Patents

Literature

58results about How to "Co-deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

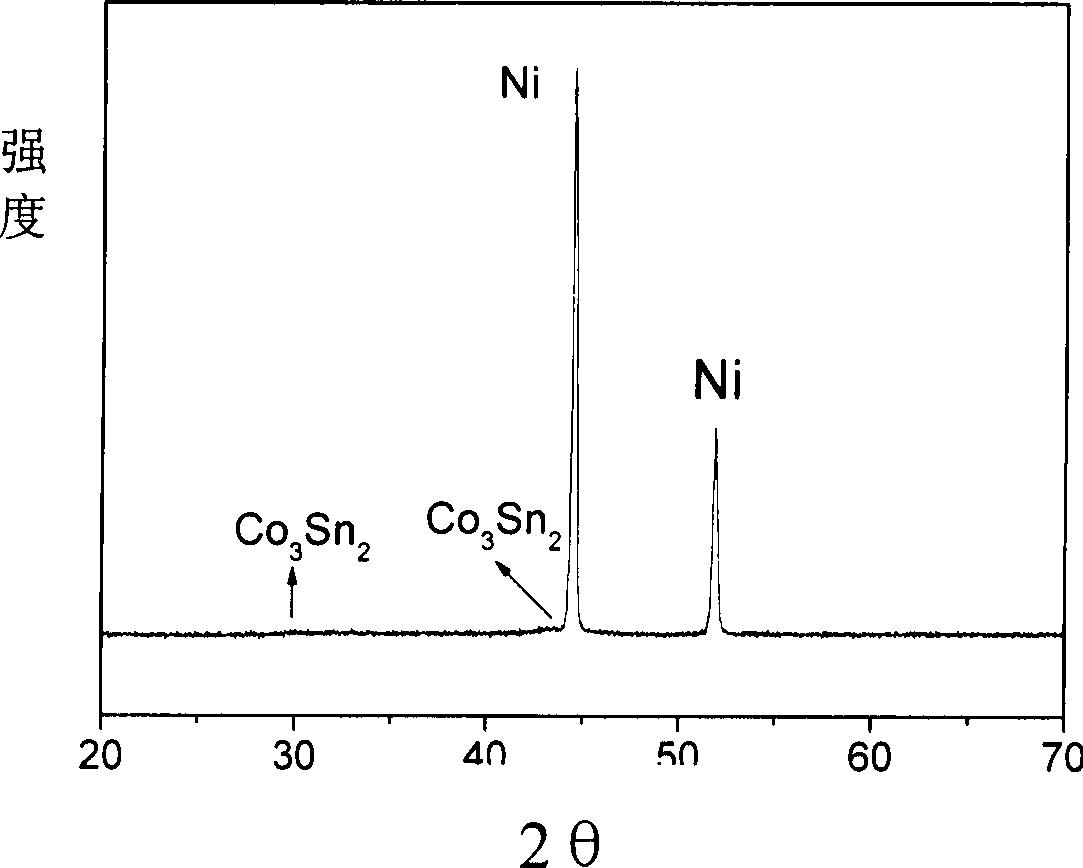

Electrochemical deposition preparation for lithium ionic cell tin-cobalt alloy film electrode

InactiveCN101476139AThe preparation process is easy to controlSimple processAlkaline accumulator electrodesThin film electrodeLyonium ion

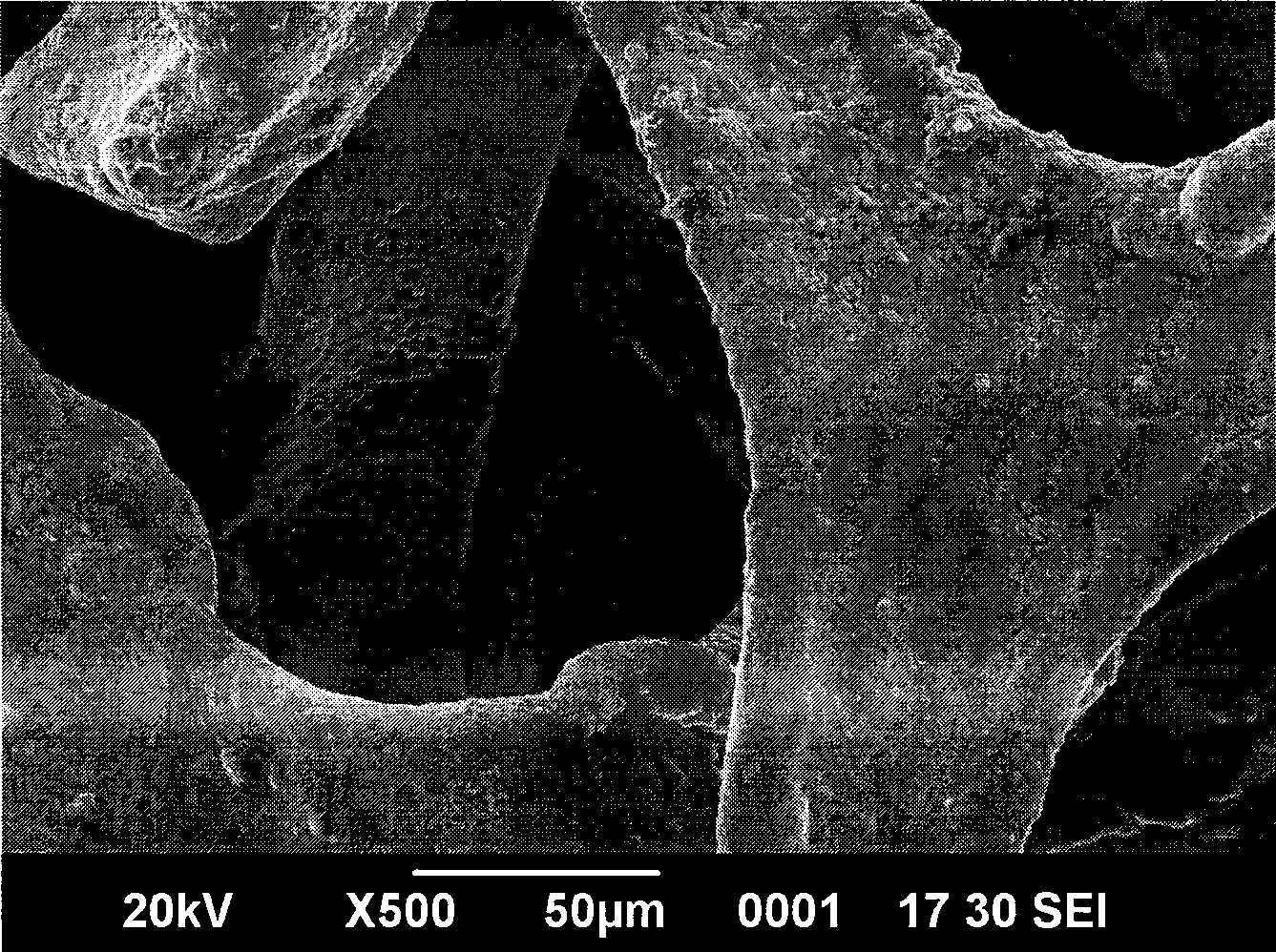

The invention provides an electrical chemical depositing method for preparing lithium battery tin-cobalt alloy thin film electrode which has characteristics that foam nickel with a plurality of holes is used as basic body, the tin-cobalt alloy thin film is obtained by electrical chemical depositing on the foam nickel basic body for manufacturing lithium battery tin-cobalt alloy thin film electrode. The method has advantages of simple practical and low cost, and the tin-cobalt alloy thin film electrode is distributed on the foam nickel basic body that can ease electrode expansion in charge / discharge cycle process for improving cycle performance of battery. The method has latent application prospect in the lithium battery electrode material field.

Owner:HEFEI UNIV OF TECH

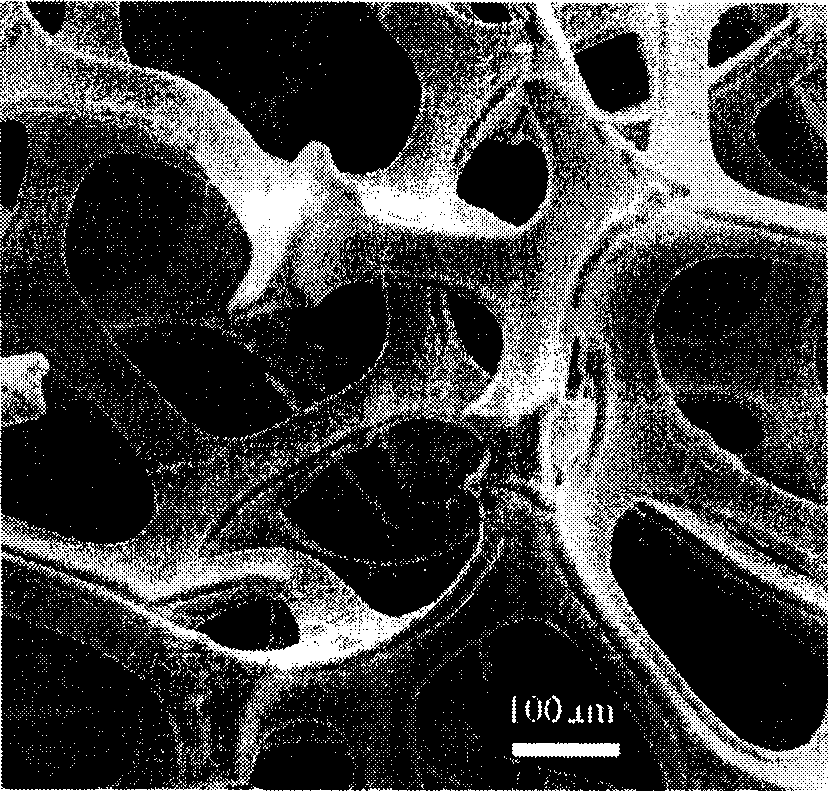

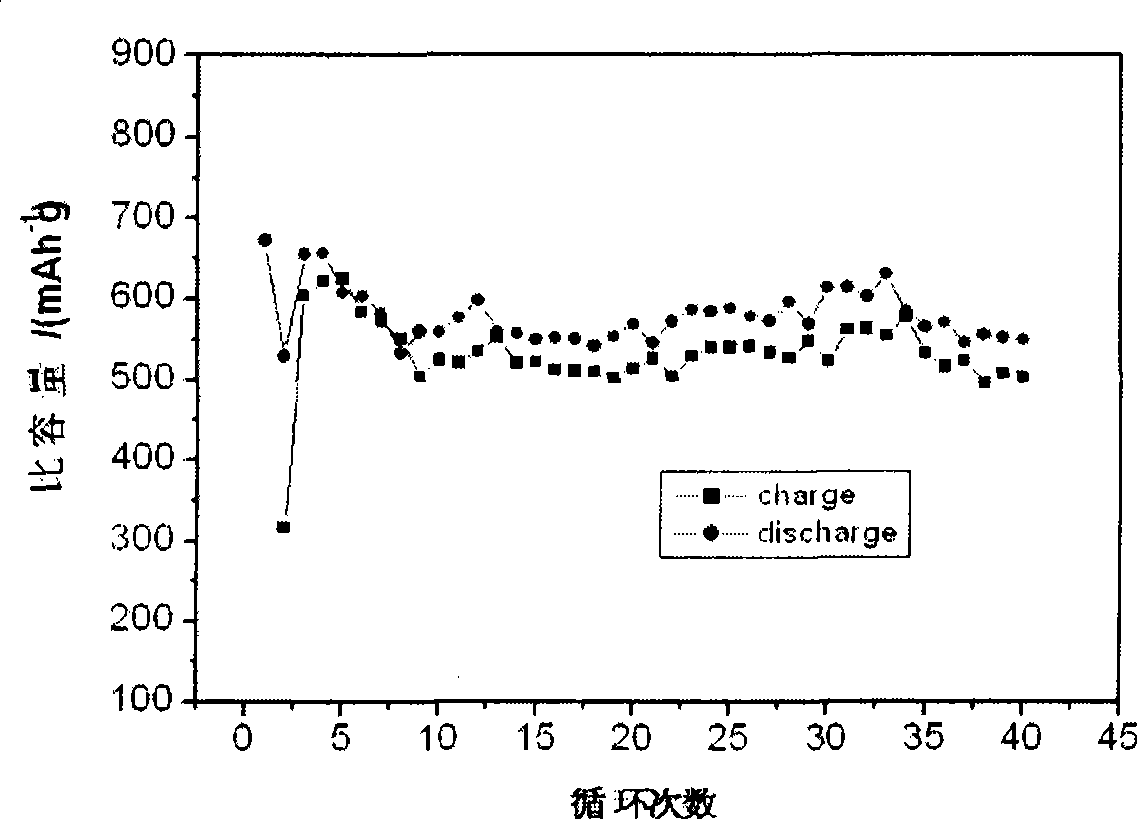

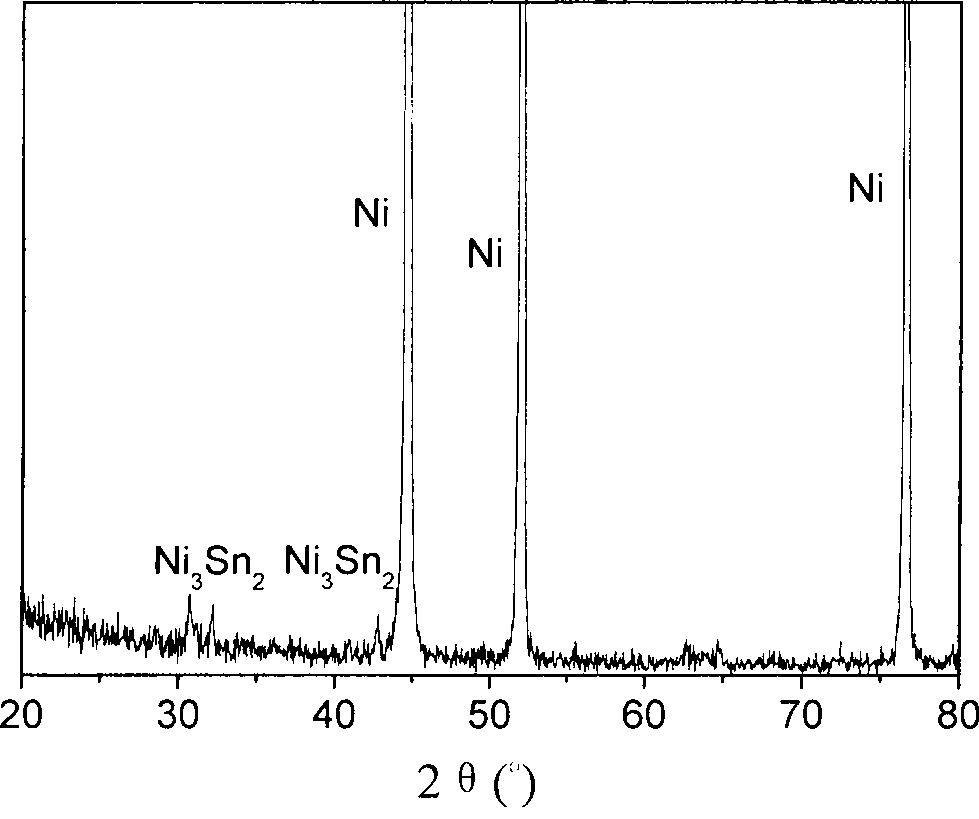

Method for preparing nickeltin thin film electrode for lithium ion battery through electrochemical deposition

InactiveCN101447567AThe preparation process is easy to controlSimple processElectrode manufacturing processesCyclic processThin film electrode

The invention relates to a method for producing lithium ion battery nickeltin thin-film electrode through electrochemical deposition. The method is characterized in that porous foamed nickel is adopts as the matrix, a nickeltin thin-film is obtained from the foamed nickel matrix through electrochemical deposition, and the lithium ion battery nickeltin thin-film electrode taking the foamed nickel as the matrix is produced. The method is simple, convenient and feasible, the cost is low, the nickeltin thin-film electrodes are distributed on the foamed nickel matrix, the expansion of the electrodes in the charging and discharging cyclic process can be eased, therefore, the cycle performance of the battery is improved, and the invention has potential application prospect on the application aspect of the electrode material of the lithium ion battery.

Owner:HEFEI UNIV OF TECH

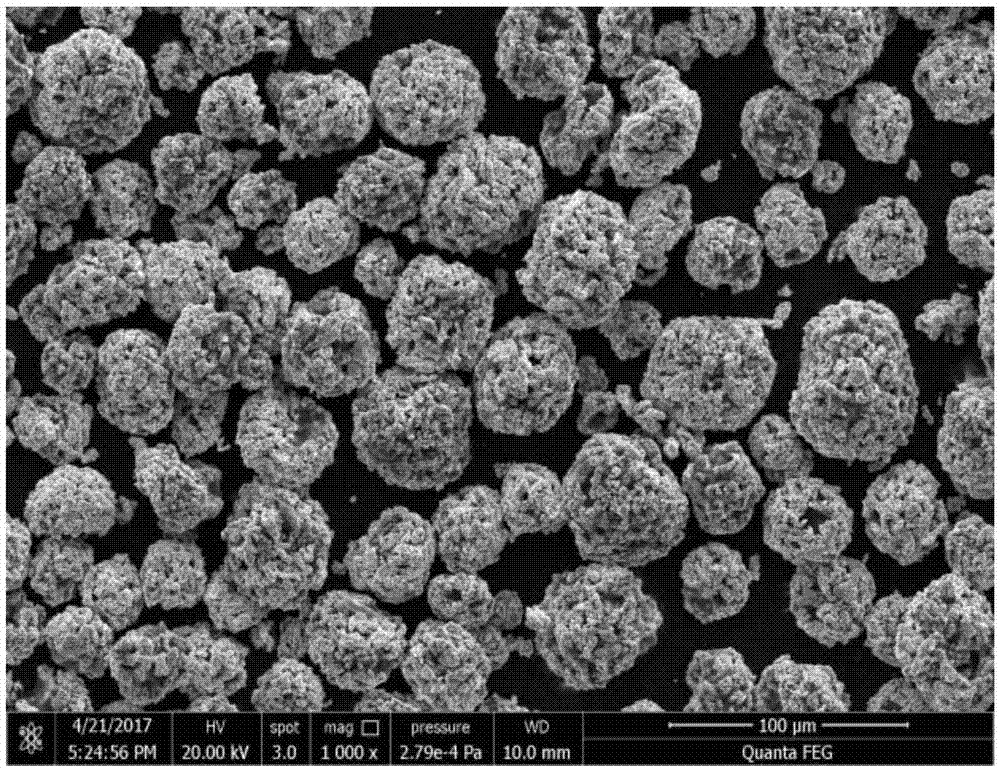

Preparation method of graphene-copper-amorphous composite coating

ActiveCN107354421AQuality improvementReduce coefficient of frictionMolten spray coatingTransportation and packagingCvd graphenePre treatment

The invention provides a preparation method of a graphene-copper-amorphous composite coating. The preparation method comprises the following steps that graphene-copper composite powder is prepared; graphene-copper-amorphous composite powder is prepared; the graphene-copper-amorphous composite coating is prepared on the surface of a workpiece through the hot spraying technology by taking the composite powder as composite feeding powder for spraying; according to the hot spraying process, the surface of a workpiece substrate is subjected to cleaning pretreatment firstly, then sand blasting is conducted, spraying is conducted through the hot spraying technology, and a bonding coating which is 80-120 microns thick is obtained; and finally, spraying is conducted on the surface of the sample treated in the last step through the hot spraying technology, and the graphene-copper-amorphous composite coating is obtained. The grain size of the graphene-copper composite powder is 10-100 microns. The friction coefficient of the composite coating is reduced by 37.5% compared with that of a single amorphous coating. The abrasion resistance of the composite coating is improved, and the abrasion weight loss of the composite coating can be reduced by 57.8% compared with that of the single amorphous coating.

