Intercalated layered double hydroxide smoke inhibitor and preparation method thereof

A technology of smoke suppressant and hydrotalcite, which is applied in the field of intercalated hydrotalcite smoke suppressant and its preparation, can solve the problems of general smoke suppression performance and lower surface temperature, and achieve remarkable smoke suppression effect, reduced smoke generation, large effect on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step: Mg(OH) with a total mass of 30kg and a molar ratio of 2:1:3 2 , Al(OH) 3 and H 2 MoO 4 They were added to 60kg of deionized water, and pretreated by a grinder to make Mg(OH) 2 , Al(OH) 3 and H 2 MoO 4 Slurry, take 10kg of this slurry and add it to the autoclave; be heated to a reaction temperature of 215°C, react for 6h under stirring conditions (350rpm), and the obtained product is dried at 70°C for 8 hours to obtain a molecular formula of Mg 4 Al 2 (OH) 12 MoO 4 ·4H 2 O-molybdate intercalated hydrotalcite smoke suppressant.

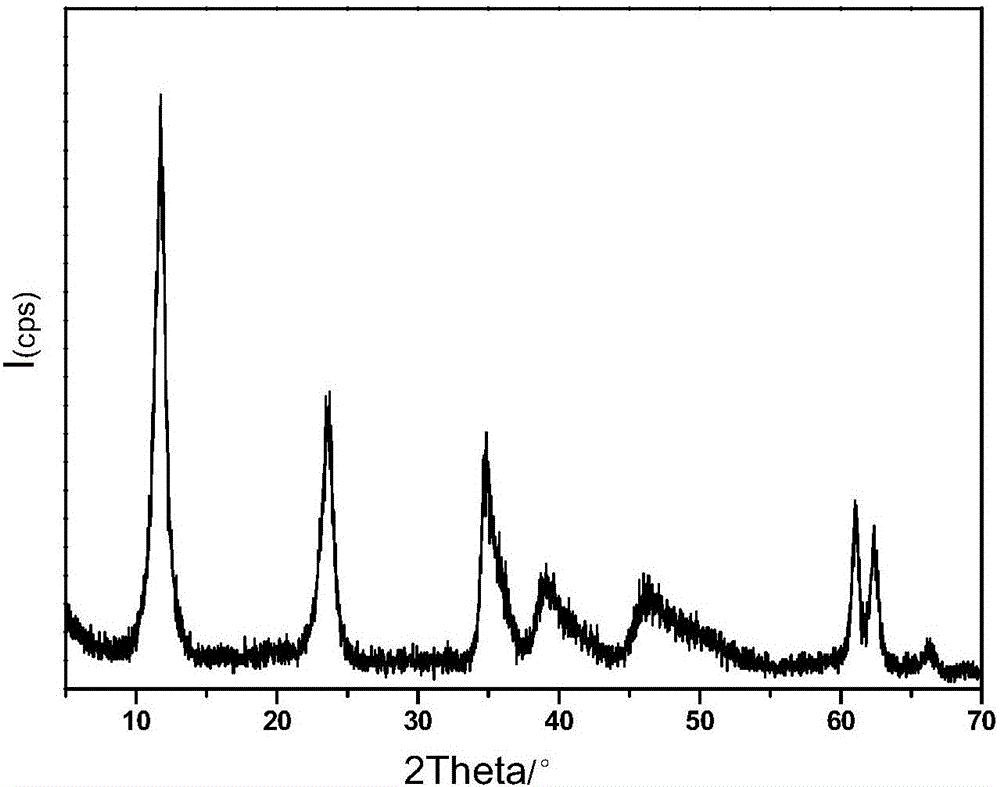

[0023] The crystal structure of the product was characterized by XRD-6000 X-ray powder diffractometer from Shimadzu Corporation of Japan. figure 1 is the XRD spectrum. It can be seen from the figure that Mg appears around 2θ=11.58°, 23.47°, 34.87° and 60.8° 2 Al-MoO 4 - The characteristic diffraction peaks of LDHs, and the peak shape is sharp and the baseline is low and flat, indicating that the product has a complete crystal ...

Embodiment 2

[0029] Mg(NO 3 ) 2 , Zn(NO 3 ) 2 and Al(NO 3 ) 3 According to the ratio of Mg / Zn / Al=3:1:2, a mixed salt solution was prepared, so that [Mg 2+]=1.2mol / L, NaOH and Na 2 SnO 3 Press n(Na 2 SnO 3 ) / n(Al 3+ )=2, n(NaOH) / [n(Mg 2+ )+n(Zn 2+ )+n(Al 3+ )] = 1.5 to prepare a mixed alkali solution, the mixed salt solution and the mixed alkali solution have the same volume, the two solutions are added to the rotating liquid film reactor at the same time, and the obtained slurry is stirred and heated to 80 ° C in a flask under a nitrogen protection environment. , the stannate intercalated hydrotalcite smoke suppressant is obtained by washing after 24h of reaction.

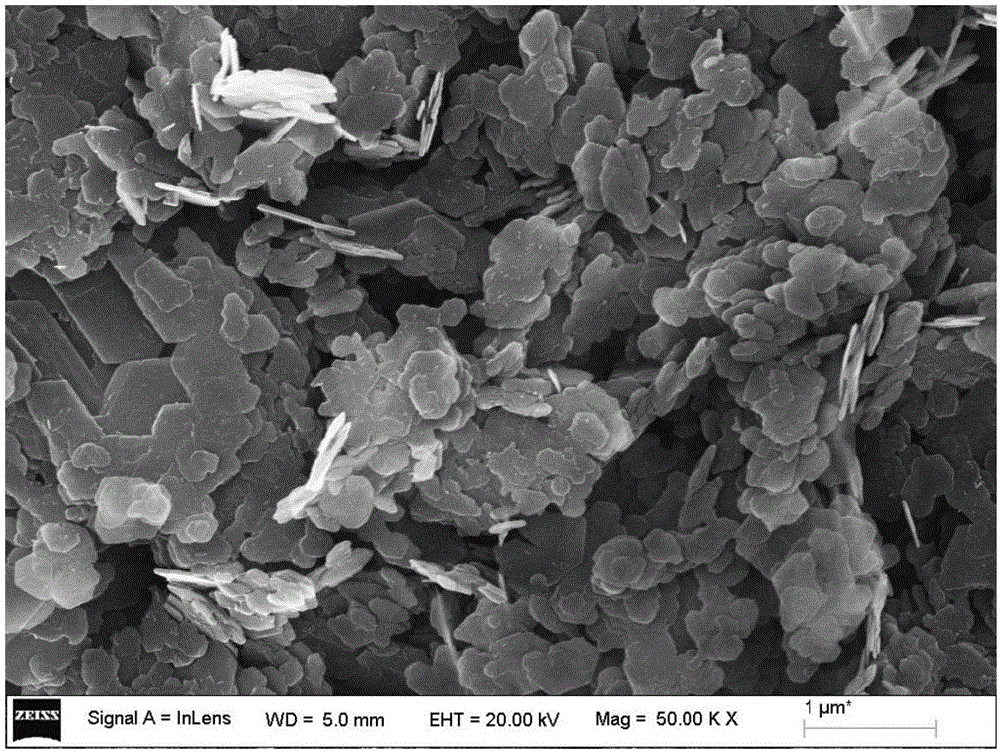

[0030] The grain size and morphology were observed with a supra55 scanning electron microscope from ZEISS, Germany. image 3 It is a SEM photo, it can be seen from the figure that the prepared product has a uniform structure and a uniform particle size.

[0031] Take 3 g of the stannate intercalated hydrotalcite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com