Patents

Literature

92results about How to "Good throwing ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

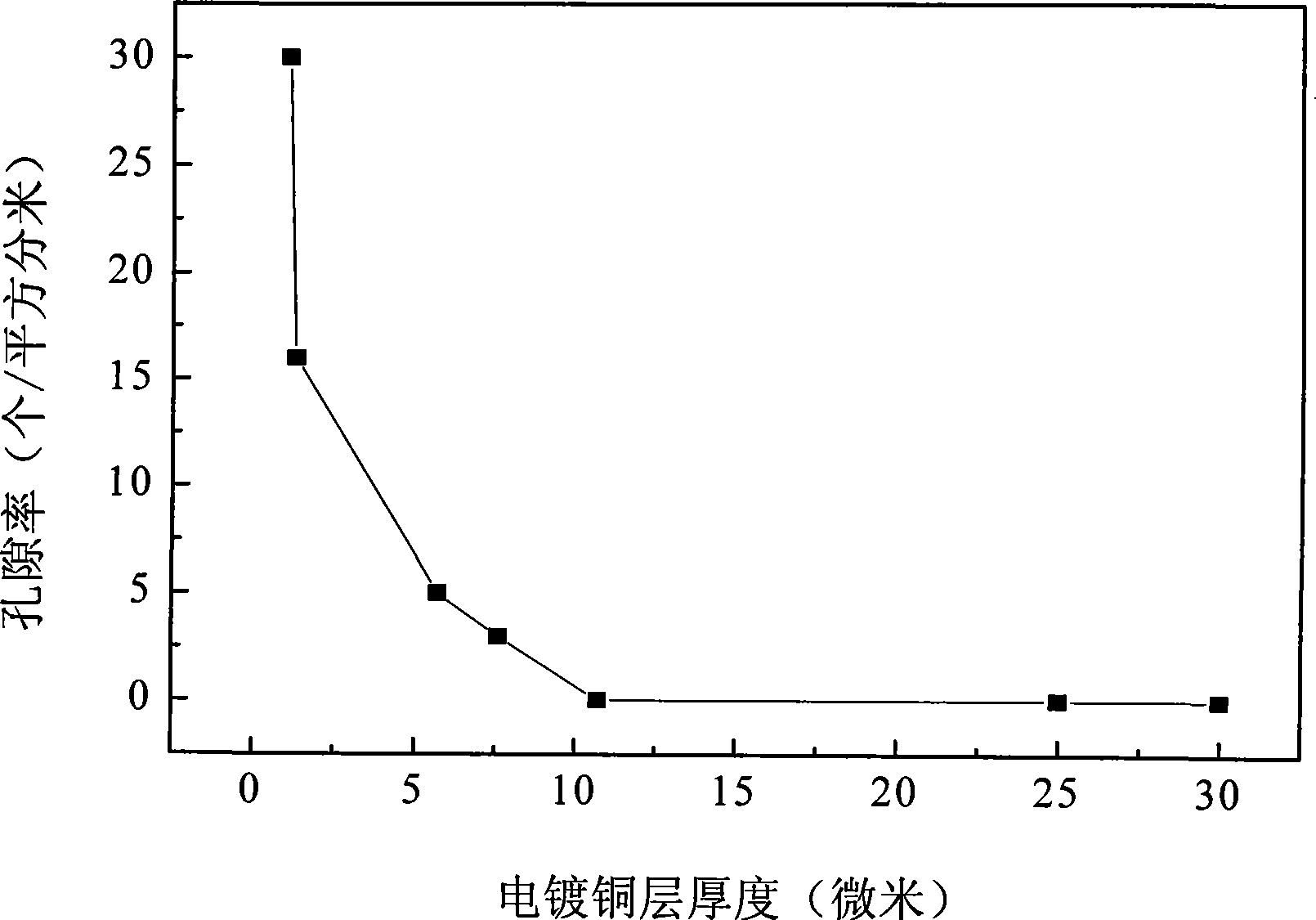

Cyanideless electro-coppering method for magnesium alloy casting parts

A method for no cyanide copper plating of a magnesium alloy casting relates to a method for the electro-coppering of a magnesium alloy. The invention solves the defects of the existing copper plating technique of the magnesium alloy of poor combining force of a plating coat, high void ratio and unstable plating bath. The method of the invention is as follows: first, alkaline cleaning; second, organic acid washing; third, activating in a magnesium alloy surface active agent under the condition of room temperature and water washing; fourth, soaking zinc alloy; fifth, plating in electro-coppering bath under the condition that the temperature is 20-50 DEG C and the intensity of cathode current is Dk=0.5-2.5A / dm<2>. The invention is not only used for strike copper plating of the magnesium alloy but also for thickening an electro-coppering coat. The copper plating coat has bright appearance, good combining force, low void ratio and convenient maintenance. The copper plating bath has good uniform coverage ability and covering power. The method has simple technique. The magnesium alloy casting that adopts the method to plate copper has wide application range and is applicable to the fields of electronic product, car and parts thereof, vessels, aerospace, etc.

Owner:HARBIN INST OF TECH

Method for direct copper non-cyanide plating of zinc alloy casting die

The invention discloses a copper plating method of zinc alloy casting piece, which comprises the following steps: a. electrolyzing cathode to remove oil; b. activating through washing by organic acid; c. immersing in the organic acid; d. plating copper directly with bivalent copper ion density at 10-25g / L and complexing agent density at 120-350 g / L, potassium carbonate density at 10-50g / L and hydroperoxide density at 1-15mL / L; maintaining pH value between 9 and 12; adjusting pH value through 50% potassium hydroxide solution; setting the current density of cathode 0.5-2.5A / dm2 at 20-50 deg.c.

Owner:HARBIN INST OF TECH

Copper plating solution for PCB (printed circuit board) through holes, and preparation method and plating method thereof

InactiveCN103572335AGood throwing abilityImprove toughnessPrinted element electric connection formationCopper platingPhysical chemistry

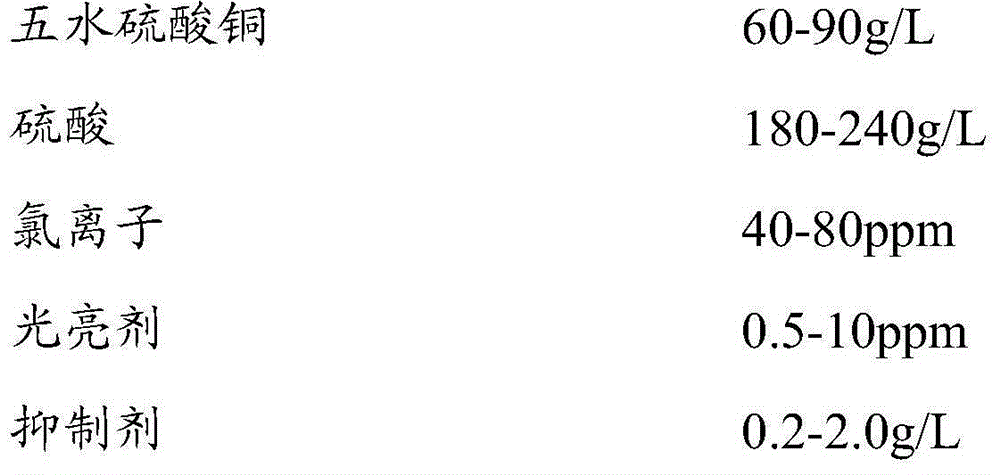

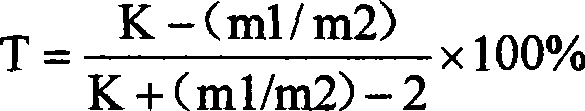

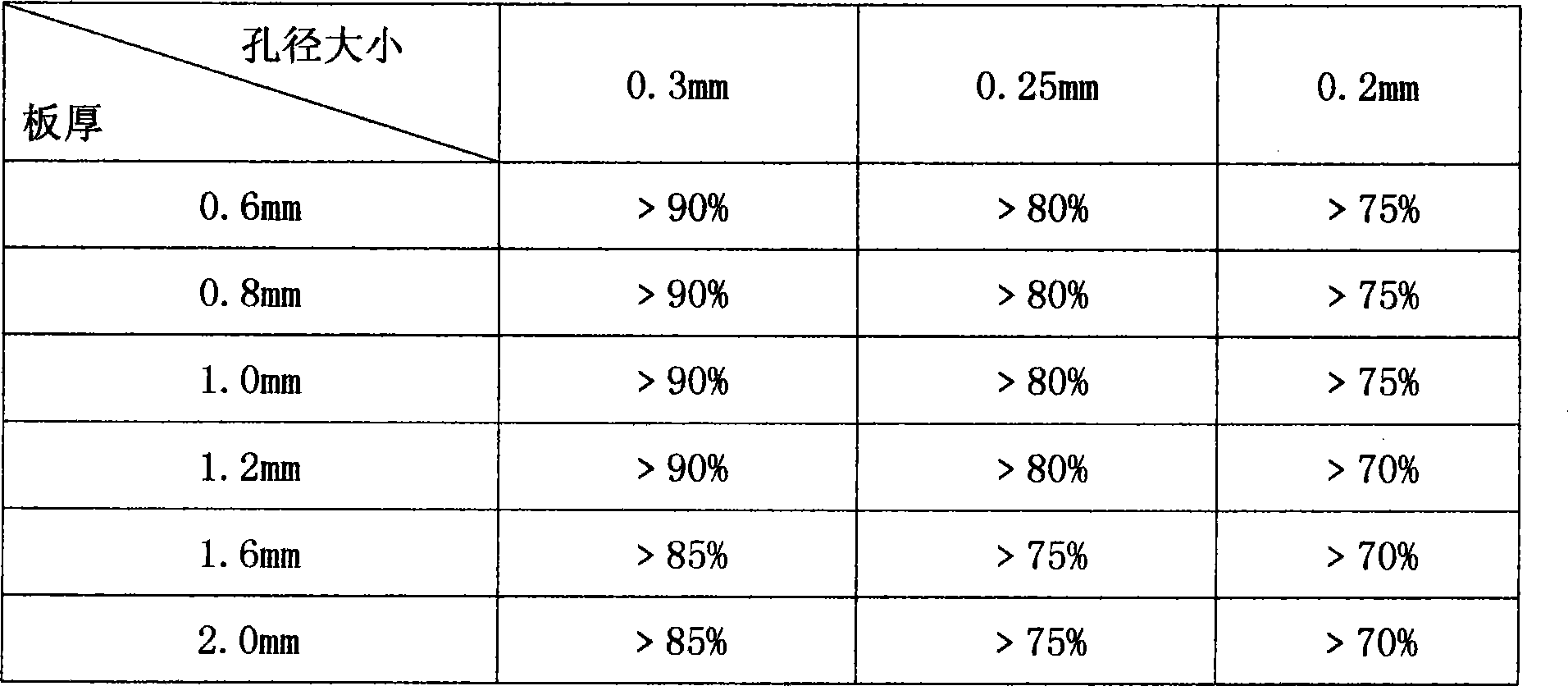

The invention relates to the technical field of PCB (printed circuit board) plating, in particular to a copper plating solution for PCB through holes, and a preparation method and a plating method thereof. Each liter of the copper plating solution comprises the following components according to contents: 70-150g of copper sulfate pentahydrate, 100-300g of sulfuric acid, 30-100ppm of chlorine ions, 5-50g of brightener, 3-30g of carrier, 2-20g of leveling agent and the balance of deionized water, wherein the concentration ratio of the copper sulfate pentahydrate to the sulfuric acid is 1: (1.5-2). The plating method comprises the following steps: putting a PCB with through holes into a plating bath with the copper plating solution; plating during air agitation to obtain a copper plating layer. The copper plating layer formed by the plating method has a good uniform plating capability as high as 95% above, and is dense, smooth, relatively good in malleability, good in gloss, high in toughness and low in internal stress.

Owner:东莞市富默克化工有限公司

Non-cyanide alkaline copper plating bath, preparation and use method thereof

The present invention is a new non-cyanide alkaline copper plating bath, preparation and use method thereof. In the copper plating bath, using copper sulfate or basic copper carbonate as main salt, using hydroxy-ethylidene diphosphonic acid as main complexant, using trisodium citrate, potassium citrate or potassium sodium tartrate as auxiliary complexant, using sodium nitrate or potassium nitrate as conductive salt, using sodium hydroxide or potassium hydrate as pH value regulator; the operation conditions are: cathode current density is 0.5-3.0 A / dm [2], pH of plating bath controlled between 12 and 13, plating bath temperature is 50-70 DEG. Comparing with the prior known technology, the invention has following advantages or positive effects: simple plating bath formula, easy control and operation, wide temperature range of plating bath using, high current efficiency, fine crystallization coating, good appearance color, stable plating bath, strong uniform plating and covering ability, low cost, easy wastewater treatment. The invention can be used for pre copper plating or direct electro-coppering instead of virulent cyaniding electro-coppering process.

