Patents

Literature

175 results about "Methylphosphonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

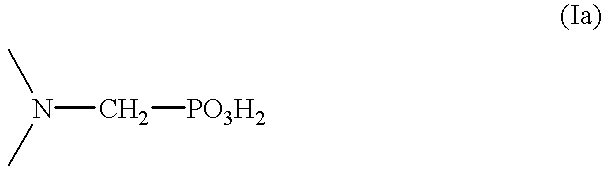

Methylphosphonic acid is an organophosphorus compound with the chemical formula. CH₃P(O)(OH)₂. The phosphorus center is tetrahedral and is bonded to a methyl group, two OH groups and an oxygen. Methylphosphonic acid is a white, non-volatile solid that is poorly soluble in organic solvent but soluble in water and common alcohols.

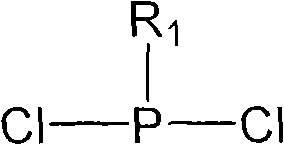

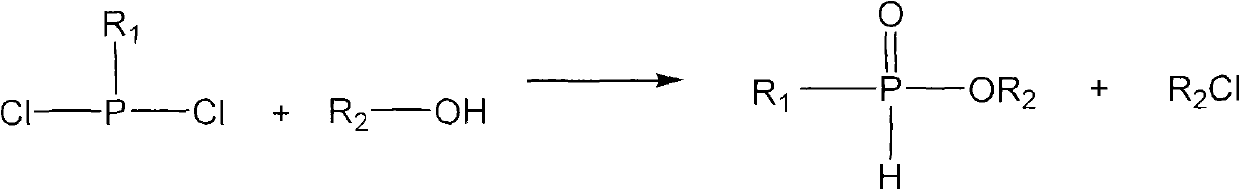

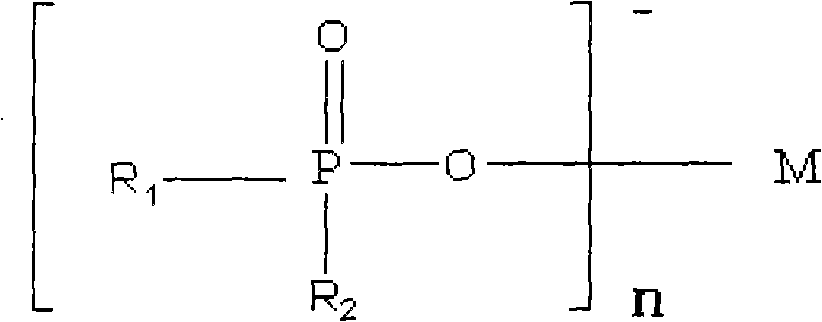

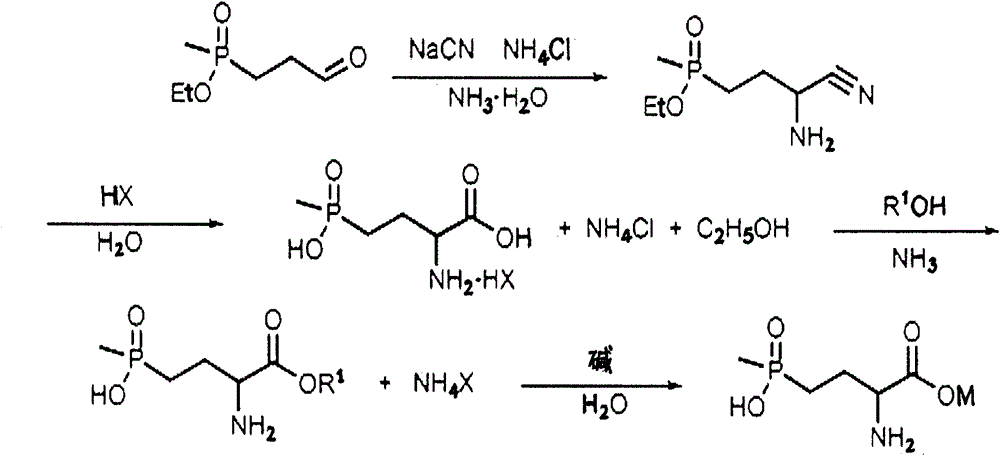

Dialkyl metal phosphinate and synthesis process of fire retardant thereof

ActiveCN101830926AEasy to prepareMild reaction conditionsGroup 5/15 element organic compoundsPhosphateStructural formula

The invention relates to a preparation method of a fire retardant, in particular to a dialkyl metal phosphinate and a synthesis process of a fire retardant thereof. The dialkyl metal phosphinate has a structural formula described in the specification, wherein R1 represents alkyl, M represents metal ions, n represents an integer from 1 to 3, and R2 represents olefin of aliphatic series. The preparation method comprises the steps of: reacting alkylphosphonous dichloride with alcohol to obtain monoalkyl phosphate; carrying out radical reaction on the monoalkyl phosphate with olefin to obtain dialkyl ester phosphinate; and reacting the dialkyl ester phosphinate with lewis acid to obtain the dialkyl metal phosphinate fire retardant. The invention has mild reaction condition; the prepared product has good thermal stability and high yield, wherein the yield can reach 87.6 percent by the count of methyl butyl ester phosphate; and the preparation method is suitable for industrialized production.

Owner:HONGHU YITAI TECH CO LTD

Method for effecting solvent extraction of metal ions using hydrocarbon soluble aminomethylene phosphonic acid compounds

Solvent extraction of one or more metal ions from an aqueous solution in the presence of hydrocarbon-soluble aminomethylenephosphonic acid derivatives.

Owner:BASF AG +1

Method of extracting rare earth from apatite

InactiveCN1514029AImprove stabilityHigh extraction rateRare earth metal compoundsProcess efficiency improvementApatiteKerosene

A process for extracting RE from the RE contained phosphorite is disclosed, which features that its immersing liquid is nitric acid, its salting-out agent is ammonium (or sodium) nitrate, its extractant is dimethylheptyl methylphosphonate (P350) or 2-ethylhexyl phosphonate-bis(2-ethylhexyl) ester (P502), its diluent is n-heptane or kerosene, its washing liquid is the solution of sodium (or ammonium) nitrate, its backextractant is the solution of nitric acid or hydrochloric acid, and its preciptant is oxalic acid. Its advantage is high purity (more than 95%) and high output rate (more than 98%) of RE.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

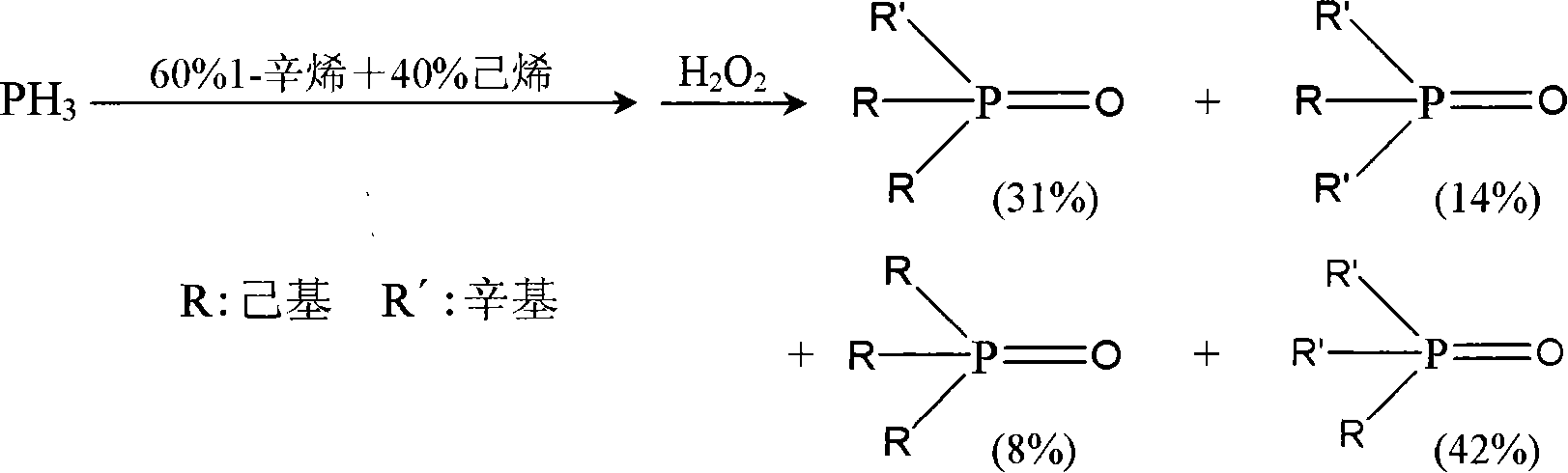

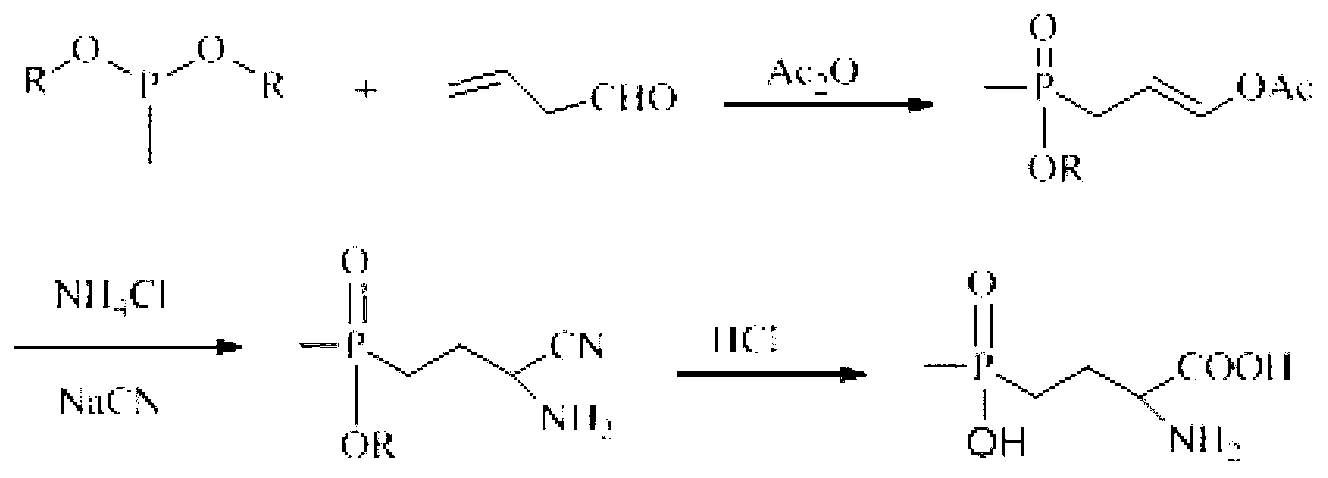

Method for synthesizing glufosinate

The invention relates to a synthesizing method for pesticide glufosinate, i.e., ((D,L)-2-amino-4-(hydroxyl(methyl)phosphinyl)butyrate) and a salt of an acid or an alkali thereof. In the synthesizing method, the pesticide glufosinate is prepared by undergoing a strecker reaction, and an intermediate compound, i.e., (3-nitrile-3-hydroxy)propyl methyl phosphonic acid directly reacts with carbon dioxide and ammonia gas in an aqueous solution to synthesize the pesticide glufosinate and a salt of an acid or an alkali thereof. The method comprises the following specific steps of: adding the intermediate compound, i.e., (3-nitrile-3-hydroxy) propyl methyl phosphonic acid into a high-pressure kettle; adding carbon dioxide, ammonia gas and water, wherein ammonium bicarbonate or ammonium carbonate and the like can be used for replacing carbon dioxide carbon and ammonium, the molar ratio of the intermediate to the carbon dioxide is between 1 and 12, and the ratio of the ammonia gas to the carbon dioxide is between 0.5 and 5; adding 15-75 times of water; heating to 120-180 DEG C; reacting for about 4-20 hours; and after the reaction, cooling, taking the reaction liquid out, and concentrating to directly obtain an ammonium salt of glufosinate. The yield is over 80 percent.

Owner:HEBEI VEYONG BIO CHEM

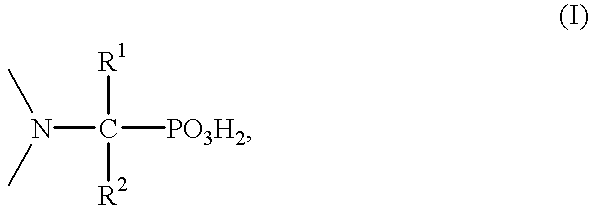

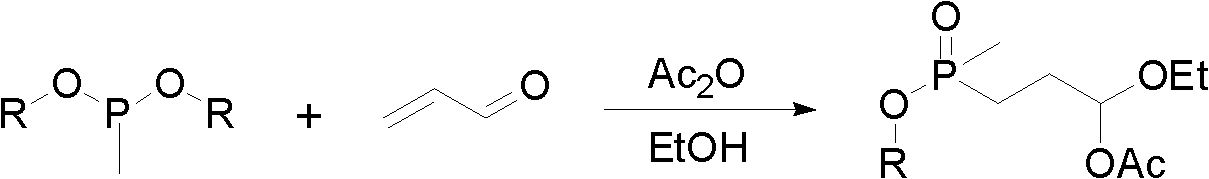

Preparation method for glufosinate

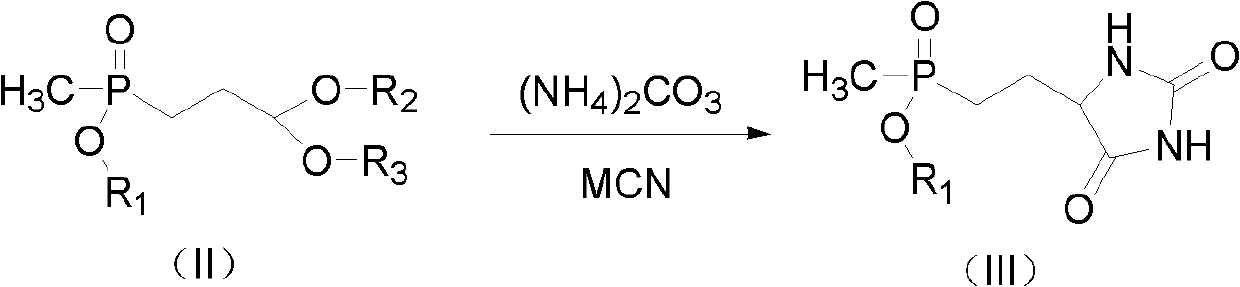

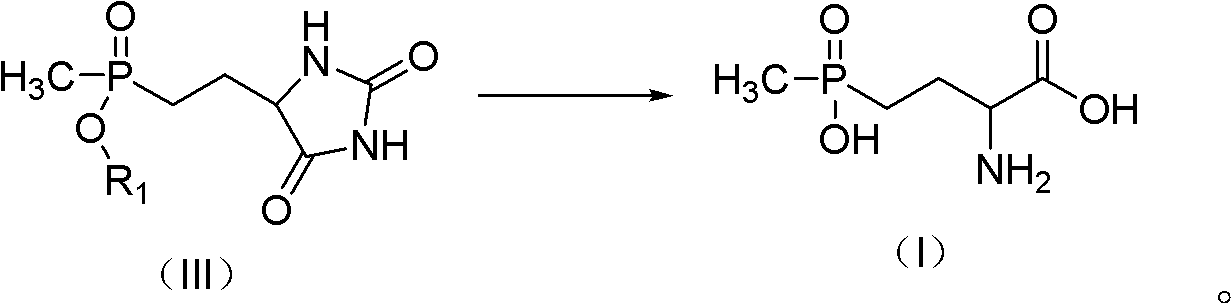

ActiveCN102584893AHigh purityHigh yieldGroup 5/15 element organic compoundsCyanideMethylphosphinic acid

The invention relates to a new preparation method for herbicide glufosinate. The method comprises the following steps of: performing Bucherer-Bergs cyclization reaction on a methylphosphonate derivative type compound (II), ammonium carbonate and cyanide serving as raw materials to obtain a compound shown by a formula (III); and then hydrolyzing to prepare glufosinate compound shown by a formula (I). According to the preparation method, hemiacetal or acetal is used as a raw material, and the Bucherer-Bergs cyclization reaction is performed to obtain a glycolylurea derivative, so that high yield, easiness for detection and mild condition are guaranteed; and after glycolylurea is cyclihydrolyzed, a product has high purity, and ammonium salt can be removed without multiple recrystallization processes.

