Patents

Literature

505results about How to "High smoke suppression effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-hardness wood-plastic building template and preparation method thereof

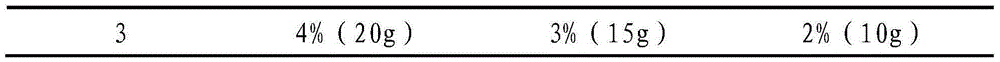

The invention relates to a high-hardness wood-plastic building template and a preparation method thereof, which belong to the technical field of polyvinyl chloride plates. The 100 parts by weight of high-hardness wood-plastic building template comprises the following raw materials in parts by weight: 20-50 parts of polyvinyl chloride resin powder, 1-4 parts of a coupling agent, 2-5 parts of a stabilizing agent, 1-15 parts of an acrylic alkyl ester processing modifier; 1-15 parts of a filling agent, 1-4 parts of a lubricant, 1-4 parts of a foaming agent, 1-8 parts of a toughening agent, 30-50 parts of wood flour, and 5-10 parts of a reinforcing agent. According to the invention, the plate stacking density is less than or equal to 700 kg / m<3>, so that the building template is good in flame retardancy and smoke suppression, meanwhile, the building template is high in hardness and strong in wood texture; and just like raw woods, the building template also has the properties that the template can be nailed, drilled, planed and adhered and the like, the surface of the template is smooth and fine, and the template is water-proof, corrosion-resistant, fireproof, mould-proof, moth-preventing, and pollution-free.

Owner:SHANDONG BODO PLASTICS CO LTD

Silicone hydride crosslinked non-halogen flame-proof smoke-restraining polyvinyl chloride cable material and manufacturing process thereof

InactiveCN101319079AEasy to processPromote degradationInsulated cablesInsulated conductorsPolyvinyl chlorideFire retardant

The invention discloses a silane crosslinking HFFR flame retardant polyvinyl chloride cable material and a preparation technique thereof. The compositions by weight portion of the cable material are: 100 portions of polyvinyl chloride resin, 10 to 100 portions of a plasticizer, 0.5 to 10 portions of a silane cross-linking agent, 0.5 to 6 portions of a heat stabilizer, 30 to 100 portions of a metal hydroxide flame retardant, 1 to 10 portions of a metallic compound flame retardant synergist, 0.1 to 5 portions of a preventing cross-linking agent, 0.1 to 5 portions of a lubricant, 0.1 to 0.5 portion of an antioxidizer, 0.05 to 0.1 portion of dibutyl tin dilaurate and appropriate amount of a colorant. The cable material has the characteristics that the mechanical property is good, the mechanical intensity is increased by 20 to 30 percent compared with the uncrosslinked PVC cable material, the heat resistance is good, the electrical property is good, the specific volume resistance is increased by 3 to 5 times compared with the uncrosslinked PVC cable material, the insulating property of the cable is improved and the aging property is good.

Owner:LIAOCHENG UNIV

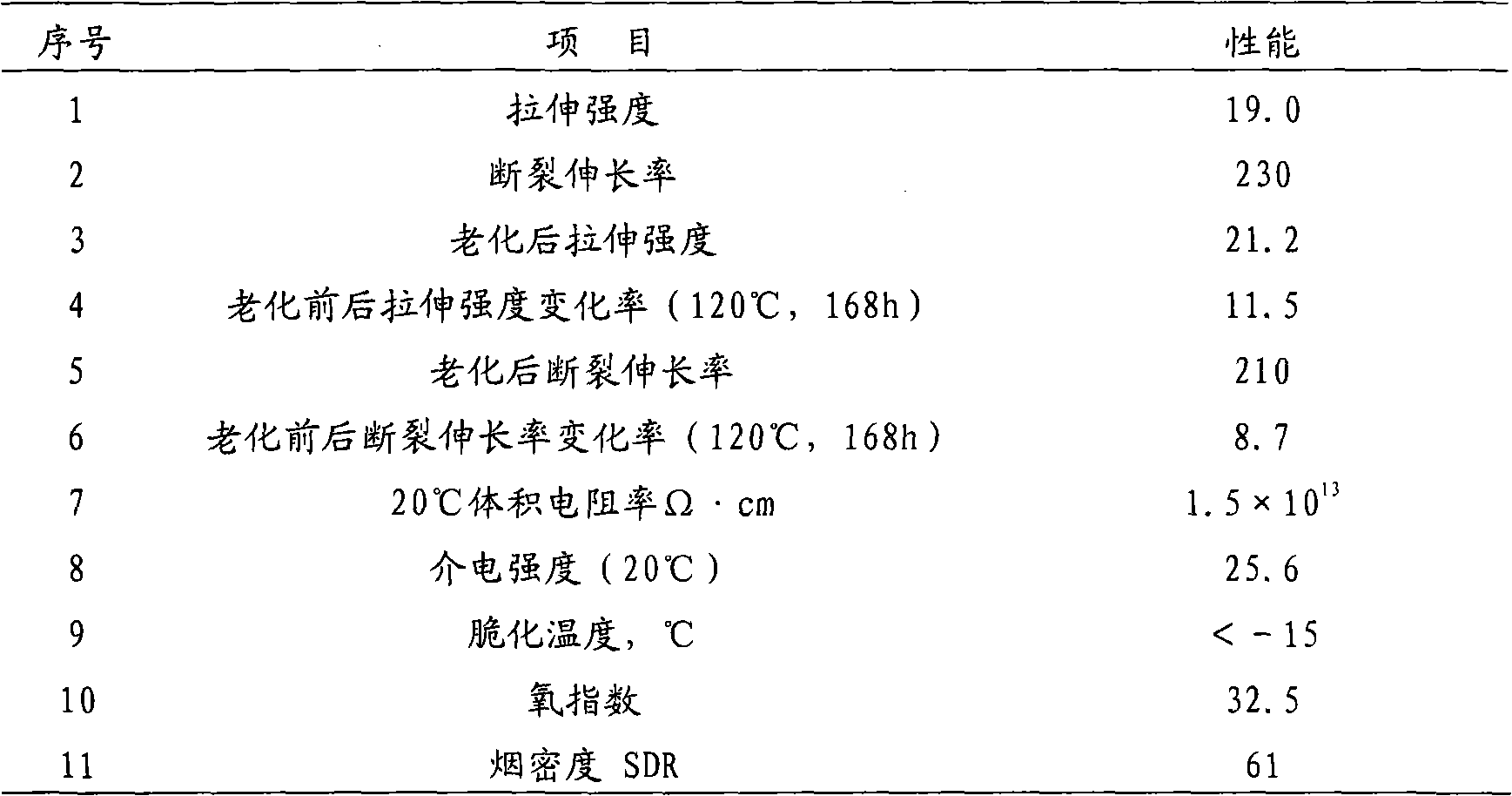

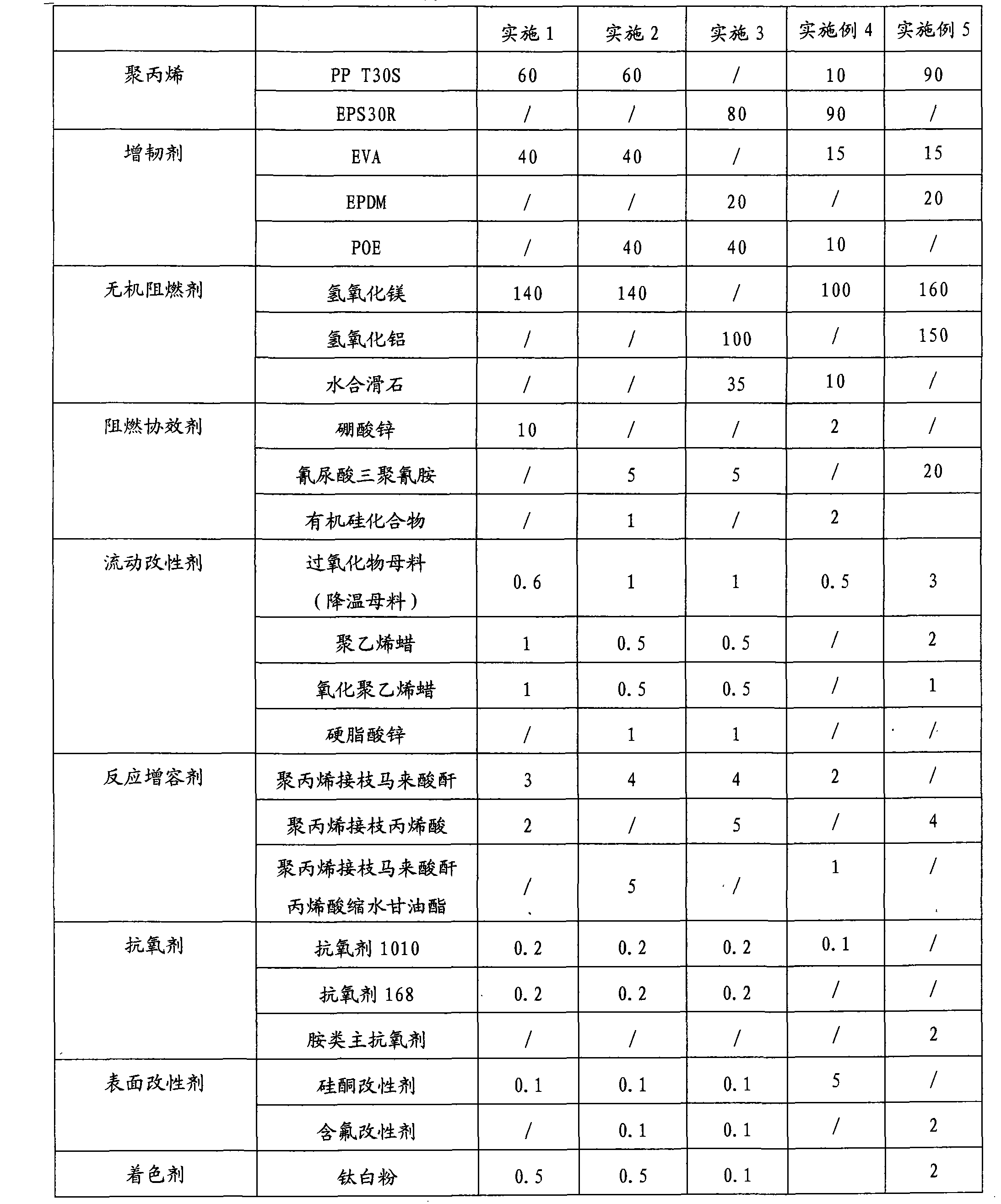

High tenacity low smoke zero halogen flame retardant polypropylene and preparation method thereof

The invention discloses a high tenacity low smoke zero halogen flame retardant polypropylene and a preparation method thereof and the polypropylene comprises the following components according to the parts by weight; 10-90 parts of polypropylene, 10-90 parts of flexibilizer, 100-160 parts of inorganic flame retardant, 2-20 parts of flame-retardant synergist, 2-5 parts of reactive compatibilizer, 0.1-2 parts of antioxidant, 0.5-5 parts of flow modifier, 0.1-5 parts of surface modifier and a defined amount of coloring agent. The low smoke zero halogen flame retardant polypropylene has the advantage of good mechanical properties, good flame resistance (the vertical flame test of the polypropylene passes UL94V-0 level), low smoke density which is not more than 20%, good aging resistance and low cost, and can meet the processing demands for injection and extrusion molding.

