Patents

Literature

111results about How to "Good gloss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ink composition for ink jet recording, recording method, and recorded matter

InactiveUS20080213548A1Good glossExcellent color reproductionMeasurement apparatus componentsDecorative surface effectsWater solublePolymer chemistry

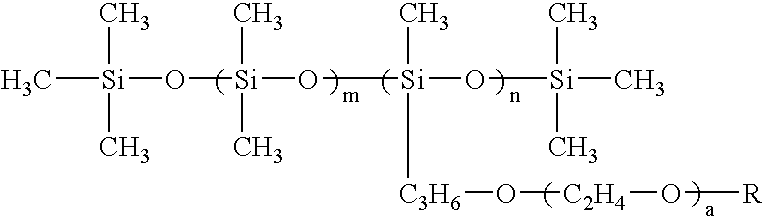

There is provided an ink composition for ink jet recording, which can yield images having excellent gloss with good color reproduction even on various recording media having a low level of water absorption, especially synthetic paper and printing paper for running-on. The ink composition for ink jet recording comprises a colorant, water, an alkanediol, and a surfactant, wherein the alkanediol comprises a water-soluble 1,2-alkanediol, a poor water-soluble 1,2-alkanediol, and a poor water-soluble both terminal alkanediol, and the alkanediol satisfies a requirement on a weight basis of A:(B+C)=2:1 to 2:3 wherein A represents the content of the water-soluble 1,2-alkanediol in the alkanediol; B represents the content of the poor water-soluble 1,2-alkanediol in the alkanediol; and C represents the content of the poor water-soluble both terminal alkanediol in the alkanediol.

Owner:SEIKO EPSON CORP

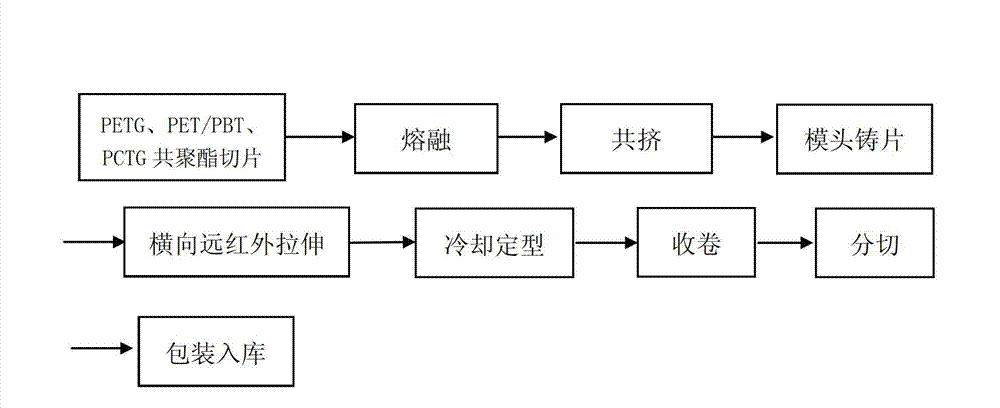

Heat shrinkage copolyester film and preparation method thereof

ActiveCN103203934AHigh light transmittance and one-way heat shrinkageGood glossSynthetic resin layered productsCopolyesterTransmittance

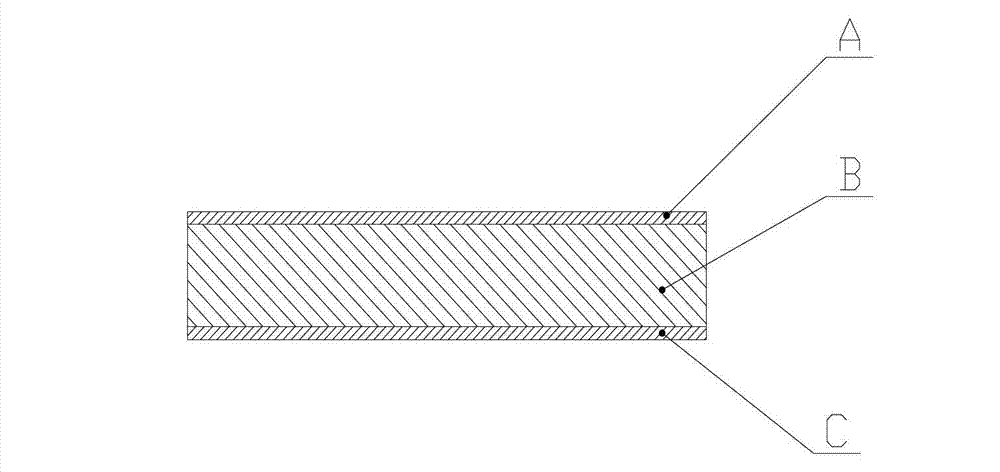

The invention discloses a heat shrinkage copolyester film and a preparation method thereof. The heat shrinkage copolyester film is characterized by comprising a surface layer A composed of PETG (polyethylene terephthalate glycol) copolyester, a core layer B composed of PET (polyethylene glycol terephthalate) / PBT (polybutylece terephthalate) copolyester and a bottom layer C composed of PCTG (di-n-octyl phthalate) copolyester. The film-used PETG copolyester slices, film-used PCTG copolyester slices and film-used PET / PBT copolyester slices are obtained through a screw extruder. Compared with regular heat shrinkage copolyester films, the three-layer co-extrusion lateral-stretching heat shrinkage copolyester film has the advantages that the three-layer co-extrusion lateral-stretching heat shrinkage copolyester film has high light transmittance and single hot-shrinkage rate, has good gloss and high stability, can be evenly shrunk, has good transparency, tractility and toughness, can be produced in the existing BOPET (polyester film) film production lines, and is suitable for direct packages of labels of various containers, food and beverage, electric products, machinery or hardware products.

Owner:JIANGSU SHUANGXING COLOR PLASTIC NEW MATERIALS

Welding-resistant low-alkaline ink for developing and photosenstive imaging

InactiveCN1390898AGood glossHigh glossInksPhotosensitive materials for photomechanical apparatusAcrylateOligomer

A weld-resistant ink for weakly alkaline developing and photosensitive imaging of PCB contains modified acrylate as photosensitive oligomer (50-70 wt.%), epoxy resin (10-20), multifunctional acrylate (5-20), optical trigger (5-15), filler (7.5-30), pigment (0.5-1) and silica oil. Its advantages are high resistance to high temp (260 deg.C or more) and lustre, and not discolouring and dropping off.

Owner:广州市乃天精密电子器材有限公司 +1

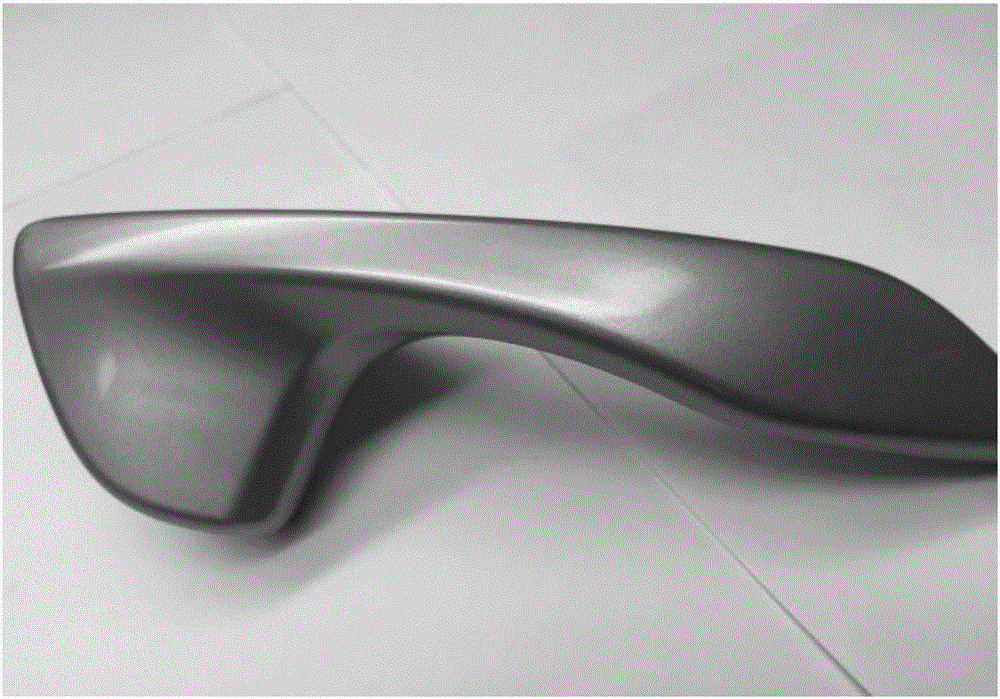

Free-spraying polyamide resin with metal effect, and preparation method thereof

The invention provides a free-spraying polyamide resin with metal effect, and a preparation method thereof. The free-spraying polyamide resin comprises, by mass, 70 to 95 parts of polyamide, 10 to 30 parts of a metal color pigment, 0.1 to 2 parts of a coupling agent, 0.1 to 0.2 part of zinc stearate, and 2 to 8 parts of a lubricating agent. The preparation method comprises following steps: the raw materials are mixed, are delivered into an extruder for melt blending and extrusion, and then cooing, drying, and cutting are carried out so as to obtain the free-spraying polyamide resin with metal effect. According to the preparation method, the metal color pigment is added into polyamide, and accessory ingredients such as the coupling agent and zinc stearate are added, so that the compatibility and dispersity of polymer matrix with the metal color pigment are improved, spraying effect of metal effect of the obtained product is achieved after injection moulding, increasing of production cost and ecological environment pollution caused by spraying are avoided, defects of injection molding products, such as flow lines and weld bond, are reduced, cost is reduced, and application prospect is promising.

