Patents

Literature

519results about How to "Good anti-scaling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

No-phosphate corrosion and scale inhibitor and its application

InactiveCN101066811AExcellent corrosion inhibition performanceIncrease polarityScale removal and water softeningNon-contaminated water treatmentPolyaspartic acidPhosphate

The present invention relates to no-phosphate corrosion and scale inhibitor and its application. The no-phosphate corrosion and scale inhibitor consists of polyaspartic acid and / or polyepoxy succinic acid 10-20 wt%, polymaleic anhydride 20-30 wt%, copolymer of acrylic acid and 2-acrylamido-2-methyl propenyl sulfonic acid 15-20 wt%, zinc salt 3-5 wt%, natural organic high molecular compound 5-12 wt%, molybdate 5-8 wt%, and other components 5-20 wt%. It has excellent corrosion retarding performance, high scale inhibiting performance and environment friendship.

Owner:WUHAN JINPO CHEM TECH

Phosphorus-free corrosion and scale inhibitor

InactiveCN101607763AReduce dosagePlay a role in corrosion inhibitionTreatment using complexing/solubilising chemicalsChelationPrecipitation types

The invention relates to a phosphorus-free corrosion and scale inhibitor, which is prepared from sodium molybdate, zinc salt, citrate, triethanolamine, benzotriazole (BTA), polyaspartic acid (PASP), polyepoxysuccinic acid (PESA), AA / AMPS terpolymer, solid alkali and water. The phosphorus-free corrosion and scale inhibitor inhibits corrosion of metals by forming oxidization type and precipitation type films on the surfaces of the metals, has the effect of inhibiting scale through chelation and dispersive action on salts causing scale in cooling water, is non-toxic and phosphorus-free, has easily biodegradable major organic compositions, does not cause environmental pollution and is not limited by phosphorus in emission.

Owner:SHANGHAI WEILAI ENTERPRISE

Composite corrosion-retarding antisludging agent for treating high-concentration multiple circulating water

InactiveCN101125715AGrowth inhibitionLimit metabolismScale removal and water softeningHigh concentrationCarboxylic acid

A compound inhibition antisludging agent is used for treating high-concentration circulation water, comprising a liquid part and a solid part. Based on that the total weight of the liquid part is deemed to be 100 percent, percentages of each component by weight are: organic phosphonic acid 5-40 percent, organic carboxylic acid 5-40 percent and water 20-90 percent; and based on that the total weight of the solid part is deemed to be 100 percent, percentages of each component by weight are: polymer with antisludging effect 5-35 percent, alkaline agent 45-80 percent, azoles 1-10 percent and zinc salt 1-10 percent. The concentrations of the liquid part and the solid part in the circulating water are that: the solid part: the dosage of the agent added into make-up water is 20-200mg / L; the liquid part: total phosphine kept in the circulating water system is 10-15mg / L. The invention has effects of inhibition, antisludging, sterilization and algae removal upon meeting the requirements of the state, can promote the concentration multiple of the circulating water system up to 7.5 or more and can be operated at normal temperature with good effect and without pre-membrane treatment.

Owner:上海潓溱环保科技股份有限公司

Corrosion-and scaling-inhibiting water treating agent

InactiveCN1435384AInhibition of localized corrosionPrevent rustFatty acids production/refiningScale removal and water softeningWater useLiquid state

A corrosion-inhibiting and scale-inhibiting agent for treating the water used as circulated cooling water or for boiler is prepared from liquid-state dielectric hydrophobic substance, oil-soluble corrosion inhibitor, water-soluble disperser, and composite sensitive emulsifier. Its advantages are high effect and low dosage.

Owner:BEIJING UNIV OF CHEM TECH

Reverse osmosis membrane scale inhibitor and preparation and use method thereof

ActiveCN101423299AGood anti-scaling effectReduce dosageScale removal and water softeningSewageChemical oxygen demand

The invention discloses a reverse osmosis membrane scale inhibitor, and a method for preparing and using the same. The reverse osmosis membrane scale inhibitor contains polymeric scale inhibitors and components selected from phosphono-carboxylic acid scale inhibitors, organic phosphonic acid scale inhibitors and auxiliary agents. The reverse osmosis membrane scale inhibitor is high in scale inhibition efficiency, small in addition, environmental-friendly, and is suitable to be used in environments with organic substances and in a reverse osmosis membrane treatment process for recycling sewage. For wastewater effluents from a biochemical treatment process with a chemical oxygen demand (COD) less than 150mg / l, the reverse osmosis membrane scale inhibitor has good scale inhibition effect on CaCO3, CaCO4, BaSO4, SrSO4 and so on, and can ensure the normal operation of a membrane component and prolong the service life of the membrane component.

Owner:CHINA PETROLEUM & CHEM CORP +1

Non-phosphate environment-friendly type inhibition anti-sludging agent and preparation method thereof

ActiveCN101062816AImprove performancePromote degradationScale removal and water softeningWater treatment systemSuccinic acid