Owner:内蒙古睿达鑫科技有限责任公司

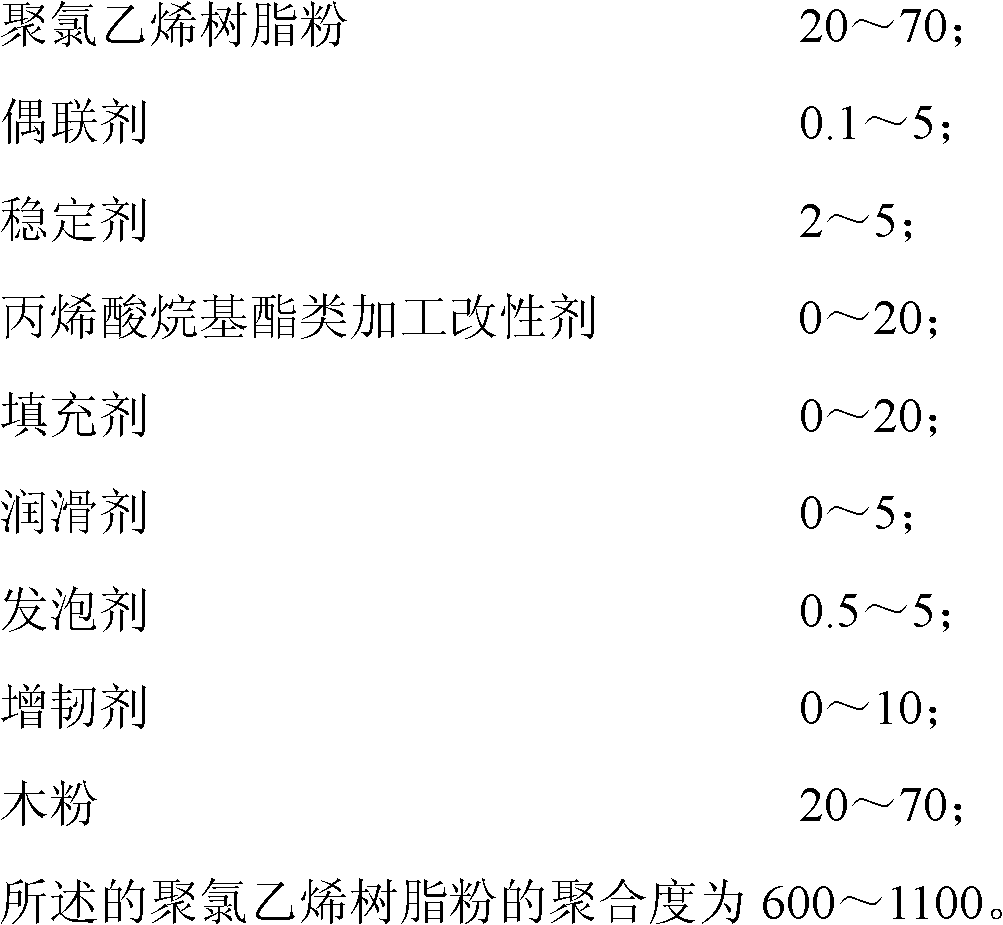

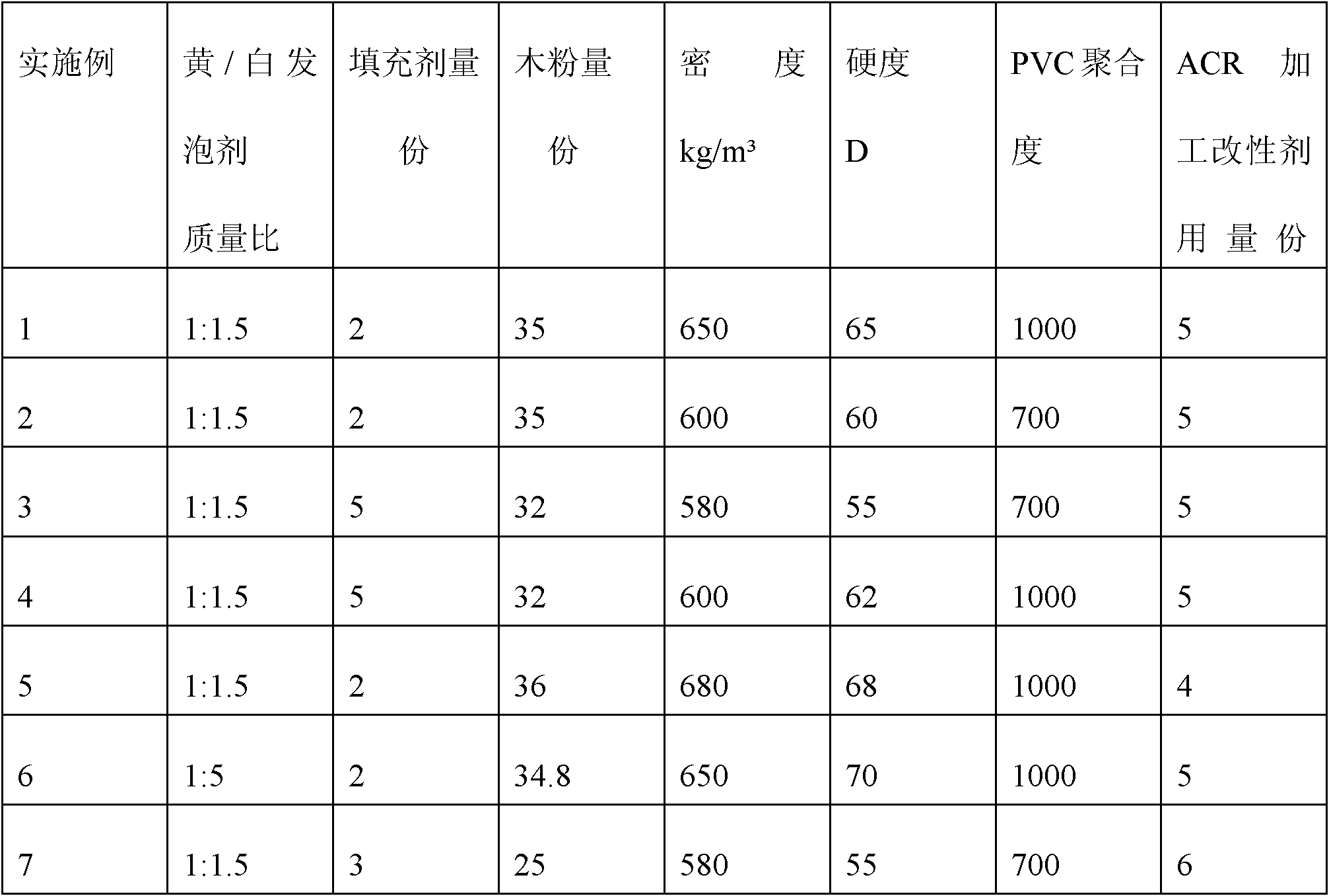

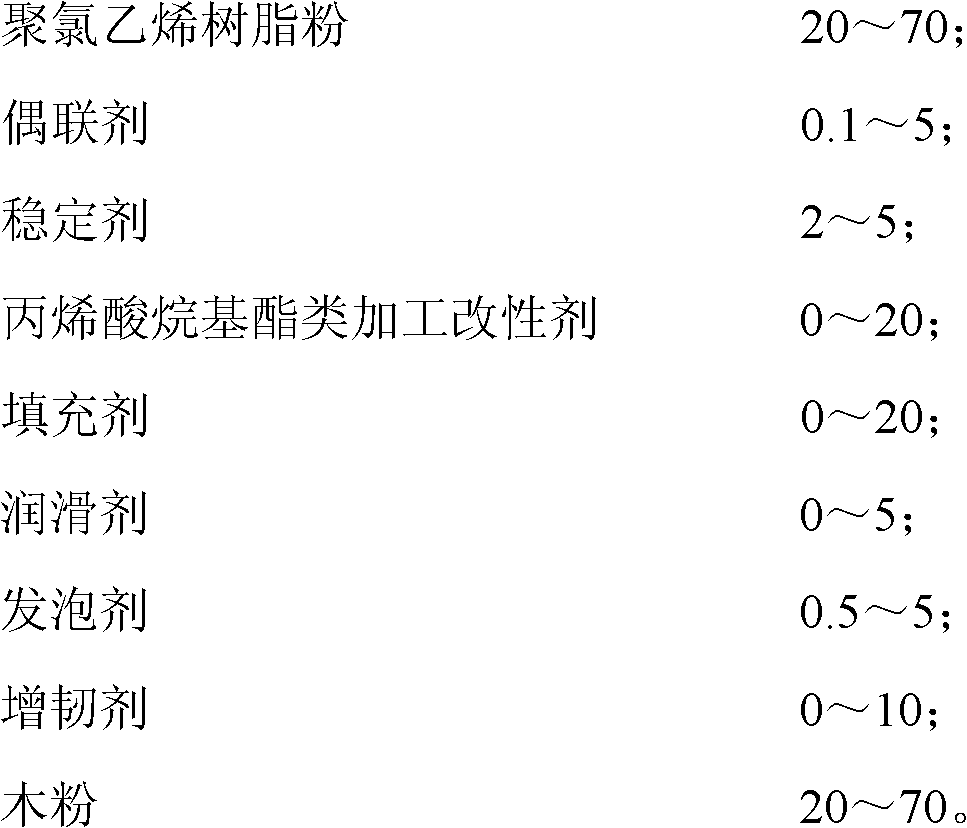

Polyvinyl chloride (PVC) wood-plastic board and preparation method thereof

ActiveCN102492242AImprove flame retardant performanceHigh smoke suppression effectPolyvinyl chlorideToughening

The invention relates to a polyvinyl chloride (PVC) wood-plastic board and a preparation method thereof, belonging to the technical field of PVC boards. The PVC wood-plastic board is composed of the following raw materials in parts by weight: 20-70 parts of PVC resin powder, 0.1-5 parts of coupling agent, 2-5 parts of stabilizer, 0-20 parts of alkyl acrylate processing modifying agent, 0-20 parts of filling agent, 0-5 parts of lubricant, 0.5-5 parts of foaming agent, 0-10 parts of toughening agent and 20-70 parts of wood flour, wherein the total weight parts of the raw materials are 100 parts. The PVC wood-plastic board has the bulk density being not more than 700kg / m<3>, and has good flame resistance and smoke suppression property, high hardness and strong wood feeling; and the same as log, the PVC wood-plastic board has the properties of being nailed, drilled, planed, stuck and the like, is smooth and fine in surface, is waterproof, corrosion-resistant, fireproof and mildewproof, is not eaten by worms and is pollution-free.