Owner:ZHEJIANG UNIV OF TECH

New method or preparing glufosinate ammonium salt

ActiveCN105481894AHigh puritySimple preparation processGroup 5/15 element organic compoundsGlufosinate-ammoniumAlcohol

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Low-trimethylene-content amino trimethylene phosphonic acid and preparation method thereof

InactiveCN103275120ALow trimethylidene contentGood compatibilityGroup 5/15 element organic compoundsPhosphorous acidWater quality

The invention relates to a preparation method of low-trimethylene-content amino trimethylene phosphonic acid, which comprises the following specific processing steps: adding ammonium chloride, an amino trimethylene phosphonic acid mother solution and formalin into a reaction kettle, and increasing the temperature to 90 DEG C; dropwisely adding formaldehyde and phosphorous acid, and keeping refluxing while controlling the temperature; after the dropwise addition, performing refluxing reaction while keeping the temperature; detecting the phosphite content, supplementing formaldehyde, and further performing refluxing reaction while keeping the temperature; performing negative pressure outer evaporation to remove the ammonium chloride, the formaldehyde and hydrogen chloride; and cooling, and adding reverse osmosis water to regulate the active matter content. According to the invention, the provided amino trimethylene phosphonic acid has the characteristic of low trimethylene content (the active matter content is 50+ / -2%, and the trimethylene content is 24-26%); and compared with the common commercially available amino trimethylene phosphonic acid, the provided amino trimethylene phosphonic acid has better compatibility with zinc corrosion inhibitor, and can regulate the amount of zinc corrosion inhibitor in a compound product in a wider range. Besides, the invention widens the application range of the amino trimethylene phosphonic acid in different water bodies.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

Method for separating cerium, reclaiming fluorin and preparing cerous fluoride ultra-micro powder for mixed extraction system

This invention discloses the method for separating cerium and recovering fluorine and preparing ultramicro-powder cerium trifluoride. In this invention method, bastnasite ore or the mixture containing bastnasite ore and eremite ore is used as raw material mixed with sulfuric acid or nitric acid or the mixture containing both in optional ratio. The extractant is the mixture containing EXTR1 and EXTR2. Said EXTR1 is trialkyl phosphine oxide or dimethyl heptyl methyl-phosphonate or tritutyl phosphate; and said EXTR2 is di(2-ethylhexyl) phosphate, or mono 2-ethyl-hexyl 2-ethyl-hexyl-phosphonate, or di (2,4,4-trimethyl pentyl) phosphonate. The diluent is paraffine or sulfonated kerosene. The products of Ce3+ and cerium trifluoride are obtained after the loading organic phase is proceeded washing and back-extraction. The purity of the cerium trifluoride is 99.9-99.999%, and the grain size distribution is 40-300nm, the recovery rate of cerium is greater than 95%, and fluorine than 98%.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

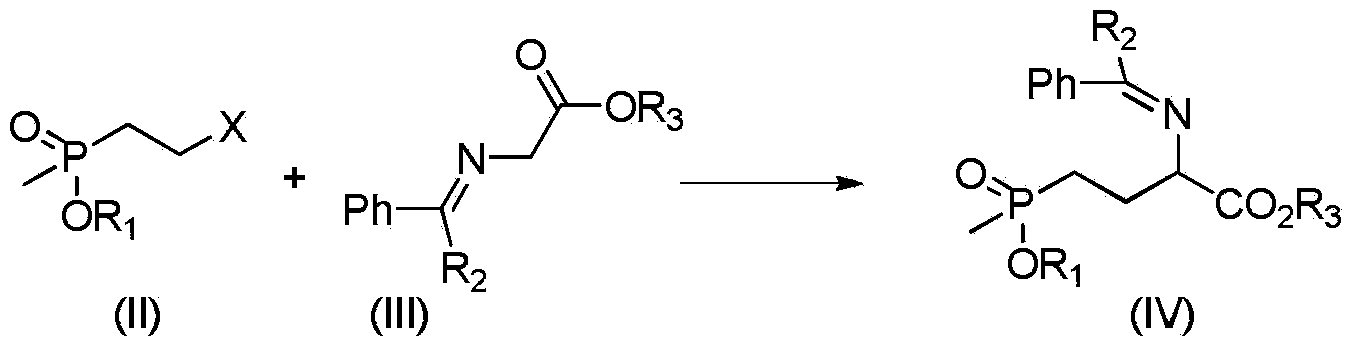

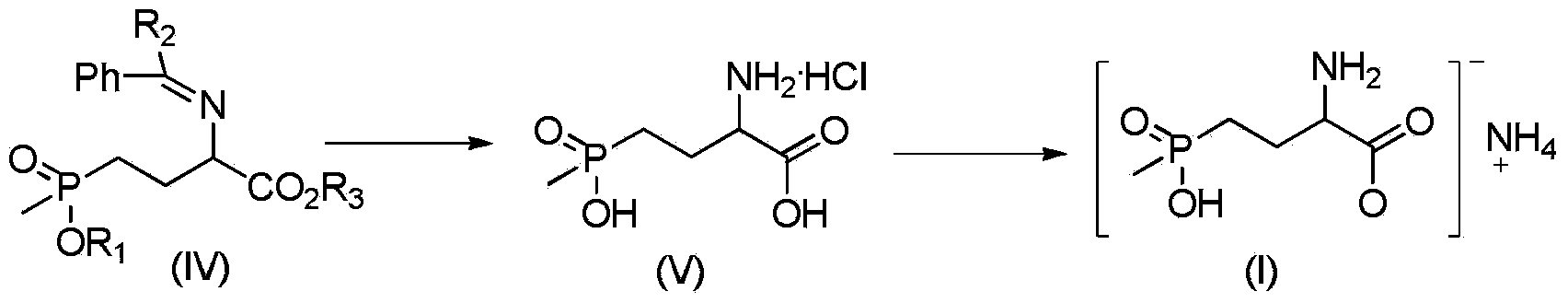

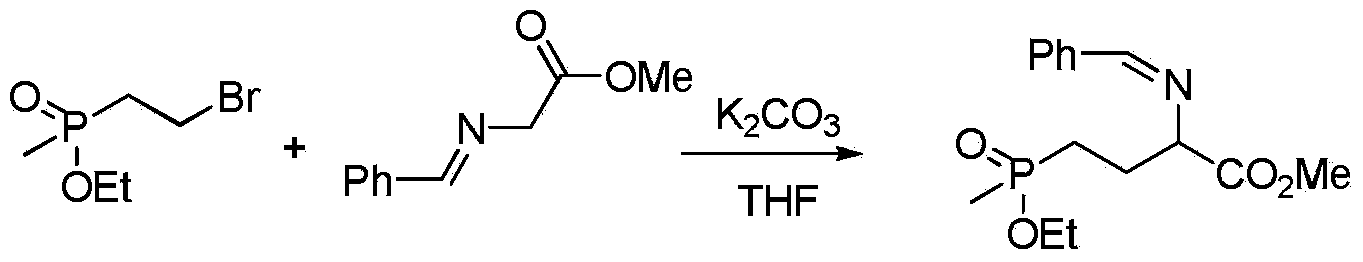

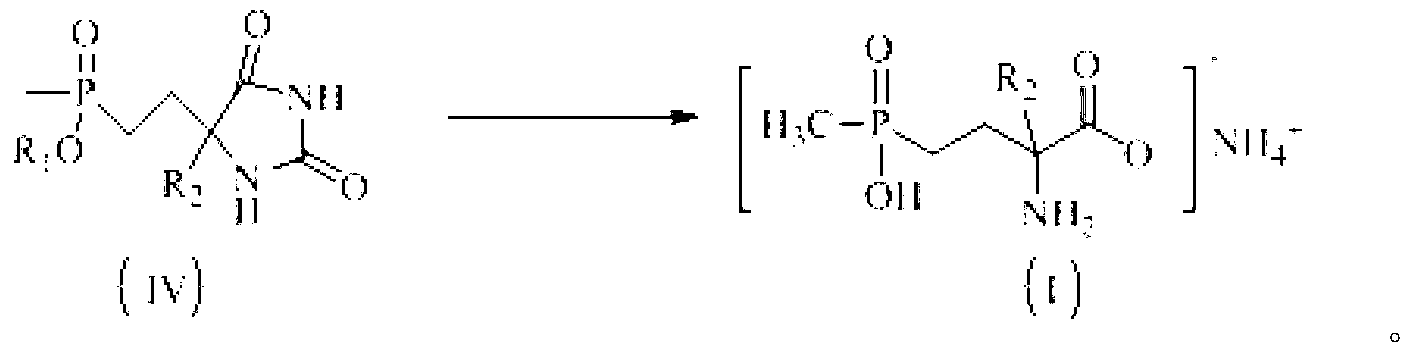

Preparation method of glufosinate-ammonium

InactiveCN103965241AHigh yieldEasy to monitorGroup 5/15 element organic compoundsGlycineInorganic salts

The invention discloses a preparation method of glufosinate-ammonium. The method comprises the steps that methylphosphonate compound (II) and benzylidene glycine ester compound (III) are reacted, so as to obtain benzylidene phosphonic butyric ester compound (IV); the benzylidene phosphonic butyric ester compound (IV) is further hydrolyzed, so as to obtain hydrochloride (V); finally, the target product glufosinate-ammonium (I) is obtained. The method has the advantages that the utilization of extremely toxic substance cyanide is avoided, the reaction condition is mild, monitoring is easy, and repeated recrystallization is not required for removing inorganic salt. (img file='DDA0000501075940000011.TIF' wi='1408' he=' 672' / ).

Owner:XIAN MODERN CHEM RES INST

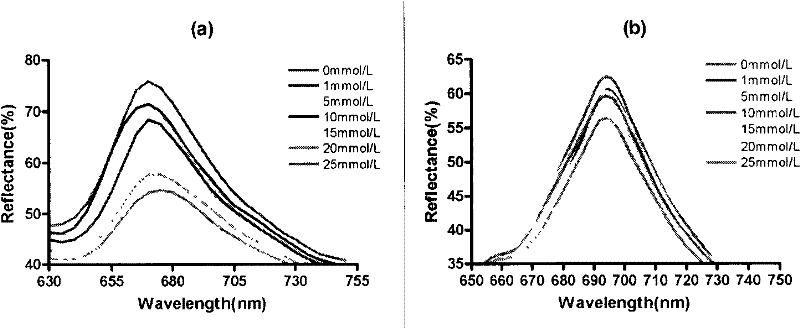

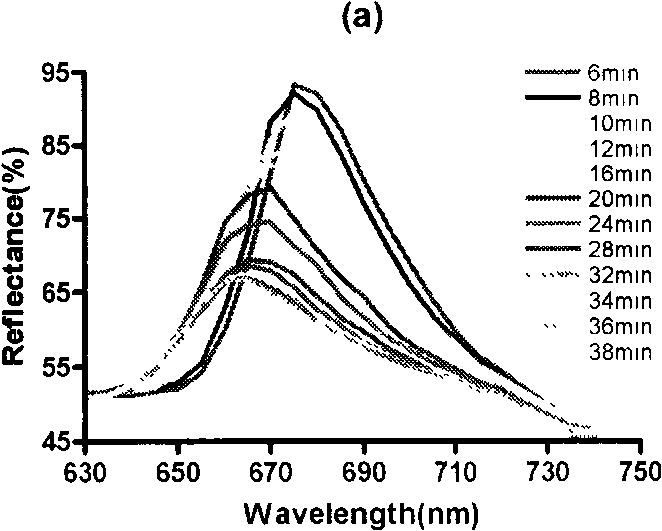

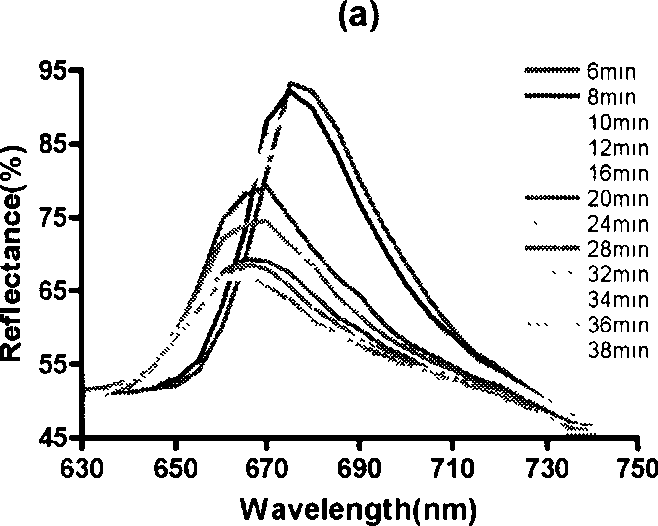

Molecularly-imprinted photonic crystal for detecting organophosphorus toxicants

InactiveCN102675531ASpecific adsorptionReduce reflected lightOther chemical processesColor/spectral properties measurementsReflectance spectroscopyToxicant

The invention discloses a novel sensor, and specifically discloses a molecularly-imprinted photonic crystal (MIPC) which is used for detecting organophosphorus toxicants timely and quickly. The MIPC employs methylphosphonic acid and ethylphosphonic acid as imprinting templates. An intensity of a reflectance spectrum of the corresponding imprinted photonic crystal decreases significantly with the increase of the concentration of a target compound or with the absorption time. The MIPC also shows some practical application values, and shows effects of low detection limit and high sensitivity in detections for the organophosphorus toxicants such as sarin, soman, VX and R-VX prototypes.

