Comprehensive utilization process for waste aluminum etching solution

A technology of aluminum etching and etching solution, which is applied in the direction of phosphorus compound, carboxylate preparation, inorganic chemistry, etc., can solve the problems that the technology cannot be used, so as to reduce energy consumption, ensure no corrosion, and reduce distillation temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

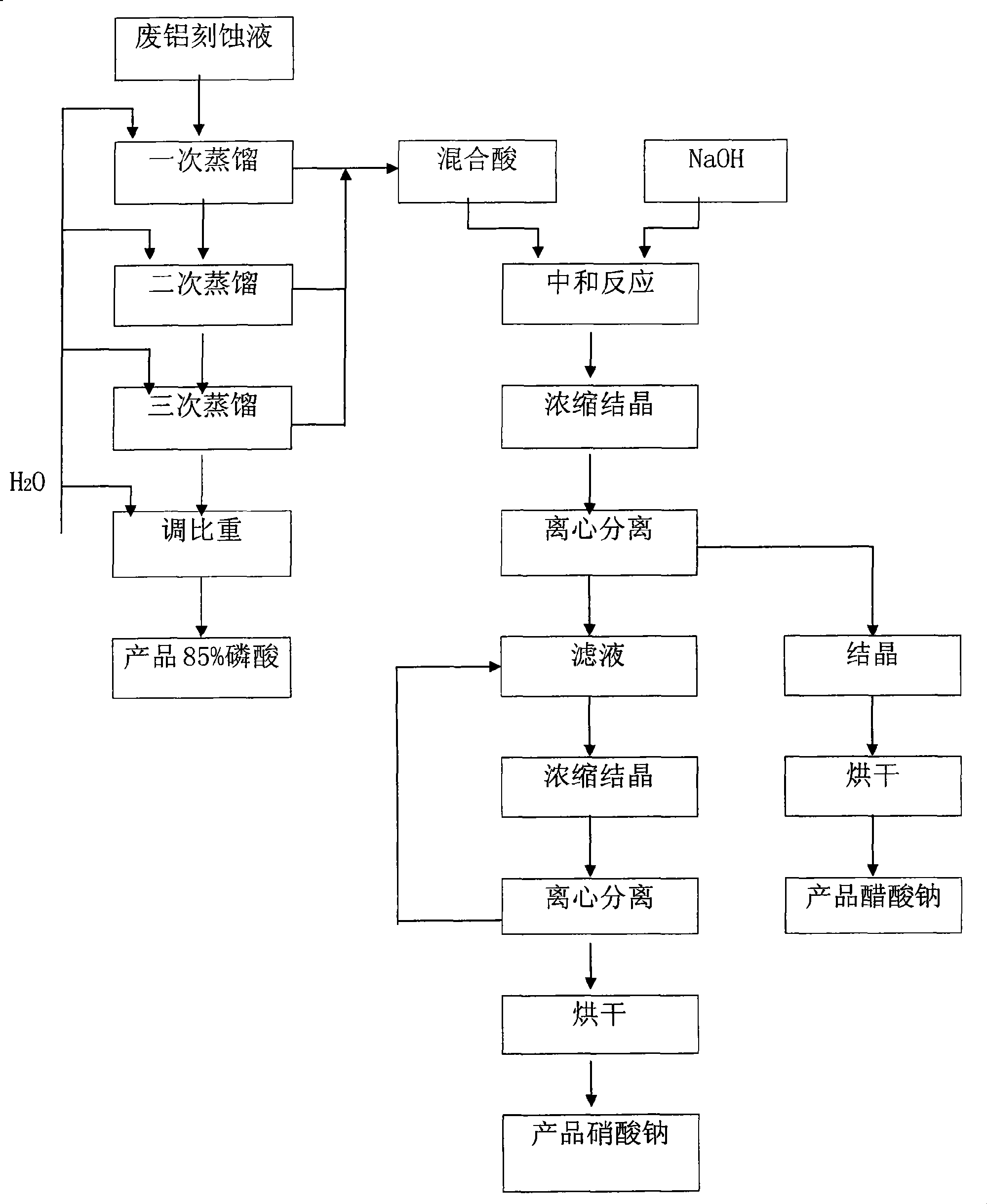

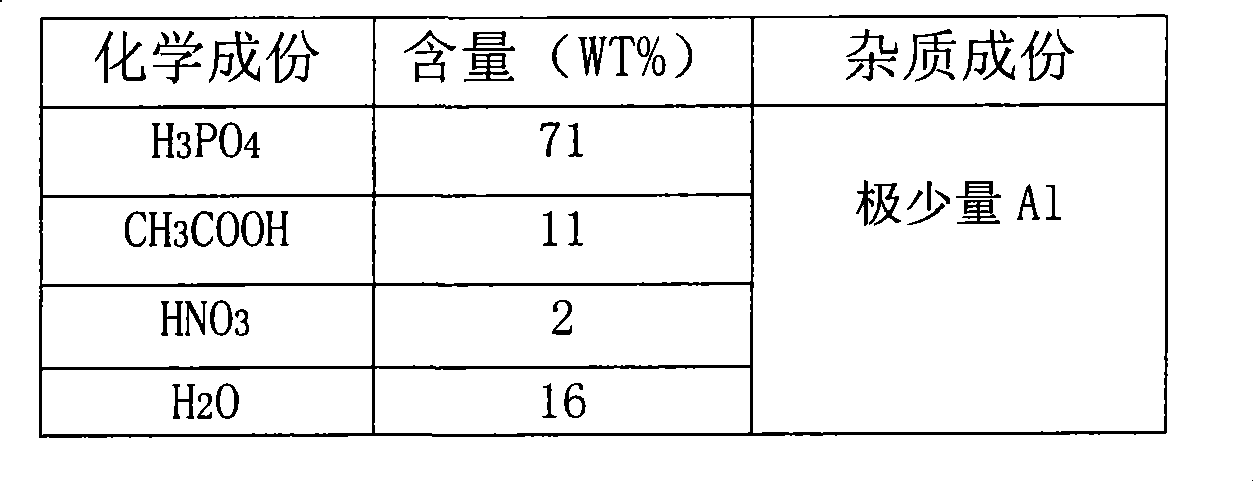

[0027] 1. Take the three-stage distillation method as an example: the waste aluminum etching solution is pumped into the distillation system, and enters the first-stage distiller through preheating, and the distillation temperature is 90-100 °C; the liquid passing through the first-stage distillation overflows from the liquid outlet Enter the secondary distiller, the distillation temperature is 100-110 ℃; the liquid through the secondary distillation overflows from the liquid outlet and enters the tertiary distiller, the distillation temperature is 110-125 ℃, the liquid passing through the tertiary distillation is filtered through the filter, and filtered out Mechanical impurities, add distilled water to adjust the specific gravity, and obtain industrial phosphoric acid with a concentration of 85%.

[0028] 2. The air outlets of the first to third stage evaporators are connected in series, the evaporated mixed acid gas is liquefied and returned to the storage tank, and sodium h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com