Scale cleaning agent and cleaning method for cinder flushing water system of iron-making plant

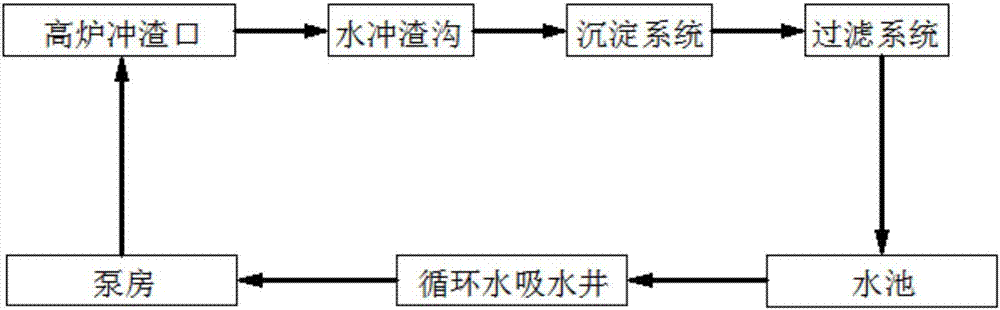

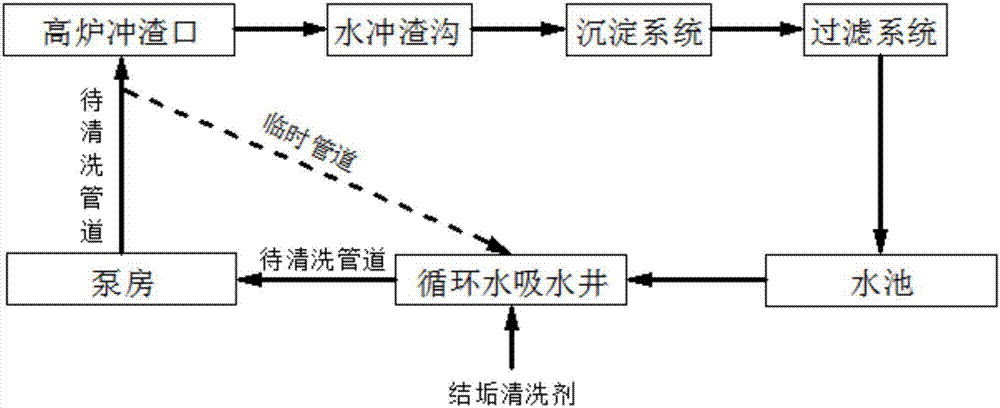

A scaling cleaning agent and slag flushing water technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc. It is difficult to maintain the stability of circulating water quality and other problems, so as to achieve the effect of improving efficiency and flexibility of operation, low cost and reasonable formula design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

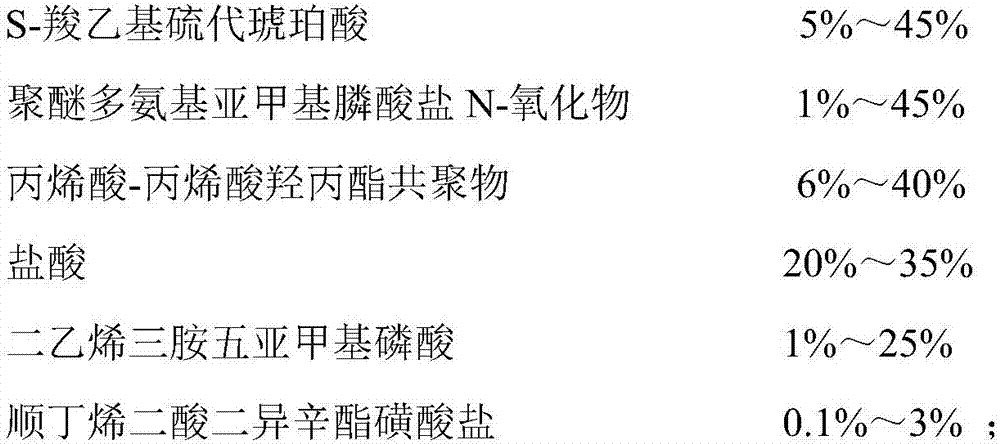

[0043] The scale cleaning agent of the slag flushing water system of the ironmaking plant in this embodiment includes the following components in terms of mass percentage:

[0044]

[0045] The scale cleaning agent is prepared by the following steps: under normal temperature and normal pressure, the components are first weighed according to the proportion, and then S-carboxyethyl sulfosuccinic acid and polyether polyaminomethylene phosphine Add salt N-sodium oxide into the enamel reactor, start the stirring motor, and then slowly add acrylic acid-hydroxypropyl acrylate copolymer, industrial grade hydrochloric acid, diethylenetriamine pentamethylene phosphoric acid and diisooctyl maleate Sodium ester sulfonate is then stirred and mixed for 2 hours to obtain a finished product. The finished product is sampled and tested, and packaged after the test is qualified. After the package is completed, it is transported to the finished product warehouse for storage, and production records a...

Embodiment 2

[0051] The scale cleaning agent of the slag flushing water system of the ironmaking plant in this embodiment includes the following components in terms of mass percentage:

[0052]

[0053] The preparation method of the fouling cleaning agent is the same as that of Example 1.

[0054] The cleaning method of the slag flushing water system of the ironmaking plant of this embodiment is the same as that of the first embodiment.

Embodiment 3

[0056] The scale cleaning agent of the slag flushing water system of the ironmaking plant in this embodiment includes the following components in terms of mass percentage:

[0057]

[0058]

[0059] The preparation method of the fouling cleaning agent is the same as that of Example 1.

[0060] The cleaning method of the slag flushing water system of the ironmaking plant of this embodiment is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com