Cyanideless electro-coppering method for magnesium alloy casting parts

A magnesium alloy and copper electroplating technology, which is applied in the field of magnesium alloy copper electroplating, can solve the problems of high porosity, poor bonding force of the coating, unstable plating solution, etc., and achieve low porosity, good bonding force, throwing ability and deep Excellent plating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Embodiment 1: In this embodiment, the method for cyanide-free copper plating of magnesium alloy castings is realized by the following steps: 1. Alkali washing: under the condition of 40-60°C, the magnesium alloy castings are soaked in alkaline washing solution 8 to 10 minutes, then washed three to five times with water; 2. Organic pickling: at room temperature, soak the magnesium alloy castings treated in step 1 in organic pickling solution for 5 to 30 seconds, and then wash with water three to five times 3. Activation: Activate the magnesium alloy castings treated in step 2 in a magnesium alloy surfactant for 5-15 minutes at room temperature, and then wash with water three to five times; 4. Dip zinc alloy: a. Under the condition of 90 ℃, the magnesium alloy casting is soaked in the zinc alloy immersion solution for 5~15min; Activate in the solution for 2-10s, and then operate once according to the process of step a; 5. Copper electroplating: at a temperature of 20-50°C...

specific Embodiment approach 2

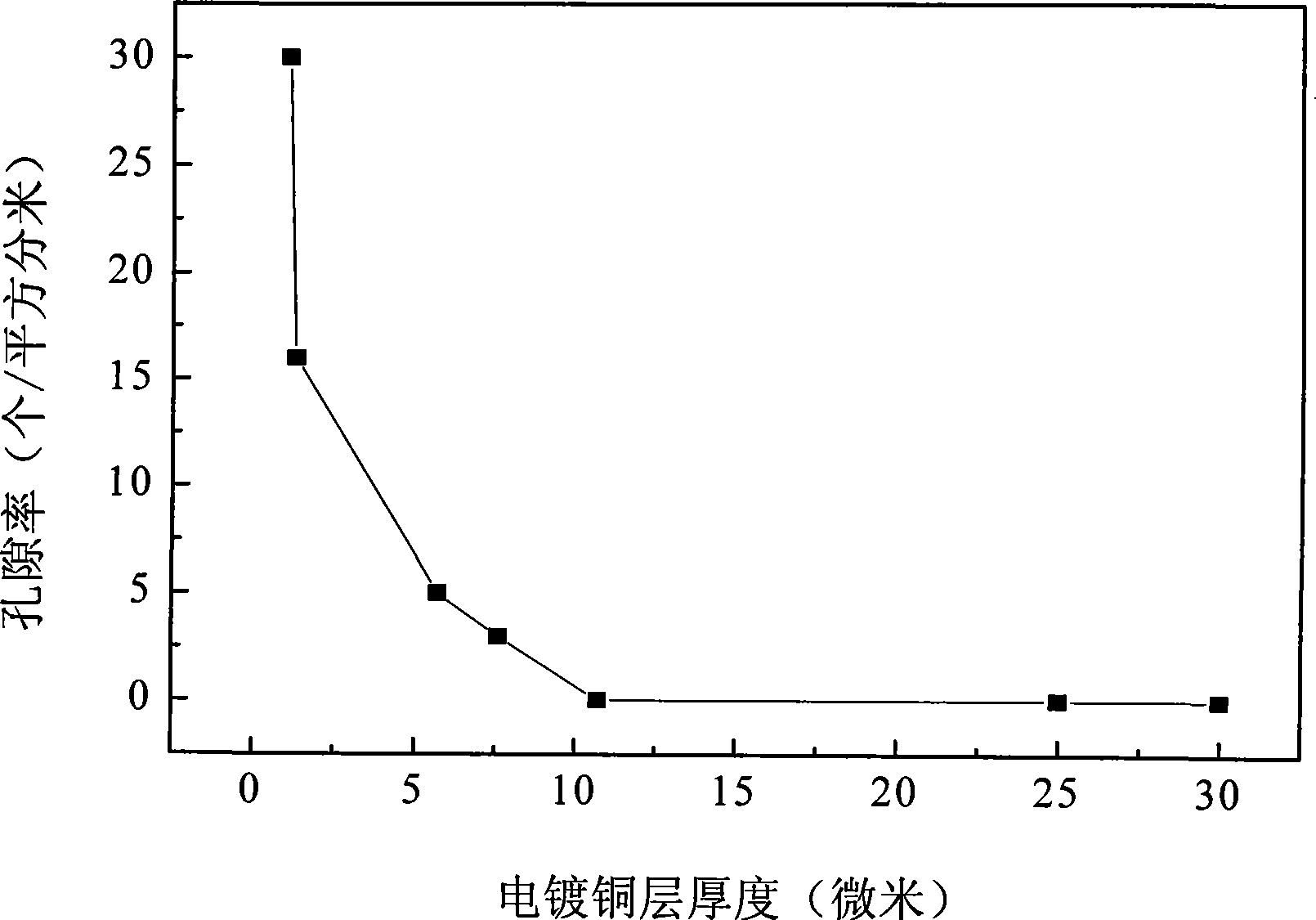

[0017] Depend on figure 1 It can be seen that the porosity of the copper coating obtained in this embodiment is low. When the thickness of the electroplated copper layer reaches more than 10 microns, the porosity of the copper layer is zero, and the protective performance of the coating is superior, which can well meet the requirements for the porosity of the coating. Require. Depend on figure 2 It can be explained that the crystal grains of the copper coating obtained microscopically are relatively fine, and the appearance of the coating is relatively smooth. Depend on image 3 It can be seen that the glossiness of the copper plating layer obtained in this embodiment is good, and the current adaptability range is wide. Adopt the scratch test method to verify that this embodiment obtains the binding force of the copper coating: use a steel needle to draw criss-cross parallel lines 2 mm apart on the copper coating surface, and the scratches reach the substrate, and the resu...

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 is that each liter of alkali washing solution in step 1 is composed of 30-60 g of sodium hydroxide, 15-25 g of sodium phosphate and the rest of water. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com