Owner:孟子晖 +2

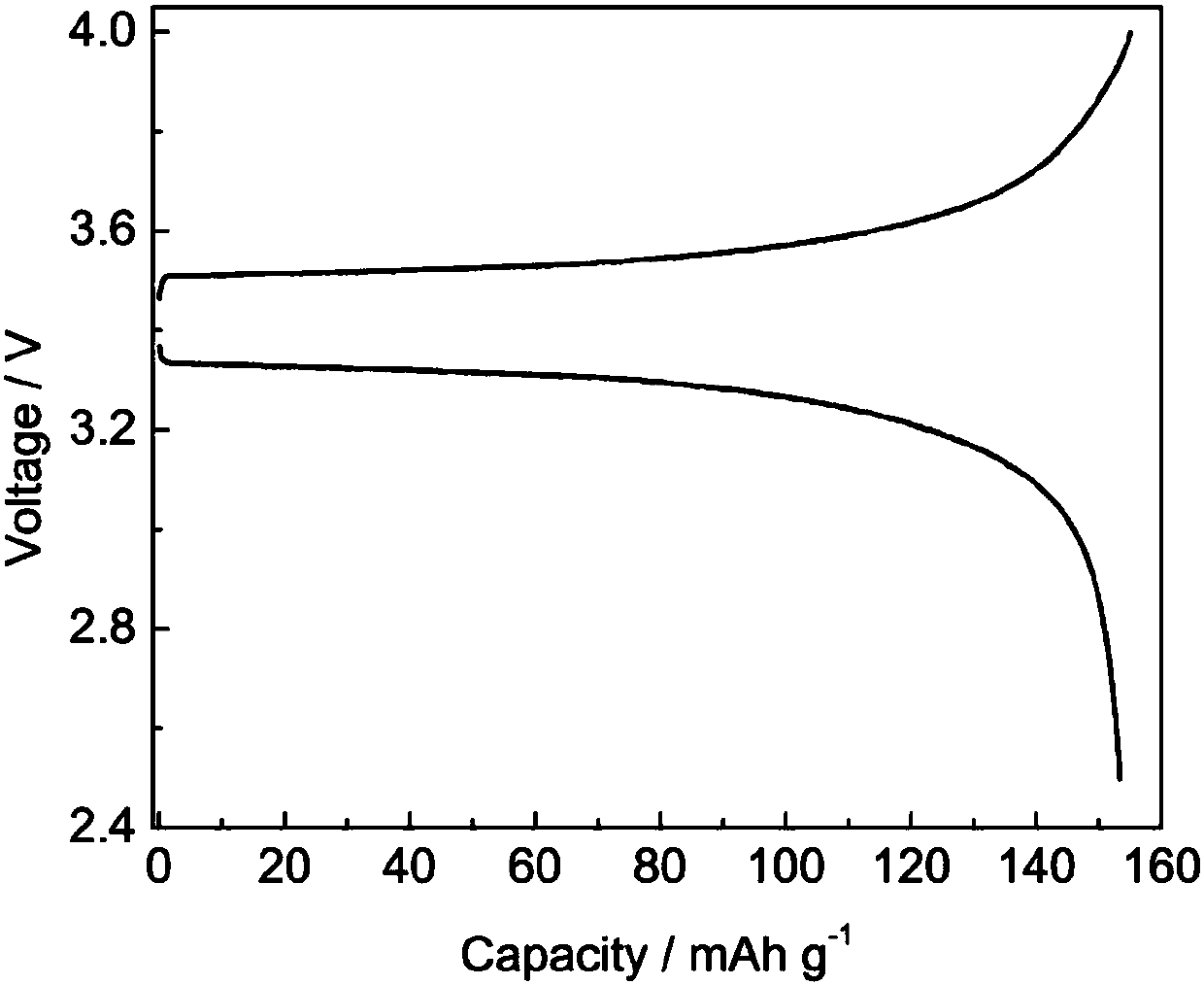

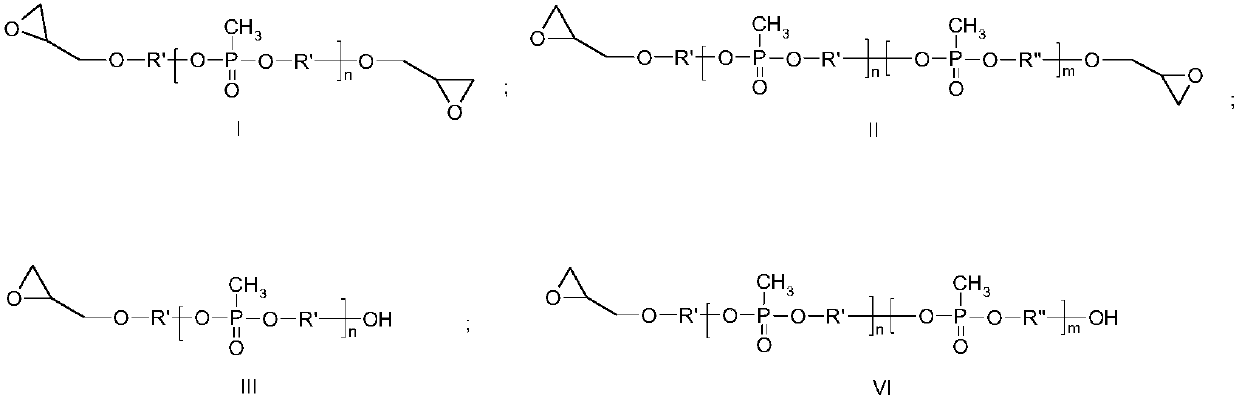

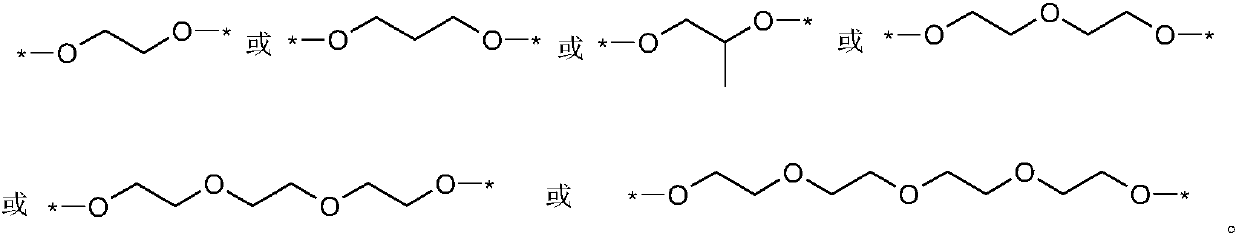

Preparation method of non-combustible solid polymer electrolyte and secondary lithium battery containing solid polymer electrolyte

ActiveCN107819156AImprove securityImprove flame retardant performanceSolid electrolytesFinal product manufactureSolid state electrolyteEpoxy

The invention discloses a preparation method of a non-combustible solid polymer electrolyte and a secondary lithium battery containing the solid polymer electrolyte. The preparation method comprises the following steps of uniformly mixing an epoxy-terminated methyl phosphonate oligomer, a lithium salt and a battery additive which are in the mass ratio of (60 to 100): (10 to 44): (0 to 14), then, injecting the mixture between positive and negative pole pieces of the battery, and carrying out in-situ polymerization curing under the condition of heating so as to prepare the non-combustible solidpolymer electrolyte. According to the preparation method, in-situ polymerization curing is carried out in the battery by using a mixed solution of the low-molecular-weight liquid epoxy-terminated methyl phosphonate oligomer, the lithium salt and the battery additive as a solid electrolyte precursor, so as to prepare the non-combustible solid polymer electrolyte; by adopting methyl phosphonate as aconstruction unit, the polymer full-solid electrolyte has excellent flame retardance and safety performance, and the safety performance of energy storage batteries, particularly high-capacity batteries and battery packs is greatly improved.

Owner:JIANGHAN UNIVERSITY

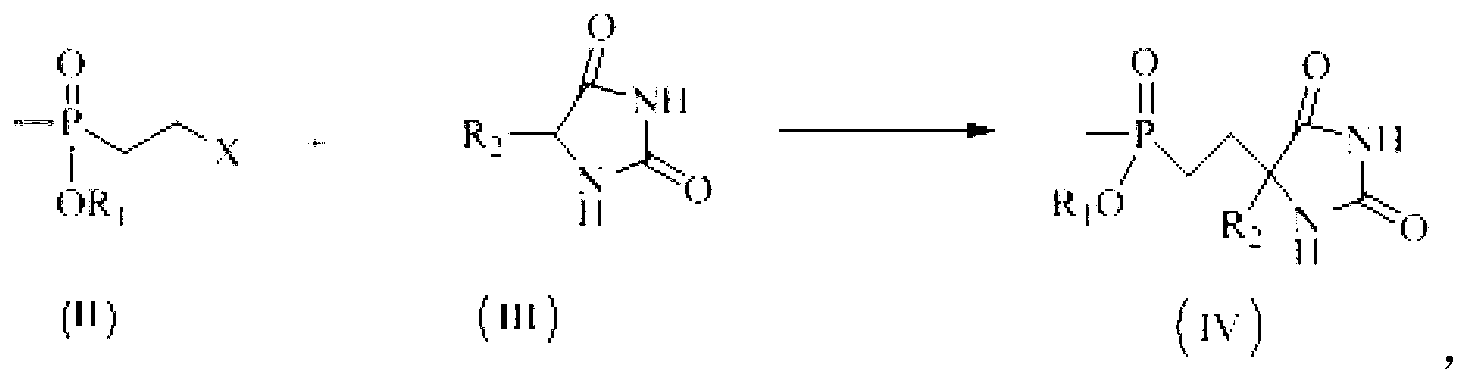

Preparation method of glufosinate-ammonium and derivatives thereof

InactiveCN103288874AHigh yieldEasy to detectBiocideGroup 5/15 element organic compoundsHydantoin derivativesReaction temperature

The invention discloses a preparation method of glufosinate-ammonium and derivatives thereof. The method comprises the following steps: (1) by using a substituted hydantoin and methylphosphonate compounds as a raw material, adding alkali, carrying out nucleophilic substitution reaction at the reaction temperature of 20-100 DEG C in a reaction solvent to obtain a hydantoin derivative, and tracing product generation condition by high performance liquid chromatography in the reaction process to judge the reaction endpoint, wherein the molar ratio of the methylphosphonate compounds, substituted hydantoin and alkali is 1:(1.0-5.0):(1.0-4.0); (2) carrying out reflux reaction for prepared hydantoin derivative prepared and an inorganic acid in water for 30-60 hours; after reaction, adding ammonia water to adjust the pH of the liquor to 12; spirally distilling to remove the solvent; adding absolute methanol for reflux for 30-60 minutes; filtering; spirally drying the mother liquor; adding methanol for recrystallization to obtain pure glufosinate-ammonium shown in formula (I) or derivatives thereof, wherein the molar ratio of the hydantoin derivative and inorganic acid is 1.0:(4.0-9.0).

