Method for preparing thermostable nano hydrotalcite used in PVC resin

A PVC resin and thermal stabilization technology, applied in the field of preparation and application of chemical products, can solve the problems such as the influence of the change of the thermal decomposition temperature of PVC on the specific surface area of nano-hydrotalcite, etc., and achieve a simple and easy preparation method and improve smoke suppression. , the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 76.8gMg(NO 3 ) 2 ·6H 2 O and 56.3gAl(NO 3 ) 3 9H 2 O was dissolved in 0.5L deionized water to form a mixed salt solution, in which Mg 2+ / Al 3+ The molar ratio is 2:1, Mg 2+ The concentration is 0.6mol / L; another 24gNaOH and 21.2gNa 2 CO 3 Dissolve in 0.5L deionized water to make a mixed alkali solution, in which NaOH / Na 2 CO 3 The molar ratio is 3:1, NaOH / Mg 2+ The molar ratio of the two solutions was 2:1; the two solutions were quickly mixed in a colloid mill, and vigorously circulated and stirred for 1 minute. The resulting slurry was poured into a crystallization tank, 5 wt% PEG200 was added, and crystallized at 120° C. for 8 hours under vigorous stirring. The crystallized slurry was dried in a freeze dryer for 40 h.

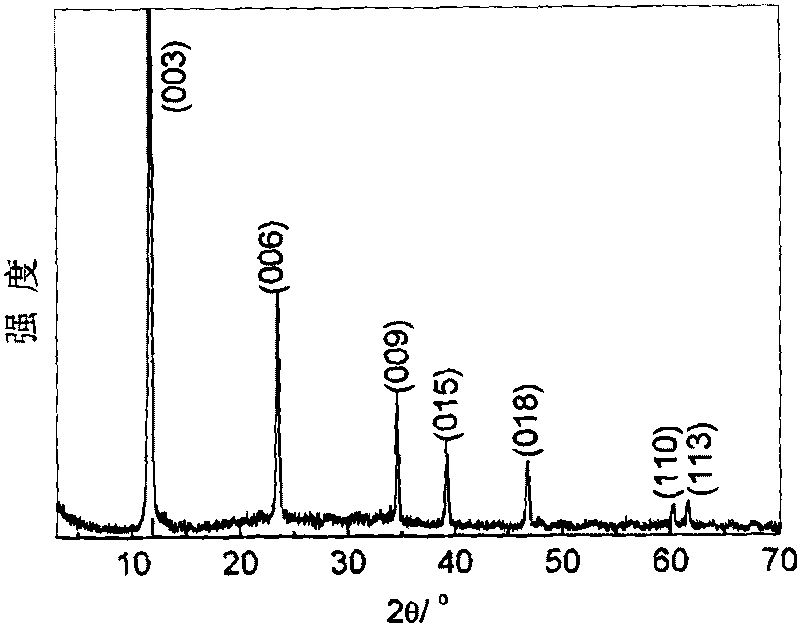

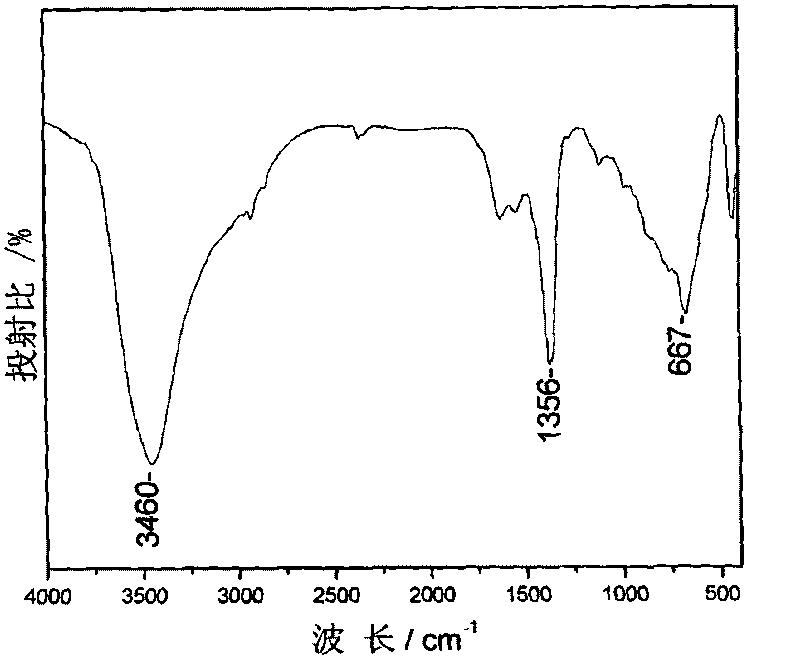

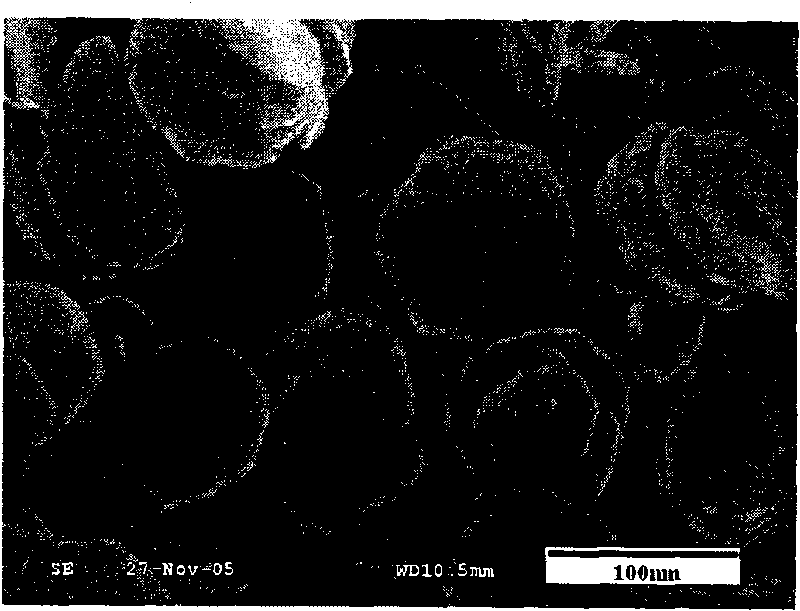

[0036] By X-ray powder diffractometer (XRD) (see figure 1 ), Fourier transform infrared spectrometer (FT-IR) (see figure 2 ), scanning electron microscope (SEM) (see image 3 ), transmission electron microscopy (TEM) (see Figu...