Owner:KUNMING UNIV OF SCI & TECH

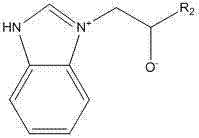

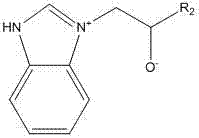

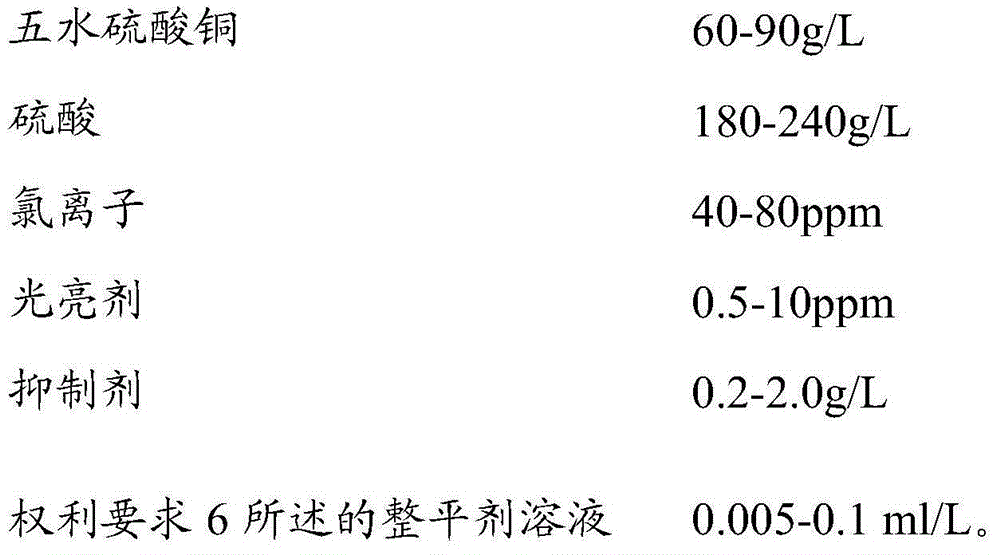

Leveling agent solution and preparation method and application thereof

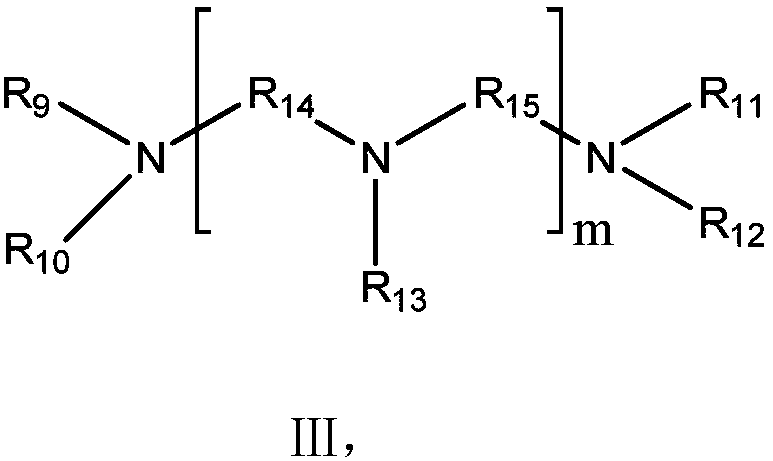

ActiveCN105002527AHas a leveling effectHas a bright effectAlkyl transferNitrogenous heterocyclic compound

The invention relate to a leveling agent solution and a preparation method and application thereof. The leveling agent solution is obtained in the mode that a nitrogenous heterocyclic compound and a diepoxide compound are polymerized and then 1,3-propane sultone is used for an alkylation reaction. The leveling agent solution, a brightener and an inhibitor are used together, and a good electroplating effect can be obtained in electroplating of circuit board through holes.

Owner:GUANGDONG GUANGHUA SCI TECH

Leveling agent, metal electroplating composition containing leveling agent, and preparation method and application of leveling agent

Owner:SHANGHAI SINYANG SEMICON MATERIALS

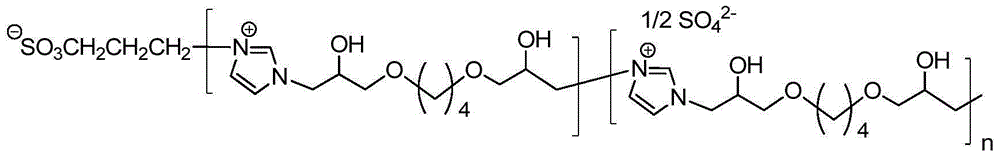

Polymers containing benzimidazole moieties as levelers

ActiveCN105705491AImprove thermal stabilityGood throwing abilityOrganic chemistryPrinted circuit manufactureElectroplatingMetal

Polymers of reaction products of dihalogens and compounds containing benzimidazole moieties are included in metal electroplating compositions to provide level metal deposits on substrates.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC +1

Electroplating method for electrically depositing Ni-Co-B alloy coatings on continuous casting crystallizer copper plates

The invention discloses an electroplating method for electrically depositing Ni-Co-B alloy coatings on continuous casting crystallizer copper plates and belongs to the technical field of electroplating. An electroplating solution used by the method comprises the following components according to mass concentration: 170-350g / L of nickel salt, 5-50g / L of cobalt salt, 0.5-4g / L of sodium borohydride,20-60g / L of ethylenediamine and 30-50g / L of buffering agents. The Ni-Co-B alloy coatings prepared from the electroplating solution have high throwing power and excellent corrosion resistance performance; the micro hardness of the Ni-Co-B alloy coatings can reach 1000HV.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

Surface treatment method for improving wear resistance and corrosion resistance of austenitic stainless steel shell

InactiveCN101709463AContent controlImprove bindingLiquid/solution decomposition chemical coatingChemical platingSand-paper

The invention discloses a surface treatment method for improving wear resistance and corrosion resistance of an austenitic stainless steel shell, which comprises the following steps: sanding the austenitic stainless steel shell with sand paper; deoiling, and washing with water to remove residual deoiling solution; and washing with acid to remove the film, activating the surface, washing with cold water and preheating, putting the austenitic stainless steel shell in a prepared plating solution to carry out plating for 1-2 hours, taking out, washing with hot water and cold water alternately to remove the residual plating solution on the sample surface, and finally drying to obtain the plating. The invention adopts the chemical plating technique to obtain the good-quality amorphous Ni-W-P ternary alloy plating on the surface of the austenitic stainless steel shell, thereby obviously improving the wear resistance of the product on the premise that the original silvery color and favorable glossiness of stainless steel are ensured.

Owner:SOUTH CHINA UNIV OF TECH

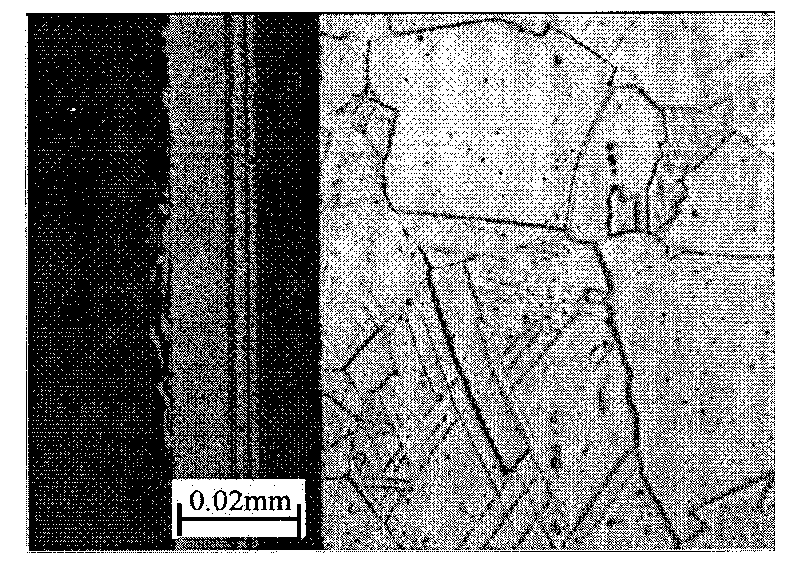

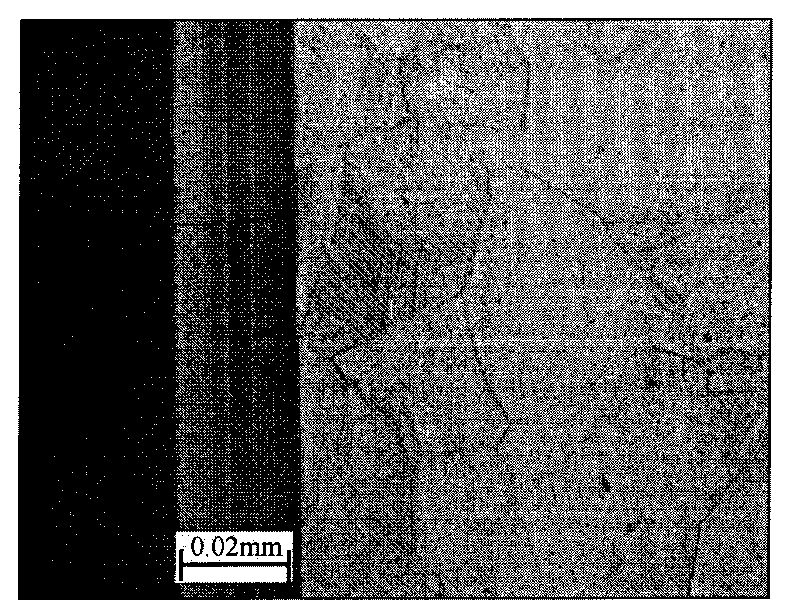

Method for non-cyanide imitation gold plating of Cu-Zn binary alloy

The invention provides a plating solution for the non-cyanide imitation gold plating of a Cu-Zn binary alloy on low carbon steel, and its use method in order to improve the problems of severe toxicity, bad anode dissolvability and high treatment cost of three wastes of cyanide-containing plating solutions and the problems of complex composition, narrow range of technological parameters and unrealistic imitation gold color of non-cyanide plating solutions in present imitation gold plating technologies. The method is characterized in that the method comprises the following steps: an activated matrix can be directly plated without cleaning, so the operation is simple; the imitation gold plating solution is composed of potassium pyrophosphate, copper sulfate, zinc sulfate and glycerin, so the imitation gold plating solution has the advantages of green property, environmental protection, good dispersity, strong homogeneous plating ability, simple composition and easy maintenance; and the prepared gold imitation plating solution can meet the requirements of the cross cut test requirements of national standard GB9286-1998 paint and varnish film; and the obtained coating is passivated and seal-protected, and the protected coating meets the 5% brine neutral salt spray test indexes of the national standard GB5938-86 Corrosion Resistance Test Method of Metal Coating and Chemical Treatment Layer of Light Industrial Product, and can be used as a decorative coating.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High-phosphorus chemical nickel-plating solution

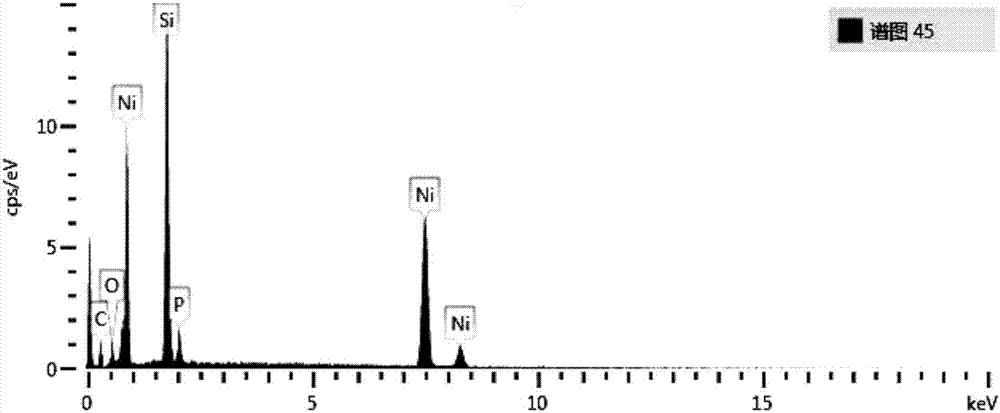

InactiveCN106756904ALow costGood throwing abilityLiquid/solution decomposition chemical coatingSodium acetateSuccinic acid

The invention discloses a high-phosphorous chemical nickel-plating solution which comprises a cylinder opening solution and a supplement solution. The cylinder opening solution contains nickel sulfate, sodium hypophosphite, citric acid, lactic acid, sodium acetate, succinic acid, potassium iodate, potassium iodide, nitrilotriacetic acid, cerous sulfate, copper sulfate, benzotriazole, benzimidazole with the concentration being 2-10 mg / L, 5-25 mL / L of OP-10 with the concentration being 5-25 mL / L and the balance pure water. The nickel-plating solution has the advantages that cost is low, the excellent plating ability is achieved, the cylinder opening solution is stable, glossiness is achieved, the magnetism level requirement is met, and the service life reaches 11.0 MTO; during the service life, the average sedimentation rate is 12-14 [mu]m / h, the phosphorus content of a plating layer is 10%-14%, the time for neutral salt spraying is longer than or equal to 96 h (the thickness of the plating layer is 18-25 [mu]m), and the time for a purification resistant nitric-acid test is longer than or equal to 8 min (the thickness of the plating layer is 18-25 [mu]m); the magnetism level is lower than or equals to 200 gamma (specifically, 1 gamma is equal to 1 nT, and in general, remanence in the aerospace field takes gamma as a unit), the western country standard is met, and the magnetism is required to meet the NMB magnetism level; and the plating solution is free of lead and cadmium, conforms to the RoHS command and is an environment-friendly high-phosphorous chemical nickel-plating solution.

