Patents

Literature

105 results about "Di-n-octyl phthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

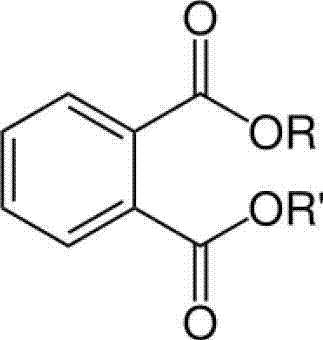

DI-N-Octyl phthalate is an ester of phthalic acid. It appears as a light-colored, odorless liquid and is used as a plasticizer for many resins and elastomers.

Functional wallpaper material capable of purifying air

InactiveCN101333788AAvoid pollutionImprove indoor air qualityNon-fibrous pulp additionSpecial paperIndoor air qualityPolyvinyl chloride

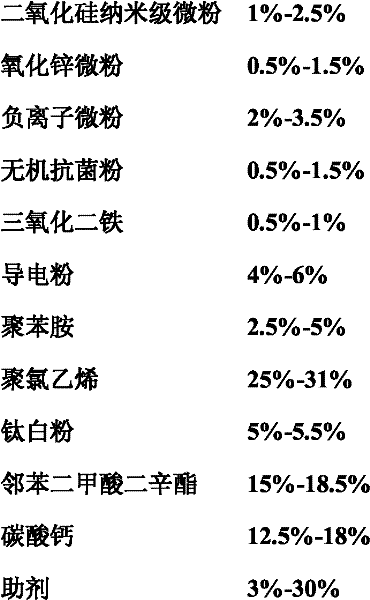

Disclosed is a functional type wallpaper material having the air purification function, belonging to the interior decoration material technique field, and containing the components, in weight percentage: 1.5 percent to 2.5 percent of titanium dioxide nano-sized powder, 1 percent to 2.5 percent of silicon dioxide nano-sized powder, 0.5 percent to 1.5 percent of zinc oxide powder, 2 percent to 3.5 percent of negative ion powder, 0.5 percent to 1.5 percent of inorganic antibacterial powder, 0.5 percent to 1 percent of iron trioxide, 4 percent to 6 percent of conductive powder, 2.5 percent to 5 percent of polyaniline, 25 percent to 31 percent of polyvinyl chloride, 5 percent to 5.5 percent of titanium pigment, 15 percent to 18.5 percent of di-n-octyl phthalate dioctyl phthalate, 12.5 percent to 18 percent of calcium carbonate, and 3 percent to 30 percent of auxiliary agent. The wallpaper prepared by the materials can remove formaldehyde and peculiar smell, and is antibacterial and mildew-proof, and can release negative ions and resist electromagnetic radiation, as well as greatly improving the indoor air quality for people and solving the indoor air pollution.

Owner:SHANGHAI JIAO TONG UNIV +1

Low-superficial area ratio marine antifouling coating of silicofluoride block polymer and its production

InactiveCN101029207ALower surface energyLow costAntifouling/underwater paintsPaints with biocidesMethacrylatePolydimethyl siloxane

A fluosilicate block polymer low-surface energy marine anti-fouling coating and its production are disclosed. The coating consists of base material polydimethyl siloxane-b-polymethylmethacrylate-b-polyfluobutyl metacrylic acid ester ternary fluosilicate block copolymer, accessory methyl silicone oil and di-n-octyl ester phthalate and coating solvent butyrin acetate. The process is carried out by mixing methyl silicone oil with di-n-octyl ester phthalate to obtain coating accessory, mixing polydimethyl siloxane-b-polymethylmethacrylate-b-polyfluobutyl metacrylic acid ester ternary fluosilicate block copolymer with pigment to obtain coating base material and pigment mixture, adding coating accessory into mixture of coating base material and pigment, mixing, dissolving it into butyrin acetate and laying aside. It has excellent anti-fouling effect and no environmental pollution.

Owner:XIAMEN UNIV

Polyvinyl chloride (PVC) synthetic leather and production method thereof for bags and suitcases

InactiveCN104213428AAntibacterial and antifungalImprove comfortSynthetic resin layered productsLaminationFiberMaltitol

The invention discloses polyvinyl chloride (PVC) synthetic leather for bags and suitcases. The PVC synthetic leather comprises, by weight, 30-60 parts of PVCSG-5, 15-30 parts of PVCSG-8, 30-60 parts of di-n-octyl phthalate, 15-30 parts of trihexyl citrate, 1-2 parts of isooctyl palmitate, 2-6 parts of moxa, 5-10 parts of pyrophillite, 2-5 parts of seaweed gel, 4-8 parts of kaoline, 4-8 parts of blanc fixe, 2-6 parts of rush powder, 0.5-1.5 parts of soybean protein fibers, 1-3 parts of maltitol, 0.5-1 part of sodium alginate, 1-2 parts of sodium thiosulfate, 5-10 parts of pigments and 5-10 parts of performance additives. According to the PVC synthetic leather for the bags and the suitcases, growing and breeding of microorganisms can be effectively inhibited, the sanitation property is good, the PVC synthetic leather is physically beneficial, the mechanical property is high, hand feel and comfort degree are good, and the PVC synthetic leather is suitable for the bags and the suitcases.

Owner:ANHUI TWINKLE TOURIST ARTICLES

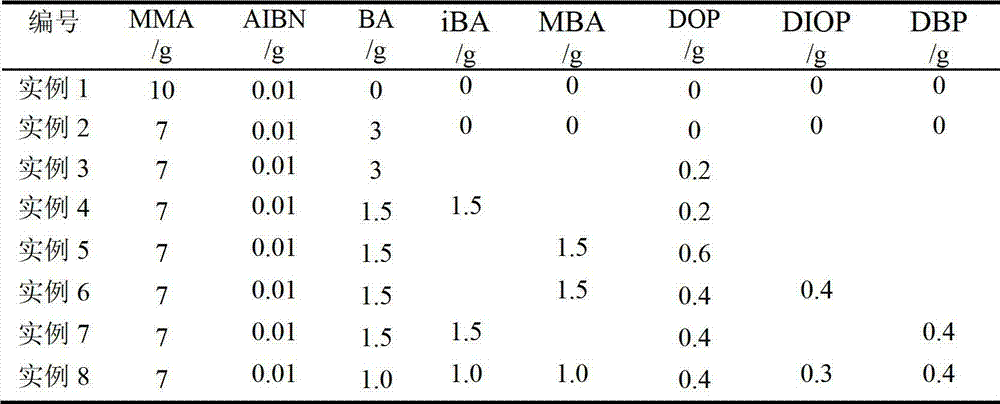

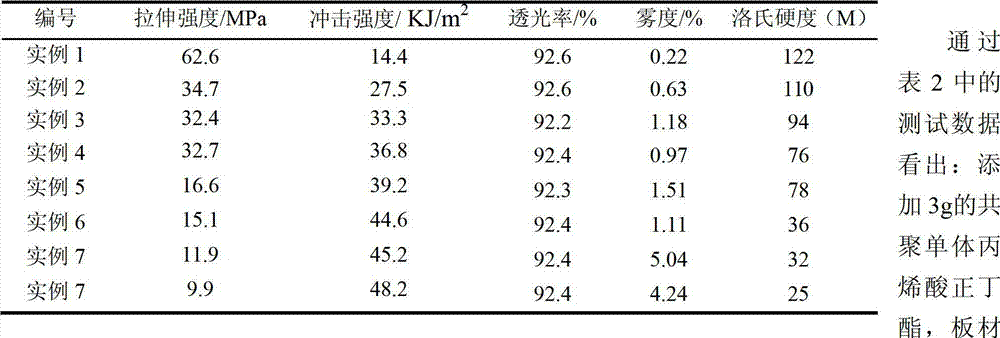

Preparation method of plasticized, copolymerized and modified organic glass

A plasticized, copolymerized and modified organic glass is prepared by copolymerizing methyl methacrylate, comonomer and plasticizer with a main body, and carrying out casting molding. The comonomer used belongs to butyl acrylate type, and includes n-butyl acrylate or n-butyl methacrylate; and the plasticizer belongs to phthalic acid esters, and includes Di-n-octyl phthalate (DOP), Diisooctyl ortho-phthalate (DIOP) and dibutyl phthalate (DBP). The preparation method is used for preparing an organic glass cast sheet with super flexibility and high light transmittance.

Owner:CHANGZHOU UNIV

Rubber cable sheathing material resistant to high and low temperature

InactiveCN105255072AGood high and low temperature resistanceEasy to processVinyl etherPolymer science

The invention discloses a rubber cable sheathing material resistant to high and low temperature. The rubber cable sheathing material comprises raw materials as follows: fluoroether rubber, hydrogenated nitrile rubber, acrylate rubber, tetrafluoroethylene-perfluoromethyl vinyl ether copolymer, zinc oxide, stearic acid, 2,5-dimethyl-2,5-di(t-butylperoxy) hexane, carbon black, nano silicon nitride, hollow glass beads, di-n-octyl phthalate, adipate di[2-(2-butoxyethoxy)ethyl ester], triallyl isocyanurate, zinc methacrylate, an accelerator, an anti-ageing agent, dyhydroxyl polydimethylsiloxane and lanthanum stearate. The rubber cable sheathing material resistant to high and low temperature has excellent high and low temperature resistance and oil resistance, good processing performance and ageing resistance and small compression deformation.

Owner:ANHUI LAND GRP

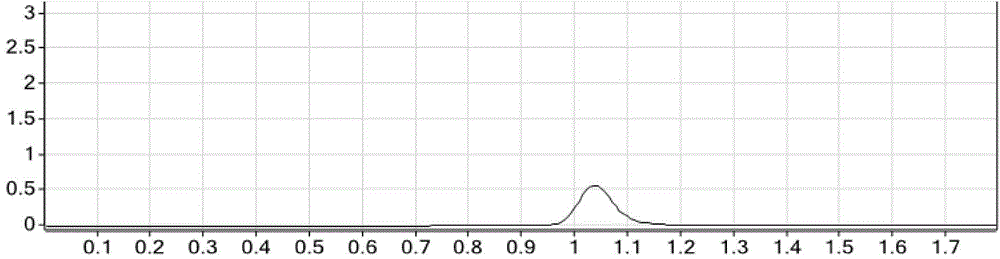

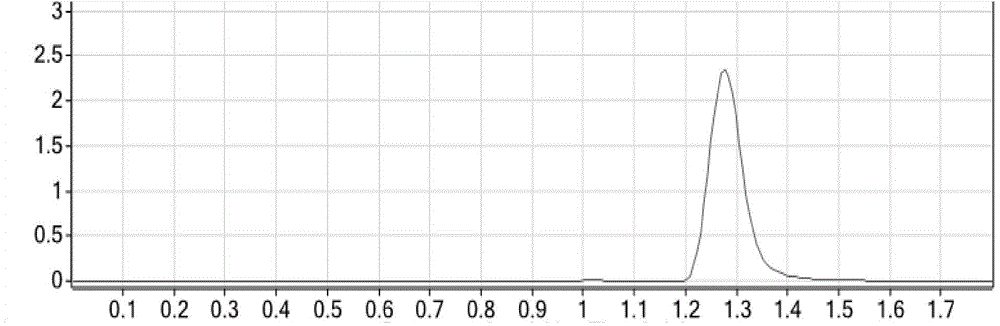

Method for detecting six phthalates in drinking water through liquid chromatography-mass spectrometry

InactiveCN104820030AEasy to operateFew samplesComponent separationButylbenzyl phthalateDi-n-octyl phthalate

The invention discloses a method for detecting six phthalates in drinking water through liquid chromatography-mass spectrometry, and belongs to the technical field of drinking water detection. The method comprises the following steps: (1) additionally arranging a protection column; (2) measuring conditions and a mode; (3) establishing a standard working curve; (4) detecting to-be-detected drinking water. According to the detection method, a sample is not required to be pretreated and can be directly fed, so that the six phthalates (DMP (Dimethyl Phthalate), DEP (Diethyl Phthalate), DBP (Dibutyl Phthalate), BBP (Benzyl Butyl Phthalate), DEHP (Di 2-Ethyl Hexyl Phthalate) and DNOP (Di N Octyl Phthalate)) in the drinking water are qualitatively and quantitatively analyzed at high speed; the method has the advantages of easiness and convenience in operation, less sampling quantity, low cost, good reproducibility, high stability and the like, is not only suitable for daily environment monitoring and is also suitable for quick screening of pollutants in emergency accidents.