Owner:SHANDONG ACADEMY OF PESTICIDE SCI +1

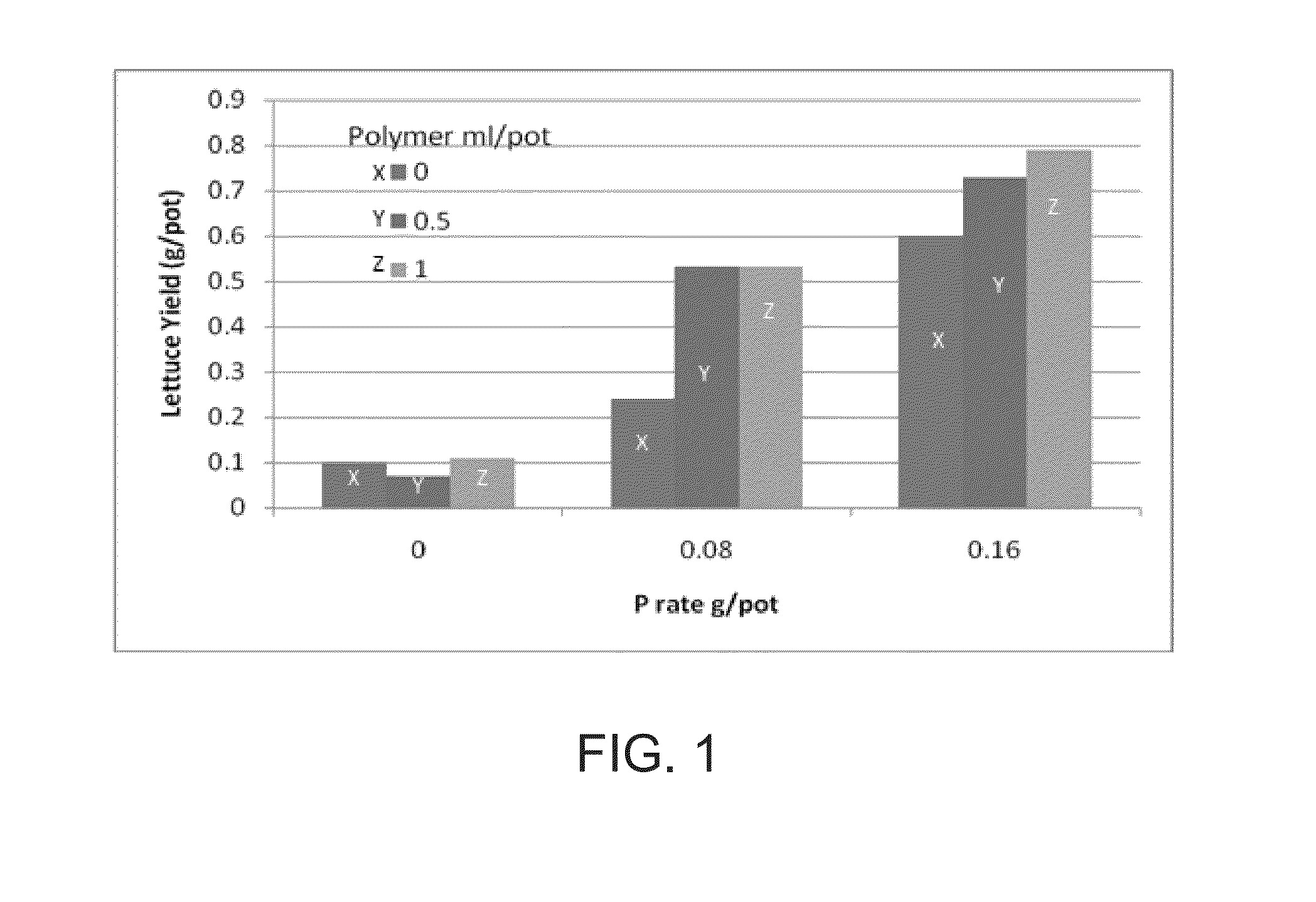

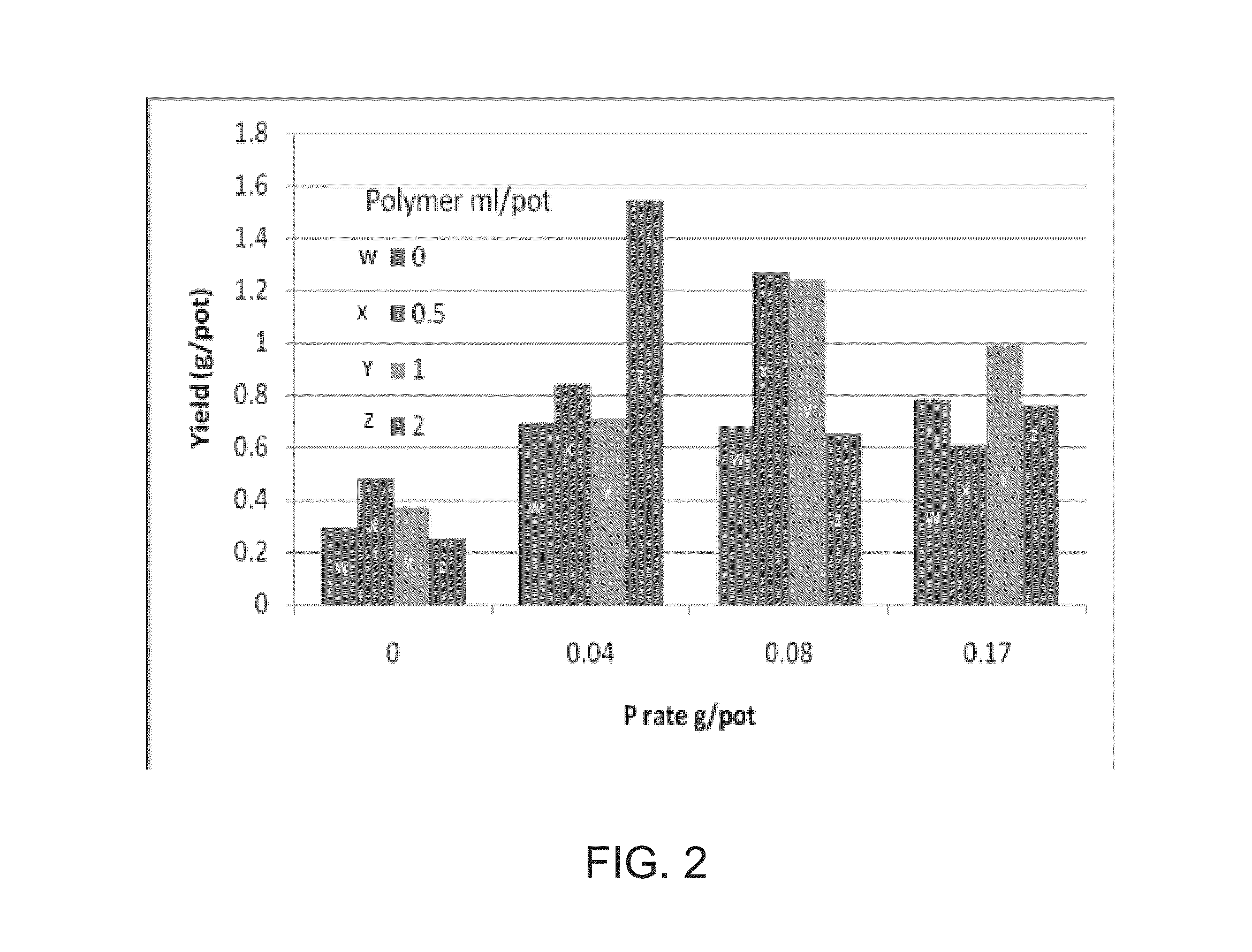

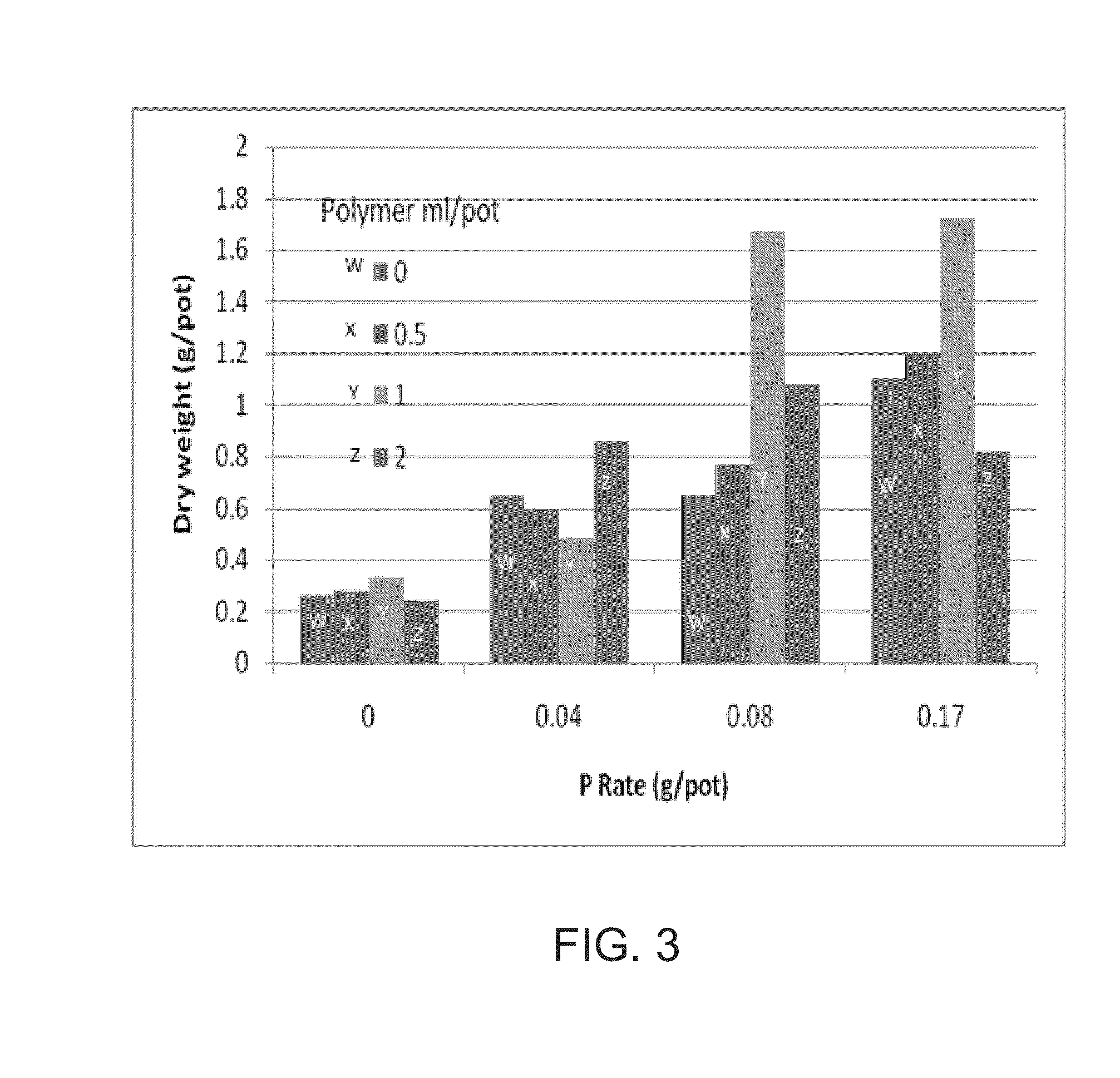

Polymers useful in agricultural applications

ActiveUS20140298872A1Programme controlLiquid fertiliser distributionSulfonateAgricultural irrigation

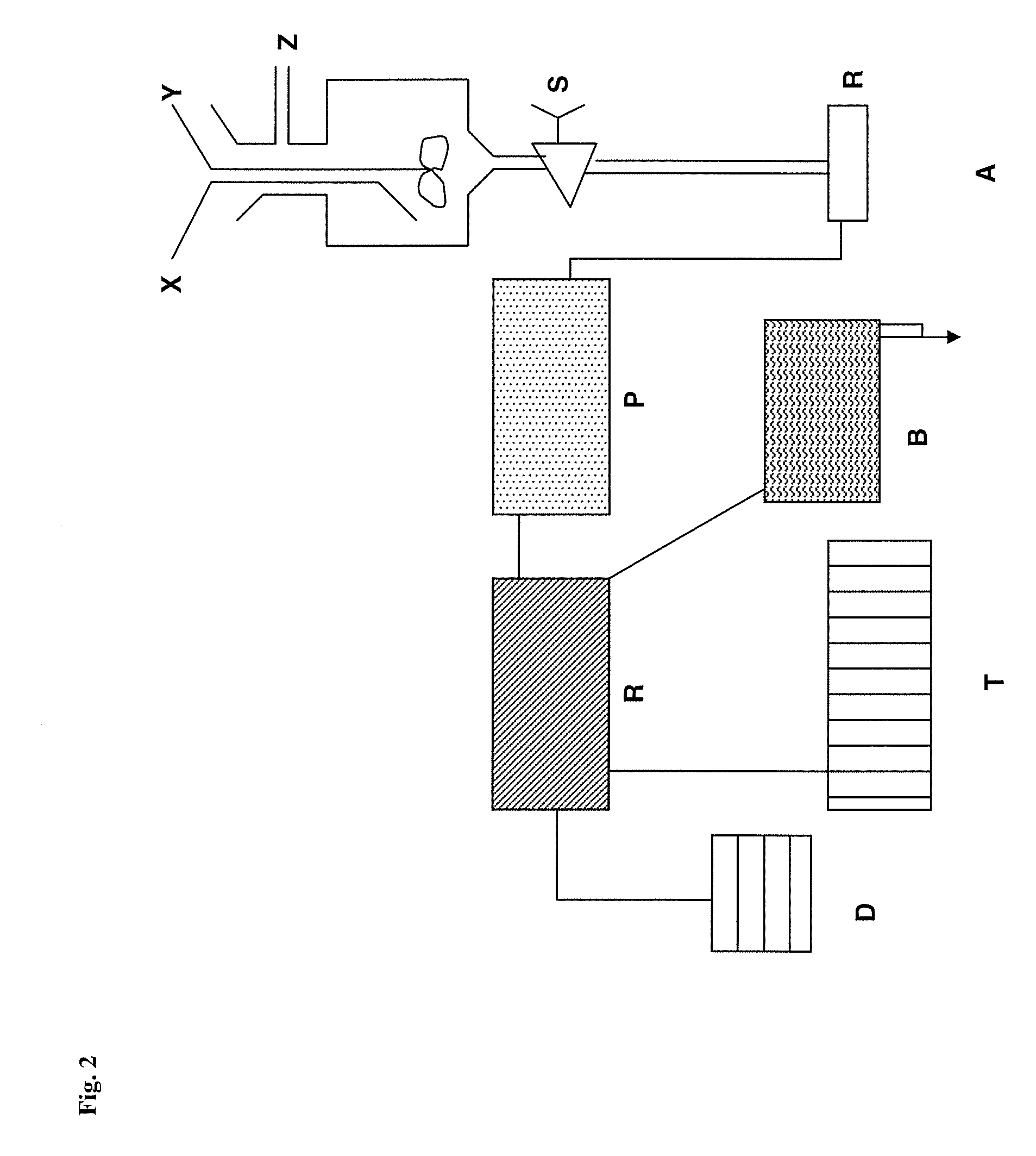

Methods of coating seeds with polymers and seeds coated with such polymers are disclosed herein. The polymers can be phosphonates, sulfonates, polymers of ethylenically unsaturated carboxylic acids, polyaminopolyethermethylene phosphonate, polysuccinic oligomers, acrylic acid / 2-acrylamido-2-methylpropane sulfonic acid, blends of acrylic acid / 2-acrylamido-2-methylpropane sulfonic acid with polyaminopolyethermethylene phosphonate, sulfomethylated acrylic acid / acrylamide, blends of sulfomethylated acrylic acid / acrylamide with polyaminopolyethermethylene phosphonate, polymaleic acid, acrylic acid / acrylamide copolymers, polyacrylic acid, trimethylglycine hydrochloride, blends of polyaminopolyethermethylene phosphonate with trimethylglycine hydrochloride, and any combination or salt of such polymers. Methods of monitoring, determining, and controlling the concentration of scale inhibitors in an agricultural irrigation system are also disclosed herein.

Owner:ECOLAB USA INC

High-density freezing-tolerant concrete

The invention discloses high-density freezing-tolerant concrete. The high-density freezing-tolerant concrete comprises the following raw materials: ordinary Portland cement, sea sand, gravel, water, silicon powder, lithium slag powder, fly ash, iron tailing sand, polypropylene fiber, glass fiber, magnesium powder, hydrogen peroxide, ethylene diamine-tetramethyl phosphoric acid, sodium dodecylbenzene sulfonate, phosphoric butanetricarboxylic acid, iron oxide yellow, sodium thiosulfate, urea, sodium chloride, ethylene glycol and a water-reducing agent. The high-density freezing-tolerant concrete disclosed by the invention has the advantages of good freezing tolerance, high density and good durability.

Owner:WUWEI HENGJI COMML CONCRETE

Scale inhibitor for circulating water

ActiveCN101412568AGood anti-scaling effectAdaptableScale removal and water softeningPolyaspartic acidALLYL SUCROSE

The invention relates to a circulating water scale inhibitor, which comprises the following components by weight portion: 2. 5 to 2.8 portions of PASP (polyaspartic acid), 1 to 1.2 portions of ATMP (amino trimethylene phosphonic acid), 2.4 to 2.6 portions of HPMA (hydrolyzed polymaleic anhydride), 1.2 to 1.4 portions of AA / AMPS (acrylic acid and 2-acrylamide-2-methyl propane sulfonic acid copolymer), 1.1 to 1.3 portions of PAA (polyacrylic acid), and 0.7 to 1.8 portions of water. The scale inhibitor prepared by the formulation is environment-friendly, has the characteristics of safety and reliability, easy preparation, convenient use and the like, and is suitable to be used as medicaments for preventing scale on circulating water systems in the fields of electric power, chemical engineering, medicine, petroleum, and the like.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

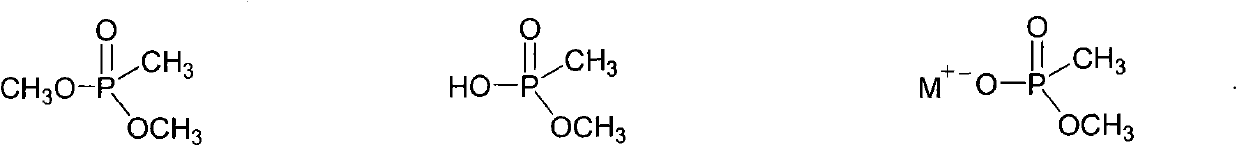

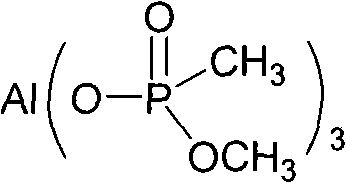

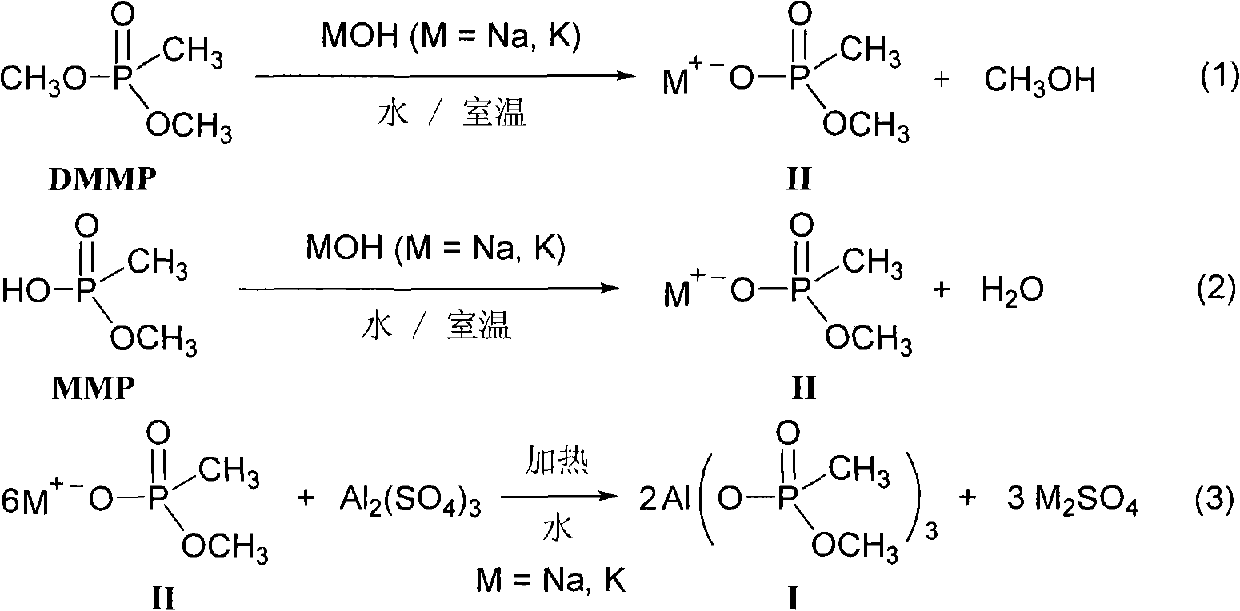

Organic aluminum phosphate fire retardant and preparation method and use thereof

The invention discloses a preparation method and use of an organic aluminum phosphate fire retardant. The method comprises: hydrolyzing dimethylmethylphosphonate under the action of sodium hydroxide or potassium hydroxide to form the sodium or potassium salt of dimethylmethylphosphonate, wherein the molar ratio of the dimethylmethylphosphonate to the sodium hydroxide or potassium hydroxide is 1:1; and reacting the aqueous solution of the sodium or potassium salt of dimethylmethylphosphonate with aluminum sulfate under heating and violently stirring CONDITIONS according to a molar ratio of 6:1 to form aluminum methyl methyl phosphonate. The aluminum methyl methyl phosphonate prepared by the invention only is formed by only reactions both of which are performed by using water as reaction medium, the process is simple and the efficiency is high. The thermal decomposition temperature of the aluminum methyl methyl phosphonate prepared by the method is above 325 DEG C, and the aluminum methyl methyl phosphonate can be used as V-0 grade fire retardant for thermoplastic plastics such as poly butylenes terephthalate (PBT) resin, poly(ethylene terephthate) (PET) resin, polyamide PA66 resin and poly(p-phenylene oxide) (PPO) resin.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