Owner:贵阳华科电镀有限公司

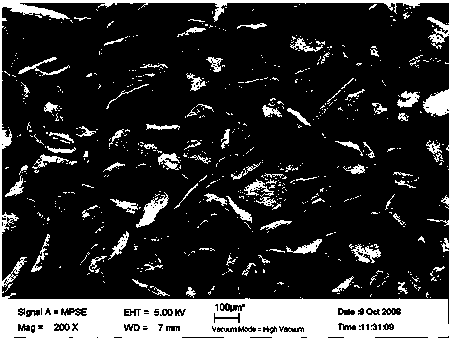

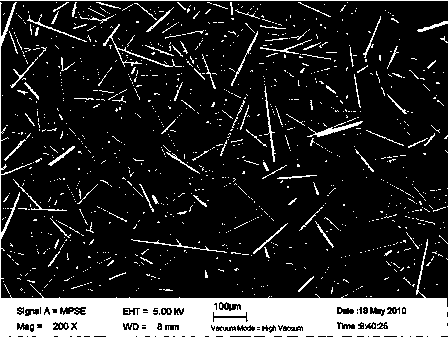

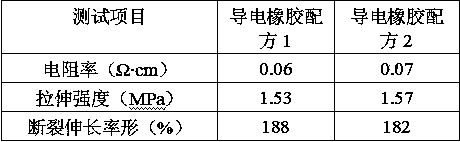

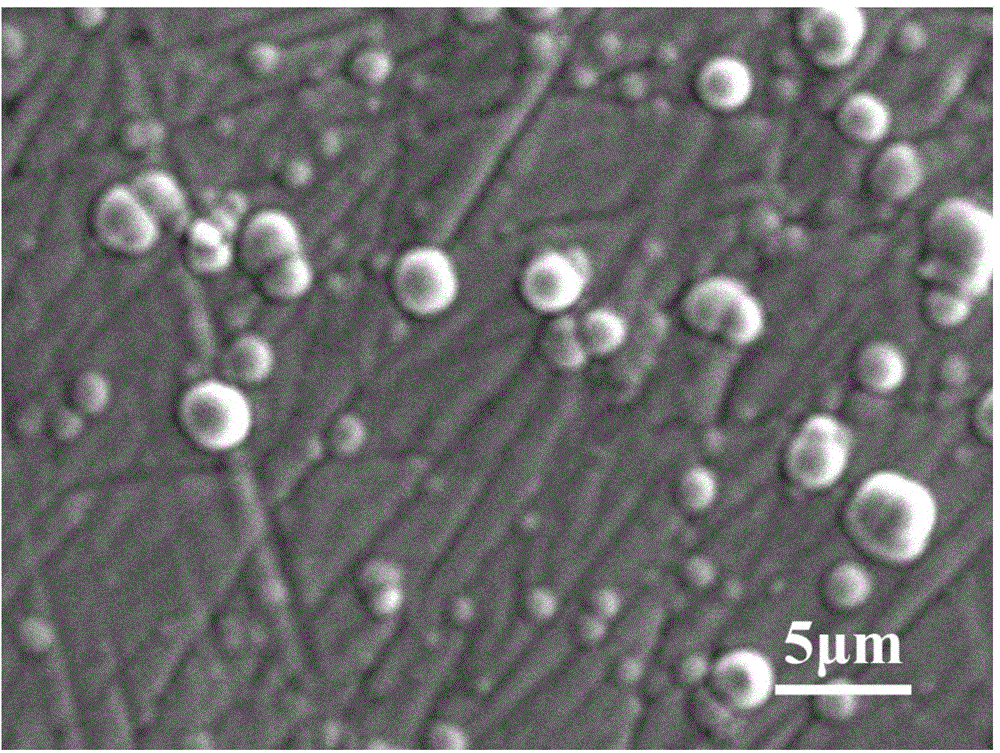

Nickel-coated graphite electric conduction powder used for electric conduction rubber and manufacturing method thereof

InactiveCN103817323ALow densityLow costLiquid/solution decomposition chemical coatingElectricityAcid etching

The invention concretely discloses a nickel-coated graphite electric conduction powder used for electric conduction rubber and a manufacturing method of the nickel-coated graphite electric conduction powder. The nickel-coated graphite electric conduction powder used for the electric conduction rubber comprises 50-80% of nickel and 20-50% of graphite. The manufacturing method of the nickel-coated graphite electric conduction powder used for the electric conduction rubber mainly includes the four steps of oil removing treatment on graphite powder, acid etching and roughening treatment on the graphite powder, surface activating treatment on the graphite powder and chemical nickel plating. The nickel-coated graphite electric conduction powder has the advantages of pure nickel and pure graphite, is low in cost and not prone to rusting and further can improve the mechanical strength of the electric conduction rubber material. The chemical nickel plating method is easy to operate and simple in technology, plated layers are even and compact, the throwing power is high, plating can be performed on particles in any shape, the covering power is high, and the even, fine and dispersed composite powder can be manufactured.

Owner:杨福河

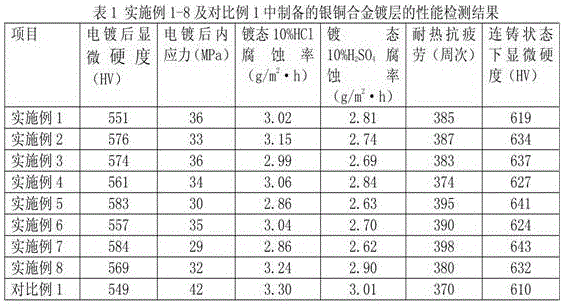

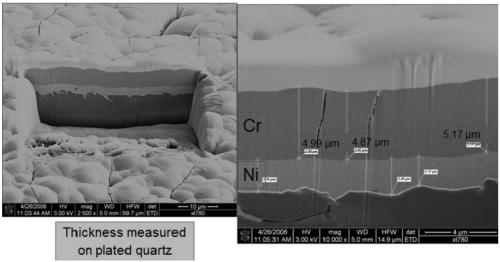

Repairing method of scrapped continuous casting crystallizer copper plate

ActiveCN105780063AImprove performanceExtended service lifeElectroforming processesSand blastingPre treatment

The invention discloses a repairing method of a scrapped continuous casting crystallizer copper plate. The repairing method comprises the steps of (1) pretreatment: carrying out degreasing treatment, mechanical sand blasting scuffing treatment, electrolytic degreasing treatment, ultrasonic degreasing treatment and acid spraying activating treatment on a copper plate base material subjected to machining, so as to obtain a to-be-cast copper plate base material; (2) electroforming solution injection: injecting an electroforming solution into an electroforming tank, adjusting the pH, and heating the electroforming solution till the temperature reaches a set value; and (3) electroforming: putting the to-be-cast copper plate base material adopted as a cathode into the electroforming tank, putting an anode into the electroforming tank, switching on the power, and stopping electroforming till the thickness of a silver-copper alloy plating reaches a set value. According to the repairing method, the crystallizer copper plate base material at the scrapping limit is repaired and reutilized through adopting an easy and feasible preparation method, the obtained crystallizer copper plate is excellent in performance, the service life of the crystallizer copper plate is prolonged through the silver-copper alloy plating, the production cost is improved, and the sustainable development property is high.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

Non-cyanide electro cooper plating bath of EDTA system and use method thereof

The present invention provides a new non-cyanide electro cooper plating bath of EDTA system and use method thereof. In the electro copper plating bath, using disodium EDTA or dipotassium EDTA as main complexant, using copper sulfate or basic copper carbonate as main salt, using trisodium citrate, potassium citrate or potassium sodium tartrate as auxiliary complexant, using sodium nitrate or potassium nitrate as conductive salt, using sodium hydroxide or potassium hydrate as pH value regulator. The invention also provides a use method of the non-cyanide electro cooper plating bath. The invention has advantages: simple plating bath formula, easy control and operation, wide temperature range of plating bath using, high current efficiency, fine crystallization coating, good appearance color, stable plating bath, strong uniform plating and covering ability, low cost, easy wastewater treatment. The invention can be used for pre copper plating or direct electro-coppering instead of virulent cyaniding electro-coppering process.

Owner:KUNMING UNIV OF SCI & TECH

High-density and high-precision printed circuit board copper electroplating process

InactiveCN103806031AIntense and even stirring actionGuaranteed cleanlinessPrinted circuit manufactureNumerical controlUltrasonic assisted

The invention belongs to the field of electroplating, and especially relates to a high-density and high-precision printed circuit board copper electroplating process used during a copper plating process in circuit board production manufacturing. According to the present invention, the electroplating solution comprises a copper sulfate solution and a dispersant; the high-density and high-precision printed circuit board copper electroplating process is characterized in that a plating tank added with a copper plating solution is placed in a numerical control ultrasonic generator, a prepared printed circuit board is placed into the plating solution, and ultrasonic waves with a certain power are applied during the electroplating process to enhance electroplating; and ultrasonic waves are adopted to enhance copper electroplating, such that the obtained plating layer has characteristics of delicate appearance, good gloss, uniform grain, tight covering and excellent comprehensive performance, and provides good bonding force and good corrosion resistance compared with the plating layer obtained through the treatment with no ultrasonic wave assisted effect.

Owner:WUXI XINSANZHOU STEEL

Electroplate copper liquor for printed circuit board

InactiveCN101457375AImprove the plating effectQuality improvementPrinted circuit manufactureCopper platingSuccinic acid

The invention belongs to the electroplating field, in particular relates to a novel electroplating solution with excellent plating property used in the process of plating copper in the production and manufacturing of a circuit board. The electroplating copper solution of a printed circuit board comprises a copper sulphate solution and a dispersant; the dispersant is mainly sodium salt solution containing sulfosuccinate group and ethylene oxide group, and the dispersant comprises alkyl ester sodium sulfonate salt of succinic acid, succinate sodium salt containing amine and the succinate sodium salt containing ethoxy. An anion surfactant containing the sodium salt of the sulfosuccinate group and the ethylene oxide group is taken as the dispersant for a used additive, which significantly improves the comprehensive electroplating property of the electroplating copper solution, and ensures that the electroplating solution has high dispersing property, excellent ductibility and better plating homogeneity. The invention can provide the novel electroplating copper solution with the high dispersing property, the excellent ductibility and the better plating homogeneity. The copper solution can meet requirements for high density and high accuracy of plating copper on the printed circuit board.

Owner:深圳市天泽科技实业有限公司

Chemical silver plating solution and preparation method thereof

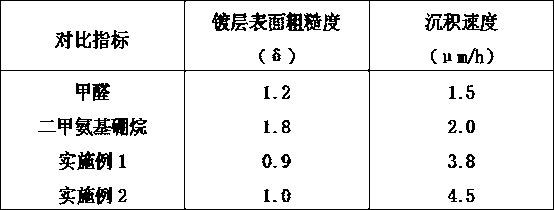

InactiveCN102747347ACrystal fineGood glossLiquid/solution decomposition chemical coatingSilver plateHydrazine compound

The invention discloses a chemical silver plating solution. The silver plating solution comprises silver nitrate, succimide, tartaric acid, trolamine, methylsulfonic acid and water. The silver plating solution per liter comprises 5-30g of the silver nitrate, 30-160g of the succimide, 10-38g of the tartaric acid and 6-68g of auxiliary complexing agents; alkali is used for adjusting the PH value of the silver plating solution to be in a range of 9-11; the auxiliary complexing agents are the trolamine and the methylsulfonic acid; the silver plating solution per liter comprises 1-38g of the trolamine and 5-30g of the methylsulfonic acid; and the alkali is sodium hydroxide or potassium hydroxide. The silver plating solution has the advantages that comprehensive quality of plating layers of the chemical silver plating solution is good, and the chemical silver plating solution can replace hydrazine, formaldehyde and dimethylamino borane, serves as a reducing agent process and is used for plating silver. The storage performance of the silver plating solution is stable, the waste of the silver plating solution can be avoided, and the application of the silver plating solution is wide. The preparation of the silver plating solution is flexible and the silver plating solution is convenient to use.