Owner:SHANGHAI ZHONGLEI NEW MATERIAL SCI CO LTD

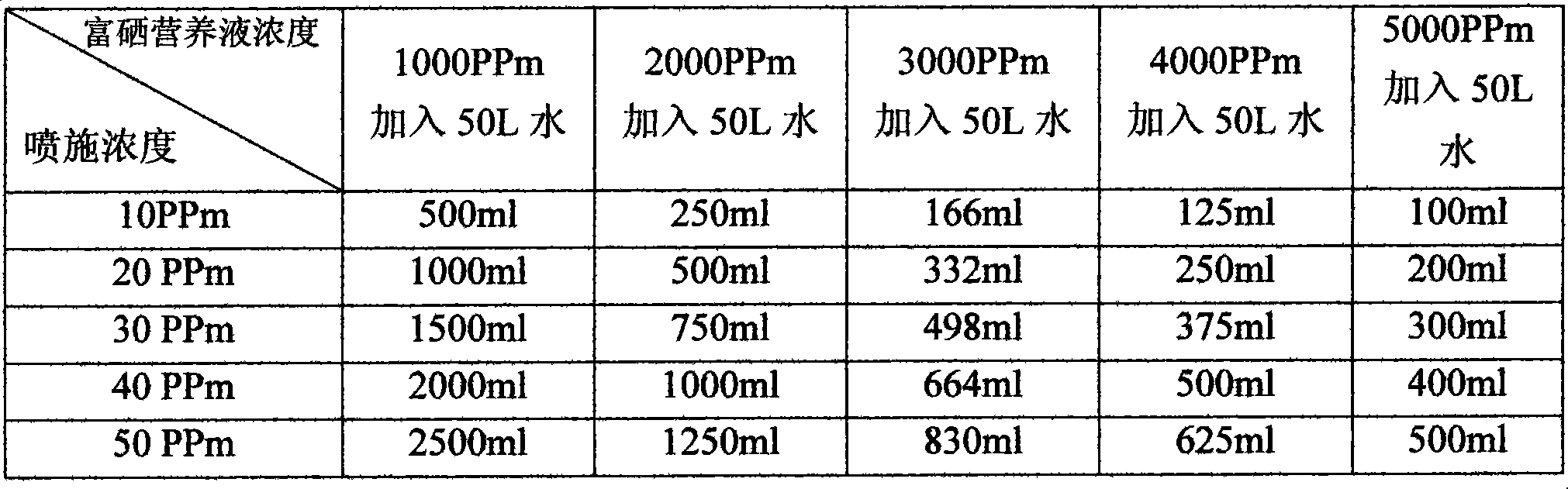

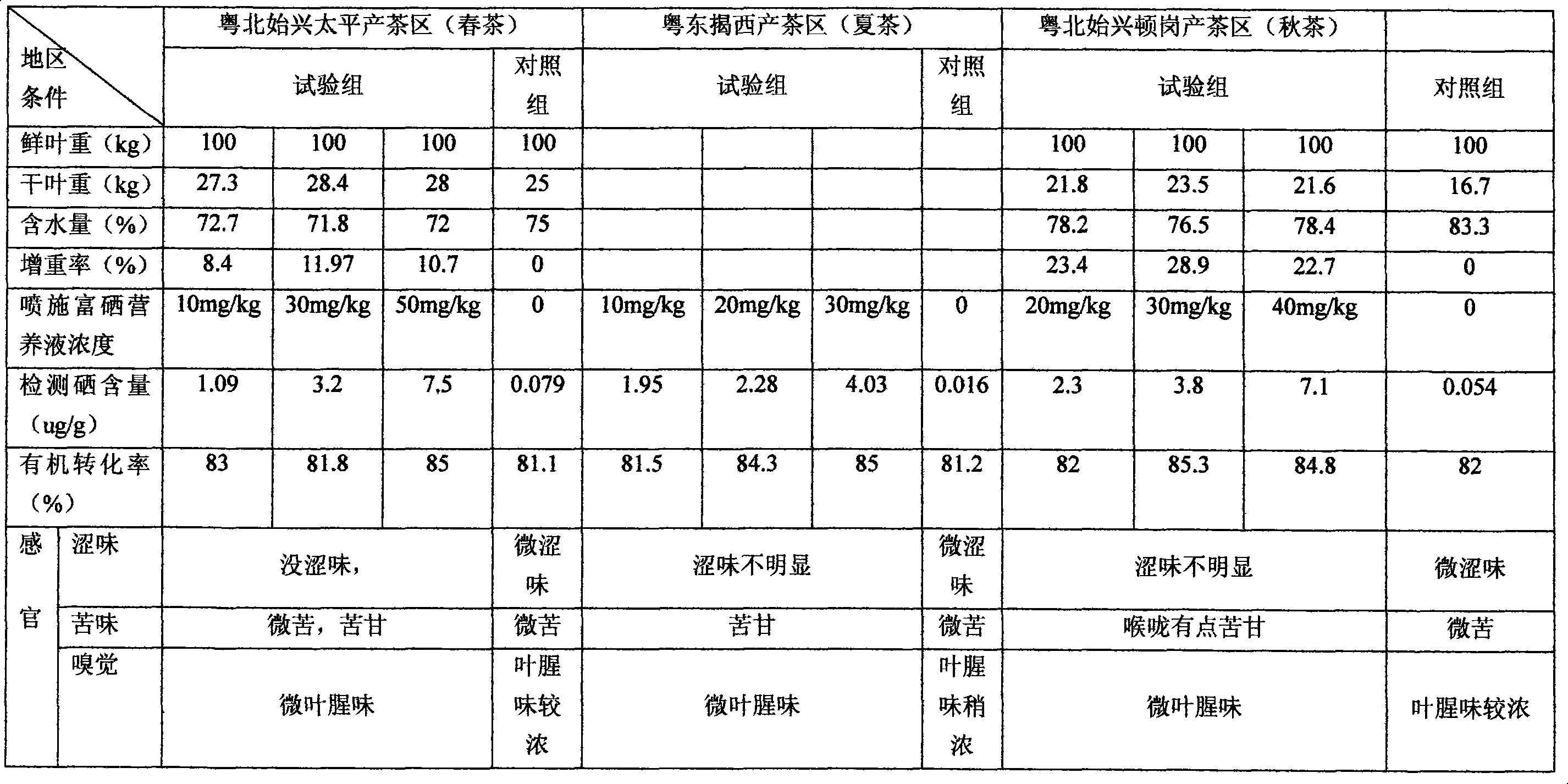

Selenium-rich green tea and its producing method

The present invention belongs to the field of tea production technology. It discloses a method for producing selenium-enriched green tea by utilizing selenium-enriched nutrient solution. Said selenium-enriched nutrient solution is made up by using inorganic salt mineral element sodium selenite or sodium selenate as raw material through a certain preparation process. The selenium content of said selenium-enriched green tea is 1-7.5 microgram / gram, and the organic coversion rate of selenium is up to above 80%.

Owner:广州卫健富素农业科技开发有限公司

Water-based paint for quick-drying alcohol-resistance plastics and preparation method thereof

The invention discloses a water-based paint for quick-drying alcohol-resistance plastics, comprising the following components by weight parts: 20-80 parts of modified polyacrylic ester water dispersoid, 1-25 parts of coloring pigment paste, 0-10 parts of filler pump, 5-25 parts of film formation assistant, 0.5-10 parts of assistant for water-based paint, and 10-50 parts of water. The invention further discloses a preparation method of the water-based paint, comprising the following steps: the water, the film formation assistant, polymer water dispersoid resin and the assistant for partial water-based paint are added in a make-up tank and are stirred uniformly, and then the coloring pigment paste and the assistant for the remaining partial water-based paint are sequentially added in and are stirred uniformly, the viscosity and pH value are regulated, filtering and discharging are carried out to obtain the water-based plastic paint finished products. The water-based paint is used for coating surface of the plastics, so as to achieve good decoration effect; in addition, the performance of the water-based paint is equivalent to that of solvent plastic paint, the water-based paint has good alcohol resistance and can be dried at 50 DEG C for 10 minutes, so as to meet the process requirements of manufacturers who use the solvent plastic paint at present.

Owner:GUANGZHOU KINTE IND

Dipping-sealing wax for electronic element coil

The invention relates to a kind of impregnation enveloping wax combination used for electronic components, which contains petroleum wax, petroleum resin, and adhesion promoter. The impregnation enveloping wax of the invention has the advantages such as high drop melting point, excellent high-temperature property, fine electrical property, low melting viscosity, good adhesivity, fine moisture resistance, and so on. Coil impregnation-enveloping materials for exclusive use to existing technology electronic components all take resin as main materials, and the impregnation-enveloping materials have higher cost. The impregnation encapsulating wax of the invention adapts to the impregnation and envelopment of inductance coil, mid-frequency and high frequency electric coil, and other electronic components.

Owner:CHINA PETROLEUM & CHEM CORP +1

Acrylate emulsion modified cement-base repair mortar

The invention discloses acrylate emulsion modified cement-base repair mortar, which consists of the following components in part by weight: 100 parts of portland cement, 50 to 220 parts of 0.50 to 2.0 millimeters of quartz sand, 10 to 100 parts of less than 0.50 millimeter of quartz sand, 5 to 80 parts of acrylate emulsion, 0 to 1.0 part of water reducing agent, 0.5 to 5.0 parts of polypropylene fiber, 0 to 1 part of cellulose ether, 0 to 1.2 parts of defoaming agent and 0 to 60 parts of water. The acrylate emulsion modified cement-base repair mortar has high breaking strength, bonding strength, volume stability, durability and compatibility with cement-base materials, has the high flowability and water-retaining property in the aspect of construction performance, can meet the requirements of different engineering constructions, and can be widely applied to the repair in fields of municipal administration, road surfaces, airports, ports, bridges, dams and the like.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD +1

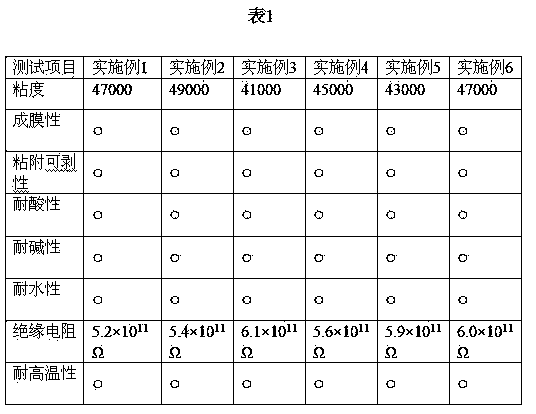

Touch screen heat curing peelable blue gel and preparing method thereof

ActiveCN103421383AGood film formingGood glossInksPolyurea/polyurethane coatingsPolymer chemistryPlasticizer

The invention relates to the technical field of touch screen peelable blue gel, in particular to touch screen heat curing peelable blue gel and a preparing method of the touch screen heat curing peelable blue gel. The touch screen heat curing peelable blue gel is composed of, by weight, 30-40% of vinyl resin, 5-10% of alkyd resin, 30-40% of amino resin, 15-32% of plasticizer, 2-4% of filler and 0.1-3% of organic pigments. The vinyl resin, the alkyd resin and the amino resin are adopted to be cooperated and mutually reinforced, the amino resin is used as the cross-linking agent of the alkyd resin and the vinyl resin, the peelable blue gel is made to be good in film-forming property, a paint film which is of a three-dimensional net structure and has obdurability can be obtained through heating, good gloss and good colour retention are achieved, good toughness and good flexibility are achieved, and good heat resistance, good insulativity and good acid and alkali resistance are achieved. After the conducting film protection process in the touch screen manufacturing process is completed, peeling is easy, and the situation that residues exist on the surface of materials, or the materials are contaminated is avoided.

Owner:DONGGUAN PINGBO ELECTRONICS

Colored glaze with favorable clarification effect and high product quality

The invention relates to a colored glaze with favorable clarification effect and high product quality, which is prepared from the following raw materials in parts by weight: 95-110 parts of quartz sand, 42-46 parts of soda ash, 10-12 parts of aluminum oxide, 45-50 parts of lead peroxide, 1-1.5 parts of cerium oxide, 3-4 parts of antimony trioxide, 0.1-0.5 part of sodium nitrate and 1-1.5 parts of pigment. The cerium oxide and antimony trioxide are combined to be used as a clarifier, and thus, the clarification effect is obviously better than that of the independently used cerium oxide or antimony trioxide; by controlling the cerium oxide:antimony trioxide ratio at 1:(2-4), the prepared colored glaze has the advantages of high gloss, few bubbles, high transparency, few stripes in the finished product, obviously improved quality and short clarification time (6-8 hours); and the colored glaze formula materials have long acting property and low softening point, and thus, are suitable for forming the colored glaze.

Owner:太仓市科教新城琉璃艺术策划中心

Image recording method, record and image recording system

InactiveUS20100209677A1Good glossImprove closenessDecorative surface effectsLayered productsImage recordingRecording system

[Problems] There is provided an image recording method that provides resulting images with an excellent gloss and an improved closeness of contact with the recording medium used.[Solving Means] An image recording method including a first step for recording a glossy image layer on a recording medium using a glossy ink composition containing a metal pigment and a second step for recording a finishing layer on the glossy image layer using a black ink composition to reduce the brightness of the glossy image.