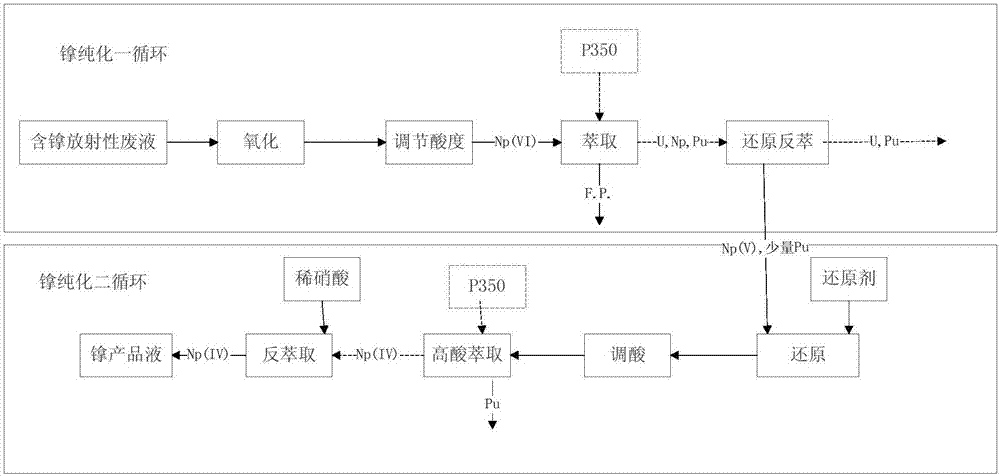

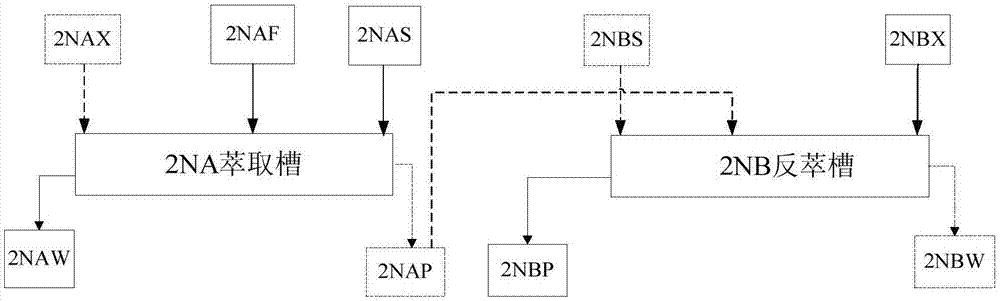

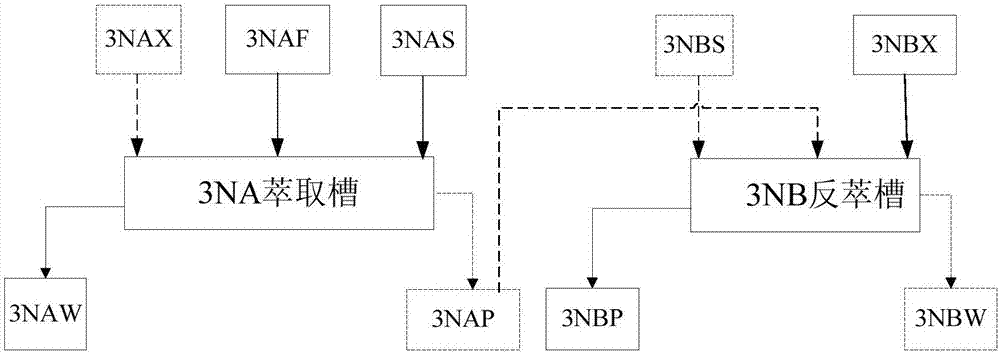

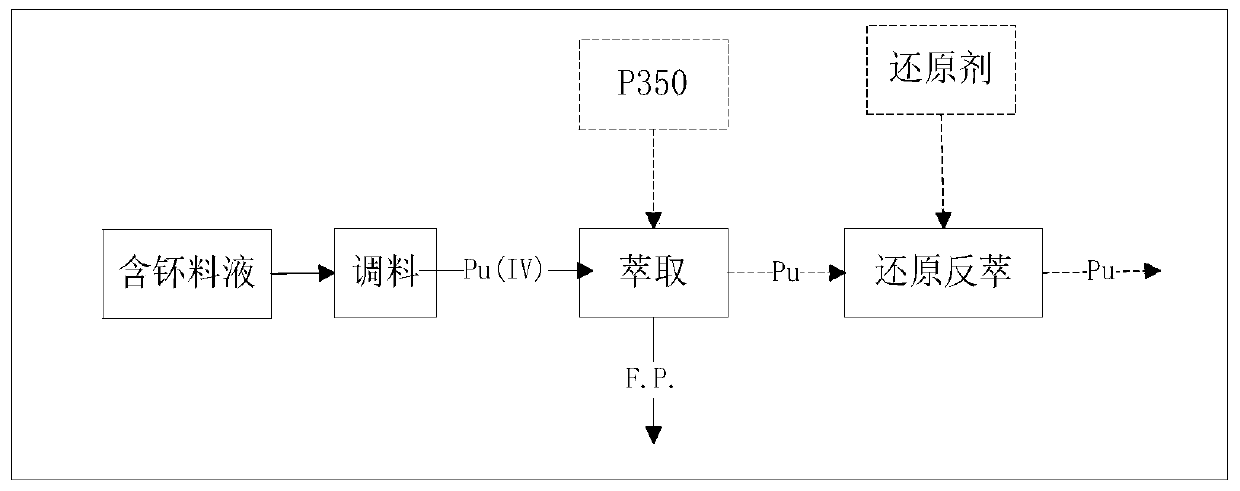

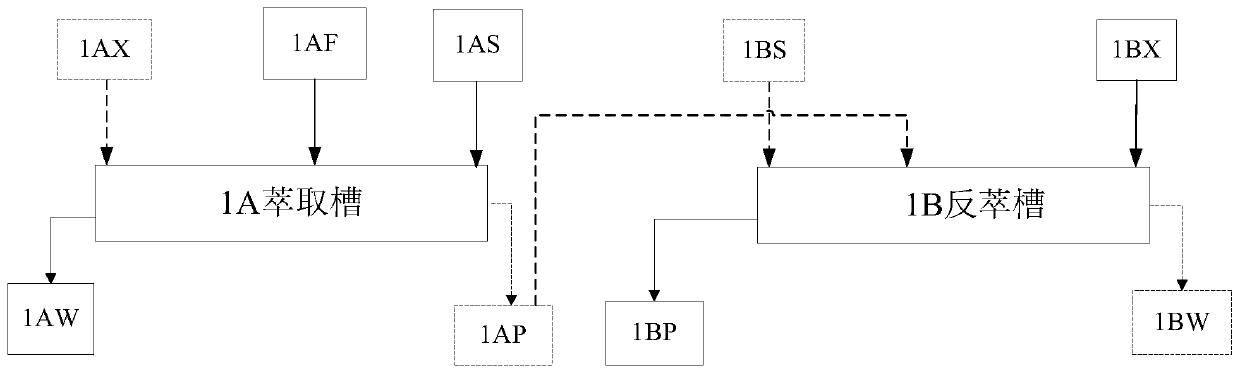

Method for extracting and recycling neptunium from spent fuel aftertreatment waste liquid

The invention belongs to the technical field of nuclear waste treatment and recycling, and relates to a method for extracting and recycling neptunium from spent fuel aftertreatment waste liquid. The method comprises following optional order-replaceable repeatable steps, and water phase back-extraction matte is finally collected. The steps comprise 1, neptunium in a neptunium-containing water phase solution is oxidized to be hexavalent, and an organic solvent containing dimethyl phosphonate (1-methyl heptyl) ester is added under the strong acid condition for extraction; organic phases are collected, a reducing agent is added, reextraction is carried out under the dilute acid condition, and therefore hexavalent neptunium in the organic phases is selectively reduced to be pentavalent and reextracted to enter a water phase; 2, a reducing agent is used for reducing neptunium in the water phase solution to be tetravalent, and an organic solvent containing dimethyl phosphonate (1-methyl heptyl) ester is added under the strong acid condition for extraction; and organic phases are collected, reextraction is carried out under the dilute acid condition, and therefore tetravalent neptunium in the organic phases is reextracted to enter the water phase. By means of the method, a neptunium nitrate solution with standard purity can be prepared.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

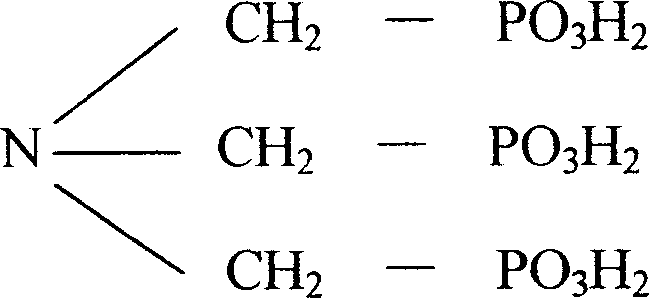

Intumescent flame retardant and preparation method thereof

InactiveCN107353437AConvenient sourceLow priceGroup 5/15 element organic compoundsPolymer scienceEvaporation

The invention relates to an intumescent flame retardant and a preparation method thereof. The intumescent flame retardant is polymethylene ammonium phosphonate which at least contains three methylammonium phosphonate groups -CH2P(O)(ONH4)2 in one molecule, and the intumescent flame retardant is prepared from polymethylene phosphonic acid and an ammonium source through a reaction, wherein the mole ratio of phosphonate groups PO3H2 to amino groups NH2 is 1:(2-2.5), a water solution is prepared from the ammonium source and water in the mass ratio being 1:(0.01-5) and dropwise added to polymethylene phosphonic acid while being stirred after complete dissolution, the reaction temperature is controlled to be 20-130 DEG C, the mixture is continuously stirred to react for 0.5-1.5 h after the water solution is dropwise added, evaporation concentration, cooling crystallization, filtration, washing, filtrate recovery for preparation of an ammonia source solution, filter cake drying and crushing are performed, and a product is obtained. The flame retardant is excellent in performance, good in stability and compatible with a polymer material, raw materials used in the preparation method are easily sourced, the cost is lower, and the process is simple, safe and environment-friendly.

Owner:青岛长荣化工科技有限公司

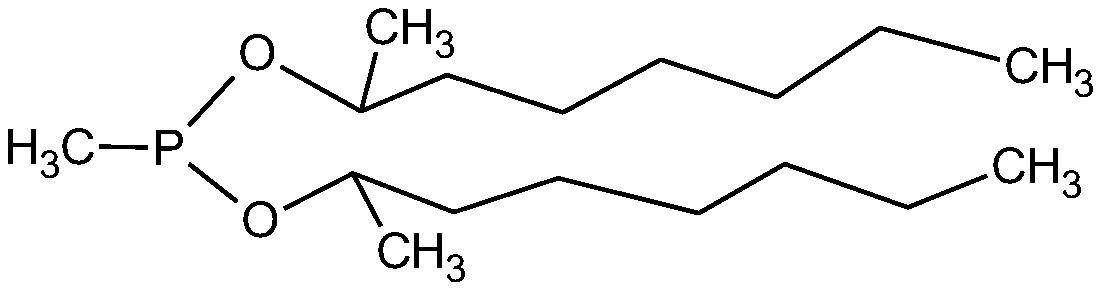

Method for extracting and recovering plutonium from plutonium-containing nitric acid solution

ActiveCN110656247AEfficient separationPurity up to standardProcess efficiency improvementFuel reprocessingPlutonium nitrate

The invention belongs to the technical field of nuclear material extraction and recovery, and relates to a method for extracting and recovering plutonium from a plutonium-containing nitric acid solution. The method comprises the following steps: oxidizing plutonium in the spent fuel reprocessing plutonium-containing nitric acid solution to tetravalent with an oxidant, adding an organic solvent containing DMHMP, Di(1-methyl heptyl)methyl phosphonate for extraction under strong acidic conditions, collecting organic phase, adding a reducing agent, performing back extraction under dilute acidic conditions to selectively reduce the tetravalent plutonium in the organic phase to trivalent, and performing back extraction to form the aqueous phase. The method for extracting and recovering plutoniumfrom the plutonium-containing nitric acid solution can efficiently separate plutonium from other impurities, such as uranium, fission product elements of plutonium, strontium, and cesium, and concentrate plutonium to obtain the plutonium nitrate product solution with standard purity.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

