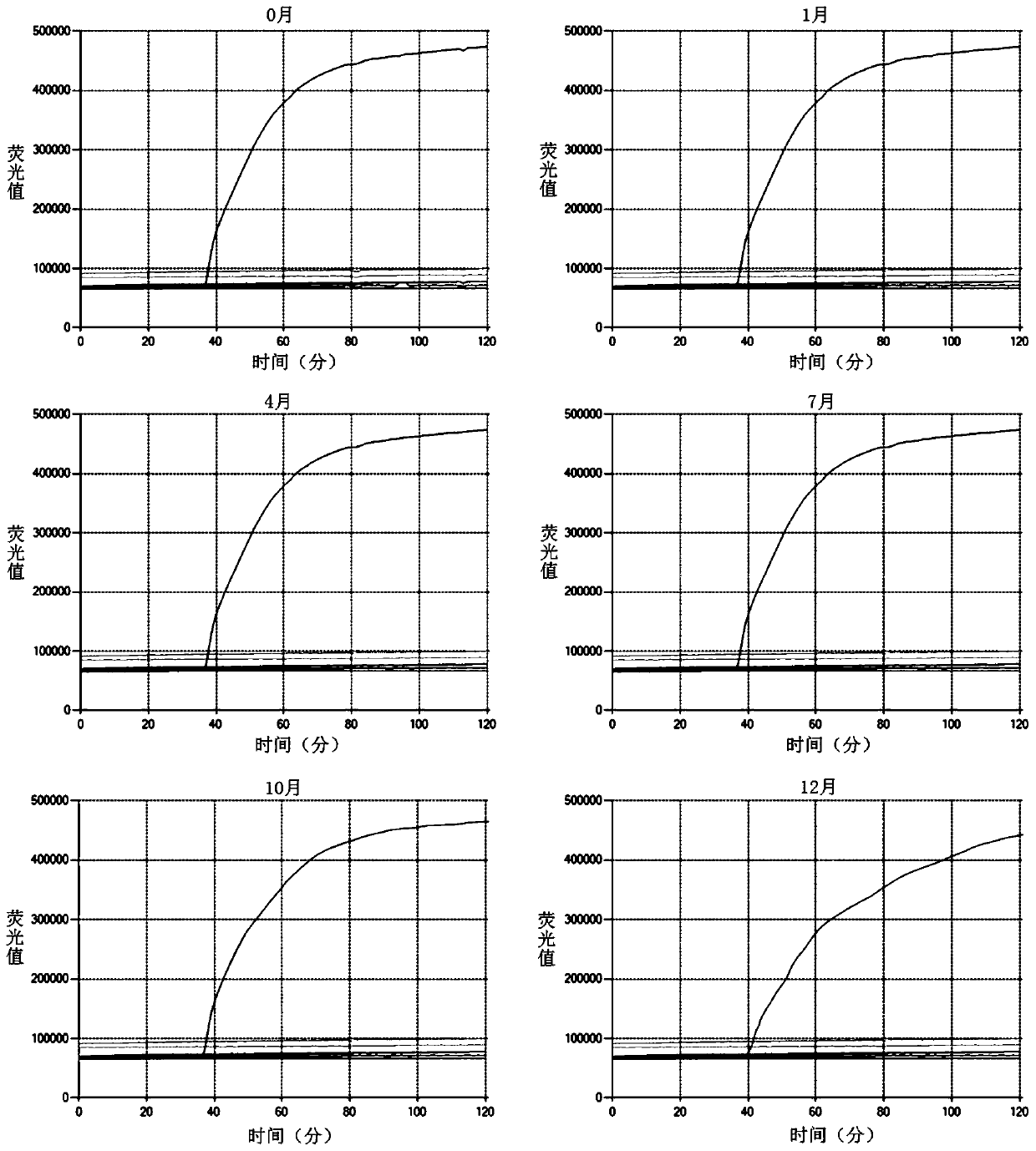

Exosome preserving fluid and exosome preserving method

The invention relates to an exosome preserving fluid and an exosome preserving method, which belong to the technical field of biology. The exosome preserving fluid comprises bovine serum albumin, trehalose, glycerol, dimethyl sulfoxide and a phosphate buffer solution. The invention also provides the exosome preserving method comprises the following steps: heating the preserving fluid at 85-95 DEGC for 10-30 minutes to form a colloidal solution, and preserving the exosome in a colloidal solution. The exosome preserving fluid provided by the invention can maintain the integrity, biological activity and inclusion stability of exosomes for a long time.

Owner:中国科学院大学深圳医院

New method and system for TSV blind hole filling

InactiveCN107675233AFacilitated DiffusionImprove adsorption capacityElectrolytic coatingsSemiconductor devicesGalvanic anodeEngineering

The invention discloses a new method and system for TSV blind hole filling. The new method includes the following steps that firstly, a silicon piece with a TSV blind hole is put into deionized water,vacuum suction pretreatment is conducted, and gas in the TSV blind hole is exhausted; secondly, the silicon piece obtained after pretreatment is integrally connected with an electroplating cathode; thirdly, an additive agent, an inhibiting agent and an accelerating agent are added into an electroplating solution, sufficient mixing is conducted, and a suspension electroplating solution is formed;fourthly, the suspension electroplating solution is added into an electroplating bath, an electroplating anode and an electroplating cathode of an electroplating power source are put into the suspension electroplating solution so that the silicon piece can be subjected to standing in the suspension electroplating solution, and the electroplating solution reaches adsorption balance preliminarily inthe TSV blind hole; fifthly, an inlet and an outlet of a circulation pump communicate with the suspension electroplating solution, the inlet communicates with the position of the electroplating anode, and the outlet communicates with the position of the electroplating cathode; and sixthly, a circulation pump is started, the electroplating power source is started at the same time, electroplating begins, and the flowing speed is provided for the suspension electroplating solution in the electroplating bath through the circulation pump. The filling efficiency can be effectively improved, and thecost is reduced.