Owner:淮安市曼蒂科技发展有限公司

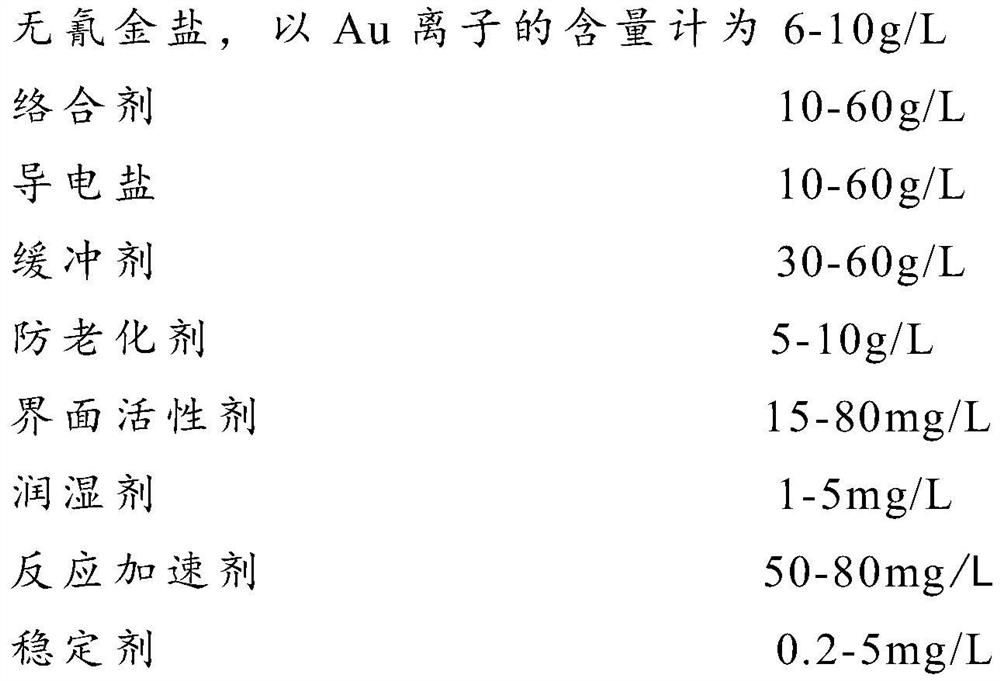

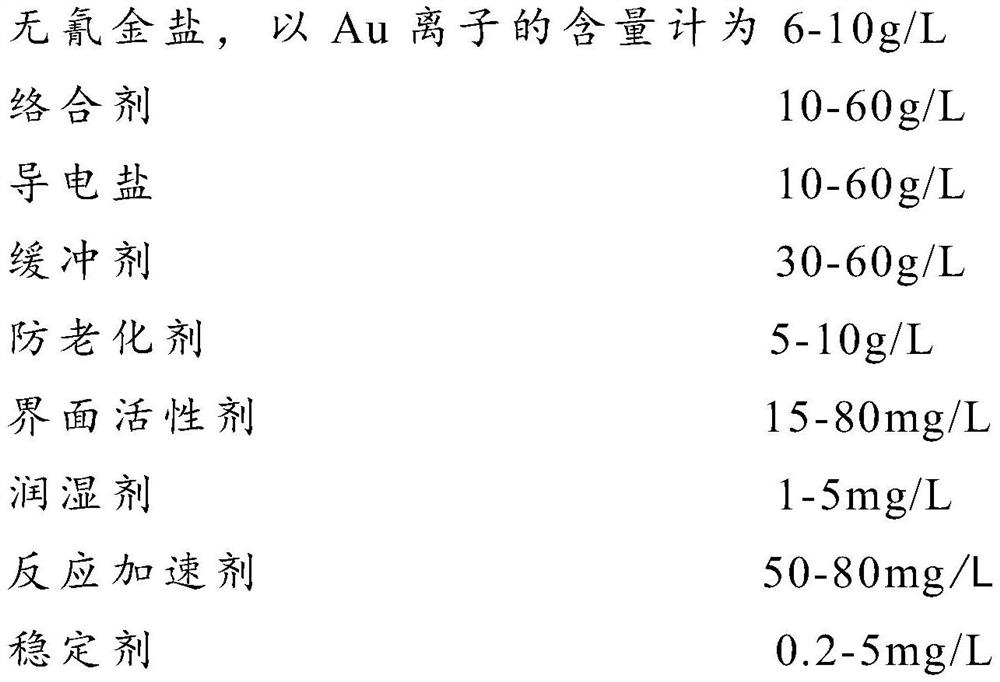

Cyanide-free chemical gold plating solution applied to advanced wafer packaging field and gold plating process thereof

ActiveCN113026068AAvoid narrow operating rangesSpeed up the activation reactionCellsSemiconductor devicesCyanideActive agent

The invention discloses a cyanide-free chemical gold plating solution applied to the advanced wafer packaging field and a gold plating process thereof. The cyanide-free chemical gold plating solution is prepared from the following components: cyanide-free gold salt with the content of Au ions being 6-10 g / L, 10-60 g / L of a complexing agent, 10-60 g / L of conductive salt, 30-60 g / L of a buffer agent, 5-10 g / L of an anti-aging agent, 15-80 mg / L of an interfacial agent, 1-5 mg / L of a wetting agent, 50-80 mg / L of a reaction accelerator, and 0.2-5 mg / L of a stabilizer, wherein the reaction accelerator is a compound of 2,6-diaminopyridine and 3-pyridine methanol, and the mass concentration ratio of the 2,6-diaminopyridine to the 3-pyridine methanol is 2:1. The solution not only ensures the stability of the plating solution, but also enables a plated part to be easily spread on the surface of an electrode so as to achieve the purpose of uniform plating, and therefore the effect of void-free and seamless filling of wafer packaging micropores is further achieved.

