Nitrogen-phosphorus-silicon synergistic coal flame-retardant dust suppressant and preparation method thereof

A technology of phosphorus-based flame retardants and silicon-based flame retardants, which is applied in the field of nitrogen-phosphorus-silicon synergistic coal flame-retardant and dust-suppressant agents and its preparation, can solve problems such as economic losses, threats to the lives of operators, mining equipment safety, and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

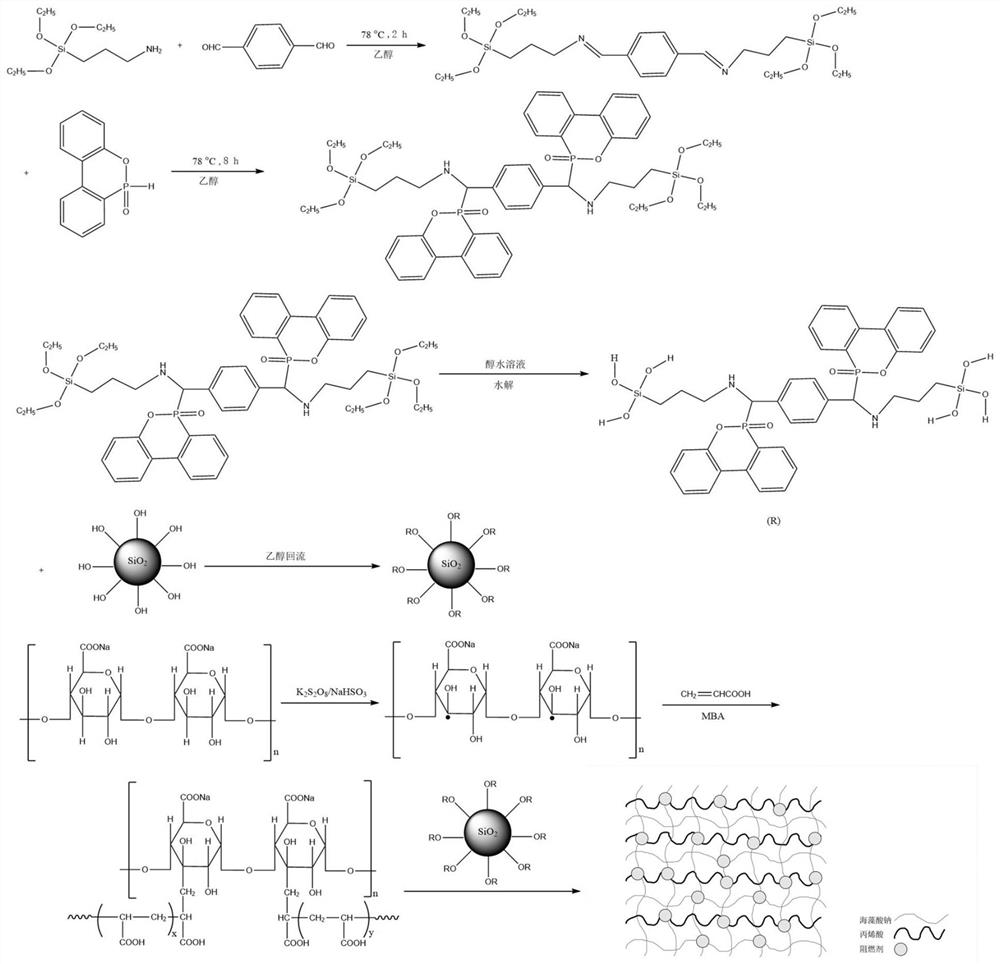

[0067] The invention also discloses a preparation method of nitrogen, phosphorus and silicon synergistic coal flame retardant and dust suppressant, comprising the following steps:

[0068] (1) Add 0.10-0.14 parts of nitrogen-containing silane coupling agent, 0.01-0.05 parts of aldehyde, and 30.0-60.0 parts of solvent into a three-necked flask filled with inert gas, and react in an oil bath at 60-120°C for 4-8 hours to obtain Solution A: Inert gas was introduced into the three-necked flask to exhaust the air and prevent the C=N bond formed in the reaction from being oxidized by oxygen.