Owner:CENT SOUTH UNIV

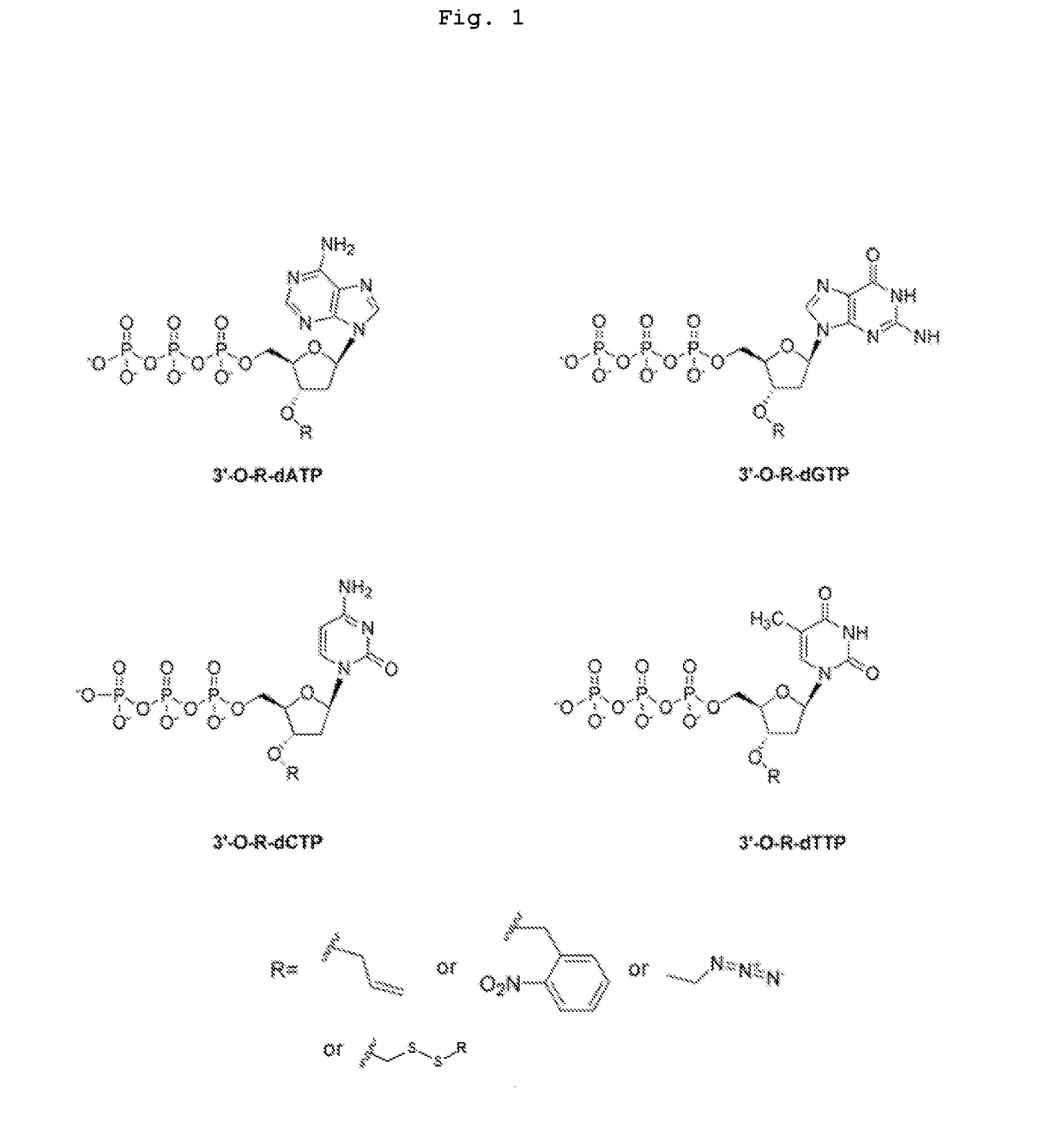

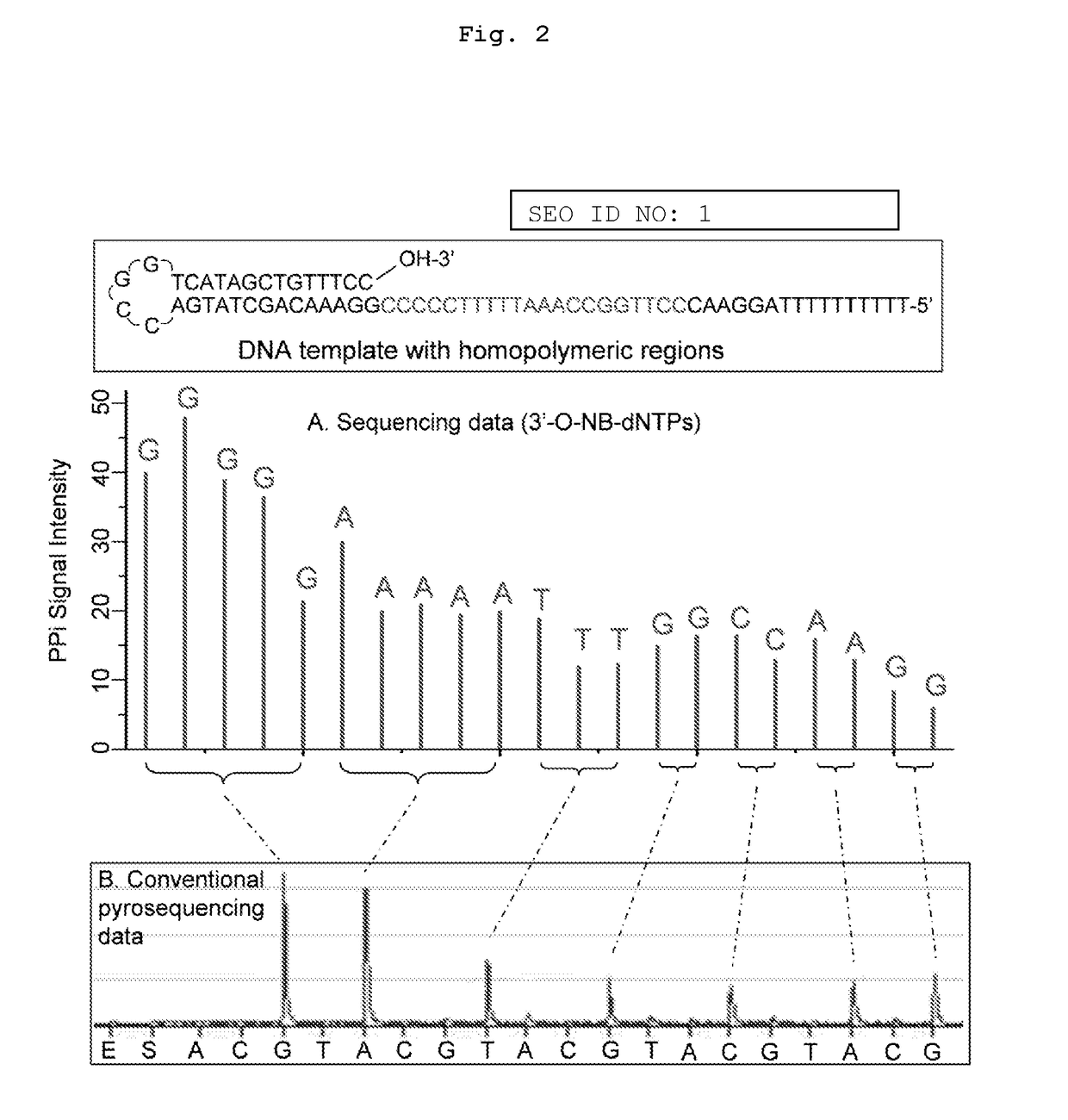

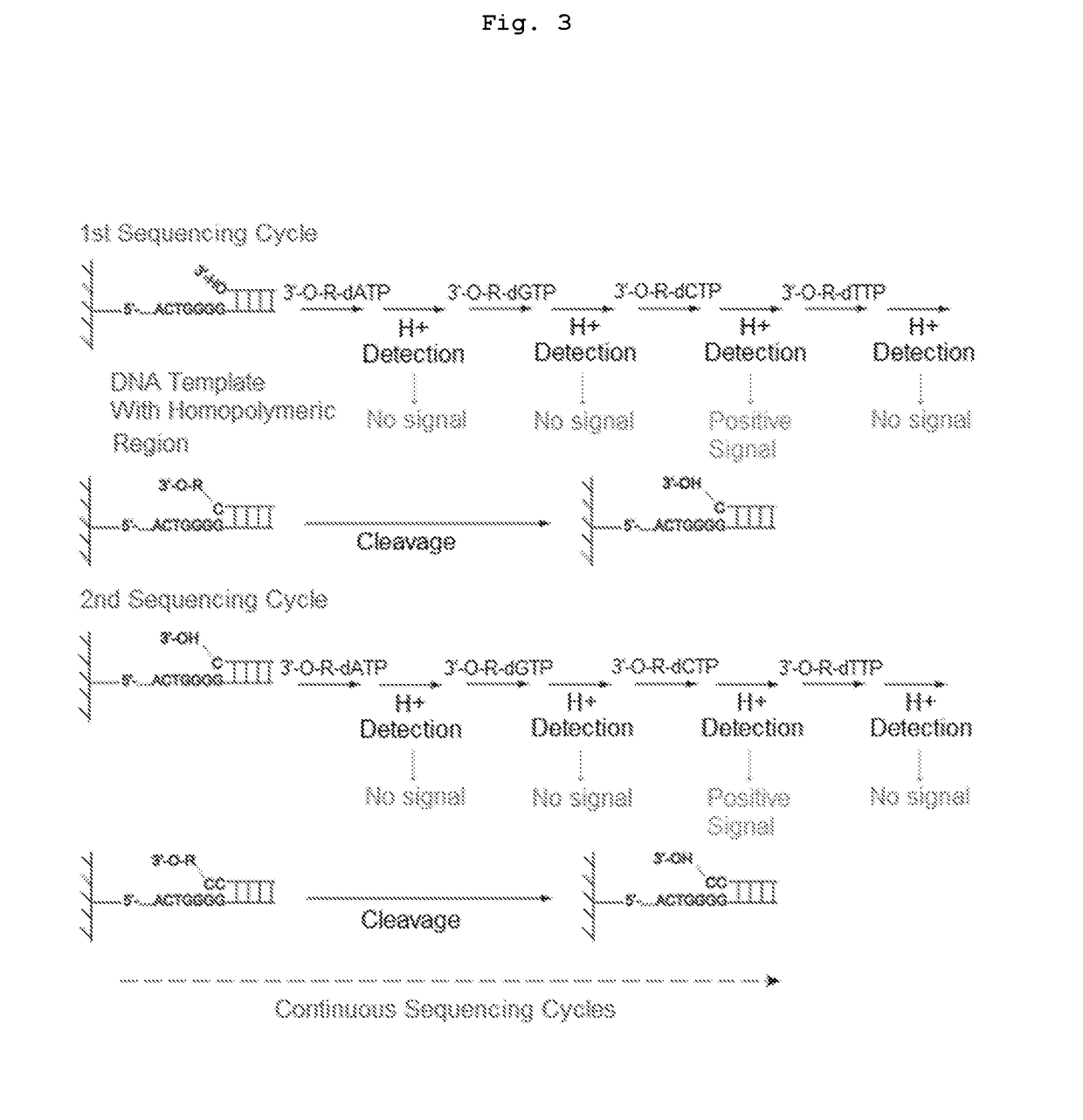

Ion sensor DNA and RNA sequencing by synthesis using nucleotide reversible terminators

InactiveUS20180327828A1Increase ion concentrationSugar derivativesMicrobiological testing/measurementSequencing by synthesisSingle strand dna

This disclosure is related to a method for determining the identity of a nucleotide residue of a single-stranded DNA or RNA, or sequencing DNA or RNA, in a solution using an ion-sensing field effect transistor and reversible nucleotide terminators.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