Owner:HEBEI UNIV OF TECH

Ni-Cu-P-Ce alloy plating layer and preparation process

InactiveCN102994991APromote formationImprove catalytic abilityLiquid/solution decomposition chemical coatingSodium acetateCerium nitrate

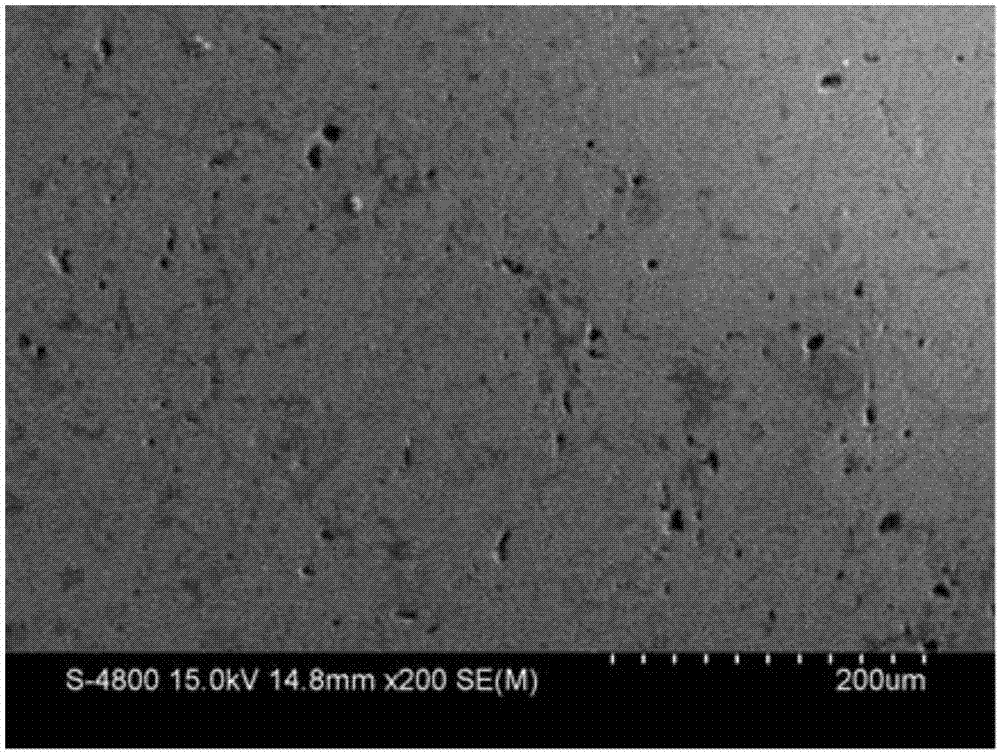

The invention relates to chemical plating on a surface of a metal material and particularly to a Ni-Cu-P-Ce alloy plating layer used for chemical plating on a surface of a low-carbon steel base material and a preparation process of the Ni-Cu-P-Ce alloy plating layer. The Ni-Cu-P-Ce alloy plating layer adopts a plating liquid composed of 35-40 g / L of nickel sulfate, 0.2-0.4 g / L of copper sulfate, 25-30 g / L of sodium hypophosphite, 8-10 g / L of sodium acetate, 25-30 g / L of trisodium citrate, 22-28 ml / L of lactic acid, 8-10 g / L of butanedioic acid, 0.2-0.4 g / L of cerium nitrate, 8 mg / L of potassium iodide, 1.5 mg / L of thiourea, 0.01 g / L of glycine and 0.2 g / L of ammonium bifluoride. For the adoption of ultrasonic chemical plating, a plating layer material formed by codeposition of Ce, Cu and Ni is obtained; and the material has increased compactness, is a microlithic texture, and is high in hardness and strong in corrosion resistance.

Owner:SHANDONG JIANZHU UNIV

Alloy nanotube and manufacturing method thereof

InactiveCN101469453AEasy to manufactureThe preparation process is easy to controlPolycrystalline material growthSingle crystal growth detailsNanoholeNanotube

The invention discloses an alloy nano-tube and a preparation method thereof, which belong to the field of nanometer material. The alloy nano-tube is a solid solution, a metal compound or an amorphous state formed by two transition metal elements, namely A and B, wherein the A accounts for 15.3 to 86.4 percent of the total amount, and the B accounts for 13.6 to 84.7 percent of the total amount. The preparation method comprises the following steps: a formwork with a layer of gold or platinum film introduced into the back side is soaked in an electrolysis bath containing metal ion A and B, and is electrodeposited under certain voltage and current conditions to obtain a binary alloy nano-tube. Binary alloy nano-tubes with different diameters, different lengths and different components can be obtained by adopting formworks with nanochannels with different inner diameters, controlling the electrodeposition time and adjusting cathode current density. The binary alloy nano-tube has simple preparation process, mild reaction conditions, strong controllability and good application prospect.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing diamond-like composite film containing gold nanoparticles

InactiveCN101205625ACo-depositionEvenly dispersedElectrolytic inorganic material coatingElectrochemistryCarbon composites

The invention relates to a preparing method of a diamond-like carbon composite film with gold nano particles. Methanol solution with gold nano particles is selected as deposit liquid; a method of electrochemical deposition is adopted; graphite is used as anode, and a conductive substrate is used as cathode; the diamond-like carbon composite film with gold nano particles is received deposited and obtained on the cathode through direct current high voltage and stirring effect. The invention has the characteristics that the equipment is simple, the temperature of deposition is low, the film is formed evenly, common deposition of nano particles and DLC film is fulfilled, and the nano particles can be evenly scattered in carbon substrate of the film.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of copper-zinc-iron ternary alloy chemical plating layer on surface of aramid fiber

InactiveCN104088138AHigh surface energyImprove wetting performancePhysical treatmentFibre typesChemical platingSurface modification

The invention discloses a preparation method of a copper-zinc-iron ternary alloy chemical plating layer on the surface of aramid fiber. The preparation method comprises the following steps: carrying out surface modification on aramid fiber; carrying out low-concentration colloid palladium treatment; and carrying out a copper-zinc-iron ternary alloy chemical plating process. The preparation method has the beneficial effects that an environment-friendly glyoxylic acid chemical plating process is used to realize co-deposition of a copper-zinc-iron ternary alloy; the plating layer is composed of following components in percentage by mass: 85%-90.5% of copper, 1.0%-3.0% of iron, 0.5%-1.5% of zinc and the balance of carbon and oxygen; through detection, the surface resistance of the plating layer keeps below 50m(omega) / sq; an adhesive tape method is used for determining the binding force between the plating layer and fabric fibers and the weight loss ratio is less than 0.1%; the plating layer is bright and a microstructure is uniform; the plating layer can resist atmosphere corrosion and meets the requirements of electric conduction, electromagnetic shielding, static electricity prevention and the like.

Owner:SHANDONG JIANZHU UNIV

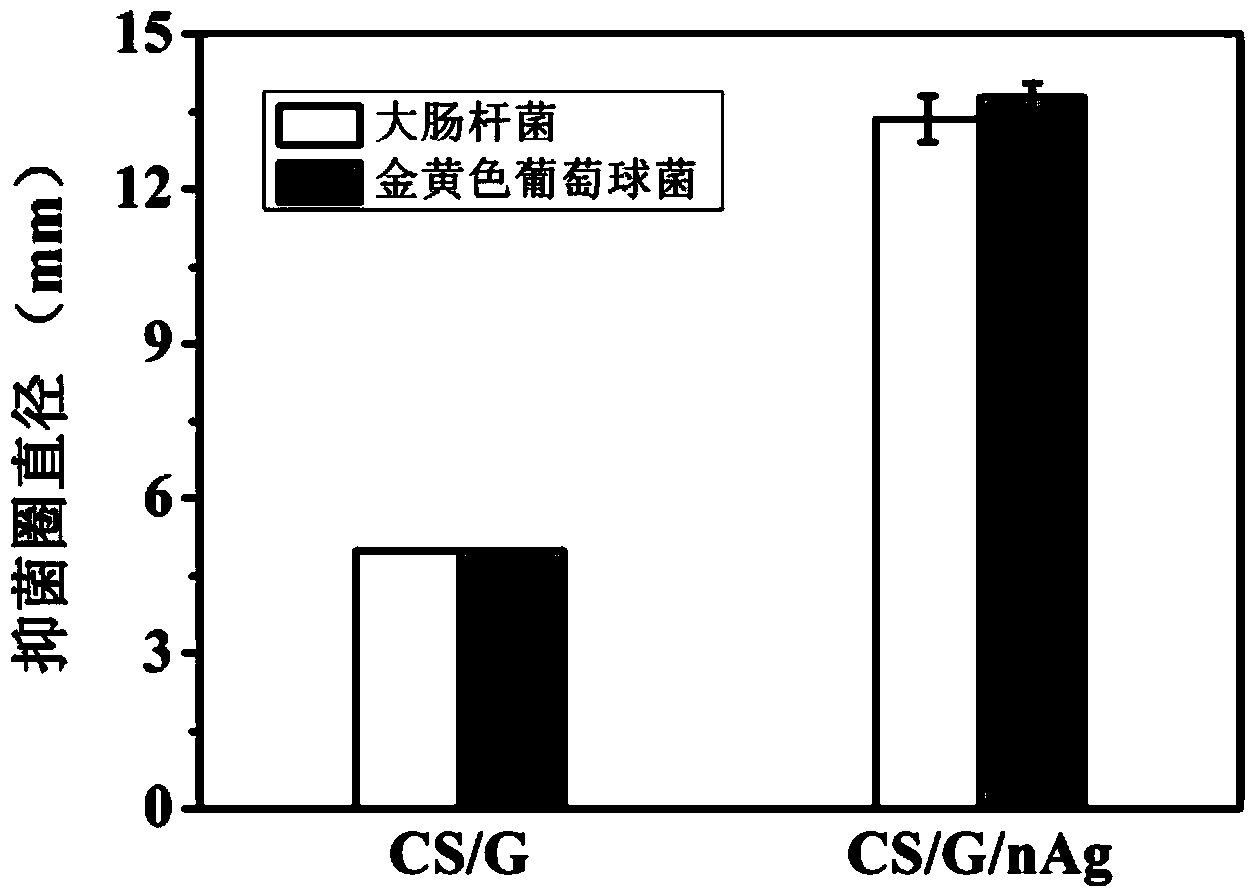

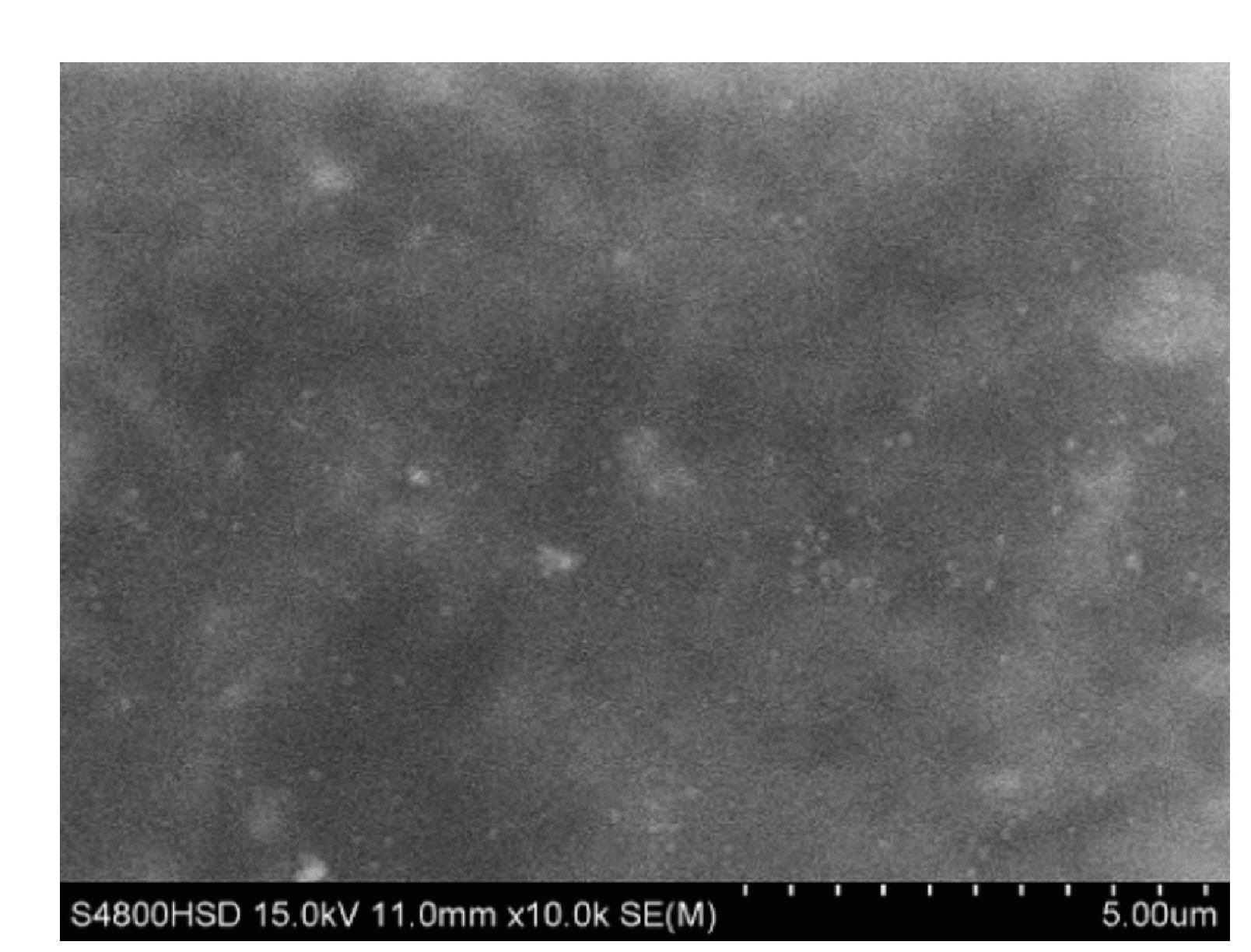

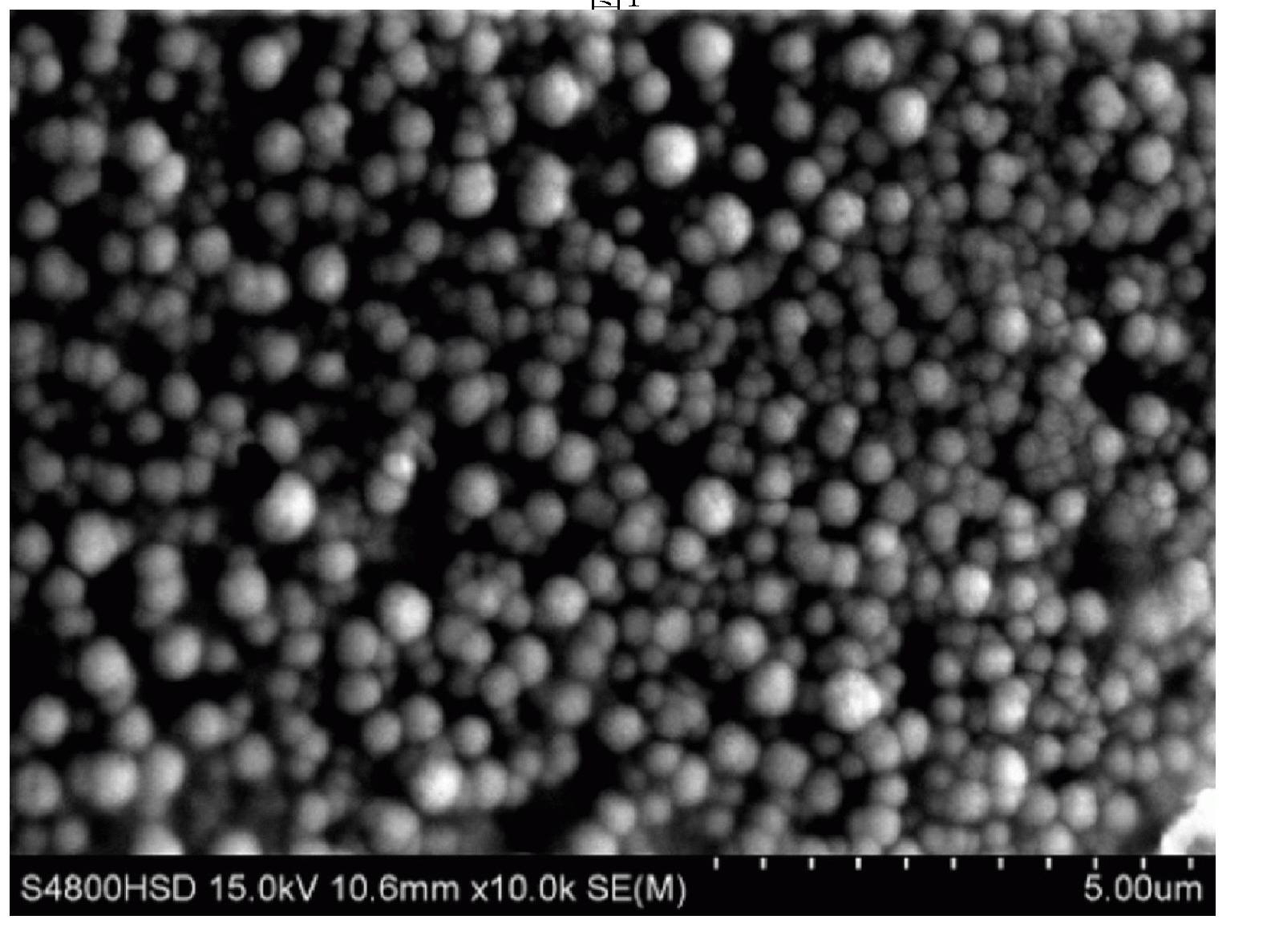

Chitosan/gelatin/nano-silver conductive antibacterial material and preparation method thereof

InactiveCN104233436AImprove mechanical propertiesCo-depositionElectrolytic coatingsNanotechnologyBiocompatibility TestingAntibacterial activity

The invention relates to a chitosan / gelatin / nano-silver conductive antibacterial material and a preparation method thereof. The preparation method comprises the following steps: (1) preparing a chitosan solution; (2) preparing an electro-deposition liquid; and (3) preparing the chitosan / gelatin / nano-silver conductive antibacterial material, namely immersing a titanium alloy plate serving as a negative pole and a platinum plate serving as a positive pole in the electro-deposition liquid prepared in the step (2), taking out and washing the titanium alloy plate with a deposition layer after electro-deposition is completed, then immersing in a 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride aqueous solution of which the concentration is 0.05-0.20mol / L, and carrying out post-treatment at the end of the reaction to obtain the chitosan / gelatin / nano-silver conductive antibacterial material. The preparation method is simple and convenient to operate and easy to control, and has the characteristics of simple equipment, mild reaction condition and the like; the prepared material has excellent biocompatibility and biodegradability and has conductive performance and excellent antibacterial activity.