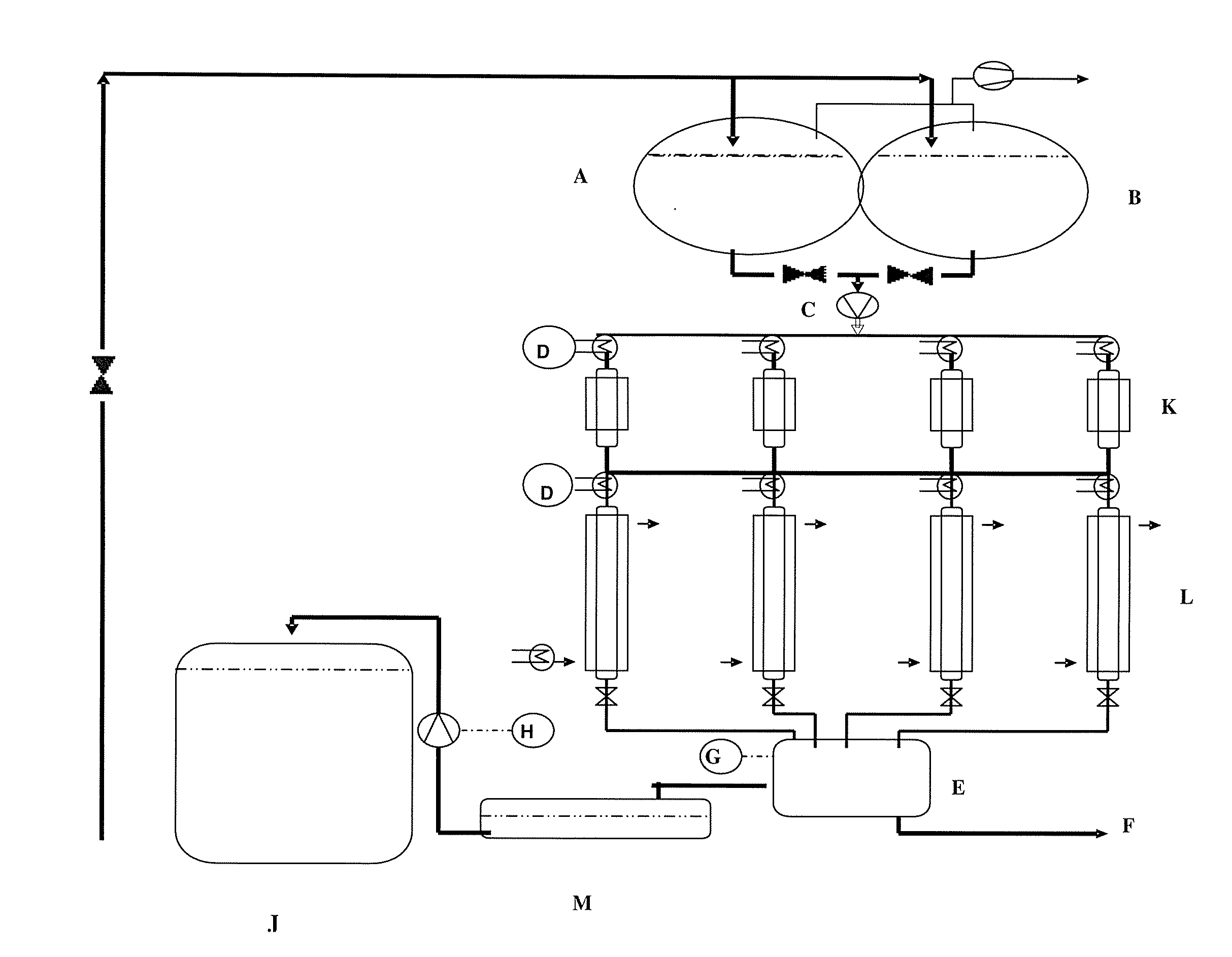

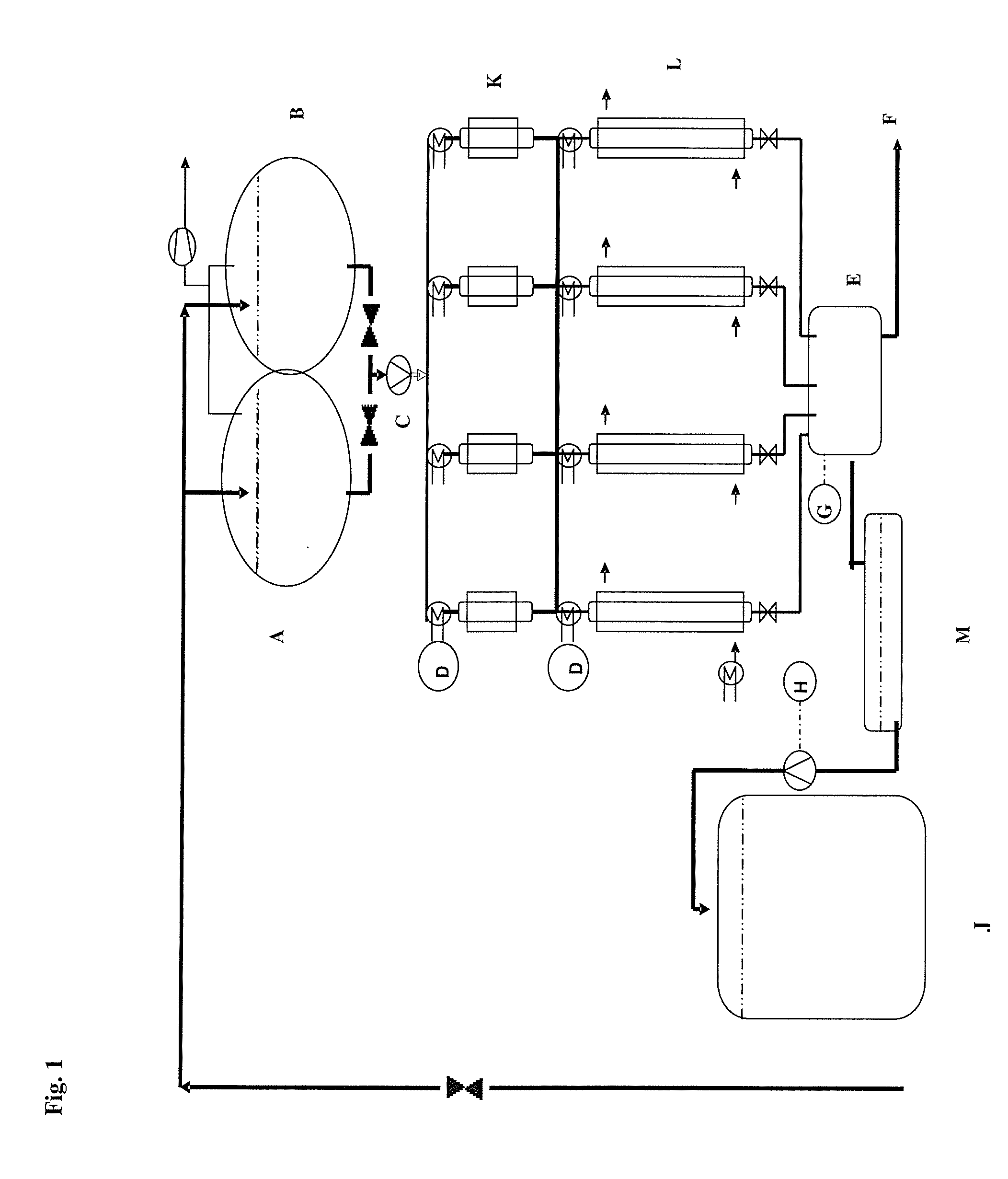

Continuous production process for amino trimethylene phosphonic acid

ActiveCN103275121ARealize continuous feedingIncrease production capacityGroup 5/15 element organic compoundsPhosphorous acidWater vapor

The invention relates to a continuous production process for an amino trimethylene phosphonic acid. The continuous production process comprises the steps of adding ammonium chloride, phosphorous acid and formaldehyde in a mixing kettle according to a certain molar ratio; adding reverse osmosis water; mixing uniformly at the temperature of 35 DEG C; pumping into a tubular reactor at a certain flow rate; reacting thoroughly; then introducing into a spraying absorption tower; and spraying from the top of the tower so as to contact with rising high temperature water vapor, condensing amino trimethylene phosphonic acid being cooled to enter the tower unreacted ammonium chloride, formaldehyde and hydrogen chloride vapor entering a rectification apparatus to be separated by rectification from the top of the tower. Continuous feeding and discharging production process is employed, and conventional intermittent production process employing single kettle mixing material is changed, so that utilization rate of the equipment is increased; production period is shorten; productivity is increased; performance is more stable; comprehensive energy consumption is reduced; and large-scale industrialized production can be achieved easily.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

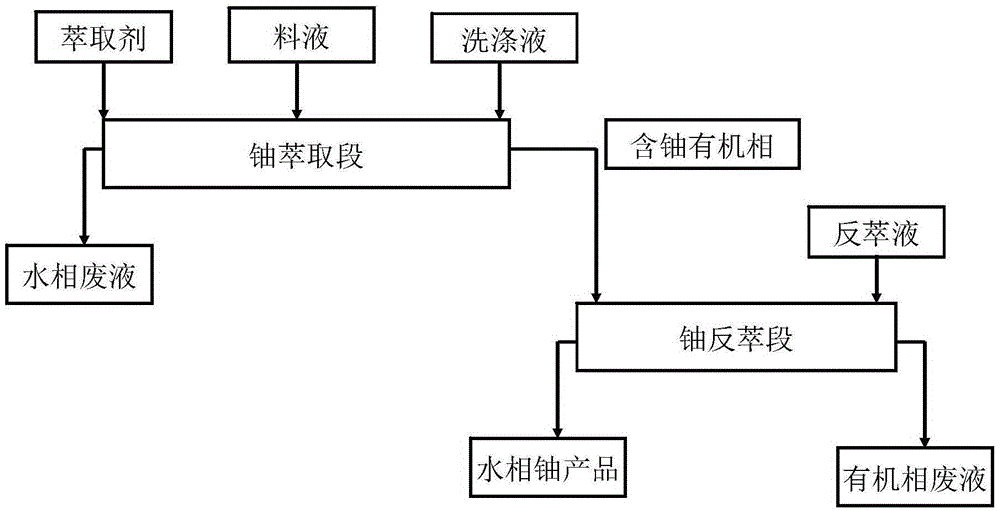

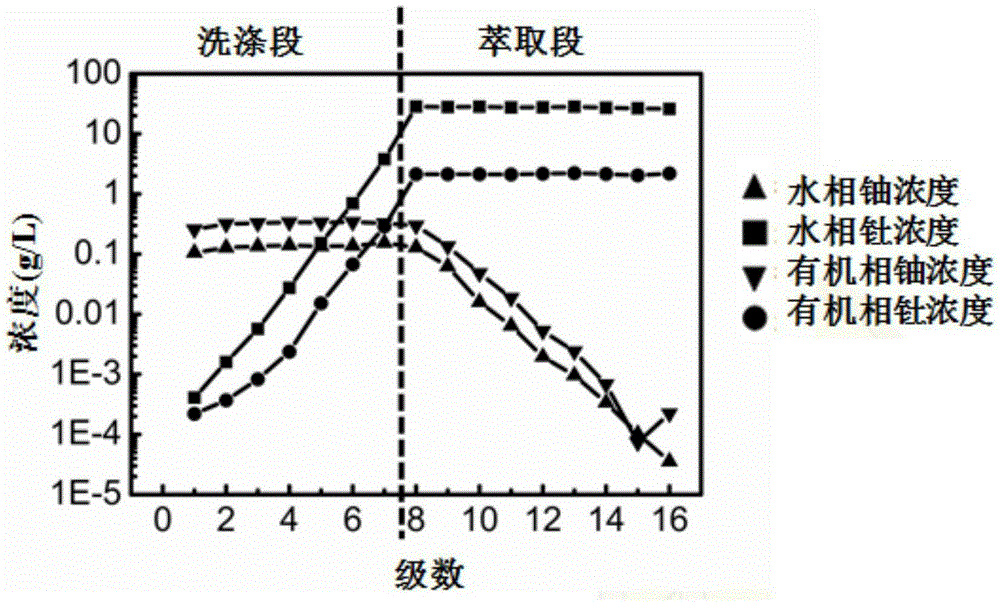

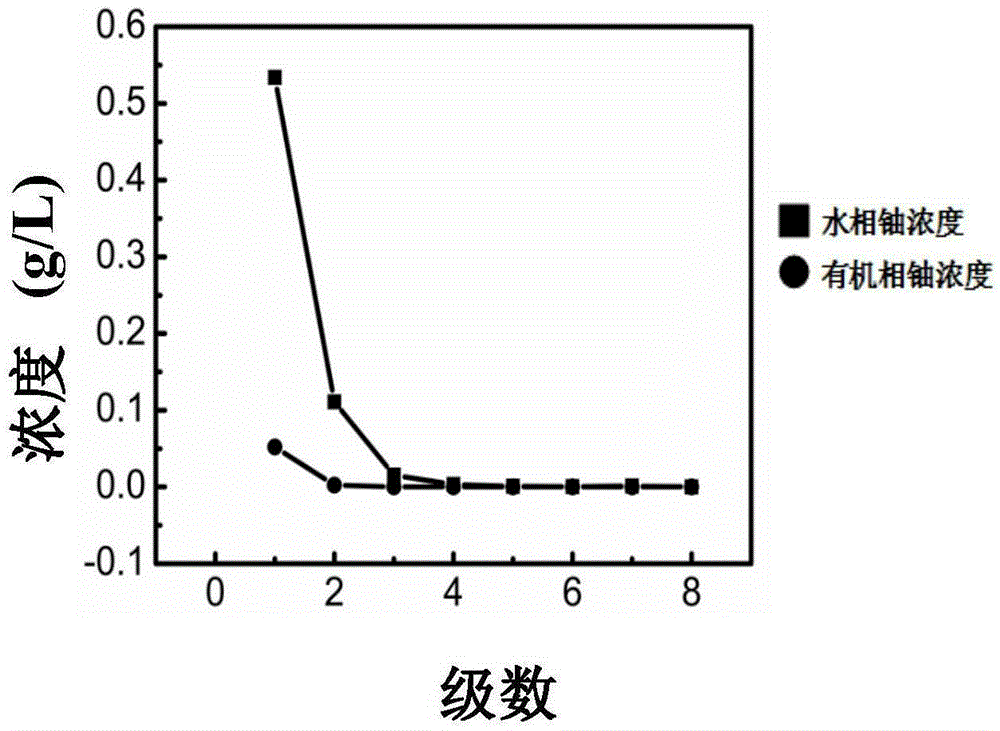

Recovery method for uranium

ActiveCN106555062AHigh separation factorHigh recovery rateProcess efficiency improvementRecovery methodOrganic solvent

The invention discloses a recovery method for uranium. The recovery method disclosed by the invention comprises the following steps of: 1) performing fractional extraction to obtain an organic phase containing uranium by taking an acidic aqueous solution containing thorium and uranium, an organic solvent containing methyl diheptyl (1-methyl) phosphonate as an extraction agent and an acidic aqueous solution as a washing liquid, wherein the volume concentration of the methyl diheptyl (1-methyl) phosphonate in the extraction agent is 1-6%; and 2) counter-extracting the organic phase containing uranium obtained in the step 1) by way of multistage countercurrent. According to the recovery method disclosed by the invention, the recovery rate of uranium is relatively high, the extraction stages are few, and the efficiency is relatively high.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