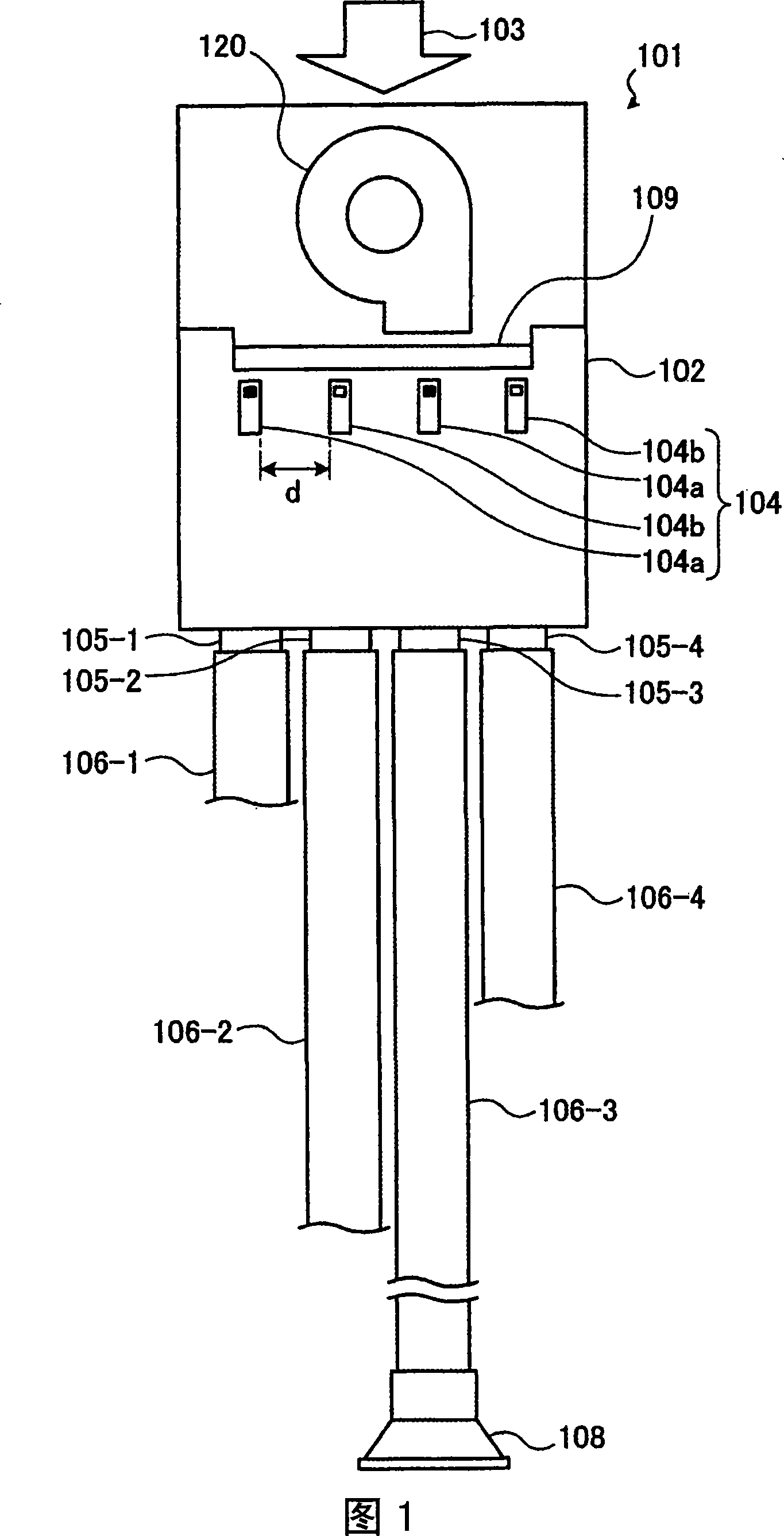

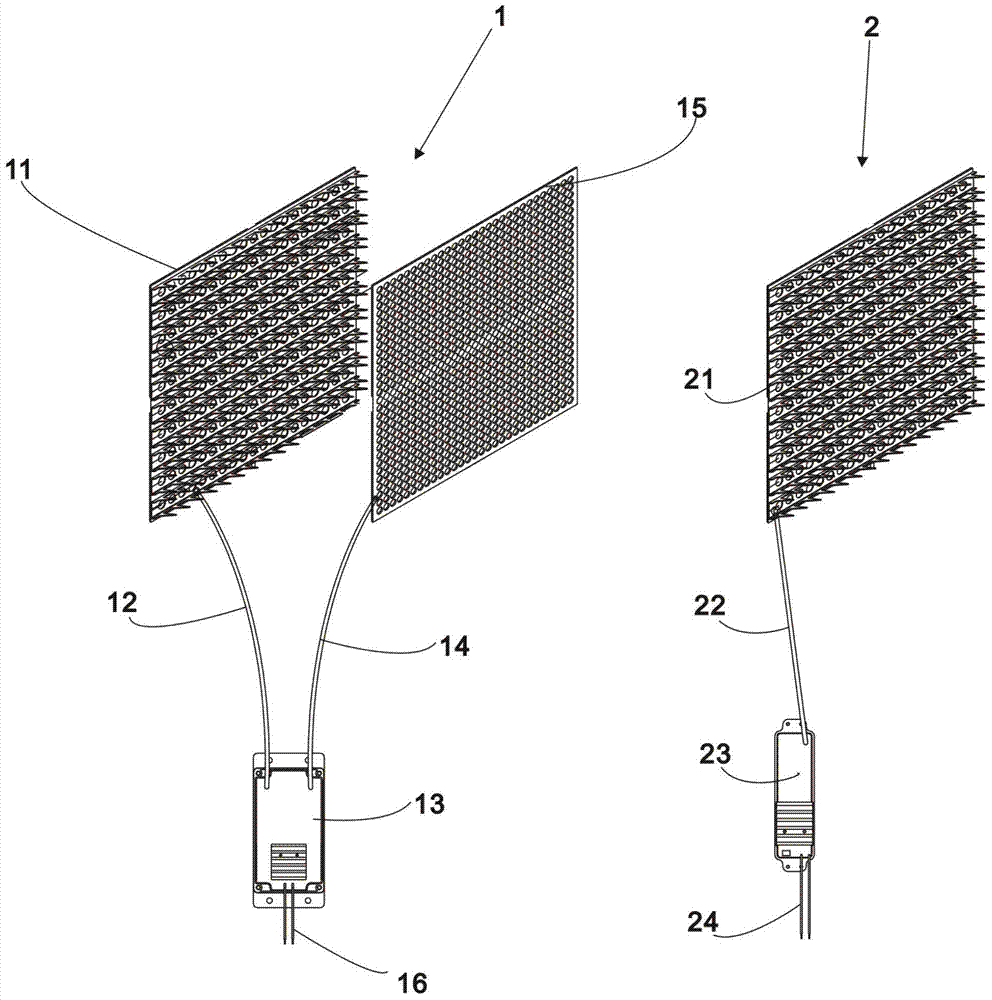

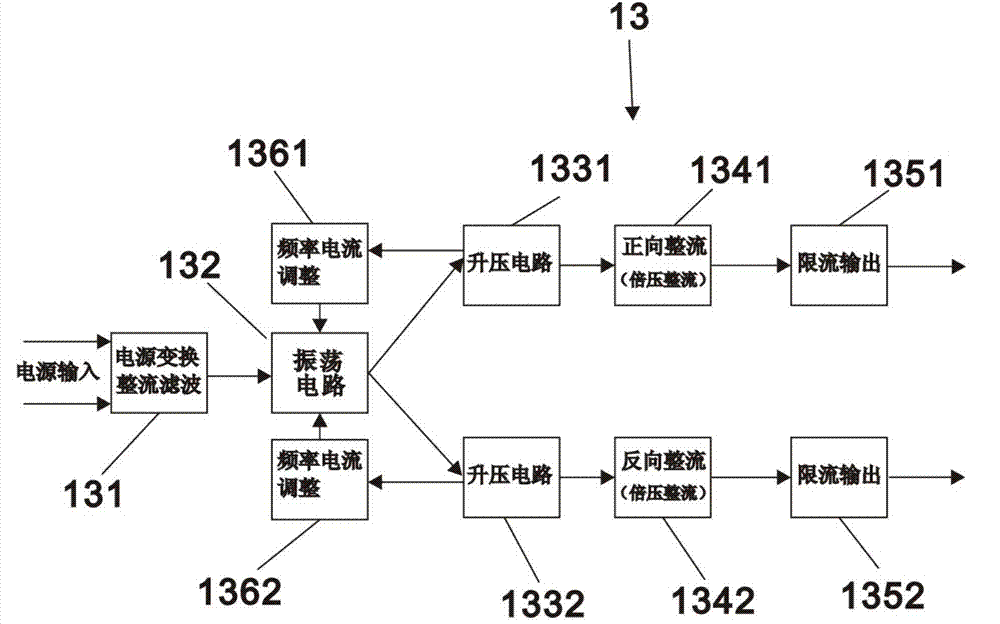

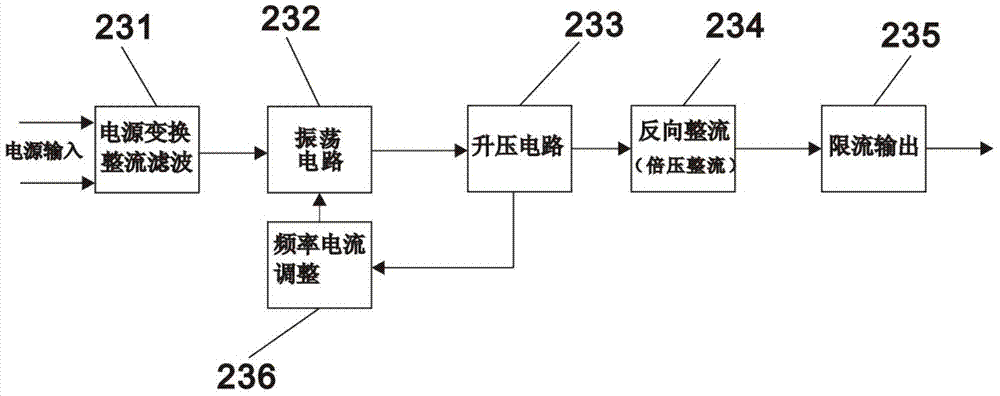

Air ion conveyance device and air ion conveyance system

InactiveCN101175510ASmall attenuationUniform supplyElectrical apparatusLighting and heating apparatusEngineeringAir conditioning

The present invention provides an air ion conveyance device as well as an air ion conveyance system, for example, for an air conditioning facility and conveys air ions to rooms of a house etc. The air ion conveyance device has an air ion production device unit, air ducts, and a control device. The air ion production device unit is provided in a housing of a centralized ventilation device and has positive ion production devices and negative ion production devices that are alternately arranged with a spacing in between, the positive ion production devices generating positive ions in air fed from the outside, the negative ion production devices generating negative ions in the air. The air ducts are connected to joints provided at the housing and individually conveys air to rooms. The control device controls the air ion production device unit. The control device regulates, according to a request from each room, whether or not to produce air ions or the amount of production of ions.