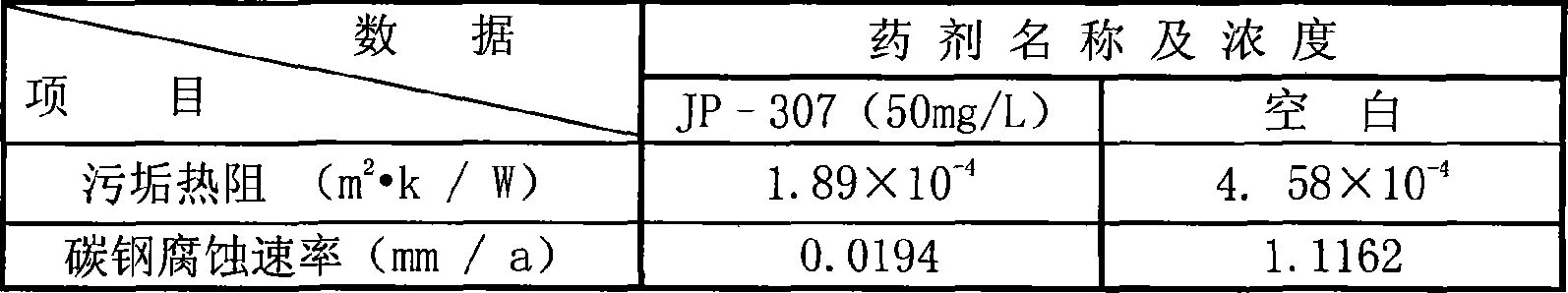

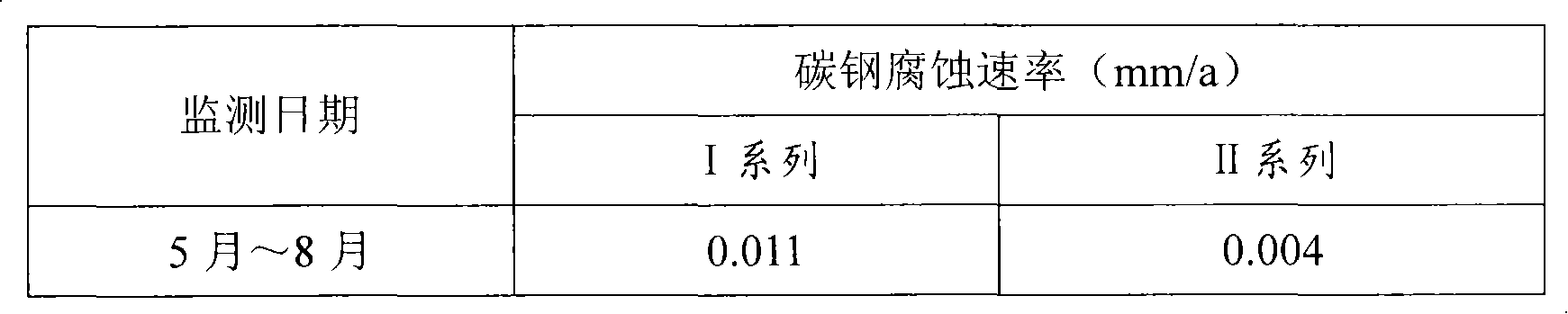

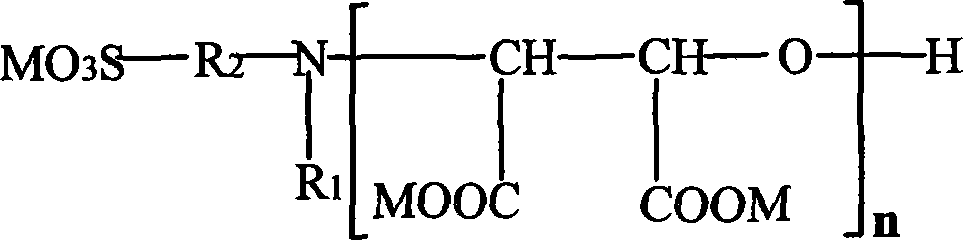

The invention discloses a non-phosphate environment-friendly type inhibiting antisludging agent and preparing method, which is characterized by the following: fitting for disposing industrial recirculated cooling water and oil-field sewage disposal system as water treatment agent; using to inhibit water quality and antisludging treatment; possessing good detergency for CaCO3, CaSO4, BaSO4 and SrSO4 dirty; possessing high bearable degree for calcium; possessing good inhibition for corrosion of carbon steel; setting the R1 of the structural general formula as H or HO(CH2)a-; setting the a as 1-5 or one of MO3SCH2CH(OH)CH2- ; setting the R2 as -(CH2)b- and b as 0-6; expressing n as polymerization degree; setting the n as 2-50; setting n as one or several mixed-ion from NH4+ or Na+ or K+ or 1 / 2Ca2+.

Owner:SOUTHEAST UNIV +1

Polyaspartic acid complex for scale inhibitor

InactiveCN102146161AAvoid stickingImprove reaction efficiencyScale removal and water softeningMaleic anhydrideChemistry

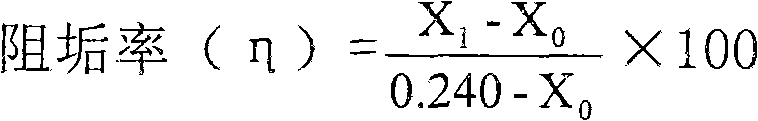

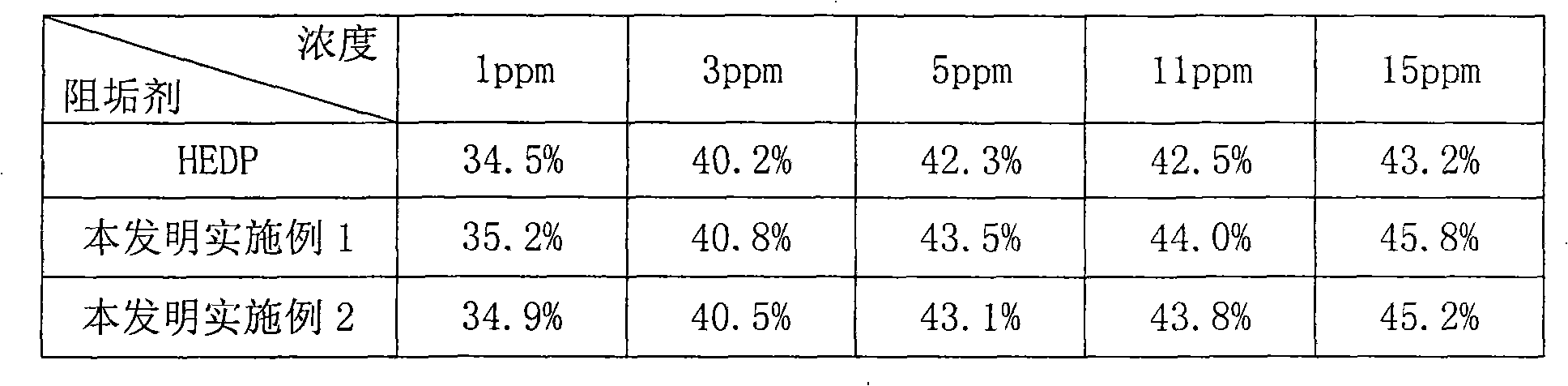

The invention provides a polyaspartic acid complex for a scale inhibitor, which is characterized by being prepared by the following steps of: 1) reacting maleic anhydride, an ammonia-containing substance and water in a mass ratio of 1:((1-1.5):(1.2-2.0) under normal pressure at the temperature of between 50 and 80DEG C for 1 to 2 hours to synthesize maleic acid ammonia; 2) performing polymerization reaction on the maleic acid ammonia at the temperature of between 160 and 200DEG C under normal pressure to generate polysuccinimide; and 3) hydrolyzing the polysuccinimide at the pH of 10-12 and the temperature of between 25 and 50DEG C to generate the polyaspartic acid salt. The polyaspartic acid complex for the scale inhibitor has better scale inhibiting effect on various scaling components such as CaCO3, CaSO4, BaSO4 and SrSO4 in a water treatment system; and through scale inhibition rate testing experiments, the scale inhibition rate is not less than 40 percent, and the polyaspartic acid complex can be widely applied to various water treatment processes, such as a circulating cooling water system, a boiler feed water system, an oil-water water injection system and a seawater desalting system.

Owner:ZHEJIANG XINHE ENVIRONMENT SCI & TECH

Modified polyphenylene sulfide coating and application thereof

ActiveCN102676048AImprove corrosion resistanceSelf-lubricatingAnti-corrosive paintsWear resistantCorrosion