Owner:WUHAN UNIV OF TECH

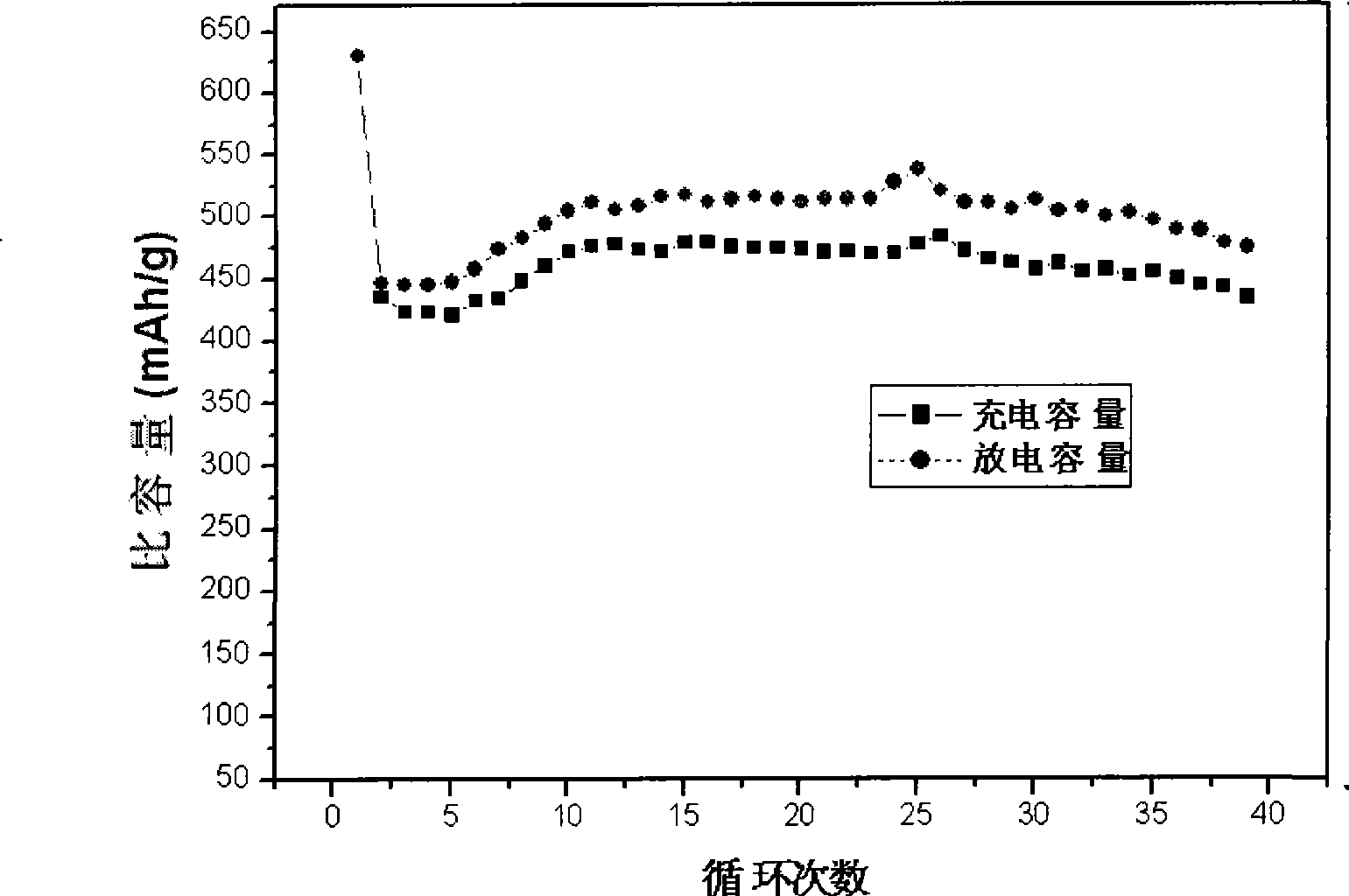

Method for electrodepositing lithium-copper alloy in ionic liquid system

The invention discloses a method for electrodepositing a lithium-copper alloy in an ionic liquid system, which relates to a method for electrodepositing the lithium-copper alloy. The method solves the problems that the conventional smelting method for preparing the lithium-copper alloy cannot control the lithium element content easily and has high energy consumption. The method comprises the following: step one, adding LiBF4, Cu(BF4)2 and an additive into BMIMBF4 in turn to prepare an electrolyte; and step two, immerging an anode material and a cathode material into the electrolyte, and adopting a constant current mode and controlling the current density and the electrodepositing time to realize the preparation of the lithium-copper alloy, wherein the two steps are performed in a glove box. The method has the advantages of concise process, simple equipment and low energy consumption; the metal lithium content in the lithium-copper alloy is adjusted and controlled by adjusting components and electrodepositing technological parameters of the electrolyte; the metal lithium content is controllable; and the atomic mass percent content is 7 to 40 percent. Simultaneously, the method realizes co-deposition of lithium and copper which have large electrode potential differences; and the obtained lithium-copper alloy can be used as a cathode material for a lithium ion battery.

Owner:HARBIN INST OF TECH

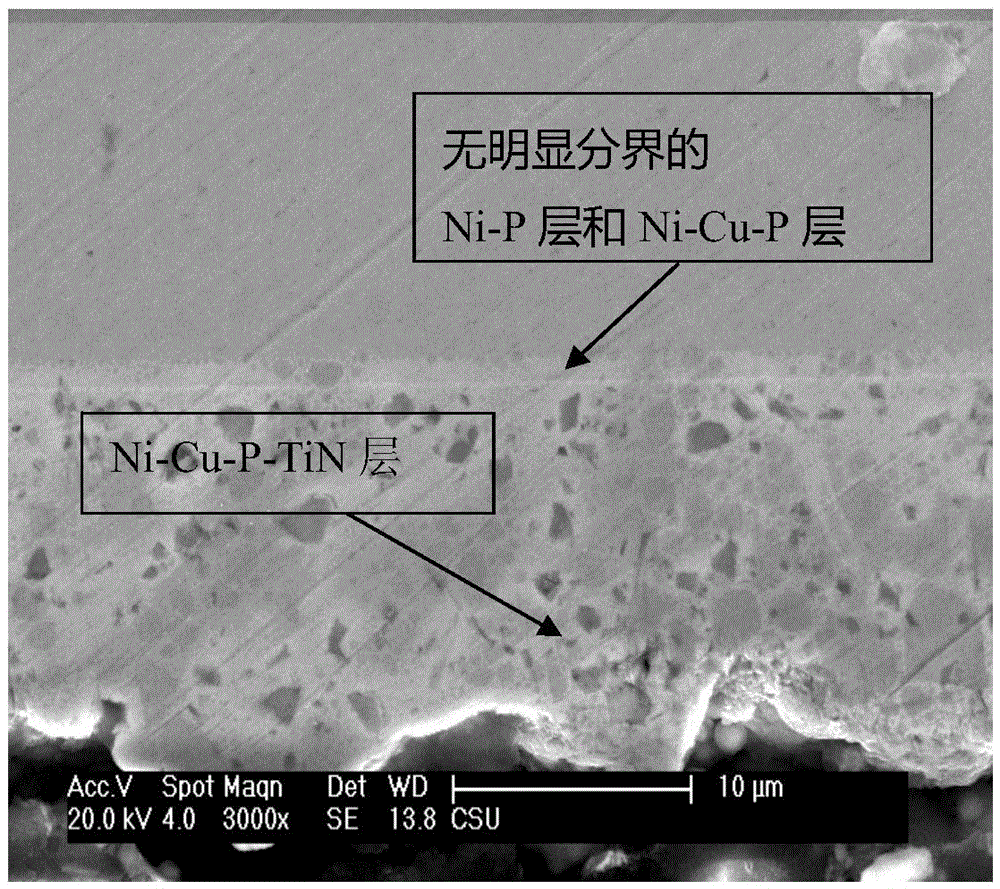

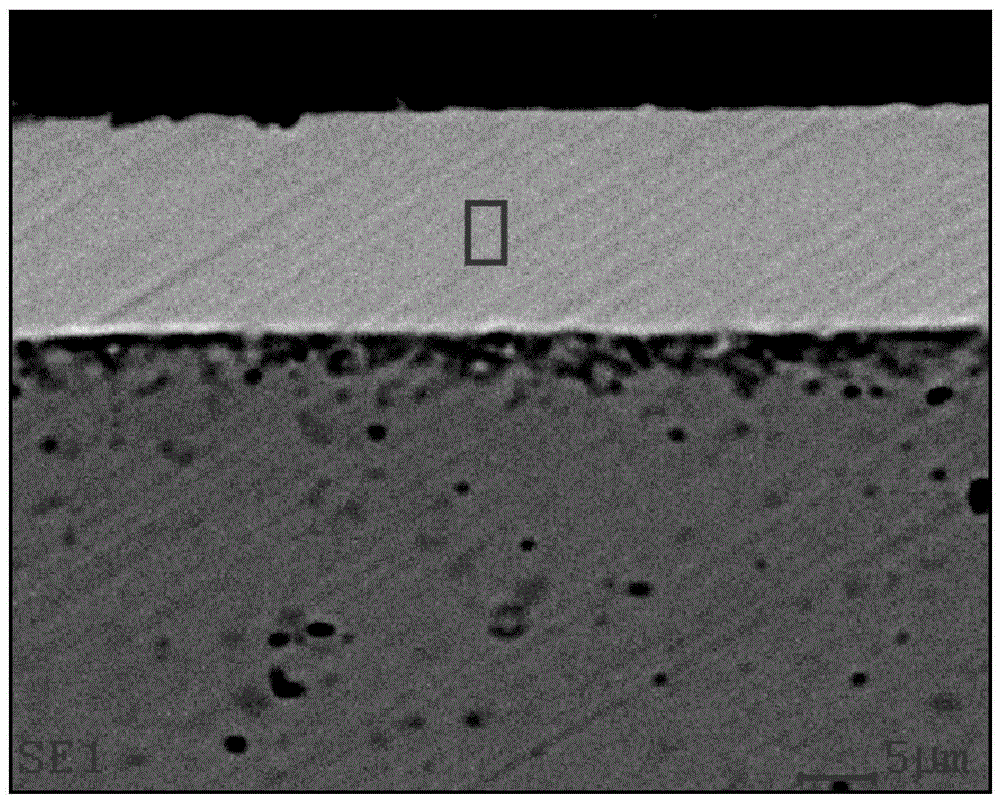

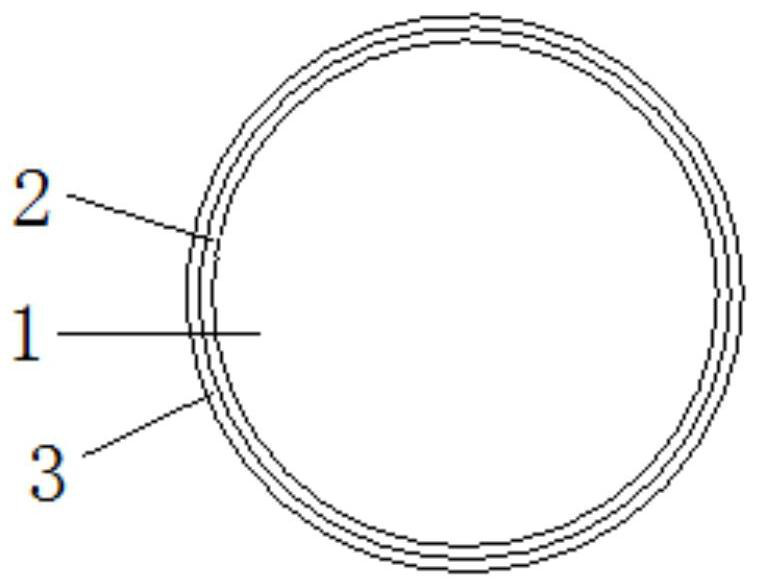

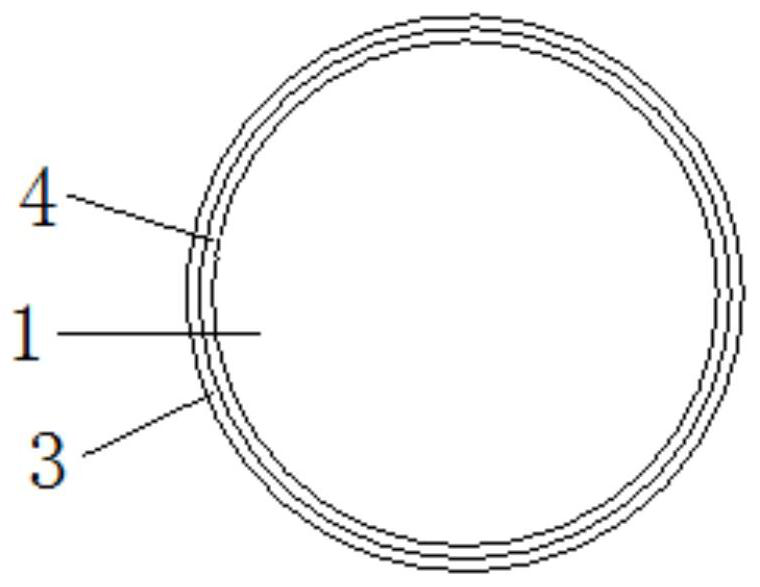

Anticorrosion abrasive-resistant material with Ni-Cu-P-TiN composite coating and preparation method of material

InactiveCN104339752AHigh hardnessLow shear strengthLiquid/solution decomposition chemical coatingMetal layered productsAlloyMetal

The invention discloses an anticorrosion abrasive-resistant material which sequentially comprises a base material, a Ni-P coating, a Ni-Cu-P coating and a Ni-Cu-P-TiN coating from inward to outward. According to the invention, flexible metal Cu and TiN nano particles are added into the Ni-P coating via a prior precipitation mechanism and a co-deposition mechanism, so that the Cu metal and the TiN particles have complementary performance advantages; meanwhile, in order to improve the wettability of the TiN particles and a Ni-P alloy, the TiN particles are subjected to Ni coating modification treatment, and the bonding intensity of the TiN particles and the coating is increased; on the other hand, by the multi-layer structural design of Ni-P / Ni-Cu-P / (Ni-Cu-P-TiN), the problem of poor bonding intensity of the coatings caused by the prior precipitation mechanism of Cu is solved. The method is simple in technology, and equipment is low in price; a subsequent technology is combined, a coating scraper with good corrosion resistance and tribology performance can be prepared, and the service life of the scraper can be multiplied.

Owner:CENT SOUTH UNIV +1

Chemical prepn process of composite hydroxyapatite/collagon layer on the surface of Ni-Ti alloy

The present invention belongs to the field of biological bone material preparing technology. The chemical preparation process of composite hydroxyapatite / collagen layer on the surface of Ni-Ti alloy includes the following steps: polishing, washing and drying the Ni-Ti alloy substrate and acid-alkali treatment; pre-calcifying of the substrate inside Na2HOP4 and Ca(OH)2 solution; and finally setting in simulating body fluid containing collagen to grow the composite hydroxyapatite / collagen layer. The process has the features of simple activating treatment and low acid-alkali treatment temperature. In the simulating body fluid containing collagen, hydroxyapatite and collagen are deposited simultaneously to form the composite hydroxyapatite / collagen layer with homogeneous surface and firm combination to the substrate. The present invention is suitable for implant with complicated shape.

Owner:TIANJIN UNIV

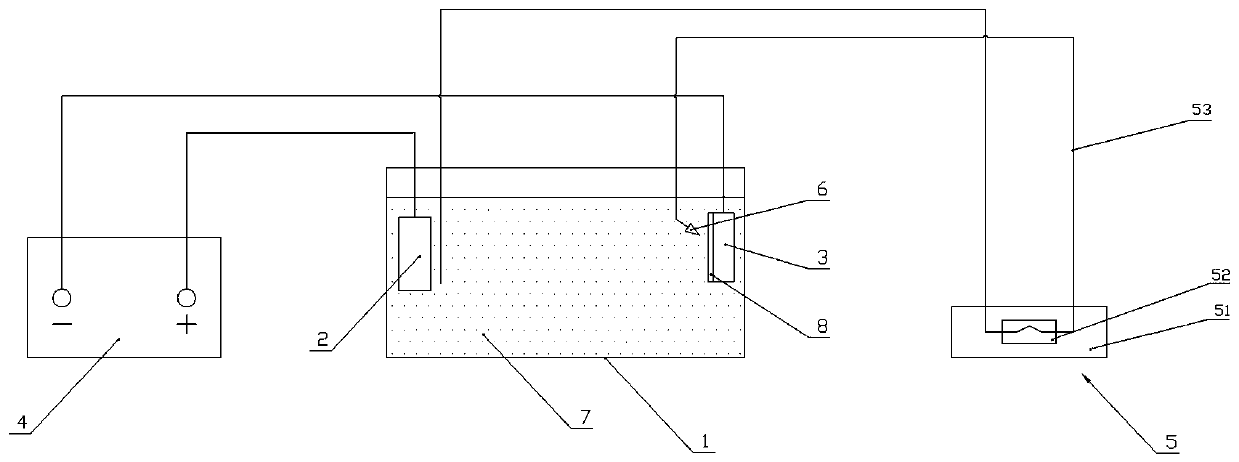

New method and system for TSV blind hole filling

InactiveCN107675233AFacilitated DiffusionImprove adsorption capacityElectrolytic coatingsSemiconductor devicesGalvanic anodeEngineering

The invention discloses a new method and system for TSV blind hole filling. The new method includes the following steps that firstly, a silicon piece with a TSV blind hole is put into deionized water,vacuum suction pretreatment is conducted, and gas in the TSV blind hole is exhausted; secondly, the silicon piece obtained after pretreatment is integrally connected with an electroplating cathode; thirdly, an additive agent, an inhibiting agent and an accelerating agent are added into an electroplating solution, sufficient mixing is conducted, and a suspension electroplating solution is formed;fourthly, the suspension electroplating solution is added into an electroplating bath, an electroplating anode and an electroplating cathode of an electroplating power source are put into the suspension electroplating solution so that the silicon piece can be subjected to standing in the suspension electroplating solution, and the electroplating solution reaches adsorption balance preliminarily inthe TSV blind hole; fifthly, an inlet and an outlet of a circulation pump communicate with the suspension electroplating solution, the inlet communicates with the position of the electroplating anode, and the outlet communicates with the position of the electroplating cathode; and sixthly, a circulation pump is started, the electroplating power source is started at the same time, electroplating begins, and the flowing speed is provided for the suspension electroplating solution in the electroplating bath through the circulation pump. The filling efficiency can be effectively improved, and thecost is reduced.