Owner:THE SHIMIZU CONSTRUCTION CO LTD +1

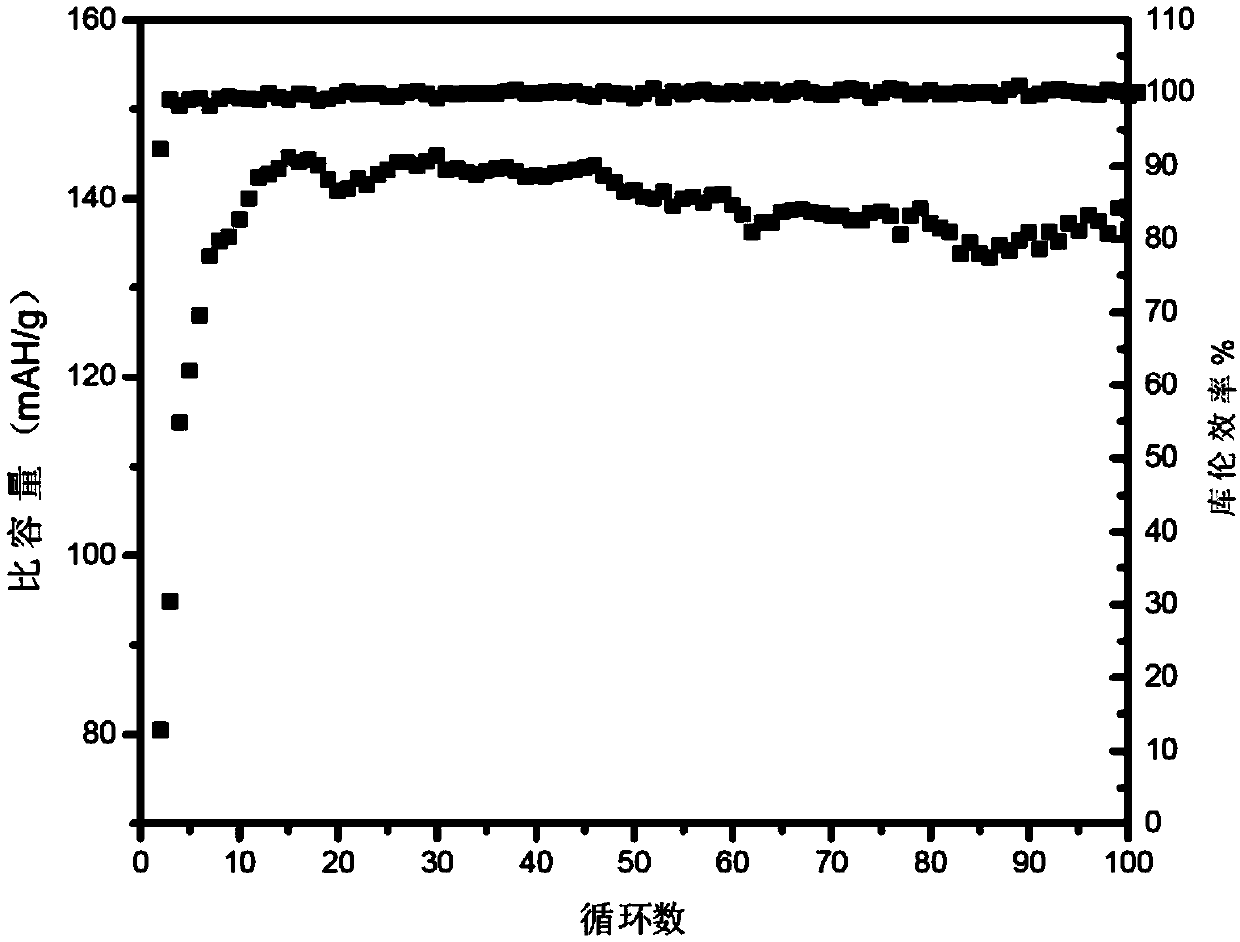

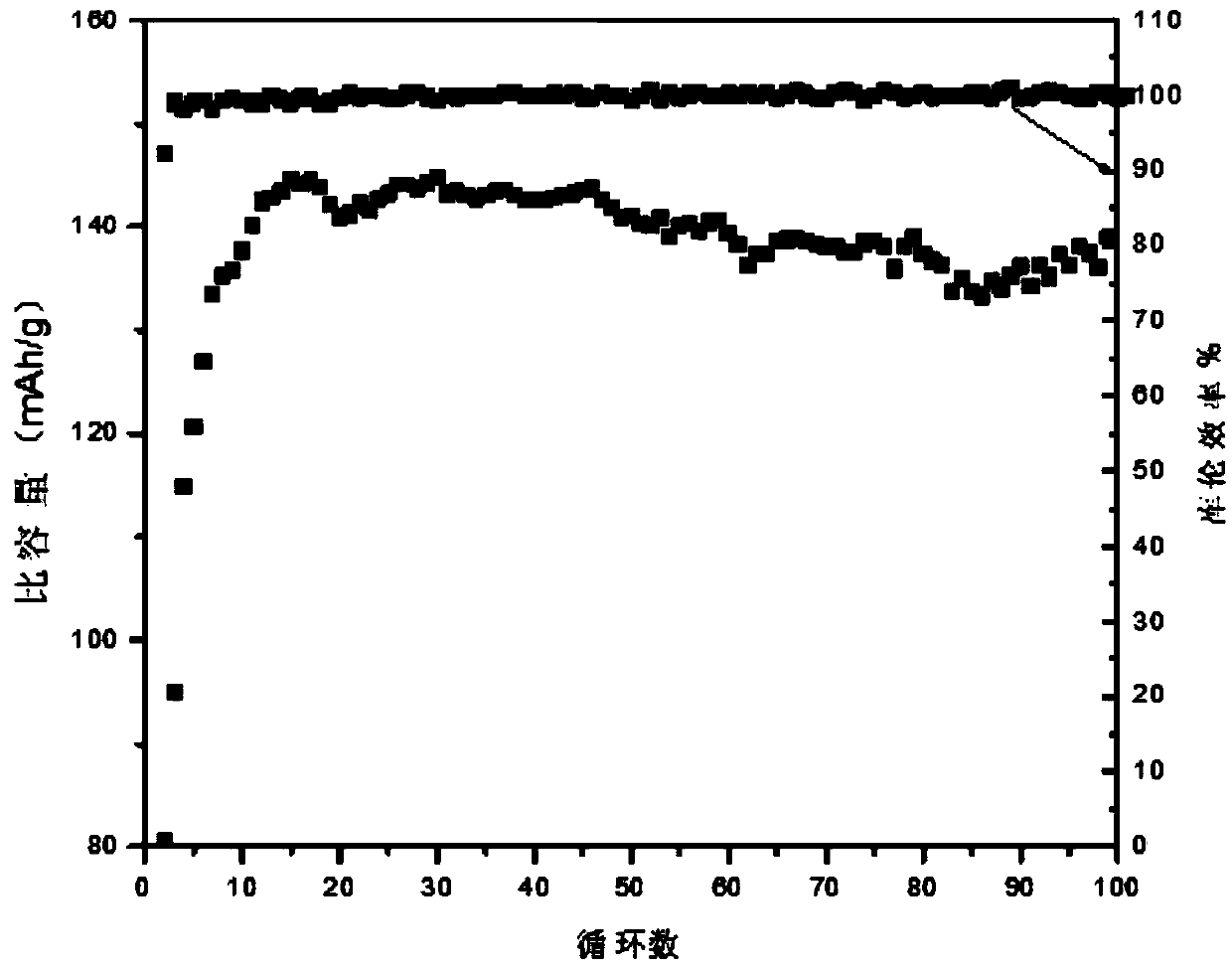

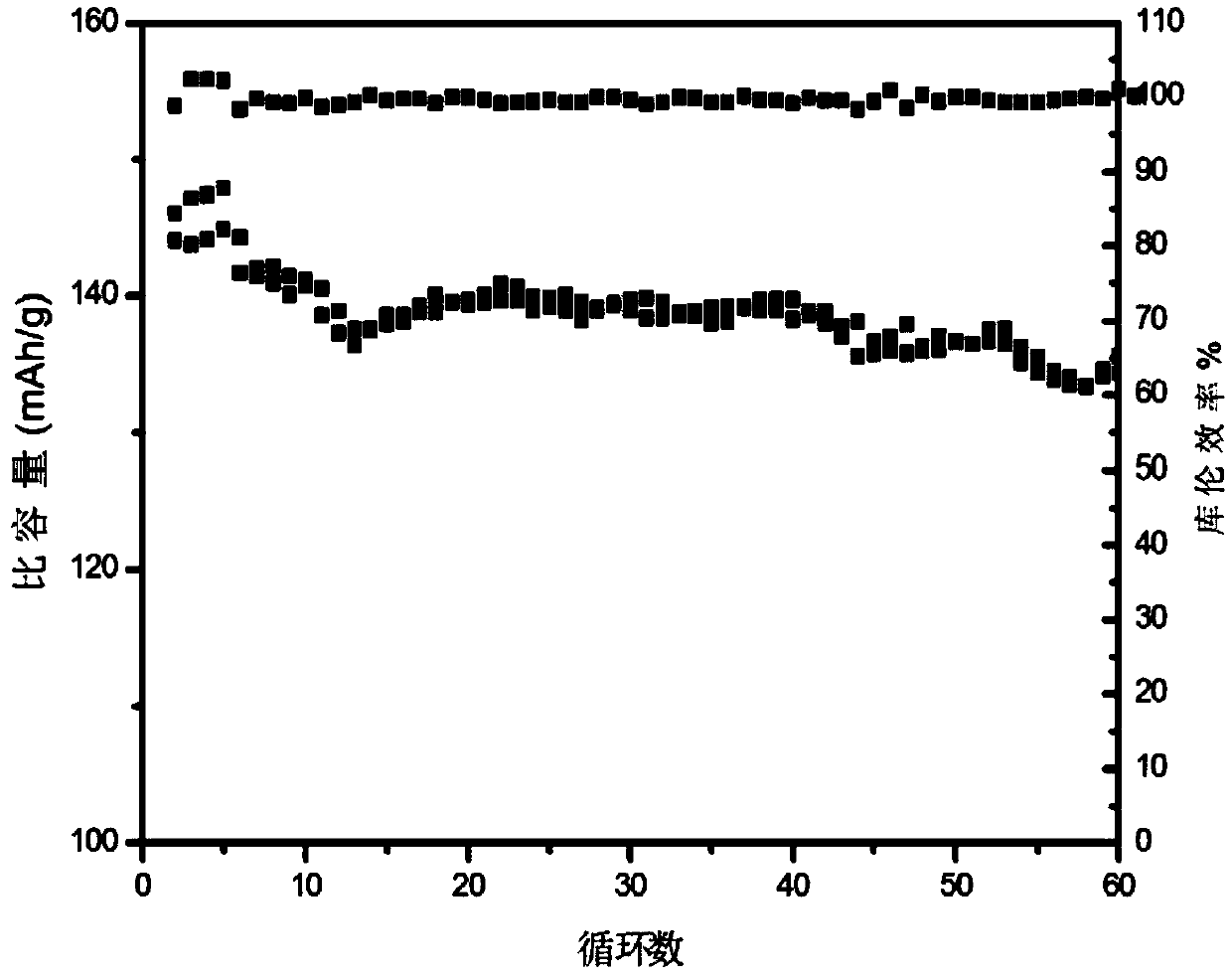

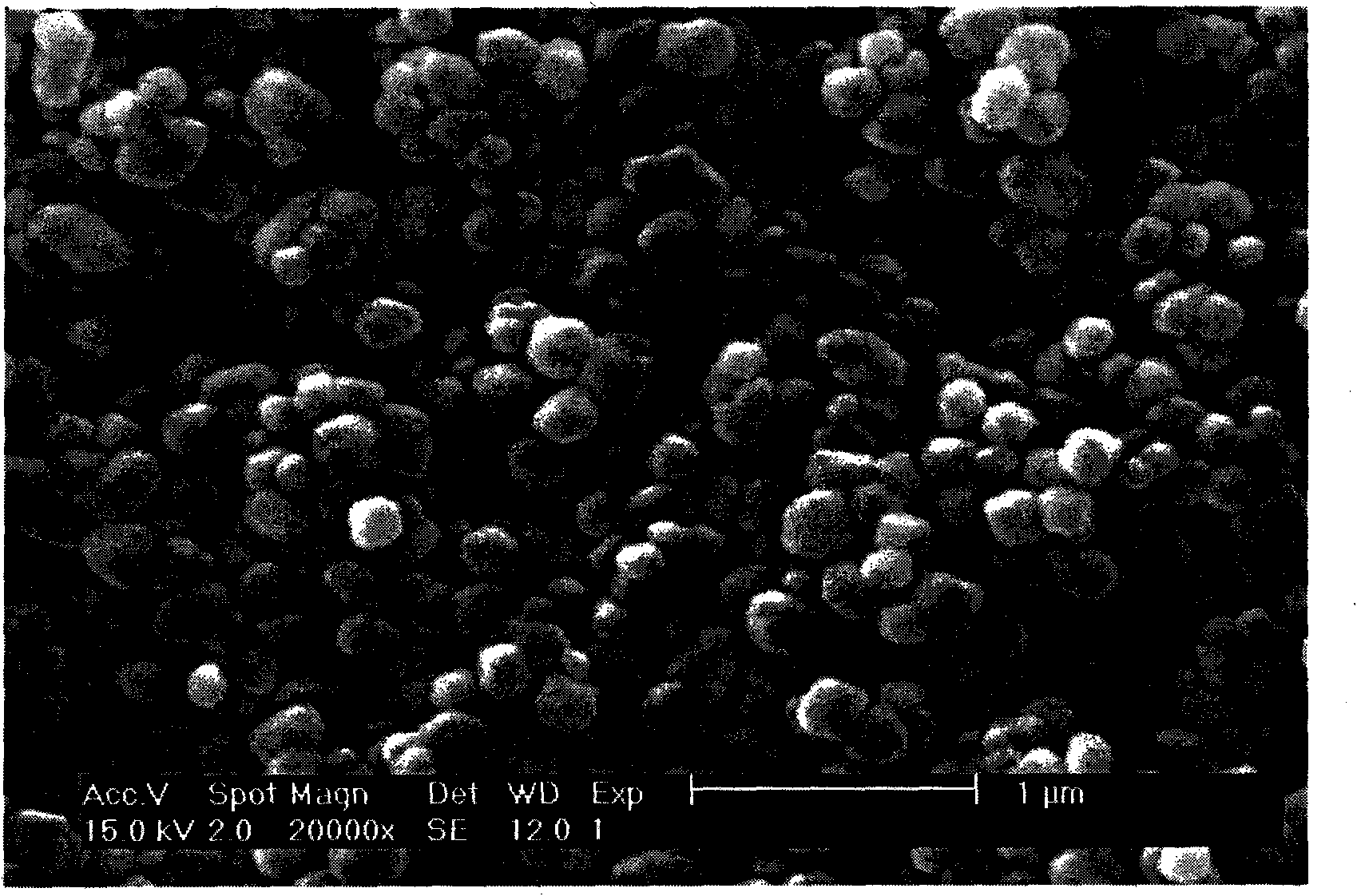

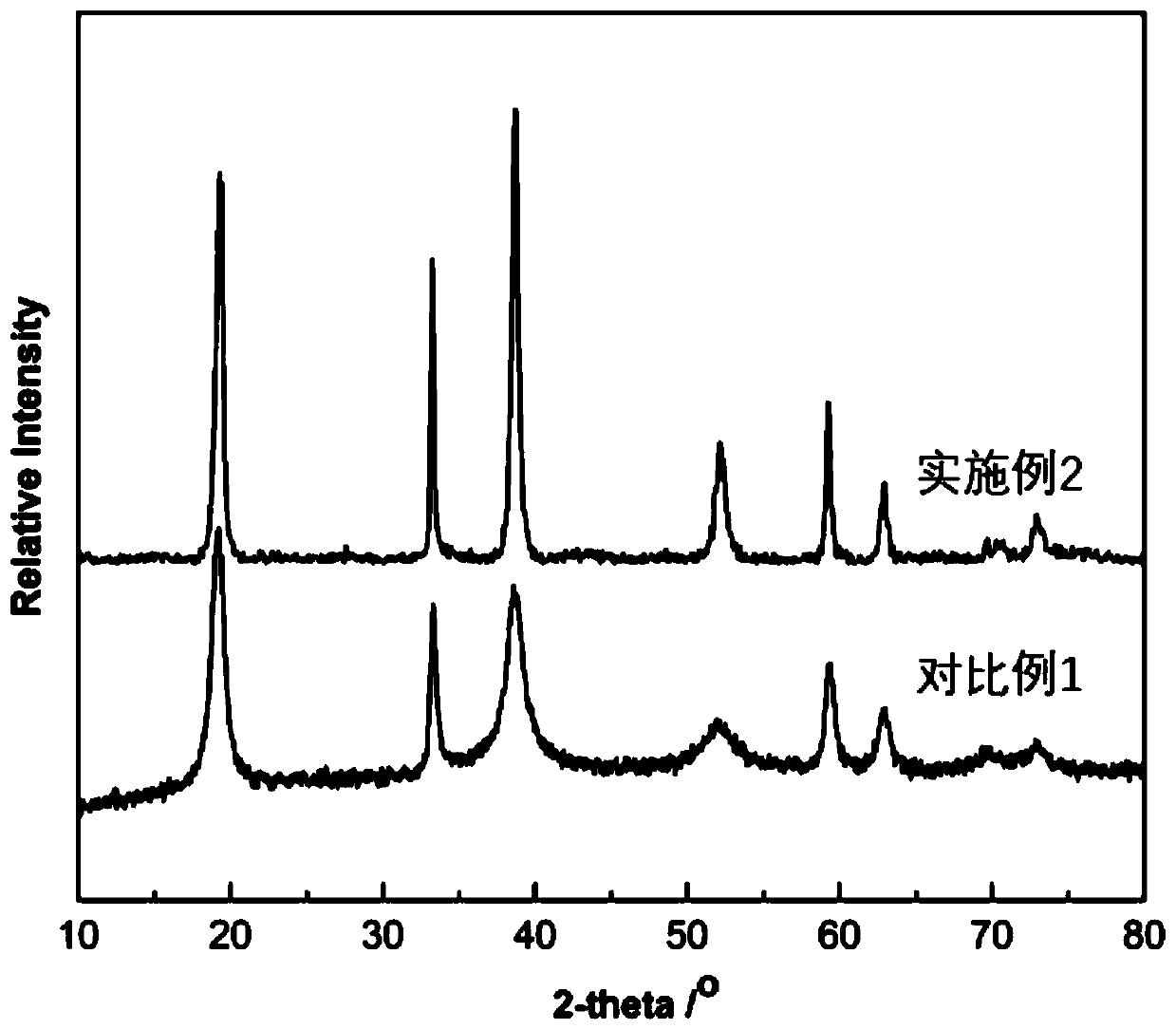

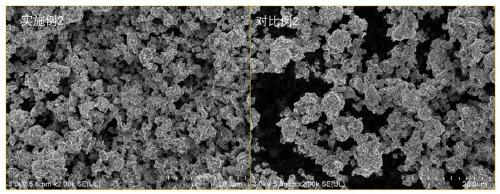

Preparation method of monocrystal-like lithium nickel cobalt manganate

ActiveCN111370683AIncrease ion concentrationReduce the effect of crystallinityCell electrodesSecondary cellsManganatePhysical chemistry