Owner:SHENZHEN CHENGGONG CHEM

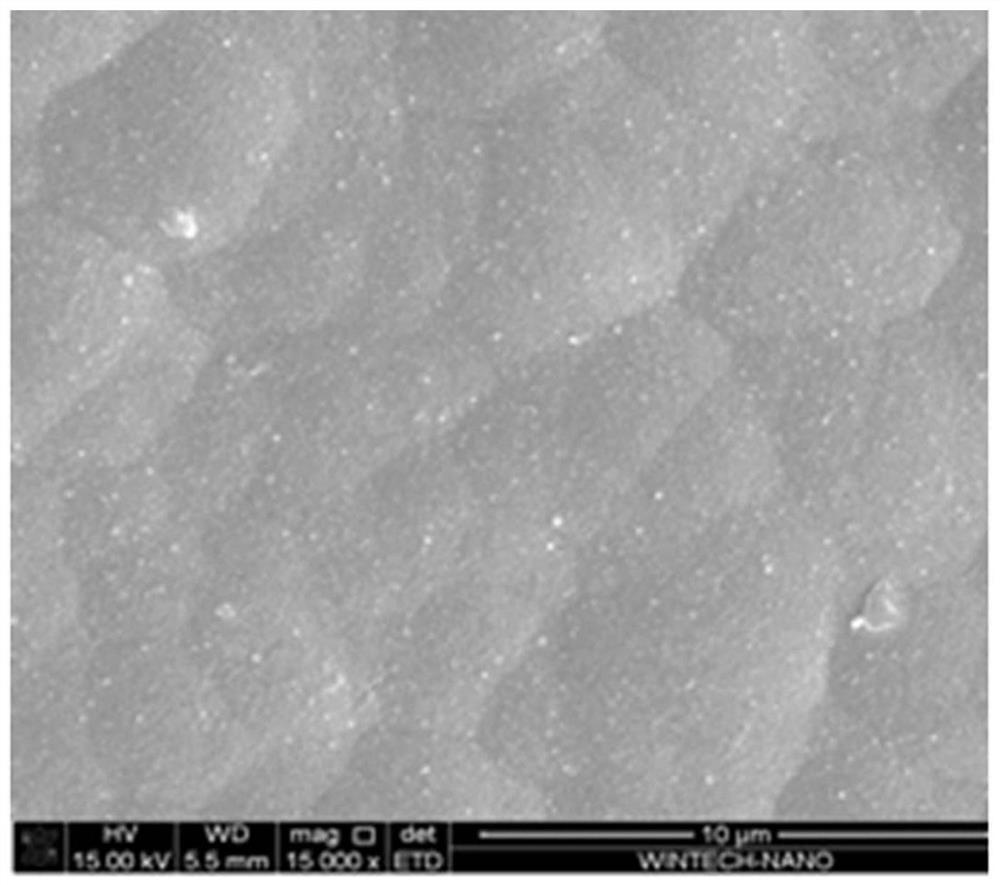

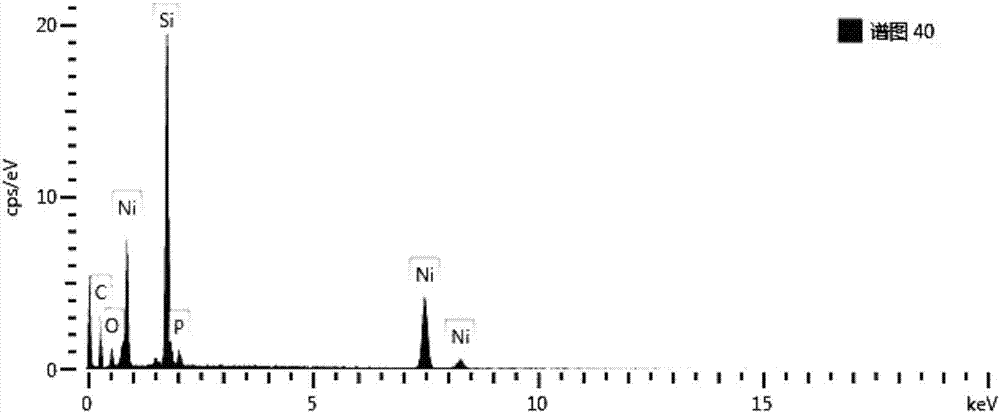

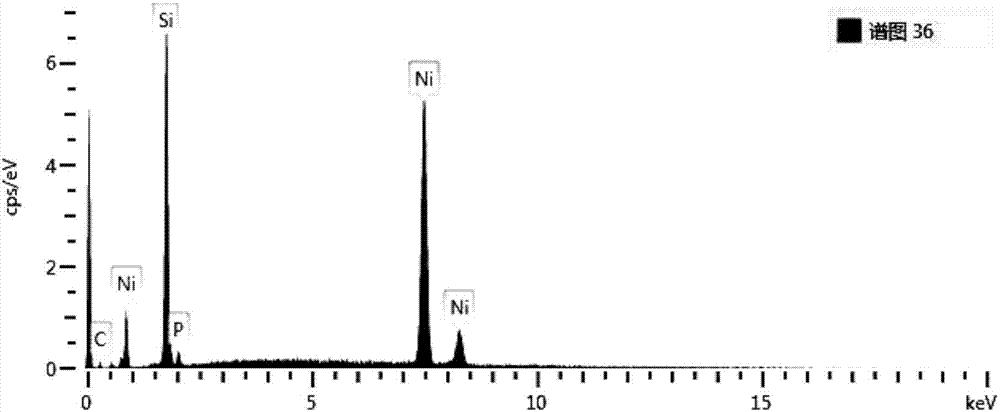

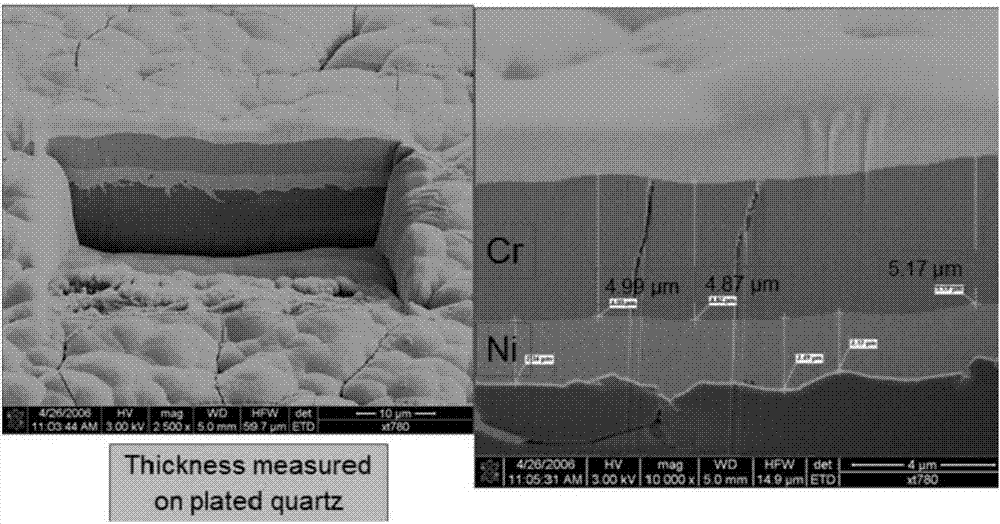

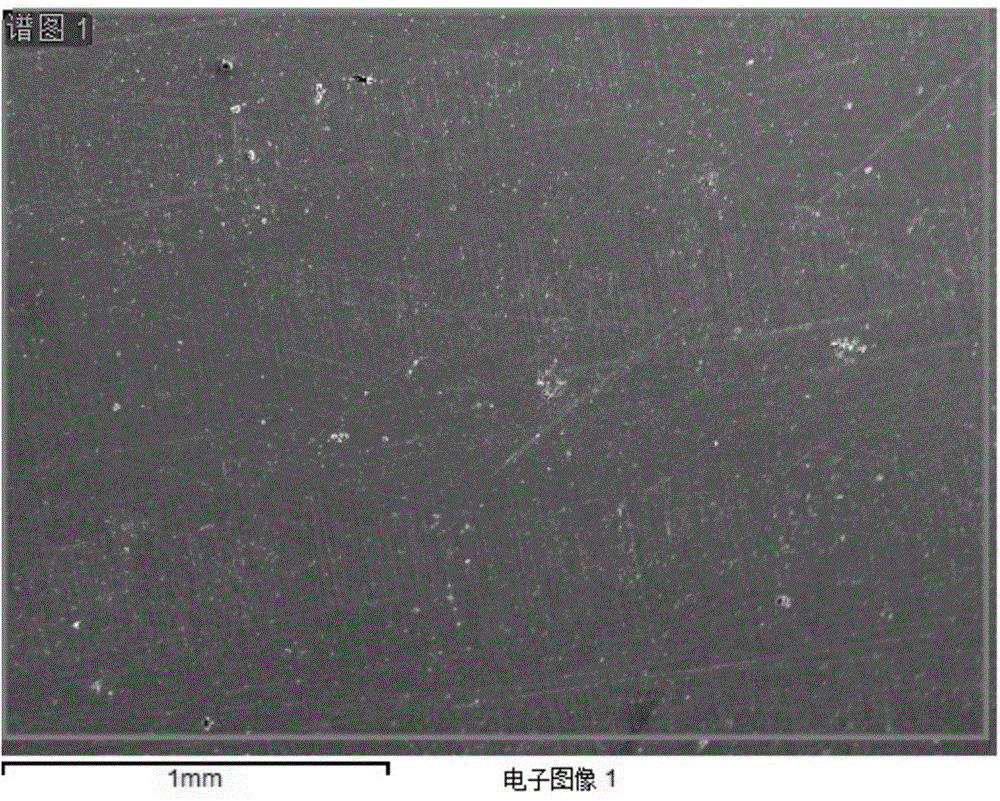

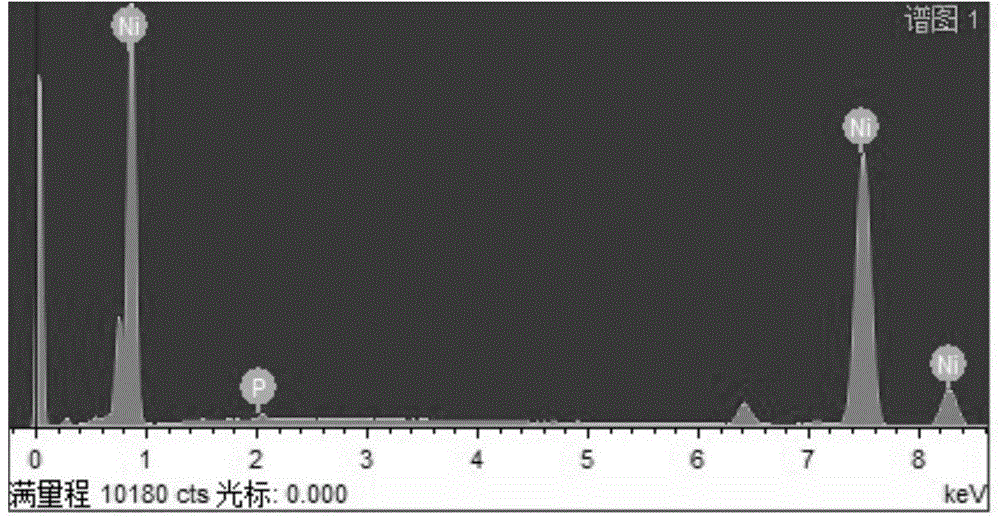

Electroless plating solution and method for cladding surfaces of SiC particles with Ni-P through electroless plating solution

InactiveCN106929835AReduce porosityImprove fracture toughnessTransportation and packagingMetal-working apparatusSurface cleaningThiourea

The invention relates to an electroless plating solution which is used for cladding the surfaces of SiC particles with Ni-P, and further relates to a method for cladding the surfaces of the SiC particles with Ni-P through the electroless plating solution. The method comprises the following steps that (1) SiC surface cleaning treatment is conducted; (2) the SiC particles are coarsened; (3) the SiC particles are activated and sensitized; (4) the electroless plating solution is prepared, and plating is conducted; and (5) electroless plating aftertreatment is conducted. The SiC surface cladding effect is the best when the concentration of [Ni2+] in the electroless plating solution is 0.25 mol / L, the concentration of [NH4+] is 0.6 mol / L, the concentration ratio of [Ni2+] to [H2PO2-] is 0.4, the concentration of citric acid is 0.1 mol / L, and trace lactic acid and thiourea exist. The electroless plating solution is used for complete nickel cladding of the SiC particles, and the problem that the SiC particles are low in wettability and consequently the SiC particles are difficult to composite with molten metal is solved; and the electroless plating solution is low in maintaining cost and long in service life.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL +1

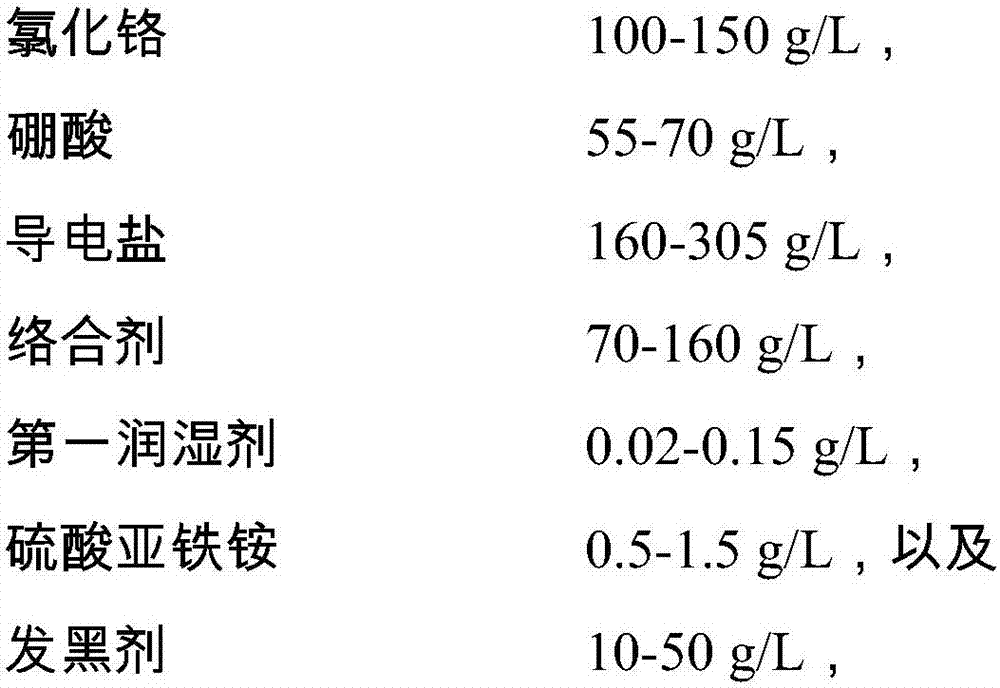

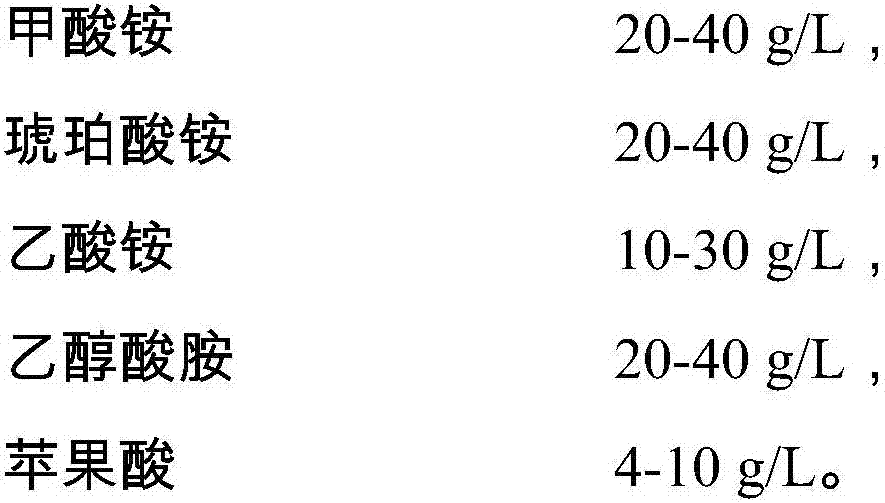

Black chromium plating solution, composite plating layer and preparing method thereof

ActiveCN107099824AUniform colorImprove coverage uniformityAmmonium ferrous sulfatePotassium thiocyanate

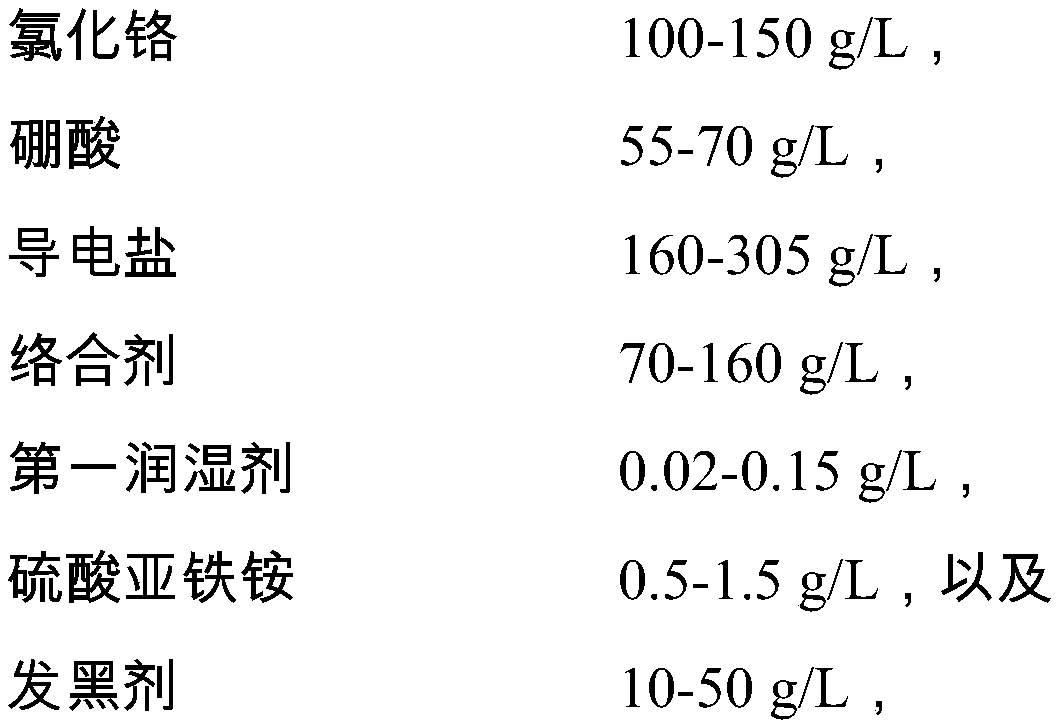

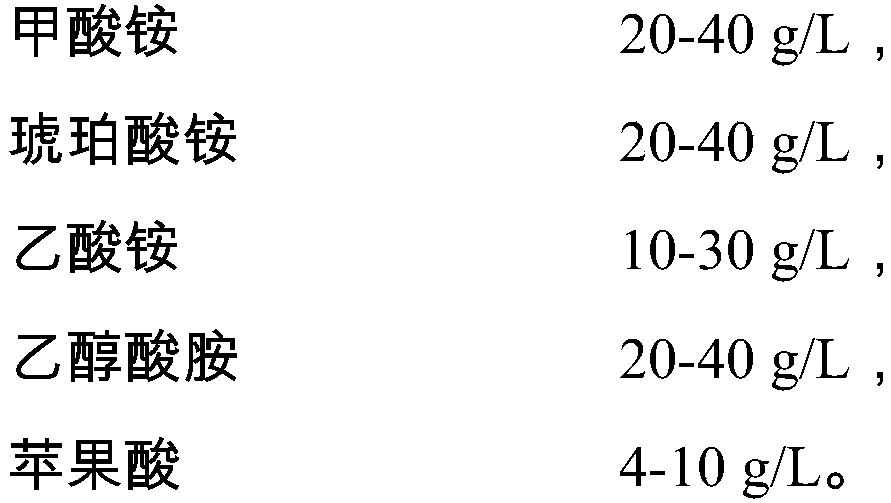

The invention relates to a black chromium plating solution, a composite plating layer and a preparing method thereof. The black chromium plating solution comprises water solutions of the following components of 100-150 g / L of chromic chloride, 55-70 g / L of boric acid, 160-305 g / L of conducting salt, 70-160 g / L of complexing agents, 0.02-0.15 g / L of wetting agents, 0.5-1.5 g / L of ammonium ferrous sulfate and 10-50 g / L of blackening agents, wherein the blackening agents are mixtures of methionine, potassium thiocyanate and aspartic acid. The trivalent black chromium plating layer formed by plating through the black chromium plating solution is in deep black, is strong in uniform covering capacity and can be matched with a bright copper layer, a semi-bright nickel layer, a bright nickel layer, a micro-porous nickel layer and a passivation film layer to enable the obtained composite plating layer to have high abrasion resistance and be in uniformly deep black.

Owner:SWELL MARUI GUANGZHOU AUTOMOBILE PARTS

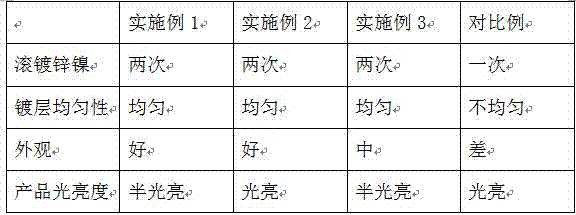

Method for barrel-plating zinc-nickel alloy on automobile part

The invention relates to a method for barrel-plating a zinc-nickel alloy on an automobile part. The method comprises the following steps of (1) hot alkali degreasing, (2) anodic electrolyzing for the first time, (3) acid pickling, (4) anodic electrolyzing for the second time, (5) activating, (6) neutralizing, (7) two-stage zinc-nickel barrel-plating, (8) dehydrogenation, (9) passivating, and (10) closing. The method for barrel-plating the zinc-nickel alloy on the automobile part has the advantages that zinc-nickel barrel-plating is conducted for two times instead of one time, a plating tank in the first stage contains more zinc and less nickel, a plating tank in the second stage contains less zinc and more nickel, the zinc contents and the nickel contents in the plating tanks in the two stages are adjusted to be the same, so that the zinc content and the nickel content of a product are guaranteed, thus, the uniformity of a plating layer is guaranteed, accordingly the appearance of the product can be effectively controlled, and the performance of the product is greatly guaranteed.