Owner:CENT SOUTH UNIV

Method for electroplating high-strength corrosion-proof cadmium-tin-titanium alloy on 304 or 316 L stainless steel surface

The invention provides a method for electroplating a protective plating layer of high-strength corrosion-proof cadmium-tin-titanium alloy on a 304 or 316 L stainless steel surface. The corrosion resistance of a plating layer is 6 to 7 times higher than that of a cadmium-plated layer, and the plating layer is uniform and fine and can be matched with cadmium-plated cyanide; after surface pre-treatment and in advanced cadmium-plating, the binding force of a cadmium-tin-titanium alloy plating layer is far more than that of the same kind of cadmium-tin plated alloy and the cadmium-plated layer; the cadmium-tin-titanium plating layer is porous, so that the hydrogen is beneficial for escaping; the cadmium-tin-titanium plating layer has good paintability, weldability, formability and low-hydrogen embrittlement; the whole preparation process is simple, cyanogen-free electroplating is achieved, and the preparation process is safe and environmentally-friendly.

Owner:无锡市恒利弘实业有限公司

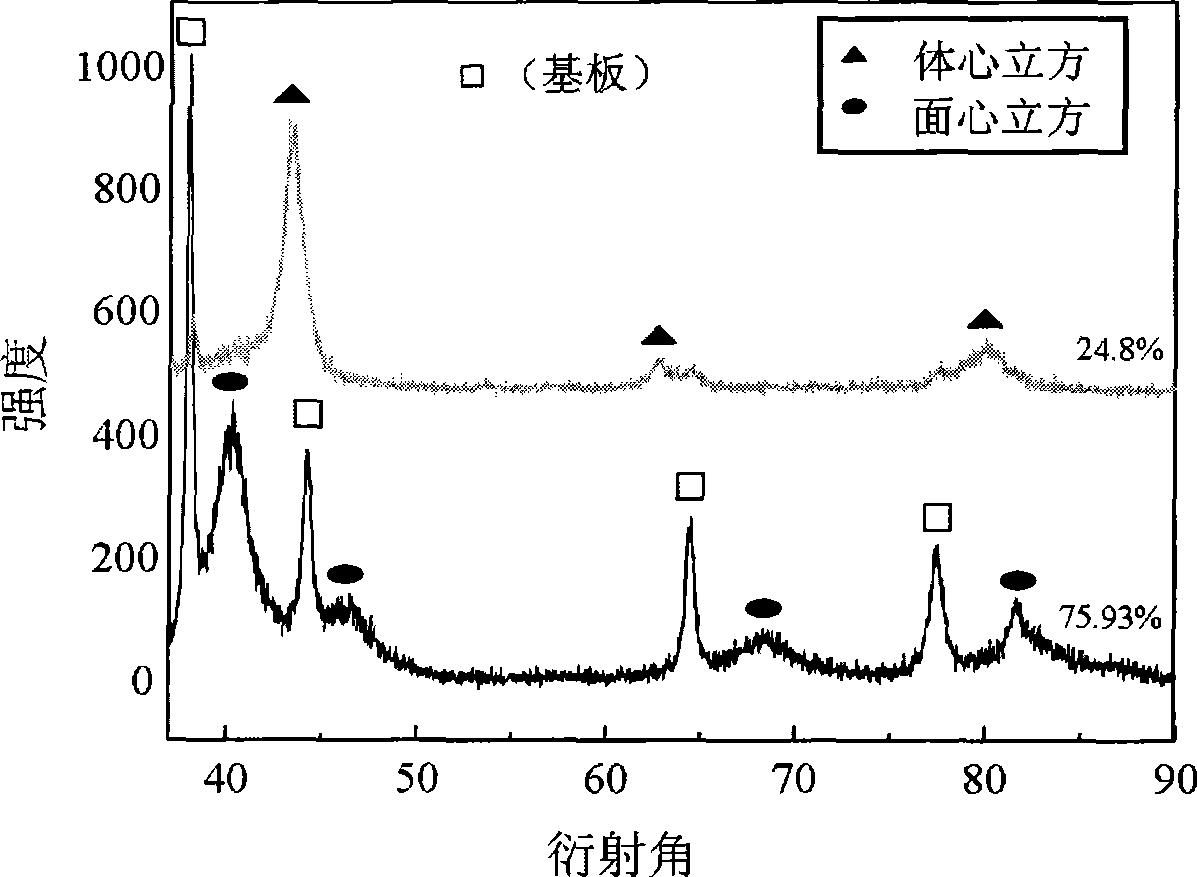

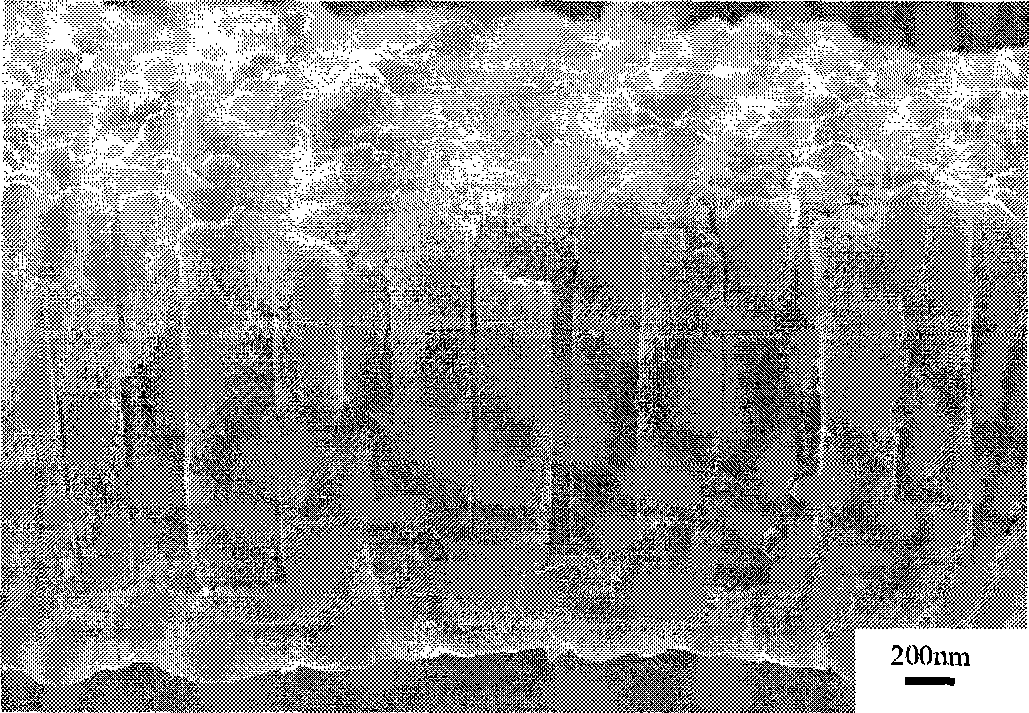

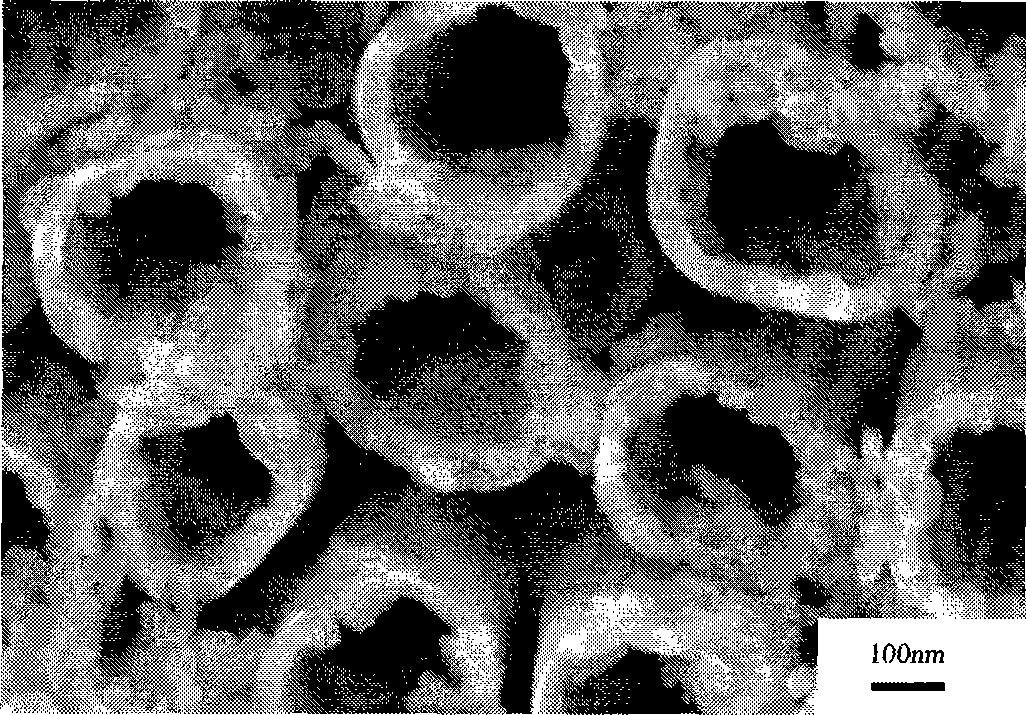

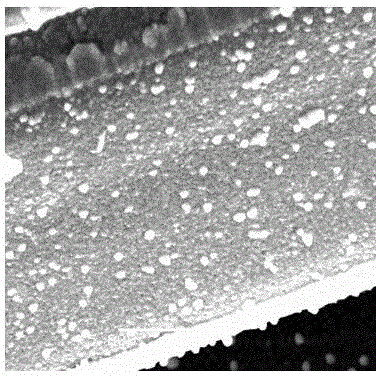

Method for preparing L10 type ultrahigh density magnetic record metal thin film

InactiveCN101593523AEasy to manufactureThe preparation process is easy to controlRecord information storageMagnetic layersVolumetric Mass DensityElectrochemistry

A method for preparing L10 type ultrahigh density magnetic record metal thin film belongs to the field of magnetic recording, storing and representation information recording. The existing magnetic recording metal thin film preparation method has the problems of rigorous conditions, high requirement of equipment, high production cost and the like. The invention prepares an alloy thin film mainly containing ferro magnetic metal A (Fe, Co or Ni) and precious metal B (Pt, Pd, Ag or Au) by electrochemical co-deposition method, controls the atom content of A to be 50% and obtains ultrahigh density magnetic recording metal thin film of vertical superlattice structure (L10 type). The thin film prepared by the invention has homotaxial magnetocrystalline anisotropy (K), ultrahigh coercivity, excellent physical and chemical stability, potential application prospect in micro-electronics storage field and ultrahigh density magnetic recording material.