The invention provides a preparation method of monocrystal-like lithium nickel cobalt manganate, which comprises the following steps: 1. preparing a transition metal salt solution, adding a complexingagent or preparing a complexing agent solution, and preparing a pH regulating solution; 2, preparing a nickel-cobalt-manganese metal precipitate; continuously pumping various solutions prepared in the first step into a reaction kettle at the same time through different feeding pipes; connecting a reactor filled with manganese salt with a feed port of a reaction kettle, introducing protective gas,heating, continuously adding an oxidant into the reactor, reacting, adjusting the flow of the protective gas, introducing manganese oxide generated by the reaction into the reaction kettle, controlling the pH value in the reaction kettle, and carrying out precipitation reaction to obtain nickel-cobalt-manganese metal precipitates after the reaction is finished; 3, pre-sintering to prepare a nickel-cobalt-manganese precursor; and 4, performing lithiation sintering, such that the monocrystal-like lithium nickel cobalt manganate positive electrode material is obtained.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Air purifying device

ActiveCN103542457AEfficient removalAvoid dirtLighting and heating apparatusElectrostatic separationParticulatesHigh concentration

The invention discloses an air purifying device which comprises an electronic filter screen component and a negative ion generator component. A first gap is formed between the electronic filter screen component and the negative ion generator component. The electronic filter screen component comprises a first negative ion transmitting board, a first negative ion transmitting line, a positive-negative high voltage module, a positive high voltage line and an electronic filter screen, wherein the positive-negative high voltage module is connected with the first negative ion transmitting board through the first negative ion transmitting line and connected with the electronic filter screen through the positive high voltage line, and a second gap is formed between the first negative ion transmitting board and the electronic filter screen which are opposite. The negative ion generator component comprises a second negative ion transmitting board, a second negative ion transmitting line and a negative ion generator, wherein the negative ion generator is connected with the second negative ion transmitting board through the second negative ion transmitting line, and the second negative ion transmitting board and the first negative ion transmitting board are disposed in the same direction. The air purifying device is capable of outputting high-concentration negative oxygen ions and effectively eliminating floating dust, especially particles within PM2.5 (particulate matter2.5).

Owner:王大君

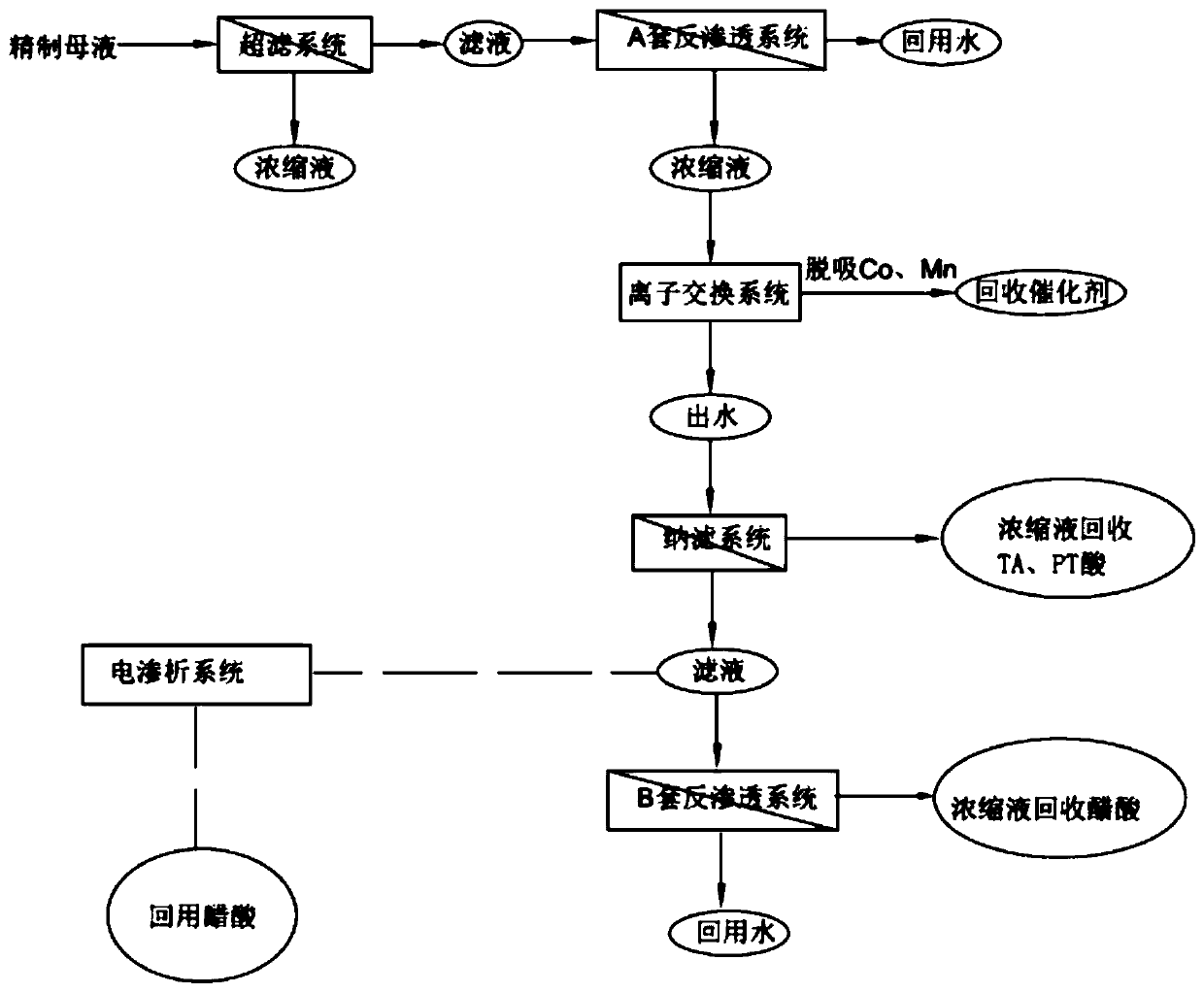

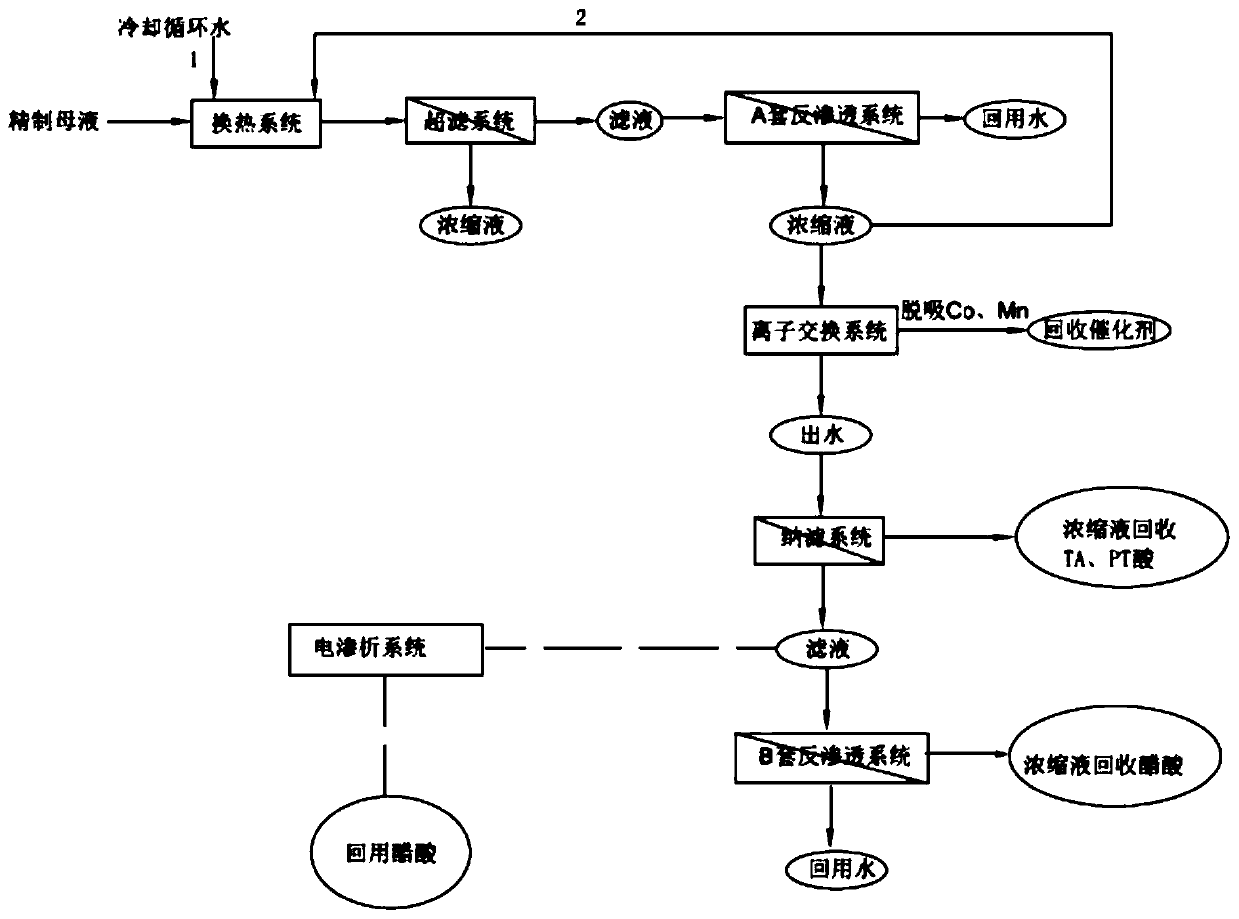

Recovery method and recovery system for PTA refined mother liquor

PendingCN110818149AAchieve recyclingEmission reductionWater contaminantsWater/sewage treatment by ion-exchangeAcetic acidReverse osmosis