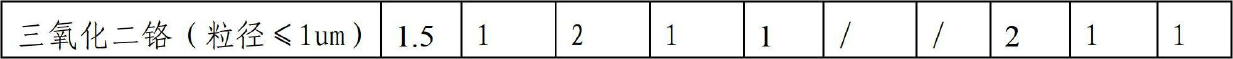

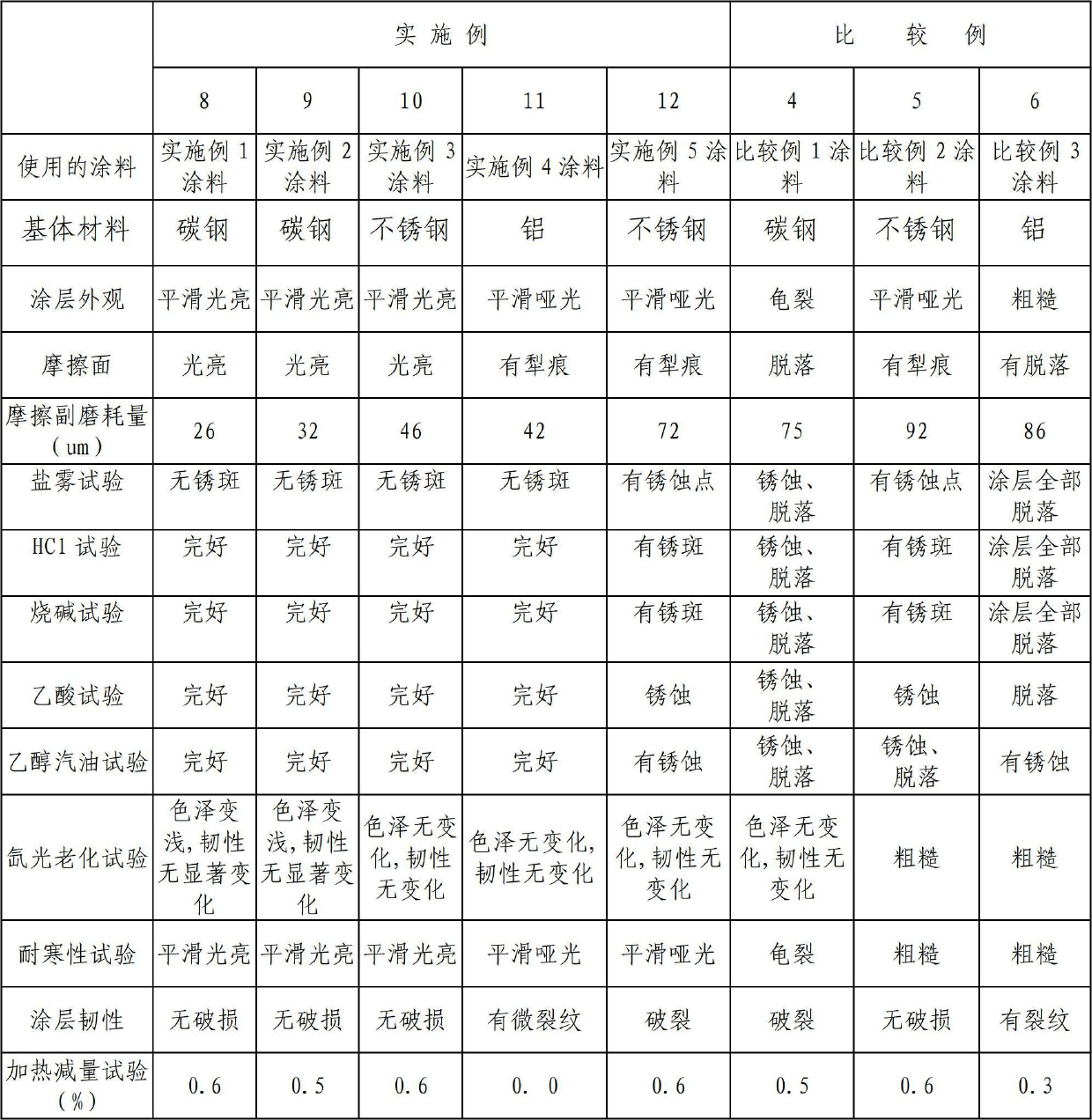

The invention discloses a modified polyphenylene sulfide coating and the application thereof. The modified polyphenylene sulfide coating consists of the following components by weight percentage: 60-90 percent of polyphenylene sulfide resin, 3-25 percent of poly-perfluorinated ethylene propylene resin, 3-20 percent of ethylene-tetrafluoroethylene copolymer resin, 1-5 percent of molybdenum disulfide, 1-5 percent of graphite and the balance of filler, wherein the filler is any one of or a mixture of zinc oxide, aluminum oxide, silicon carbide and chromium sesquioxide. The modified polyphenylene sulfide coating disclosed by the invention has the advantages that the compatibility among the components is good; a prepared coating layer has higher corrosion resistance, higher self-lubricity and strong wear-resistant ability, is resistant to high temperature, is highly insulated, has good toughness, can bear impact force capable of being borne by a metal surface, has excellent bond performance with a metal material and is particularly suitable for the using and working condition of cold / hot sudden changes which cannot be borne by glass lining equipment; and through spraying the coating disclosed by the invention on the surface of the metal matrix material, a manufactured work piece has excellent physical-chemical performance, a long service life and a wide application range.

Owner:CHENGDU LETIAN PLASTICS

Composite corrosion inhibition antisludging agent for ultralow rigidity circulation cooling water and preparation method thereof

InactiveCN102718329AGood anti-scaling effectGood dispersionTreatment using complexing/solubilising chemicalsPhosphateDiethylenetriamine

The invention provides a composite corrosion inhibition antisludging agent for ultralow rigidity circulation cooling water. The composite corrosion inhibition antisludging agent comprises the following raw materials in parts by weight: 5-15 parts of amino trimethylene phosphonic acid, 5-15 parts of hydroxyethylidene diphosphonic acid, 1-15 parts of diethylenetriamine pentamethylene phosphonic acid, 5-15 parts of hydrolytic polymaleic anhydride, 2-15 parts of terpolymer, 2-20 parts of heptahydrate, 0.1-2 parts of hydroxy benzotriazole and 3-79.9 parts of pure water. The hydroxy benzotriazole is added after the amino trimethylene phosphonic acid, the hydroxyethylidene diphosphonic acid, the diethylenetriamine pentamethylene phosphonic acid, the hydrolytic polymaleic anhydride and the terpolymer are stirred and mixed; and the composite corrosion inhibition antisludging agent is obtained by adding the water and the heptahydrate until the hydroxy benzotriazole is entirely dissolved. The hydrolytic polymaleic anhydride and the terpolymer used by the invention have a good diffusion effect, and can effectively prevent carbonates, phosphates and the like from being deposited and scaled. Meanwhile, the hydrolytic polymaleic anhydride and the terpolymer belong to a non-phosphate monomer, so that the agent phosphate content is reduced. Therefore, the composite corrosion inhibition antisludging agent is beneficial to environmental protection.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

Corrosion and scale inhibitor for industrial recirculated cooling water

InactiveCN101302060AGood anti-scaling effectGood synergyScale removal and water softeningEutrophicationTricarboxylic acid

The invention provides a corrosion and scale inhibitor for industrial circulated cooling water, which is applicable to a composite for mitigating metal corrosion added into a water body with ultra-low hardness, low alkalinity and strong corrosiveness. The corrosion and scale inhibitor is characterized by comprising the following compositions in percentage by weight: 5 to 20 percent of 2-hydroxyphonoacetic acid, 5 to 25 percent of 2-phosphonobutane-1, 2, 4 - tricarboxylic acid, 10 to 40 percent of acrylic acid-2-acrylamido-2-methylpropane sulfonic acid copolymer, 1 to 8 percent of zinc chloride, 1 to 5 percent of copper corrosion inhibitor, and the balance being water. The corrosion and scale inhibitor has lower contents of inorganic phosphorus and zinc salt, can prevent scale sedimentation of medicine on one hand, and can reduce eutrophication of the water body and heavy metal pollution on the other hand, thereby facilitating the environmental protection.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD +1

Composite water treatment agent of closed type circulating water system

InactiveCN102557276AEasily biodegradableGood environmental performanceScale removal and water softeningRare-earth elementSoftened water

The invention discloses a composite water treatment agent of a closed type circulating water system. The formula of the composite water treatment agent comprises carboxylic polymer, gluconate, molybdate, zinc salt, rare-earth element nitrate, azoles corrosion inhibitor and water. The composite water treatment agent of the closed type circulating water system has good corrosion and scale inhibition performance and environmental protection performance, is suitable for systems taking the softened water and tap water as make-up water, is phosphorus-free and nontoxic, is easy for biological degradation, and is also suitable for carbon steel and copper material systems.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH +1

High-COD special non-phosphorus corrosion and scale inhibitor and preparation method thereof

ActiveCN104261575AGood anti-scaling effectGood corrosion inhibition effectSpecific water treatment objectivesTreatment using complexing/solubilising chemicalsTungstateWater quality

The invention provides a high-COD (Carbon Oxide Demand) special non-phosphorus corrosion and scale inhibitor and preparation method thereof. The corrosion and scale inhibitor mainly comprises cyclodextrin or cyclodextrin derivatives, a soluble metal salt, a copolymer containing a sulfonic acid group, a homopolymer containing carboxylic acid, an acrylic acid / ethyl acrylate / 2-acrylamide-2-methallylsulphonate copolymer, tetrahydroglyoxaline matters, sodium gluconate, and quaternary ammonium salt. The non-phosphorus corrosion and scale inhibitor is suitable for an open circulated cooling water system, and suitable for surface water high in COD and free of treatment, and the non-phosphorus corrosion and scale inhibitor is added into the circulated cooling water system by an automatic reagent feeding device. The non-phosphorus corrosion and scale inhibitor is environmentally-friendly, avoids using phosphorous compounds or non-renewable molybdate or tungstate, has the characteristic of being free from phosphorus and nitrogen, meets the requirement of environmental protection, reduces the environmental burden, has a sterilizing ingredient at the same time, and effectively reduces the problems of bacterial corrosion and algae growth in a circulated water system.

