Preparation method of non-combustible solid polymer electrolyte and secondary lithium battery containing solid polymer electrolyte

A solid polymer and secondary lithium battery technology, applied in the field of lithium ion batteries, can solve problems such as easy liquid leakage, achieve the effects of solving fire and explosion, reducing interface impedance, and improving room temperature charge and discharge capabilities and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

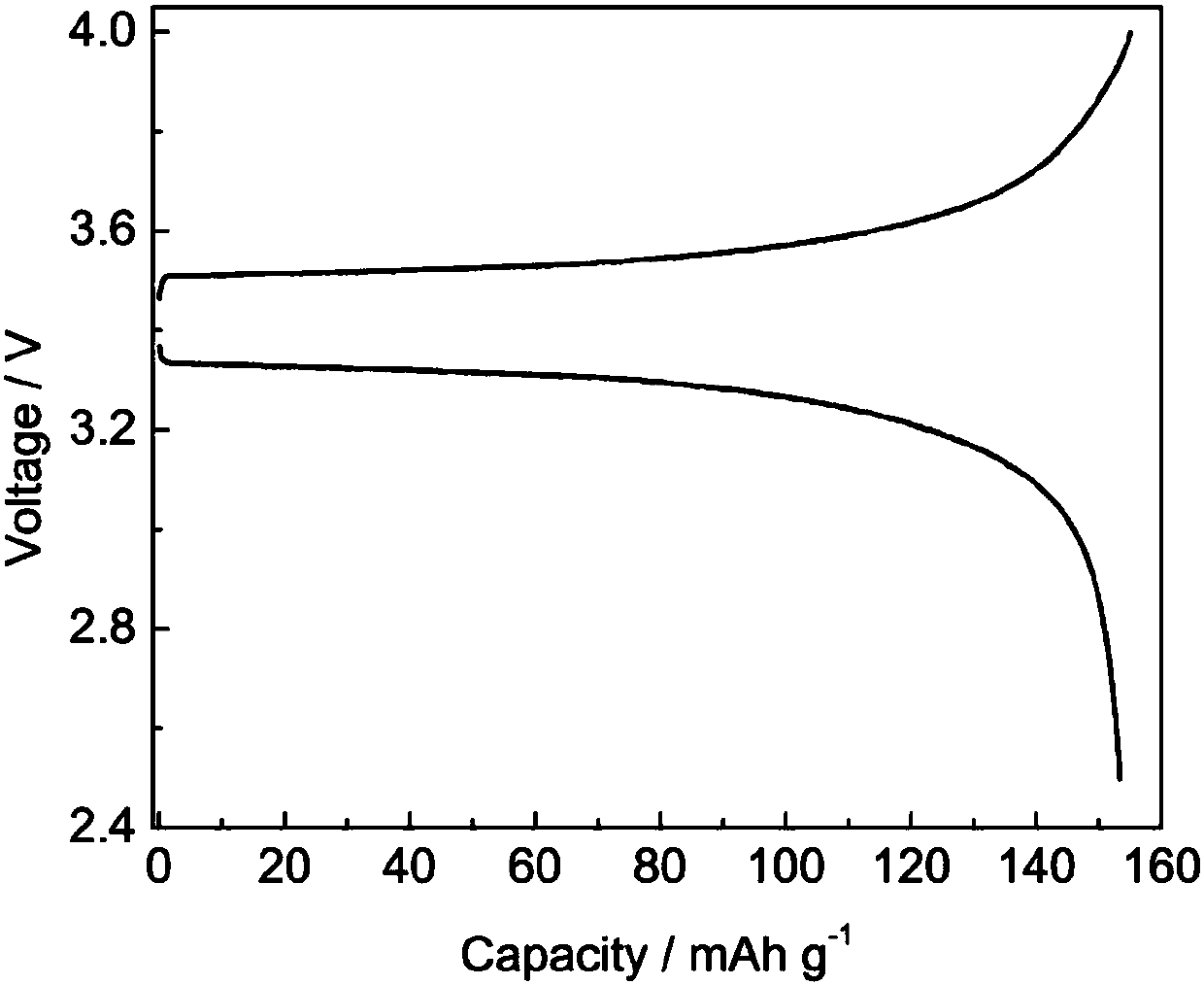

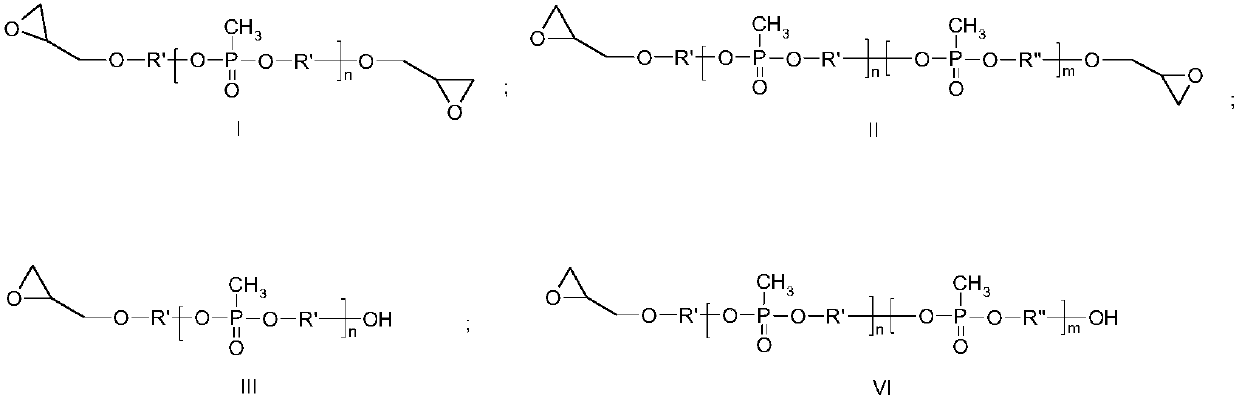

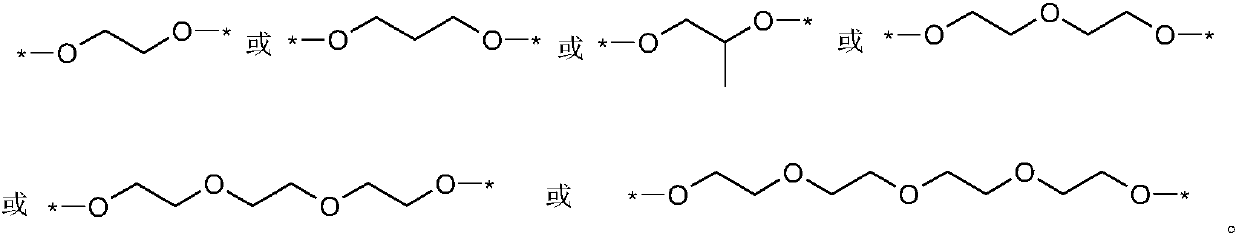

[0035] In a glove box filled with argon, the LiPF 6 , LiTFSI dissolved in double-ended epoxy polymethyl phosphate (propylene glycol) ester monomer, magnetically stirred for 4h to mix evenly; inject the evenly mixed solution into Li / / SL, SL / / SL (SL is a stainless steel pole piece) Between the positive and negative electrodes of the battery, place it at 80°C for 4 hours to polymerize, and then test the electrochemical stability window and ionic conductivity of the non-combustible solid polymer electrolyte.

[0036] Among them, double-ended epoxy polymethyl phosphate (propylene glycol) ester and LiPF 6 The mass ratio of LiTFSI and LiTFSI is 100:4:40, and the ratio of raw materials is shown in Table 1. The room temperature ionic conductivity of the prepared lithium-ion battery polymer is 1.3×10 -4 S / cm, the electrochemical window is 4.0V.

[0037] Table 1

[0038]

Embodiment 2

[0040] In a glove box filled with argon, the LiPF 6 , LiTFSI is dissolved in double-ended epoxy polymethyl phosphate (diethylene glycol) ester monomer, after adding lithium lanthanum zirconium oxide nanoparticles, magnetically stir for 4 hours and mix well; inject the well