Owner:桂林市环境监测中心站

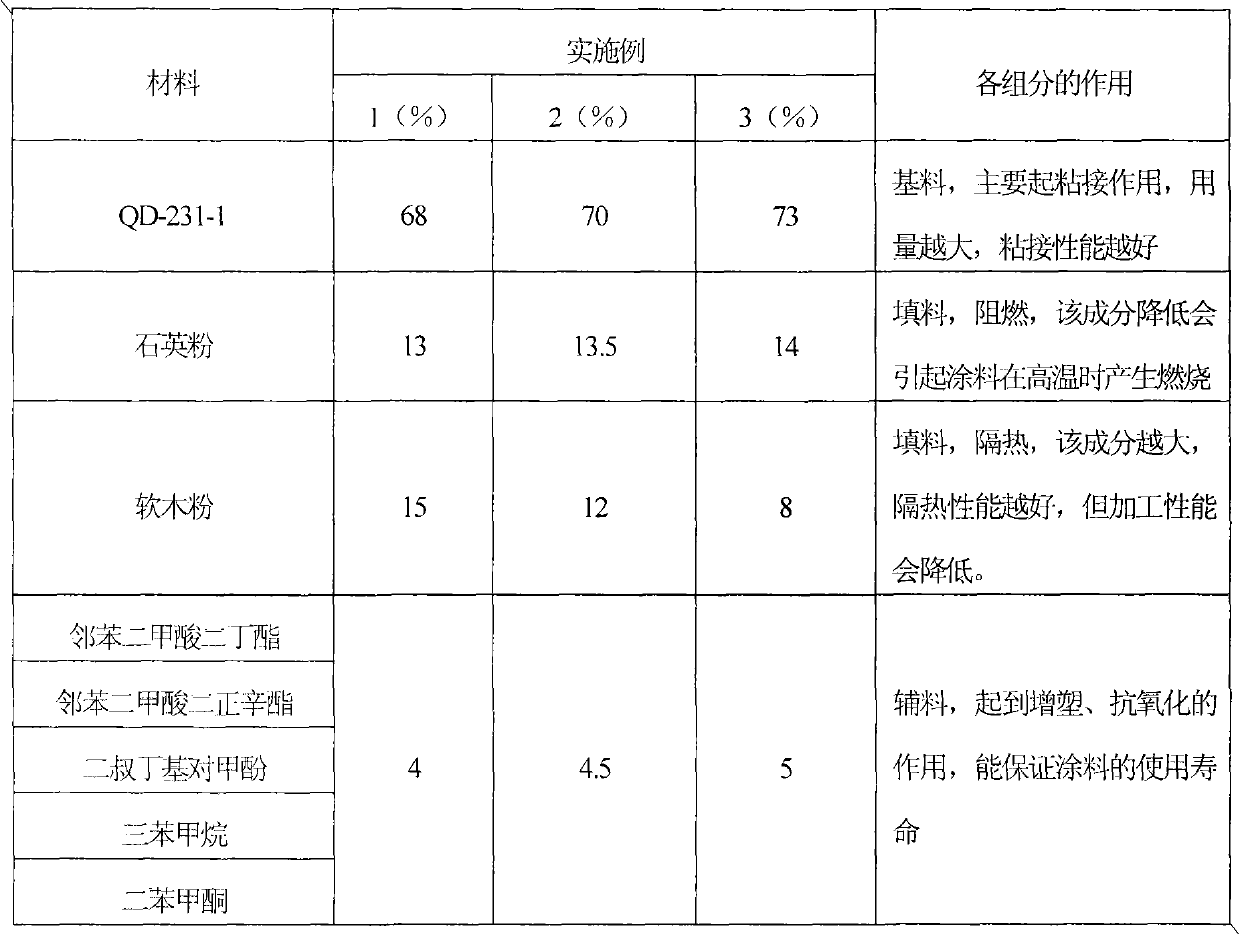

Ablative heat-insulating coating and preparation method thereof

ActiveCN101845273AFast vulcanizationEasy constructionFuselage insulationCoatingsVulcanizationAntioxidant

The invention provides an ablative heat-insulating coating and a preparation method thereof. The ablative heat-insulating coating comprises a base material, a filler and an auxiliary material based on weight percent. The base material is room temperature vulcanization block methyl silicone rubber and accounts for 68 to 73 weight percent; the filler comprises 13 to 14 weight percent of quartz powder and 8 to 15 weight percent of cork powder; and the auxiliary material is a plasticizer and an antioxidant and accounts for 4 to 5 weight percent. The auxiliary material is a mixture of the following components in percentage by weight: 0.3 to 0.5 percent of triphenylmethane, 0.3 to 0.5 percent of benzophenone, 0.4 to 0.6 percent of di-tert-butyl- p-cresol, 1.5 to 1.7 percent of dibutyl phthalate, and 1.5 to 1.7 percent of di-n-octyl ortho-phthalate. The quartz powder has the granularity of 200 meshes and has the purity of 99.8 percent; and the cork powder has the granularity of more than 80 meshes and has the moisture content of less than 10 percent. The ablative heat-insulating coating is coated on the surface of a device after being diluted by gasoline, and a layer of aluminum powder is sprayed on the outer surface of the coating. The ablative heat-insulating coating has the characteristics of low cost, convenient construction, good heat-insulating performance, strong adhesive force, and long service life.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

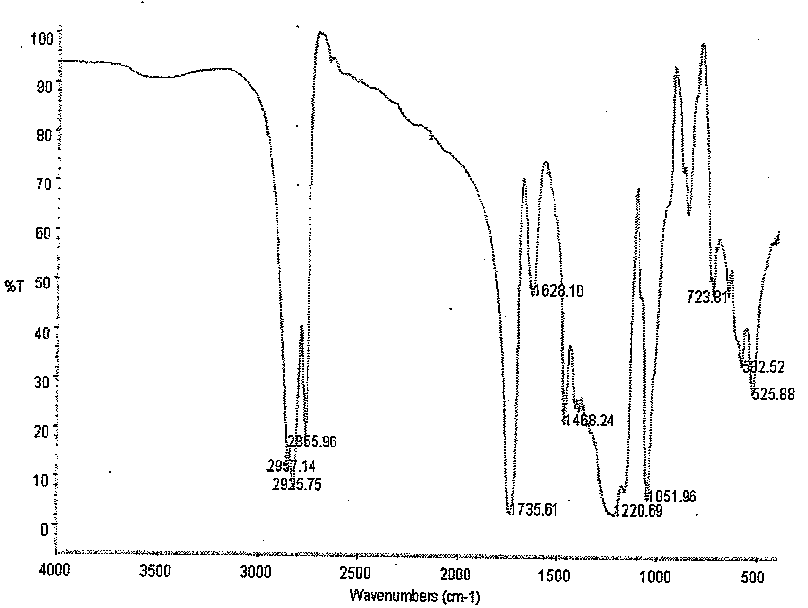

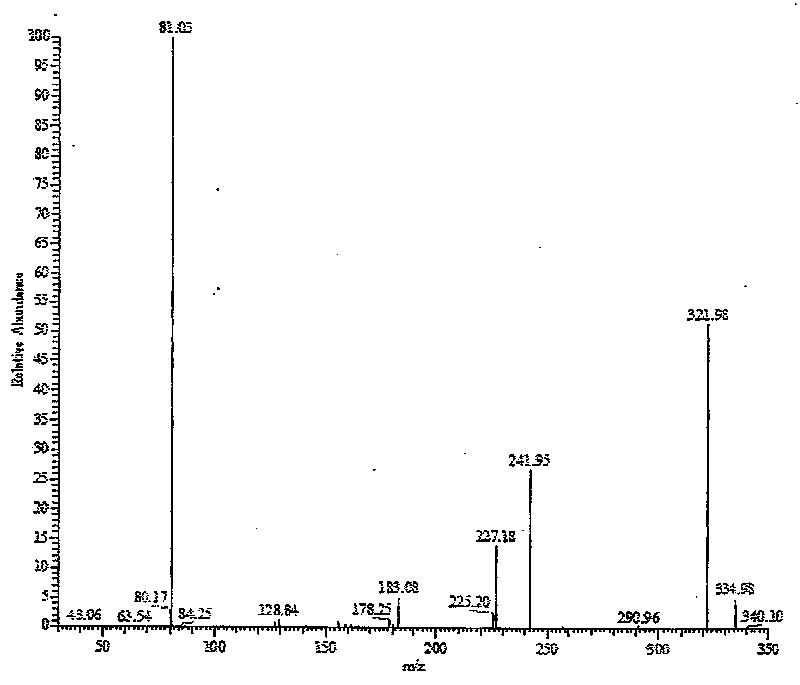

A kind of carbon paste electrode and preparation method thereof

ActiveCN102269730AIncrease the hydrogen evolution overpotentialGood reproducibilityMaterial electrochemical variablesHydrogenCarbon paste electrode

The invention provides a carbon paste electrode. The carbon paste electrode comprises an electrode tube shell, a carbon paste filled in the electrode tube shell, and an electrode lead contacted with the carbon paste and led out from the electrode tube shell, wherein the carbon paste comprises graphite and a DNOP (di-n-octyl phthalate). The carbon paste electrode provided by the invention is low in residue current, simple in preparation method, non-toxic, easy to update the surface, low in price and wide in potential use range; the hydrogen overpotential is 200 mV higher than the carbon paste mixed by silicone oil and graphite powder and the reproducibility is good. The invention further provides a preparation method of the carbon paste electrode.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Fungus for degrading phthalate ester and application thereof

InactiveCN102409000AImprove repair efficiencyEfficient degradation abilityFungiContaminated soil reclamationPullulanDi-n-octyl phthalate