Owner:SHANDONG TIANQING TECH DEV

Four-element polymerization type corrosion inhibition antisludging agent and method for preparing same

InactiveCN101289256AAvoid corrosionSimple processTreatment using complexing/solubilising chemicalsPeroxydisulfateNuclear chemistry

The invention discloses a quaternary polymeric form corrosion and scale inhibitor which consists of maleic anhydride, hydroxy-propyl acrylate, acrylic acid, sodium alkyl sulfonate, sodium peroxydisulfate, sodium hypophosphite, isopropyl alcohol and water. The invention also discloses a preparation method of the quaternary polymeric form corrosion and scale inhibitor. The corrosion and scale inhibitor has good performance in inhibiting calcium carbonate scale, calcium sulphate scale, calcium phosphate scale and zinc scale and good dispersing performance for dispersing ferric oxide and is also characterized by corrosion resistance, high temperature resistance, stable molecule structure and low phosphorus content; the whole production process has no emission of 'the three wastes'. The technique of the product of the invention for treating circular cooling water is simple and the product of the invention has the advantages of little dosage, low cost, good effect and good economic benefit and wide social benefit.

Owner:NANJING FORESTRY UNIV

Compound corrosion and scale inhibitor

InactiveCN105502704AHigh water saving rateReduce pollutionSpecific water treatment objectivesScale removal and water softeningHigh concentrationAzole

The invention provides a compound corrosion and scale inhibitor. The compound corrosion and scale inhibitor is a liquid preparation which is prepared by mixing a first liquid preparation with a second liquid preparation according to the ratio of 1:1; a compound preparation prepared from organic phosphonic acid, polycarboxylic acid, a dispersing agent and water is adopted as the first liquid preparation; a compound preparation prepared from solid agentia and water according to the weight ratio of 1:1 is adopted as the second liquid preparation, wherein a compound preparation which has the scale inhibition effect and is prepared from polymers, an alkaline agent, azoles and zinc salt is adopted as the solid agentia. The compound corrosion and scale inhibitor can achieve the effects of corrosion inhibition, scale inhibition and sterilization and algae removal which meet the national requirements, can be applied to a circulating cooling water system with the high concentration multiple, is convenient to put, does not need to be prefilmed, can be used at normal temperature and is good in using effect.

Owner:HEBEI AGRICULTURAL UNIV. +1

Scale and corrosion inhibitor

InactiveCN103319010AReduce eutrophication pollutionImprove protectionScale removal and water softeningEutrophicationFluorescence

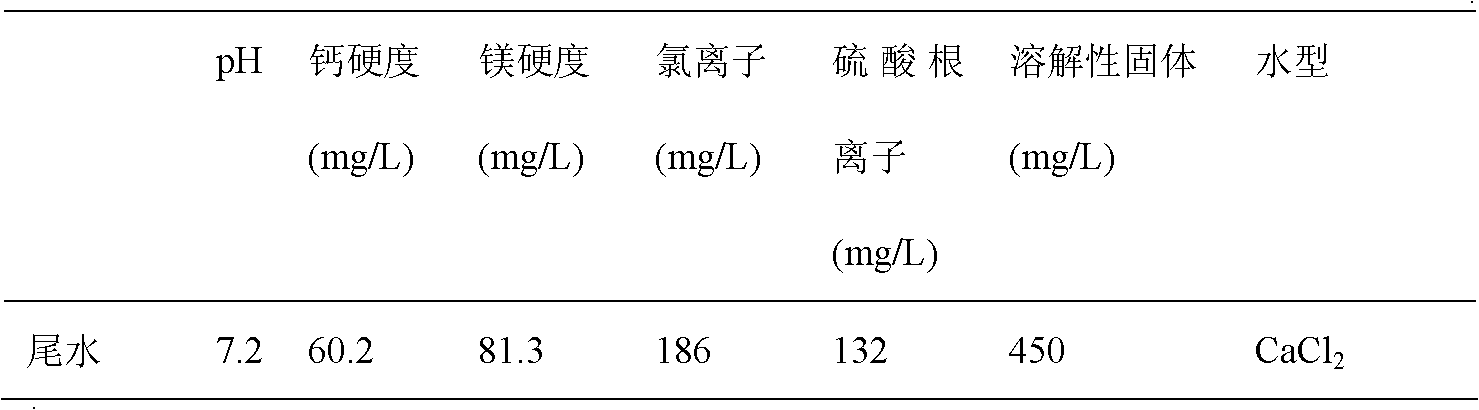

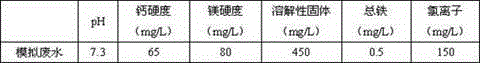

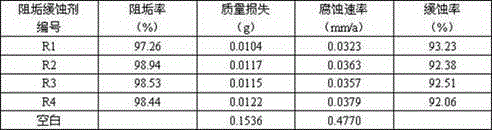

The invention relates to a scale and corrosion inhibitor, comprising organic phosphonate, an inorganic scale and corrosion inhibition component, a carboxylic acid containing copolymer, zinc salt, a heterocyclic compound and a fluorescence tracing component. The scale and corrosion inhibitor is easy to compound, has good stability, and has good scale and corrosion inhibition performances for reusing tail water of a sewage plant into a circulating cooling system under a low addition amount; the scale and corrosion inhibitor can be directly added into a reclaimed water reusing pipeline, without needing to supplement calcium and alkali into the tail water in advance and regulating a pH value, and has a good treating effect; the scale and corrosion inhibitor does not contain a toxic compound and inorganic phosphatic, contains little phosphor, can reduce eutrophication pollution of a water body, and is in favor of environment protection.

Owner:常州市排水管理处 +1

Compound corrosion and scale inhibitor

InactiveCN101560022AGood sedimentationImprove the coordination effectScale removal and water softeningCalcium biphosphateSulfonate

The invention relates to a compound corrosion and scale inhibitor which comprises the following raw materials according to mass ratio: 15%-30% of organic phosphonic acid, 10%-20% of acrylic acid or acrylic acid copolymer, 2%-10% of poly-maleic acid, 1%-3% of azole ramifications, 15%-30% of multivariate organic sulfonate, 2%-6% of dimethyl formamide and 20%-35% of water. The compound corrosion and scale inhibitor of the invention is used for a system which employs normal water as circulating cooling water, so as to solve corrosion problem caused by circulating water of normal-water to equipment. Corrosion rate of copper product is lower than the national standard of 0.005mm / a, thereby generating no equipment scaling caused by calcium phosphate deposition. Compared with corrosion inhibitors of the same kind, the compound corrosion and scale inhibitor has a lower dosage and is effective in corrosion and scale inhibiting. The compound corrosion and scale inhibitor is simple in operation, convenient, quick, safe and efficient.

Owner:XIAN XIELI POWER TECH

Multifunctional scale and corrosion inhibitor and preparation method thereof

InactiveCN104355419AReduce usageGood synergyWaste water treatment from quariesSemi-permeable membranesSoftened waterReverse osmosis

The invention discloses a multifunctional scale and corrosion inhibitor which integrates four effects, namely, scale inhibition, scale removal, corrosion inhibition and perfillmimg, and a preparation method thereof. The scale and corrosion inhibitor is of a nitrogen-free, non-phosphorus and molybdenum formula, and is prepared by compounding a non-phosphorus scale and corrosion inhibition component, methylbenzotriazole, hydrolytic polymaleic anhydride, sodium molybdate and sodium gluconate. According to the multifunctional scale and corrosion inhibitor, usage of phosphorus and nitrite is avoided, usage of molybdate is reduced, the multifunctional scale and corrosion inhibitor has the characteristics of being efficient, practical, non-toxic, environment-friendly, and low in cost, is applicable for scale and corrosion inhibition of water with high salinity and high degree of mineralization, can be widely applied to water treatment fields such as cold and hot circulating water, softened water and reverse osmosis, and the oilfield exploitation field.

