Compositions, methods and systems for polishing aluminum oxide and aluminum oxynitride substrates

A technology for compositions and substrates, applied in polishing compositions, polishing compositions containing abrasives, chemical instruments and methods, etc., and can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

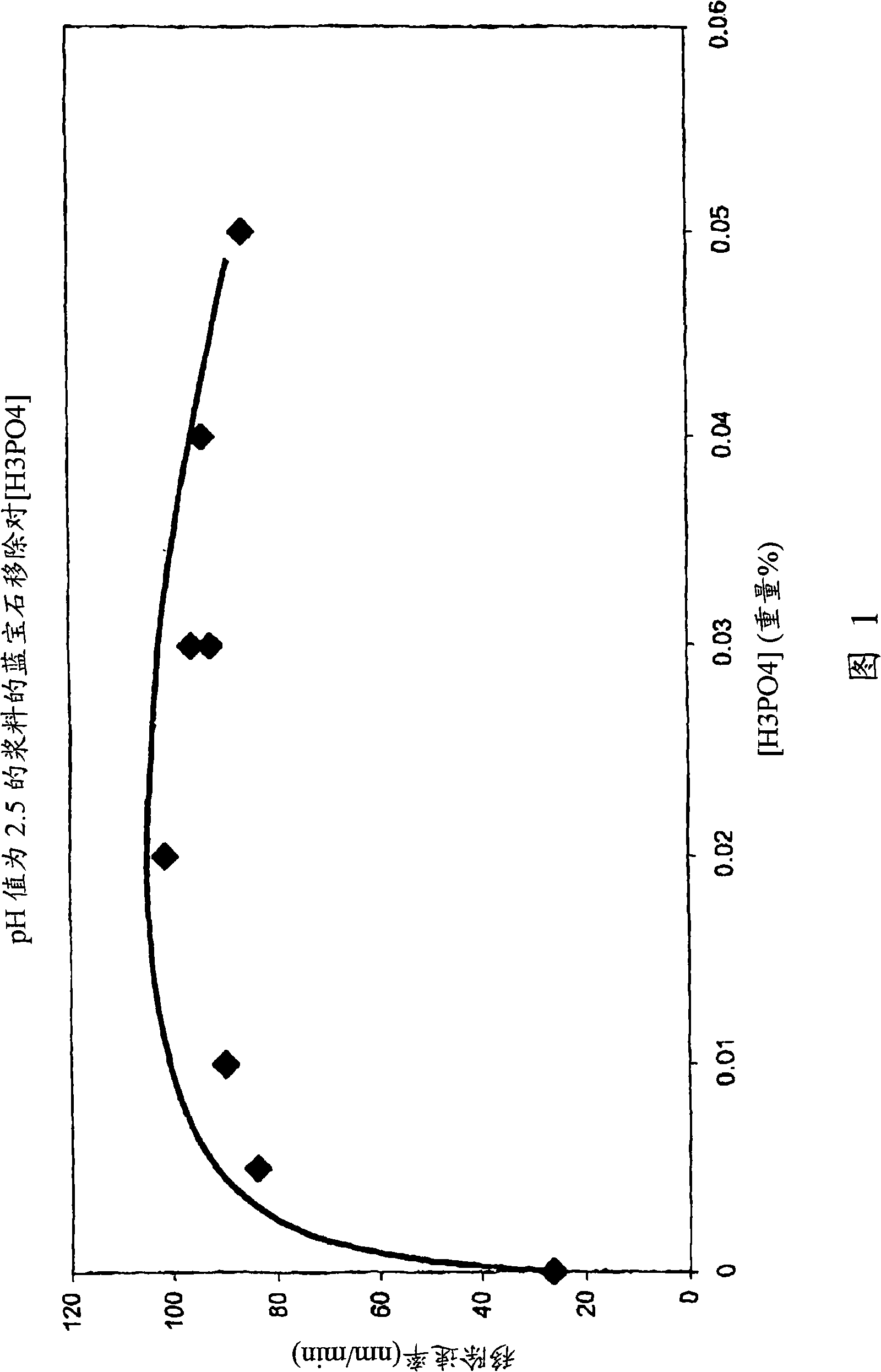

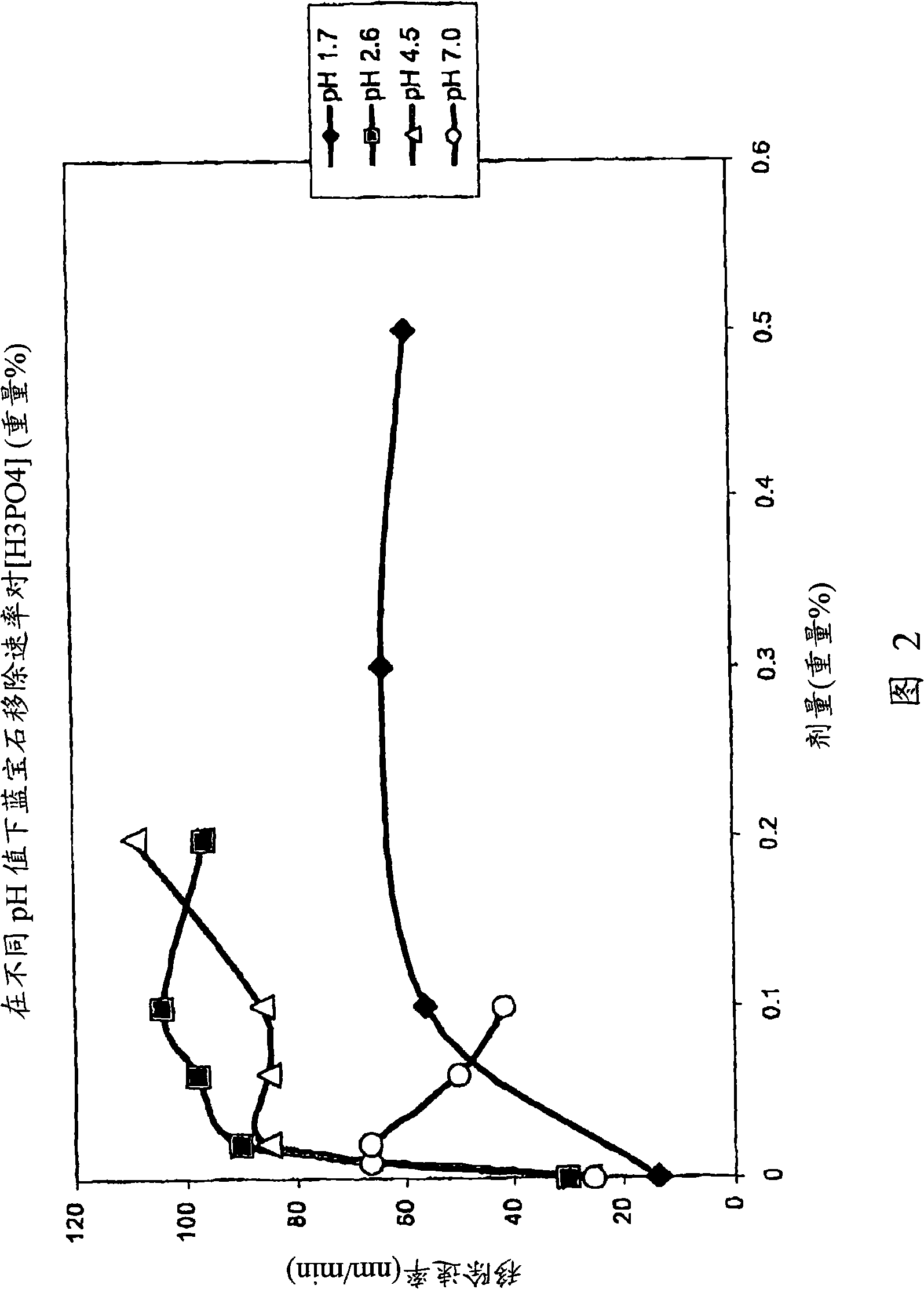

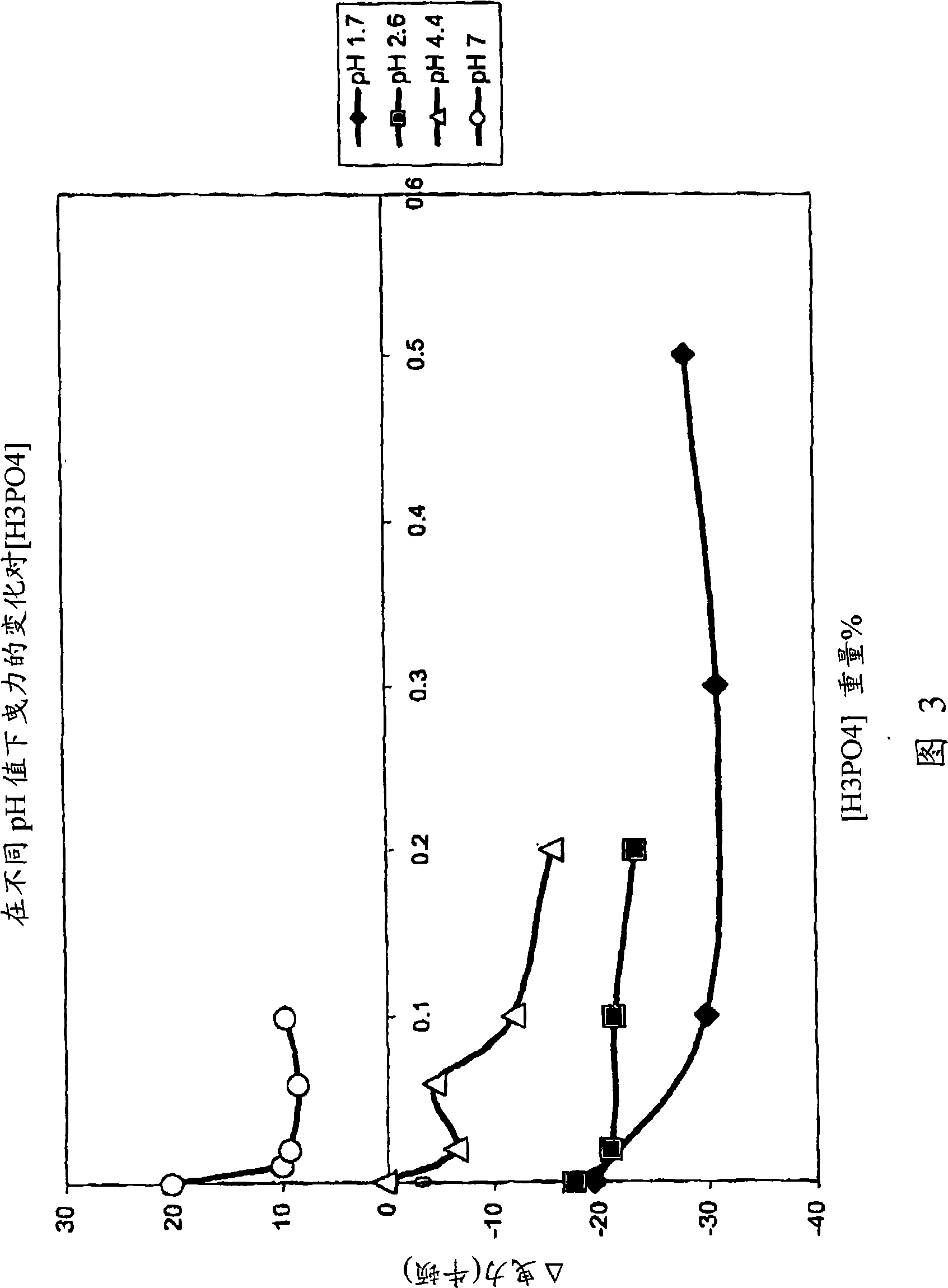

Embodiment 1

[0033] A 2.5 g aliquot of the 40% phosphoric acid solution was added to 997 g deionized water with stirring. To this solution was added 1000 g of colloidal silica (40% solids, average particle size about 110 nm) with stirring. The pH was adjusted to 2.0 with 10% HCl solution. The resulting solution contained a final phosphoric acid concentration of 0.05%.

Embodiment 2

[0035] A control slurry was prepared as described in Example 1 except that the phosphoric acid was omitted. Adjust the pH to 2.3.

Embodiment 3

[0037] A 1.40 g aliquot of the 100% phosphonoacetic acid solution was added to 998 g deionized water with stirring. To this solution was added 1000 g of colloidal silica (40% solids, average particle size about 110 nm) with stirring. The pH was adjusted to 2.17 with 10% HCl solution. The resulting solution contained a final phosphonoacetic acid concentration of 0.07%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com