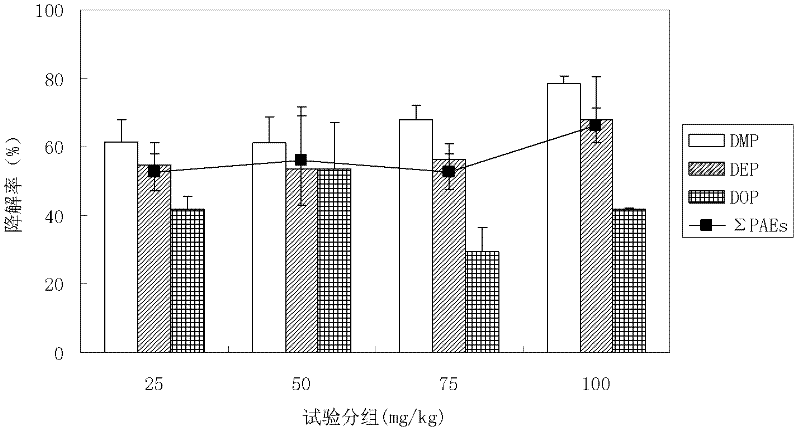

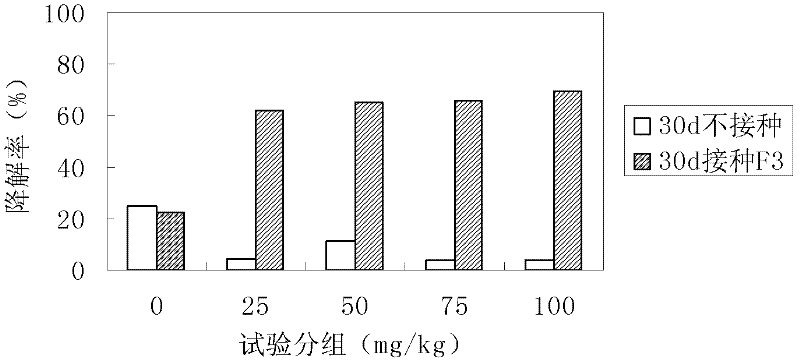

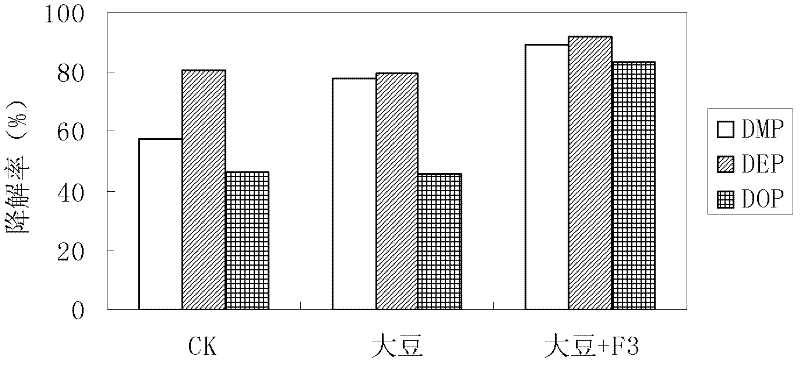

The invention belongs to the technical field of biological treatment of environmental organic pollutant and discloses a fungus for degrading phthalate ester and an application thereof in biological treatment of polluted soil and in environmental pollution remediation. The fungus for degrading phthalate ester is bundle pullulan (Isaria sp.) F3 with a preservation number of CCTCC No. M 2011299. The bundle pullulan (Isaria sp.) F3 has a total degrading rate of 52.7-66.2% in the mixed system of DMP (dimethyl phthalate), DEP (diethyl phthalate) and DOP (dinoctyl orthophthalate) within 7 days under a culturing condition; wherein the degrading rate of DMP is 61.5-78.4%, the degrading rate of DEP is 53.7-68.1%, and the degrading rate of DOP is 29.5-53.7%. The 300 mg / kg of PAEs in the sterilized soil is degraded to 69.0% within 30 days; the efficiency for soil phytoremediation polluted by DMP, DEP and DOP can be obviously improved. Compared to other strains, the fungus has efficient phthalate ester degradation capacity.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

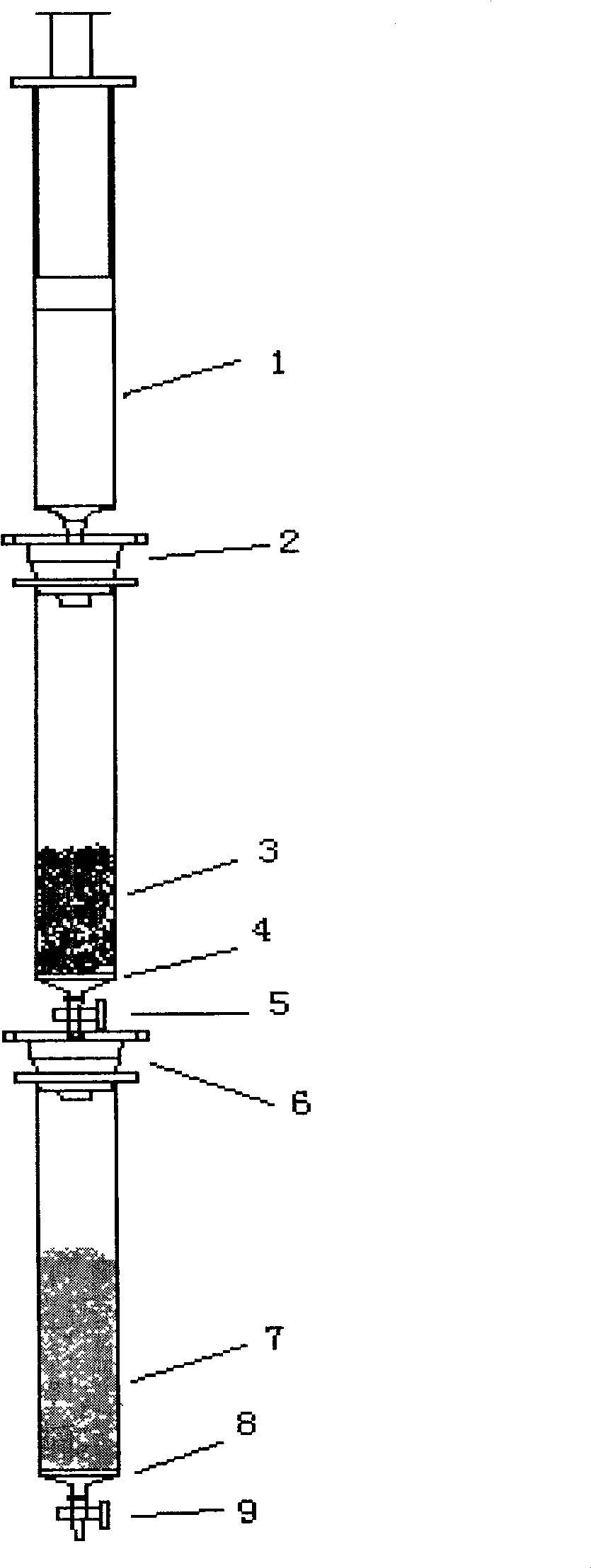

Two-step separation-purification column and use thereof

InactiveCN101530780AEasy to detectLow detection limitOther chemical processesOrganic compound preparationActivated carbonDi n butyl phthalate

The invention provides a two-step separation-purification column and use thereof, relating to separation-purification column and the use of separating and purifying Reomol in food safety testing. The column is made by activated carbon particle filled column at the upper end and Rory silica filled column at the lower end. The two-step separation-purification column is used for separating and purifying Reomol. The invention combines the activated carbon particle column and Rory silica column to purify and enrich di-n-octyl phthalate (DNOP) and di-n-butyl phthalate (DBP), which can reduce the detection limit of the detection limit coarse extract. The detection limit of the DNOP and DBP in the membrane coarse extract is ten times that that purified and enriched by the activated carbon particle column and Rory silica column; the detection limit of the DNOP and DBP in the apple coarse extract is 8.3 times and ten times than that purified and enriched by the activated carbon particle column and Rory silica column. The invention is easy for detecting a large number of samples in large scale.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

High strength, anti-aging natural rubber/nitrile rubber cable material

The invention discloses a high strength, anti-aging natural rubber / nitrile rubber cable material. The raw material comprises the following components: natural rubber, nitrile rubber, precipitated silica, nano calcium carbonate, calcium sulfate whisker, zinc oxide, stearate, sulfur, 1,3-phenylene-di(1H-2,5-pyrrole-dione), 2-mercaptobenzothiazole thiazole parts, N-oxydisuccinic ethylenebis-2-benzothiazole sulfenamide, phthalate, di-n-octyl phthalate, dioctyl maleate, silane coupling agent and an antioxidant. The high strength, anti-aging natural rubber / nitrile rubber cable material disclosed by the invention is high in strength, and high in aging resistance, and the cable made from the material has good property and is long in service life, so that the cost is reduced.

Owner:繁昌县菲德通讯材料设计有限公司

Flame retardation control cable with excellent mechanical performances

InactiveCN105273282AGood thermal stabilityImprove mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesInsulation layerDiethylenetriamine

The invention discloses a flame retardation control cable with excellent mechanical performances. The flame retardation control cable comprises a cable core, an insulation layer, a shielding layer and a sheath layer, the insulation layer is coated outside the cable core, the shielding layer is coated outside the insulation layer, and the sheath layer is coated outside the shielding layer, wherein the insulation layer is made of modified polypropylene. Raw materials of the modified polypropylene comprise polyethylene, polypropylene, chloroprene rubber, vinyltriethoxysilane, tert-amylperoxy 2-ethylhexyl carbonate, diethylenetriamine, dibutyltin dilaurate, styrenated N-phenylbenzenamine, 3,5-di-t-butyl-4-hydroxycinnamic acid, di-n-octyl phthalate, carboxymethylcellulose sodium, paraffin, magnesium stearate, diatomite and talcum powder. The cable has the advantages of good thermal stability, excellent flame retardation performance and excellent mechanical performances.

Owner:ANHUI LAND GRP

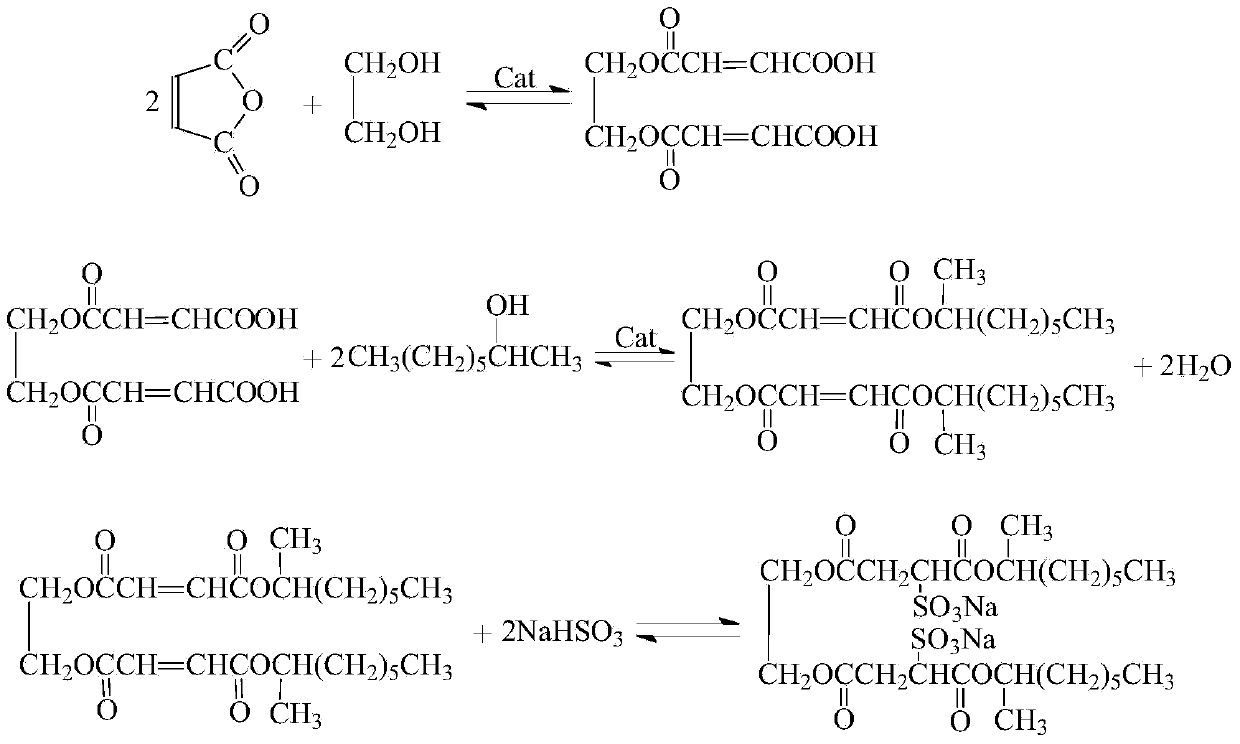

Preparation method of ethylene glycol gemini di-sec-octyl phthalate sodium sulfosuccinate