Owner:SHANDONG BODO PLASTICS CO LTD

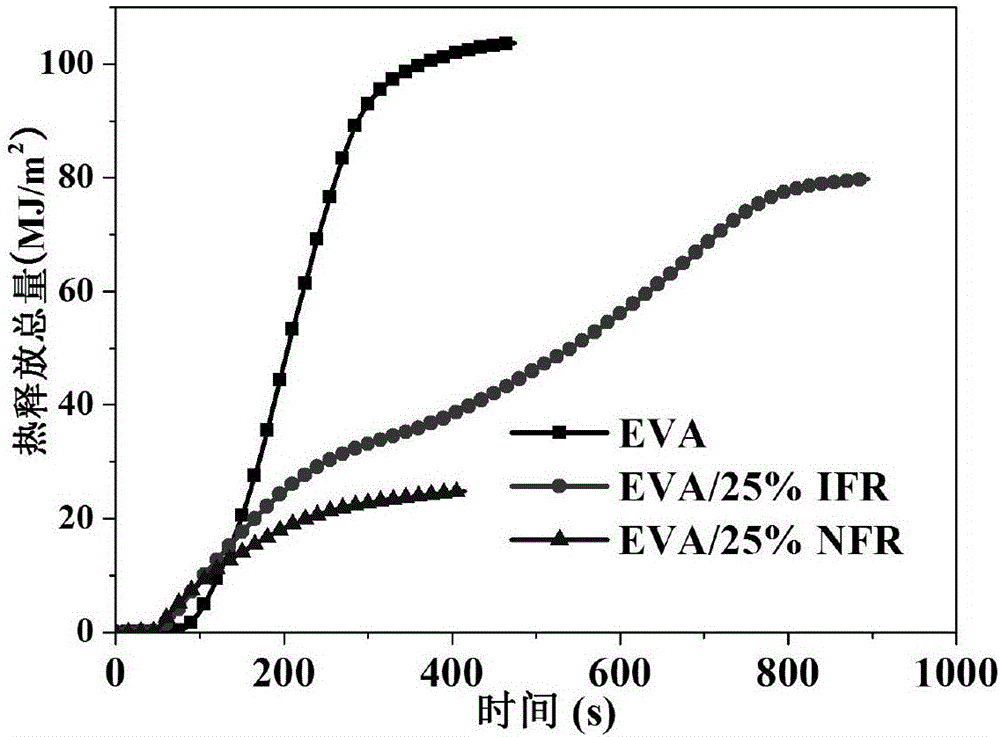

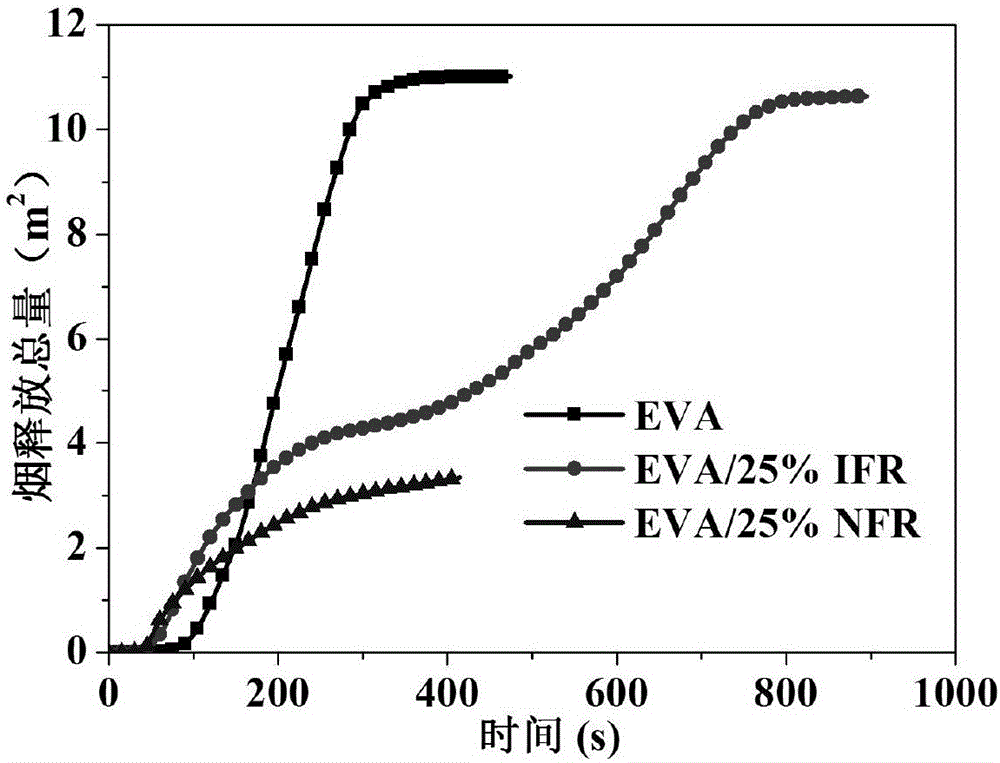

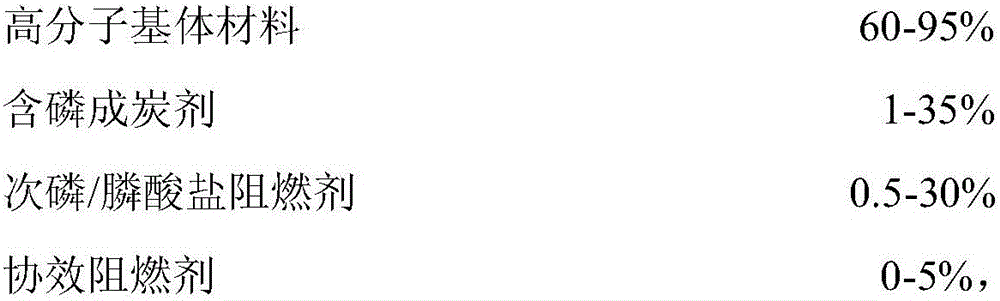

Flame-retardant high polymer material based on compounding of phosphorus containing char-forming agents and hypophosphite/phosphonate

ActiveCN106496729AHigh flame retardant efficiencyGood char formationPolymer scienceLimiting oxygen index

The invention discloses a flame-retardant high polymer material based on compounding of phosphorus containing char-forming agents and hypophosphite / phosphonate. The flame-retardant high polymer material is formed by blending, in weight percentage, 60-95% of high polymer base materials, 1-35% of phosphorus containing char-forming agents, 0.5-30% of hypophosphite / phosphonate and 0-5% of synergistic flame retardants. The compound main flame retardants used in the material have double char-forming functions, the material has excellent flame-retardant and smoke suppression properties, limit oxygen index reaches up to 27.0-49.5%, vertical burning test level ranges from UL-94V-1 to V-0, the total heat release of the material in cone calorimeter is reduced by 48.2-90.5% as compared with that of a pure base material, and total smoke release is reduced by 41.6-88.5%. Besides, the flame retardants used in the flame-retardant high polymer material have excellent water resistance, so that the material also has excellent water resistance, after the material is soaked in 70 DEG C for 168 hours and then dried, the vertical burning test level is unchanged, and the oxygen index is only reduced by 0-0.5%.

Owner:SICHUAN UNIV

Xylem filber-polyvinyl chloride composite material and method for producing the same

A wood fiber-polyvinyl chloride composite material and a preparation method thereof, which relate to a composite material and a preparation method thereof. It solves the problem that the wood fiber-polyvinyl chloride composite material has high flammability and produces a large amount of black smoke and toxic gas when burned. The wood fiber-polyvinyl chloride composite material is mainly composed of 100-600 parts of polyvinyl chloride resin, 30-700 parts of wood fiber material, 3-145 parts of intumescent flame retardant, 1-55 parts of copper oxide, 6 ~75 parts of heat stabilizer, 4~60 parts of plasticizer and 4~65 parts of compatibilizer. Preparation method: 1. premixed material; 2. extrusion molding. According to the GB / T8924-2005 standard test of the wood fiber-polyvinyl chloride composite material of the present invention, the oxygen index of the wood fiber-polyvinyl chloride composite material of the present invention is greater than 35%, the ignition time is long, no melting drops occur, and it belongs to the flame retardant grade Material. The preparation method of the wood fiber-polyvinyl chloride composite material of the invention is simple, easy to operate, has low requirements on equipment, and is convenient for popularization and application.