Owner:SEIKO EPSON CORP

Stainless steel blackening agent and blackening method

ActiveCN101935833AThe film layer is black and uniformGood glossMetallic material coating processesKitchen utensilsAqueous solution

The invention belongs to the technical field of surface treatment and relates to a stainless steel blackening agent, which contains aqueous solution which is formed by dissolving sodium hydroxide, sodium nitrate and sodium molybdate in deionized water, the content of the sodium hydroxide is 400-540g / L, the content of the sodium nitrate is 28.5-114g / L, and the content of the sodium molybdate is 5.7-57g / L. The invention also provides a blackening method for stainless steel, which comprises the following step: a stainless steel work piece is put into the stainless steel blackening agent to be oxidized and blackened, and the stainless steel blackening agent is the stainless steel blackening agent in any of claims 1-4. The stainless steel blackening agent and the blackening method are applicable to the fields of electronic industry, kitchen utensils, household appliances, instruments and meters, automotive industry, chemical equipment and the like.

Owner:江苏扬先科技有限公司

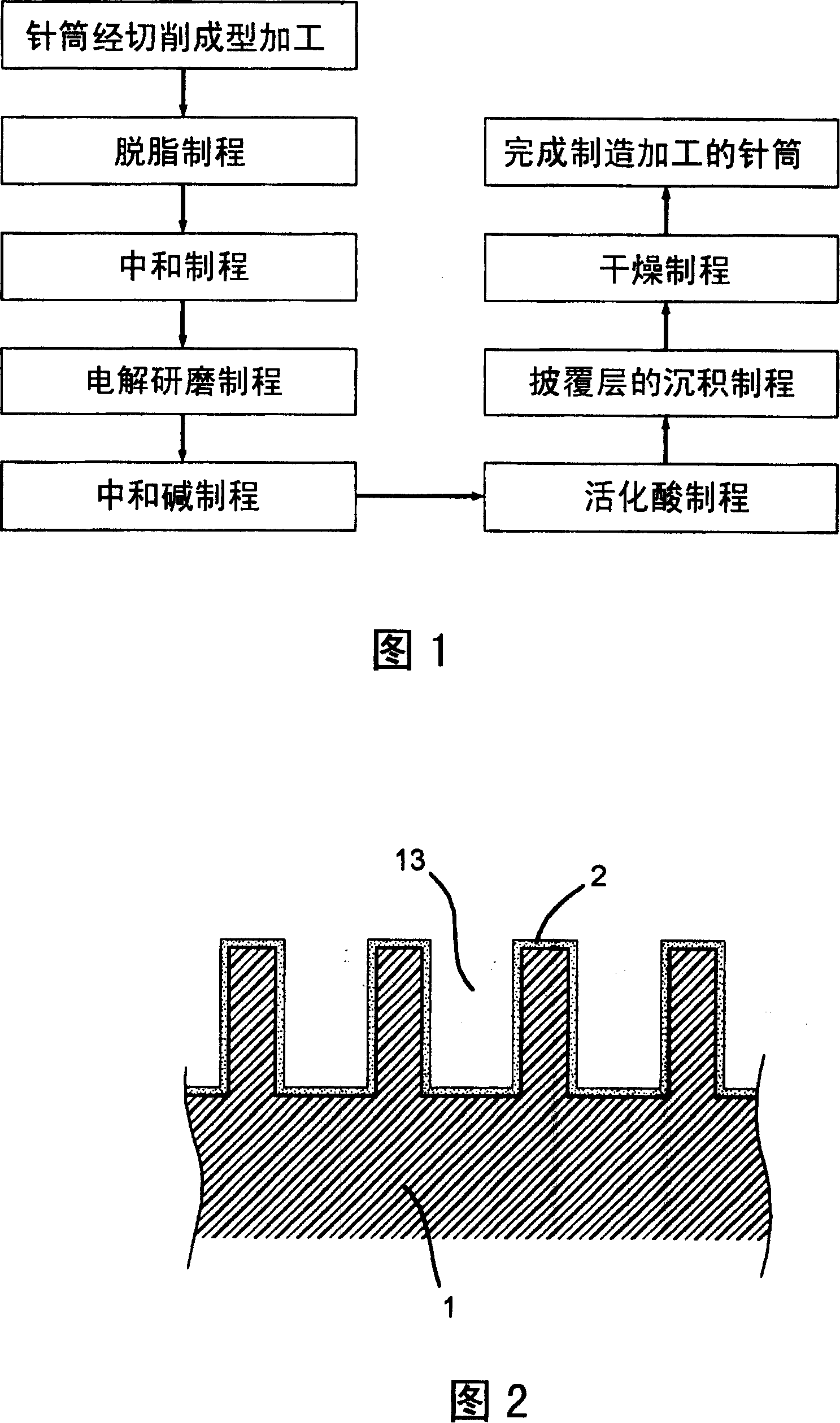

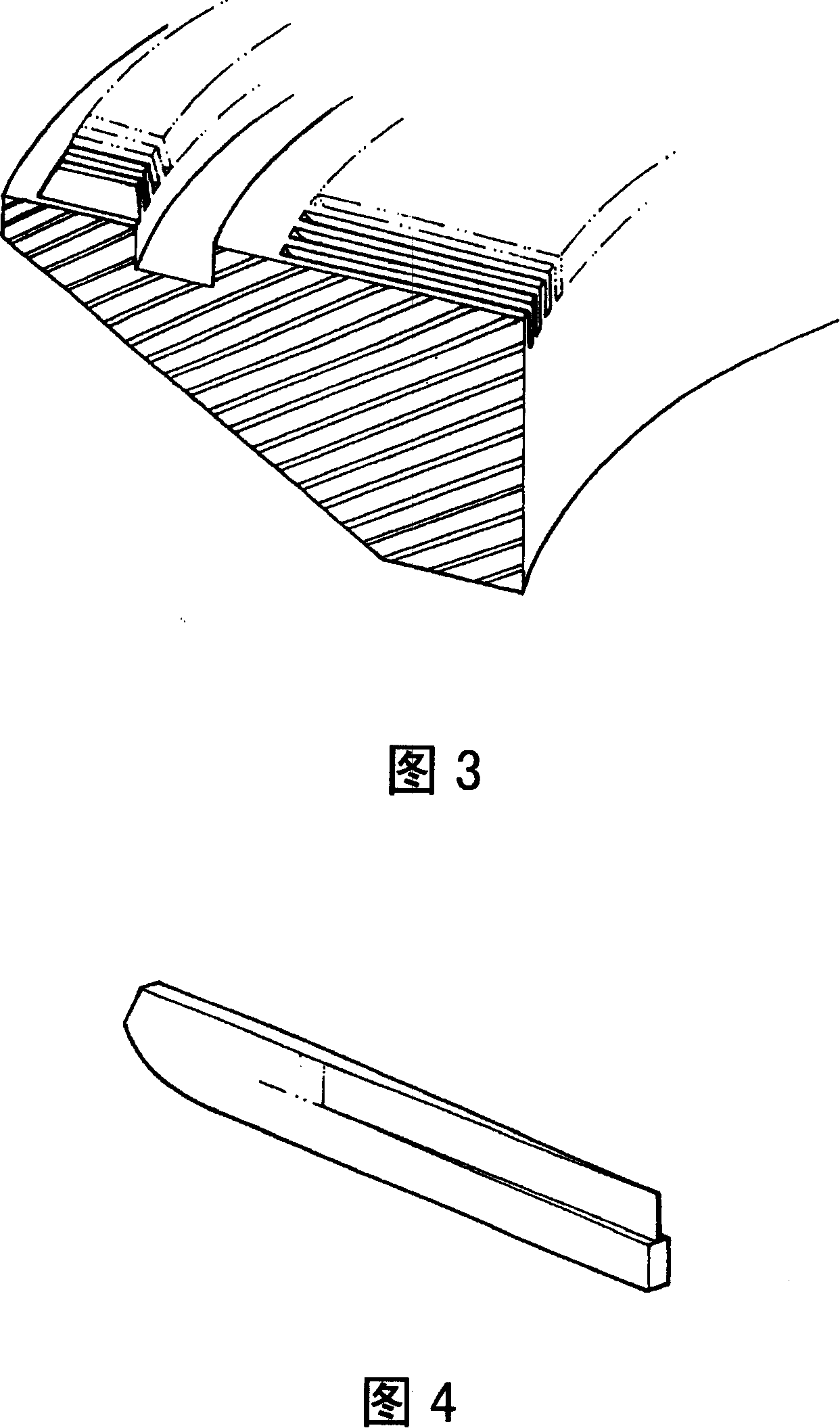

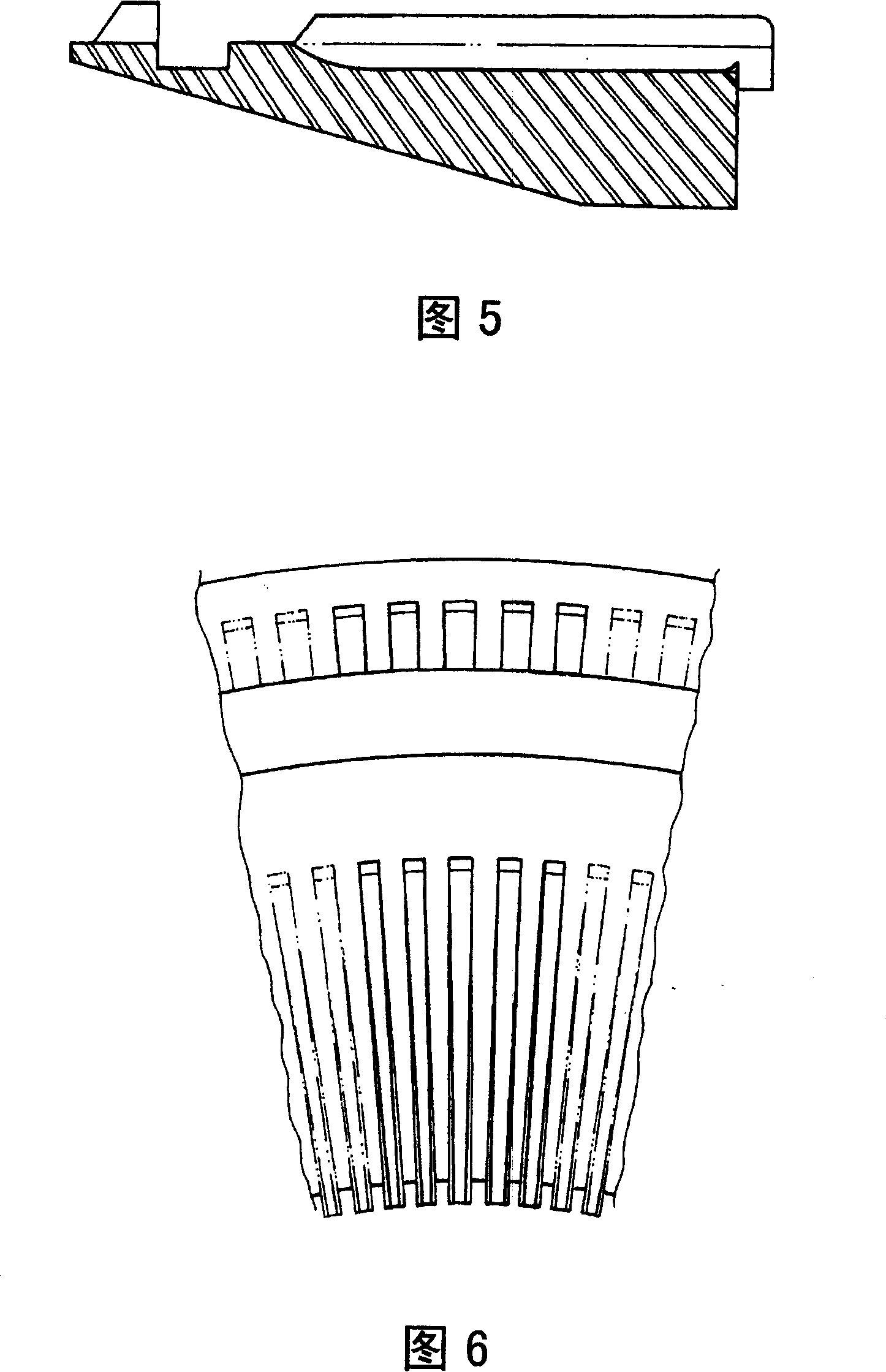

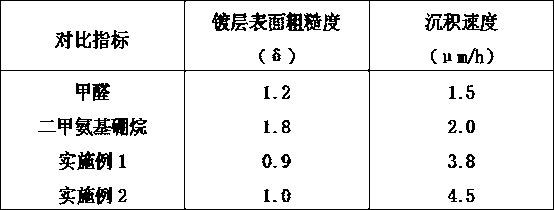

Circular knitter cylinder and its manufacturing method

InactiveCN101130875AGood glossImprove surface roughnessWeft knittingLiquid/solution decomposition chemical coatingNickelMetal

The present invention relates to a needle cylinder of round knitting machine and its production method. It is characterized by that a covering layer made of special material is formed on the surface of needle cylinder, and said covering layer mainly is a settled layer of nickel material, and its production method includes degreasing process, acid neutralization process, electrolytic grinding process, alkali neutralization process, activating acid process, covering layer settling process and drying process.

Owner:蔡志欣 +1

Defatted cheese and preparation method thereof

InactiveCN101167499ADense tissue structureGood glossCheese manufactureFood preparationFat substituteSucrose

The invention relates to a fermentation dairy product in food field, which is a lean cheese and process for preparation. Crystalline cellulose is utilized as fat substitute and sucrose fatty acid ester is utilized as fat imitation to produce novel low-caloric lean cheese with rich nutrition. During producing, the crystalline cellulose and the sucrose fatty acid ester is pro rata mixed and swelled with part butter milk as premix compound. After high speed shearing type stirring, the crystalline cellulose forms a micro-mesh shape cellulose dispersion with high viscosity, and the stereo meshed structure is filled with fat imitation sucrose fatty acid ester for improving physical arrangement of products. Then the above premix compound is charged to the rest butter milk or low-caloric butter milk powder reconstructed milk to evenly stir, to high pressure homogeneously treat, and to be charged with leaven and other addition agents, such as perfume compounds, condiment, coloring matter and the like, thereby producing the lean cheese product of the invention after fermenting, with missible oil shape appearance and taste similar to that of whole cheese.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Manufacturing method for woven imitation knitting rib fabric

The invention provides a manufacturing method for woven imitation knitting rib fabric. According to the manufacturing method, cationic intermingle yarn (ITY) polyester composite yarns are used as raw materials of warp yarns and weft yarns, and each cationic ITY polyester composite yarn is formed by compounding a cationic fully-drawn yarn (FDY) and polyester pre-oriented yarn (POY) or a FDY and the cationic POY. The manufacturing method comprises the following processes: winding the cationic ITY polyester composite yarns onto a bobbin; performing a twisting operation on the cationic ITY polyester composite yarns on the bobbin; respectively setting the warp yarns and the weft yarns to form greige cloth; performing open-width continuous refining on the greige cloth in sodium carbonate and scouring agent-contained solution under the condition that the temperature is controlled to be 90-100 DEG C; performing presetting treatment; performing alkali peeling treatment; dyeing and finishing for coloring; and finally, performing tenter setting. The fabric obtained by the manufacturing method provided by the invention has the following characteristics: the strength of strands is ensured while the extensibility and the elasticity of the yarns are ensured. Moreover, as the environment cannot be polluted by a twisting process, and the process is varied and is easy to operate, a technical support is provided to imitation knitting.