Owner:南通创源电化学科技有限公司

Chemical nickel-plating liquor

ActiveCN104152877ARaw materials are easy to getLow costLiquid/solution decomposition chemical coatingNickel saltPhosphor

The invention discloses chemical nickel-plating liquor. The chemical nickel-plating liquor is characterized by comprising the following components: 22g / L-35g / L of nickel salt, 15g / L-25g / L of hypophosphite, 200mL / L-250mL / L of compound complexing agent, 0.5mL / L-1.5mL / L of stabilizer and 0.5mL / L-2.0mL / L of phosphor content inhibitor. The liquor is worked in a nearly neutral condition, and is free of obvious alkaline corrosion and acid corrosion on a workpiece; and the mass content of the phosphor in the obtained coating is 0.3%-3.5%, and the coating is high in hardness and good in weldability.

Owner:广东致卓环保科技有限公司

Nickel-iron alloy plating solution of neodymium-iron-boron permanent magnet material and method for preparing plated nickel-iron alloy

The invention provides a nickel-iron alloy plating solution of neodymium-iron-boron permanent magnet material and a method for preparing plated nickel-iron alloy. The method comprises chamfer polishing, degreasing, pickling dust removing, activating acid liquor and plated nickel-iron ally film-forming; and the nickel-iron alloy plating solution comprises 200-220g / L of nickel sulfate, 10-30g / L of six hydrated nickel chloride, 10-20g / L of ferrous sulfate, 30-50g / L of boric acid, 30-40g / L of sodium citrate, 2.5-3ml / L of NI-1305A, 10-12ml / L of NI-1305B and 0.2-0.4g / L of lauryl sodium sulfate. The method provided by the invention is not polluted by the iron in neodymium-iron-boron base materials; the binding force between the plated layer and the base body is increased; the nickel-iron alloy plating layer is soft and crystallized meticulously; the binding force between the plating layer and the base body is excellent; and the invention has excellent deeply plating and uniform plating capabilities.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