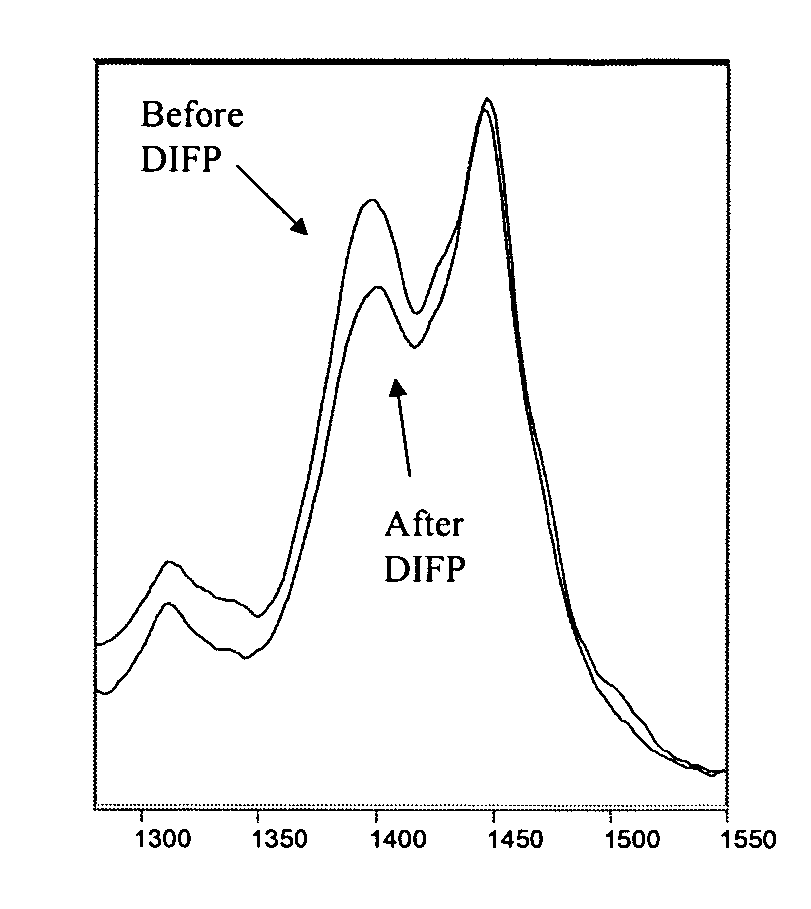

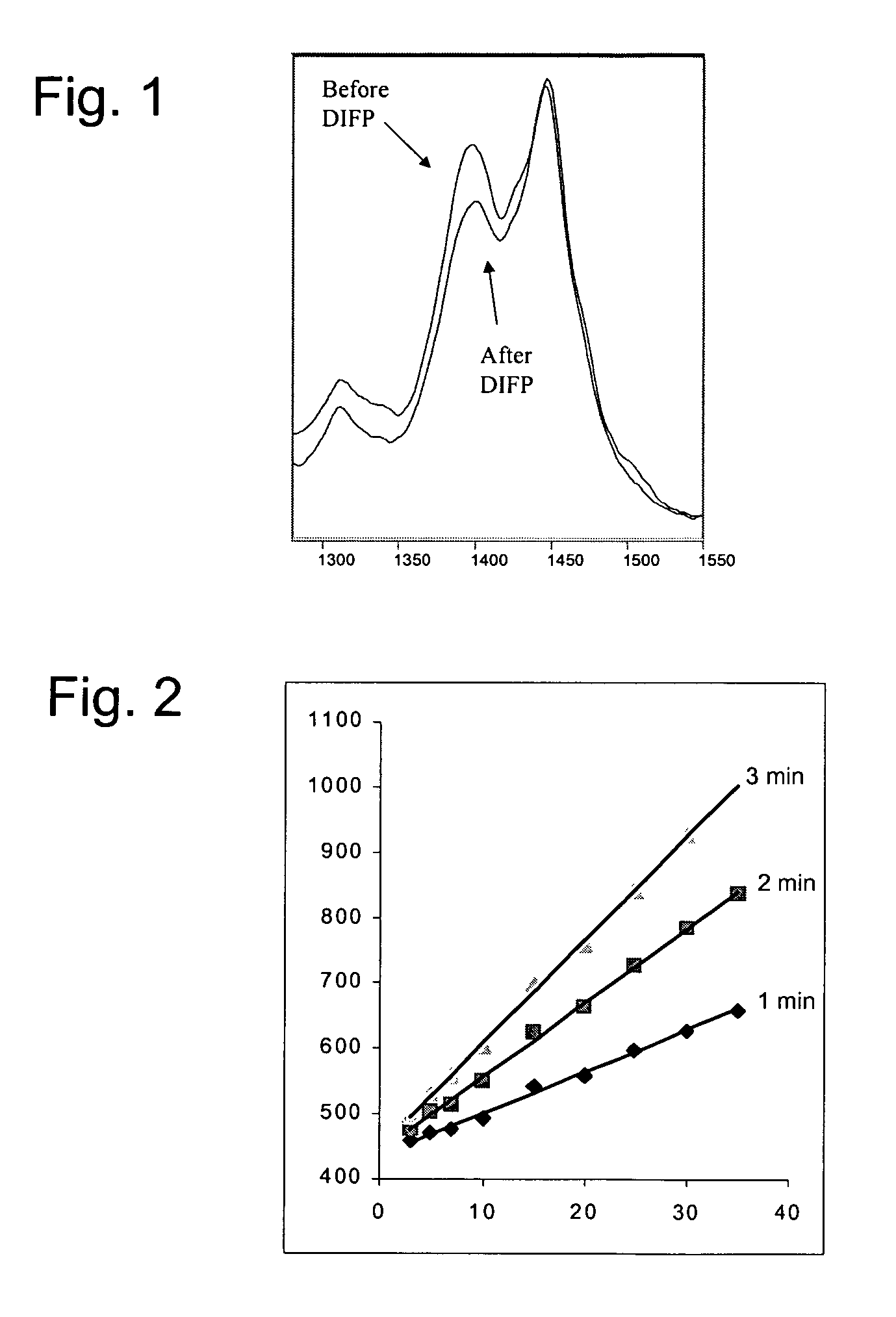

Compositions and methods for detecting nerve agents

ActiveUS7674627B2Rapid optical readoutGood leaving groupCompound screeningApoptosis detectionLeaving groupModerately good

Owner:UNIVERSITY OF WYOMING

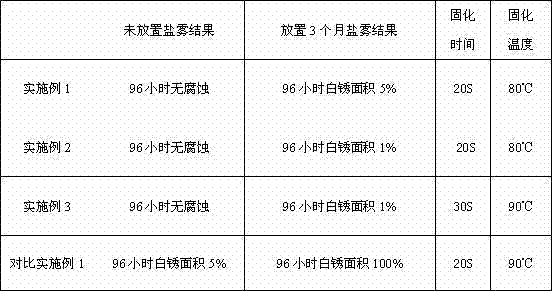

Chromium-free metal surface treatment composition

ActiveCN103046040AImprove stabilityFast film formationMetallic material coating processesChromium freeTricarboxylic acid

The invention relates to a chromium-free metal surface treatment composition. The composition is characterized by comprising the following components: A) hydroxy-terminated water-soluble polydimethylsiloxane, B) silane coupling agent with alpha-functional group, C) bivalent or high-valent metal ions of Zr<2+>, Ca<2+>, Ce<3+> or Mo<6+> selected from at least one of Zr(CH3COO)2, Ca(CH3COO)2, Ce(NO3)3 and (NH4)6Mo7O24, D) pH regulator selected from at least one of hydroxyethylidene-1,1-diphosphonic acid, 2-phosphonic acid butane-1,2,4-tricarboxylic acid and amino trimethylene phosphonic acid, and E) deionized water, wherein the concentration range of the component A) is 50 to 100 g / L, the concentration range of the component B) is 2 to 10 g / L, the concentration range of the component C) is 0.2 to 5 g / L, and E) the balance of the component shown in the specification.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Method for improved removal of cations by means of chelating resins

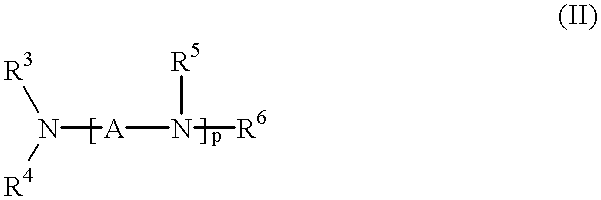

InactiveUS20110089116A1Large capacityCation exchanger materialsElectrolysis componentsAlkaline earth metalAbsorption capacity

The present invention relates to a method for improved removal of cations, preferably alkaline earth metals, in particular calcium and barium, from aqueous solutions using chelating resins having aminomethylphosphonic acid groups and iminodimethylphosphonic acid groups having high dynamic absorption capacity for cations at a low residual content of the cations and high regeneration efficiency, and a markedly lengthened loading duration of the chelating resin, to the chelating exchangers themselves, and also to uses thereof.

Owner:LANXESS DEUTDCHLAND GMBH

Preparation process for a solid aminotrimethylenephosphonic acid (ATMP) or 1-hydoxy ethyidene-1.1-diphosphonic acid

InactiveCN101597305AReduce packaging costsGroup 5/15 element organic compoundsMethylphosphinic acidMethylphosphonic acid

The invention relates to a preparation process for a solid aminotrimethylenephosphonic acid (ATMP) or 1-hydoxy ethyidene-1.1-diphosphonic acid, in particular to a high purity preparation process for the solid aminotrimethylenephosphonic acid (ATMP) or the 1-hydoxy ethyidene-1.1-diphosphonic acid, comprising the following steps: a, crystallization: controlling the temperature of the aminotrimethylenephosphonic acid (ATMP) or 1-hydoxy ethyidene-1.1-diphosphonic acid with 68-85% of the content of effective substance at 30-90 DEG C, adding ice crystal particles, and then precipitating the crystal; b, solid-liquid separation: carrying out centrifugal dewatering on the materials after crystal precipitation, and obtaining the sold aminotrimethylenephosphonic acid (ATMP) or the 1-hydoxy ethyidene-1.1-diphosphonic acid; c, product post-treatment: drying the solid aminotrimethylenephosphonic acid (ATMP) or the 1-hydoxy ethyidene-1.1-diphosphonic acid, removing crystal water under the temperature of 60-120 DEG C, then solid packing. The preparation process in the invention solves the problem of introducing impurity crystal nucleus in the solid preparation process of the aminotrimethylenephosphonic acid (ATMP) or the 1-hydoxy ethyidene-1.1-diphosphonic acid.

Owner:CHANGZHOU YAOS TONGDE CHEM

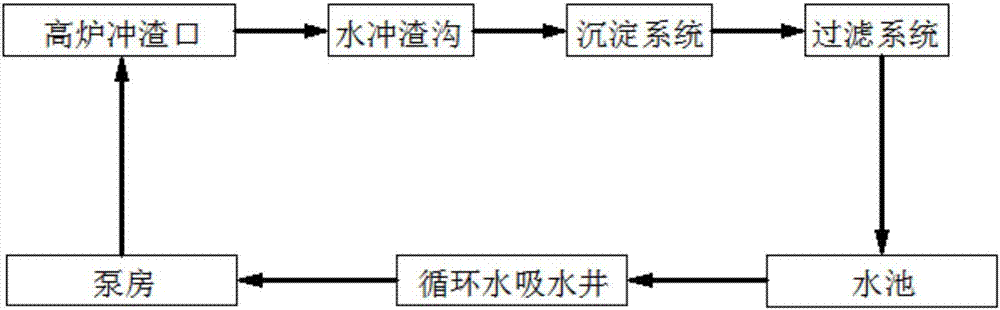

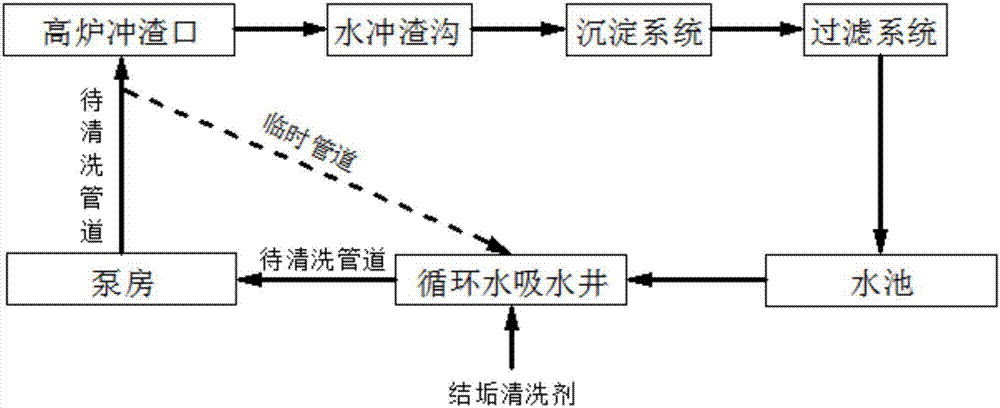

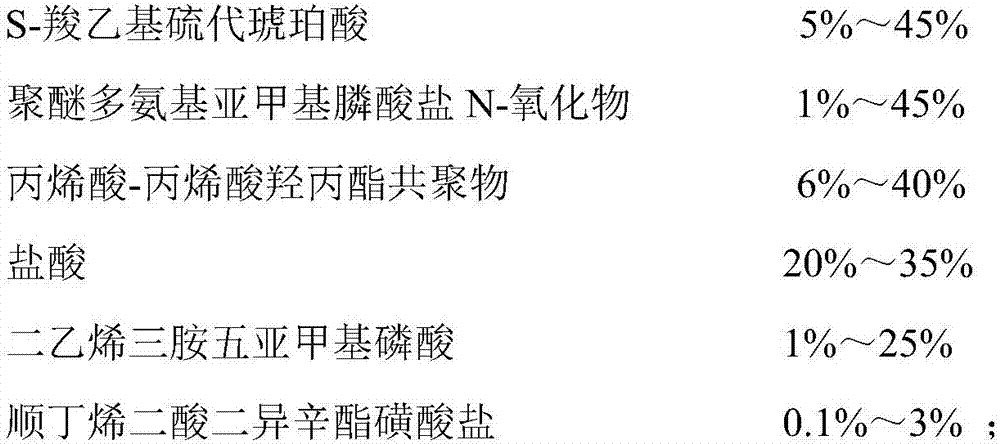

Scale cleaning agent and cleaning method for cinder flushing water system of iron-making plant

ActiveCN107324512AChange crystal structureAchieve cleaningScale removal and water softeningPhosphateDiethylenetriamine

The invention relates to a scale cleaning agent for a cinder flushing water system of an iron-making plant. The scale cleaning agent contains the following components in percentage by mass: 5%-45% of S-carboxyethyl thiosuccinic acid, 1%-45% of polyether polyamino methylene phosphonate N-oxide, 6%-40% of an acrylic acid-hydroxypropyl acrylate copolymer, 20%-35% of hydrochloric acid, 1%-25% of diethylenetriamine pentamethylene phosphate and 0.1%-3% of diisooctyl cis-butenedioate sulfonate, wherein the mass concentration of hydrochloric acid is 30%-36%. The invention further relates to a cleaning method for the cinder flushing water system of the iron-making plant. According to the scale cleaning agent, scale of equipment and pipelines in the cinder flushing water system of the iron-making plant can be effectively cleared; the scale cleaning agent has the advantages that the pertinence is strong, a formula is environment-friendly, the cost is low, and the preparation is simple; and the cleaning method has the advantages that the operation steps are simple and feasible, the cleaning is flexible, and use equipment is few.

