A kind of manufacturing process of conductive ball

A production process and technology of conductive balls, applied in the direction of manufacturing tools, metal processing equipment, machine tools with surface polishing, etc., can solve the problems of working environment pollution, health hazards of operators, etc., to reduce environmental pollution, increase oxidation resistance and resistance. Corrosion, the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

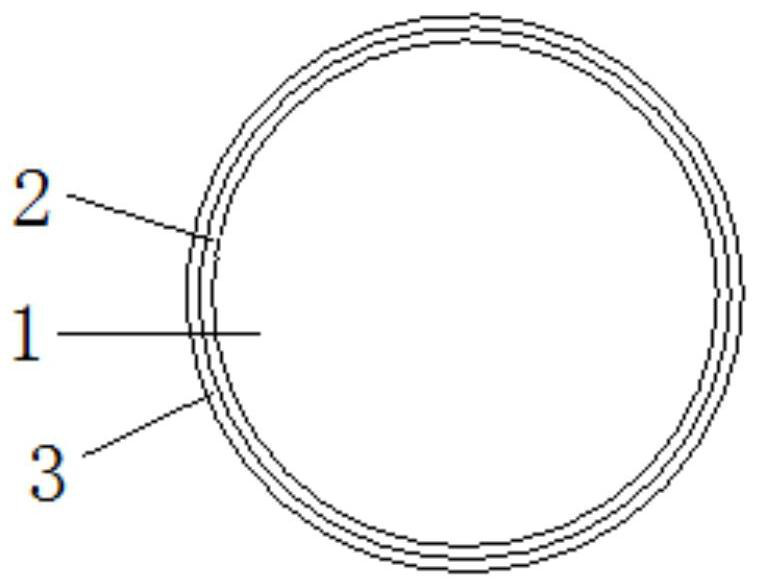

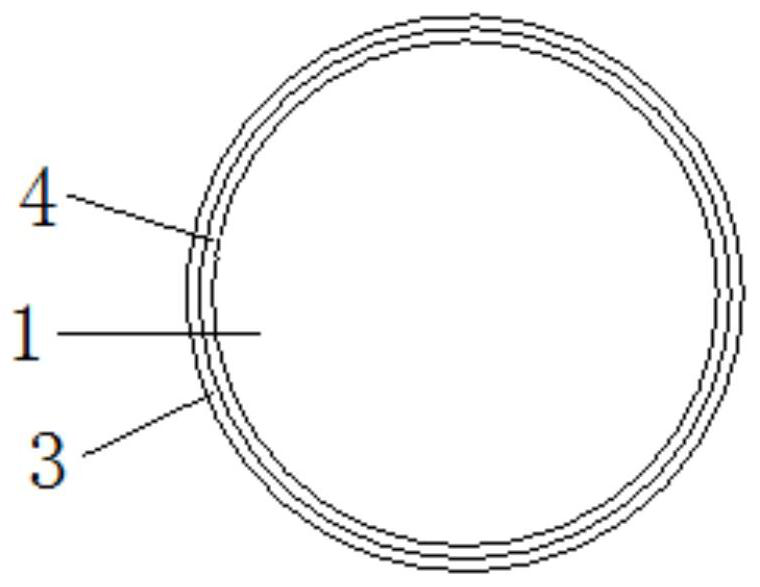

Image

Examples

Embodiment 1

[0035] The manufacturing process of the conductive ball of the present embodiment comprises:

[0036] 1) Select the available high-carbon steel shot blasting size. What this embodiment uses is the national standard S170 shot blasting. Take a sample of 250kg and place it in a barrel. At the same time, put 30kg of alumina ceramic balls with a diameter of 6mm and grind at a speed of 20rpm. After 10 hours, the alumina ceramic balls were separated and removed to obtain a high carbon steel substrate.

[0037] 2) Enter the electroplating line to electroplate the nickel-iron alloy layer. The plating solution used includes: nickel sulfate 230g / L, nickel chloride 40g / L, ferrous sulfate 18g / L, boric acid 40g / L, iron control agent 30mL / L, nickel plating Wetting agent 3mL / L, add water to make up 1L, wherein the iron control agent includes hydroquinone and catechol with a weight ratio of 2:1, and at the same time add hydrochloric acid with a concentration of 30g / L to make the pH value of ir...

Embodiment 2

[0041] The manufacturing process of the conductive ball of the present embodiment comprises:

[0042] 1) Select the available high-carbon steel shot blasting size. What this embodiment uses is the national standard S110 shot blasting. Take a sample of 250kg and place it in a barrel. At the same time, put 40kg of alumina ceramic balls with a diameter of 6mm and grind at a speed of 15rpm. After 12 hours, the alumina ceramic balls were separated and removed to obtain a high carbon steel substrate.

[0043]2) Enter the electroplating line to electroplate the nickel-iron alloy layer. The plating solution used includes: nickel sulfate 225g / L, nickel chloride 46g / L, ferrous sulfate 15g / L, boric acid 50g / L, iron control agent 15mL / L, nickel plating Wetting agent 4mL / L, add water to make up 1L, wherein the iron control agent includes hydroquinone and catechol with a weight ratio of 2.5:1, and at the same time add sulfuric acid with a concentration of 40g / L to make the pH value of iron ...

Embodiment 3

[0047] The difference between the manufacturing process of the conductive ball of this embodiment and embodiment 1 is that the nickel-iron plating solution, tin plating solution and corresponding electroplating process used are different, specifically:

[0048] 2) Enter the electroplating line to electroplate the nickel-iron alloy layer. The plating solution used includes: nickel sulfate 240g / L, nickel chloride 32g / L, ferrous sulfate 24g / L, boric acid 36g / L, iron control agent 45mL / L, nickel plating Wetting agent 2.5mL / L, add water to make up 1L, wherein the iron control agent includes hydroquinone and catechol with a weight ratio of 5:3, and at the same time add hydrochloric acid with a concentration of 40g / L to make the pH value of iron control 2.6 , when electroplating, the temperature of the plating solution is 55°C, the pH is 3.7, and the current density is 5.8A / dm 2 , Plating time is 72min.

[0049] 3) When the tin layer is electroplated on the surface of the nickel-iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com