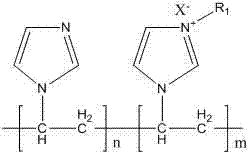

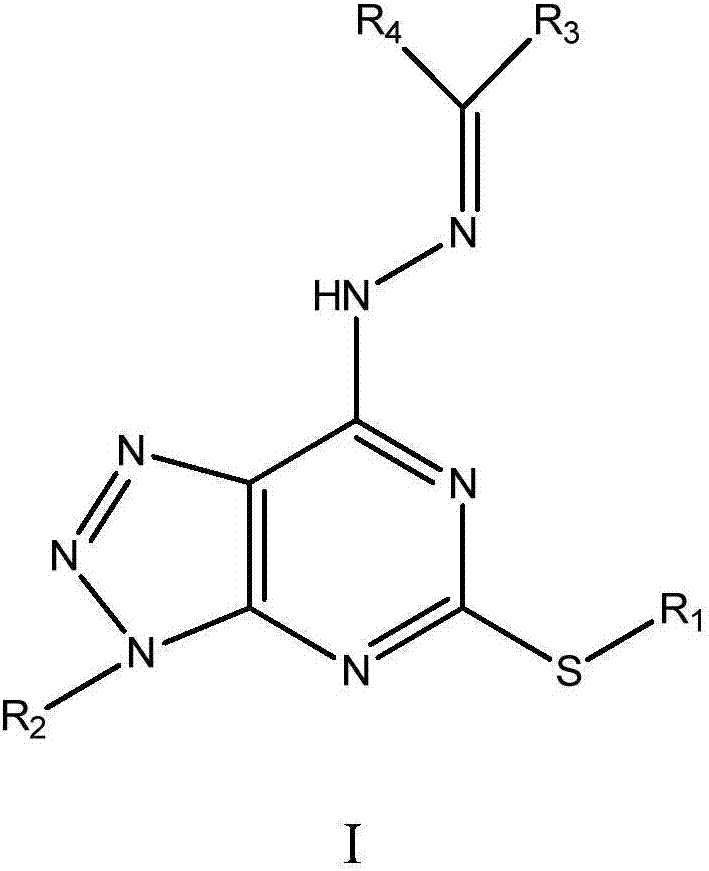

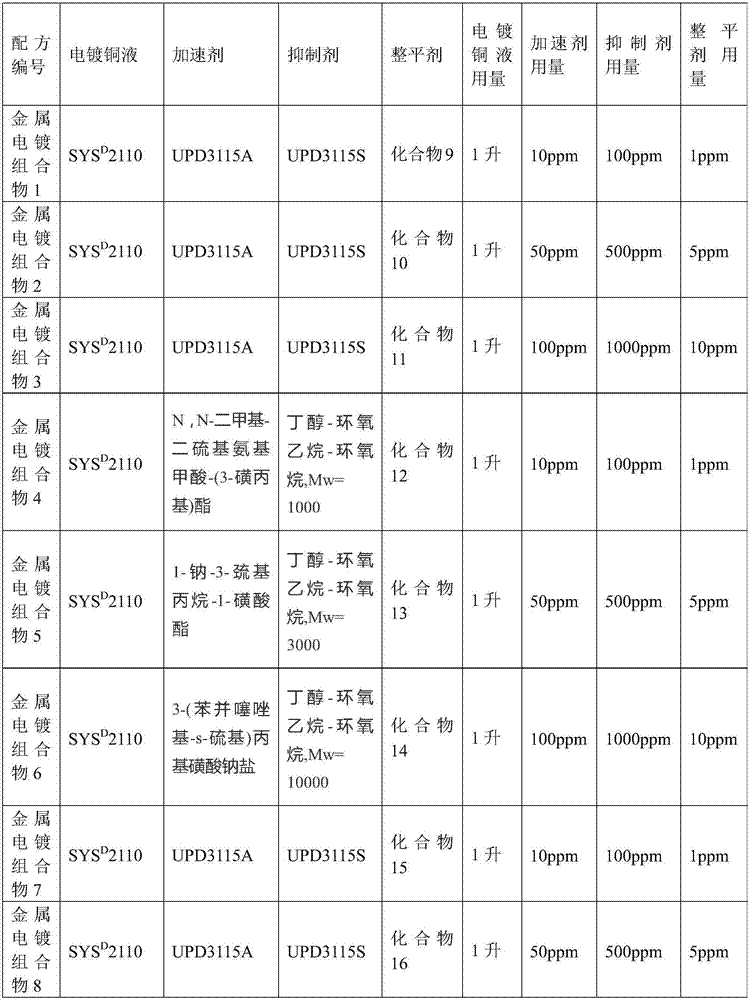

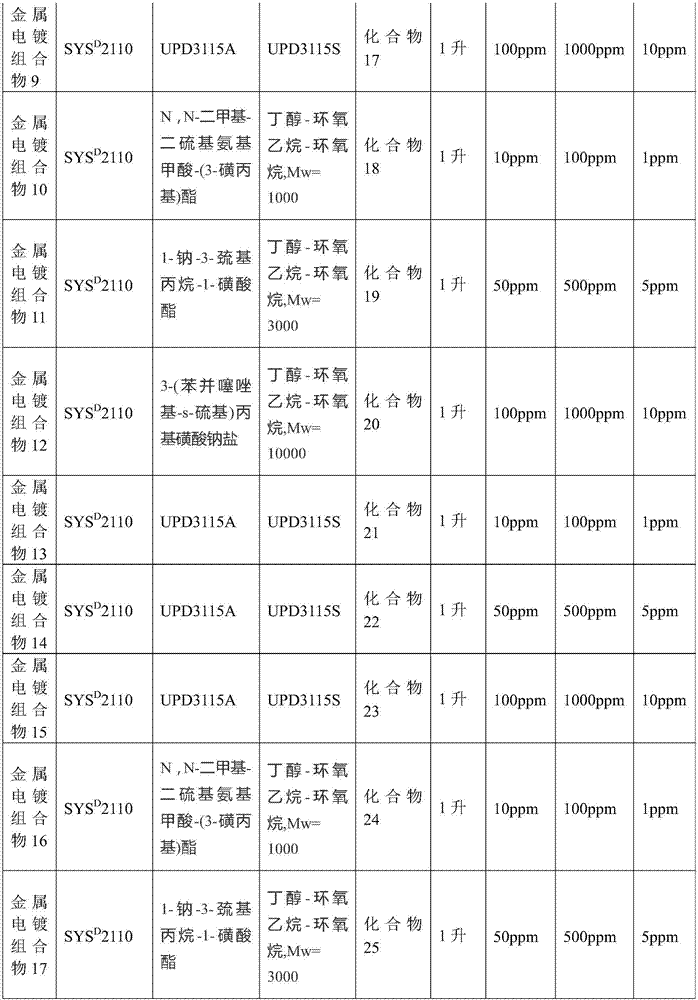

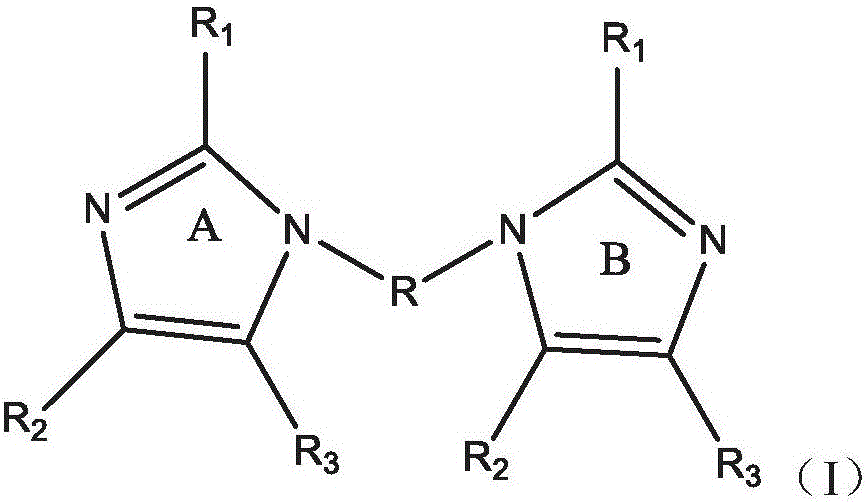

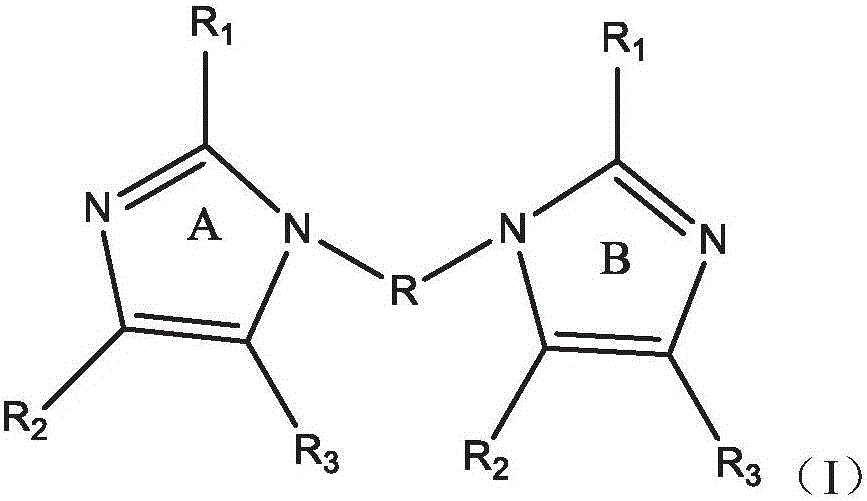

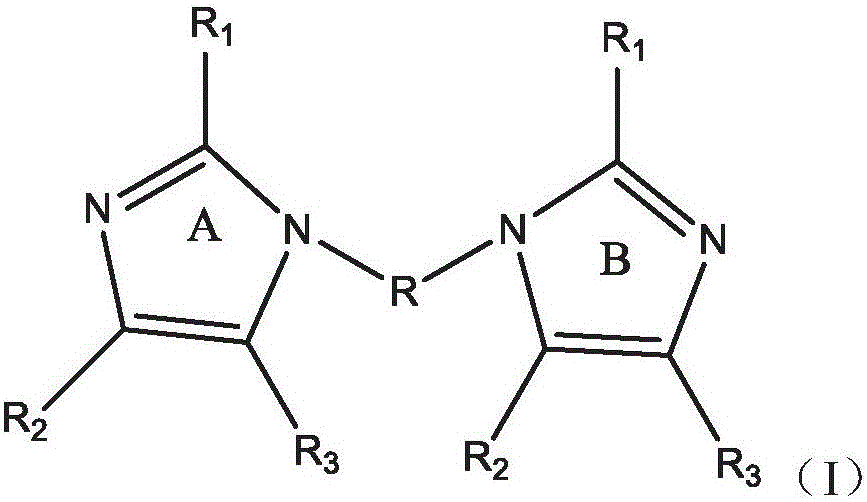

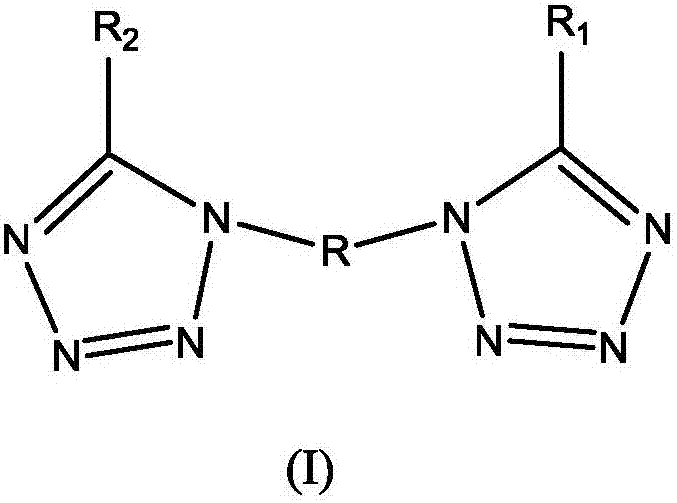

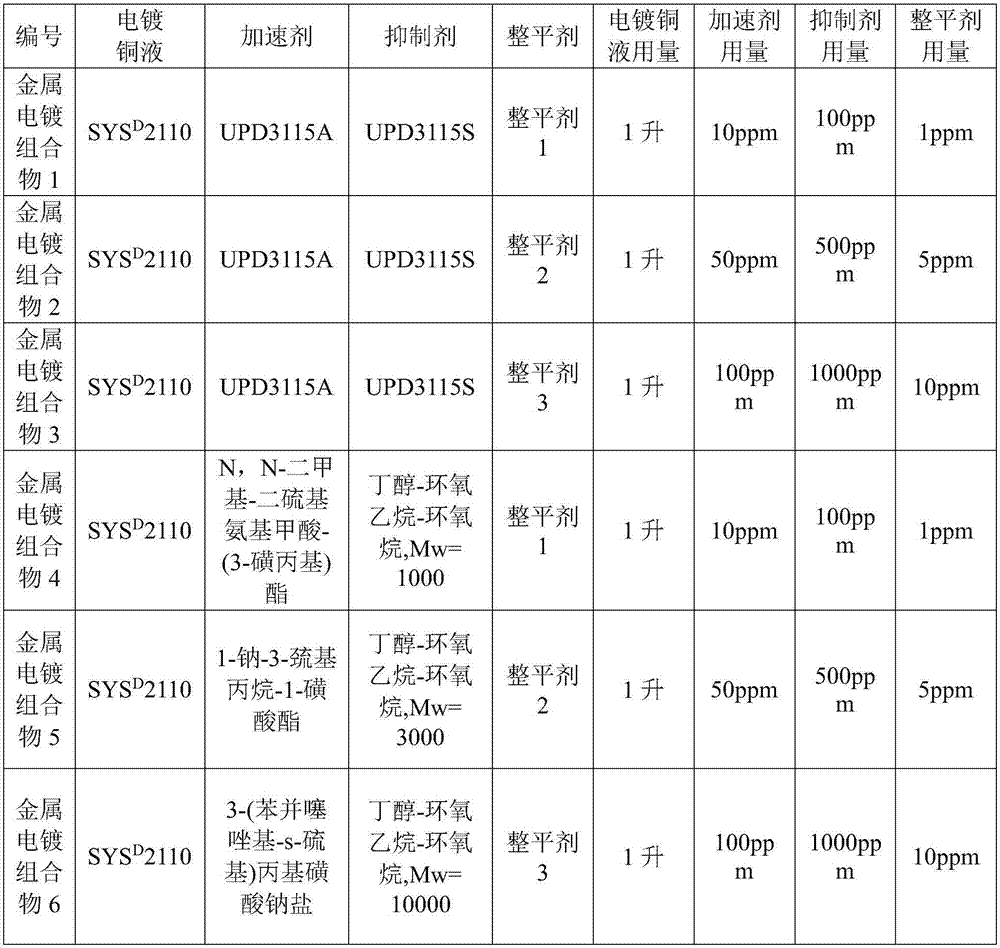

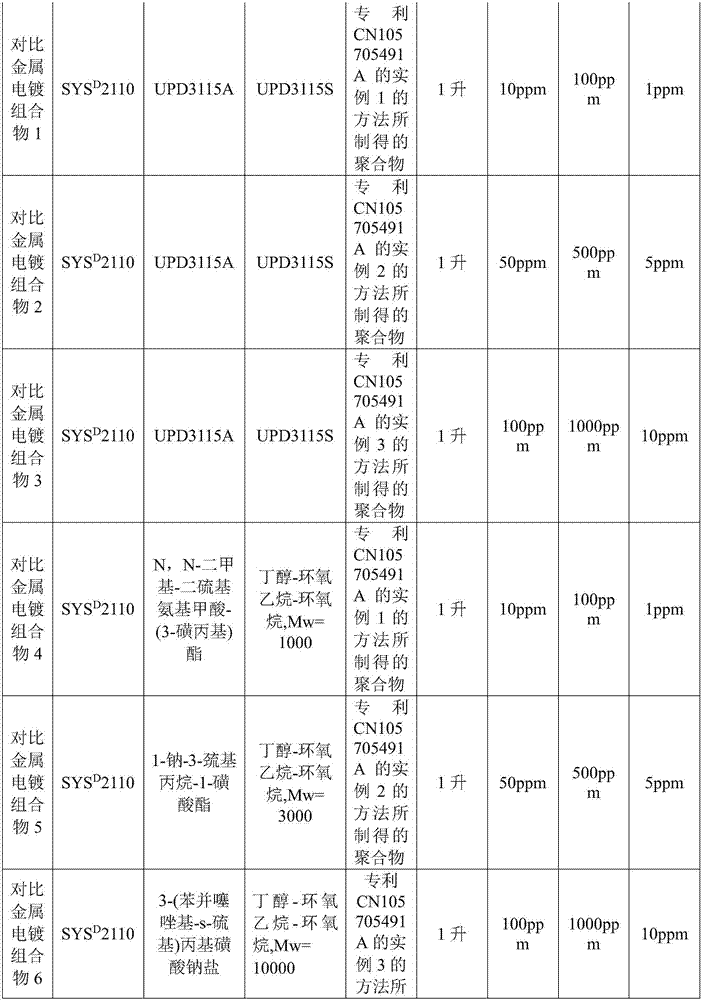

Leveling agent, metal electroplating composition containing leveling agent, preparation method and application thereof

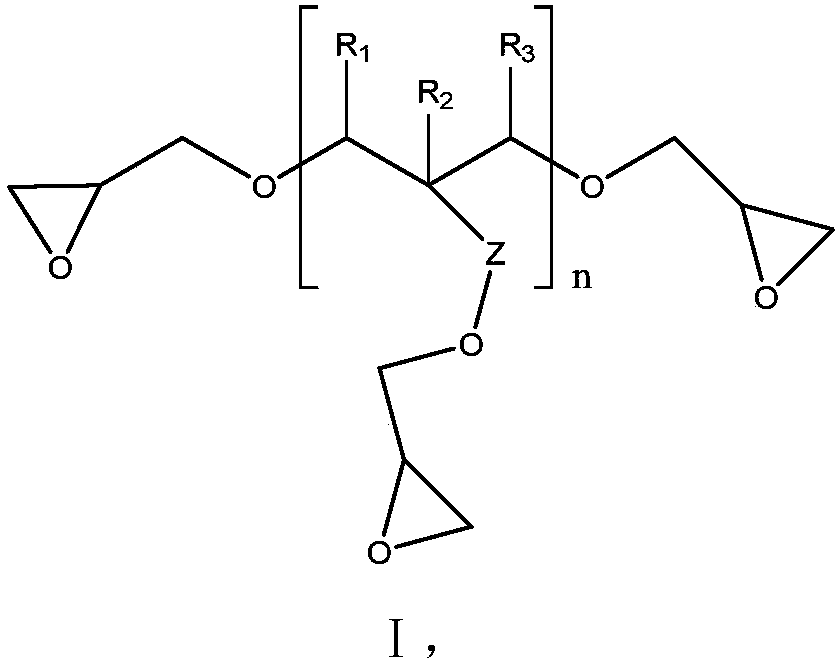

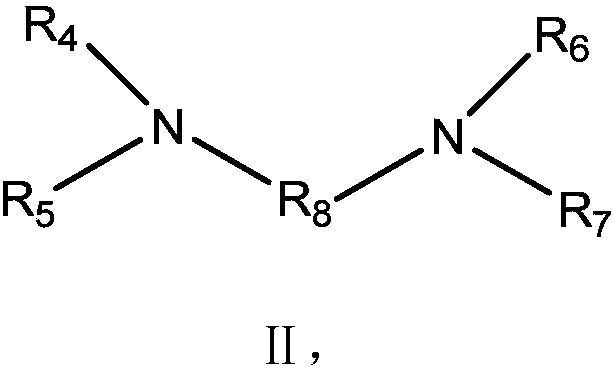

The invention discloses a leveling agent, a metal electroplating composition containing the leveling agent, a preparation method and the application thereof. The raw materials of the metal electroplating composition comprise a metal electroplating solution and the leveling agent, wherein the metal electroplating solution comprises copper salt, acidic electrolyte, halide ion source and water. The preparation method of the leveling agent comprises the following step: in a second organic solvent, one or more Rxs and one or more compounds with the structure as shown in the formula I are subjected to reaction. The metal electroplating composition can be used in a printed circuit board electroplating technology and an integrated circuit copper interconnection electroplating technology, the effects that no voids and defects exists, the impurities of the coating are low, the uniformity of plating is good, the structure is compact and the surface roughness is small can be achieved, and the metal electroplating composition has good industrial application value. (Please see the figure (I) in the specification for the formula of reaction.)

Owner:SHANGHAI SINYANG SEMICON MATERIALS

Process for plating copper on surface of magnesium alloy shell

The invention discloses a process for plating copper on the surface of a magnesium alloy shell. The process comprises the following steps: (1) cleaning: cleaning by using alkali, water and acid in sequence; (2) activating: activating in an activation solution for 5-15 minutes; (3) performing zinc alloy soaking: soaking a magnesium alloy casting in zinc alloy immersion liquid at the temperature of 75-85 DEG C for 10-15 minutes; (4) plating copper: plating under the condition that the pH is 8-8.5, the current density is 3-3.5 A / dm<2>, and the temperature is 35-45 DEG C. By adjusting the zinc immersion liquid and plating solution components for plating copper, the defects in the prior art are overcome, and the bonding force between a plating and a substrate is enhanced.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

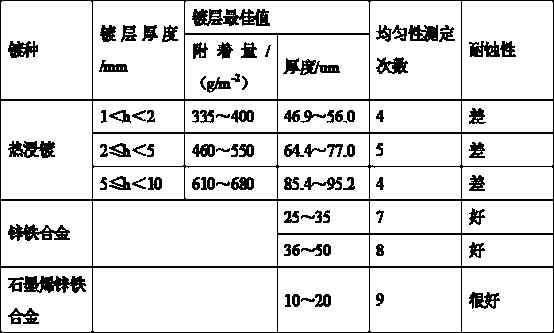

Alkaline graphene zinc-iron alloy electroplating liquid, preparation method and electroplating technology

InactiveCN109137016AEvenly dispersedPlating solution is stableElectrolytic coatingsPropylaminePyrophosphate

The invention discloses alkaline graphene zinc-iron alloy electroplating liquid, a preparation method and an electroplating technology. Each liter of the electroplating liquid comprises main salt including 80-100g of zinc chloride and 5-12g of ferrous sulfate, 200-250g of conducting salt namely ammonia chloride, 200-300ml of an ammonia solution, 20-100mg of graphene quantum dots, 25-40g of a buffering agent namely boric acid, 8-16g of a brightener namely benzotriazole, 1-2g of a reducing agent, 10-22g of a complexing agent, 3-5g of a coordination agent namely stannous pyrophosphate, 0.2-1g ofsodium dodecyl sulfate, 1-3g of alkalization tetra-isopropyl amine and the balance of water, wherein the temperature of the electroplating liquid is 20-55 DEG C, and the pH of the electroplating liquid is 9-14. According to an electroplated product obtained through the formula of the electroplating liquid disclosed by the invention, a graphene-zinc ferrum composite plating layer can be formed through a simple electrodeposition technology, the plating layer is 10-20 microns, and through a cupric sulphate maceration and corrosion test, the plating layer shows excellent corrosion resistance and has excellent combination properties.