Owner:XUZHOU SILK FIBER TECH

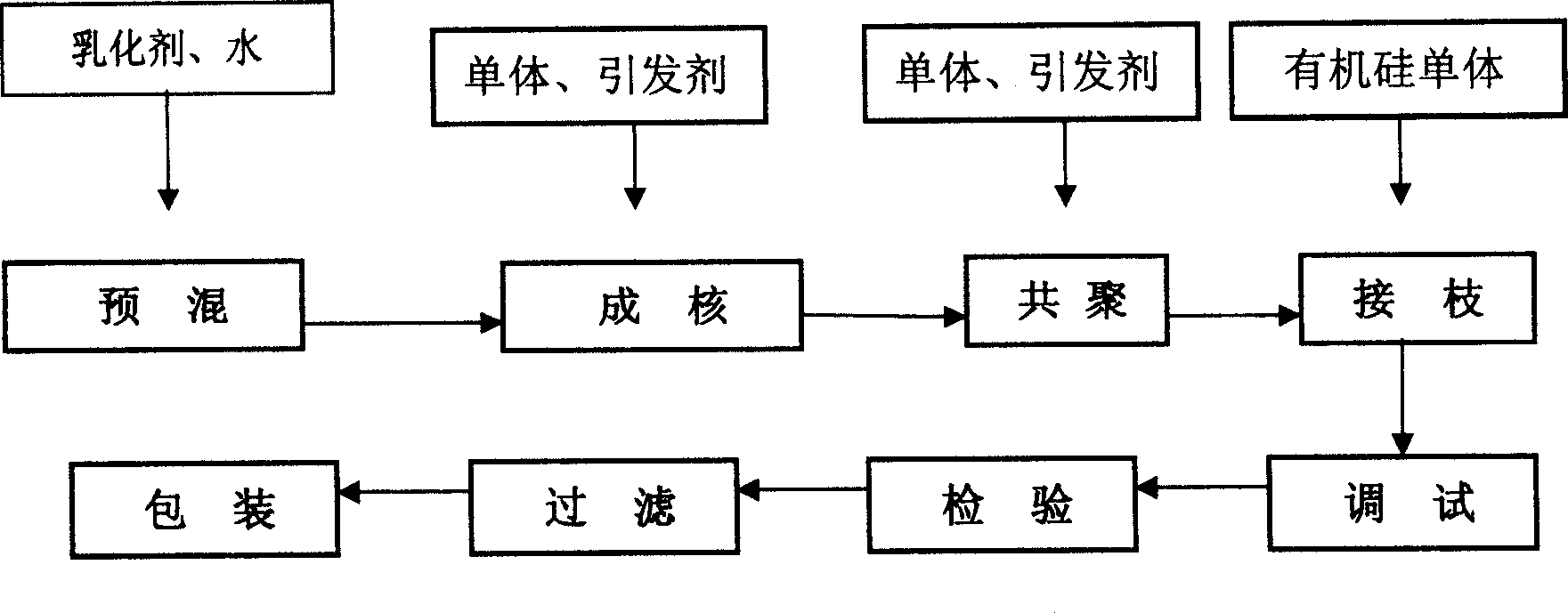

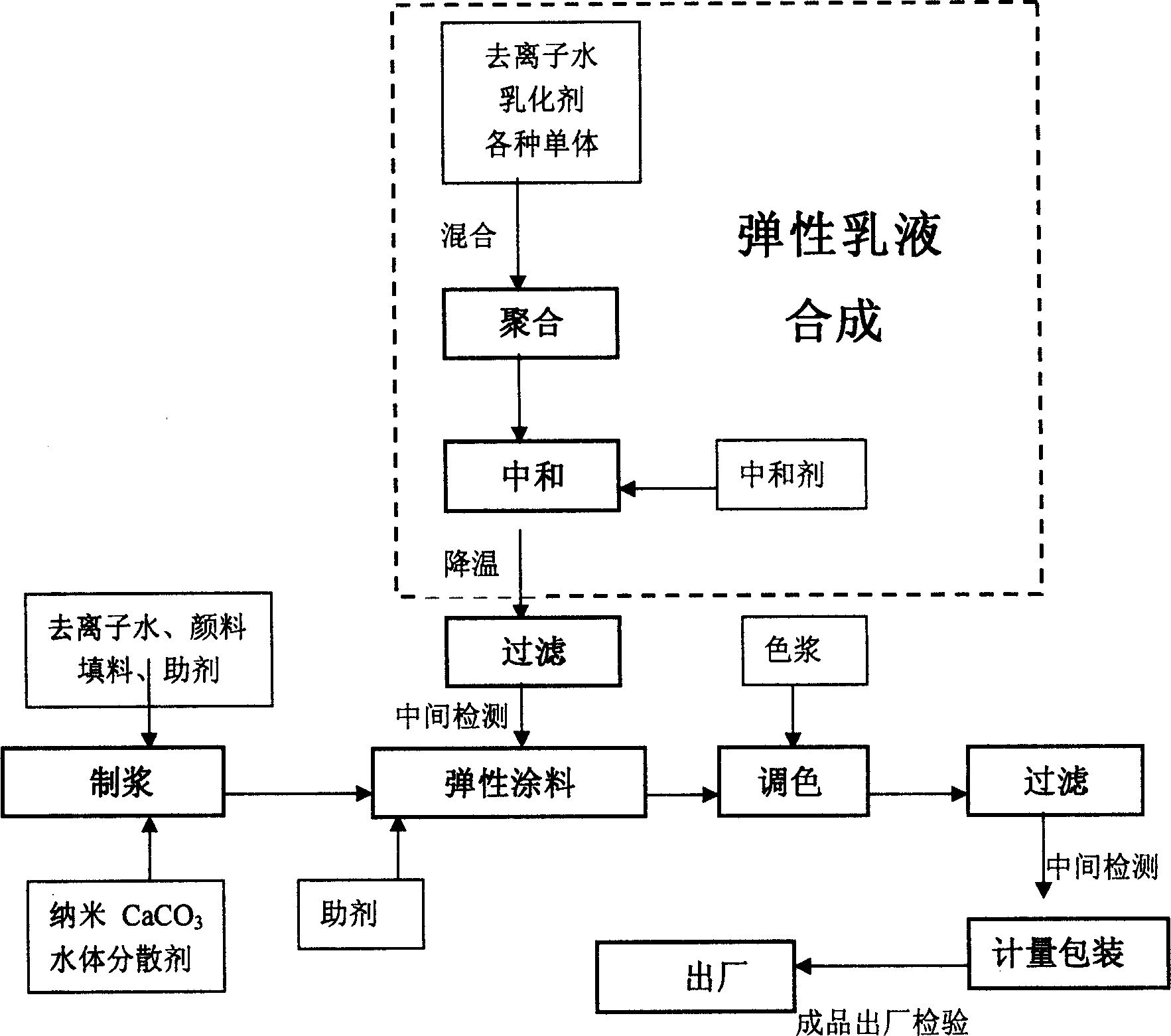

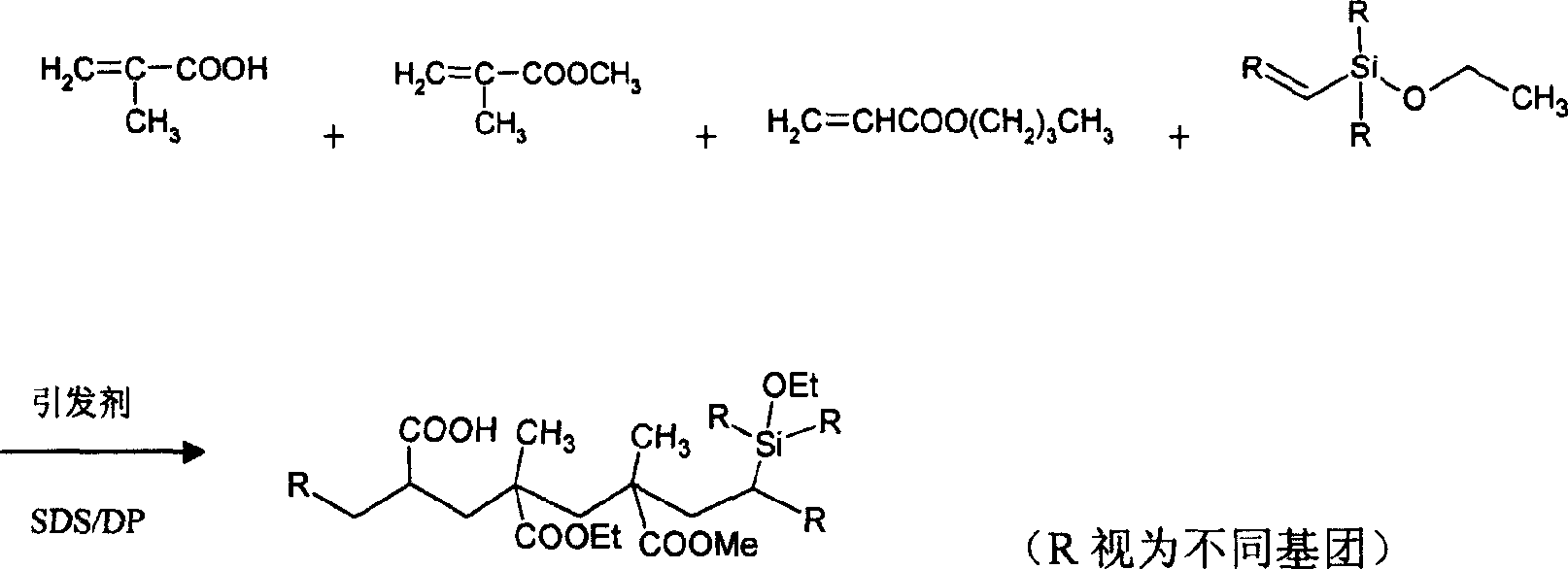

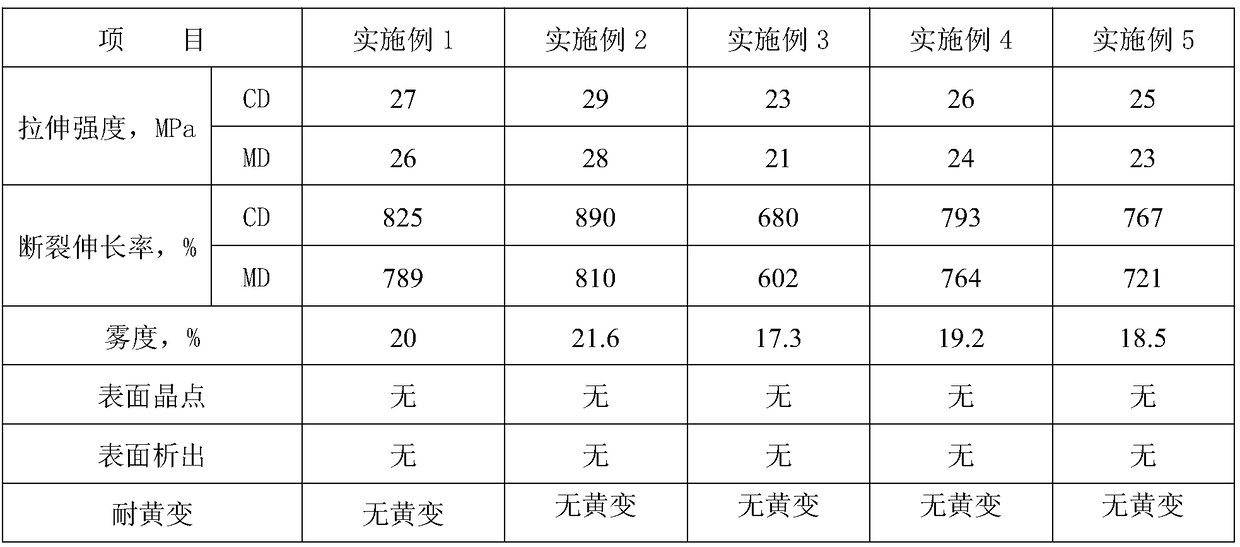

Super whether resistant high antipollution composite elastic construction paint

InactiveCN1912031AStable chemical propertiesGood glossAntifouling/underwater paintsPaints with biocidesButyl acrylateEmulsion

The invention relates to a super-weather resistance, high-stain resistance, composite elastic building coating, mainly comprising acrylate silicon elastic emulsion 45-55wt%, rutile TiO2 15-20wt%, nano CaCO3 2-3wt% and water the rest, where the silicon-acrylate elastic emulsion mainly comprises methyl methacrylate 11-13wt%, butyl acrylate 32-37wt%, acrylate 1.5-3wt%, organic silicon monomers 6-8wt%, emulsifier 5-3wt%, initiating agent 0.2-0.7wt%, PH regulator 0.1-0.15wt% and water the rest. And it has beneficial effects of: selecting nano CaCO3 and rutile TiO2 to modified-prepare silicon-acrylate elastic building coating, cooperatively improving synthetic performances of the coating and implementing optimum balance of elasticity, resistance, rigidity and stain-resistance.

Owner:ZHEJIANG ZHONGCHENG CONSTR GRP

Oil paint for coating metal surface

InactiveCN101096497AStrong corrosion resistanceGood glossLiquid surface applicatorsCoatingsSolventDefoaming Agents

Disclosed is a paint for applying to metal surfaces, wherein the main constituents include (by weight portions): thermoplastic acrylic resin 20-60, acrylic resin copolymer 10-50, and hardening agent 20-50, adhesive force promoter 0.5-5, levelling agent 0.05-0.5, defoaming agent 0.1-1, solvent 1-10 and epoxy resin 3-15.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

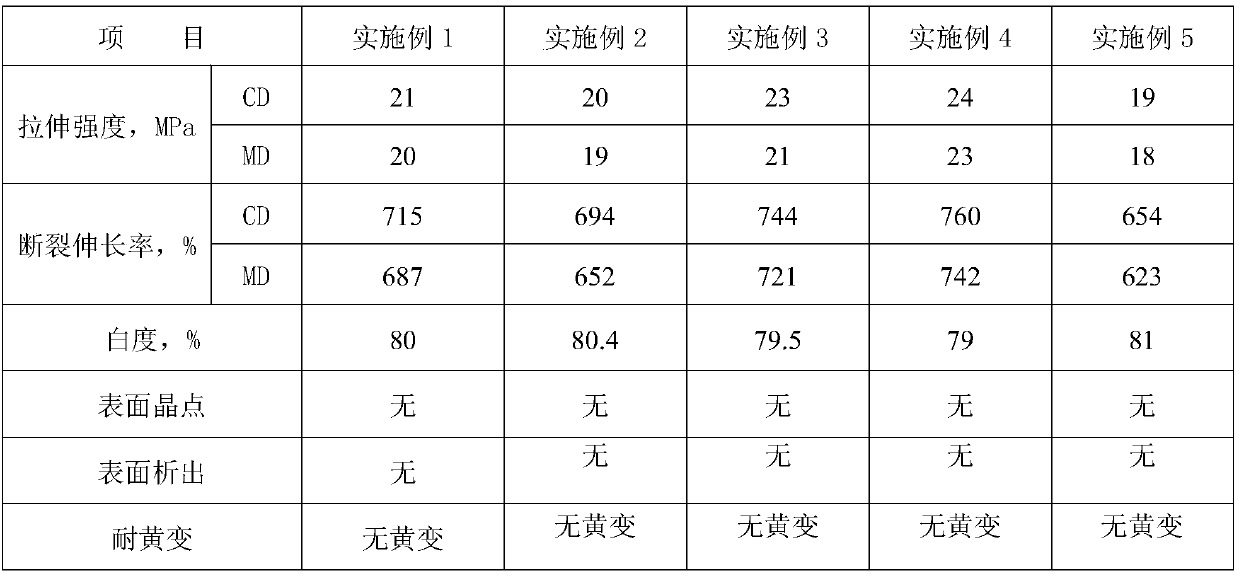

Transparent PE label film and production method thereof

The invention relates to a transparent PE label film. The transparent PE label film comprises an outer film layer, a middle film layer and an inner film layer; the outer film layer and the inner filmlayer are prepared from 68.5-70.5 wt% of LDPE, 29-31 wt% of casting-level HDPE and 0.2-0.8 wt% of PPA, and the middle film layer is prepared from 44-46 wt% of film-blowing-level HDPE, 53.5-55.5 wt% ofLDPE and 0.2-0.8 wt% of PPA. The invention further provides a production method of the transparent PE label film. The transparent PE label film has the advantages of being low in crystal point, freeof surface precipitation, high in stiffness and resistant to yellowing, and the printing and use requirements are met.

