Method for extracting and recovering plutonium from plutonium-containing nitric acid solution

A nitric acid solution and extraction technology is applied in the field of extracting and recovering plutonium from a plutonium-containing nitric acid solution, and can solve the problems of precipitation, incomplete back extraction of actinide elements, and "retention of heavy metals".

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

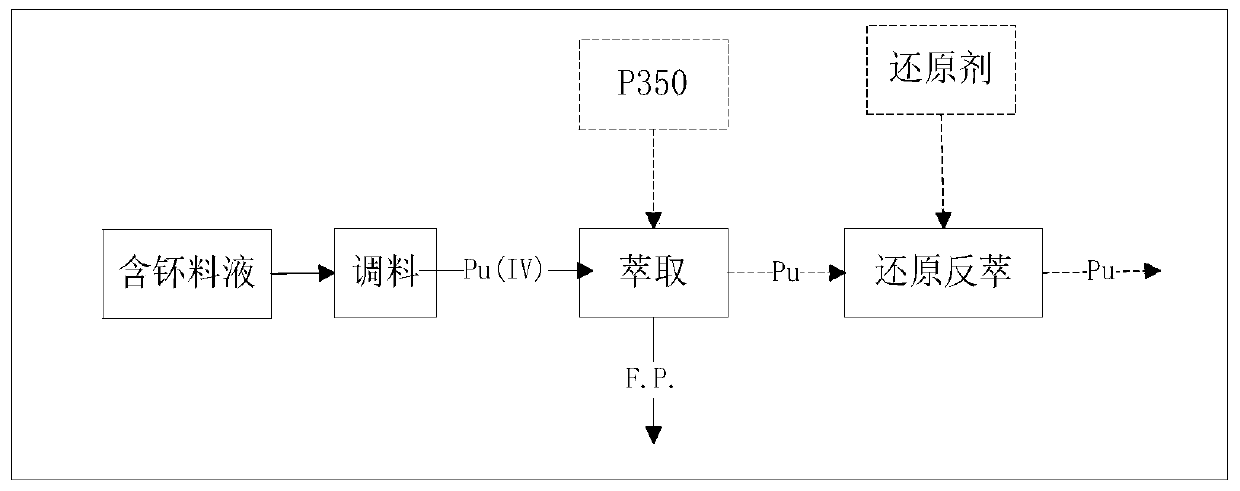

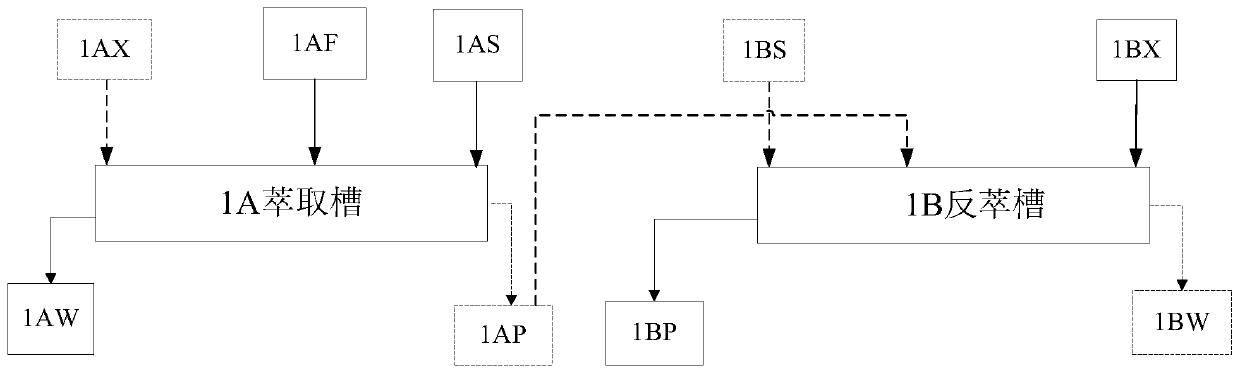

[0027] Install the test bench in the glove box to extract and recover the plutonium. Extraction-stripping process such as figure 2 As shown, the process steps are:

[0028] (1) Prepare plutonium-containing simulated feed solution (0.5g / L Pu, 1.0g / L U, tracer Tc, 1.0mol / LHNO 3 ), use N 2 o 4 As an oxidant seasoning, 10-15mol / L HNO 3 Adjust the acidity to 2-4mol / L to obtain the feed liquid 1AF to be purified. Pu contained in 1AF mainly exists as Pu(IV).

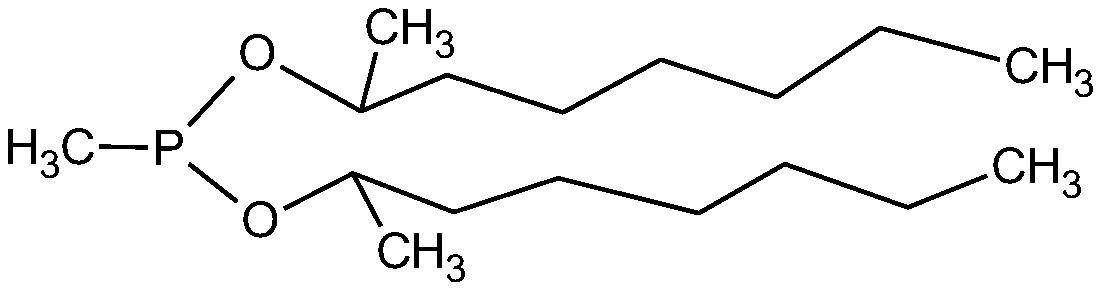

[0029] (2) 1AF is introduced into the 1A extraction tank, and 5%-50% (v / v) P350-kerosene is also introduced into the 1A extraction tank as the extraction agent 1AX, 1-6mol / L HNO 3 As detergent 1AS. After extraction, more than 99.9% of Pu is extracted into the organic phase 1AP, and the fragment elements enter into the aqueous phase 1AW.

[0030] (3) Introduce the organic phase 1AP obtained in step (2) as 1BF into the 1B stripping tank, and also introduce 0.1-0.3mol / L dimethylhydroxylamine-0.1-0.5mol / L hydrazine- in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com