New method and system for TSV blind hole filling

A new method, the technology of blind vias, is applied in electrolytic coatings, circuits, semiconductor devices, etc., and can solve problems such as high production costs, high aspect ratio TSV plating filling efficiency, low current density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

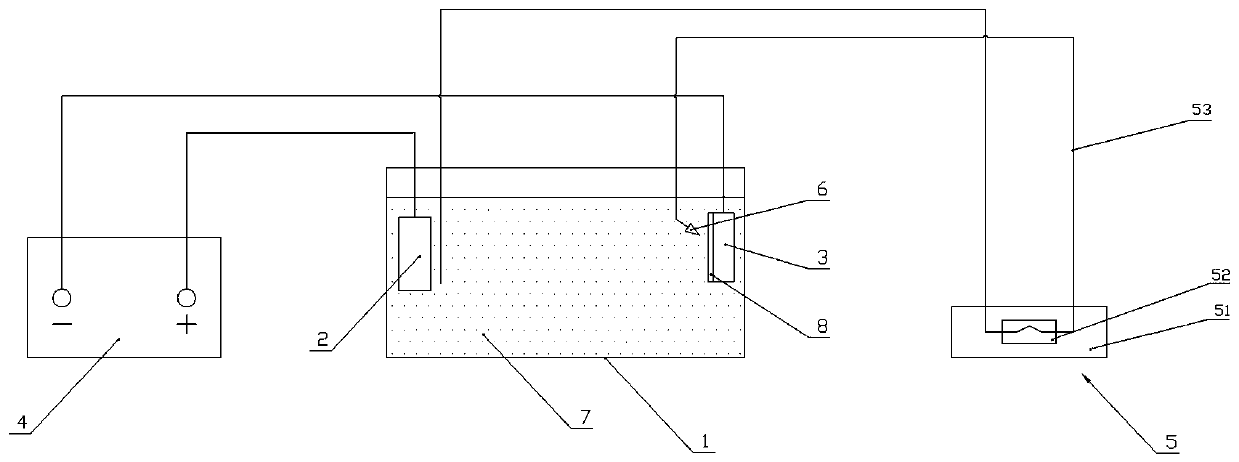

[0026] Such as figure 1 As shown, the TSV blind hole filling system provided in this embodiment includes an electroplating tank 1, an electroplating anode 2, an electroplating cathode 3, an electroplating power supply 4, a peristaltic pump 5, a nozzle 6 and an electroplating solution 7 added to the electroplating tank . Wherein the peristaltic pump 5 includes a driver 51, a pump head 52 and a flexible pipe 53, the nozzle 6 is connected to the outlet of the flexible pipe, and the electroplating solution 7 is a mixed suspension electroplating solution of copper sulfate electroplating solution, nanoparticles, inhibitors and accelerators, electroplating The anode and the electroplating cathode respectively extend into the electroplating solution and are located on both sides of the electroplating tank.

[0027] This embodiment also provides a new method for filling TSV blind holes, which includes the following steps: Step 1. Put the silicon wafer 8 with TSV blind holes into deion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com