Embodiment 2

[0040] Weigh 76.8gMg(NO 3 ) 2 ·6H 2 O and 56.3gAl(NO 3 ) 3 9H 2 O was dissolved in 1L deionized water to form a mixed salt solution, in which Mg 2+ / Al 3+ The molar ratio is 2:1, Mg 2+ The concentration is 0.3mol / L; another 24gNaOH and 21.2gNa 2 CO 3 Dissolve in 1L deionized water to make a mixed alkali solution, in which NaOH / Na 2 CO 3 The molar ratio is 3:1, NaOH / Mg 2+ The molar ratio of the two solutions was 2:1; the two solutions were quickly mixed in a colloid mill, and vigorously circulated and stirred for 1 minute. The resulting slurry was poured into a crystallization kettle, 2 wt% PEG200 was added, and crystallized at 100° C. for 8 hours under vigorous stirring. The crystallized slurry was dried in a freeze dryer for 48 hours.

Embodiment 3

[0042] Weigh 76.8gMg(NO 3 ) 2 ·6H 2 O and 28.15gAl(NO 3 ) 3 9H 2 O was dissolved in 0.5L deionized water to form a mixed salt solution, in which Mg 2+ / Al 3+ The molar ratio is 4:1, Mg 2+ The concentration is 0.6mol / L; another 18gNaOH and 15.9gNa 2 CO 3 Dissolve in 0.5L deionized water to make a mixed alkali solution, in which NaOH / Na 2 CO 3 The molar ratio is 3:1, NaOH / Mg 2+ The molar ratio of the two solutions was 1.5:1; the two solutions were quickly mixed in a colloid mill, and vigorously circulated and stirred for 1 minute. The resulting slurry was poured into a crystallization kettle, 5 wt% PEG300 was added, and crystallized at 110° C. for 6 hours under vigorous stirring. The crystallized slurry was dried in a freeze dryer for 35 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com