The invention relates to a recovery method and a recovery system for PTA refined mother liquor, and belongs to the technical field of water treatment and resource recycling. An alkali is added into the PTA refined mother liquor and then the mother liquor is fed into an ultrafiltration system; ultrafiltration is carried out, and an ultrafiltration concentrated solution and an ultrafiltration filtrate are obtained; the ultrafiltration filtrate is fed into a reverse osmosis system A; wherein the filtrate of the reverse osmosis system A is produced water, and reuse is performed; a concentrated solution of the reverse osmosis system A enters an ion exchange system for adsorption of cobalt and manganese ions and other metal ions; effluent obtained after ion exchange separation enters a nanofiltration system, nanofiltration filtrate enters a reverse osmosis system B or an electrodialysis system, a main component in a concentrated solution of the reverse osmosis system B or a concentrated chamber of the electrodialysis system is acetic acid and can be recycled, and filtrate of the reverse osmosis system B and water in a light chamber of the electrodialysis system can be recycled. Comparedwith the prior art, the method has the advantages that various effective components and heat energy in the PTA refined mother liquor can be efficiently recovered and utilized, the discharge amount ofpollutants is reduced, and the PTA production cost and the wastewater treatment difficulty are reduced.

Owner:SHANGHAI KAIXIN ISOLATION TECH CO LTD

Ionized gas detection device

ActiveCN101915801AReduce volumeAvoid separationMaterial analysis by electric/magnetic meansCorona dischargeAmount of substance

The invention relates to the technology of trace material detection, and discloses an ionized gas detection device. An open corona discharge ionic generator is adopted to improve the performance of the ionic generator. The invention adopts a technical scheme that: the ionized gas detection device comprises the ionic generator, an ionic filter and an ionic detector, wherein the ionic generator generates detecting ions; the ionic filter is used for generating an electric field so as to prevent non-detected ions from passing and allow detected ions to pass; the ionic detector is used for detecting the ions passing through the ionic filter; the ionic generator is formed by a rectangular metal box which is arranged in a passage of sample gas flow and carrier gas flow, so that the sample gas flow and the carrier gas flow pass from two sides of the rectangular metal box respectively; one side of the rectangular metal box is opened, and the open side faces the sample gas flow; and a spray point is arranged in the metal box, and the sample gas flow is ionized through discharging between the spray point and the metal box. The device can be used for a miniature gas detection device.

Owner:CHENGDU ACTION ELECTRONICS JOINT STOCK

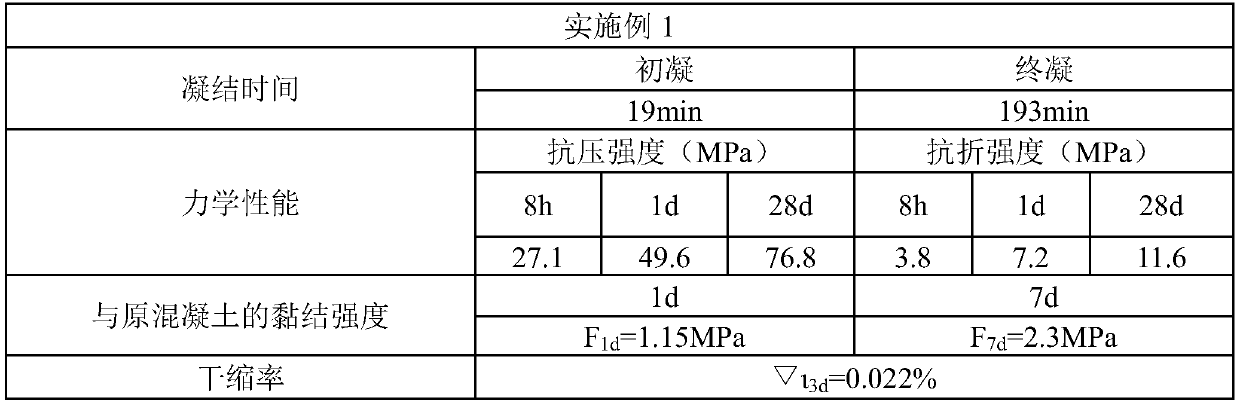

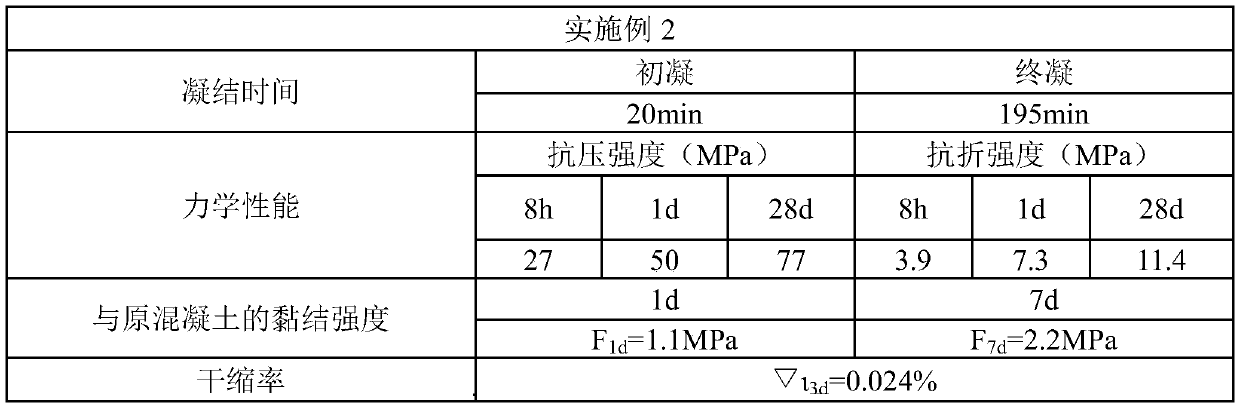

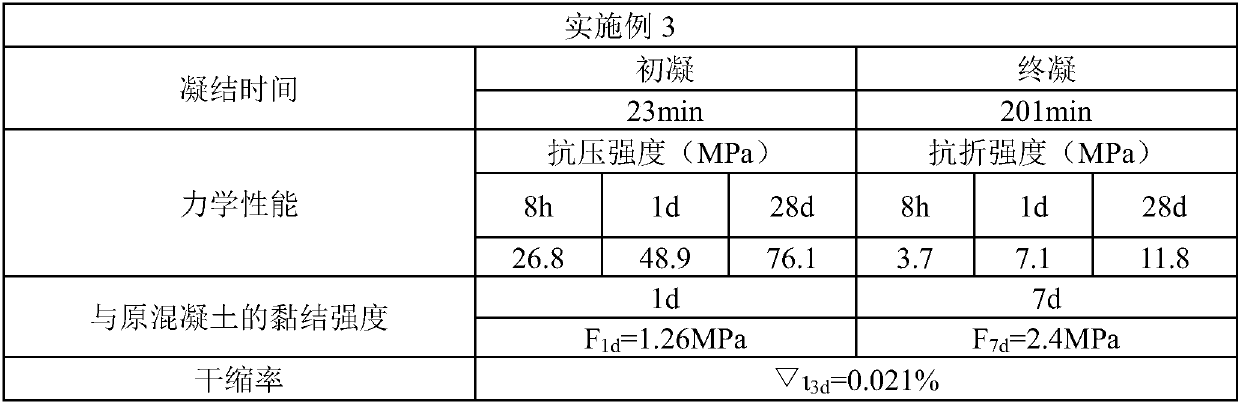

Rapid hardening early strength type composite repair mortar

The invention belongs to the technical field of building materials, and provides rapid hardening early strength type composite repair mortar. The rapid hardening early strength type composite repair mortar comprises, by weight, 5%-10% of water, 20%-30% of cement, 1%-5% of silica fume, 1%-5% of fly ash, 50%-70% of quartz sand, 0.4%-0.5% of composite early strength agents, 0.06%-0.1% of water reducing agents, 1%-5% of gelatin powder and 0.06%-0.8% of hybrid fibers. The composite early strength agents comprise components A and components B, the components A are nanometer calcium carbonate whiskers, the components B are mixtures of triisopropanolamine and aluminum sulfate, the quartz sand comprises coarse sand, medium sand and fine sand, and the hybrid fibers include basalt fibers and polypropylene fibers. The rapid hardening early strength type composite repair mortar has the advantage that the problems of strength decreasing, high dry shrinkage and low bonding strength of repair mortar in the prior art can be solved by the aid of the rapid hardening early strength type composite repair mortar.