Owner:永新股份(黄山)包装有限公司

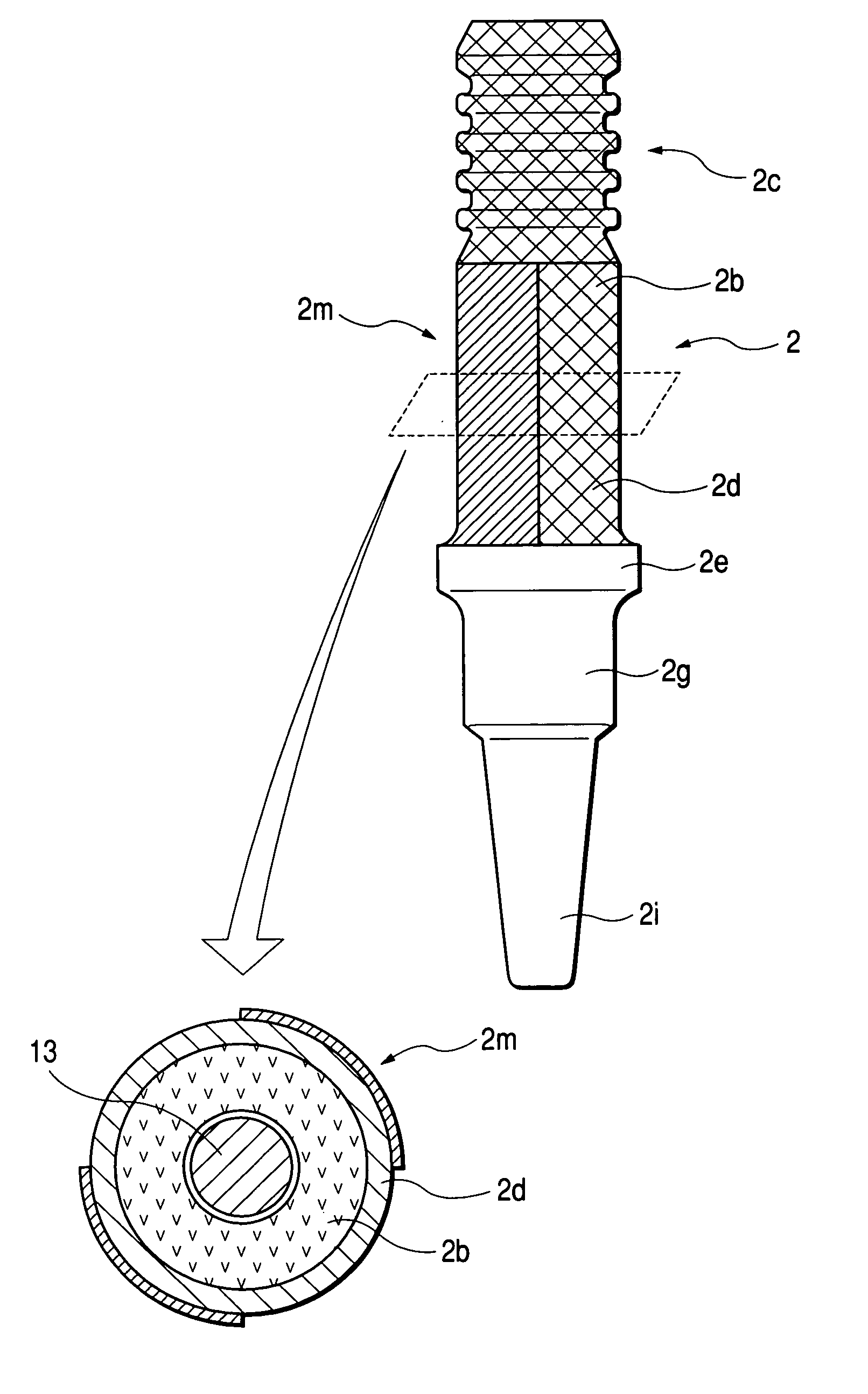

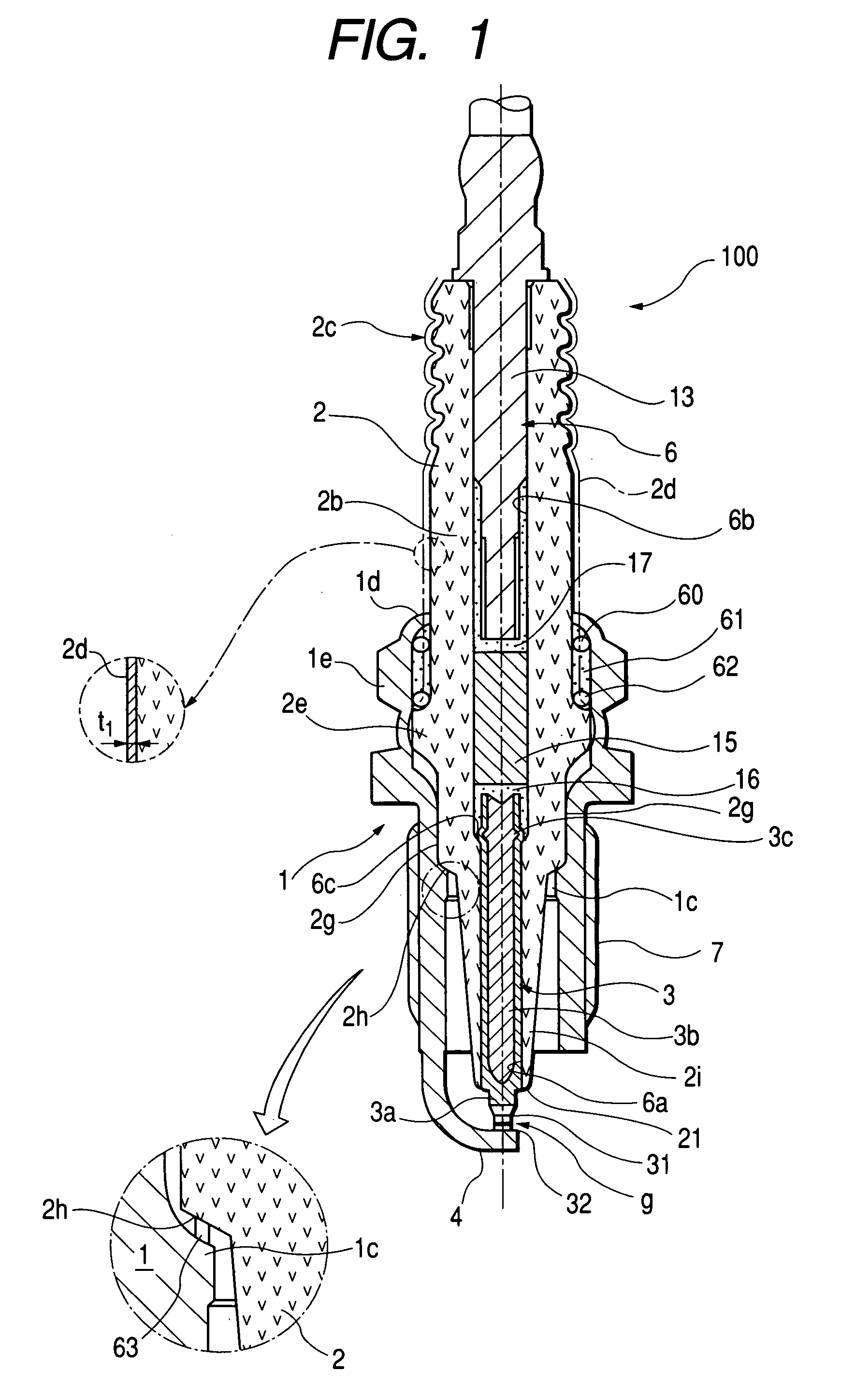

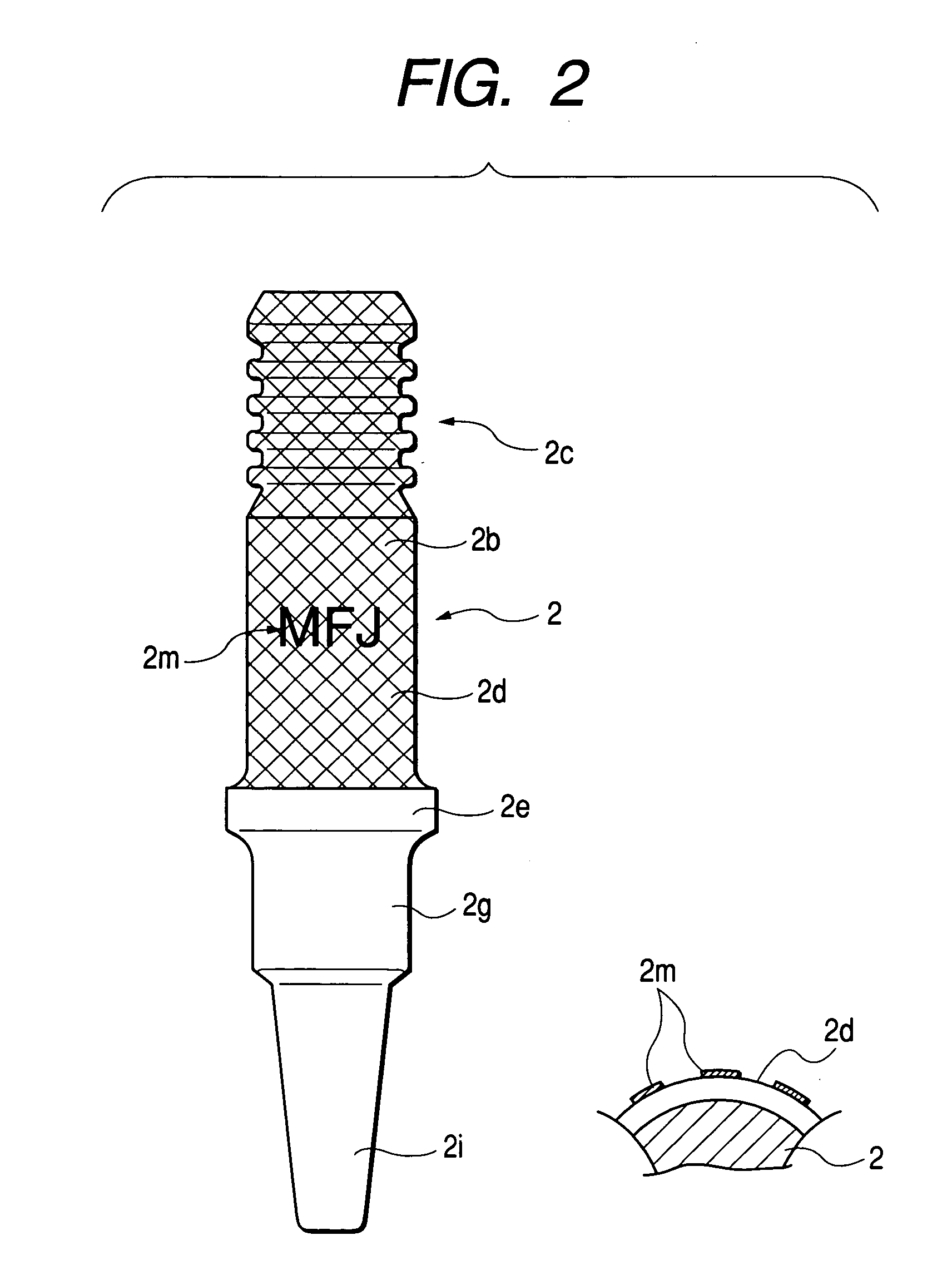

Spark plug

InactiveUS20040135483A1Good glossGood color stateSparking plugsFuel injection apparatusSpark plugAlkali metal

A spark plug comprising an insulator, on at least a part of a surface of the insulator being formed a marking layer and a glaze layer, wherein the marking layer is exposed on the surface of the insulator and contains: a Pb component of not more ton 5% by mole in terms of PbO; an Si component of from 36% by mole to 72% by mole in tens of SiO2; an Al component of from 0.1% by mole to 18% by mole in terms of Al2O3; an alkali metal component containing at least one of an Li component, an Na component and a K component of from 0.1% by mole to 9% by mole in terms of Li2O, Na2O and K2O, respectively; a B component of from 3% by mole to 30% by mole in terms of B2O3; and a color developing component containing at least one of a V component, a Cr component, an Mn component, an Fe component, a Co component, an Ni component, a Cu component, a Pr component, an Nd component, an Au component, a Cd component, an Sn component, an Sb component, an Se component, an S component and an La component of more than 0% by mole but not more than 50% by mole in terms of V2O5, Cr2O3, MnO2, Fe2O3, CoO, NiO, CuO, Pr2O3, Nd2O3, Au2O3, Cd2O3, SnO2, Sb2O5, SeO2, SO3 and La2O3, respectively.