Owner:湖州金业表面科技有限公司

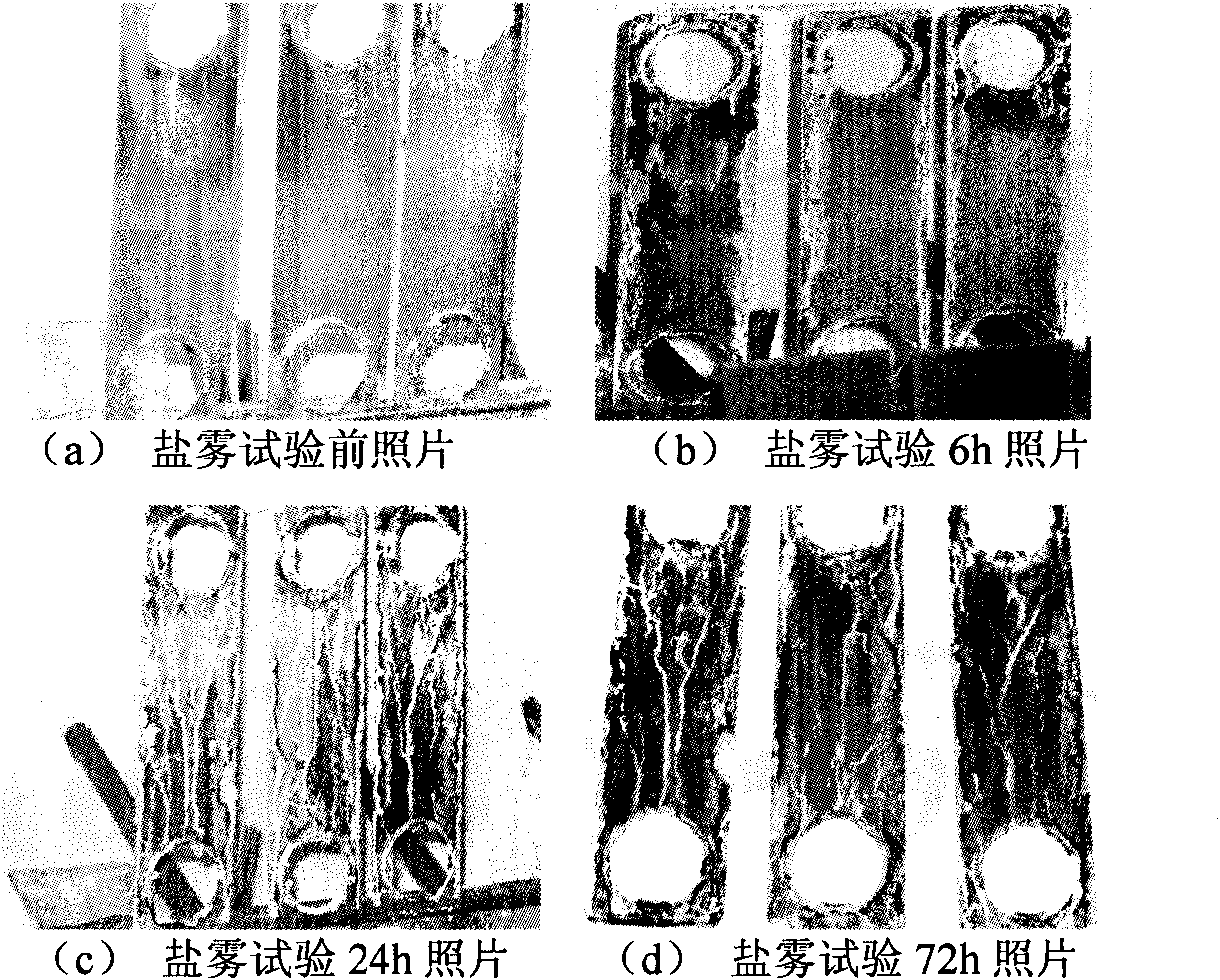

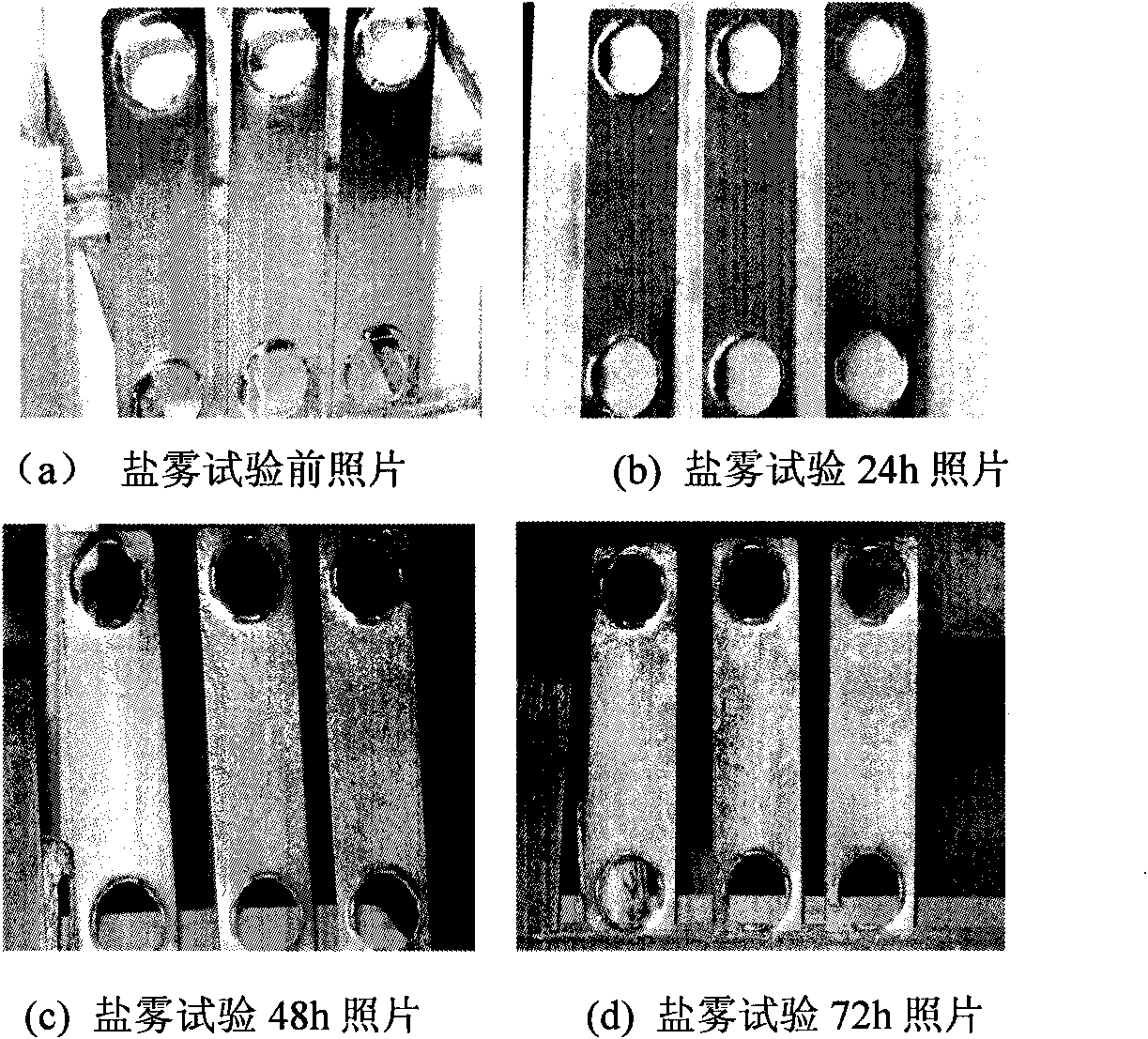

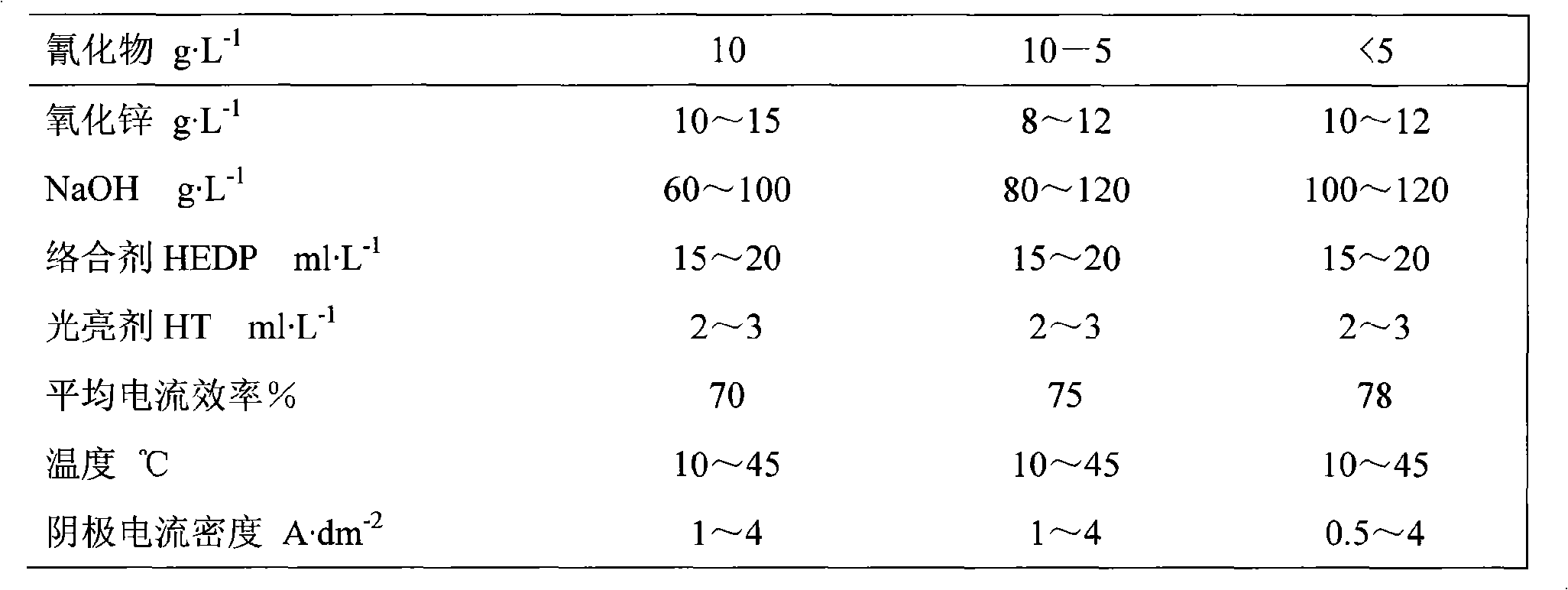

Non-cyanide converting method for cyanide plated zinc

The invention relates to a non-cyanide converting method for cyanide plated zinc. Non-cyanide conversion is as follows: a brightening agent (HT) and a complexing agent (HEDP) are added into plating liquid to carry out zinc plating by stopping adding NaCN and ZnO into the plating liquid. The plating liquid comprises the following components (g*L-1): 10-less than 5 of cyanide, 8-15 of zinc oxide, 60-120 of NaOH, 15-20 of HEDP and 2-3 of HT. The electroplating technical condition comprises the temperature of 10-45 DEG C, the cathode current density (A*dm<-2>) of 0.5-4 and the average current efficiency of 70-78 percent. The corrosion resistance, the bonding capability and the color change resistance of a plating layer completely meet the practical production requirement. The plating liquid has high impurity resistance and is still stable for continuously using for one month. The converted process does not use the cyanide, is easy to process electroplating wastewater and is a more clean production process, thereby replacing a cyanide zinc plating process in a peace way.

Owner:DALIAN MARITIME UNIVERSITY

A kind of black chromium electroplating solution, composite coating and preparation method thereof

The invention relates to a black chromium electroplating solution, a composite coating and a preparation method thereof. The black chromium electroplating solution includes an aqueous solution of the following concentration components: chromium chloride 100-150g / L, boric acid 55-70g / L, conductive salt 160-305g / L, complexing agent 70-160g / L, wetting agent 0.02 -0.15g / L, ferrous ammonium sulfate 0.5-1.5g / L and blackening agent 10-50g / L; wherein said blackening agent is a mixture of methionine, potassium thiocyanide and aspartic acid. The trivalent black chromium coating formed by electroplating with this black chromium electroplating solution has deep black color and strong uniform coverage, and can be matched with bright copper layer, semi-bright nickel layer, bright nickel layer, microporous nickel layer and passivation film layer , so that the composite coating obtained as a whole has strong corrosion resistance and is uniform and dark black.

Owner:SWELL MARUI GUANGZHOU AUTOMOBILE PARTS

Leveling agent

InactiveCN109989076AUniform thicknessGood throwing abilityHigh densityNitrogenous heterocyclic compound

The invention discloses a leveling agent. The leveling agent is a polymer with the number-average molecular weight distribution being 500-20000, and the polymer is formed by reacting one or more kindsof nitrogenous heterocyclic compounds, two or more kinds of polyepoxy compounds and one or more kinds of poly-amino compounds. When the leveling agent is used for electrocoppering, copper layers withthe thicknesses being uniform and surfaces being smooth and flat can be obtained at the opening positions and the insides of high-aspect-ratio through holes as well as the surface of a base materialor the surface of the base material and the insides of high-density interconnected blind holes, copper electroplating liquid has good plating homogenization power and throwing power, good plating capacity is achieved especially for the through holes with the aspect ratio reaching 15 or above and the high-density interconnected blind holes, and the problem that the plating homogenization power andthrowing power of an existing leveling agent cannot meet the practical needs is solved.

Owner:GUANGDONG TONESET SCI & TECH

Electroplating liquid with good stability

The invention discloses electroplating liquid with good stability. The electroplating liquid with good stability comprises a dispersant, a water reducing agent and a silane coupling agent, wherein the dispersant is sodium dodecyl sulfate, the water reducing agent is polycarboxylic acid, the silane coupling agent is butadiene triethoxy silane, the sodium dodecyl sulfate accounts for 35-45% of the total weight of the electroplating liquid with good stability, the polycarboxylic acid accounts for 22-33% of the total weight of the electroplating liquid with good stability, and the butadiene triethoxy silane accounts for 30-36% of the total weight of the electroplating liquid with good stability. The electroplating liquid with good stability, provided by the invention, has the advantages of good stability, excellent uniform coverage ability and high electroplating speed.

Owner:常熟市伟达电镀有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com