Owner:BEIJING UNIV OF CHEM TECH +1

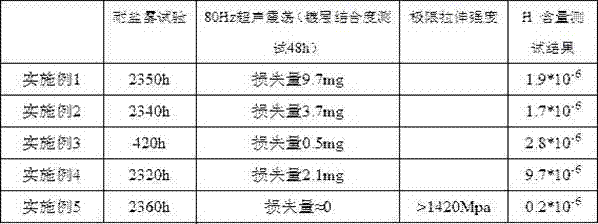

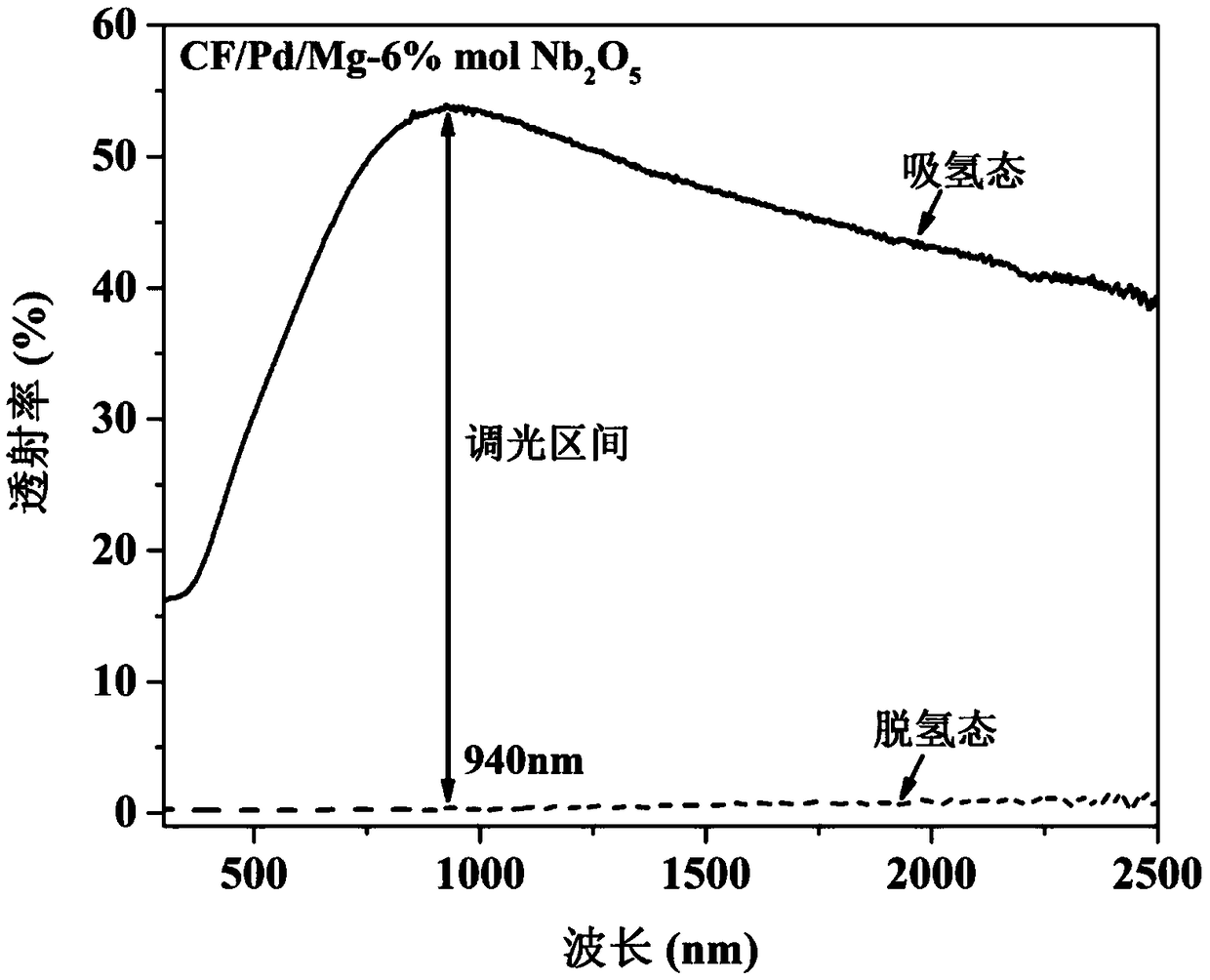

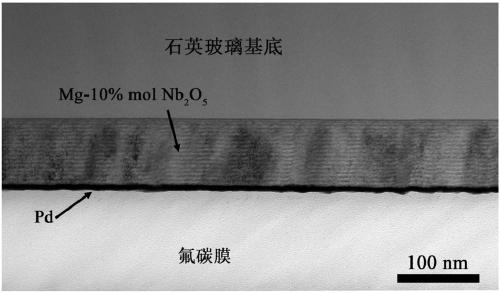

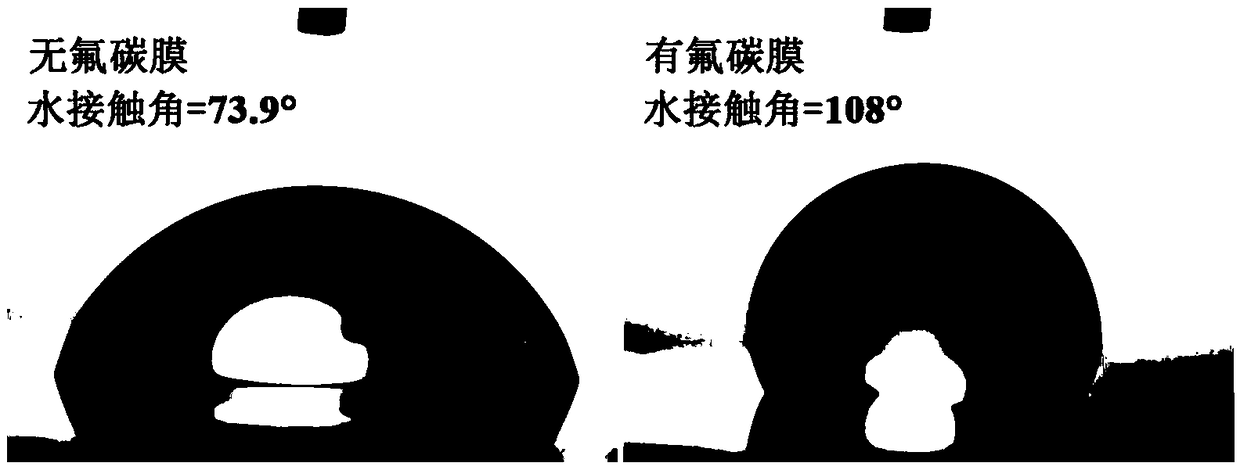

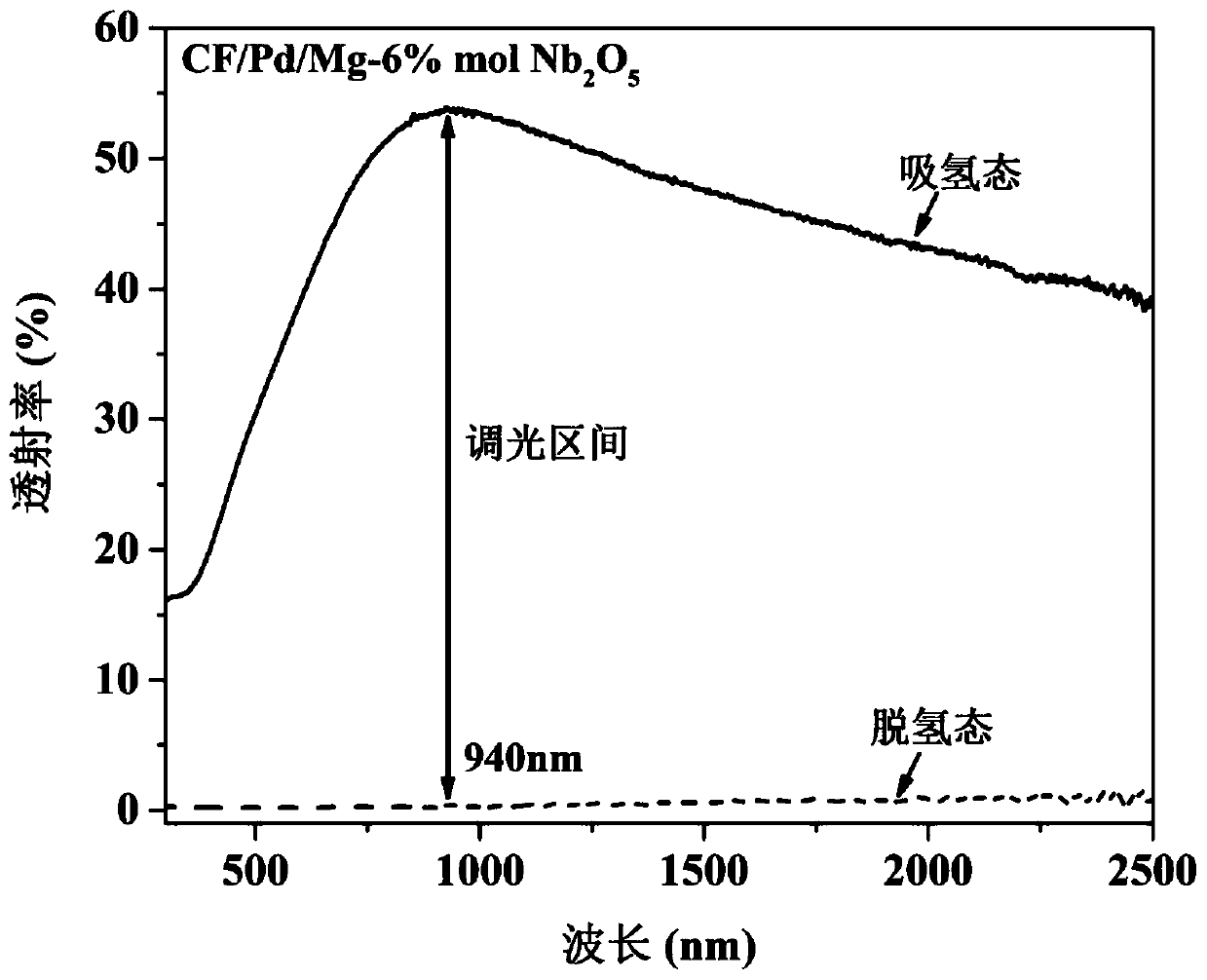

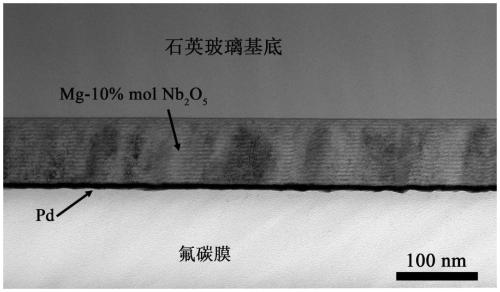

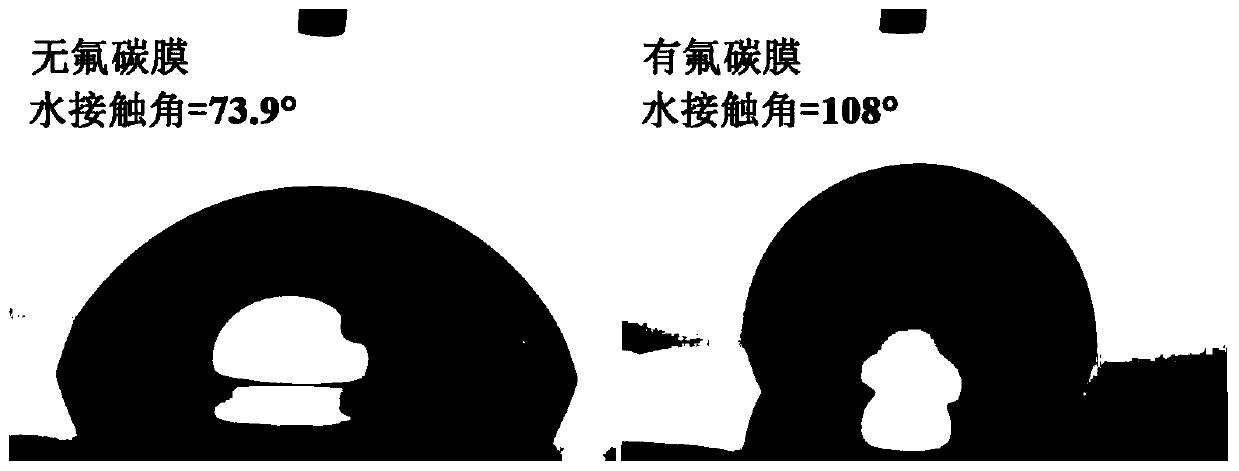

Fluorocarbon/palladium/magnesium-niobium pentoxide gas dimming film and preparation method thereof

ActiveCN109136841AHigh degree of automationFacilitated DiffusionVacuum evaporation coatingSputtering coatingRoom temperatureFluorocarbon

The invention discloses fluorocarbon / palladium / magnesium-niobium pentoxide gas dimming film and a preparation method thereof. The fluorocarbon / palladium / magnesium-niobium pentoxide gas dimming film comprises a magnesium-niobium pentoxide composite film layer, a palladium catalytic layer and a fluorocarbon hydrophobic layer which are arranged sequentially on a substrate. The preparation method includes: growing the magnesium-niobium pentoxide composite film layer on the substrate, growing the palladium catalytic layer in situ on the magnesium-niobium pentoxide composite film layer, and depositing the fluorocarbon hydrophobic layer outside the fluorocarbon hydrophobic layer. Catalytic effect of palladium helps promote reversible conversion of hydrogen gas and hydrogen atoms in the hydrogen absorbing and hydrogen removal stages; niobium pentoxide is added to accelerate diffusion of hydrogen atoms in a magnesium substrate, magnesium hydroxide forms and decomposes faster, and the film can be repeatedly converted between a reflecting state and a transaprent state. The fluorocarbon film can effectively resist corrosion of inner film due to the external environment. The whole reaction process can be implemented at room temperature. The fluorocarbon / palladium / magnesium-niobium pentoxide gas dimming film has good weatherability, short response time, short recovery time and good process simplicity, and has important application prospect in the field of intelligent glass.

Owner:SHANGHAI JIAO TONG UNIV +1

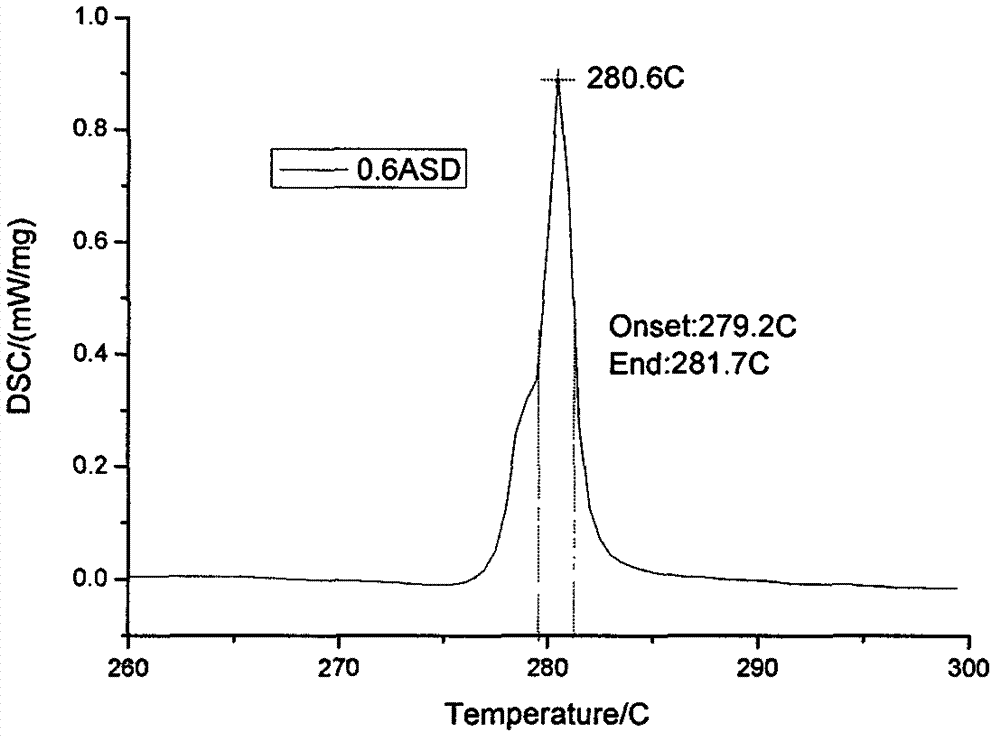

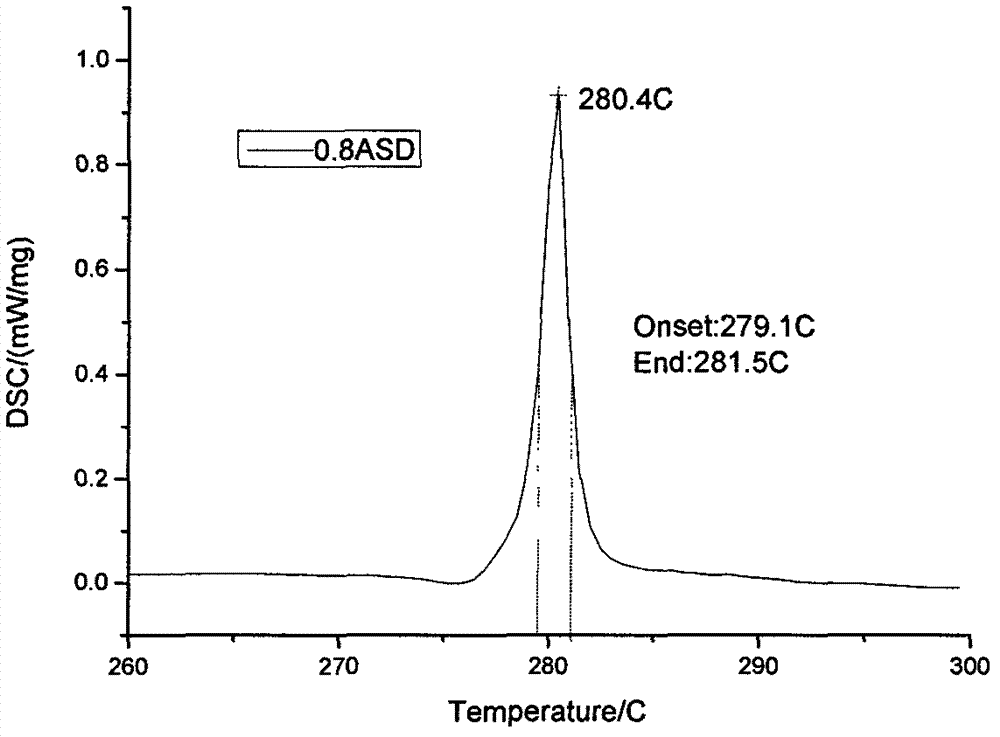

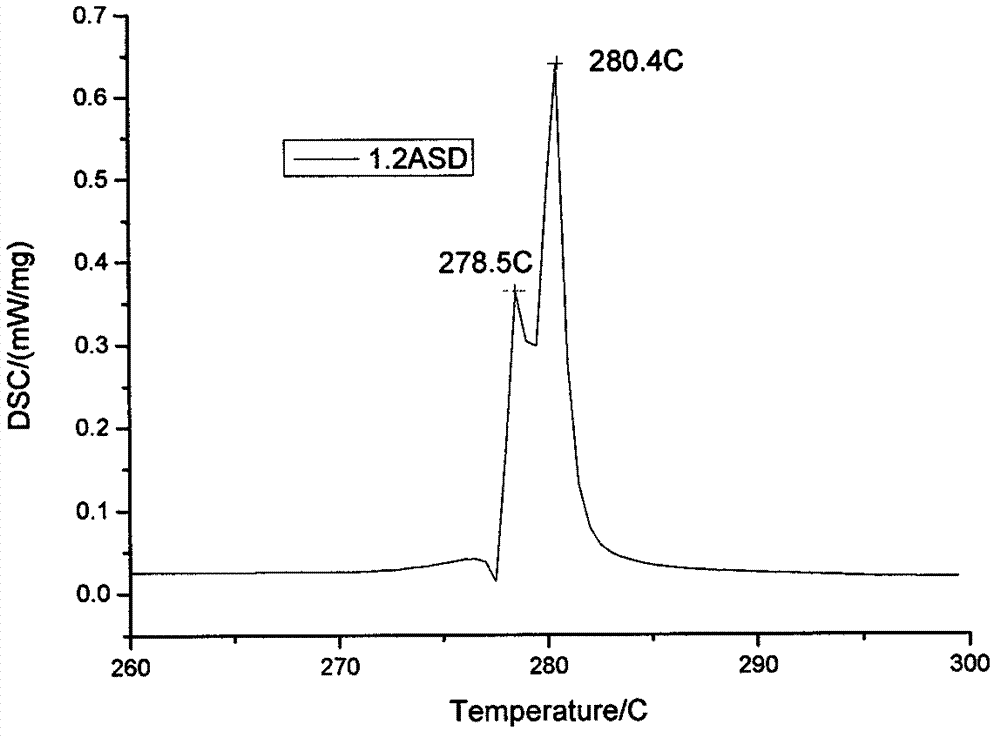

Gold-tin eutectic solder (AuSn20) electroplating solution and preparation method thereof

The invention relates to a gold-tin eutectic solder (AuSn20) electroplating solution and a preparation method thereof. The solution is characterized in that: novel gold potassium citrate is used for replacing traditional gold potassium cyanide, such that the pollution to the environment is reduced; bivalent tin is complexed by using another complexing agent, such that the stability of tin salt is improved. Every liter of the electroplating solution comprises 1-20g of gold salt, 1-20g of tin salt, 10-50g of a buffering agent, 10-50g of a complexing agent, 0.1-10g of a brightening agent, and 0.1-5g of an anti-oxidant. The electroplating solution provided by the invention is environment-friendly, and has relatively wide range of available current density. The obtained plating coat has good brightness, the gold and tin components are precisely controlled, and the melting point is 278-282 DEG C. The electroplating solution is suitable for welding and packaging of photoelectric devices in fields with relatively high requirements on reliability, such as communication, satellite, remote sensing, radar, automobile, aviation, and the like.