Owner:NORTHEAST FORESTRY UNIVERSITY

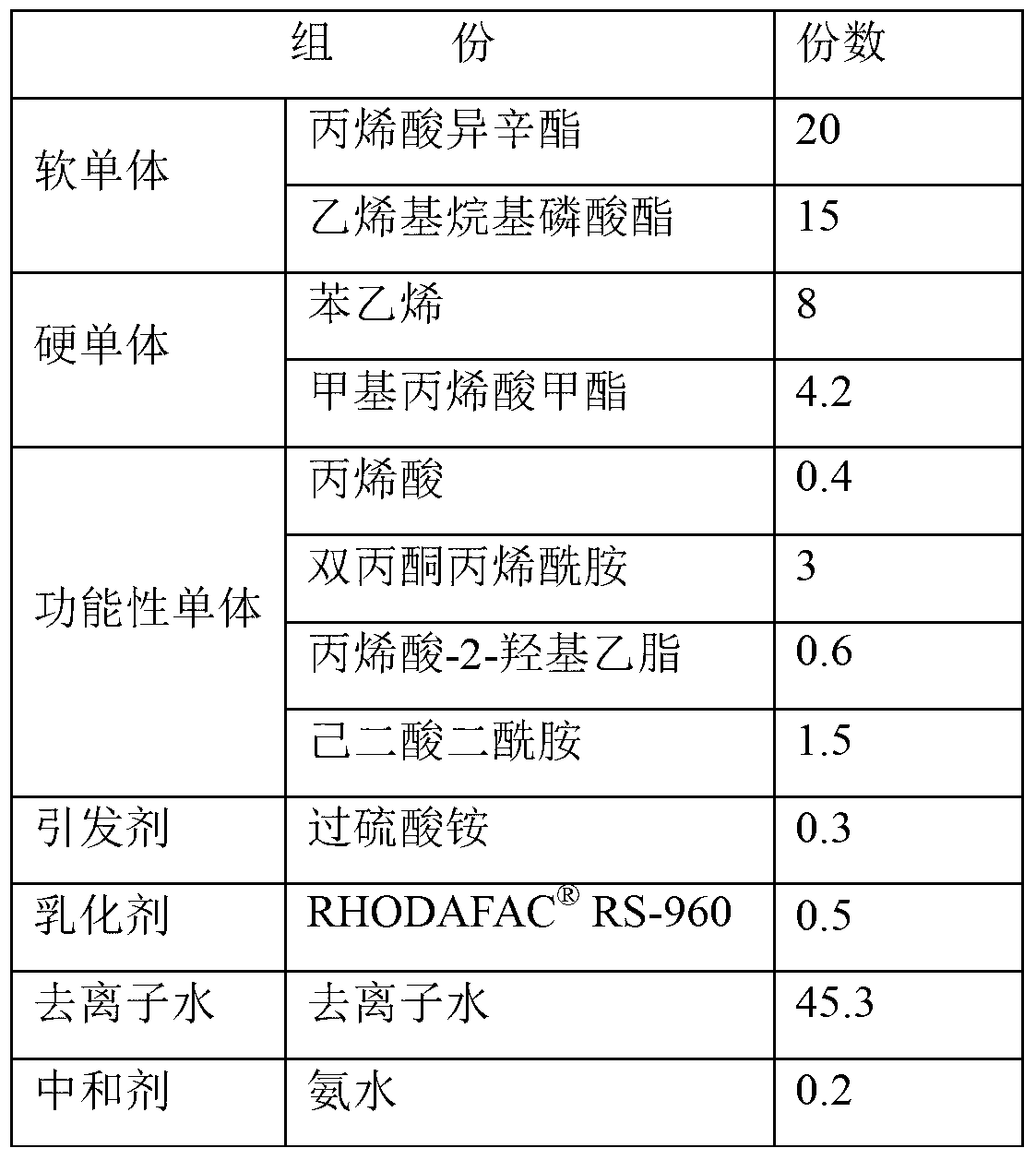

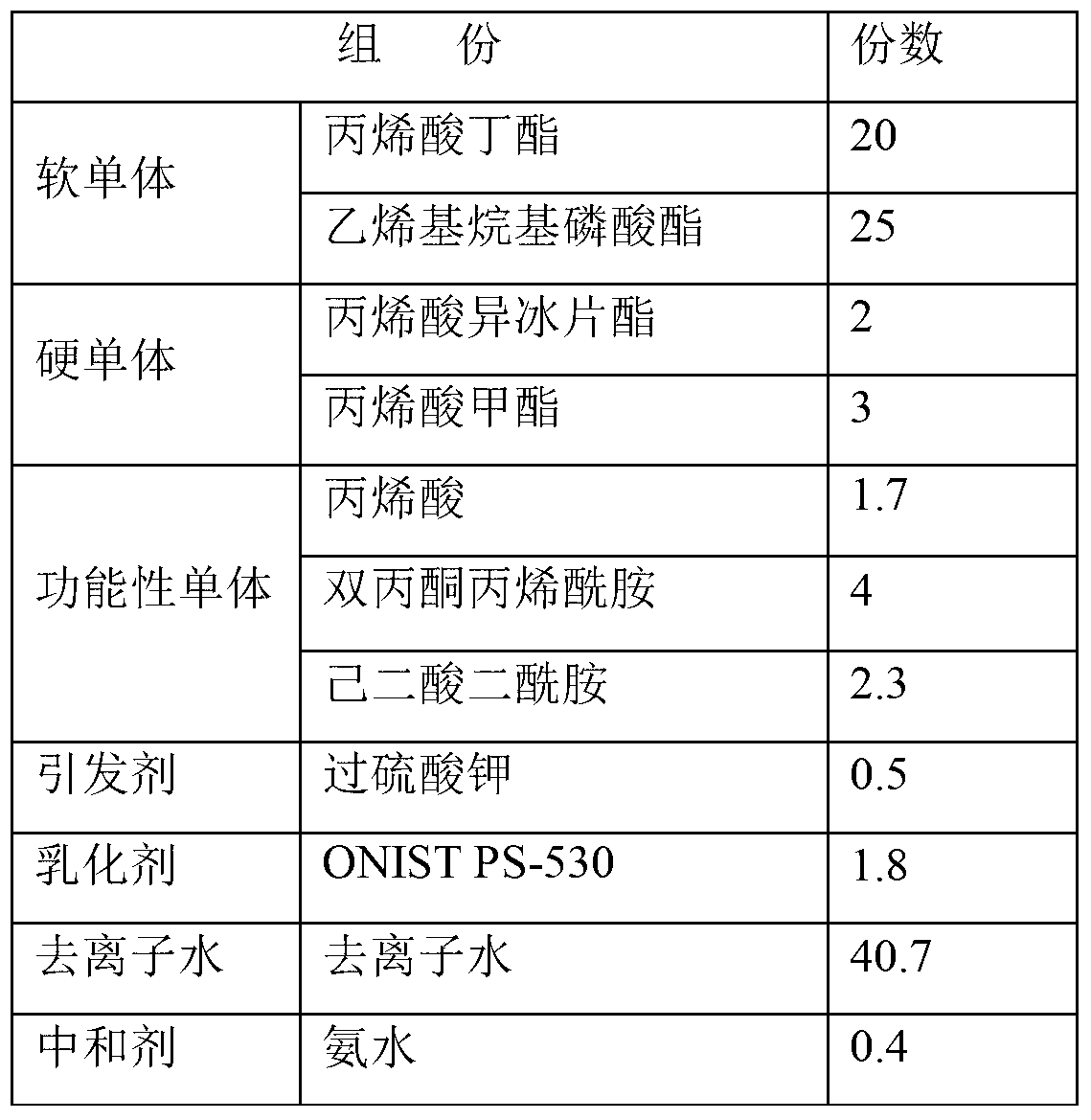

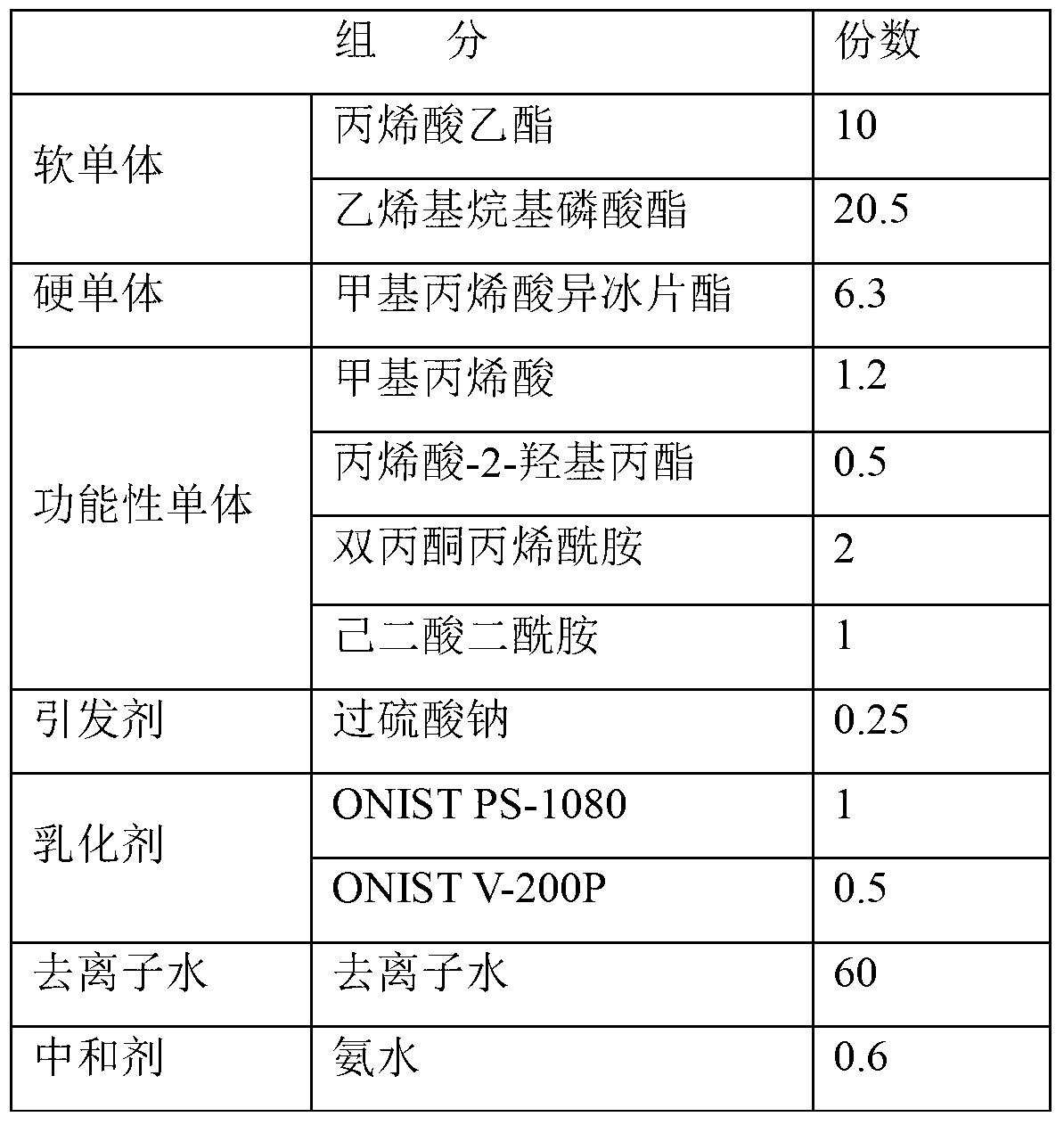

Environmental protection fire retardation type textile printing coating material and preparation method thereof

ActiveCN103225215AImprove flame retardant performanceFeel goodDyeing processTextile printerEngineering

The present invention discloses an environmental protection fire retardation type textile printing coating material and a preparation method thereof. According to the present invention, a fire retardation type acrylate is adopted as a main base material to prepare a fire retardation type coating material for textile printing, wherein the prepared fire retardation type coating material self-extinguishes within 5 seconds after leaving fire, and has characteristics of good fire retardation effect, good elasticity, low cost, excellent washing fastness resistance, and excellent color fastness; during a production process and a use process of the product, no formaldehyde is released, an environmental protection characteristic is provided, and the product does not contain heavy metals and alkyl phenol substances, and is an environmentally friendly and green product; and the preparation method has characteristics of easy production process control, high production efficiency and stable system, and is suitable for industrial scale production.

Owner:连云港百利合新材料发展有限公司

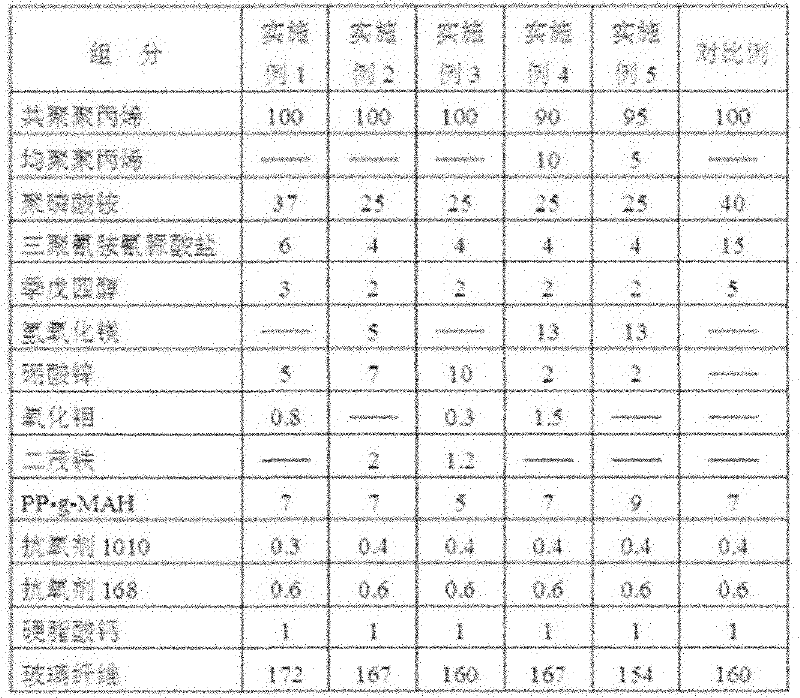

High-performance low-smoke halogen-free flame-retardant polypropylene composite material and preparation method thereof

ActiveCN102532693AImprove mechanical propertiesLow smoke productionGlass fiberPolypropylene composites

The invention discloses a high-performance low-smoke halogen-free flame-retardant polypropylene composite material which comprises the following components in parts by weight: 154-172 parts of continuous glass fiber, 100 parts of polypropylene resin, 41-60 parts of halogen-free flame retardant, 4-11 parts of flame-retardant synergist, 4-14 parts of smoke inhibitor, 5-9 parts of compatibilizer, 0.9 part of antioxidant and 1 part of lubricant. The preparation method of the high-performance low-smoke halogen-free flame-retardant polypropylene composite material comprises the following steps: preparing a low-smoke halogen-free flame-retardant polypropylene master batch; extruding the flame-retardant master batch by an extruding machine; evenly coating onto a continuous glass fiber surface to be evenly compounded with the continuous glass fiber; and carrying out multilayer high-temperature pressing to obtain a hard composite board. The high-performance low-smoke halogen-free flame-retardant polypropylene composite material has the advantages of excellent mechanical properties, excellent flame retardancy and favorable smoke elimination performance; and the preparation technique is simple, halogen-free, flame-retardant, green and environment-friendly, and can be widely used in the fields having strict requirements for flame retardancy and smoke generation amount, such as public occasions, automobile interior ornaments, decorating and the like.

