Chemical silver plating solution and preparation method thereof

A technology of chemical silver plating and silver plating solution, which is applied in the field of chemical plating, can solve the problems of poor electrical conductivity, thermal conductivity and welding performance, waste of prepared solution, poor stability of plating solution, etc., and achieve good weldability, avoid waste, and uniformity The effect of strong plating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Every liter of electroless silver plating solution carries out component distribution ratio by the raw material described in table 1:

[0026] Table 1

[0027] Silver nitrate 15g Succinimide 85g tartaric acid 30g Triethanolamine 10g methanesulfonic acid 20g water margin sodium hydroxide Appropriate amount PH value 10

[0028] The composition of electroless silver plating solution in table 1 is prepared according to the following steps:

[0029] (1) Dilute silver nitrate with distilled water to form a transparent solution;

[0030] (2) Dissolve succinimide with distilled water;

[0031] (3) The solution obtained in step (1) is slowly added to the solution obtained in step (2) under stirring conditions;

[0032] (4) Slowly add tartaric acid, triethanolamine and methanesulfonic acid in the solution of step (3), make it fully complexed;

[0033] (5) Add an appropriate amount of sodium hydroxide to the solution ob...

Embodiment 2

[0037] Every liter of electroless silver plating solution carries out component distribution ratio by the raw material described in table 2:

[0038] Table 2

[0039] Silver nitrate 22g Succinimide 115g tartaric acid 22g Triethanolamine 16g methanesulfonic acid 15g water margin Potassium hydroxide Appropriate amount PH value 11

[0040] The components of the electroless silver plating solution in Table 2 were prepared according to the steps described in Example 1.

[0041] The method of using the plating solution: the immersion plating time is 5 minutes at 35°C.

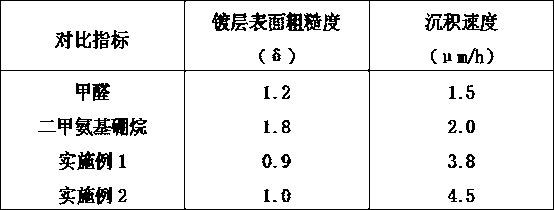

[0042] The present invention will be further described by test below:

[0043] One, implement electroless plating with plating solution provided by the invention

[0044] 1. The silver plating solution provided by the present invention is to carry out chemical silver plating on epoxy resin boards to a batch of substrate materials, and the remaining silver p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com