Owner:NGK SPARK PLUG CO LTD

Material for producing natural degradable deep-cavity thin-wall soft bottle for tableware and soft bottle thereof

InactiveCN101429328AGood glossGood tensile strengthFlexible coversWrappersSmokeLimiting oxygen index

The invention relates to a material for producing a soft bottle for natural degradable deep-cavity thin-walled tableware, and the soft bottle. The material consists of the following components in weight percentage: 85 to 90 percent of polylactic acid ester, 9 to 14 percent of polyethylene terephthalate, and the balance being additive of the polyethylene terephthalate. The soft bottle produced from the material has the characteristics of good glossiness, tensile strength and ductility, innocuity, no pungency, good biocompatibility, biodegradability and biological absorption and the like. The soft bottle does not pollute the environment and cannot distribute poison gas and cause pollution in combustion. The soft bottle has the advantages of higher limit oxygen index (LOI 24-29), good self extinguishing after ignition, low smoke development in combustion, better flame retardant property, and the same combustion value as that of paper incineration. The material is a sustainable ecological fiber. In the process of using the soft bottle, the advantages of health and innocuity, no need of cleaning, environmental protection, and natural degradation are achieved.

Owner:深圳市阳成世纪科技有限公司

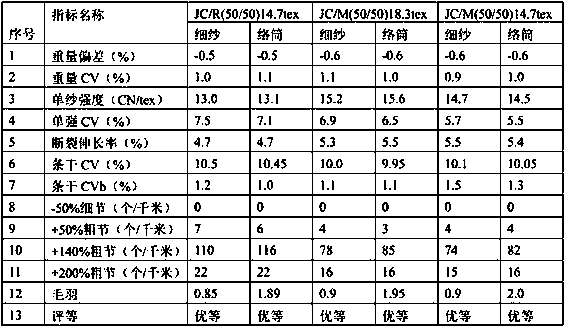

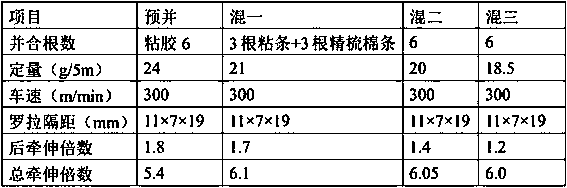

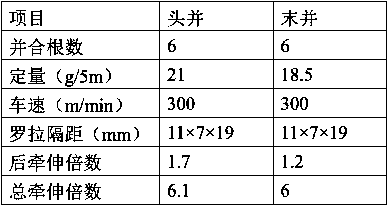

Production technology for siro compact spinning combed cotton and cellulosic fiber blended yarn

The invention discloses a production technology for siro compact spinning combed cotton and cellulosic fiber blended yarn. The technology includes the following steps that 1, fiber ribbons are spun; 2, spinning of the blended yarn includes the processes of drawing, roving, spinning and spooling. Cellulosic fibers in chemical fibers are used for replacing part of cotton fibers, through a siro compact spinning technology, combed cotton and cellulosic fibers are blended to prepare yarn, and combed cotton and cellulosic fibers are blended to prepare yarn with part of differentiated chemical fibers, the advantages of multi-component fibers are exerted, performance complementation of all the fibers is realized, respective defects are overcome, the quality of the yarn is remarkably improved, andthe gloss is improved; after the yarn is processed into a fabric, serviceability and home textile performance are more comprehensive, and the fabric quite accords with the pursue of people for clothing, costumes and home use.

Owner:河南省禹州市神禹纺织有限公司

Chemical silver plating solution and preparation method thereof

InactiveCN102747347ACrystal fineGood glossLiquid/solution decomposition chemical coatingSilver plateHydrazine compound

The invention discloses a chemical silver plating solution. The silver plating solution comprises silver nitrate, succimide, tartaric acid, trolamine, methylsulfonic acid and water. The silver plating solution per liter comprises 5-30g of the silver nitrate, 30-160g of the succimide, 10-38g of the tartaric acid and 6-68g of auxiliary complexing agents; alkali is used for adjusting the PH value of the silver plating solution to be in a range of 9-11; the auxiliary complexing agents are the trolamine and the methylsulfonic acid; the silver plating solution per liter comprises 1-38g of the trolamine and 5-30g of the methylsulfonic acid; and the alkali is sodium hydroxide or potassium hydroxide. The silver plating solution has the advantages that comprehensive quality of plating layers of the chemical silver plating solution is good, and the chemical silver plating solution can replace hydrazine, formaldehyde and dimethylamino borane, serves as a reducing agent process and is used for plating silver. The storage performance of the silver plating solution is stable, the waste of the silver plating solution can be avoided, and the application of the silver plating solution is wide. The preparation of the silver plating solution is flexible and the silver plating solution is convenient to use.

