Gold-tin eutectic solder (AuSn20) electroplating solution and preparation method thereof

A plating solution and electroplating gold technology, applied in the field of plating solution and preparation of bright AuSn20, can solve the problems of low current density, harmful to human body and environment, difficult to deposit gold-tin alloy, etc., and achieve production cost reduction and throwing performance Strong, bright coating effect

Active Publication Date: 2012-10-17

GUANGZHOU AURORA TECHNOLOGIES CO LTD +1

View PDF9 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the pH of the plating solution is 9, which greatly limits the use of solder in the field of optoelectronic device welding that requires photolithography masks, and the patent does not mention the precise melting point of the prepared gold-tin alloy solder

[0009] To sum up the above invention patents, the current density of the plating solution containing cyanide is higher, but the plating solution must be plated under the condition of pH less than 3, CN - easy with h + Combined, it is extremely harmful to human body and environment

However, the available current density of the cyanide-free plating solution is small, and the plating solution is not very stable. It is difficult to deposit bright gold-tin alloys in complex pattern electroplating.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

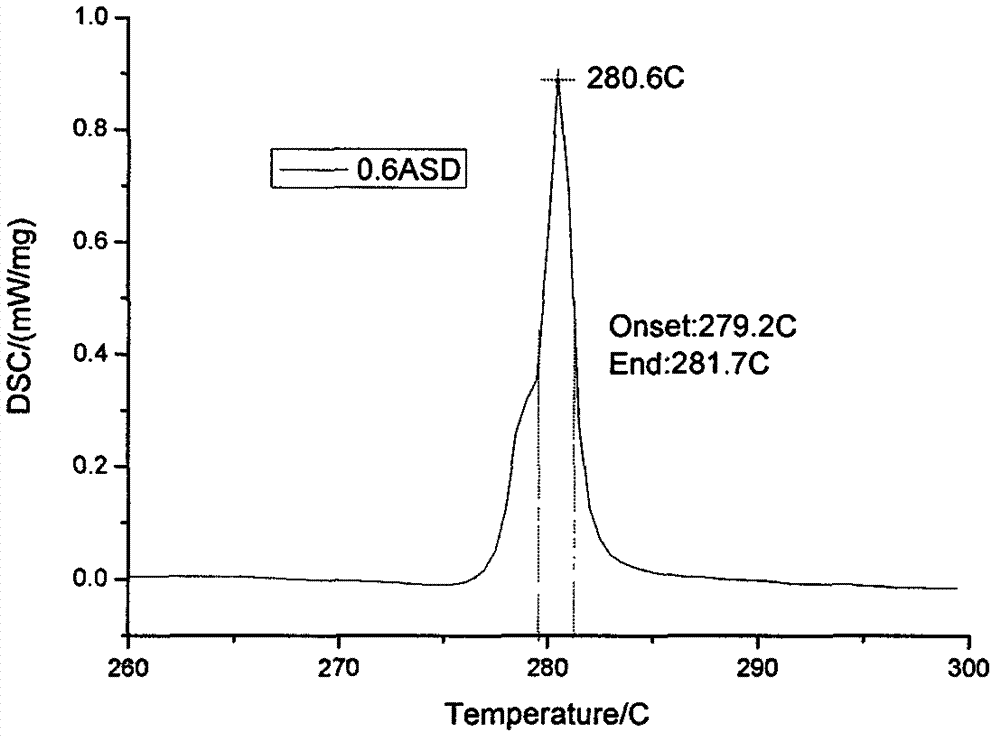

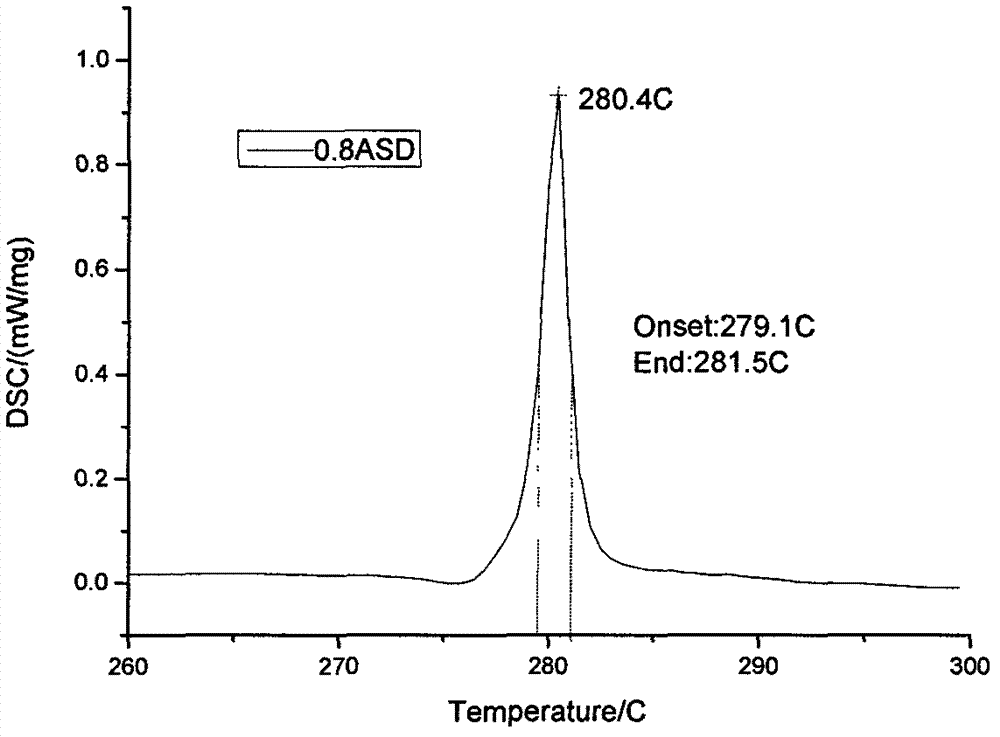

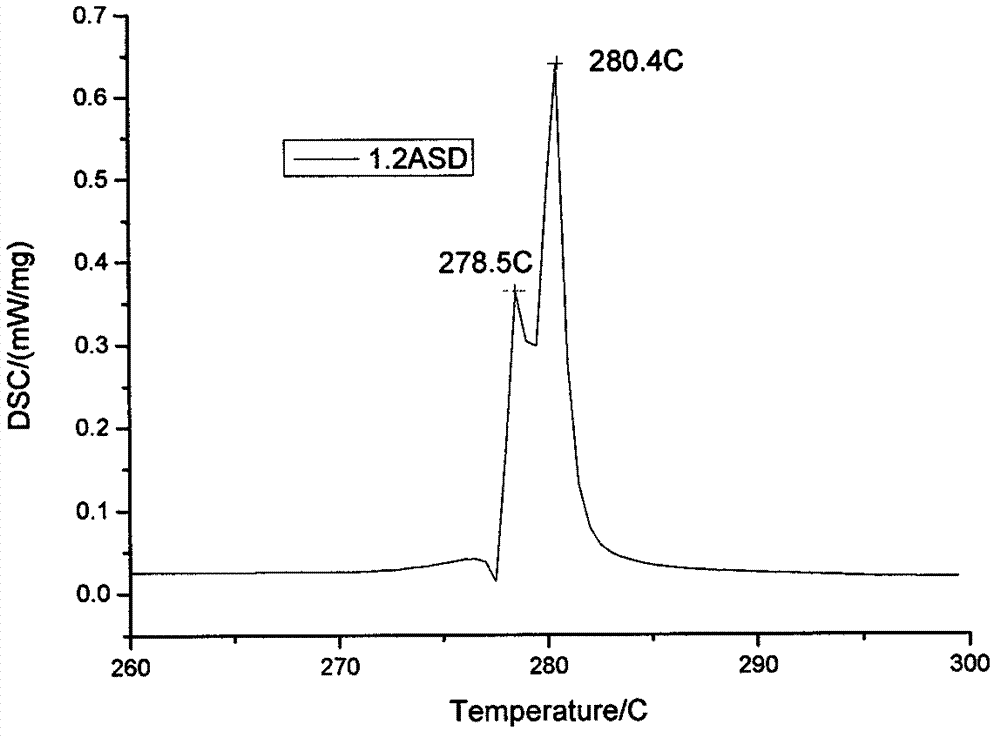

The invention relates to a gold-tin eutectic solder (AuSn20) electroplating solution and a preparation method thereof. The solution is characterized in that: novel gold potassium citrate is used for replacing traditional gold potassium cyanide, such that the pollution to the environment is reduced; bivalent tin is complexed by using another complexing agent, such that the stability of tin salt is improved. Every