Owner:LIAONING LIAOJIE SCI & TECH

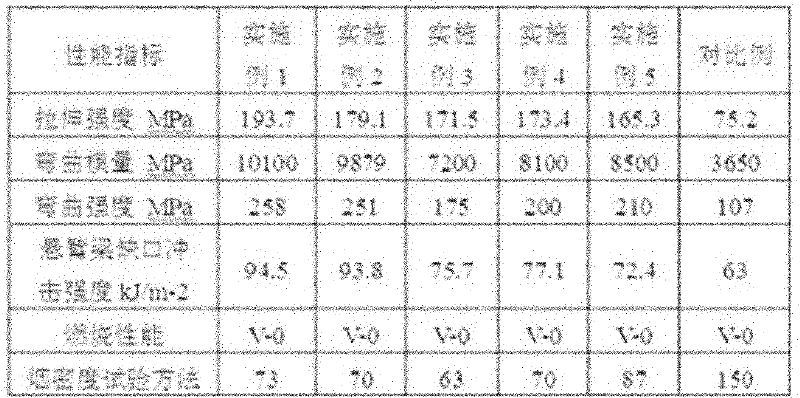

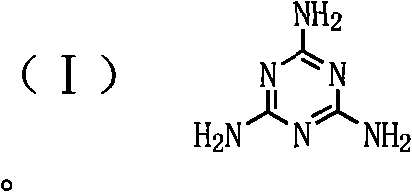

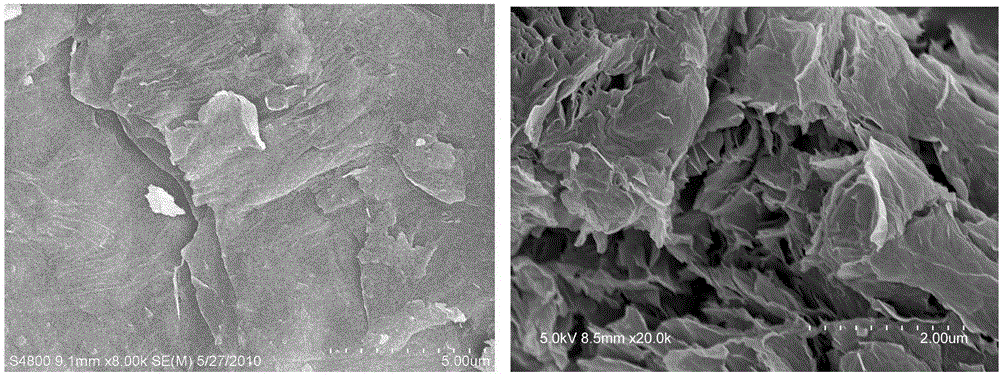

Preparation method of high flame retardant expansible graphite

The invention relates to a preparation method of high flame retardant expansible graphite, which comprises the following steps: dissolving the graphite into a mixing solution of perchloric acid and concentrated nitric acid, wherein the dosage of the solution is 100-600% of the mass of the solution; oxidizing the graphite by using solid oxidant of which the dosage is 0.5-50% of the mass of the oxidant to obtain the primary expansible graphite, wherein the temperature of the expansible graphite is 20-80 DEG C, and the reaction time is 20-300min; dissolving tripolycyanamide or the derivants thereof and the solid oxidant into phosphoric acid of which the mass fraction is 85+ / -10% to form a phosphoric acid solution, wherein the dosage of the solid oxidant is 0.5-50% of the mass thereof, and the mass concentration of the tripolycyanamide or the derivants thereof of the formed phosphoric acid solution is 0.02-2g / ml; carrying out reaction of the primary expansible graphite and the phosphoric acid solution at the temperature of 20-80 DEG C for 20-300min to prepare the high flame retardant expansible graphite. The method has the advantages that the tripolycyanamide or the derivants thereof are inserted between the expansible graphite layers, thereby improving the expansibility, start expansion temperature and fire resistance of the expansible graphite, and can be widely used for the flame retardant of multiple materials such as plastic, rubber, paint, foam and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Micro foam polystyrene group composite material of wood and plastic, and method of producing the same

A micro-foaming polystyrene wood-plastic composite material and the preparation method relates to a micro foaming wood-plastic composite material and the preparation method. The present invention solves the problems of poor impact resistance and easy combustion of the current wood-plastic composite material. The present invention is made of wood fiber material, coupling agent, plasticizer, lubricant, polystyrene, foamer, assistant foamer, fire retardants and smoke suppressant according to a weight portion. The preparation method is as follows: first, hot mixing; secondly, cooling and mixing; thirdly, extruding and molding. Then the micro-foaming polystyrene wood-plastic composite material can be made. The micro-foaming polystyrene wood-plastic composite material of the present invention has the advantages of small density, good fire-resistant and smoke-suppression effects, and impact resistance.

Owner:NORTHEAST FORESTRY UNIVERSITY

Multifunctional laminated veneer composite board and manufacturing method thereof

InactiveCN102554987AFlame retardantAchieve smoke suppressionWood impregnation detailsPhosphateAtmospheric temperature

The invention discloses a multifunctional laminated veneer composite board and a manufacturing method thereof, and belongs to the field of building materials. The manufacturing method comprises the following steps of: 1, mixing and dissolving 35 to 79 parts by mass of amidinourea phosphate, 5 to 40 parts by mass of ammonium dihydrogen phosphate, 1 to 10 parts by mass of diammonium hydrogen phosphate and 22 to 35 parts by mass of boric acid to prepare a multifunctional wood protectant treatment solution at the concentration of 6 to 20 percent; 2, performing veneer treatment, namely impregnating an air-dried wood veneer in the treatment solution for 0.5 to 120 hours; 3, performing veneer drying, namely drying the veneer under the condition of room temperature or atmospheric temperature to 170 DEG C until the moisture content of the veneer is 8 to 12 percent; 4, performing gluing; 5, performing assembly; and 6, performing hot-pressing to obtain the multifunctional laminated veneer composite board. The multifunctional laminated veneer composite board and the manufacturing method thereof have the beneficial effects that: the method is simple and easy to operate; production requirements can be met only by adding a veneer impregnation treatment procedure in an ordinary plywood production line; the updating and the upgrading of the conventional technical products of a man-made board enterprise are facilitated; and the products have high added value, and the multifunctional laminated veneer composite board and the manufacturing method thereof are really meaningful for ensuring the fire safety of wood materials.

Owner:XUZHOU SHENGHE WOOD

High-strength tear-resistant modified cable material and preparation method thereof

The invention discloses a high-strength tear-resistant modified cable material. The high-strength tear-resistant modified cable material comprises the following raw materials in part by weight: 36-42 parts of polyurethane rubber, 52-56 parts of butadiene-vinylpyridine rubber, 6-9 parts of hydrogenated nitrile rubber, 10-13 parts of nano-cellulose whisker, 1.8-2.2 parts of silane coupling agent A-151, 2-2.5 parts of sulphur, 1.1-1.4 parts of accelerant TMTD (tetramethyl thiuram disulfide), 1.5-1.8 parts of accelerant AC, 7-8 parts of light calcium carbonate, 5-6 parts of modified graphene, 24-28 parts of hard clay, 20-23 parts of mica powder, 2-3 parts of diethyl phthalate DEP, 3-5 parts of epoxy butyl oleate, 2-3 parts of pentaerythritol fatty acid ester, 2.3-2.6 parts of melamine phosphate, 8-11 parts of microencapsulated red phosphorus, 11-14 parts of zinc borate, 1.5-1.8 parts of anti-aging agent ODA and 0.9-1.2 parts of anti-aging agent DFC-34. The invention discloses a preparation method of the high-strength tear-resistant modified cable material.

Owner:ANHUI ELECTRIC GRP SHARES

Low-smoke halogen-free flame-retardant cable material

InactiveCN105037899ASoft textureHigh tensile strengthPlastic/resin/waxes insulatorsInsulated cablesEpoxyAntioxidant

The invention discloses a low-smoke halogen-free flame-retardant cable material, and belongs to the field of materials. The low-smoke halogen-free flame-retardant cable material solves the problem that an existing cable material is poor in mechanical property and electrical property. The low-smoke halogen-free flame-retardant cable material is composed of 50-60 parts of high density polyethylene, 20-30 parts of ethylene-ethyl acrylate copolymers, 20-30 parts of methyl vinyl silicone rubber resin, 1-3 parts of magnesium stearate, 2-5 parts of novolac epoxy resin, 15-25 parts of isopropyl phenyl diphenyl phosphate, 1-2 parts of dilauryl thiodipropionate, 10-20 parts of dimellitate, 1-2 parts of antioxidants 1010, 1-1.5 parts of antioxidants CA, 10-20 parts of maleic anhydride grafting ethylene-octylene copolymers, 5-10 parts of polysiloxane, 20-30 parts of nano magnesium hydroxide, 13-18 parts of nano clay, 3-7 parts of zinc oxide, 5-10 parts of polyethylene wax and 3-8 parts of calcium stearate. The low-smoke halogen-free flame-retardant cable material can be widely used as insulation and sheathing materials of various electric wires and cables.