Owner:淮安市曼蒂科技发展有限公司

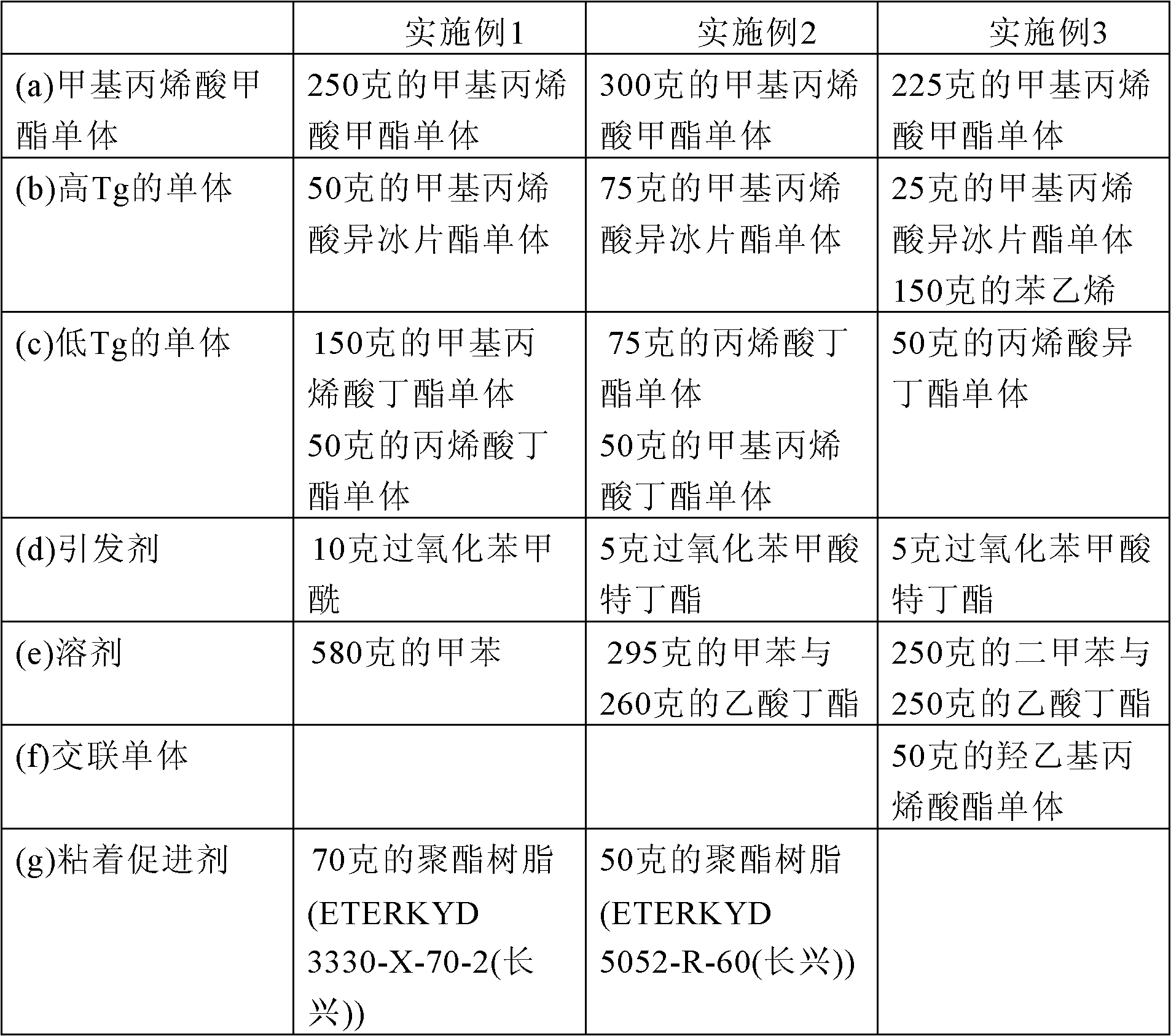

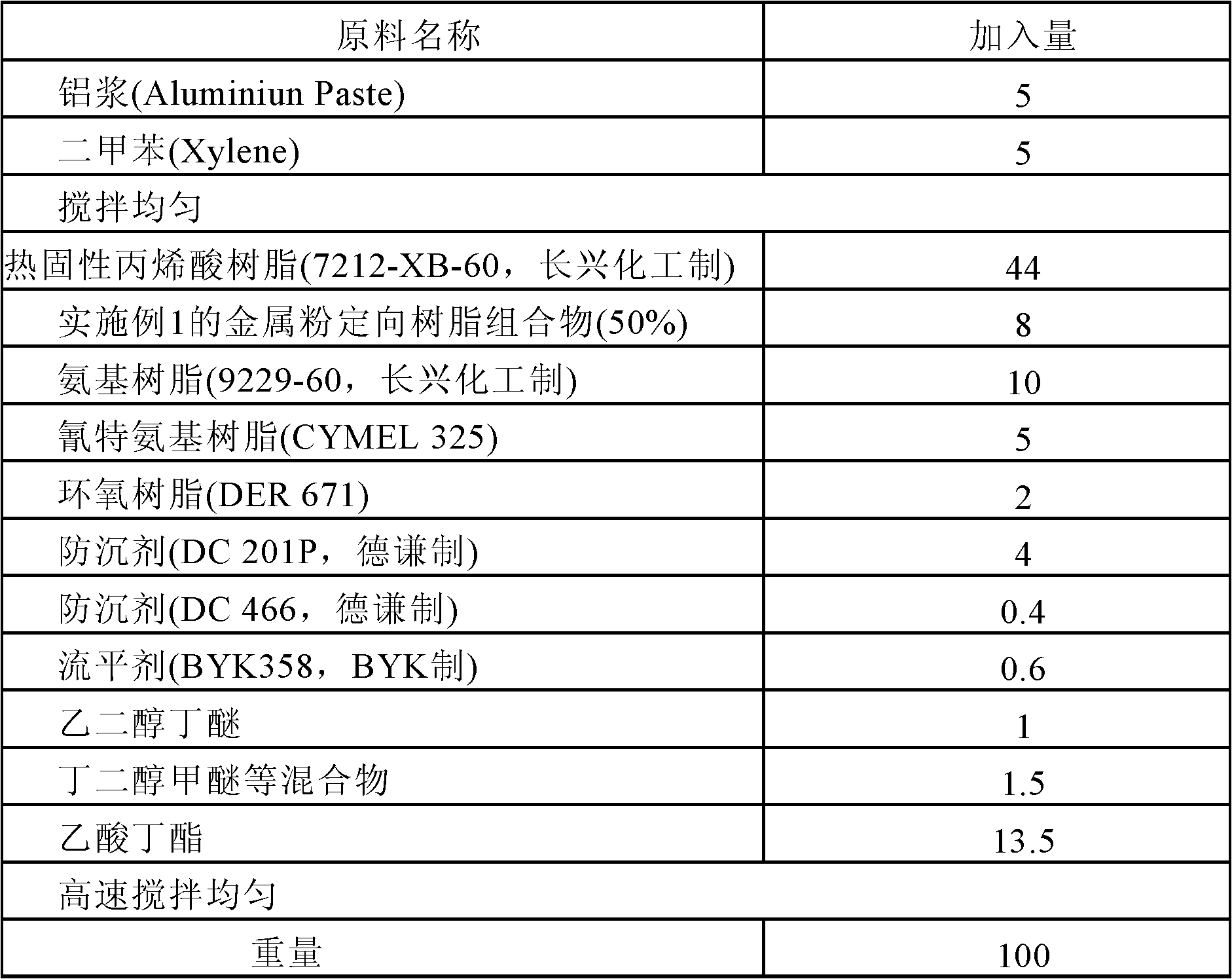

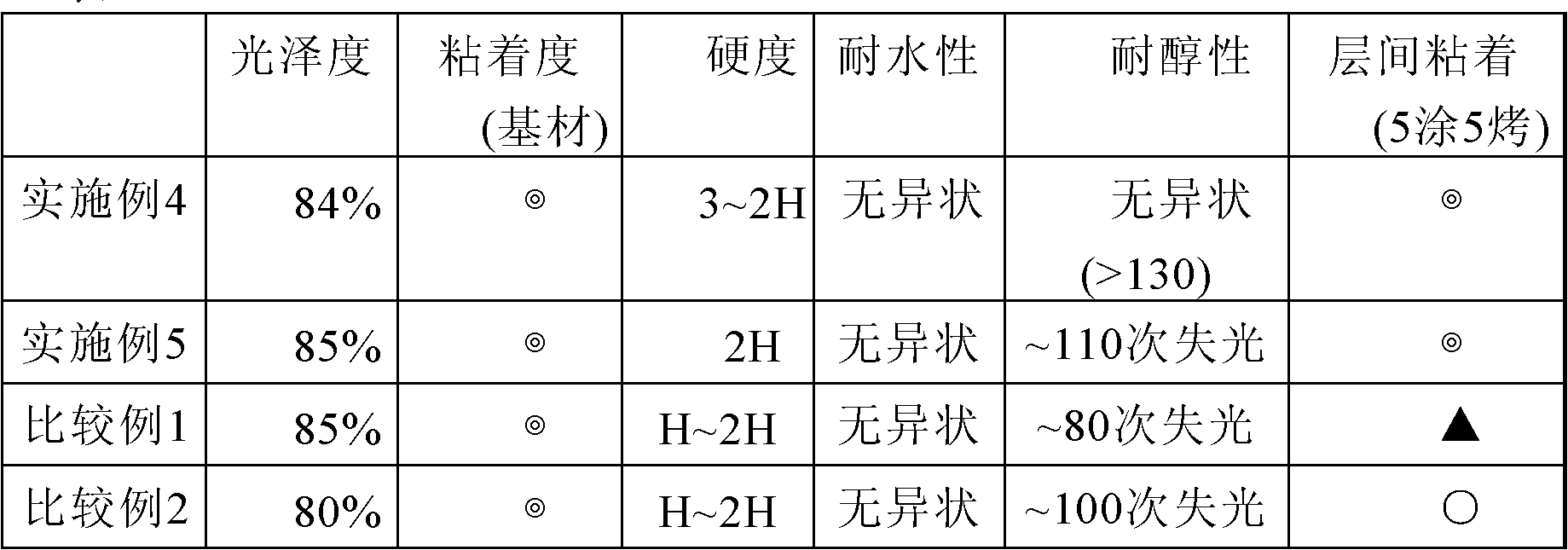

Metal powder directional resin composition

The present invention provides a metal powder directional resin composition comprising polymer and solvent, wherein the polymer comprises following monomers as polymerization units: (a) a methyl methacrylate monomer; (b) a monomer with a high glass-transition temperature; and (c) a monomer with a low glass-transition temperature, wherein, weight-average molecular weight of the polymer is at least about 50000. The metal powder directional resin composition of the present invention has a significant effect for direction arrangement of metal power, and can be used in metallic paint. In addition, the metal powder directional resin composition has the advantages of good water resistance and good alcohol resistance, perfect compatibility with other resin, capacity for showing higher brightness and metal mirror effect.

Owner:ETERNAL MATERIALS CO LTD

Preparation method of high-performance conductive glass fiber

InactiveCN104532214AGood electrical conductivityGood glossLiquid/solution decomposition chemical coatingElectroless nickel platingGlass fiber

The invention discloses a preparation method of a high-performance conductive glass fiber, and relates to the technical field of production of glass fibers. The preparation method comprises four process steps of purification and coarsening treatment, sensitization and activation treatment, cleaning and chemical nickel plating. According to the preparation method disclosed by the invention, a layer of a conductive metal is plated on the surface of the glass fiber by adopting a nickel plating method to ensure that the glass fiber has good conductivity; by completing purification, coarsening, sensitization and activation treatments of the glass fiber in the prior period of nickel plating, nickel can be well combined with the glass fiber; the glass fiber is relatively good in luster, high in plated layer stability and difficult in oxidation; and optimized sensitizing solution and palladium chloride activating solution accelerate the proceeding of later-period nickel plating and shorten the reaction time. The preparation method is simple in whole process and strong in operability.

Owner:ANHUI DANFENG ELECTRONICS MATERIAL

Fine denier light terylene short fine with luminous function

InactiveCN101195936AGood glossUniform shrinkageMonocomponent polyesters artificial filamentArtifical filament manufactureFluorescencePolyester

The invention aims to provide fine denier (1 to 33 dtex) bright polyester staple fiber with luminescence function. The invention adopts the technical proposal that the supper bright PET sliced sheet is adopted as the spinning raw material; before the sliced sheet being transmitted, the fluorescence luminescence agent with the mass percentage concentration of 0.15% is added and mixed with the sliced sheet; the high temperature tension hot-setting technology condition is adopted to reduce the boiling water shrinkage ratio (or the dry heat shrinkage ratio) of the fiber. The product of the invention has the function of emitting fluorescence under normal conditions, the function can not be lost after coloring, and on the contrary, can realize the function of foiling essential color. Simultaneously, because the supper bright PET sliced sheet is adopted during the production, the glossiness of the product itself is good. The unique technical conditions ensure the product shrinkage to be concordant and uniform, the yarn weaved by utilizing the fiber has the advantages that the shrinkage is small and the dimensional stability is good. The invention can be commonly used for producing the computer metallic yarn and the sewing thread.

Owner:SHENGHONG GRP CO LTD

Rice noodle

The invention discloses a rice noodle. The rice noodle is prepared from the following raw materials in parts by weight: 500 parts of rice, 3-3.5 parts of lotus root starch, 2-2.5 parts of honey, and 75-100 parts of water. The rice noodle is produced by virtue of the following steps: taking the raw materials in parts by weight, washing the rice, soaking for 30 minutes and then draining; grinding the rice, adding the water, the lotus root starch and the honey, stirring evenly, and then forming the noodles in a rice noodle machine. The rice noodles have the characteristics of good tenacity, difficulty in breakage, easiness in separation, cooking resistance, good taste and high nutritive value.

Owner:修文县佳家乐米粉加工厂

Water-based gravure ink vehicle and preparation method thereof