mixed solution into Li / / SL , SL / / SL (SL is a stainless steel pole piece) between the positive and negative pole pieces of the battery, and then placed at 60 ° C for 8 hours of polymerization, and then tested the ionic conductivity and electrochemical stability window of the non-combustible solid polymer electrolyte. Among them, double-ended epoxy polymethyl phosphate (diethylene glycol) ester and LiPF 6 The mass ratio of LiTFSI, LiTFSI and lithium lanthanum zirconium oxygen is 100:2:35:7, and the ratio of raw materials is shown in Table 2. The ion conductivity of the prepared polymer for lithium ion batteries at room temperature is 2.6×10 -4 S / cm, the electrochemical window is 4.0V.

[0041] Table 2

[00...

Embodiment 3

[0044] In a glove box filled with argon, the LiPF 6 , LiTFSI and double-end epoxy-based polymethyl phosphate (propylene glycol) ester and single-end epoxy-based polymethyl phosphate (propylene glycol) ester mixed monomer, add aluminum oxide nanoparticles and then magnetically stir for 4h to mix evenly; The uniformly mixed solution was injected between the positive and negative electrodes of Li / / SL, SL / / SL (SL is a stainless steel electrode), and then placed at 80°C for 4 hours of polymerization, and then respectively tested the non-combustible solid polymer electrolyte Ionic conductivity and electrochemical stability window.

[0045] Among them, double-ended epoxy polymethyl phosphate (propylene glycol) ester and single-ended epoxy polymethyl phosphate (propylene glycol) ester, LiPF 6 The mass ratio of LiTFSI, LiTFSI and Al2O3 is 80:20:5:32:7, and the ratio of raw materials is shown in Table 3. The ion conductivity of the prepared polymer for lithium-ion batteries at room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com