InactiveCN103435519ASimple methodEasy to operateTransportation and packagingSulfonic acids salts preparationAlcoholHydrogen

The invention discloses a preparation method of ethylene glycol gemini di-sec-octyl phthalate sodium sulfosuccinate. The preparation method of ethylene glycol gemini di-n-octyl phthalate sodium sulfosuccinate comprises the following steps: carrying out a mono-esterification reaction for combining maleic anhydride with two hydroxyls on ethylene glycol, so as to generate ethylene glycol di-maleic acid monoester, then carrying out a double-esterification reaction on ethylene glycol di-maleic acid monoester and sec-octyl alcohol to obtain ethylene glycol di-maleic anhydride di-sec-octyl phthalate, and finally carrying out a conjugate addition sulfonation reaction on ethylene glycol di-maleic anhydride di-sec-octyl phthalate and sodium hydrogen sulfite to obtain the ethylene glycol gemini di-sec-octyl phthalate sodium sulfosuccinate product, wherein a catalyst used in the mono-esterification reaction is carbon-based solid acid, and the carbon-based solid acid after the mono-esterification reaction is carried out is directly taken as a catalyst of the double-esterification reaction. The preparation method of ethylene glycol gemini di-sec-octyl phthalate sodium sulfosuccinate is simple, easy to operate and good in environmental protection property.

Owner:NANTONG UNIVERSITY

High-hydroscopicity polyvinyl chloride (PVC) material and preparation method

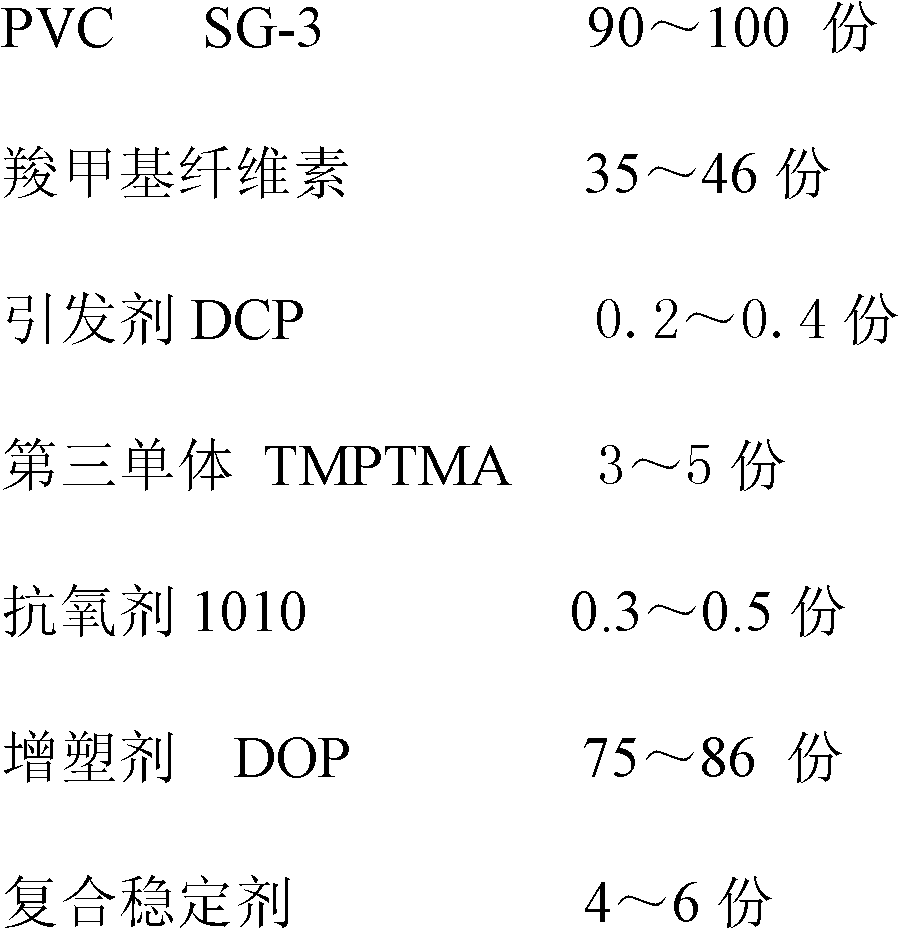

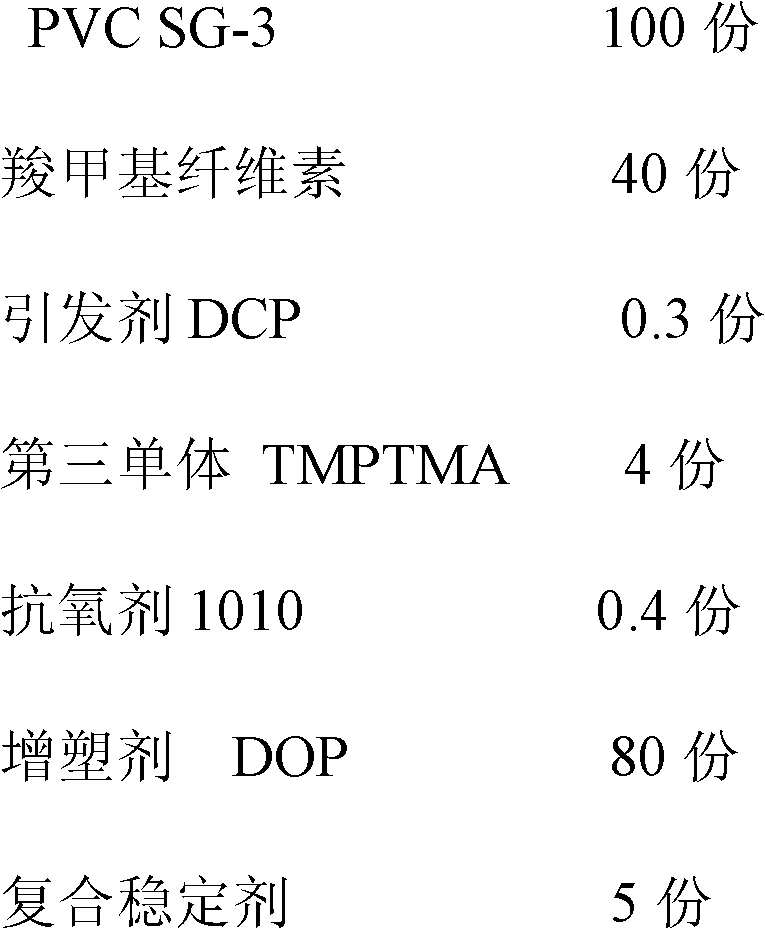

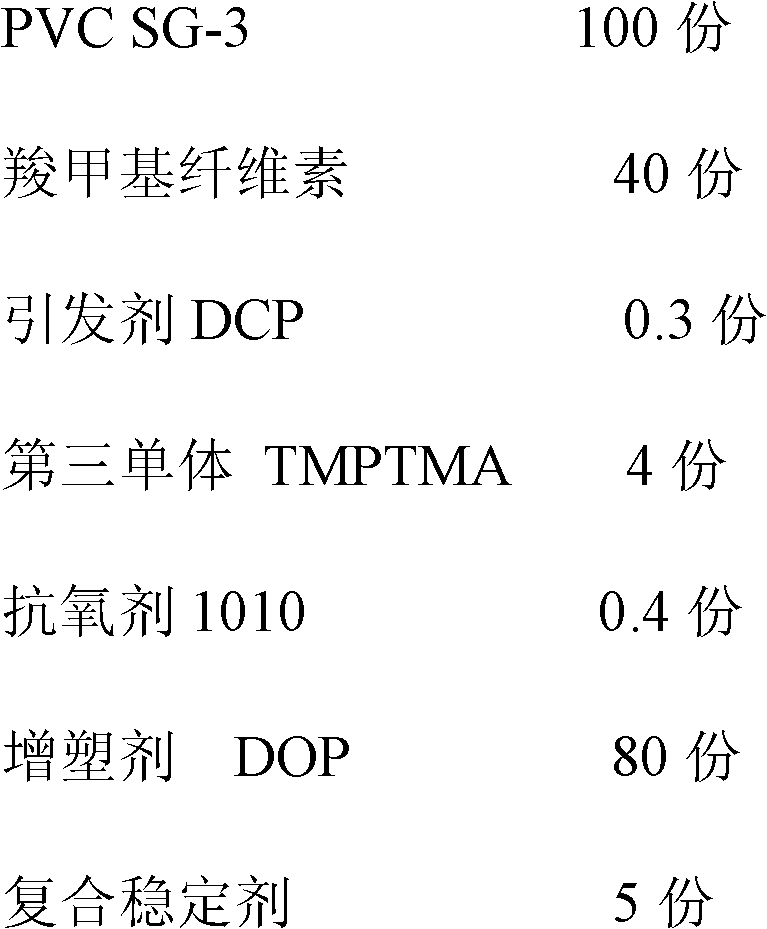

The invention provides a high-hydroscopicity polyvinyl chloride (PVC) material and a preparation method. The material is prepared by the following raw materials according to parts by weight: PVC SG- 3: 90-100, carboxymethylcellulose: 35-46, initiator dibasic calcium phosphate (DCP): 0.2-0.4, a third monomer trimethylopropane trimethacrylate (TMPTMA): 3-5, an antioxygen 1010: 0.3-0.5, a plasticizer Di N octyl phthalate (DOP): 75-86, and a compound stabilizer: 4-6. The preparation method for the PVC granular material includes the following steps: the PVC SG-3, the third monomer TMPTMA, the antioxygen 1010, the plasticizer DOP and the compound stabilizer are placed in a mixer to be mixed until mixed material temperature is 50-56 DEG C, an initiator and carboxymethylcellulose are then added to be mixed and mixing does not stop until mixed material temperature is 90-92 DEG C. Finally, the mixed material is placed in a hopper and extruded and granulated through a double-screw extruder, and the high-hydroscopicity PVC granular material is obtained.

