Heat shrinkage copolyester film and preparation method thereof

A technology of copolyester and heat shrinkage, which is applied in the field of highly transparent three-layer co-extrusion copolyester heat shrinkable film and its preparation, can solve the problems of unsatisfactory tensile strength, shrinkage uniformity and toughness, etc., and achieve excellent transparency , Uniform shrinkage and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

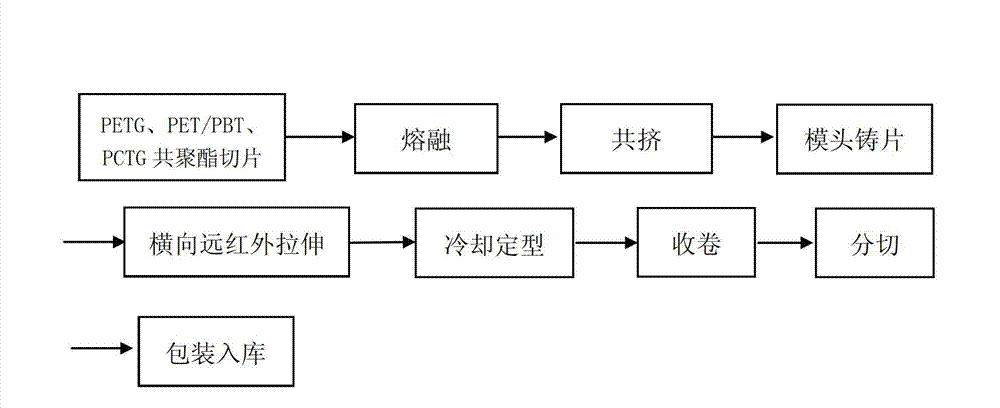

Method used

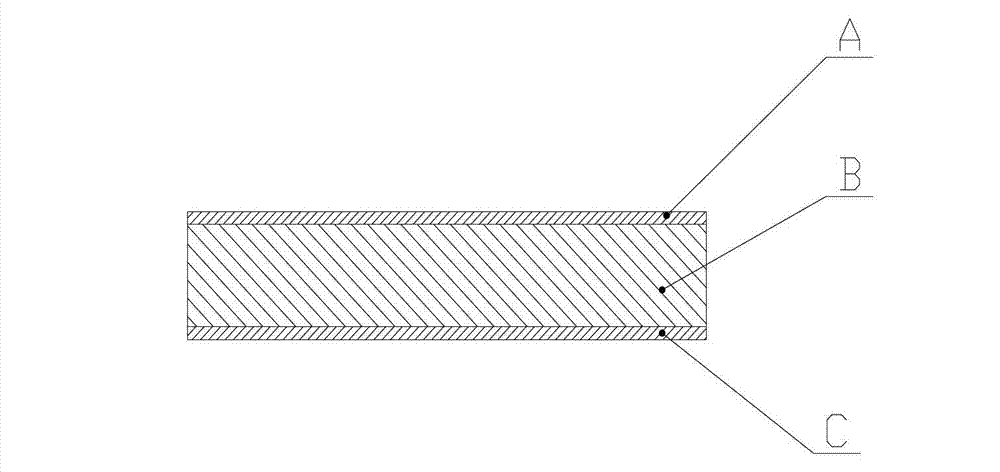

Image

Examples

Embodiment 1

[0028] Add 5.0Kg of purified terephthalic acid, 2.2Kg of ethylene glycol, 1.8Kg of 1,4-cyclohexanedimethanol (CHDM), 0.1g of ethylene glycol antimony catalyst, and 100g of calcium carbonate in a 20L general-purpose reactor Additive, 10g of nano-scale calcium acetate additive, carry out esterification reaction under the conditions of 230-250°C and 0.2-0.3Mpa, and release the system pressure to normal pressure after the water output reaches the theoretical value. React under these conditions, add 0.03g triethyl phosphate stabilizer, stir at normal pressure for 6min, after vacuuming, raise the temperature inside the reactor to 285°C, and drop the pressure below 100Pa, react under these conditions for 3h, and finally PETG copolyester chips for films with an intrinsic viscosity of 0.75 dl / g were obtained through polymerization melt extrusion, pelletizing and drying.

[0029] Add 3.5KgPET prepolymer (esterified product of purified terephthalic acid and ethylene glycol) and 2.5KgPBT ...

Embodiment 2

[0033] Add 5.0Kg of purified terephthalic acid, 2.4Kg of ethylene glycol, 1.6Kg of 1,4-cyclohexanedimethanol (CHDM), 0.1g of tetrabutyl titanate catalyst, and 120g of calcium acetate anti-sticking into a 20L general-purpose reactor Binder, 20g nano-scale calcium acetate additive, carry out esterification reaction under the conditions of 230-250°C and 0.2-0.3Mpa, and release the system pressure to normal pressure after the water output reaches the theoretical value. React under these conditions, add 0.03g triethyl phosphate stabilizer, stir at normal pressure for 6min, after vacuuming, raise the temperature inside the reactor to 285°C, and drop the pressure below 100Pa, react under these conditions for 3h, and finally PETG copolyester chips for films with an intrinsic viscosity of 0.80 dl / g were obtained through polymerization melt extrusion, pelletizing and drying.

[0034] Add 3.7KgPET prepolymer (esterified product of purified terephthalic acid and ethylene glycol) and 2.3Kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com