Three-sources-integrated intumescent flame retardant, and synthesis method and application thereof

A technology of intumescent flame retardant and synthesis method, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc. problems, to achieve the effect of high synthesis efficiency, mild reaction conditions and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

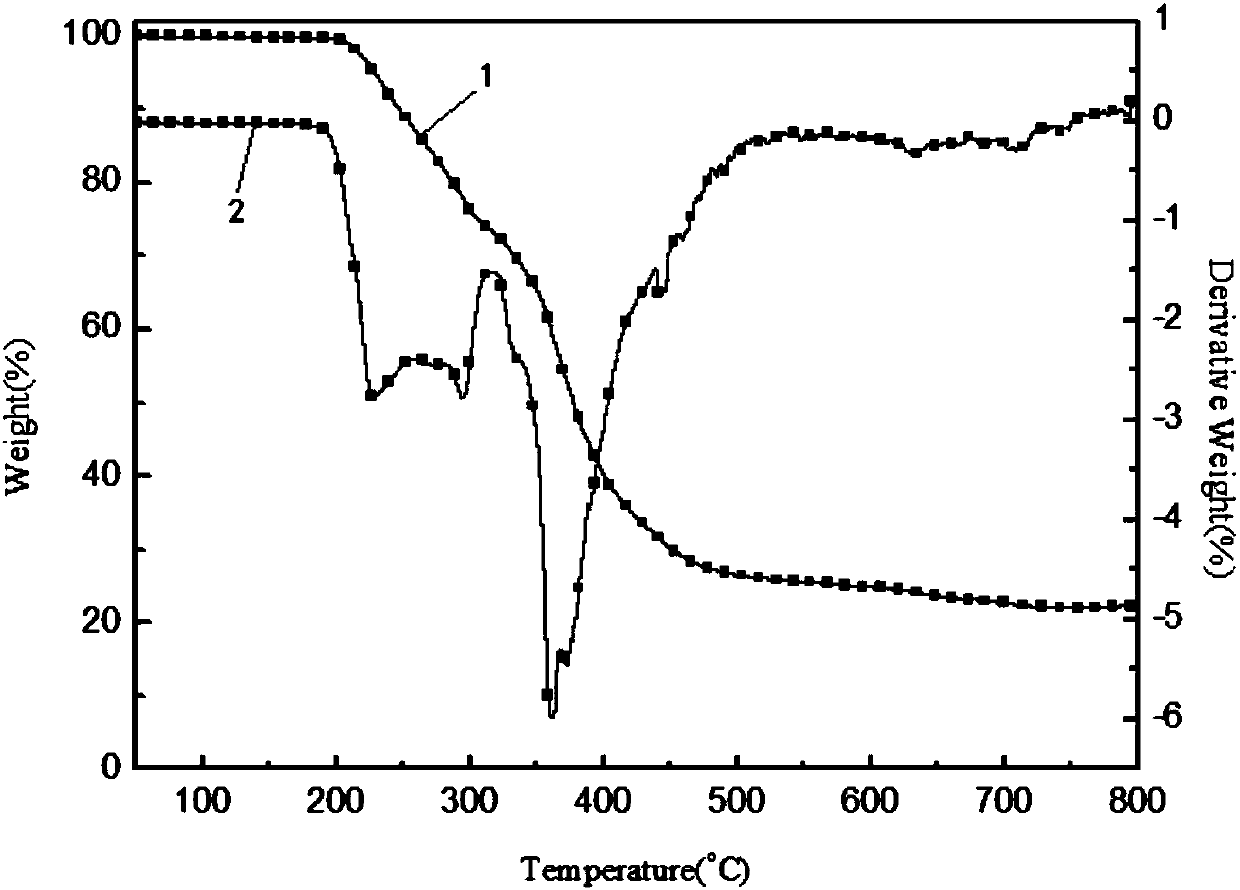

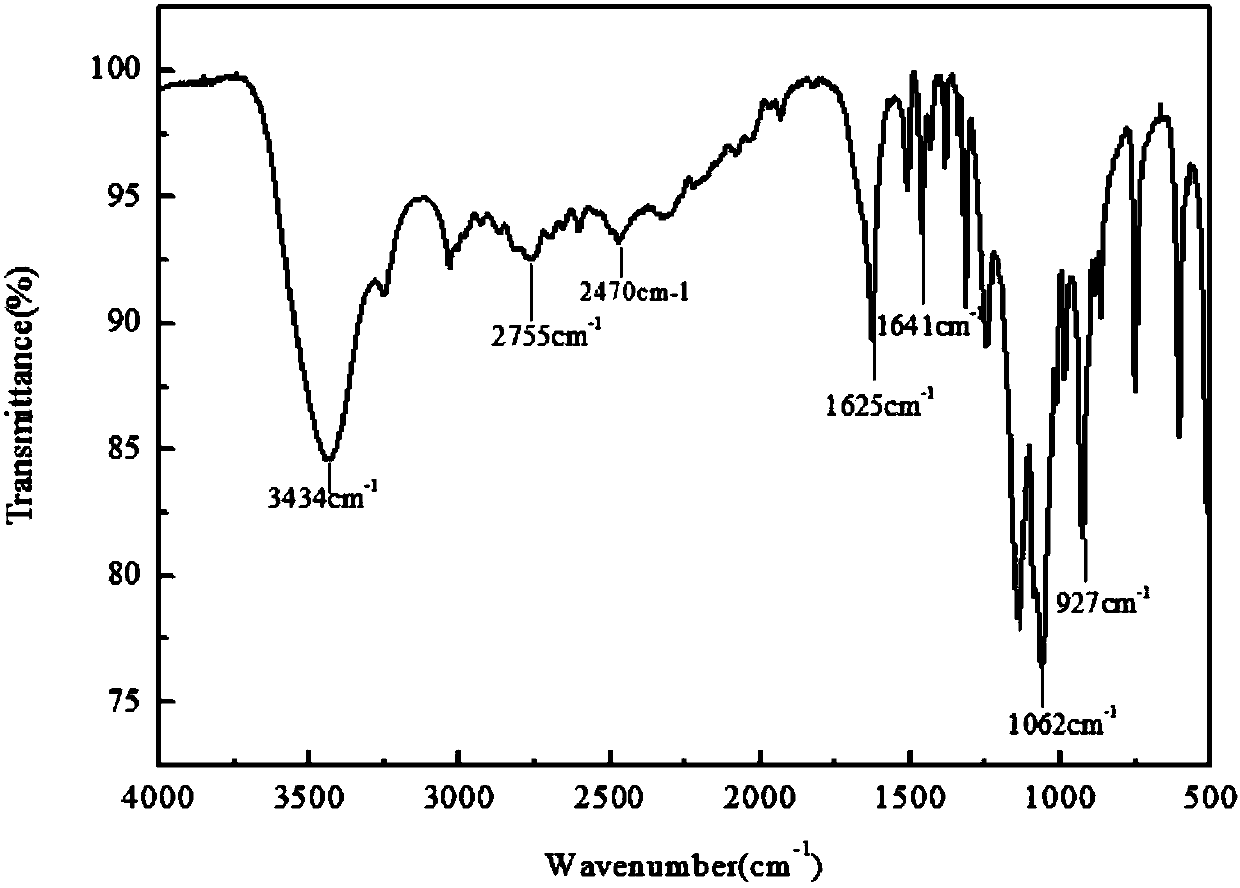

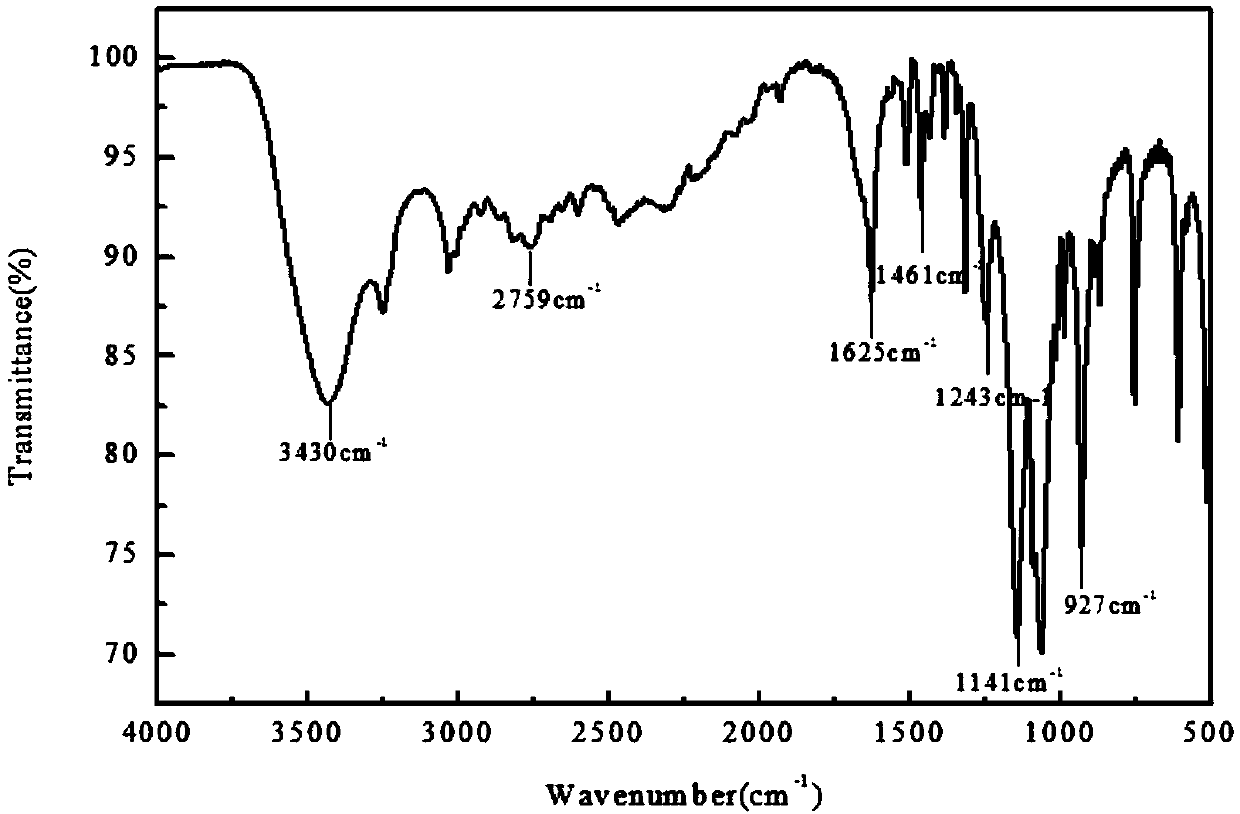

Image

Examples

specific Embodiment approach 1

[0034] Specific implementation mode 1: The structural formula of the three-source intumescent flame retardant in this implementation mode is:

[0035]

[0036] where n≥1.

specific Embodiment approach 2

[0037] Specific embodiment two: The synthesis method of the three-source intumescent flame retardant in this embodiment includes the following steps:

[0038] 1. Add piperazine and distilled water to a four-neck flask equipped with a stirring device, a constant pressure dropping funnel, a thermometer and a reflux condenser. The mass ratio of piperazine and distilled water is 1:1, and heat until completely dissolved;

[0039] Add distilled water to the methylphosphonic acid to dissolve the methylphosphonic acid at room temperature to obtain a saturated aqueous solution of methylphosphonic acid, drop the saturated aqueous solution of methylphosphonic acid into a four-necked flask through a constant pressure dropping funnel, and add dropwise After completion, raise the temperature of the system to 85-90°C, react at this temperature for 3-5 hours, then place the colorless, transparent, viscous liquid obtained in a rotary evaporator for concentration, and then put it in a vacuum dry...

specific Embodiment approach 3

[0041] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the molar ratio of methylphosphonic acid to piperazine in step 1 is 2:1. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com