Owner:GUANGZHOU AURORA TECHNOLOGIES CO LTD +1

CA scanning assisted preparation method and applications of Pd-Cu/Ti electrode

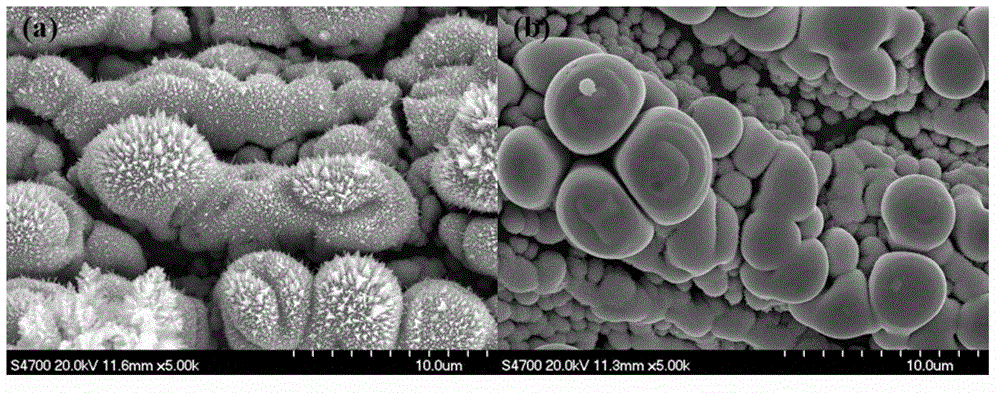

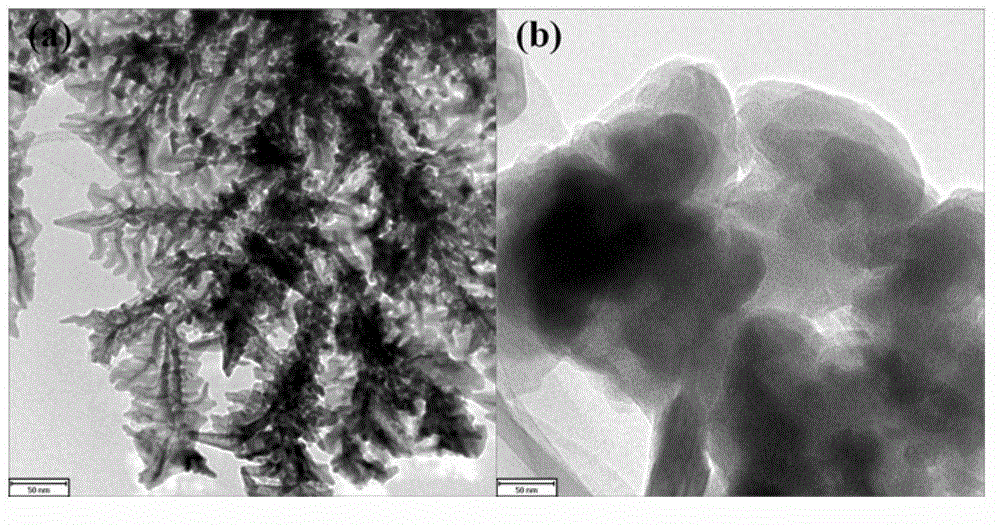

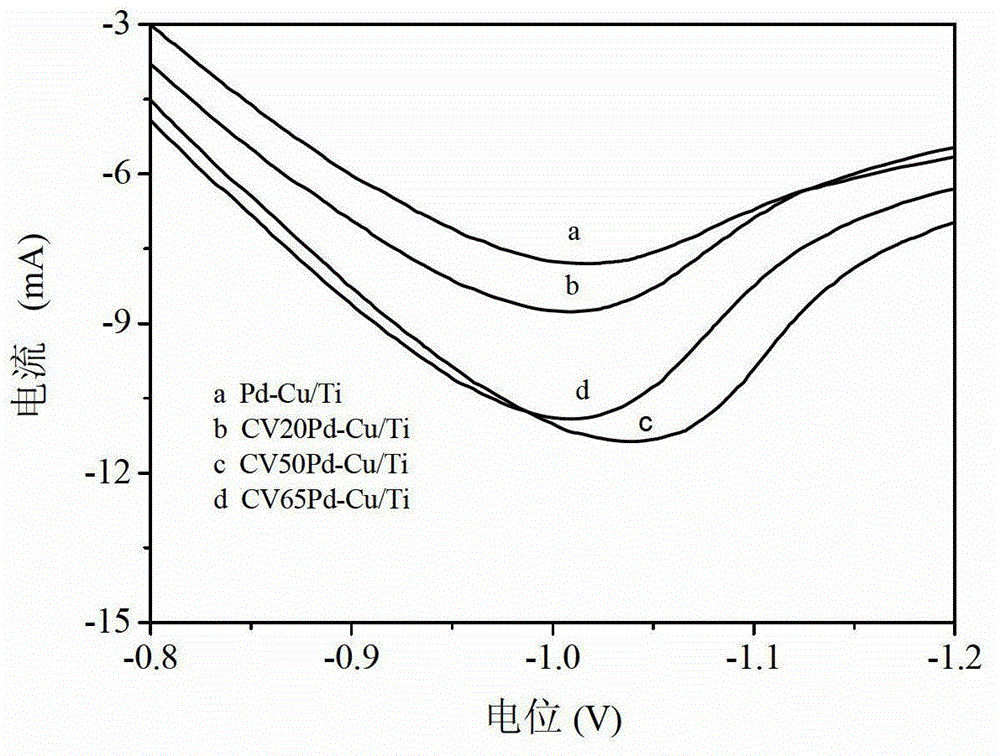

ActiveCN103334121ALong electrode lifeThere will be no secondary pollution problemsWater/sewage treatmentElectrodesPlatinumElectrochemistry

The invention discloses a CA scanning assisted preparation method and applications of a Pd-Cu / Ti electrode, and belongs to the field of electrochemical water treatment technologies. The CA scanning assisted preparation method comprises following steps: firstly, preparing a PdCl2 solution containing CuSO4, and adjusting the pH value of the solution to 1.0; taking a titanium mesh as a cathode, and a platinum sheet as an anode, and performing deposition with a constant potential so as to obtain the Pd-Cu / Ti electrode, wherein the constant potential relative to the potential of a Hg / Hg2SO4 electrode is -0.9V; and then subjecting the Pd-Cu / Ti electrode to CV scanning in a H2SO4 solution of 0.5M, wherein the potential scanning range is -800mV to 700mV, the scanning speed is 50Mv / S, and the scanning circles are 1 to 65. The Pd-Cu / Ti electrode can be used for electrocatalytic reductive dechlorination of PCP, and the reaction solution is close to neutral after the reaction by controlling an initial pH value, so that it is convenient for subsequent processing.

Owner:BEIJING UNIV OF TECH

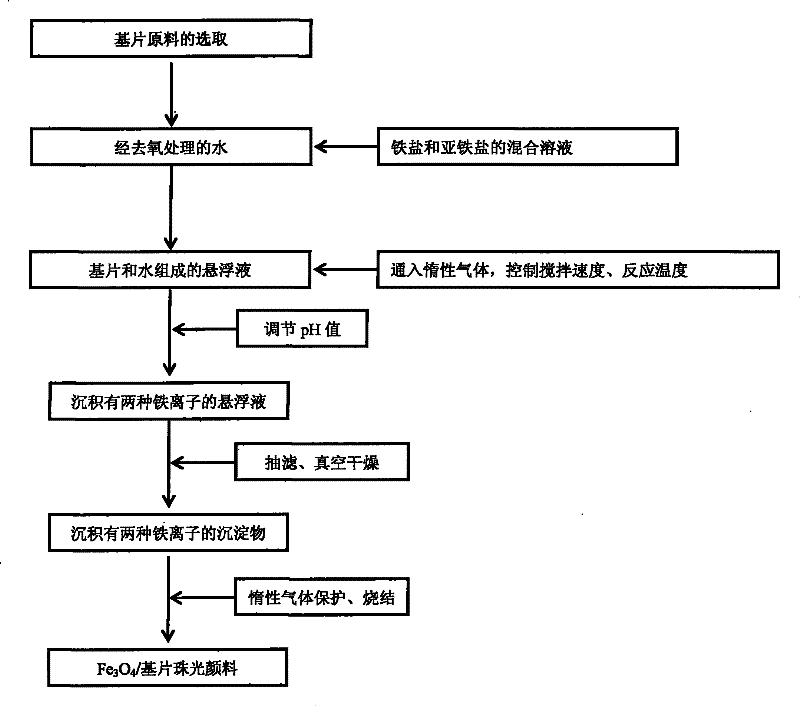

A kind of magnetic pearlescent pigment and preparation method thereof

InactiveCN101445674BCo-depositionCoated evenlyInorganic pigment treatmentCoprecipitationOxide coating

The invention discloses a magnetic pearlescent pigment and a preparation method thereof. The magnetic pearlescent pigment has black luster, and a substrate with a particle diameter of 10-60 μm is used as a coating substrate, and the substrate is coated with Fe3O4. The preparation method of the magnetic pearlescent pigment is to drip ferric and ferrous salt solutions into the mica suspension at a certain temperature, and under the protection of an inert gas, control the pH of the co-precipitation to allow the precipitated Iron ferric oxide is uniformly and densely deposited on the mica, and calcined in an inert atmosphere, so as to prepare the magnetic pearlescent pigment. The surface deposition of the magnetic pearlescent pigment prepared by the invention is smooth and dense, the coating rate is high, and the pearlescent effect is obvious. The preparation method realizes the co-deposition of ferric iron and ferrous iron, so that ferric ferric oxide can be uniformly coated on the sericite substrate. The invention is applicable to the preparation of various pearlescent pigments, and the introduction of the co-precipitation method and the control of the sintering atmosphere provides the possibility for the deposition and coating of oxides in different valence states.