Owner:ZHEJIANG HONGSHENGYUAN CAR ACCESSORIES

Silicone-acrylate low surface energy ocean anti-fouling paint and preparation method thereof

InactiveCN101250378AImprove economyImprove antifouling performanceAntifouling/underwater paintsPaints with biocidesEngineeringSolvent

The invention relates to a silicone-acrylic low surface energy marine anti-fouling paint and the process for preparation, which relates to a marine anti-fouling paint. The invention provides a silicone-acrylic low surface energy marine anti-fouling paint with lower surface energy which can keep environmental protection property, economy and excellent dust-proof effect, can be permanently used, and utilizes a novel multi-component silicone-acrylic block polymer to be base material and the process for preparation. The silicone-acrylic low surface energy marine anti-fouling paint is remixed by base material, pigments, additives and paint solvent, wherein the base material is dimethyl silicone polymer-b-polymethyl methacryate-b-poly butyl methacrylate ternary silicone-acrylic block copolymer, and the additive is methyl silicone oil and di-n-octyl phthalate. Methyl silicone oil and di-n-octyl phthalate are mixed to get coating auxiliary A, dimethyl silicone polymer-b-polymethyl methacryate-b-poly butyl methacrylate ternary silicone-acrylic block copolymer and pigments are mixed to get a mixture B, the coating auxiliary A is added in the mixture B to get a mixture C, and the mixture C is dissolved in solvent solvent to get a mixture D, and products are got after stewing.

Owner:XIAMEN UNIV

Acrylonitrile-butadiene rubber and phenolic resin blended foamed sponge and preparation method thereof

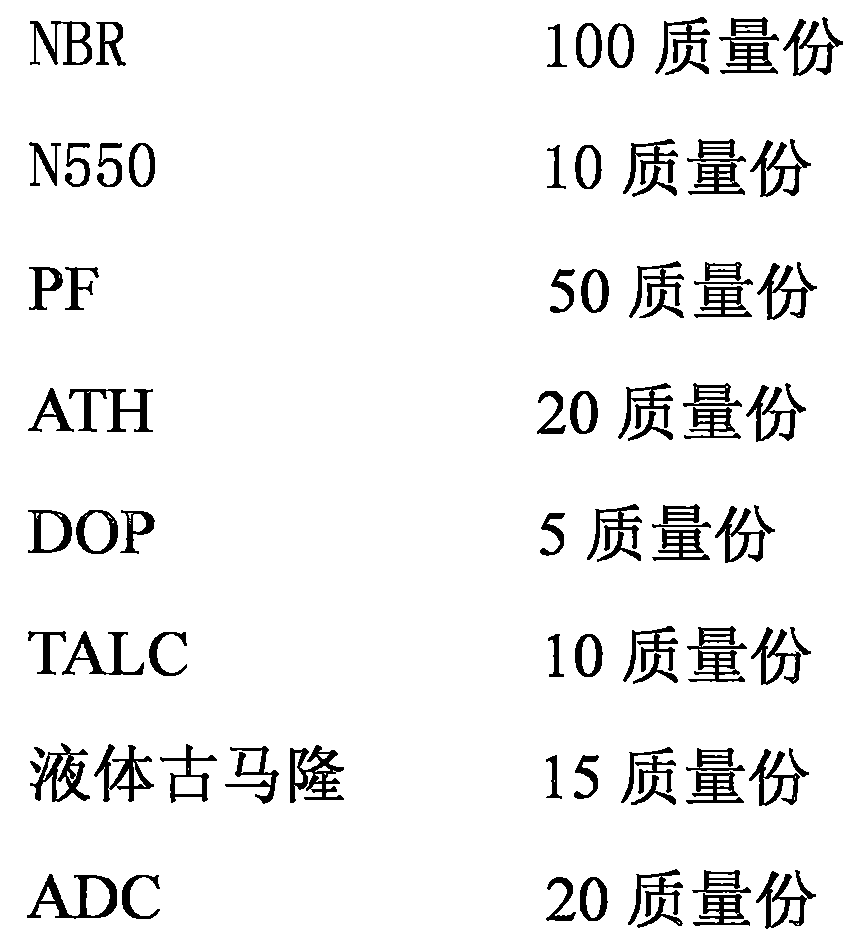

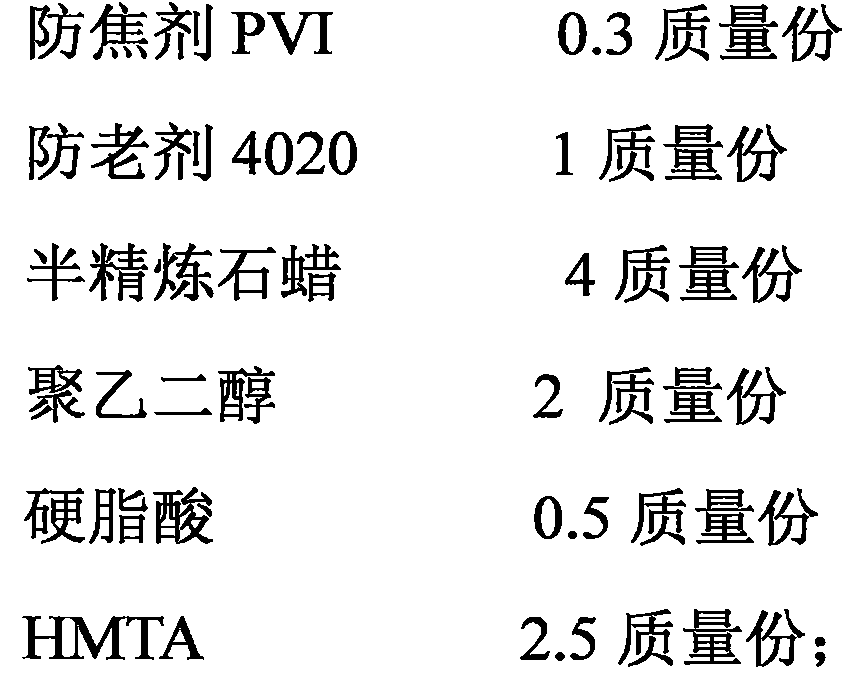

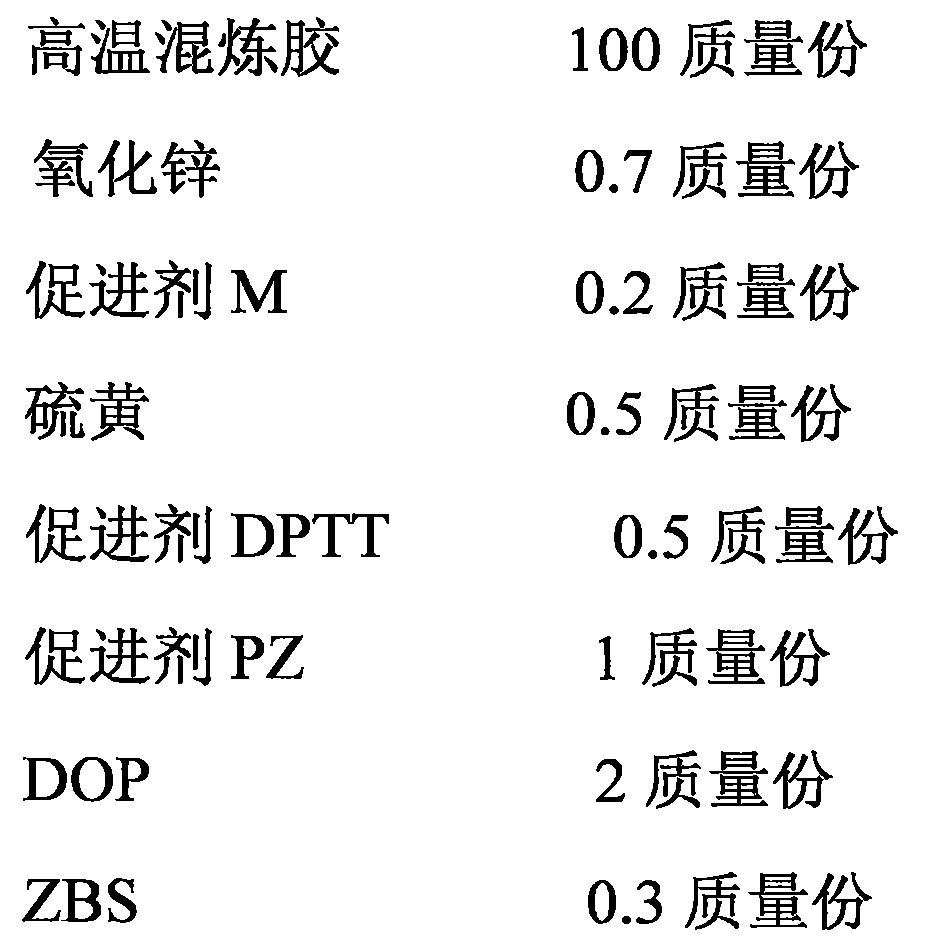

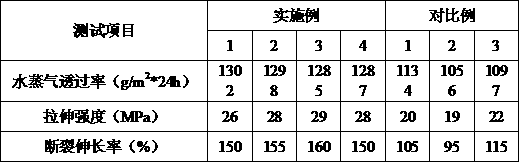

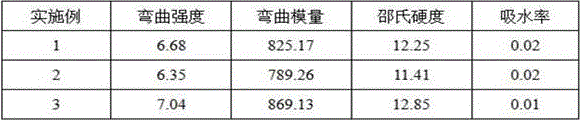

The invention discloses a preparation method for acrylonitrile-butadiene rubber and phenolic resin blended foamed sponge. According to the method, acrylonitrile-butadiene rubber with medium / high acrylonitrile content and linear phenolic resin are blended, and phenolic resin is used to modify acrylonitrile-butadiene rubber; semi-reinforcing carbon black N550 is employed for reinforcing the blended rubber, a plasticizer employs di-n-octyl phthalate and liquid coumarone resin, a curing agent of phenolic resin employs hexamethylene tetramine, a filling agent employs aluminium hydroxide and talcum powder, and thus cost is reduced and the flame resistance of the blended rubber is improved. A sulfuration system employs a sulfur sulfuration system, and a foaming agent employs azodicarbonamide (ADC). A sulfuration and foaming synchronous technology is employed for production.

Owner:陈玉龙

Formula of modified polymethyl methacrylate

InactiveCN103304944AImprove mechanical propertiesImprove toughnessDi-n-octyl phthalateTitanium oxide

The invention discloses a formula of modified polymethyl methacrylate. The formula includes polymethyl methacrylate and additives, wherein the additive include a flexibilizer, an anti-impact modifier, a filling agent, a plasticizer, and a nucleating agent, the flexibilizer is carboxylated nitrile rubber, the anti-impact modifier is polymethyl methacrylate-butadiene-styrene, the filling agent is kaolin, the plasticizer is di-n-octyl phthalate, and the nucleating agent is titanium oxide. The prepared modified polymethyl methacrylate has the effects of being good in mechanical property, large in mechanical strength, good in flexibility and the like.

Owner:常熟市慧丰塑料制品有限公司

Low-hardness polyurethane elastomer material

The invention discloses a low-hardness polyurethane elastomer material which is prepared from the following materials in parts by weight: 1-3 parts of hydroxypropyl methyl cellulose, 2 parts of fatty alcohol-polyoxyethylene ether, 45 parts of diethylene glycol dibenzoate, 2 parts of trimethylolpropane, 180 parts of polyester polyol, 0.2 part of stannous octoate, 8 parts of triisopropanolamine, 7 parts of dibutyl phthalate, 31 parts of butyl benzyl phthalate, 18 parts of dipropylene glycol dibenzoate, 3 parts of glycerol, 68 parts of toluene diisocynate, 0.4 part of tin dibutyl dicaprylate, 11 parts of di-n-octyl phthalate, 5 parts of triethanolamine, 0.3 part of bismuth isocaprylate, 40 parts of filler, 0.1 part of bismuth carboxylate, 23 parts of dimethoxyethyl phthalate, 13 parts of diethyl phthalate, 7 parts of diethanol amine, 2 parts of an organic silicon de-foaming agent, 0.5 part of dibutyltin dilaurate and 4 parts of trimethylol ethane. The low-hardness polyurethane elastomer material disclosed by the invention has good mechanical performance, good solvent resistance and good cutting processing performance.