Owner:天津天和环能科技有限公司

Solid corrosion and scale inhibitor for oil field

InactiveCN101805597ALow cost of corrosion and scale inhibitionReduce filling operationsDrilling compositionBorehole/well accessoriesPolyethylene glycolTricarboxylic acid

The invention discloses a solid corrosion and scale inhibitor for an oil field, which relates to the technical field of chemical medicine reagents used for the oil field. The solid corrosion and scale inhibitor comprises the following ingredients: 2-phosphonic acid butane 1, 2, 4-tricarboxylic acid PBTCA, polyethyleneglycol, sodium hexametahposphate, span-60 and stearic acid, wherein each ingredient accounts for the mass percent of the sum of all the ingredients as follow: 30 percent to 40 percent of 2-phosphonic acid butane 1, 2, 4-tricarboxylic acid PBTCA, 10 percent to 15 percent of polyethyleneglycol, 10 percent to 15 percent of sodium hexametahposphate, 15 to 25 percent of span-60 and 20 percent to 30 percent of stearic acid. The invention is particularly suitable for well tubes of oil-gas wells with server corrosion and scale conditions, and has good corrosion and scale inhibition effects on underground pipe posts and equipment.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Efficient low-phosphorus corrosion and scale inhibitor

InactiveCN101560023AReduce phosphorus contentImprove performanceScale removal and water softeningAlkalinityTricarboxylic acid

The invention relates to a low-phosphorus compound corrosion and scale inhibitor and applications in the treatment of high-alkalinity and high-hardness circulating cooling water thereof. The efficient low-phosphorus corrosion and scale inhibitor is characterized by adding the following components according to the circulating water: 0.2-1.2mg / L of hydroxyethylidene diphosphonic acid, 0.125-1mg / L of 2-phosphonic acid-1,2,4-tricarboxylic acid, 0.14-1.2mg / L of sulphonate copolymer, 0.625-5mg / L of maleic acid-acrylic acid copolymer, 0-1.6mg / L of polyacrylic acid and 0-0.4mg / L of copper relief agent. The low-phosphorus compound corrosion and scale inhibitor can be used for the treatment of circulating cooling water, has the total phosphorus content less than or equal to 0.5mg / L in the circulating water, has the advantages of good comprehensive performance, excellent CaCO3 scale resistance function, corrosion inhibition performance and small dosage of less than or equal to 20mg / L under normal condition, is applicable to the treatment of circulating cooling water, and reduces the hazards of phosphorus emission on environment.

Owner:兰州华星高科技开发有限公司

Composite corrosion and scale inhibitor, and its application in circulating cooling water treatment

ActiveCN103787516AGood anti-scaling effectGood synergistic corrosion inhibition effectScale removal and water softeningCarboxylic acidCopolymer

The invention discloses a composite corrosion and scale inhibitor, and its application in circulating cooling water treatment. The composite corrosion and scale inhibitor contains oxalic acid and / or oxalate, a sulfonic group-containing copolymer, a scale inhibition additive and a zinc salt, the scale inhibition additive is at least one of organic phosphonic acid, phosphorus-free polycarboxylic acid and phosphorus-free polyacid anhydride, and a weight ratio of oxalic acid and / or oxalate to the sulfonic group-containing copolymer to the scale inhibition additive to the zinc salt by zinc ion is 10-30:2.5-5.5:2-12:1. The composite corrosion and scale inhibitor contains no phosphorus or has a low concentration of total phosphorus, is environmentally-friendly, and is especially suitable for circulating water with the sum of the total alkalinity and the total hardness of above 100mg. The above zinc salt formula containing oxalic acid and / or oxalate realize excellent scale and corrosion inhibition effects.

Owner:CHINA PETROLEUM & CHEM CORP +1

Corrosion and scale inhibitor for high-chlorine and high-calcium water-quality

InactiveCN101028957AIncrease the allowable concentrationControl formationScale removal and water softeningManganeseWater quality

A corrosion-retardant scaling inhibitor for the high-Cl and -Ca water contains proportionally phosphonylic acid, polyphosphonic acid, organic phosphonate, Zn sale, Mn salt, polyacrylic acid, antimildew agent and purified water.

Owner:BAOSHAN IRON & STEEL CO LTD +1

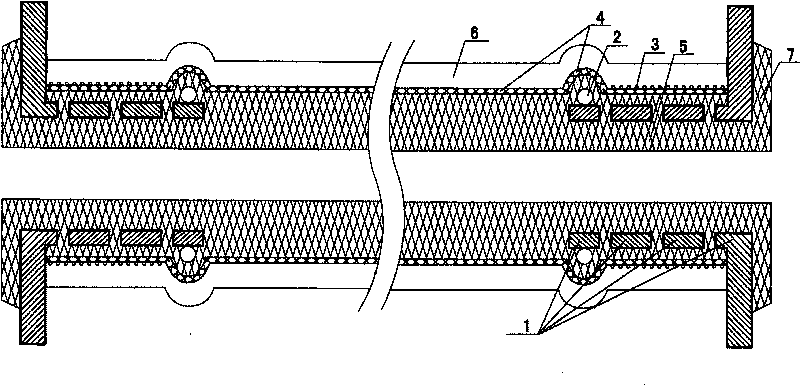

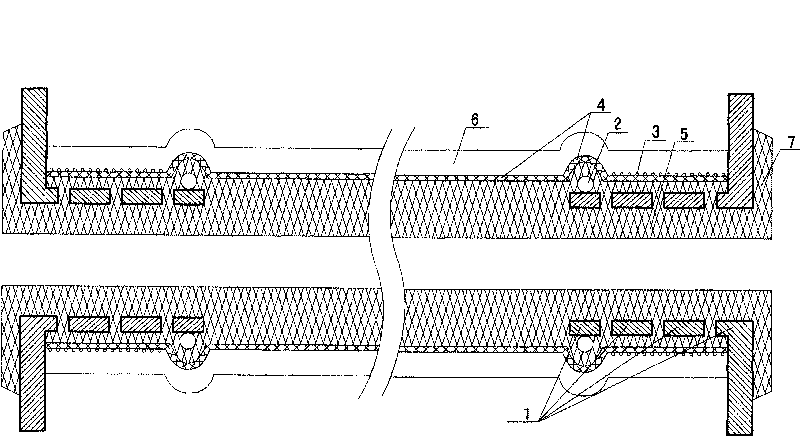

Wear-resistant rubber polyurethane compound hose

InactiveCN101694253AIncrease elasticityReduce wearFlanged jointsFlexible pipesWear resistantFlanging

A wear-resistant rubber polyurethane compound hose is characterized by comprising a bearing layer (4), a wear-resistant layer (5) and a protective layer (6). The inner wall of a pipeline is formed by the wear-resistant layer (5), the bearing layer (4) is arranged on the outer wall of the wear-resistant layer (5), the protective layer (6) is disposed on the outer layer of the bearing layer (4); the wear-resistant layer (5) is an elastic pipe body formed by pouring polyurethane materials inside a die, and is arranged to be an integral structure with a flange steel ring (1) via a pouring hole on the flange steel ring (1). A circular sealing flanging (7) is disposed outwards on the wear-resistant layer (5) along a flange disk, the bearing layer (4) is formed by weaving more than one layer of cord threads in a cross-intertwining arrangement outside the tube body of the wear-resistant layer (5), and one layer of steel wires is wound on the outer side of a reinforced steel ring (2) at the position of the flange steel ring (1) once every 2-4 layers of cord threads are wound. The wear-resistant rubber polyurethane compound hose has the advantages of fine wear resistant property, scale prevention, low running resistance, fine water resistant property, fine aging resistant property, fine combination and long service life.

