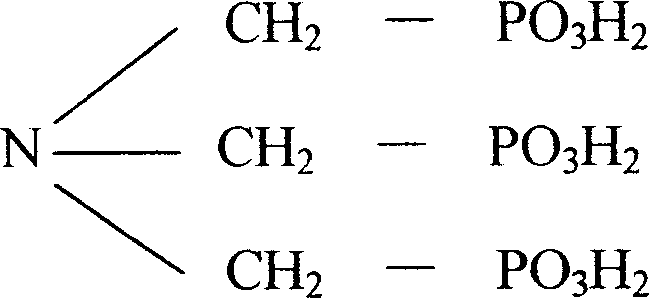

Amino trimethylene phosphonic acid with content of greater than or equal to 90 percent and process for making same

An aminotrimethylene phosphonic acid and process technology, applied in the chemical industry, can solve the problems of difficult packaging, difficult control of on-site application, large storage and transportation energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0035] One of the specific embodiments, a preparation process of aminotrimethylene phosphonic acid with a content of 91%, uses commercially available aminotrimethylene phosphonic acid with a liquid weight percentage of 50% as raw material, and proceeds in accordance with the following steps :

[0036] 1. Prepare materials, take 1000kg liquid amino trimethylene phosphonic acid and put it into the reaction kettle;

[0037] 2. Slowly add 15g of sodium acetate;

[0038] 3. Stir. Stir slowly by hand in the same direction, and observe its crystallization status at any time;

[0039] 4. Slowly add 25g of absolute ethanol and stir slowly;

[0040] 5. Stand still for 10 to 12 hours, and dehydrate with a centrifugal dehydrator;

[0041] 6. The dehydrated solid aminotrimethylene phosphonic acid is dried by reverse convection with hot air at 70°C to obtain a solid aminotrimethylene phosphonic acid product with a content of 91%.

[0042] 7. Packaged and marketed after testing.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com