Stone-wood-plastic material

A wood-plastic material and plastic technology, applied in the direction of adhesive types, starch-derived adhesives, etc., can solve the problems of poor mechanical properties of composite materials, deterioration of mechanical properties of wood-plastic composite materials by flame retardants, etc., and achieve flame retardant effect. Good, significant economic and social benefits, excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

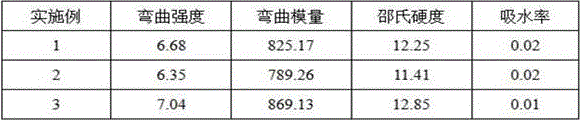

Examples

preparation example Construction

[0037] The preparation method of the stone-wood-plastic material comprises the following steps:

[0038] S1: preparing an adhesive, a preparation method thereof, comprising the following steps:

[0039] S11: the preparation concentration is 20-30Be ', the cassava starch slurry A that pH value is 3.4-3.7;

[0040] S12: Add triglycerides, percarbamide, 2,5-dimethyl-2,5-bis(benzoylperoxy)-hexane with a concentration of 2%-4% to the tapioca starch slurry A in step S11 alkane, nickel catalyst, and then at a temperature of 50-58°C and a stirring speed of 100-150r / min, carry out cross-linking and grafting reaction for 2-2.5h to prepare slurry B;

[0041] S13: Add potassium hydroxide to the slurry B in step S12, adjust the pH value to 9.3-9.7, then add epichlorohydrin, urea, azobisisobutyric acid (ethylene glycol acrylate), citric acid ester, Polypropylene rubber, propyltrimethoxysilane, and then conduct a crosslinking reaction at a temperature of 60-64°C and a stirring speed of 100-1...

Embodiment 1

[0050] A stone-wood-plastic material, in parts by weight, comprising the following raw materials: 90 parts of heavy calcium powder, 50 parts of polyhexene plastic, 25 parts of poplar wood powder, 12 parts of adhesive, 0.9 part of fatty acid amide, and 0.8 part of silica gel , 0.7 parts of flame retardant, 0.7 parts of smoke suppressant, 0.4 part of aerosol generator, 0.6 part of titanate coupling agent, 0.5 part of PP-g-MAH compatibilizer, 0.4 part of WINGSTAYL antioxidant, 0.5 part of JINHASS regulator 0.6 part, 0.6 part of strengthening agent, 0.8 part of polyaluminum ferric chloride, 0.7 part of di-n-octyl phthalate, 0.3 part of potassium stearate, 0.2 part of styrene;

[0051] The flame retardant includes the following raw materials in parts by weight: 7 parts of antimony trioxide, 4 parts of vinyltriethoxysilane, 3.5 parts of triethyl phosphate, 6 parts of magnesium chloride, 3 parts of phenolic resin, 0.8 parts of bentonite share;

[0052] The smoke suppressant includes...

Embodiment 2

[0066] A kind of stone-wood-plastic material, in parts by weight, comprising the following raw materials: 82 parts of heavy calcium powder, 42 parts of polyhexene plastic, 21 parts of poplar wood powder, 8 parts of adhesive, 0.6 part of fatty acid amide, and 0.6 part of silica gel , 0.6 parts of flame retardant, 0.5 parts of smoke suppressant, 0.4 parts of aerosol generating agent, 0.6 parts of titanate coupling agent, 0.3 parts of PP-g-MAH compatibilizer, 0.2 parts of WINGSTAYL antioxidant, 0.3 parts of JINHASS regulator 0.3 part of strengthening agent, 0.6 part of polyaluminum ferric chloride, 0.5 part of di-n-octyl phthalate, 0.2 part of potassium stearate, 0.2 part of styrene;

[0067] The flame retardant includes the following raw materials in parts by weight: 5 parts of antimony trioxide, 3 parts of vinyltriethoxysilane, 3 parts of triethyl phosphate, 5 parts of magnesium chloride, 2 parts of phenolic resin, 0.6 parts of bentonite share;

[0068] The smoke suppressant i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com