Owner:梁宝忠

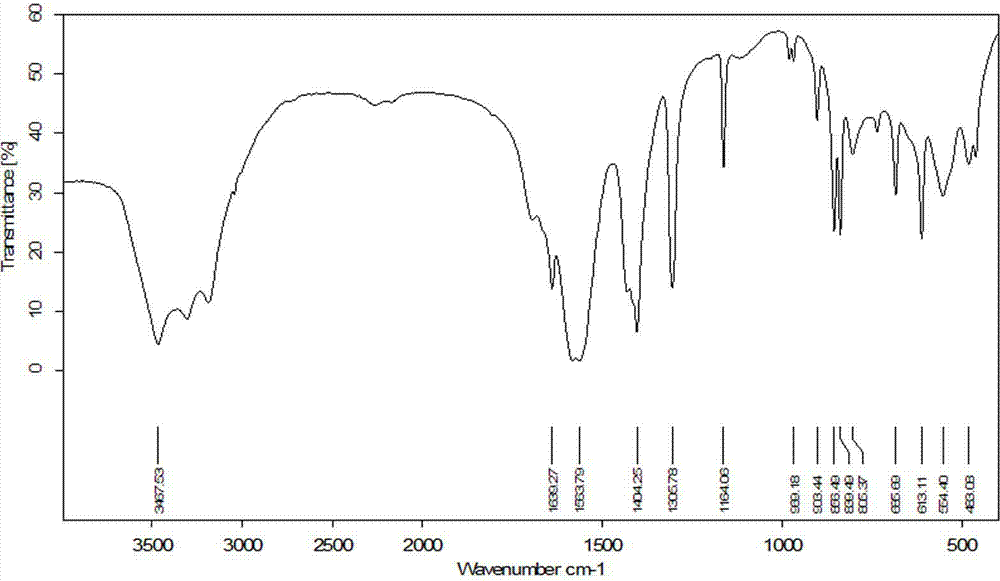

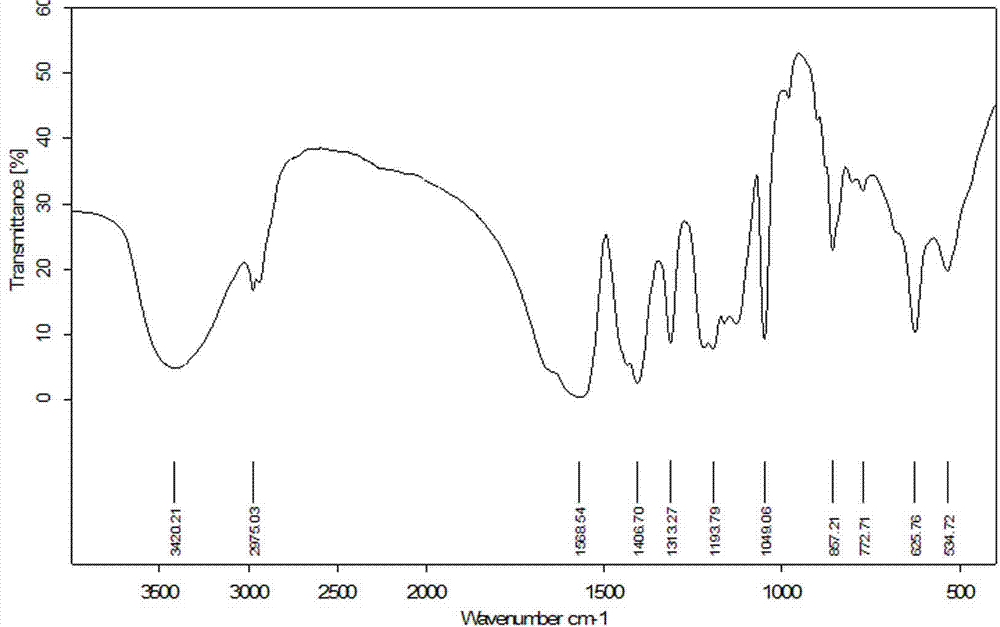

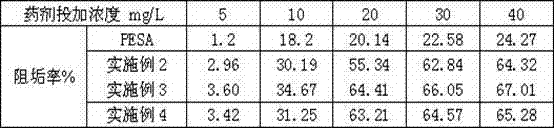

Preparation method of epoxysuccinate /acrylic acid/2-acrylamido-2-methyl propane sulfonic acid copolymer

InactiveCN102766232AGood anti-scaling effectOrganic chemistryScale removal and water softeningHigh concentrationPhosphate

The invention discloses a preparation method of a novel scale inhibitor epoxysuccinate / acrylic acid / 2-acrylamido-2-methyl propane sulfonic acid copolymer which is prepared by the polymerization of epoxysuccinate, acrylic acid and 2-acrylamido-2-methyl propane sulfonic acid under appropriate condition. Compared with the polyepoxysuccinic acid, the ESA / AA / AMPS terpolymer prepared by the method provided by the invention can improve the scale inhibition performance greatly and the scale inhibition effect of calcium carbonate is roughly equal to polyepoxysuccinic acid, while the ability of blocking calcium phosphate scale, calcium sulfate scale and stabilizing zinc are significantly better than that of the polyepoxysuccinic acid. The epoxysuccinate / acrylic acid / 2-acrylamido-2-methyl propane sulfonic acid terpolymer is a new water-treatment chemical which has the advantages of excellent comprehensive scale inhibition performance, is free of phosphate, is applicable to a circulating water system with high alkali, high hardness and high concentration rate, and has broad application prospect.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Reverse osmosis compound scale inhibitor

InactiveCN101973644AExcellent chelating solubilizationExtended shelf lifeScale removal and water softeningReverse osmosisCarboxylic acid

The invention provides a reverse osmosis compound scale inhibitor and belongs to the field of reverse osmosis water treatment. The scale inhibitor comprises the following components in percentage by weight: 10 to 20 percent of 1-hydroxyethylidene-1,1-diphosphonic acid, 30 to 40 percent of hydrolytic polymaleic anhydride, 30 to 40 percent of polyacrylic acid and 10 to 20 percent of sulfonated styrene-maleic anhydride copolymer, and the scale inhibitor comprises also comprises a bactericide. The reverse osmosis compound scale inhibitor fully utilizes the synergistic effect among organic phosphorous scale inhibitors, polycarboxylic acid scale inhibitors and sulfonic acid scale inhibitors, has good scale inhibition and dispersion performance; and when used in a reverse osmosis water inflow system, the scale inhibitor can effectively lighten pollution of calcium carbonate, calcium sulfate and silicate to reverse osmosis membranes and prolongs the cleaning period and service life of the reverse osmosis system.

Owner:NANJING UNIV

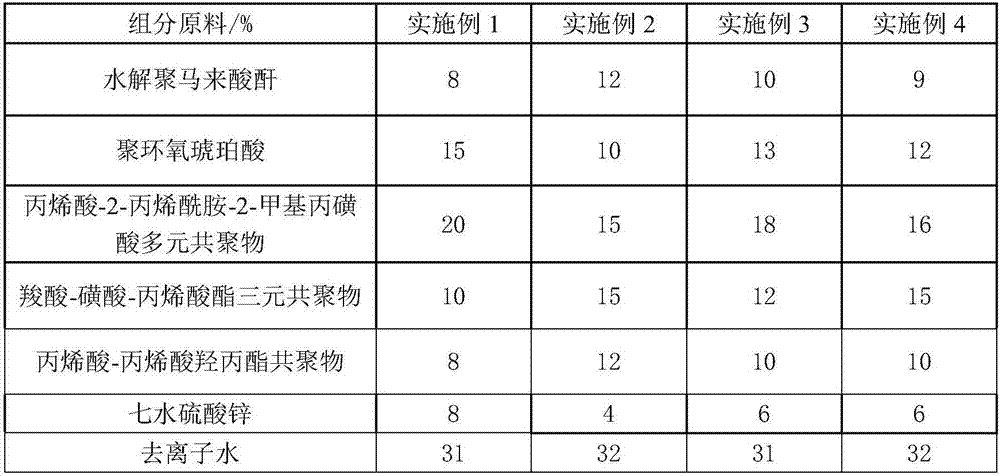

Non-phosphorus corrosion and scale inhibitor

InactiveCN108002558AGood chemical stabilityImprove thermal stabilitySpecific water treatment objectivesScale removal and water softeningEutrophicationZinc sulphate heptahydrate

The invention discloses a non-phosphorus corrosion and scale inhibitor. The non-phosphorus corrosion and scale inhibitor is prepared from the following components in percentage by weight: 8 to 12 percent of hydrolytic polymaleic anhydride, 10 to 15 percent of polyepoxysuccinic acid, 15 to 20 percent of acrylic acid-2-acrylamido-2-methylpropanesulfonic acid multipolymer, 10 to 15 percent of carboxylic acid-sulfonic acid-acrylate terpolymer, 8 to 12 percent of acrylic acid-hydroxypropyl acrylate copolymer, 4 to 8 percent of zinc sulphate heptahydrate and the balance of deionized water. The invention further discloses a preparation method of the corrosion and scale inhibitor. The preparation method comprises the following steps: weighing the components according to the formula; adding the components into a stirrer in sequence; stirring at normal temperature and under normal pressure to obtain the corrosion and scale inhibitor. The corrosion and scale inhibitor disclosed by the invention has the advantages of freeness from phosphorus, adoption of safe and environment-friendly components, simple production process, high scale-inhibiting efficiency, high corrosion-inhibiting performance, prevention of eutrophication of a water body caused by discharge of phosphorus, and very high compatibility; the adhesion of microorganisms to equipment can be reduced effectively, and the corrosionand and scale inhibiting performance can be enhanced greatly.