[0069] Then weigh 0.08-0.12 parts of phosphorus-based flame retardant and fully dissolve it with 20.0-40.0 parts of solvent to obtain solution B;

[0070] Use a dropping funnel to slowly add solution B dropwise to a three-necked flask for 30-60 minutes, and react at 60-120°C for 8-16 hours to obtain a crude product;

[0071] The crude product was washed three times with a solvent, filtered wit...

Embodiment 1

[0084] A preparation method of nitrogen, phosphorus and silicon synergistic coal flame retardant and dust suppressant, comprising the following steps:

[0085] (1) Add 0.12g KH550, 0.03g terephthalaldehyde and 30.0g absolute ethanol into a three-necked flask filled with inert gas, and react in an oil bath at 78°C for 6 hours to obtain solution A;

[0086] Then weigh 0.10g DOPO and fully dissolve it with 20.0g absolute ethanol to obtain solution B;

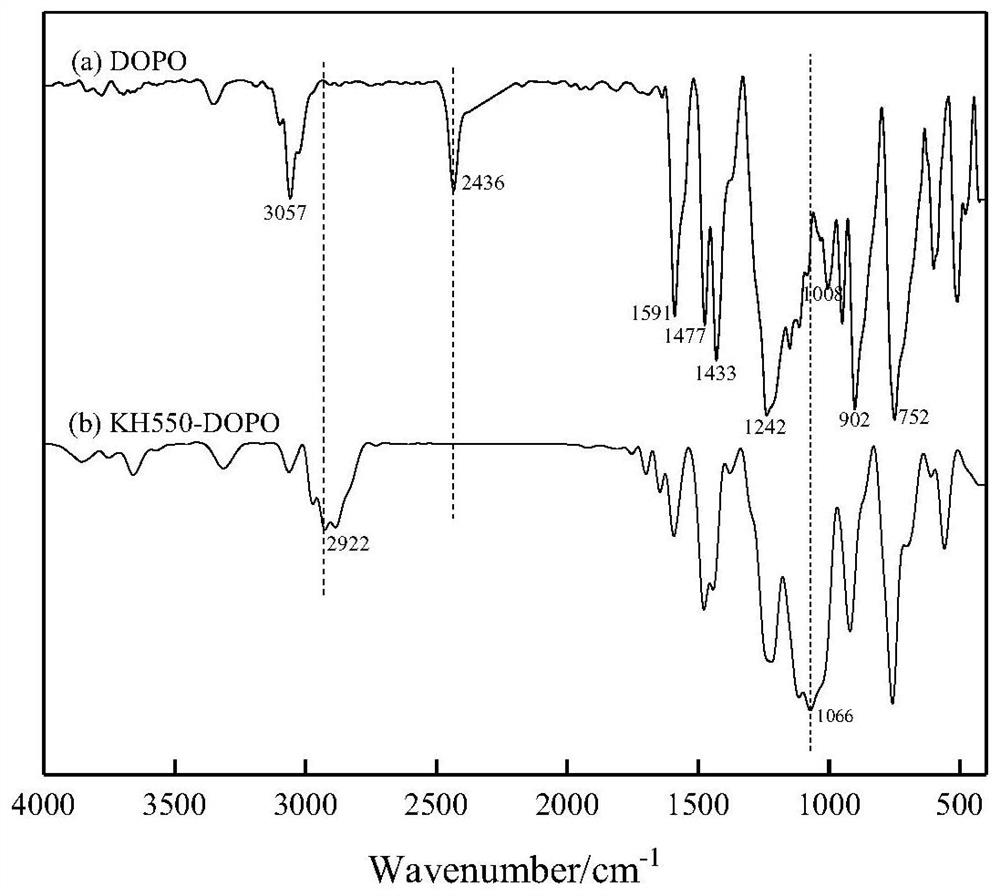

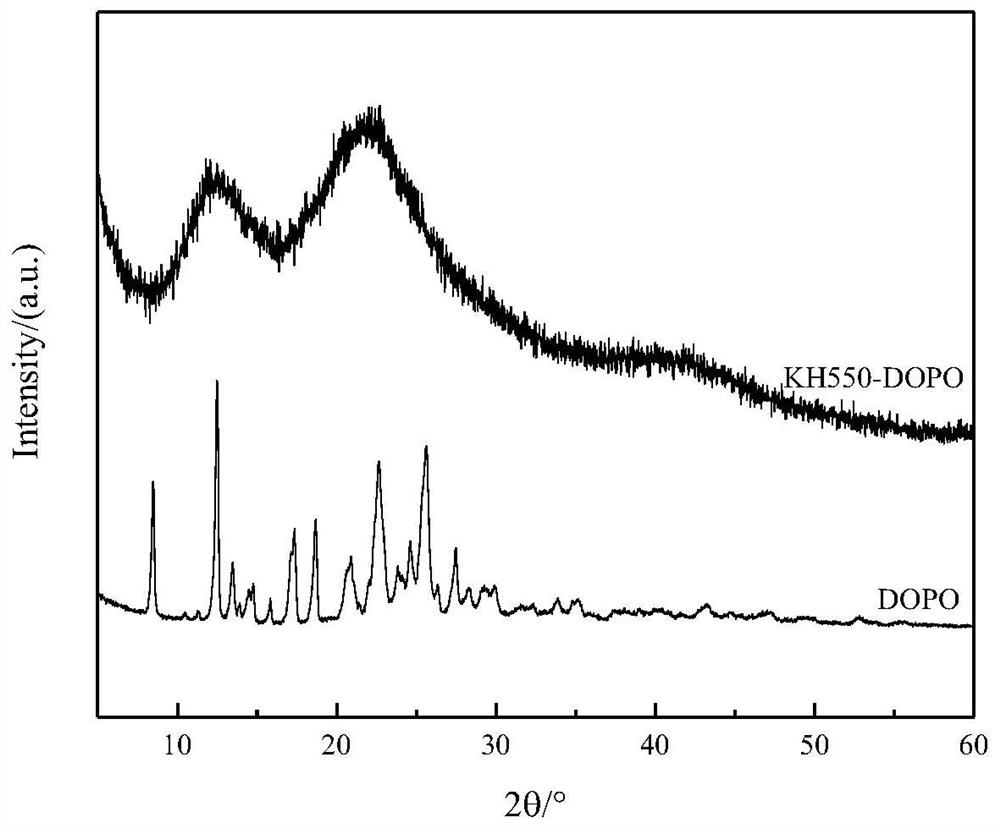

[0087] Use a dropping funnel to slowly drop solution B into solution A for 40 minutes, continue to react at 78°C for 12 hours to obtain a crude product, add absolute ethanol to wash the crude product three times and suction filter, dry at 60°C for 12 hours to obtain a flame retardant intermediate;

[0088] (2) Add the flame retardant intermediate in the beaker, add 57.0g ethanol and 3.0g deionized water to the flame retardant intermediate, then add 0.12g acetic acid to adjust the pH to 4.0, ultrasonically hydrolyze for 2h, and obta...

Embodiment 2

[0095] A preparation method of nitrogen, phosphorus and silicon synergistic coal flame retardant and dust suppressant, comprising the following steps:

[0096] (1) Add 0.14g KH550, 0.042g terephthalaldehyde and 30.0g absolute ethanol into a three-necked flask filled with inert gas, and react in an oil bath at 78°C for 6 hours to obtain solution A;

[0097] Then weigh 0.12g DOPO and fully dissolve it with 20.0g absolute ethanol to obtain solution B;

[0098] Use a dropping funnel to slowly drop solution B into solution A for 40 minutes, continue to react at a constant temperature for 12 hours to obtain a crude product, add absolute ethanol to wash the crude product three times and suction filter, and dry at 60°C for 12 hours to obtain a flame-retardant intermediate;

[0099] (2) Add a flame retardant intermediate to a beaker, add 57.0 g of ethanol and 3.0 g of deionized water to the flame retardant intermediate, then add 0.12 g of acetic acid to adjust the pH to 4.0, and ultras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com