Owner:WENZHOU UNIVERSITY +1

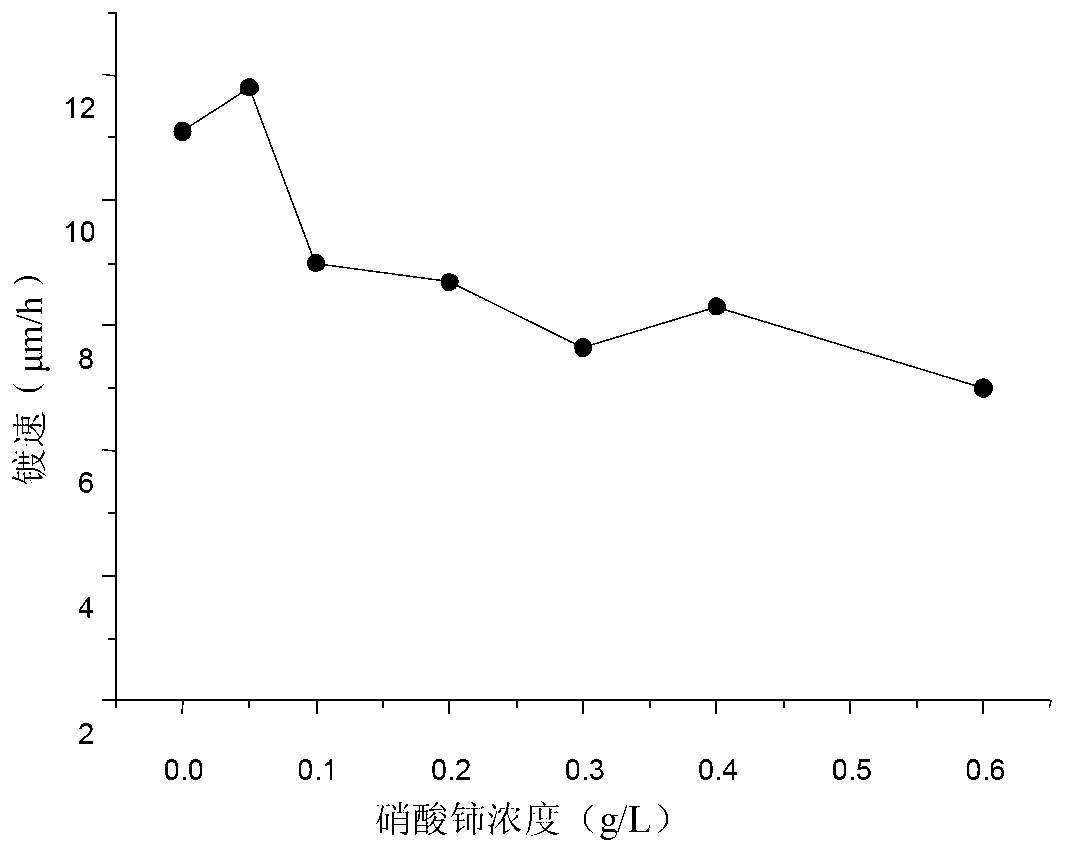

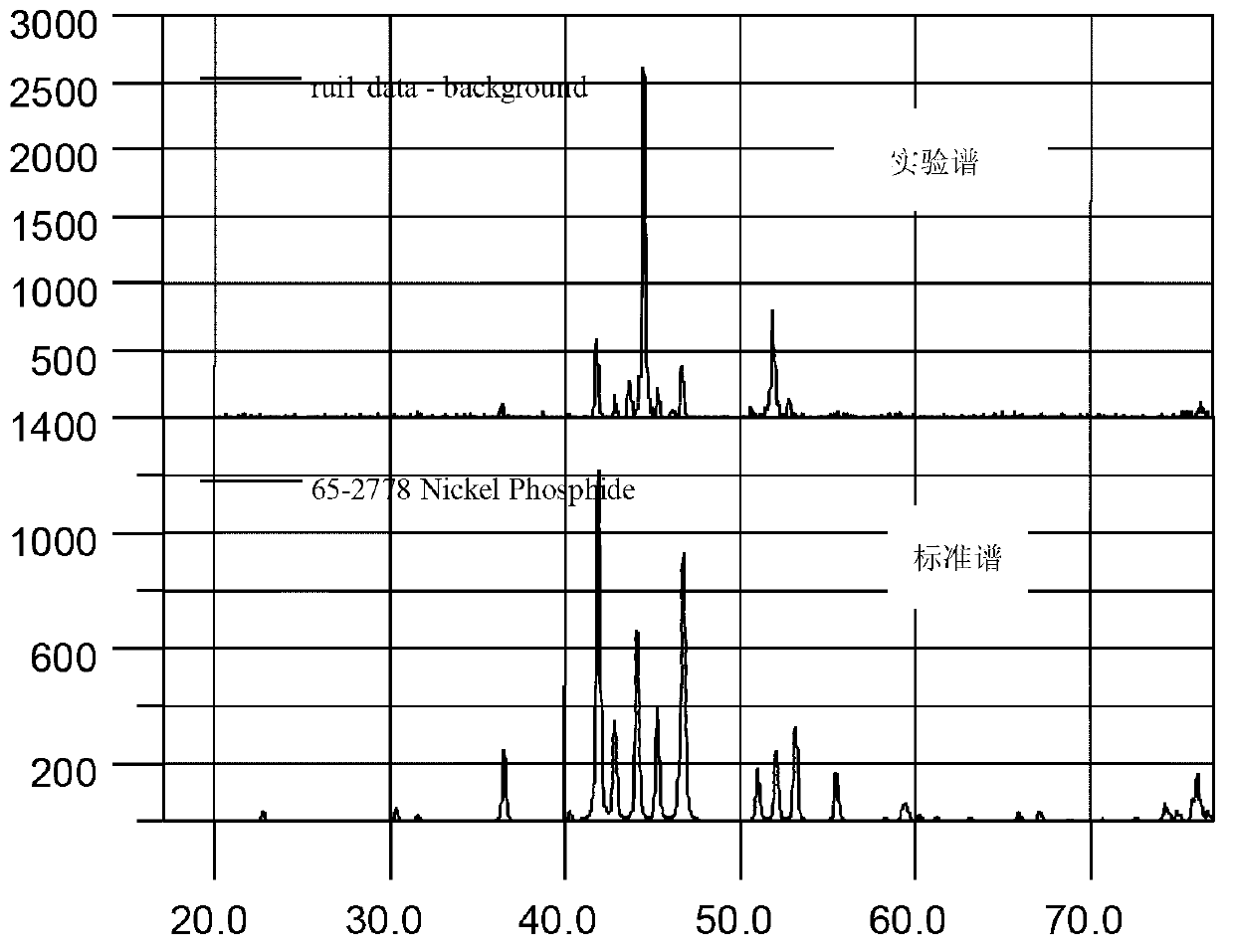

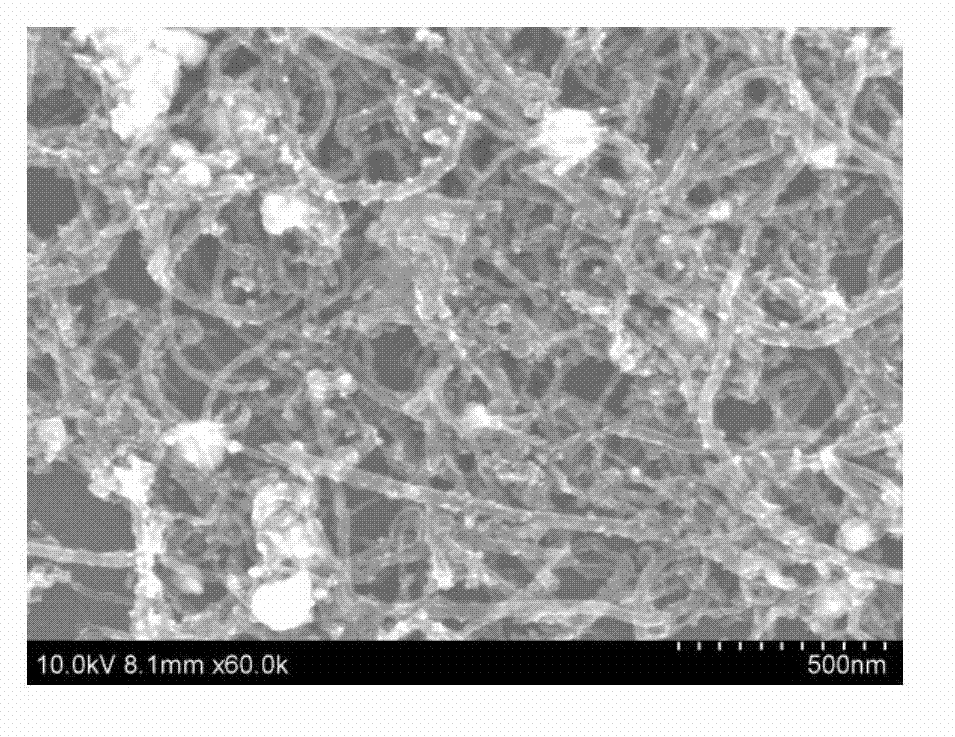

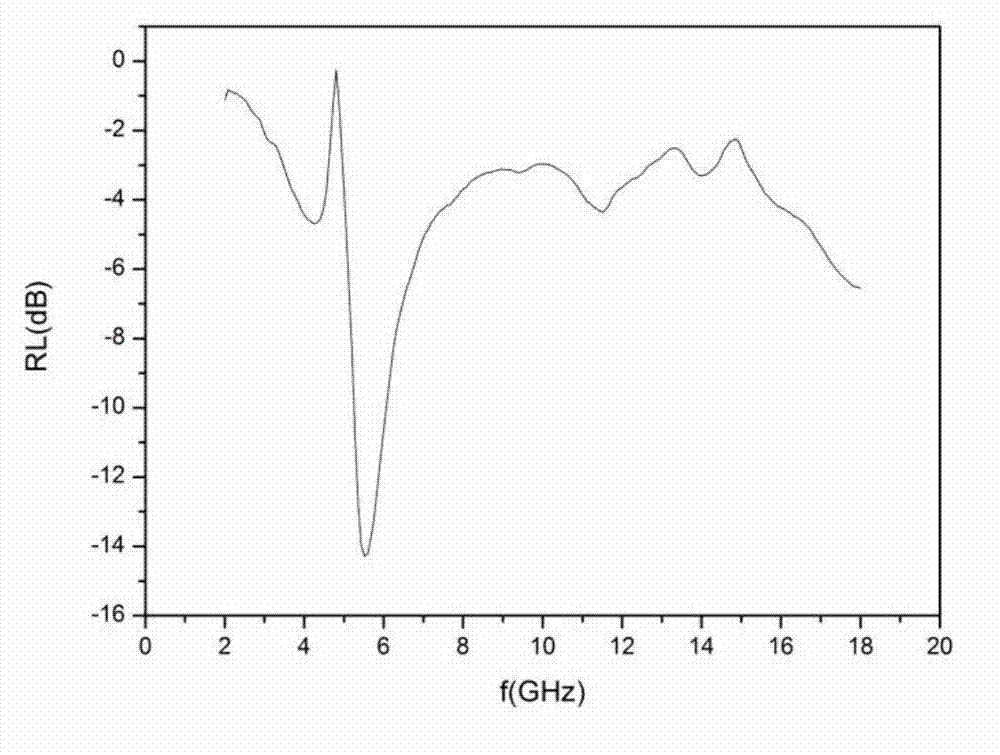

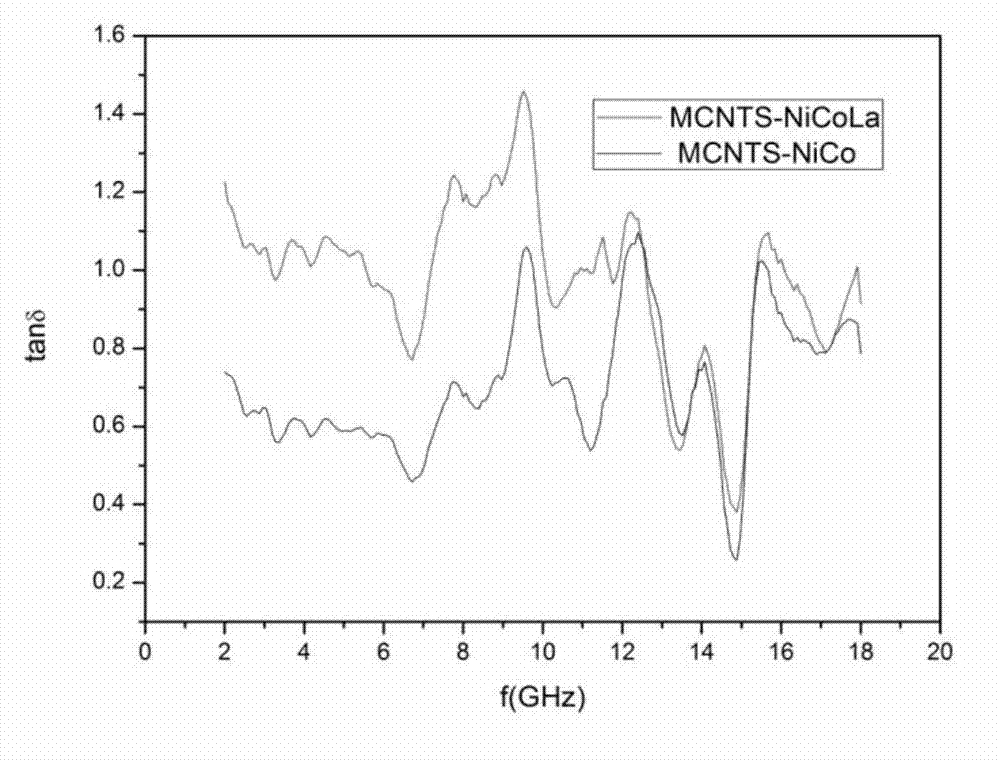

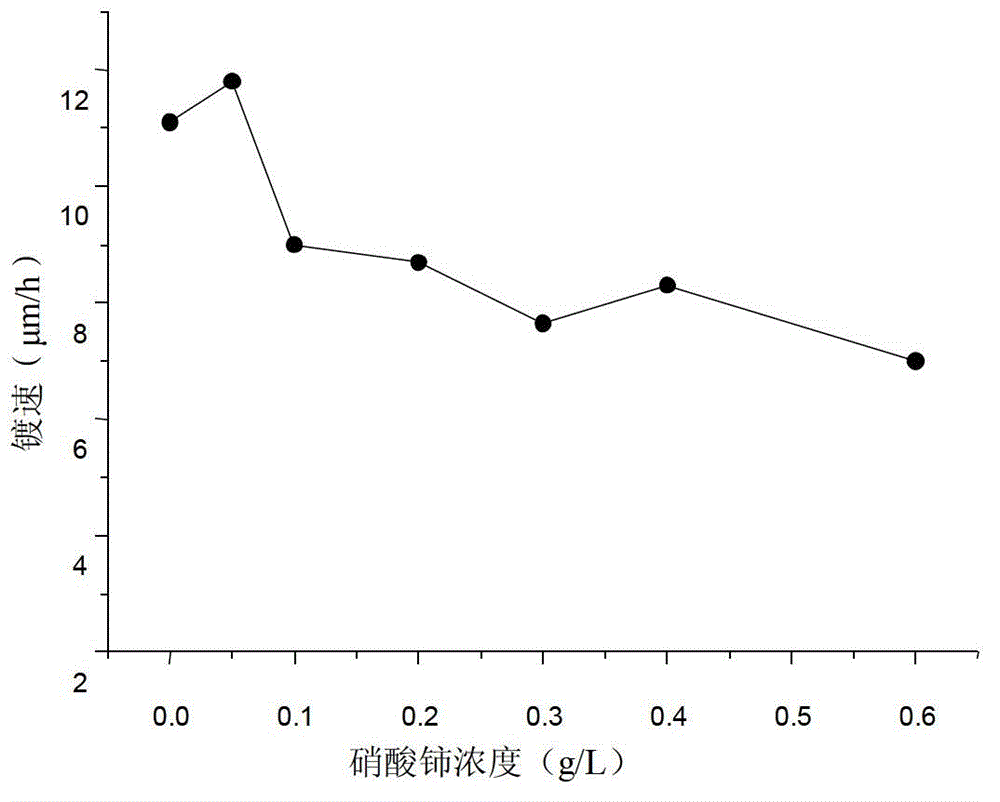

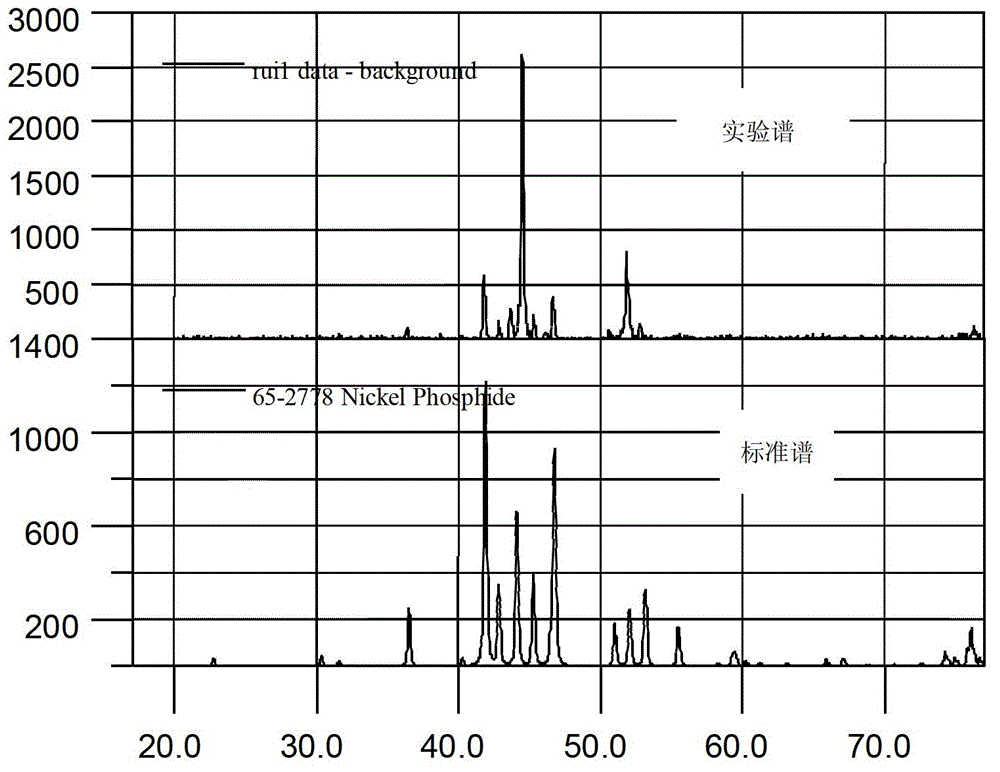

Chemical nickel-cobalt-lanthanum ternary alloy plating solution for carbon nano tube, and chemical plating method

InactiveCN102877048APromote reductionCo-depositionLiquid/solution decomposition chemical coatingIonRare-earth element

The invention relates to a wave-absorbing material and a preparation method thereof, in particular to a chemical nickel-cobalt-lanthanum ternary alloy plating solution for a carbon nano tube, and a preparation method and a chemical plating method thereof. According to the method, a hydrochloric acid solution of lanthanum oxide is added into a chemical plating solution for the carbon nano tube, and the electrode potentials of rare-earth elements La move positively by adjusting the concentration of all components in the plating solution, so that deposition potentials of the rare-earth elements L are close to those of metal Ni and Co; and therefore, alloy co-deposition is realized. One part of the rare-earth elements L in the chemical plating solution exist in the form of positive ions to exert the function of a reducing agent, so that the reduction of metal ions in an alloy plating layer is accelerated, and the phosphorus content in the plating layer is reduced. The chemical plating method has the advantages that according to a chemical nickel-cobalt-lanthanum ternary alloy plating material prepared by the chemical plating method, the lanthanum atom content in the alloy plating layer can reach 4.16 percent.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A kind of anti-corrosion and anti-wear material with ni-cu-p-tin composite coating and preparation method thereof

InactiveCN104339752BHigh hardnessLow shear strengthLiquid/solution decomposition chemical coatingMetal layered productsWear resistantAlloy

The invention discloses an anticorrosion abrasive-resistant material which sequentially comprises a base material, a Ni-P coating, a Ni-Cu-P coating and a Ni-Cu-P-TiN coating from inward to outward. According to the invention, flexible metal Cu and TiN nano particles are added into the Ni-P coating via a prior precipitation mechanism and a co-deposition mechanism, so that the Cu metal and the TiN particles have complementary performance advantages; meanwhile, in order to improve the wettability of the TiN particles and a Ni-P alloy, the TiN particles are subjected to Ni coating modification treatment, and the bonding intensity of the TiN particles and the coating is increased; on the other hand, by the multi-layer structural design of Ni-P / Ni-Cu-P / (Ni-Cu-P-TiN), the problem of poor bonding intensity of the coatings caused by the prior precipitation mechanism of Cu is solved. The method is simple in technology, and equipment is low in price; a subsequent technology is combined, a coating scraper with good corrosion resistance and tribology performance can be prepared, and the service life of the scraper can be multiplied.

Owner:CENT SOUTH UNIV +1

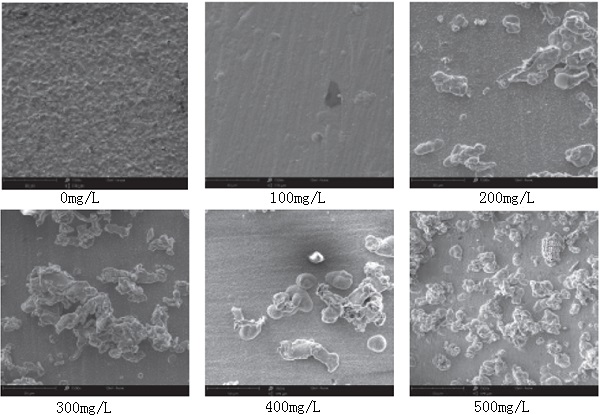

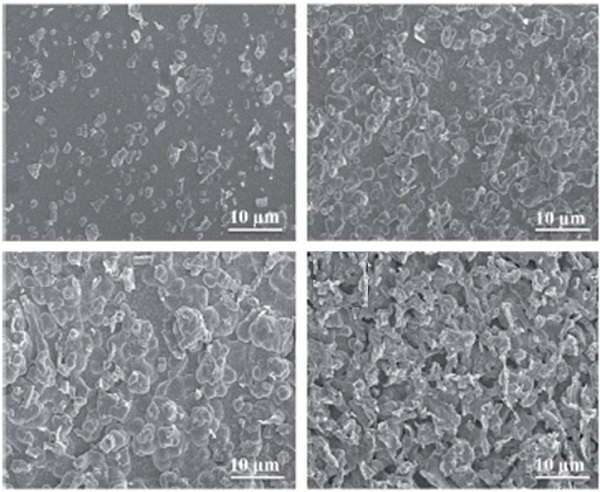

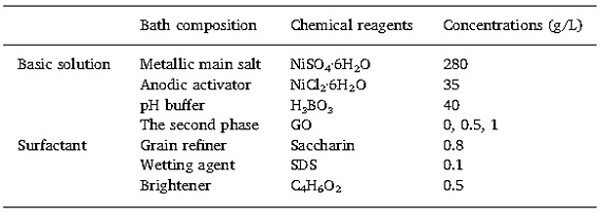

Composite electrolyte for preparing corrosion-resistant surface of petroleum pipeline and preparation method of corrosion-resistant layer of petroleum pipeline through ultrasonic-assisted electrodeposition

ActiveCN110484944AImprove corrosion resistanceImprove wear resistanceElectrolytic coatingsPetroleumElectrophoresis

The invention discloses a composite electrolyte for preparing a corrosion-resistant surface of a petroleum pipeline and a preparation method of the corrosion-resistant layer of the petroleum pipelinethrough ultrasonic-assisted electrodeposition, and belongs to the technical field of electrolysis or electrophoresis processes. The electrolyte per liter is prepared from solute raw material components of 150-200 g of nickel sulfate, 50-80 g of nickel chloride, 30-60 g of sodium hydrogen phosphate, 0.1-0.2 g of sodium dodecyl sulfate, 6 g of nano silicon carbide, 10-30 g of sodium sulfate and 30-50 g of citric acid, and the solvent is deionized water. In an electrodeposition process, the nickel and phosphorus in the electrolyte are subjected to a reduction reaction on a stainless steel substrate as a negative electrode to be co-deposited on the stainless steel substrate to form a nickel-phosphorus alloy with an amorphous structure and a smooth surface, and therefore the corrosion resistance of the coating is improved; since the nano silicon carbide is inlaid in the nickel-phosphorus alloy, on the one hand, the nano silicon carbide forms a micro-nano double-roughness structure with thenickel-phosphorus alloy, and forms an air layer between the nano silicon carbide and water drops when making contact with the water drops, so that a hydrophobic structure is formed, and the corrosionresistance is improved; and on the other hand, the wear resistance of the coating is improved, and the service life of the coating is prolonged.

Owner:胜利油田金岛实业有限责任公司 +1

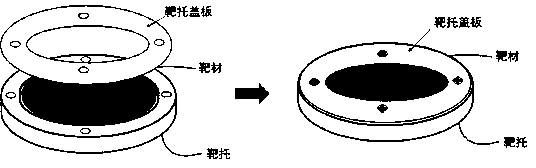

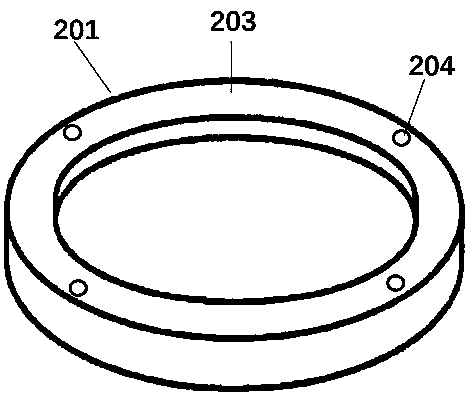

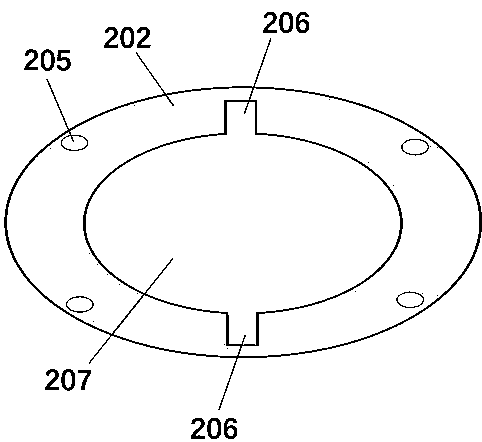

Target holder applied to pulsed laser co-deposition and mounting method

ActiveCN111519144APrecise positioningCo-depositionVacuum evaporation coatingSputtering coatingEngineeringMechanical engineering

The invention provides a target holder applied to pulsed laser co-deposition and a mounting method of the target holder. The target holder comprises a target holder bottom and a target cover plate. Aprotruding peripheral wall is formed in the periphery of the target holder bottom, a round groove is formed in the middle of the target holder bottom, multiple screw holes are formed in the peripheralwall, and the target holder cooperates with a target. The target comprises a round target module and an annular target module, wherein the round target module and the annular target module can be independently dismounted and mounted. Through holes are formed in the side walls of the round target module and the annular target module, and through columns are arranged in the through holes. Two oppositely-arranged adjusting regions are further arranged on the target cover plate, and the two ends of the through columns are arranged in the adjusting regions. By means of the target holder, the position of the target can be arranged and fixed in the process of mounting the target, and the bombarded position of the target is effectively controlled. The utilization rate of the whole target is increased, pits generated by local losses of the target are avoided, and the scrapping speed of the target is reduced.

Owner:HENAN UNIVERSITY

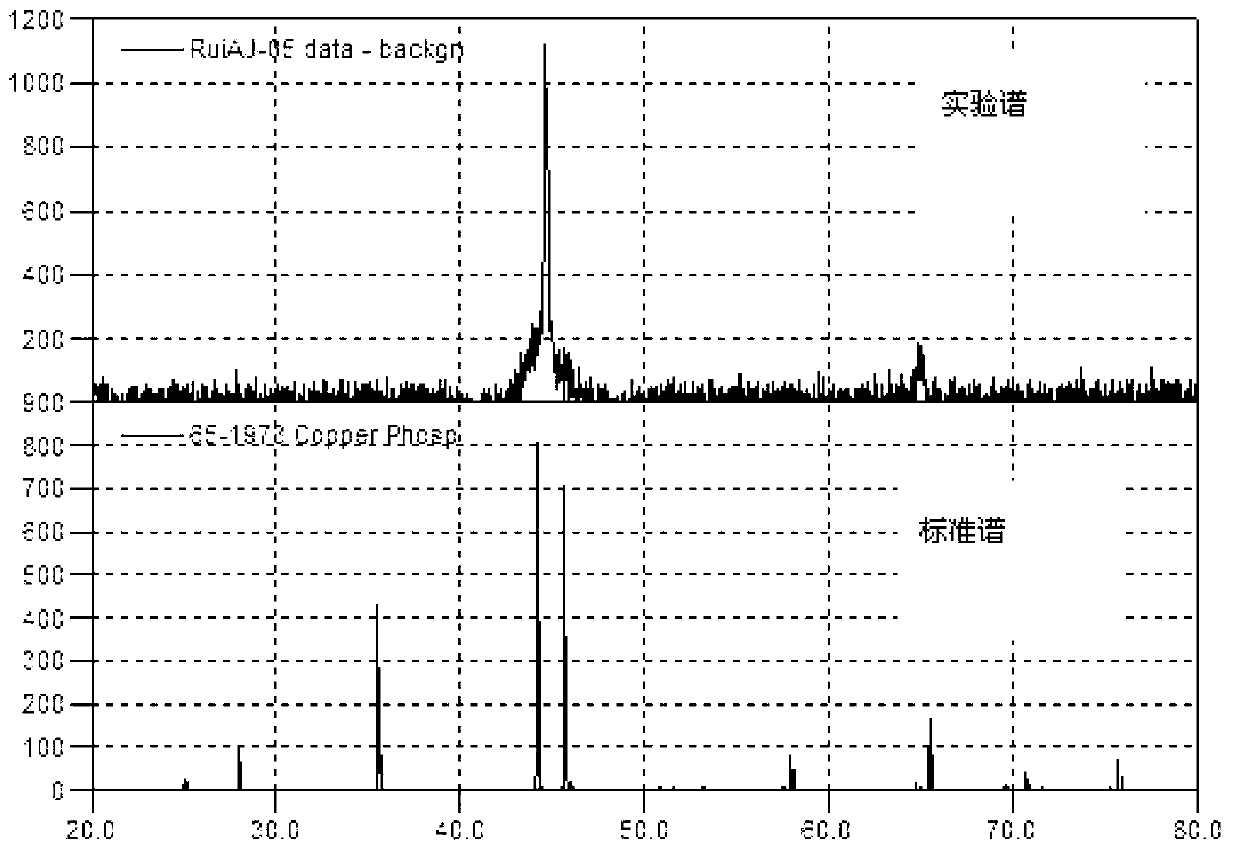

Preparation method of aluminum alloy and rare earth nickel base electromagnetic shielding layer

ActiveCN102383118AImprove microcrystallization and microporous structureIncreased corrosion resistance and electromagnetic shielding effectivenessLiquid/solution decomposition chemical coatingChemical platingHardness

The invention discloses a preparation method of an aluminum alloy and rare earth nickel base electromagnetic shielding layer. The method comprises the steps of placing the aluminum alloy base material into chemical plating solution for 10-15 minutes and taking out, so that a rare earth nickel base electromagnetic shielding layer with the thickness of 0.01-0.1mm and the plated state hardness of 550-650Hv is obtained on the surface of the aluminum alloy base material, wherein the chemical plating solution comprises 0.10-0.13mol / L NiC12.6H2O, 0.02-0.03mol / L FeSO4.7H2O, 0.03-0.04mol / L reducing agent, 0.07-0.09mol / L Na2C4H4O6.2H2O, 0.07-0.075mol / L aminoacetic acid, 0.035-0.05mol / L H3BO3, (1-2)*10<-3>mol / L stabilizing agent and 3-5g / L micro nano molybdenum disulfide particles; and the PH value of the chemical plating solution is adjusted to 7-8 by KOH and / or NaOH, and the aluminum alloy base material is placed into the solution. The preparation method can perform modification treatment for the aluminum alloy surface, so that the wear resistance, corrosion resistance, conductivity and hardness of the aluminum alloy surface layer are greatly improved.