Owner:新疆水处理工程技术研究中心有限公司

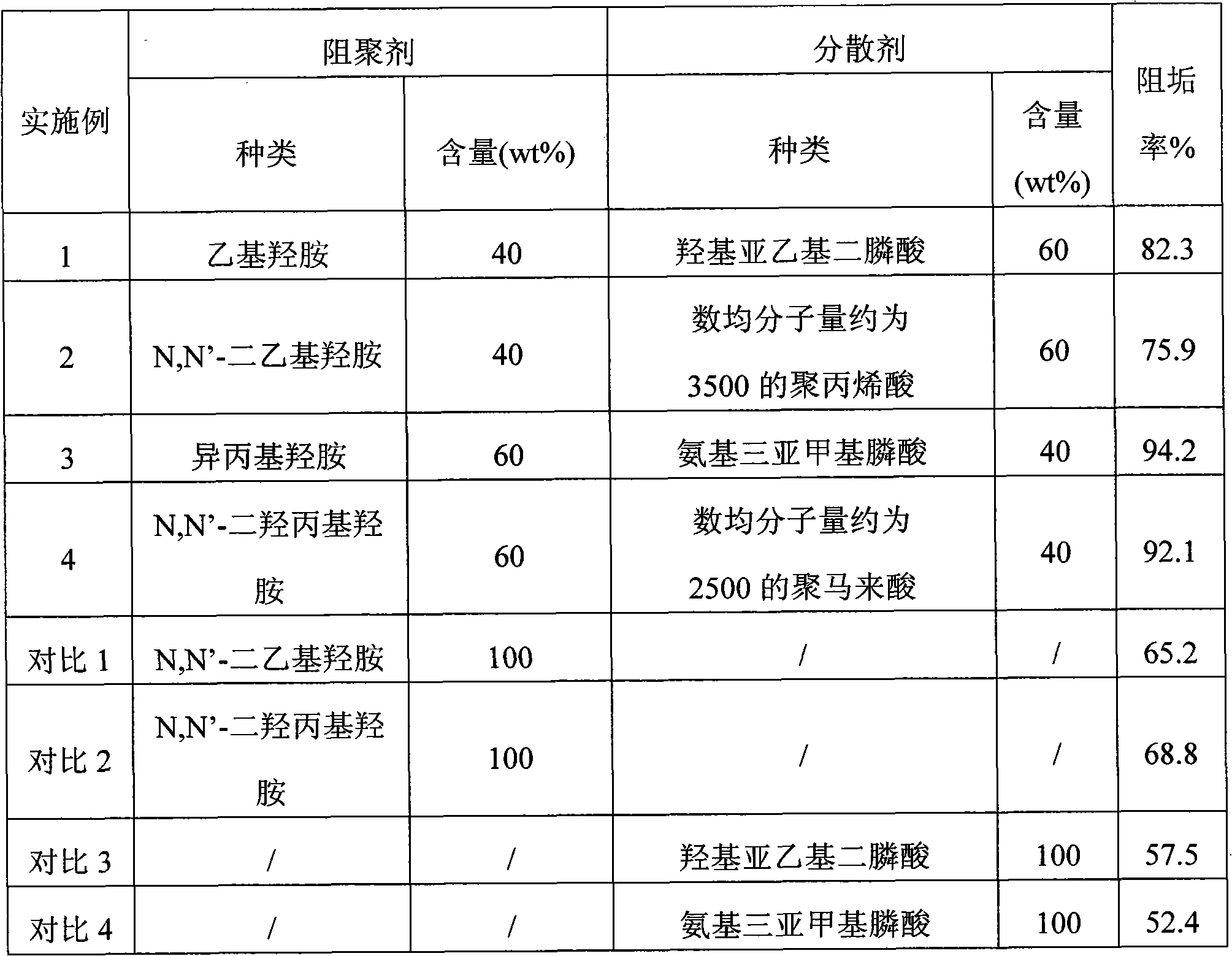

Scale inhibitor of ethylene device process water system and using method thereof

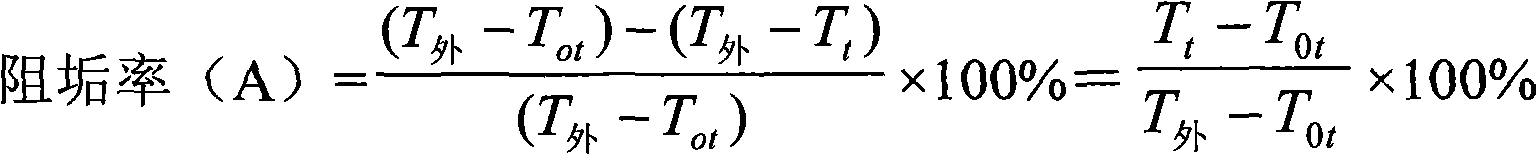

ActiveCN101838058AExtended operating cycleGood anti-scaling effectScale removal and water softeningNature of treatment waterChemistryPolymerization

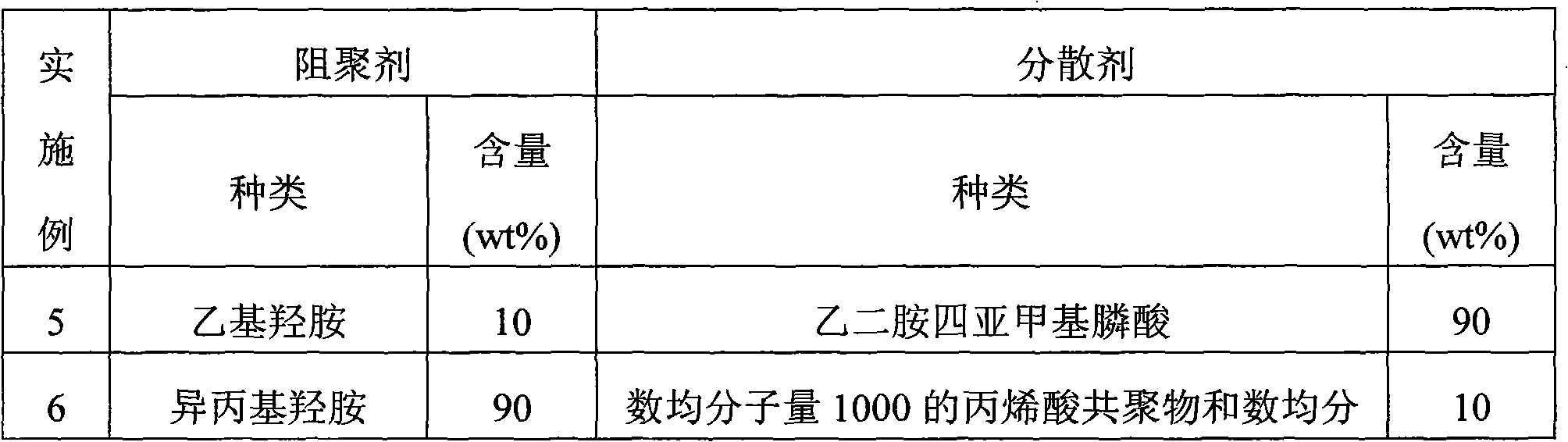

The invention discloses a scale inhibitor of an ethylene device process water system and a using method thereof. The scale inhibitor of the ethylene device process water system comprises the following components in percentage by mass: 10 to 90 percent of polymerization inhibitor and 10 to 90 percent of dispersant. The using method comprises the step of adding the scale inhibitor of the ethylene device process water system into a water system of an ethylene device process water stripper, wherein the adding concentration of the scale inhibitor of the ethylene device process water system is 5 to 1,000 ppm of the feeding amount of the process water stripper. The scale inhibitor has good double functions of polymerization inhibition and dissipation, is in particular suitable for the ethylene device process water system and can meet the requirement of the process water system on the stable long-period operation.