Owner:CHANGSHU YONGLI CHEM

Flame-retardant polyvinyl chloride friction material and preparation method thereof

InactiveCN106243570ALarge specific surface areaLarge apertureOther chemical processesCarbon nanotubePolyvinyl chloride

The invention discloses a flame-retardant polyvinyl chloride friction material. The flame-retardant polyvinyl chloride friction material is prepared from the following raw materials in parts by weight: 0.3-0.5 part of alkylphenol polyoxyethylene, 3-4 parts of dodecyl mercaptan, 0.7-1 part of alkanolamide, 5-6 parts of multi-walled carbon nanotube, 2-3 parts of ammonium polyphosphate, 5-7 parts of di-n-octyl phthalate, 1-2 parts of magnesium fluoride, 3-5 parts of polyvinylpyrrolidone, 140-170 parts of polyvinyl chloride, 6-8 parts of ethyl orthosilicate, 0.01-0.02 part of 1,3,5-trimethylbenzene, 37-40 parts of melamine, 50-60 parts of 37-40% formalin, 0.2-0.3 part of triethanolamine, 2-3 parts of dialkyl pentasulfide RC2540, 1-2 parts of potassium hexatitanate crystal whisker, 0.3-1 part of titanate coupling agent kt105, 1-2 parts of stearic acid, 0.1-0.2 part of stannous octoate and 1-2 parts of sodium carboxymethyl cellulose. The flame-retardant polyvinyl chloride friction material is high-temperature-resistant and friction-resistant, and has favorable comprehensive properties and high stability.

Owner:来安县隆华摩擦材料有限公司

Preparation method of breathable polytetrafluoroethylene film for fabric

InactiveCN109912909AEnhanced water vapor transmission rateSmooth dischargeUndergarmentsProtective garmentDiacetone alcoholN dimethylformamide

The invention discloses a preparation method of a breathable polytetrafluoroethylene film for fabric. The method comprises the steps as follows: S1, adding N,N-dimethylformamide, ethyl acetate, diacetone alcohol, di-n-octyl phthalate and a silane coupling agent to a reactor, and stirring the mixture uniformly; S2, putting sodium carboxymethylcellulose and nano graphene to the reactor, and performing high-speed dispersion; S3, adding polytetrafluoroethylene resin, fluorine-containing polyacrylate, PEEK (polyether-ether-ketone), hydroquinone and chitosan to the reactor, and performing heating and melting; S4, performing blow molding by a film blowing machine. The prepared polytetrafluoroethylene film has high water vapor permeability and can guarantee waterproof property, discharge water vapor formed by sweat on skin surface smoothly through the fabric, prevent bacterium breeding and make wearing experience more comfortable after being applied to clothes fabric.

Owner:南通东屹高新纤维科技有限公司

Stone-wood-plastic material

InactiveCN106317657AImprove flame retardant performanceHigh smoke suppression effectStarch derivtive adhesivesPlastic materialsAntioxidant

The invention discloses a stone-wood-plastic material which is prepared from heavy calcium carbonate powder, polyhexylene plastic, poplar powder, an adhesive, fatty acid amide, silica gel, a flame retardant, a smoke inhibitor, an aerosol generator, a titanate coupling agent, a PP-g-MAH (polypropylene graft maleic anhydride) compatilizer, a WINGSTAYL antioxidant, a JINHASS regulator, a reinforcer, polyaluminum ferric chloride, di-n-octyl phthalate, potassium stearate and styrene. The stone-wood-plastic material has the advantages of favorable flame-retardant effect, high impact resistance, high toughness and low water absorptivity, obtains excellent flame retardancy on the premise of keeping favorable mechanical properties of the stone-wood-plastic material, is a stone-wood-plastic material with favorable properties, can be widely used for decorating hotels, restaurants and buildings, and has obvious economic and social benefits.

Owner:GUANGXI NANNING ZHICUI SCI TECH CONSULTATION CO LTD

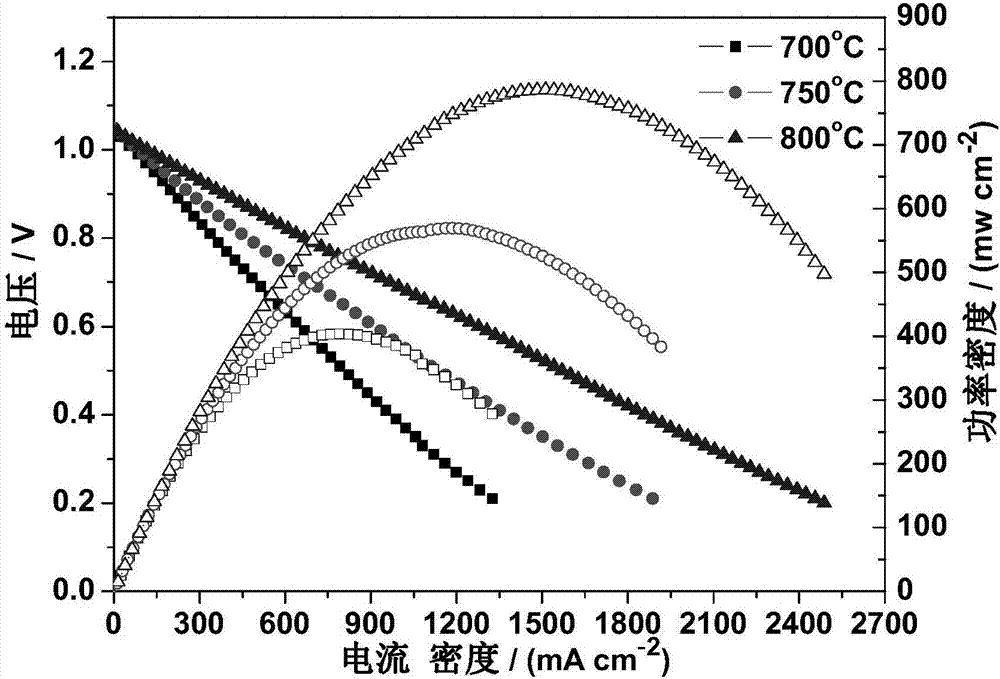

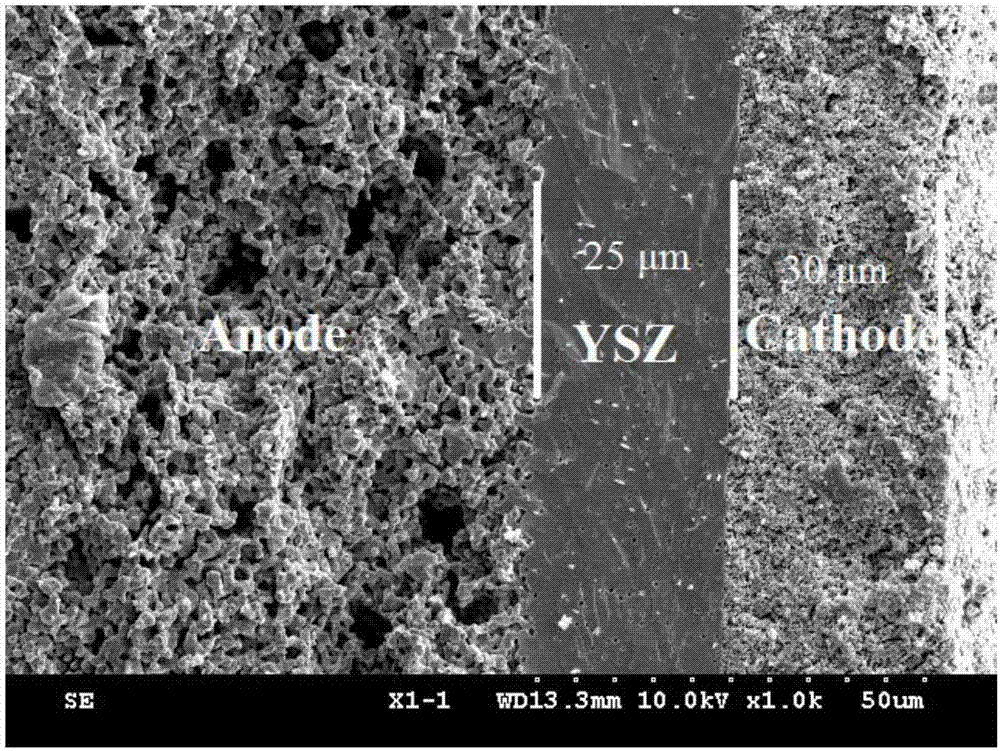

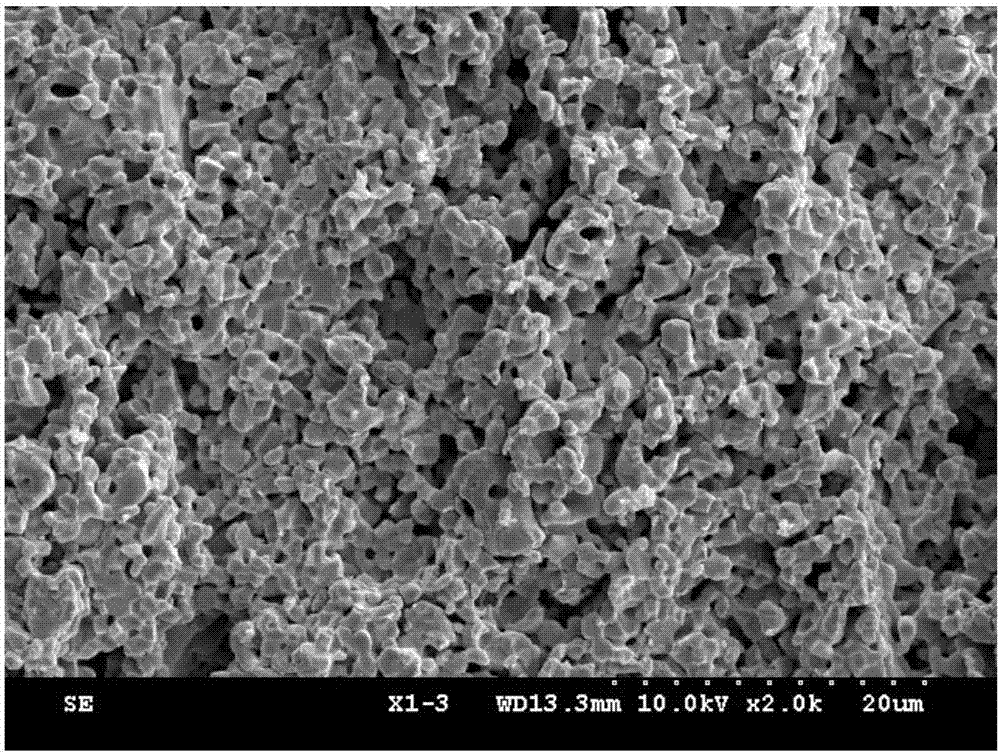

Simple preparation method for anode support of solid oxide fuel cell

InactiveCN107275657AHigh green strengthImprove toughnessFinal product manufactureFuel cellsPolyvinyl butyralPolyethylene glycol

The invention relates to the technical field of preparation of a solid oxide fuel cell and specifically relates to a simple preparation method for an anode support of the solid oxide fuel cell. The method comprises the following steps: 1) preparing a sizing agent: ball-milling and mixing NiO and YSZ at a weight ratio of 1:1, graphite powder and an organic additive for 3-4h, thereby forming a suspending sizing agent, wherein the organic additive includes polyvinyl butyral, triethanolamine, polyethylene glycol, di-n-octyl phthalate and absolute ethyl alcohol and the weight percent ratio of NiO to YSZ to graphite powder to polyvinyl butyral to triethanolamine to polyethylene glycol to di-n-octyl phthalate to absolute ethyl alcohol is (16-18%):(16-18%):(2-4%):(5-8%):(1.5-2%):(3-4%):(3-4%):(45-47%); 2) molding by adopting a scraper: pouring the anode sizing agent onto a glass plate, using the scraper for uniformly and smoothly filling the sizing agent into a glass carrier area between the adhesive tapes and molding; and 3) sintering under a high temperature. The method has the advantages of fast molding, simple and convenient operation, capability of realizing small scale production, and the like.