Owner:长春昌驰新材料科技有限公司

Method for detecting elements in solutions and device for realizing the same

InactiveUS6518567B1Increase rangeReduce detectionTime-of-flight spectrometersMaterial analysis by electric/magnetic meansMass analyzerTime of flight

The present invention pertains to the construction of analytical instruments and may be used for analysing naturel or industrial waters, biological samples as well as geological samples. The method for detecting elements in solutions comprises pulverising the samples using pulses, ionising the pulverised atoms during Penning's collisions and recording the ions thus formed during a mass spectral analysis while carrying out a separation of the ion time-of-flight. The pulse pulverisation of the sample is carried out from a surface which is heated at a temperature of between 1000 and 1500% C. and on which the sample dried in a flow of ballast gas forms a dry residue. The ballast gas may consist of Kr, Xe or mixtures thereof wich Ar under a pressure of between 1 and 2 torrs. The device for detecting elements in solutions comprises an ionising device which is arranged in a gas-discharge chamber filled with an inert gas. The detection device further includes a time-of-flight mass spectrometer which comprises an ion sampling and focusing system as well as a reflective mass in the shape of a spectral analyser. The ionising device is made in the shape of a thin-wall, metallic, cylindrical and hollow cathode that comprises a dosing opening which is used for introducing the sample to be analysed and which is located on a same axis with a vacuum port.

Owner:GANEEV ALEXANDR AKHATOVICH +1

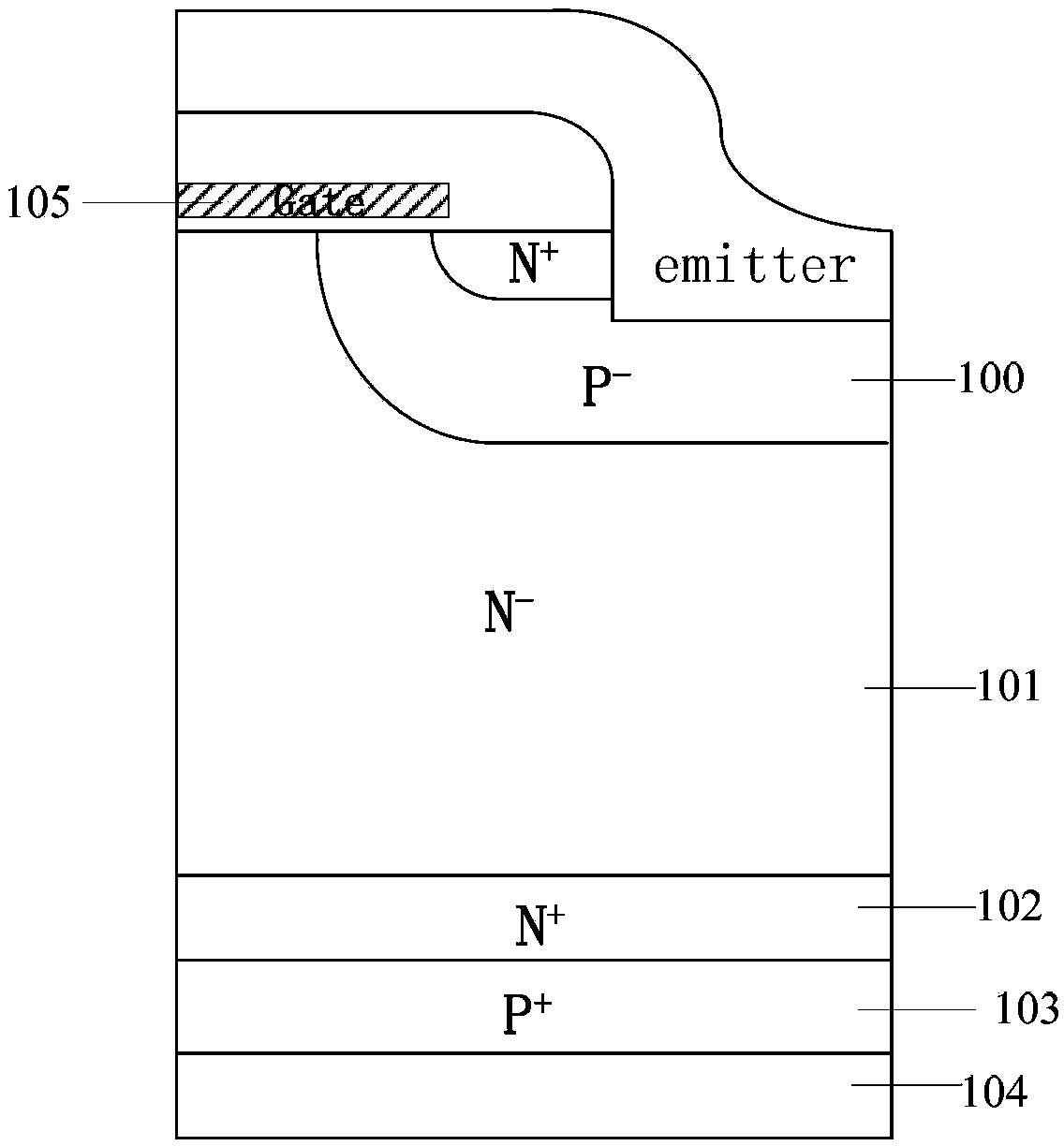

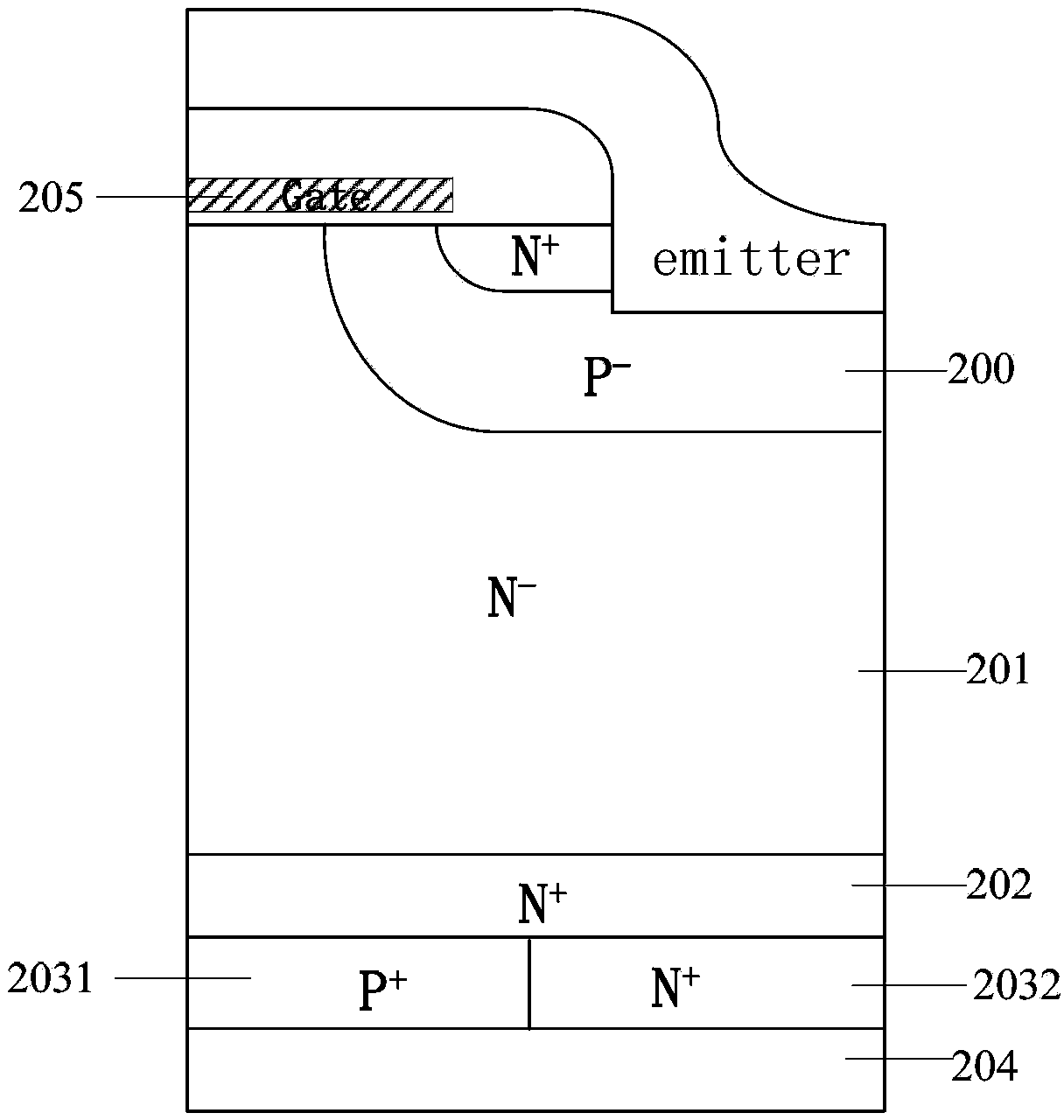

Reverse-conduction-type IGBT device and formation method thereof

ActiveCN103855198AIncrease ion concentrationImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical resistance and conductanceTitanium metal

The embodiment of the invention discloses a reverse-conduction-type IGBT device which includes a semiconductor substrate; a collection electrode formed in the lower surface of the semiconductor substrate, wherein the collection electrode includes a collector region and a short-circuit region, which are arranged in parallel; an aluminum metal layer formed on the surface of the collection electrode, wherein the aluminum metal layer at least covers the collector region; and a titanium metal layer formed on the surface of the aluminum metal layer. The titanium metal layer covers the collector region and the short-circuit region completely so that excellent ohmic contact is formed between the collector region and the metal layers on the surface of the collector region, and excellent ohmic contact is formed between the short-circuit region and the metal layer on the surface of the short-circuit region so that the contact resistance between the collection electrode and the metal layers on the surface of the collection electrode is reduced and thus the performance of the reverse-conduction-type IGBT device is improved.

Owner:SHANGHAI LIANXING ELECTRONICS +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com