Owner:国网山东莒南县供电公司 +2

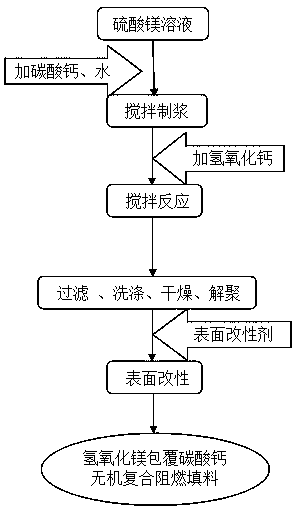

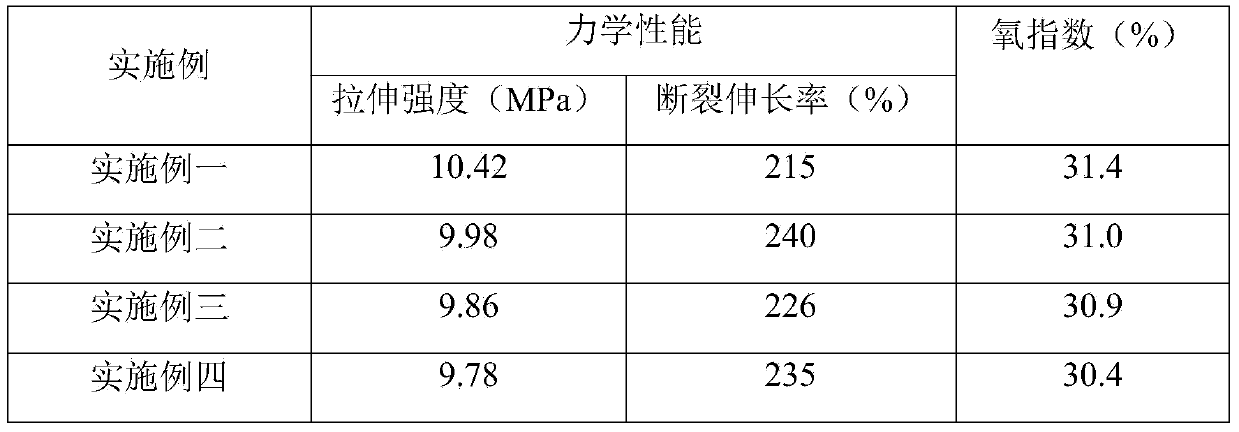

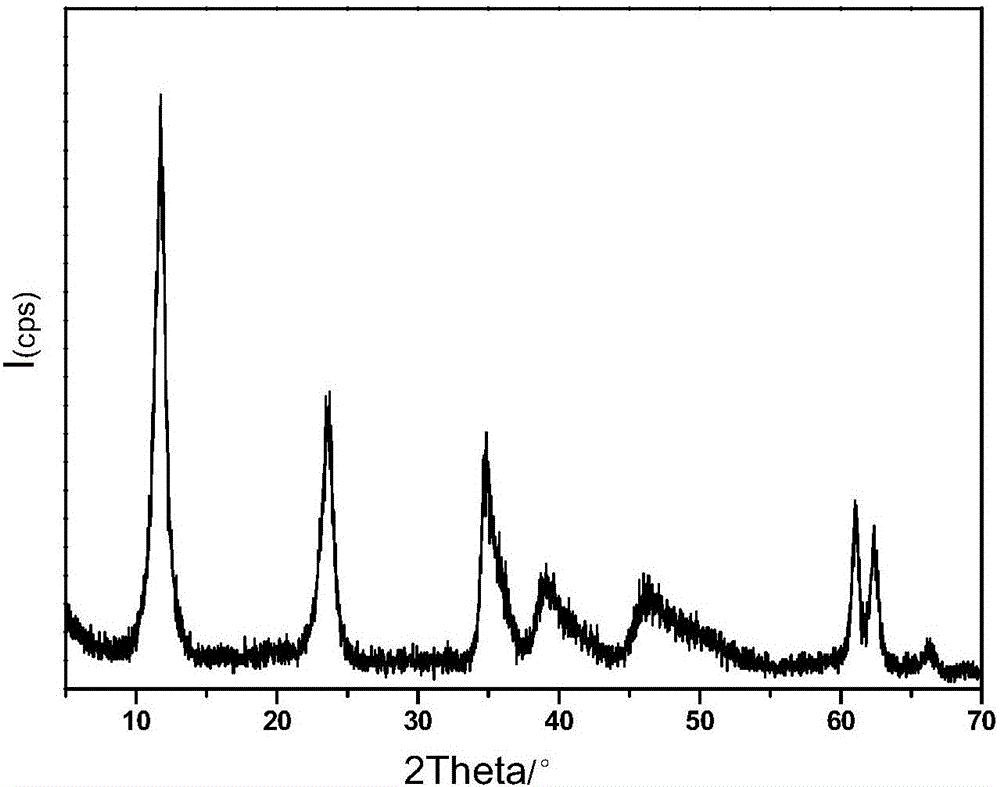

Preparation method of magnesium-hydroxide-coated calcium carbonate inorganic composite flame retardant filler

ActiveCN103773082AImprove flame retardant performanceGood smoke suppressionPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsCalcium hydroxideSlurry

The invention relates to a preparation method of magnesium-hydroxide-coated calcium carbonate inorganic composite flame retardant filler. The preparation method comprises the following steps: adding water to calcium carbonate powder and magnesium sulfate so as to prepare slurry, adding calcium hydroxide to the slurry at a certain temperature, stirring, reacting for a certain time, then filtering, washing, drying, depolymerizing, and carrying out surface modification, thus obtaining the magnesium-hydroxide-coated calcium carbonate inorganic composite flame retardant filler. The inorganic composite flame retardant filler prepared by using the method has the excellent flame retardant property and smoke suppression property of magnesium hydroxide, also has the excellent filling technological property of calcium carbonate and the enhanced mechanical property and auxiliary flame retardant and smoke abatement property of calcium sulphate dehydrate, integrates multiple functions of filling enhancement, flame retardancy, smoke abatement and the like; the production cost of a magnesium hydroxide flame retardant is reduced, the functions of the calcium carbonate filler are added; and the magnesium-hydroxide-coated calcium carbonate inorganic composite flame retardant filler has good application prospect.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

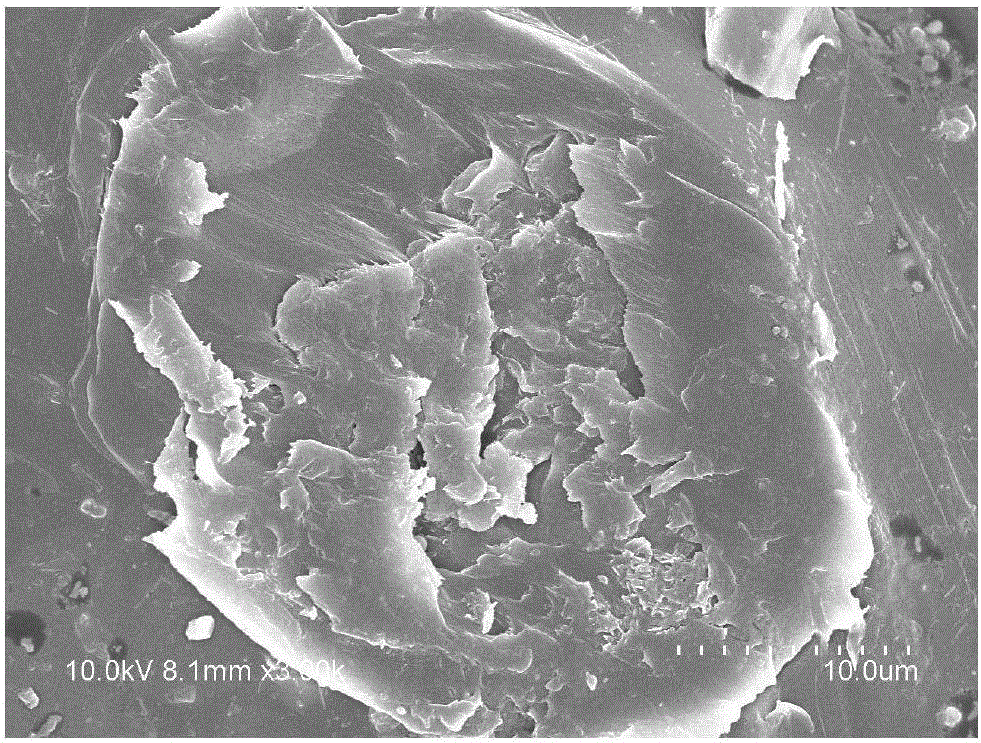

High-flame-retardant DOPO functionalized graphene oxide/ZIF-8 composite material and preparation method thereof

The invention relates to a high-flame-retardant DOPO functionalized graphene oxide / ZIF-8 composite material and a preparation method thereof, wherein the composite material has a synergistic flame retardant effect; compared with a single-component flame retardant, the flame retardant property of the composite material is more excellent. The preparation method comprises the following steps: dissolving 1.5-3.0 parts of zinc nitrate into 8 parts of deionized water, magnetically stirring the mixture for 10min, then adding 0.3-0.6 part of DOPO functionalized graphene oxide, stirring the mixture, and carrying out ultrasonic treatment for 30min to obtain a solution A; dissolving 28.7-57.4 parts of 2-methylimidazole into 80 parts of deionized water, magnetically stirring the mixture for 10 minutesto obtain a solution B, pouring the solution B into the solution A, and stirring the mixture for 120 minutes; centrifuging a reaction product for 10 min at 10000 r / min, repeatedly washing the reaction product with deionized water, and drying the reaction product at 65 DEG C so as to obtain the DOPO functionalized graphene oxide / ZIF-8 composite material.

Owner:SHAANXI UNIV OF SCI & TECH

Intercalated layered double hydroxide smoke inhibitor and preparation method thereof

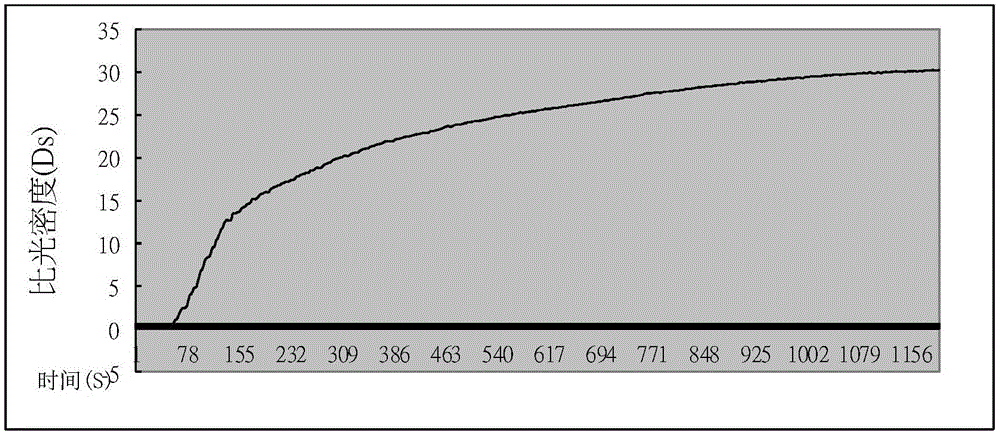

The invention discloses an intercalated layered double hydroxide smoke inhibitor and a preparation method thereof. The smoke inhibitor is a layered structural material formed by assembling a laminated sheet consisting of metal cations and interlayer anions, wherein a specific composition general formula of the smoke inhibitor is M<2+>1-xM<3+>x(OH)2(A<n->)n / 2.mH2O. According to the preparation method disclosed by the invention, the intercalated layered double hydroxide smoke inhibitor is prepared by adopting a one-step coprecipitation method or a clean hydrothermal reaction at one step; the preparation method is simple and practical; according to the obtained intercalated layered double hydroxide smoke inhibitor, smoke inhibiting groups such as molybdate anions, an octamolybdate radical, a cuprate radical and a stannate radical are arranged at an interlayer, and smoke inhibiting elements such as iron and copper are introduced into the laminated sheet, so that a good carbon forming effect is realized, the smoke generating amount can be reduced, and the smoke inhibiting effect is synergically enhanced; meanwhile, a layered double hydroxide laminated sheet forms an alkaline porous substance at high temperature; the alkaline porous substance has greater specific surface area and can effectively adsorb smog; the prepared intercalated layered double hydroxide smoke inhibitor is applied to an ordinary rubber-plastic product and a high-temperature rubber-plastic product; the maximum density (Ds, max) at low additive amount (1phr) can be reduced by 87.3 percent; the intercalated layered double hydroxide smoke inhibitor is remarkable in smoke inhibiting effect and is a smoke inhibitor material with excellent performance.

Owner:BEIJING UNIV OF CHEM TECH

Wood-plastic material

InactiveCN105907121AImprove flame retardant performanceHigh smoke suppression effectPlastic materialsAdhesive

The invention discloses a wood-plastic material which is prepared from the following raw materials in parts by weight: 32-60 parts of jujube tree powder, 22-40 parts of rice straw powder, 8-12 parts of book paper powder, 6-10 parts of plastic bag particles, 6-8 parts of fillers, 4-6 parts of a synthetic agent, 1-2 parts of a lubricant, 1-2 parts of an anti-mildew and anti-bacterial agent, 1-2 parts of a moisture absorbent, 2-4 parts of a fire retardant, 2-4 parts of a smoke suppressor and 6-10 parts of an adhesive. The wood-plastic material can be widely applied to decoration and renovation of hotels, restaurants and buildings, is good in flame-retardant effect, cannot combust or form a flame, and is stable and reliable in performance.

Owner:广西南宁桂尔创环保科技有限公司

Wood protecting agent and method of producing the same

The invention discloses a wood additive and making method to solve the problem of low solubility and bad penetrability of boron system compound as wood protective in the water, which is made of 100wt% borate and 0. 1-5wt% composite surface activator. The making method comprises the following steps: 1. blending boric acid and borax evenly to place in the 25-75 deg. c environment to do solid-phased reaction; drying; obtaining the borate; 2. blending the composite surface activator and borate evenly to obtain the wood protective. The invention has the function of preservation, insect protection, termite-resistant, flame-proof and smoke inhibition, which doesn't harm human and animals without influencing the appearance, dynamics and manufacturing property of the wood.