Owner:云南探源者科技股份有限公司

Functional wallpaper material capable of purifying air

InactiveCN101333788BEliminate formaldehydeEliminate odorNon-fibrous pulp additionSpecial paperIndoor air qualityPolyvinyl chloride

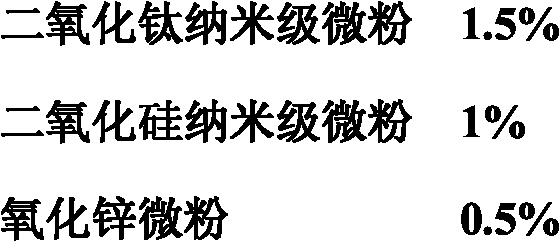

Disclosed is a functional type wallpaper material having the air purification function, belonging to the interior decoration material technique field, and containing the components, in weight percentage: 2.5 percent of titanium dioxide nano-sized powder, 2.5 percent of silicon dioxide nano-sized powder, 1.5 percent of zinc oxide powder, 3.5 percent of negative ion powder, 1.5 percent of inorganic antibacterial powder, 1 percent of iron trioxide, 6 percent of conductive powder, 5 percent of polyaniline, 31 percent of polyvinyl chloride, 5.5 percent of dioctyl phthalate, 18.5 percent of di-n-octyl phthalate dioctyl phthalate, 18 percent of calcium carbonate, and 3.5 percent of auxiliary agent. The wallpaper prepared by the materials can remove formaldehyde and peculiar smell, and is antibacterial and mildew-proof, and can release negative ions and resist electromagnetic radiation, as well as greatly improving the indoor air quality for people and solving the indoor air pollution.

Owner:SHANGHAI JIAO TONG UNIV +1

Plastic handle material for automobile door and preparation method of same

The invention discloses a plastic handle material for an automobile door, which is prepared from, by weight, 25-30 parts of polystyrene, 45-55 parts of phenolic resin, 8-10 parts of polymethacrylate, 7-11 parts of polyphenylene thioether, 12-16 parts of tetraphenyl tin, 22-25 parts of abietic acid, 8-10 parts of nano aluminum oxide, 14-18 parts of polyamide, 11-18 parts of polyvinyl formal fiber, 4-9 parts of di-n-octyl phthalate, 6-8 parts of diisodecyl phthalate, 7-11 parts of alkylphenol ethoxylates, 3-7 parts of talcum powder, 16-20 parts of barium sulfate, 5-7 parts of mica powder, 22-25 parts of carbon black, 4-9 parts of zinc borate, 3-9 parts of calcium silicate hydrate, 12-17 parts of nano molybdenum disulfide, 3-5 parts of zirconium oxide, 14-16 parts of triethylene tetramine, and 21-26 parts of boron nitride. The plastic handle material has high wear resistance, is anti-aging, is high in structural strength, is free of surface electroplating treatment and can be applied directly, thereby reducing processing steps and reducing cost.

Owner:芜湖天鸿汽车零部件有限公司

Conductive antistatic light-aging-resistant cable material and preparation method thereof

InactiveCN105061936AImprove conductivityTimely guidancePlastic/resin/waxes insulatorsBenzoyl peroxideSodium phosphates

The invention discloses a conductive antistatic light-aging-resistant cable material which is characterized by being prepared from the following raw materials in parts by weight: 13-15 parts of carbon nanotubes, 0.02-0.04 part of benzoyl peroxide, 12-14 parts of ethyl acrylate, 1-1.5 parts of a titanate coupling agent TC-101, 5-6 parts of melamine sodium phosphate, 68-70 parts of PVC resin, 2-4 parts of rosin, 10-12 parts of conductive carbon black, 1-2 parts of magnesium stearate, 8.5-10 parts of dioctyl phthalate, 1-2 parts of an ultraviolet light absorber 3030, and 7-9 parts of an auxiliary agent. With addition of the carbon nanotubes and conductive carbon black, the cable material has excellent electrical conductivity, thereby timely dredging revealed surface static electricity and avoiding potential safety hazard; with addition of the auxiliary agent, the lubricity and processing liquidity of the product are increased, and the glossiness of the product is improved; and with addition of the ultraviolet light absorber 3030, the anti-UV-light ability is increased, the light aging resistance is good, and the service life is prolonged.

Owner:安徽电信器材贸易工业有限责任公司

Sterile rubber foot cover for surgery

The invention discloses a sterile rubber foot cover for surgery. The foot cover is prepared from, by weight, 30-40 parts of silicone rubber, 25-40 parts of epichlorohydrin rubber, 5-13 parts of stearic acid, 10-15 parts of paroline, 1-6 parts of titanium dioxide, 3-12 parts of anti-ageing agent, 1-10 parts of accelerant, 2-9 parts of di-n-octyl phthalate, 5-10 parts of carbon black, 5-10 parts ofzinc oxide, 0.25-0.75 part of polyethylene glycol PEG4000, 1-5 parts of coagent and 1-5 parts of plasticizer. The foot cover is simple in formula, diversified in function, not prone to bacteria breeding and low in cost, the raw materials are diversified, the service life of the rubber foot cover can be effectively prolonged, various mechanical indexes are all excellent, and the current use requirements are met.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

Rubber sheath rubber matrix

The invention discloses a rubber sheath rubber matrix, relating to the technical field of sealing materials. The rubber sheath rubber matrix is prepared from the following raw materials in parts by weight: 30-40 parts of silicon rubber, 25-40 parts of epichlorohydrin rubber, 5-13 parts of stearic acid, 10-15 parts of paraffin oil, 1-6 parts of nano titanium dioxide, 3-12 parts of anti-aging agent, 1-10 parts of accelerator, 2-9 parts of di-n-octyl phthalate and 5-10 parts of carbon black. The rubber sheath rubber matrix uses the silicon rubber and epichlorohydrin rubber as the base raw materials and uses the stearic acid, paraffin oil, nano titanium dioxide, anti-aging agent and other assistants as the auxiliary materials; and the rubber sheath rubber matrix product has the advantages of low production cost, favorable elasticity, favorable aging resistance, favorable oil resistance, favorable bonding property and longer service life.