Owner:晋宁理工恒达科技有限公司

Ni-Cu-P-Ce alloy plating layer and preparation process

InactiveCN102994991BDense tissueTissue particles are tightly distributedLiquid/solution decomposition chemical coatingSodium acetateChemical plating

The invention relates to chemical plating on a surface of a metal material and particularly to a Ni-Cu-P-Ce alloy plating layer used for chemical plating on a surface of a low-carbon steel base material and a preparation process of the Ni-Cu-P-Ce alloy plating layer. The Ni-Cu-P-Ce alloy plating layer adopts a plating liquid composed of 35-40 g / L of nickel sulfate, 0.2-0.4 g / L of copper sulfate, 25-30 g / L of sodium hypophosphite, 8-10 g / L of sodium acetate, 25-30 g / L of trisodium citrate, 22-28 ml / L of lactic acid, 8-10 g / L of butanedioic acid, 0.2-0.4 g / L of cerium nitrate, 8 mg / L of potassium iodide, 1.5 mg / L of thiourea, 0.01 g / L of glycine and 0.2 g / L of ammonium bifluoride. For the adoption of ultrasonic chemical plating, a plating layer material formed by codeposition of Ce, Cu and Ni is obtained; and the material has increased compactness, is a microlithic texture, and is high in hardness and strong in corrosion resistance.

Owner:SHANDONG JIANZHU UNIV

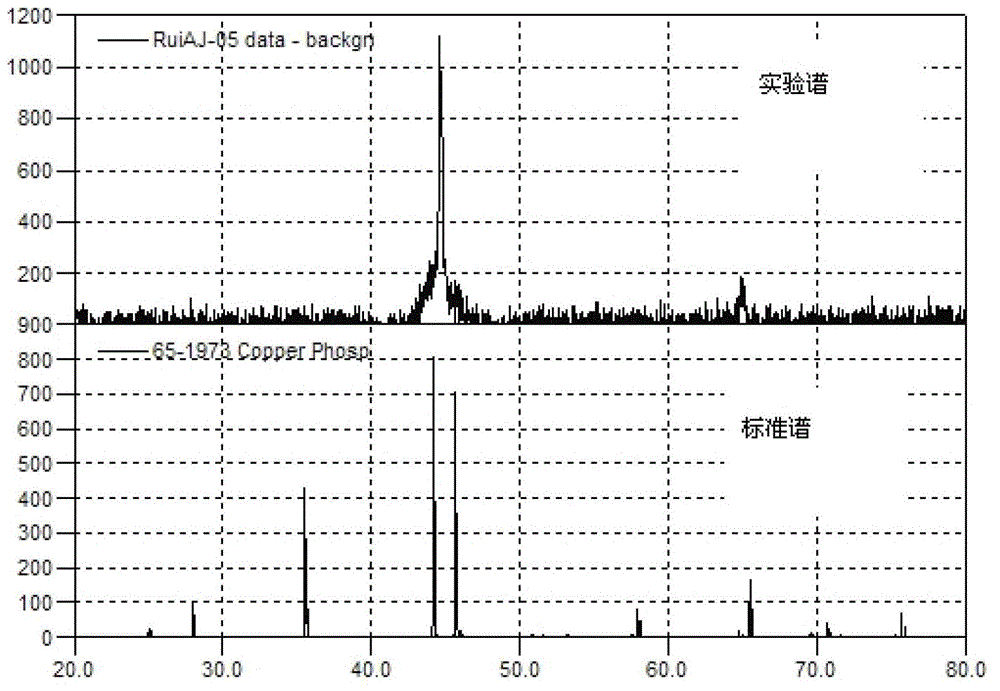

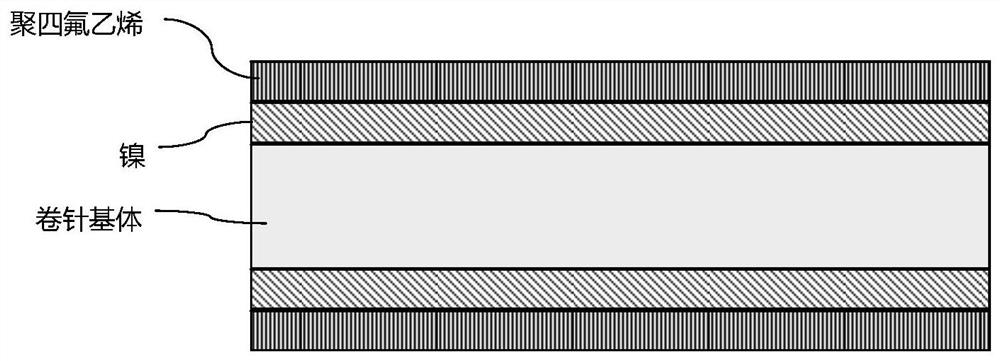

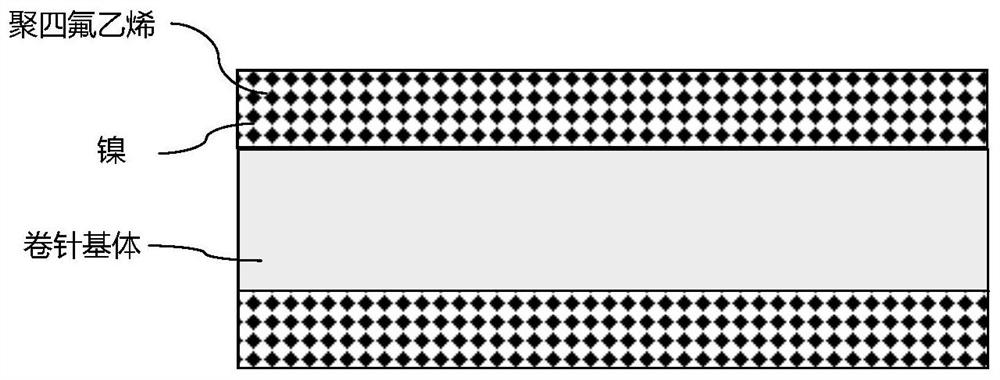

Nickel-polytetrafluoroethylene plating and wear-resistant anti-static rolling needle comprising plating

ActiveCN111636090AReduce frictional resistanceReduce defective rateElectrolytic coatingsFinal product manufactureTetrafluoroethyleneNickel salt

The invention provides a nickel-polytetrafluoroethylene plating and a wear-resistant anti-static rolling needle comprising the plating. The plating comprises nickel metal particles and polytetrafluoroethylene particles, wherein the nickel metal particles and the polytetrafluoroethylene particles are dispersed in the plating. The plating is obtained by electroplating of a mixed plating solution containing ammonia water, nickel salt and the polytetrafluoroethylene particles, wherein the mixed plating solution is stable in performance, and the polytetrafluoroethylene particles have high dispersity in the mixed plating solution and do not coagulate. In the electroplating process, when nickel ions of nickel-ammine complexing cations adsorbing the polytetrafluoroethylene particles are reduced and deposited on a cathode plate, the polytetrafluoroethylene particles can be released and uniformly co-deposited on the cathode plate along with the nickel ions, and therefore the nickel-polytetrafluoroethylene mixed plating with a smooth and dense surface is obtained.

Owner:ZHUHAI COSMX BATTERY CO LTD

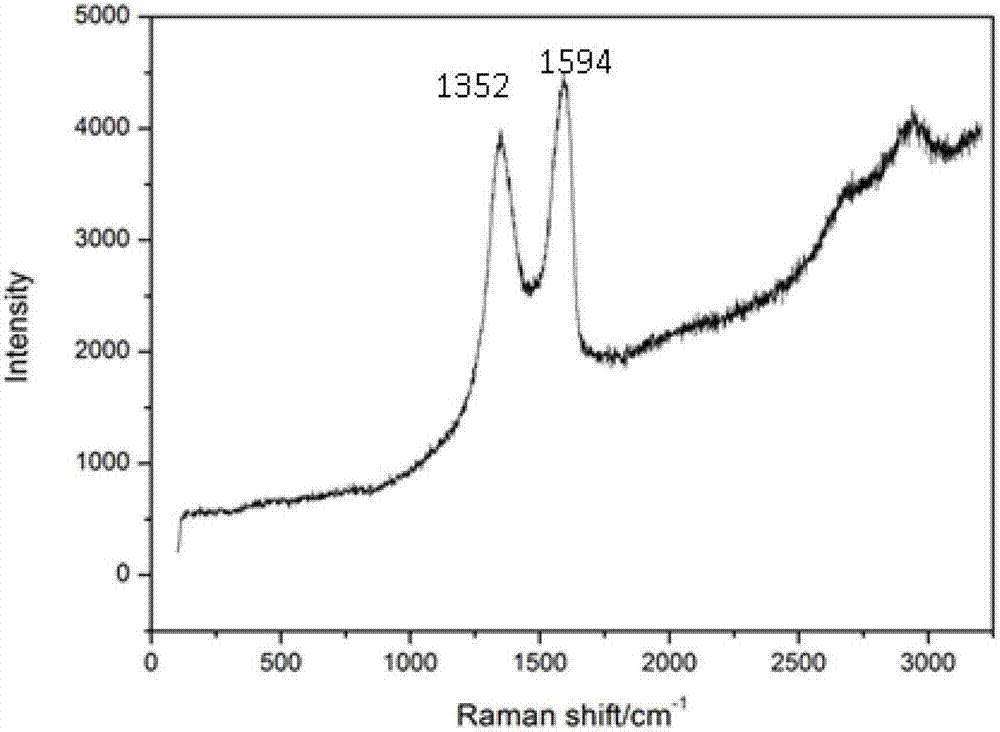

A kind of preparation method of metal-graphene composite electroplating material

ActiveCN109628983BCo-depositionAvoid reunionElectrolytic coatingsElectrodesElectrolytic agentGraphite

Owner:SOUTHWEST UNIV

A composite electrolyte for preparing the corrosion-resistant surface of petroleum pipelines and a method for preparing the corrosion-resistant layer of petroleum pipelines by ultrasonic-assisted electrodeposition

ActiveCN110484944BImprove corrosion resistanceExtended service lifeElectrolytic coatingsMicro nanoSodium sulfate

The invention discloses a method for preparing a composite electrolyte for preparing the corrosion-resistant surface of petroleum pipelines and an ultrasonic-assisted electrodeposited corrosion-resistant layer of petroleum pipelines, belonging to the technical field of electrolysis or electrophoresis, and the concentration of the solute raw material components in the electrolyte is: Nickel sulfate 150~200g / L, nickel chloride 50~80g / L, sodium hydrogen phosphate 30~60g / L, sodium lauryl sulfate 0.1~0.2g / L, nano silicon carbide 6g / L, sodium sulfate 10~ 30g / L and citric acid 30-50g / L, the solvent is deionized water. During the electrodeposition process, the nickel and phosphorus in the electrolyte undergo a reduction reaction on the stainless steel substrate as the negative electrode and co-deposit on the stainless steel substrate to form a nickel-phosphorus alloy with an amorphous structure and a smooth surface, which improves the resistance of the coating itself. Corrosion, nano-silicon carbide embedded in nickel-phosphorus alloy forms a micro-nano double-roughness structure with nickel-phosphorus alloy on the one hand, forms an air layer with water droplets when it contacts water droplets, forms a hydrophobic structure, and improves corrosion resistance; on the other hand, it improves corrosion resistance. The wear resistance of the coating increases its service life.

Owner:胜利油田金岛实业有限责任公司 +1

A kind of manufacturing process of conductive ball

ActiveCN109576745BReduce usageReduce pollutionEdge grinding machinesPolishing machinesTin platingMaterials science

The embodiment of the invention discloses a manufacturing process of a conductive ball, and belongs to the technical field of electronic elements. The process comprises the following steps that 1) physical derusting treatment is carried out on high-carbon steel shot blasting to obtain a high-carbon steel base material; 2) a nickel-iron alloy layer is electroplated on the surface of the high-carbonsteel base material; 3) a nickel alloy layer or a tin layer is electroplated on the surface of the nickel-iron alloy layer; and 4) the nickel-iron alloy layer is taken out, washed with water and alcohol, and drying is performed. According to the process, the physical rust removal and the nickel-iron plating solution process are adopted, so that the process is characterized in that the environmental pollution is reduced, the cost is saved, and the environment-friendly effect is achieved; an iron control agent can effectively inhibite ferrous ions to be oxidized into trivalent iron, the concentration of the ferrous ions in the plating solution is balanced, so that the nickel-iron co-deposition is realized without the influence of iron impurities in the continuous production process; nickel / tin plating machining is performed on the nickel-iron alloy layer, separation of iron in the subsequent use process can be effectively isolated, the oxidation resistance and the corrosion resistance of the conductive ball are improved, and the conductive performance of the conductive ball is improved.

Owner:徐九生

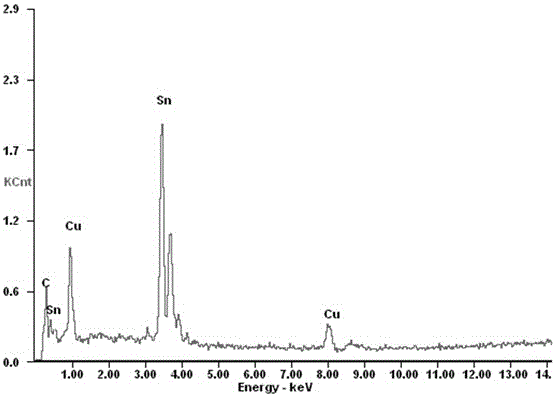

Tin-copper carbon nanotube composite coating, electroplating solution and electroplating method for automobile terminal

The invention discloses a tin and copper carbon nanotube composite coating of an automobile terminal, electroplating liquid and an electroplating method for the tin and copper carbon nanotube composite coating of the automobile terminal. The thickness of the coating is 0.5 micrometers, and the coating is prepared from, by mass, 1-3% of copper, 0.2-0.8% of carbon nanotube and the balance tin. The electroplating liquid is prepared from 30 g / L of tin sulfate, 3 g / L of copper sulfate, 50 g / L of citric acid, 35 g / L of tartaric acid, 100 mL / L of 98% sulfuric acid, 0.4 mg / L of 2-mercapto benzimidazole, 0.1g / L of sodium dodecyl sulfate and 1g / L of carbon nanotube. The treated automobile terminal is electroplated for 8-12 minutes in the electroplating liquid at 25 DEG C with the cathode-current density of 3 A / dm<2> and the rolling speed of 8 turns per minute. The problems that the plugging force of the automobile terminal obtained after tin plating is increased too much and assembling is difficult are solved, and the electroplating processes and the thickness of the coating are reduced; and while the cost is reduced, the plugging force is reduced, the protection performance of the terminal is improved, and the capability of resisting zinc diffusion which causes color changing of the coating is improved.

Owner:HENAN THB ELECTRIC

Fluorocarbon/palladium/magnesium-niobium pentoxide gas-switchable film and preparation method thereof

ActiveCN109136841BOvercoming Sputtering DifficultiesCo-depositionVacuum evaporation coatingSputtering coatingComposite filmHydrogen

The invention discloses fluorocarbon / palladium / magnesium-niobium pentoxide gas dimming film and a preparation method thereof. The fluorocarbon / palladium / magnesium-niobium pentoxide gas dimming film comprises a magnesium-niobium pentoxide composite film layer, a palladium catalytic layer and a fluorocarbon hydrophobic layer which are arranged sequentially on a substrate. The preparation method includes: growing the magnesium-niobium pentoxide composite film layer on the substrate, growing the palladium catalytic layer in situ on the magnesium-niobium pentoxide composite film layer, and depositing the fluorocarbon hydrophobic layer outside the fluorocarbon hydrophobic layer. Catalytic effect of palladium helps promote reversible conversion of hydrogen gas and hydrogen atoms in the hydrogen absorbing and hydrogen removal stages; niobium pentoxide is added to accelerate diffusion of hydrogen atoms in a magnesium substrate, magnesium hydroxide forms and decomposes faster, and the film can be repeatedly converted between a reflecting state and a transaprent state. The fluorocarbon film can effectively resist corrosion of inner film due to the external environment. The whole reaction process can be implemented at room temperature. The fluorocarbon / palladium / magnesium-niobium pentoxide gas dimming film has good weatherability, short response time, short recovery time and good process simplicity, and has important application prospect in the field of intelligent glass.

Owner:SHANGHAI JIAOTONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com