Method for producing lithium ion battery negative electrode material by asphalt secondary coating process

A technology for lithium-ion batteries and negative electrode materials, which can be applied to battery electrodes, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

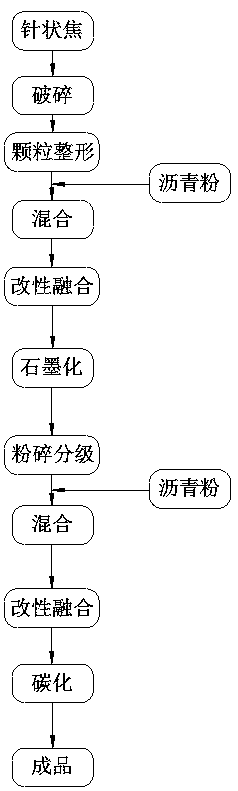

[0019] The method for producing a lithium ion battery negative electrode material by the pitch secondary coating process of the present invention comprises the following sequential steps:

[0020] S1. After the needle coke is crushed, the particles are shaped and the edges are removed, the particles are made as round as possible to reduce the fusion resistance between the particles and the asphalt powder, and the asphalt powder with a particle size of 20 μm is mixed with the asphalt powder with a particle size of 20 μm in a mixer for 20 minutes to obtain a mixture A. , in mixture A, the volume ratio of asphalt powder is 8%;

[0021] S2. The mixture A is subjected to surface modification and fusion treatment respectively to obtain a primary asphalt-coated material, wherein the surface modification can improve the activity of carbon, and the fusion treatment can make the material evenly distributed, and then enter the kiln in high-purity N 2 After being graphitized at a high tem...

Embodiment 2

[0025] The method for producing a lithium ion battery negative electrode material by the pitch secondary coating process of the present invention comprises the following sequential steps:

[0026] S1. After the needle coke is crushed, the particles are shaped and the edges are removed, the particles are made as round as possible to reduce the fusion resistance between the particles and the asphalt powder, and the asphalt powder with a particle size of 30 μm is mixed with the asphalt powder with a particle size of 30 μm in a mixer for 25 minutes to obtain a mixture A. , in mixture A, the volume ratio of asphalt powder is 8%;

[0027] S2. The mixture A is subjected to surface modification and fusion treatment respectively to obtain a primary asphalt-coated material, wherein the surface modification can improve the activity of carbon, and the fusion treatment can make the material evenly distributed, and then enter the kiln in high-purity N 2 After being graphitized at a high tem...

Embodiment 3

[0031] The method for producing a lithium ion battery negative electrode material by the pitch secondary coating process of the present invention comprises the following sequential steps:

[0032] S1. After the needle coke is crushed, the particles are shaped and the edges are removed, the particles become as round as possible, reducing the fusion resistance between the particles and the asphalt powder, and mixing with the asphalt powder with a particle size of 40 μm in a mixer for 30 minutes to obtain a mixture A , in mixture A, the volume ratio of asphalt powder is 8%;

[0033] S2. The mixture A is subjected to surface modification and fusion treatment respectively to obtain a primary asphalt-coated material, wherein the surface modification can improve the activity of carbon, and the fusion treatment can make the material evenly distributed, and then enter the kiln in high-purity N 2 After being graphitized at a high temperature of 800°C under the protection, it is cooled t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com