Owner:韶关市雅鲁环保实业有限公司

Compositions, methods and systems for polishing aluminum oxide and aluminum oxynitride substrates

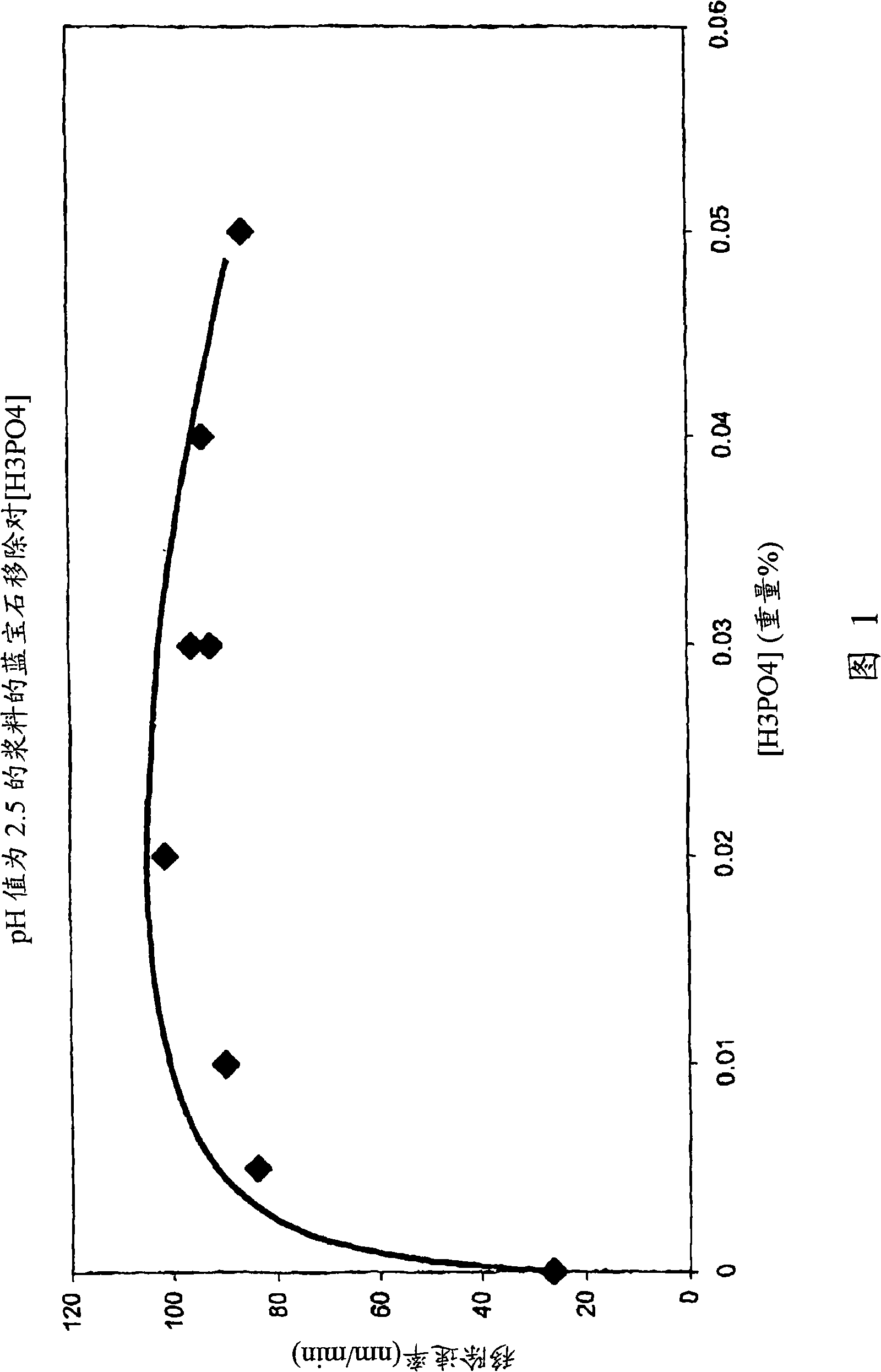

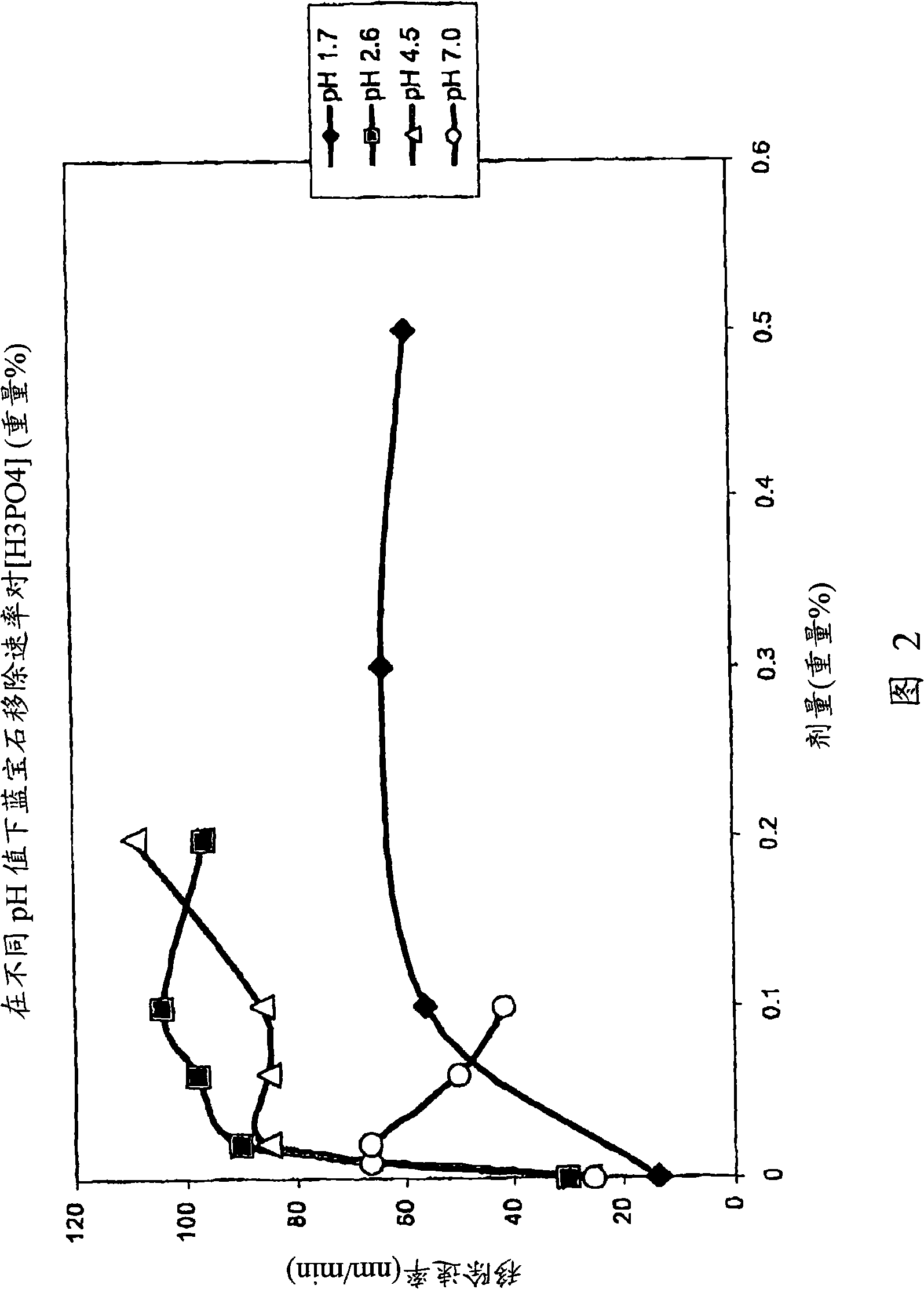

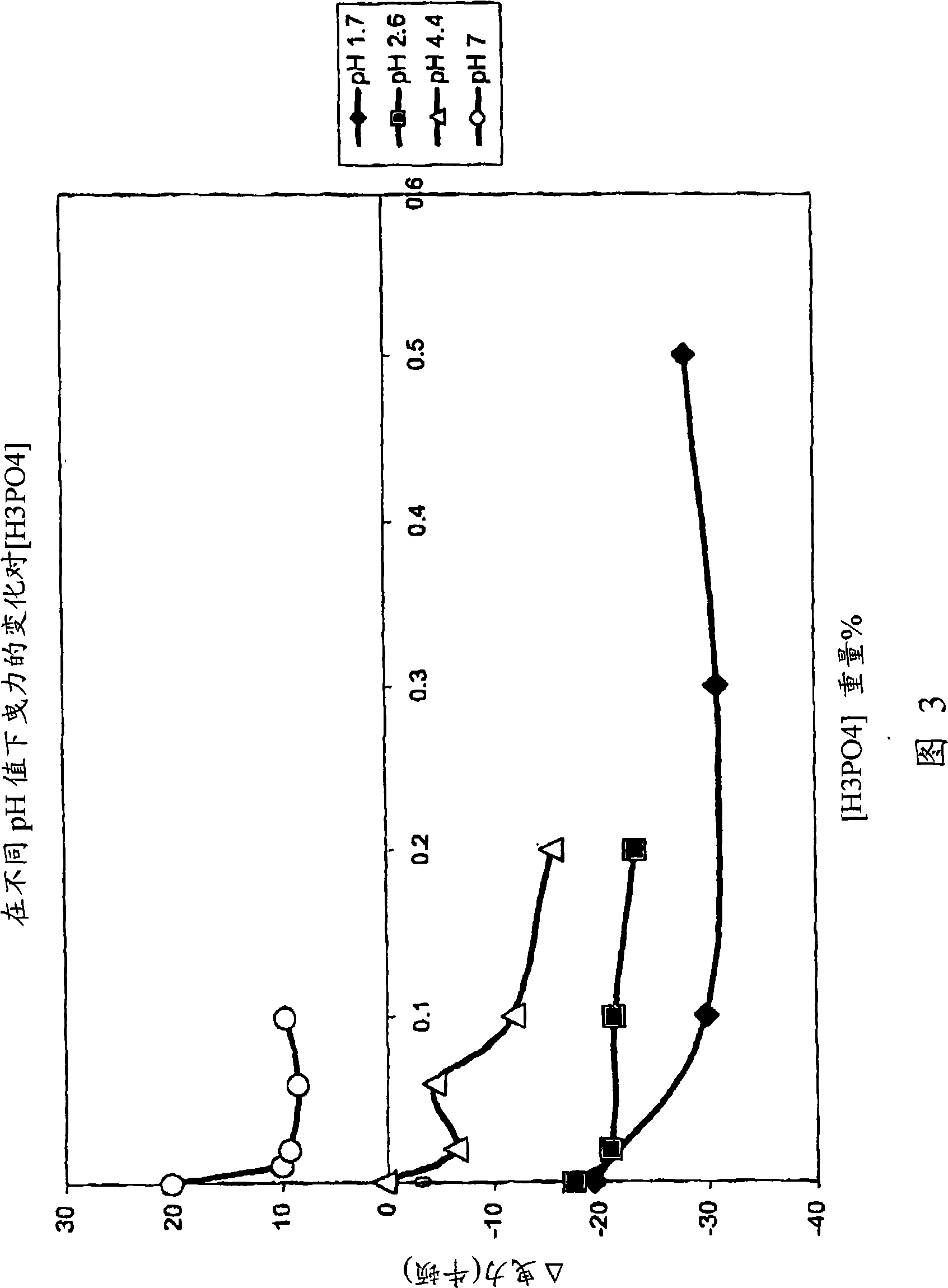

A method and system is provided for improved polishing or planarizipg of aluminum oxide and / or aluminum oxyrptride substrates. Specifically, the composition comprises an abrasive, a liquid carrier, and a phosphorus-type mono-acid. Preferably, the phosphorus-type mono-acid is phosphoric acid, phosphonoacetic acid, phosphorous acid, methyl phosphonic acid, or mixtures thereof. The control of the pH of the composition further improves polishing rates.

Owner:CABOT MICROELECTRONICS CORP

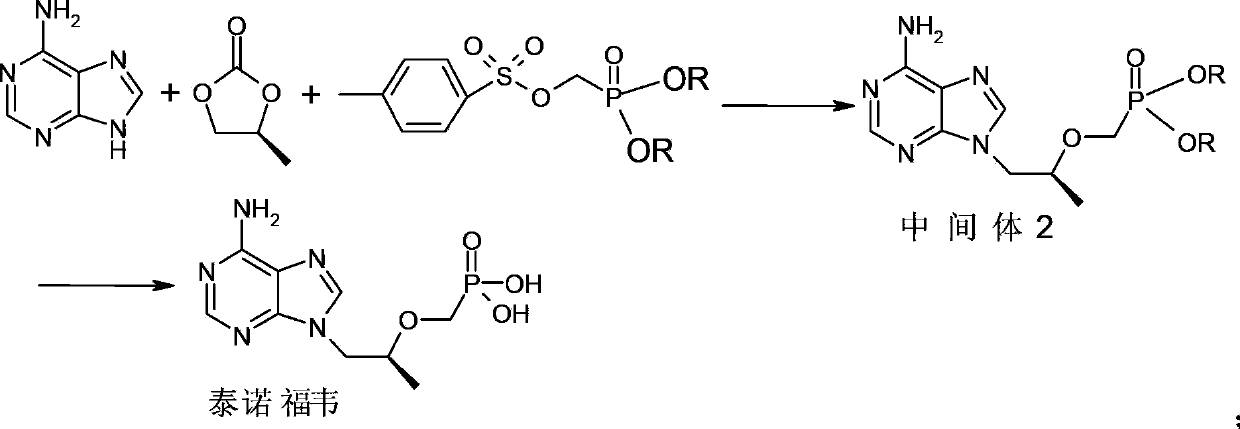

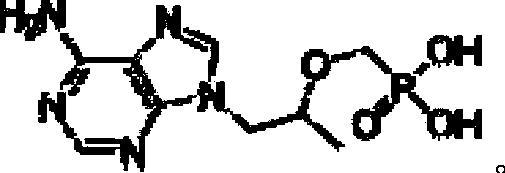

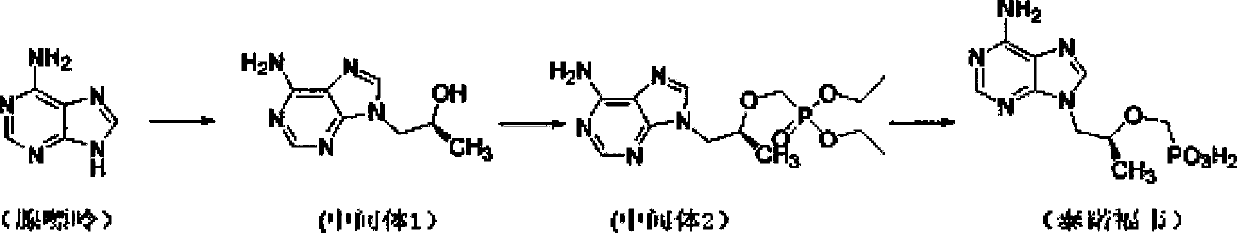

Process for preparing tenofovir

ActiveCN103864847AEasy to operateShort reaction timeGroup 5/15 element organic compoundsTosylhydrazoneHydrolysis

The invention discloses a process for preparing tenofovir. The method is characterized by comprising the steps: with adenine, (R)-propylene carbonate and p-toluenesulfonyloxy methyl phosphonic diester as raw materials, adopts a one-pot process to prepare an intermediate 2, and followed by hydrolyzing the intermediate 2 by an inorganic acid to obtain tenofovir, wherein the following reaction formula is shown in the description. With utilization of the process, the purpose that high-purity tenofovir is synthesized with utilization of cheap and easily available raw materials and with simple operation, mild reaction conditions, low cost and high yield is achieved; and the process has the advantages of energy saving and environmental protection, is suitable for large scale production, and has practical value in realization of industrial production of tenofovir.

Owner:SHANGHAI DESANO CHEM PHARMA

Methods of cleaning copper surfaces in the manufacture of printed circuit boards

ActiveUS20050098538A1Easy to cleanReduce etch rateInsulating substrate metal adhesion improvementDecorative surface effectsDicarboxylic acidCopper

The present invention sets forth an improved method of microetching a metal substrate by contacting the substrate with an aqueous composition comprising a sodium persulfate or hydrogen peroxide oxidizing agent, acid, and one or more additives. When the oxidizing agent is sodium persulfate, the one or more additives generally comprise an aliphatic saturated dicarboxylic acid. When the oxidizing agent is hydrogen peroxide, the one or more additives generally comprise a stabilizer and amino tris(methylene phosphonic acid).

Owner:MACDERMID ACUMEN INC

Amino trimethylene phosphonic acid with content of greater than or equal to 90 percent and process for making same

InactiveCN1699380AIncrease contentEasy to packGroup 5/15 element organic compoundsSodium acetateAlcohol

The invention discloses an amino trimethylene phosphonic acid (ATMP) with content of greater than or equal to 90 percent and process for preparation, wherein the product comprises (by weight percentage) amino trimethylene phosphonic acid 90-98%, unavoidable impurity substance 1-2%, and balancing water. The production process comprises the steps of stock preparation, charging sodium acetate as crystal nucleon, agitating, charging anhydrous alcohol as crystallizing aid agent, dewatering, and drying.

Owner:CHANGZHOU JIAYOU CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com