Electroless plating solution and method for cladding surfaces of SiC particles with Ni-P through electroless plating solution

A technology of chemical plating solution and surface coating, applied in liquid chemical plating, transportation and packaging, coating and other directions, can solve the problems of low wettability, difficult metal liquid compounding, etc., and achieve dense plating and strong uniform plating ability. , the effect of less pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

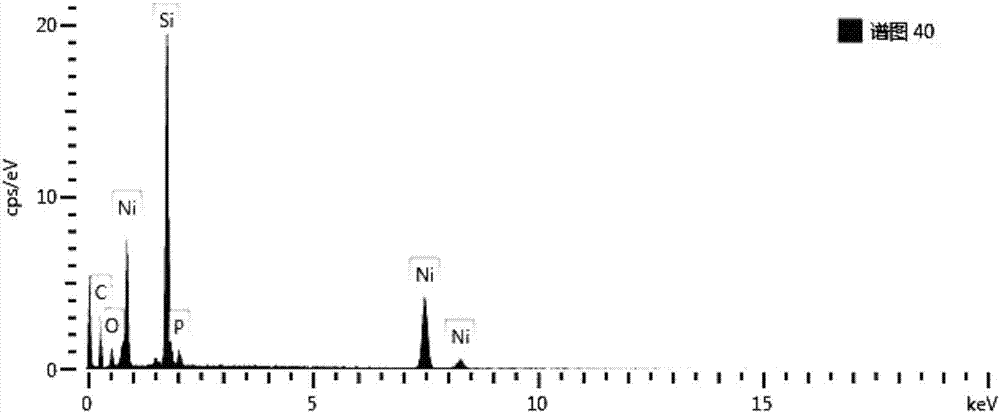

[0072] Embodiment 1 (orthogonal experiment 20)

[0073] Configure chemical plating solution 250mL, the specific composition of this chemical plating solution is that the concentration of nickel sulfate hexahydrate is 0.20mol / L, the concentration of sodium hypophosphite is 0.333mol / L, the concentration of ammonium sulfate is 0.7mol / L, and the concentration of trisodium citrate is 0.20mol / L. The content is 0.1mol / L, and traces of lactic acid and thiourea, and dilute to 250mL solution with deionized water.

[0074] Take 5 g of activated and sensitized SiC particles and place them in the plating solution (thus, the content of SiC particles in the plating solution is 20 g / L), adjust the pH of the solution to 9.5, and place the reaction system in a water bath at a constant temperature of 40°C. , reacted under magnetic stirring for 60 minutes, after the reaction was completed, the plating solution was left to settle, filtered, placed in a blast drying oven at 80°C, and dried for 10 h...

Embodiment 2

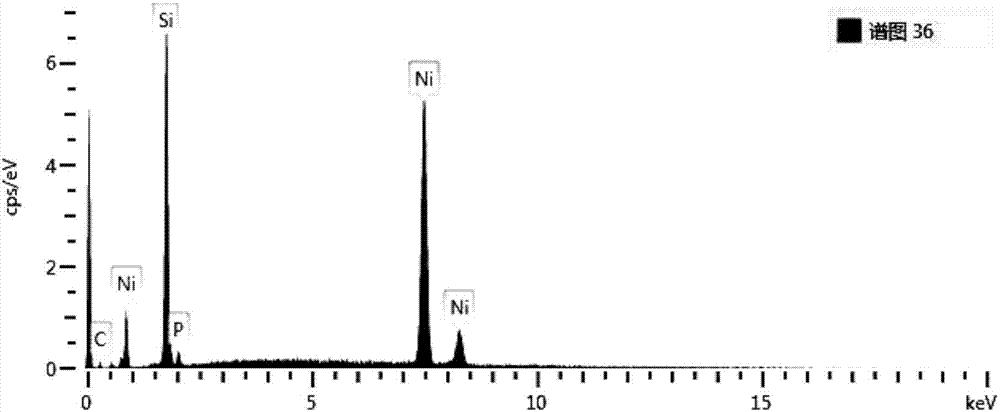

[0078] Embodiment 2 (orthogonal experiment 16)

[0079] Configure 250mL of chemical plating solution, the chemical plating solution composition is nickel sulfate hexahydrate concentration is 0.20mol / L, the concentration of sodium hypophosphite is 1.0mol / L, the concentration of ammonium sulfate is 0.8mol / L, the content of trisodium citrate 0.2mol / L, and traces of lactic acid and thiourea, dilute to 250mL solution with deionized water.

[0080] Take 5 g of activated and sensitized SiC particles and place them in the prepared plating solution (thus, the content of SiC particles in the plating solution is 20 g / L), adjust the pH of the solution to 10, and place the reaction system in a water bath at 40°C React in a constant temperature water bath for 60 minutes under magnetic stirring. After the reaction, the plating solution is left to settle, filtered, and dried in a blast drying oven at 80°C for 10 hours to obtain nickel-coated SiC particles. Figure 6 It is the SEM photo of th...

Embodiment 3

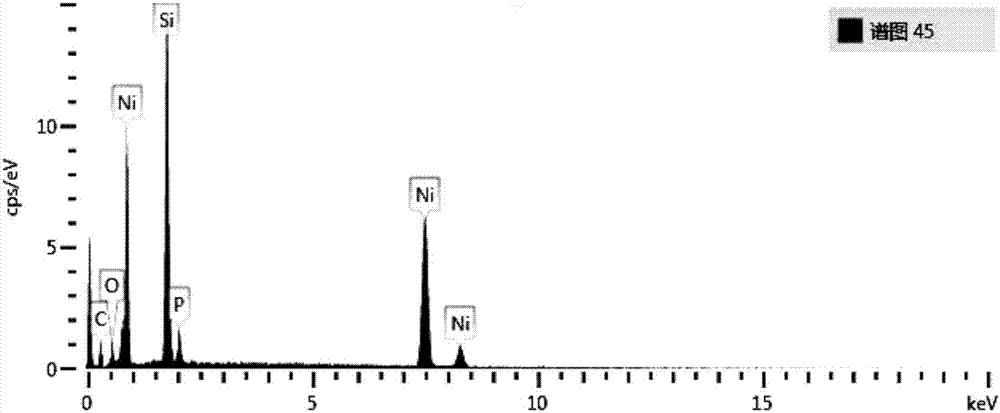

[0084] Embodiment 3 (orthogonal experiment 23)

[0085] Configure chemical plating solution 250mL, the composition of this chemical plating solution is that the concentration of nickel sulfate hexahydrate is 0.25mol / L, the concentration of sodium hypophosphite is 0.625mol / L, the concentration of ammonium sulfate is 0.6mol / L, and the concentration of trisodium citrate is 0.25mol / L. The content is 0.1mol / L, and traces of lactic acid and thiourea, and dilute to 250mL solution with deionized water.

[0086] Take 5g of activated and sensitized SiC particles and place them in the prepared plating solution (thus, the content of SiC particles in the plating solution is 20g / L), adjust the pH of the solution to 10, and place the reaction system in a water bath at 45°C React in a constant temperature water bath for 60 minutes under magnetic stirring. After the reaction, the plating solution is left to settle, filtered, and dried in a blast drying oven at 80°C for 10 hours to obtain nicke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com