liter of the electroplating solution comprises 1-20g of gold salt, 1-20g of tin salt, 10-50g of a buffering agent, 10-50g of a complexing agent, 0.1-10g of a brightening agent, and 0.1-5g of an anti-oxidant. The electroplating solution provided by the invention is environment-friendly, and has relatively wide range of available current density. The obtained plating coat has good brightness, the gold and tin components are precisely controlled, and the melting point is 278-282 DEG C. The electroplating solution is suitable for welding and packaging of photoelectric devices in fields with relatively high requirements on reliability, such as communication, satellite, remote sensing, radar, automobile, aviation, and the like.

Description

Technical field [0001] The invention relates to an electroplating bath, in particular to a bright AuSn 20 (Gold-tin eutectic solder) plating solution and preparation method. Background technique [0002] AuSn eutectic solder 20 (80-20wt%) is located at the Au-Sn eutectic site, the eutectic point is 280℃, and the alloy can be melted and infiltrated with a small degree of superheat. Because of its moderate brazing temperature, high yield strength, no need for flux, good wettability, low viscosity, high corrosion resistance, high creep resistance and good thermal and electrical conductivity, it is widely used in communications , Welding and packaging of optoelectronic devices in the fields of satellites, remote sensing, radar, automobiles, aviation, etc. [0003] The traditional gold-tin alloy preparation methods include casting-draw rolling method, laminated cold-rolled composite method, and physical vapor deposition method. The casting drawing rolling method needs to add the third...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C25D3/56C25D3/60C25D3/62

Inventor 庄彤崔国峰杨俊锋

Owner GUANGZHOU AURORA TECHNOLOGIES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com