Owner:NORTHEAST FORESTRY UNIVERSITY

High-flame-retardancy paint

InactiveCN106366740AHigh tensile strengthImprove adsorption capacityFireproof paintsPolyurea/polyurethane coatingsWater basedDimethyl methylphosphonate

The invention discloses a high-flame-retardancy paint which is prepared from a water-based acrylate emulsion, a water-based polyurethane resin, aluminasol, an epoxy resin, polydimethylsiloxane, zinc oxide, hollow glass microspheres, nano zirconium oxide, montmorillonite, nano silicon dioxide, a film forming aid, a defoaming agent, a leveling agent, a wetting agent, a flame retardant and water. The flame retardant is formed by mixing boron oxide, dimethyl methyl phosphonate, phosphorus pentoxide, tri(2-chloropropyl) phosphate, guanylurea phosphate, ammonium polyphosphate, pentaerythritol, melamine and hexamethyl disiloxane. The high-flame-retardancy paint has the advantages of favorable water resistance, favorable wear resistance, excellent flame retardancy and long service life.

Owner:ANHUI JINDUN PAINT

High-strength heat-resistant modified silicon rubber power cable sheath material

InactiveCN104292836AHigh strengthImprove heat resistanceRubber insulatorsInsulated cablesPolymer scienceBenzoyl peroxide

The invention discloses a high-strength heat-resistant modified silicon rubber power cable sheath material which is prepared from the following raw materials in parts by weight: silicone rubber, fluorine rubber, nano calcium carbonate, modified silica, potassium titanate whiskers, aluminum hydroxide, ferric oxide, tin oxide, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, methyltris(methylethylketoximino)silane, benzoyl peroxide, hydroxyl silicone oil, an amino silane coupling agent, dibutyltin dilaurate, magnesium oxide, a hydroxy stearic acid, an accelerant, an antiager, and a plasticizer. The high-strength heat-resistant modified silicon rubber power cable sheath material disclosed by the invention is high in strength and good in heat resistance, and a cable sheath prepared by using the high-strength heat-resistant modified silicon rubber power cable sheath material is good in comprehensive performance and long in service life.

Owner:ANHUI CONSTANT CRYSTAL CABLE GROUP

Modified graphene cable material

The invention discloses a modified graphene cable material. The modified graphene cable material comprises, by weight, 68-72 parts of natural rubber, 18-22 parts of nitrile rubber, 9-12 parts of ethylene-vinyl acetate copolymer, 3-4 parts of sulfur powder, 0.5-0.8 part of accelerant M, 1.1-1.4 parts of accelerant D, 1.4-1.8 parts of aluminum-zirconium coupling agent TL-5, 3-6 parts of modified graphene, 22-25 parts of sea-foam stone powder, 23-27 parts of calcined kaolin, 5-6 parts of titanium nitride, 12-15 parts of carbon black N660, 2-5 parts of triphenyl phosphate TPP, 3-4.5 parts of citrate, 2.3-3.6 parts of triazine-2,4,6-triamine phosphate, 5-8 parts of magnesium sulfate heptahydrate, 1.2-1.8 parts of anti-aging agent MBZ and 1.2-1.6 parts of anti-aging agent NBC. The modified graphene cable material has the advantages of being high in elasticity and abrasion-resisting performance and is excellent in heat resisting and flame resisting performance.

Owner:ANHUI ELECTRIC GRP SHARES

High performance polyurethane paint

InactiveCN106318181AImprove water resistanceHigh mechanical strengthFireproof paintsAntifouling/underwater paintsWater basedPolymer science

The invention discloses a high performance polyurethane paint. The high performance polyurethane paint is prepared from water-based polyurethane resin, water-based acrylic emulsion, bisphenol F epoxy resin, toluene diisocyanate, zinc oxide, silicon carbide, zinc stannate, expanded graphite, calcined kaolin, nano titanium dioxide, calcium chloride, coalescing agents, (2, 3-dibromo) boron n-propoxide, hexahydro-1, 3, 5-tris(hydroxyethyl)-s-triazine, modified silica sol, tetrahydro perfluorinated trichlorodecyl-silan, silver stearate, hexamethyldisiloxane, Gamma-isocyanate propyl triethoxy silane, hydroxyl-terminated polybutadiene liquid rubber, defoaming agent, wetting agent, and water. The high performance polyurethane paint has good water resistance and wear resistance, and excellent flame retardant performance.

Owner:ANHUI JINDUN PAINT

Graphene modified rubber material with high bending strength

InactiveCN106433083AImprove flame retardant performanceHigh smoke suppression effectWaxMaleic anhydride

The invention discloses a graphene modified rubber material with high bending strength. The material is prepared from the following raw materials: epichlorohydrin rubber, neoprene rubber, graphene, tributoxyethyl phosphate, dibutyl phthalate, tris(2,4-ditert-butylphenyl)phosphite, stearyl acrylate, maleic anhydride grafted polymer, magnesium hydroxide, kaolin, carbon black, calcium hexadecanesulfonate, zinc diethyldithiocarbamate, chlorinated polyethylene, isoprene, amide wax, polybutylene terephthalate fiber, dimethicone, carbon fiber, polyamide fiber, carboxyethyl cellulose, surfactant, initiator, chain extender, crosslinking agent, degassing agent, leveling agent, catalyst, promoting agent, plasticizer, dispersant, tackifier, curing agent, antibacterial agent, antioxidant, light stabilizer, heat stabilizer, anti-aging agent, ultraviolet absorber, flame retardant and smoke suppressant. The material has good flame retardancy and high impact resistance and toughness, can be widely used in manufacture of tires, hoses, tapes, cables and other products, and has significant economic and social benefits.

Owner:黄宇

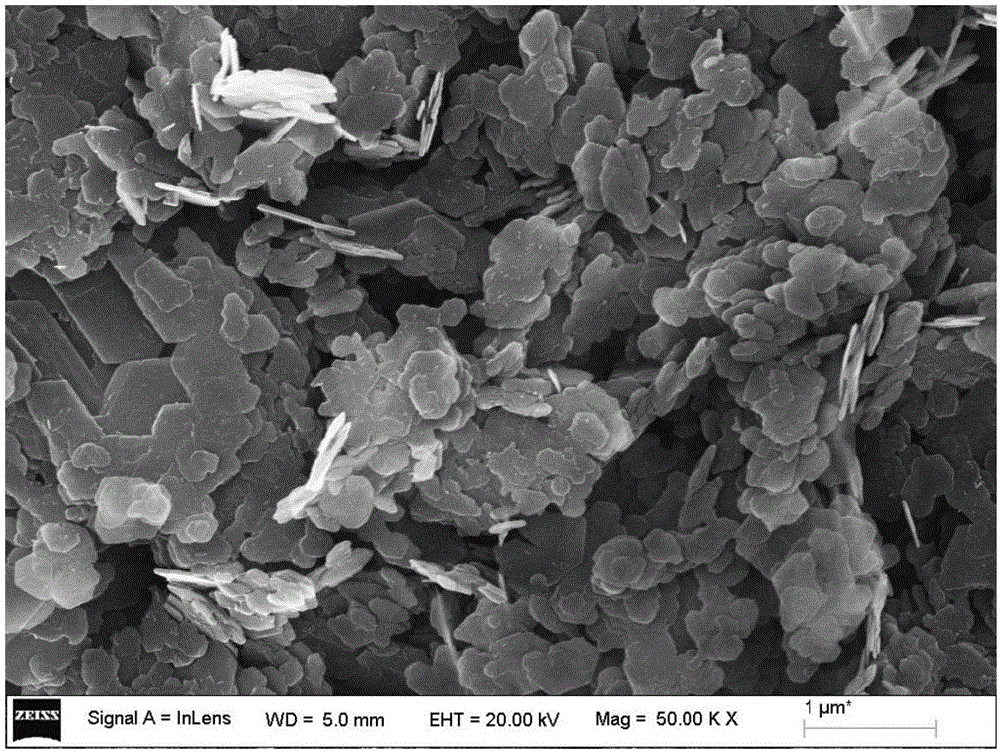

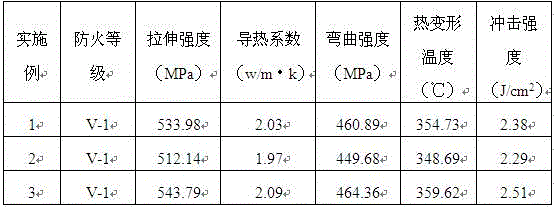

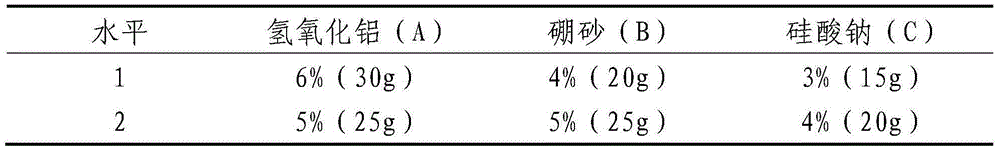

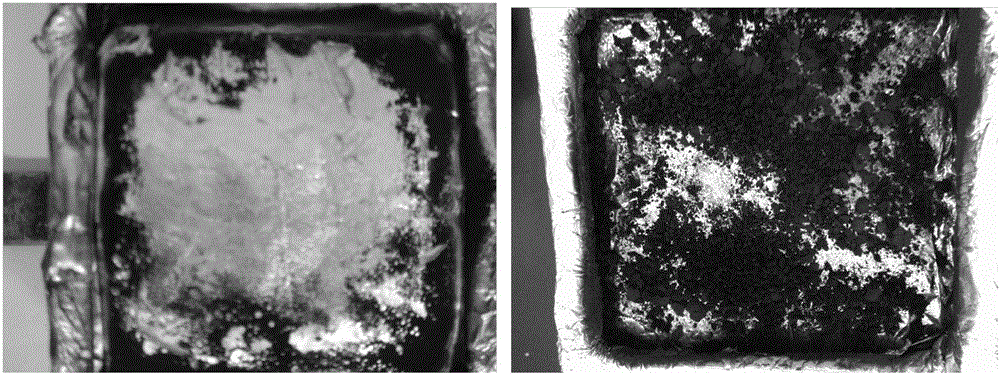

Composite flame retardant and method for preparation of flame retardant fiber board from the same

ActiveCN105131627AGood flame retardant effectGood smoke suppressionDomestic articlesFlat articlesSodium silicateFire retardant

Belonging to the technical field of fireproof material development, the invention specifically relates to a composite flame retardant and a method for preparation of a flame retardant fiber board from the same. The composite flame retardant is composed of aluminum hydroxide, borax and sodium silicate in a mass ratio of 4-6:3-5:2-4. The composite flame retardant provided by the invention has the advantages of good flame retardant effect, low toxicity, good smoke suppression and environmental friendliness, can significantly improve the flame retardant properties of the fiber board, and has cheap price, thus being suitable for industrial production of the flame retardant fiber board.