The invention discloses a water-based gravure ink vehicle comprising the components in percentage by weight as follows: epoxy resin E-44, a ring opener, a solvent, an assistant, a waterborne polyurethane resin and a diluent, wherein the assistant is a mixture of a catalyst, an inhibitor, a chain extender, a cross-linking agent, an antifoaming agent and a flatting agent. The invention further discloses a preparation method of the water-based gravure ink vehicle. The preparation method comprises the steps as follows: firstly weighing the components, diluting the epoxy resin E-44 with ethyl acetate, reacting in a constant-temperature bath with a modifier for 4.5 h under the catalyst action, enabling the epoxy resin to open rings, and introducing hydroxyl groups; then adding the modified epoxy resin into a mixed liquor of the waterborne polyurethane resin, the chain extender and the cross-linking agent for reaction, then adding the flatting agent, the antifoaming agent and the diluent, and collecting the product to obtain the water-based gravure ink vehicle. The water-based gravure ink vehicle is free of solvent emission, safe and free of pollution; the preparation method is simple, the reaction condition is simple, and the preparation method is easy to realize; and used equipment is low in price and small in size.

Owner:珠海悦美水墨新材料股份有限公司

Colored high-transparency melt block and method for preparing same

The invention discloses a colored high-transparency melt block and a method for preparing the same. The colored high-transparency melt block comprises main chemical compositions including 10-20 parts of Al2O3, 40-50 parts of SiO2, 0.05-0.10 part of Fe2O3, 10-15 parts of CaO, 5-10 parts of MgO, 1-3 parts of K2O, 0.5-2.0 parts of Na2O, 0.01-0.05 part of TiO2, lower than 0.01 part of SrO, 0.1-1.0 part of Li2O, lower than 0.01 part of PbO, 0.001-0.005 part of ZnO, 1-5 parts of B2O3, 0.10-0.50 part of P2O5, 2-6 parts of BaO, 0.010-0.050 part of SO3, 3-7 parts of ZrO2, 0.50-1.00 part of CeO2 and 1-5 parts of F. The ignition loss of the colored high-transparency melt block is 3-5%. The colored high-transparency melt block and the method have the advantages that the colored high-transparency melt block can be closely bonded with sintered ceramic substrates without separation or layering; expansion coefficients of the colored high-transparency melt block and blanks are matched with one another, and accordingly sintered products have flat surfaces; the surfaces of the sintered products are free of bubbles and pinholes, and the sintered products are good in glossiness and high in transparency.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD

Milky white PE (polyethylene) label film and production method thereof

ActiveCN109616005AGood glossImprove opticsStampsSynthetic resin layered productsHigh-density polyethyleneLow-density polyethylene

The invention relates to a milky white PE (polyethylene) label film. The milky white PE label film comprises an outer film layer, an intermediate film layer and an inner film layer, wherein the outerfilm layer and the inner film layer respectively comprise 68.5-70.5 wt% of LDPE (low-density polyethylene), 29-31 wt% of casting grade HDPE (high-density polyethylene) and 0.2-0.8 wt% of PPA (phenyl-propanolamine), and the intermediate film layer comprises 44-46 wt% of blown film grade HDPE, 35.5-37.5 wt% of LDPE, 17-19 wt% of white masterbatch and 0.2-0.8 wt% of PPA. In addition, the invention also provides a production method of the milky white PE label film. The milky white PE label film has the characteristics of low crystal point, no surface precipitation, high stiffness and yellowing resistance, and meets requirements for printing and use.

Owner:永新股份(黄山)包装有限公司

Conductive reinforced PC/ABS alloy

The invention discloses a conductive reinforced PC / ABS alloy. The conductive reinforced PC / ABS alloy comprises following ingredients, by mass, 40 to 60% of PC, 20 to 30% of ABS, 5 to 10% of alkali-free glass fiber, 8 to 15% of a conductive filling material, 2 to 8% of phosphorus-nitrogen flame retardant, 0.5 to 2% of a light stabilizer, 1 to 3% of a flexibilizer, 0.1 to 0.5% of an antioxidant, and 0.5 to 1% of a lubricant. The conductive filling material is one selected from polyacrylonitrile-based carbon fiber, vapor grown carbon nano-fibers, and conductive carbon black. Beneficial effects of the conductive reinforced PC / ABS alloy are that: the conductive reinforced PC / ABS alloy possesses advantages of PC and ABS, and excellent mechanical properties, flame resistance, aging resistance, conductivity, and glossiness; and is low in cost; a preparation method is simple; and industrialized production can be easily realized.

Owner:殷培花

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com