Owner:南京中配橡塑制品有限公司

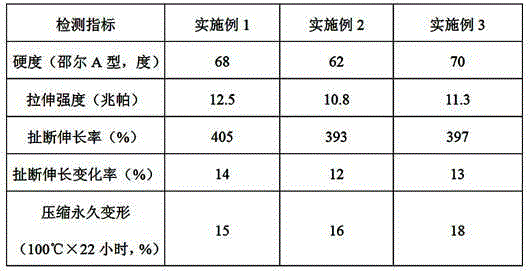

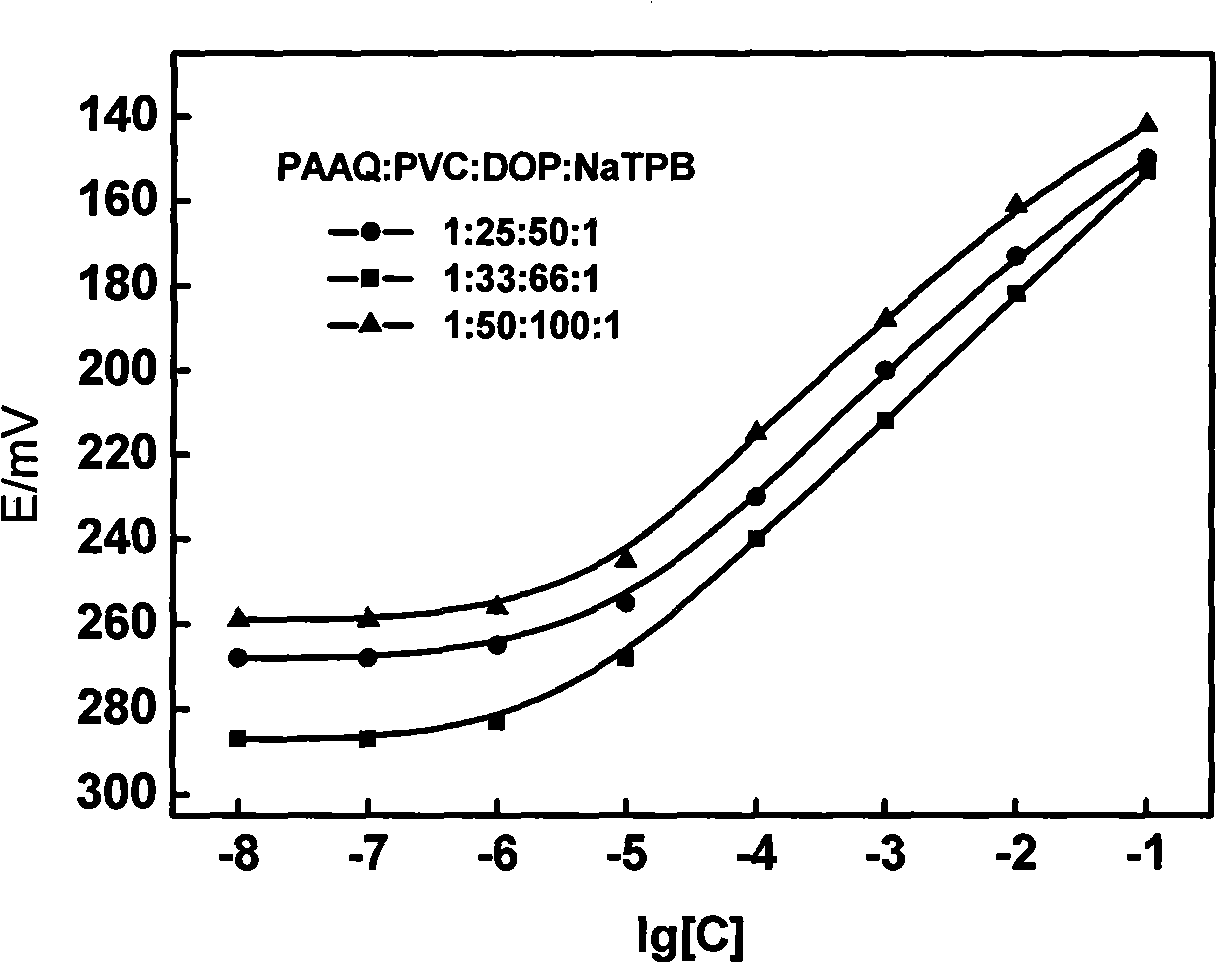

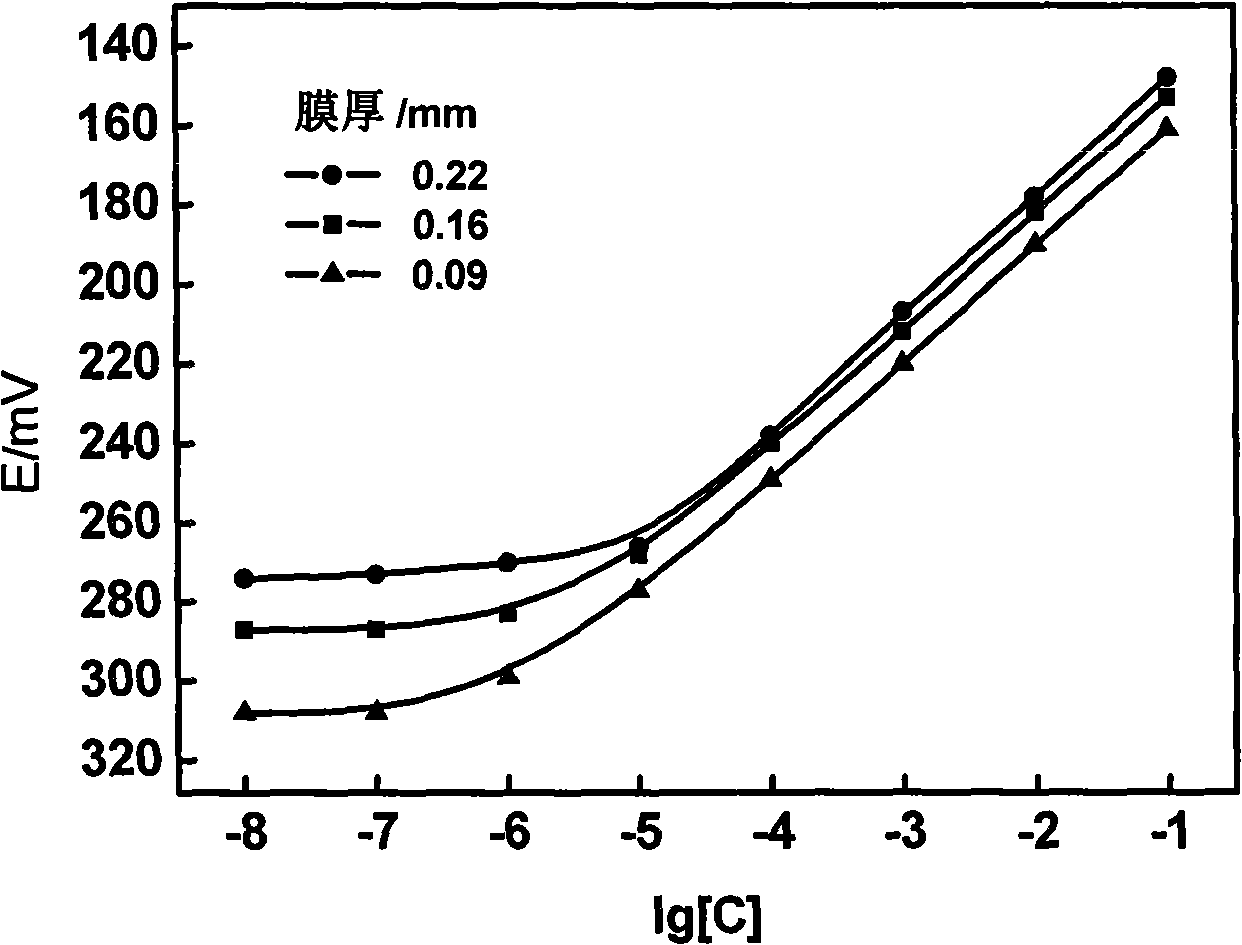

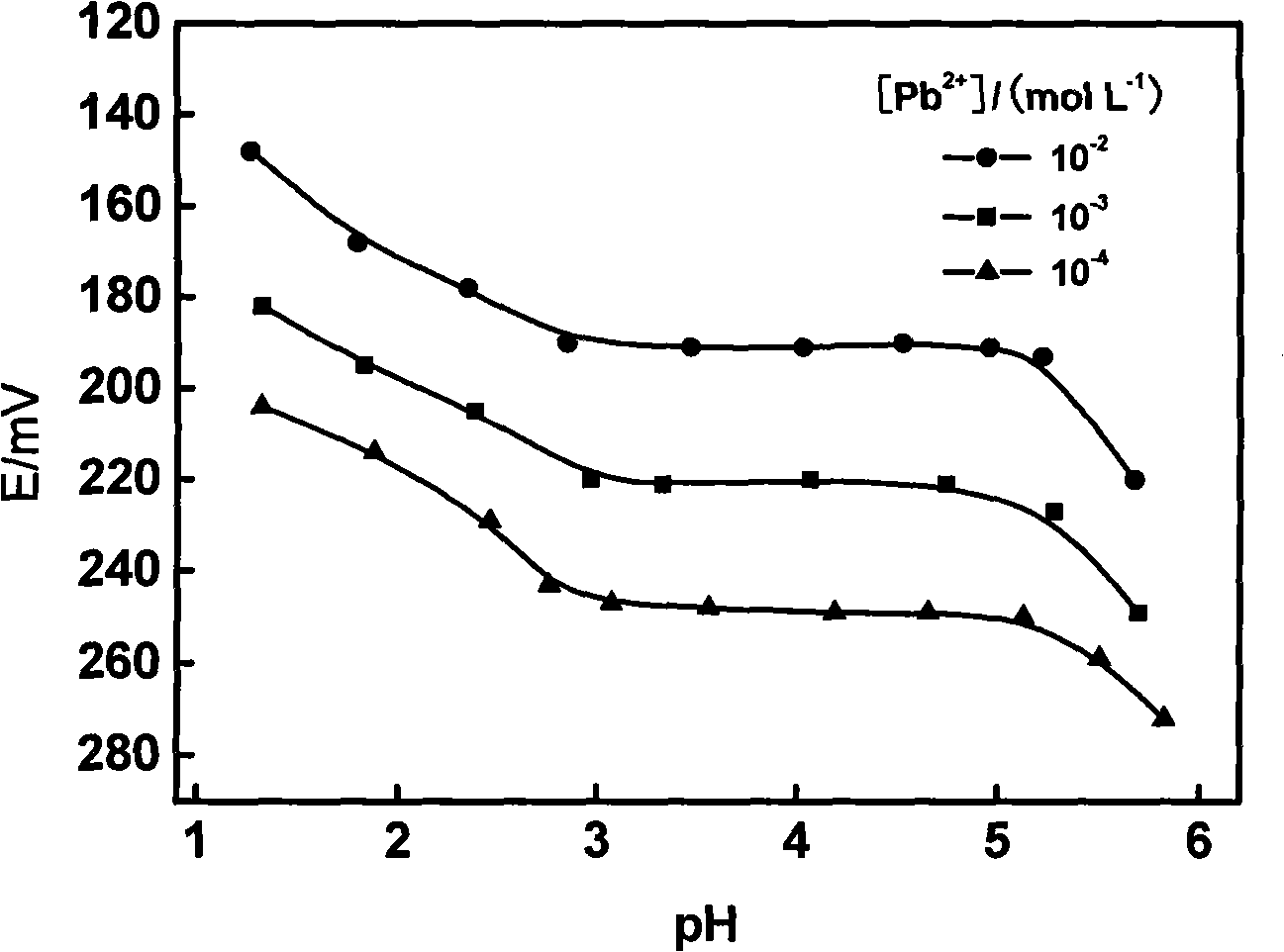

Lead ion selective electrode film using poly-1-aminoanthraquinone as carrier, its preparation method and uses thereof

InactiveCN101308113ALow costHigh yieldMaterial analysis by electric/magnetic meansAnthraquinonesPhysical chemistry

The invention discloses a membrane used for a lead ion selective electrode and taking a poly 1-aminoanthraquinone as a carrier, which is characterized in that: the membrane comprises poly 1-aminoanthraquinone, polyvinyl chloride and di-n-octyl phthalate. The invention also discloses a process for preparing the membrane used for the lead ion selective electrode and taking the poly 1-aminoanthraquinone as the carrier as well as purposes thereof.

Owner:TONGJI UNIV

High-strength impact-resistance acrylate adhesive and preparation method thereof

ActiveCN105482747AImprove impact resistanceImprove fatigue resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceCarvacryl acetate

The invention discloses high-strength impact-resistance acrylate adhesive and a preparation method thereof. The high-strength impact-resistance acrylate adhesive is prepared from raw materials of methyl methacrylate, tetrahydrofuran metacrylic acid ester, polyoxytertramethylene glycol, diphenyl-methane-diisocyanate, cumene hydroperoxide, 2,6-di-tert-butyl-p-cresol, tetramethylthiourea, butadiene-acrylonitrile rubber, diethylaminoethanol, isophorone diamine, di-n-octyl phthalate, hydrogenated rosin resin, ethylene vinyl-acetate copolymer, lead sulfate tribasic, polyacrylic acid, nano-calcium titanate and the like. According to the high-strength impact-resistance acrylate adhesive and the preparation method thereof, provided by the invention, a flexibilizer, namely the butadiene-acrylonitrile rubber and chlorinated polyethylene are modified, so that the impact resistance and fatigue resistance of an adhesive layer are greatly strengthened, filler such as fumed silica is added so as to reduce the shrinking percentage of a curing process and improve impact-resistant toughness and other mechanical strength of the adhesive layer, and can form a hydrogen bond chain-bridged effect by being dispersed into the adhesive to generate a reversible three-dimensional network structure, so that the adhesive is endowed with the optimum flowing deformation effect.

Owner:JIANGSU AOTIANLI NEW MATERIAL CO LTD

Hot melt type strippable protective material and preparation method thereof

InactiveCN105482694AImprove performanceGood chemical resistanceAntifouling/underwater paintsPaints with biocidesParaffin waxPhosphate

The invention relates to a hot melt type strippable protective material and a preparation method thereof. The material is composed of a component A and a component B at a weight ratio of (3-5) to 1, wherein the component A comprises the following components in parts by weight: 3-5 parts of titanium dioxide, 5-7 parts of di-n-octyl phthalate, 3-5 parts of castor oil and 5-7 parts of malic anhydride resin; and the component B comprises the following components in parts by weight: 14-18 parts of cellaburate, 24-28 parts of mineral oil, 24-28 parts of di-n-octyl phthalate, 8-10 parts of triorthocresol phosphate, 1-2 parts of anhydrous lanolin, 1-2 parts of solid paraffin wax and 1-2 parts of octyl phenol. The hot melt type strippable protective material is readily available in raw materials, wide in market prospect and simple in preparation method; the coating obtained by the material has acid resistance, base resistance, aging resistance and excellent corrosion resistance; the material has strong applicability and can be used for protection of the surface of the structural component; and the material can be stripped at normal temperature, and the stripped material can be recycled, thereby realizing energy-saving, environment-friendly, and pollution-free effects.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com