Owner:GUANGXI UNIV

High-flame retardant rubber material in extrusion molding and preparation method thereof

ActiveCN103146081AImprove interface performanceStrong neutralization abilityRubber materialPolymer science

The invention relates to a low-smoke halogen-free high-flame retardant ethylene propylene rubber material in extrusion molding. A preparation method of the rubber material is as follows: uniformly mixing the di-ethylene propylene rubber and ethylene-vinyl acetate copolymer at 100+ / -10 DEG.C by using an open mill or a internal mixer, cooling to the room temperature, orderly adding carbon black, modified mmicron hydroxide, plasticizer, flame retardant synergist, assistant crosslinker and crosslinking agent in proportion, uniformly mixing, adding the rubber compound in a single-screw extruder, controlling the temperature of the extruder body, the screw and the head at 70-90 DEG.C and the revolving speed of the screw within 20-30r / min (revolutions per minute) so that the rubber can be continuously extruded, heating and forming in a direct vulcanizing tank. The retardant ethylene propylene rubber provided by the invention has the advantages of good dynamic performance, low-smoke halogen-free flame retardance and good extrusion performance, and is adapted to a high-flame retardant rubber seal product.

Owner:JIANGYIN HAIDA RUBBER & PLASTIC GROUP

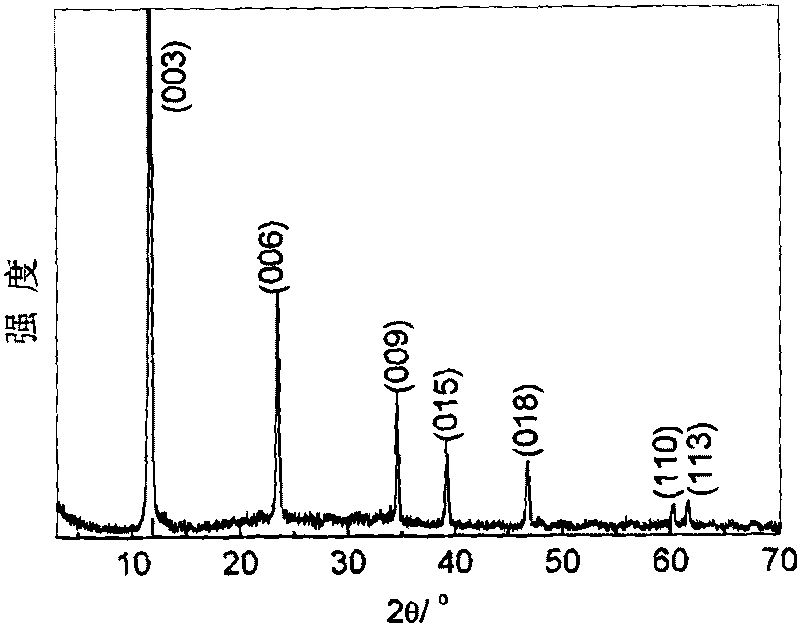

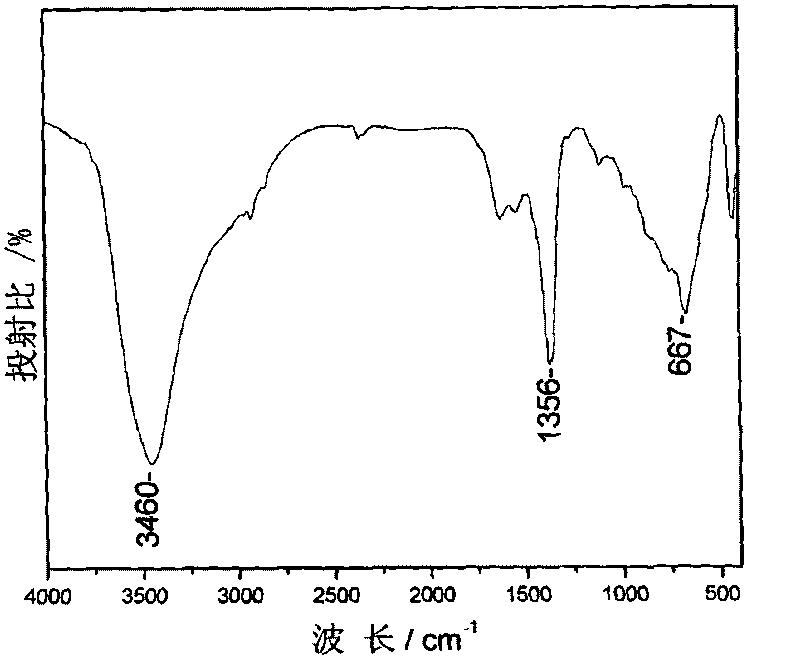

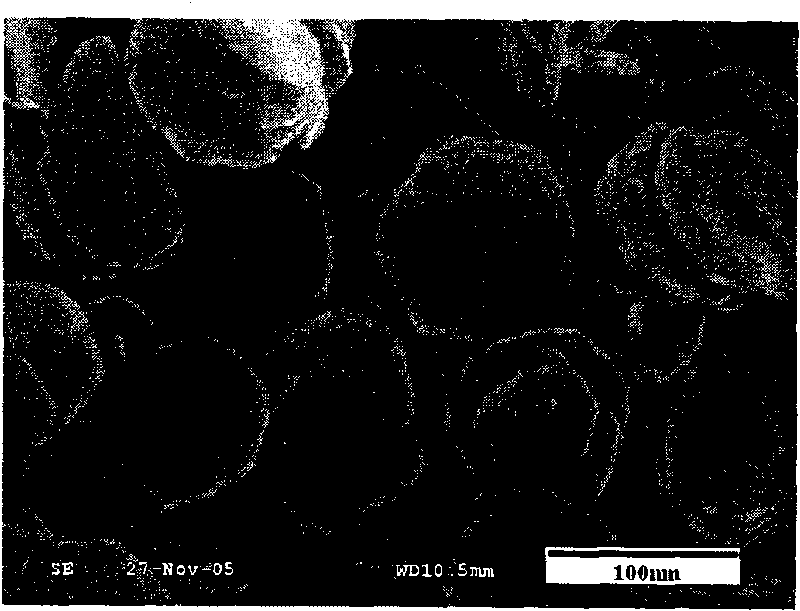

Method for preparing thermostable nano hydrotalcite used in PVC resin

The invention relates to a method for preparing thermostable nano hydrotalcite used in PVC resin, belonging to the technical field of chemical product preparation and application. The method can improve the thermostability and the smoke suppression performance of the PVC resin. The specific method comprises: A. 10-800g of soluble bivalent metal salts M2+Y and Al (NO3) 3.9 H2O are weighed, are dissolved in 0.2-1L of deionized water and are prepared into mixed salt solution, wherein the molar ratio of M2+ / Al3+ is 2-4:1 and the concentration of M2+ is 0.05-1mol / L; 2-370g of NaOH and Na2CO3 are weighed, are dissolved in 0.2-1L of deionized water and are prepared into mixed alkali solution, wherein the molar ratio of NaOH / Na2CO3 is 1-3:1 and the molar ratio of NaOH / M2+ is 1.5-2.5:1; and the two kinds of solution are rapidly mixed in a colloid mill and are violently and cyclically agitated for one minute; B. the obtained slurry is poured into a crystallization kettle, 1-5 percent of modifier is added by weight percent, and the obtained mixture is violently agitated and is crystallized under 70-150 DEG C for 2-24 hours; and C. the crystallized slurry is put in a lyophilizer for being lyophilized for 24-48 hours. The invention has the advantages that the preparation method is simple and feasible and the hydrotalcite can be widely used in the PVC preparation industry.

Owner:辽宁法库陶瓷工程技术研究中心

A kind of silicon magnesium boron wood nano flame retardant

ActiveCN102294719AGood flame retardant effectGood smoke suppression effectWood impregnation detailsMagnesium carbonate hydroxideSodium silicate

The invention discloses a silicon magnesium boron lumber nano combustion inhibitor, the combustion inhibitor comprises the following raw materials by weight percentage: 30%-36% of sodium silicate hydrate, 24%-30% of elemental silicon, 4%-6% of tin chloride, 20%-30% of zinc borate, 15%-17.5% of basic magnesium carbonate and 2%-2.5% of magnesium chloride, the sodium silicate hydrate, elemental silicon and basic magnesium carbonate have particle sizes of 15nm, 30nm and 50nm and are mixed according to the mass ratio of 1:1:1, the tin chloride, zinc borate and magnesium chloride are micron-grade, sodium silicate hydrate, elemental silicon and basic magnesium carbonate are uniformly mixed, a mixture of the combustion inhibitor and water are performed a disperse treatment for 30-40 minutes by polyethylene glycol, sodium dodecanesulphonate, sodium acid pyrophosphate or sodium hexametaphosphate under the condition of supersonic wave and microwave, the dispersed suspension fluid of the combustion inhibitor is mixed with the aqueous solution of tin chloride, zinc borate and magnesium chloride and stirred for 20m minutes to obtain the silicon magnesium boron lumber nanometer combustion inhibitor. The present invention has the advantages of good fireproof effect, simple technology, easy industrialization, cleanness and no pollution.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Use of trialkyl phosphate as a smoke suppressant in polyurethane foam

InactiveUS20140206786A1Generates significantly less smoke whenHigh smoke suppression effectPhosphateCarbon atom

Described is a method for using a trialkyl phosphate as a smoke suppressant in a polyurethane foam. The trialkyl phosphate having at least one alkyl group with two carbon atoms is included in the polyurethane foam, which has an absence of halogenated flame retardants.

Owner:DOW GLOBAL TECH LLC

Flame-retardant type wood-plastic material

The invention discloses a flame-retardant type wood-plastic material. The material is prepared from, by weight, 60-70 parts of wood fibers, 11-16 parts of pentaerythritol, 21-28 parts of modified fire retardant, 21-28 parts of modified smoke inhibitor, 17-25 parts of polypropylene, 17-25 parts of high-density polyethylene, 8-13 parts of vermiculite, 5-9 parts of dioctyl phthalate, 6-13 parts of polyethylene glycol monostearate, 12-15 parts of unsaturated polyester resin, 5-9 parts of vinyl trimethoxy silane, 2-5 parts of luffa stems, 2-5 parts of polyethylene wax, 1-3 parts of PE wax, 1-3 parts of magnesia, 1-2 parts of graphite, 1-2 parts of herba taraxaci, 1-2 parts of ligusticum sinense olivers and 0.1-0.3 part of peanut oil. The wood-plastic material has high flame retandance and a good smoke inhabitation effect and does not release toxic and harmful substances at the high temperature, secondary harm to the human body is avoided, the heat insulation property is quite good, scalds to the human body are avoided, the quite good insulating property is achieved, and meanwhile the wood-plastic material is compact in material, good in mechanical performance and quite durable.

Owner:ANHUI YINUO WOOD PLASTIC SHEET TECH CO LTD

Graphene-molybdenum oxide nano flame-retardant composite material

The invention relates to a graphene-molybdenum oxide nano flame-retardant composite material. The preparation method comprises the following steps: (1) mixing graphene oxide and ammonium molybdate in a mass ratio of (1.8-8):1; (2) carrying out ball milling on the mixture obtained in the step (1) to obtain a graphene oxide-ammonium molybdate composite; (3) heating the composite obtained in the step (2) to 100-1050 DEG C, keeping the temperature in a nitrogen protective atmosphere, and cooling to obtain a graphene-molybdenum oxide nano composite; (4) putting the graphene-molybdenum oxide nano composite obtained in the step (3) and a polystyrene resin into a torsion rheometer, and banburying, wherein the mass percent of the graphene-molybdenum oxide nano composite is 0.5-10%, and the mass percent of the polystyrene resin is 90-99.5%; and (5) carrying out extrusion granulation on the material obtained in the step (4) to obtain the graphene-molybdenum oxide nano flame-retardant composite material. The graphene in the composite material has favorable barrier actions; and the molybdenum oxide has the synergistic actions of flame retardancy and smoke inhibition, and can obtain favorable flame retardancy and mechanical properties when being slightly added.

Owner:NANJING HONGRUI PLASTIC PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com