Owner:上海良田化工有限公司

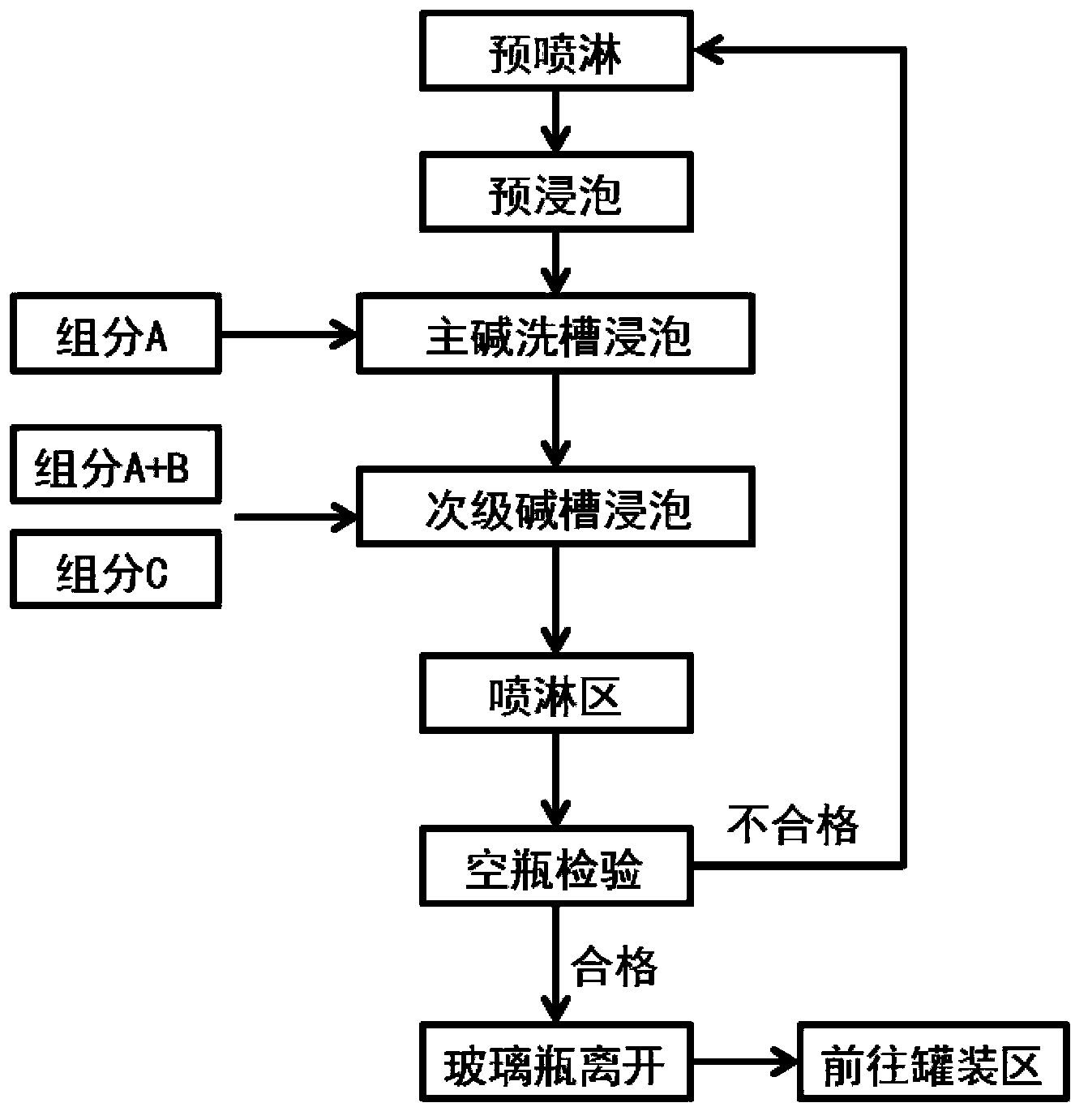

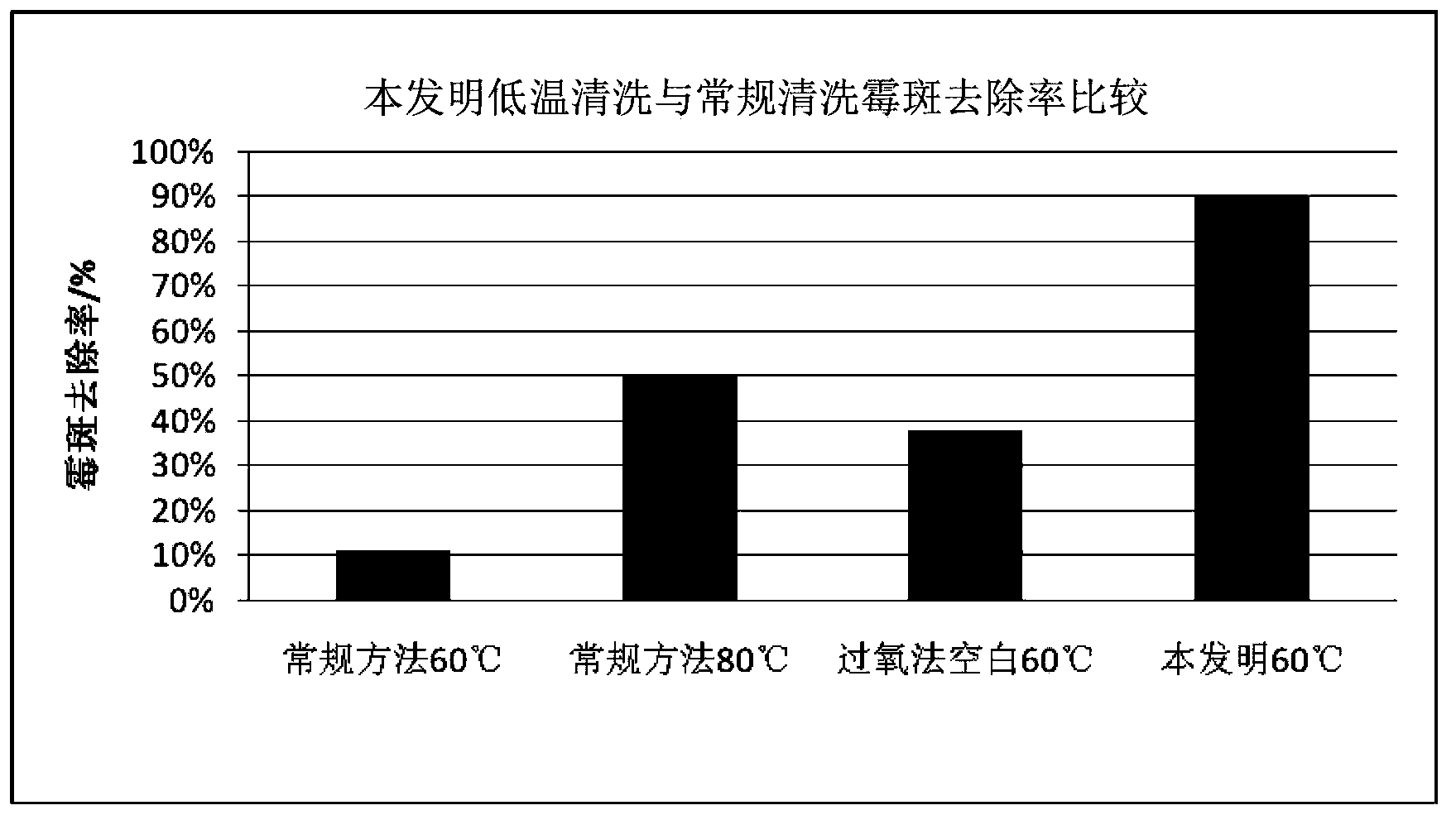

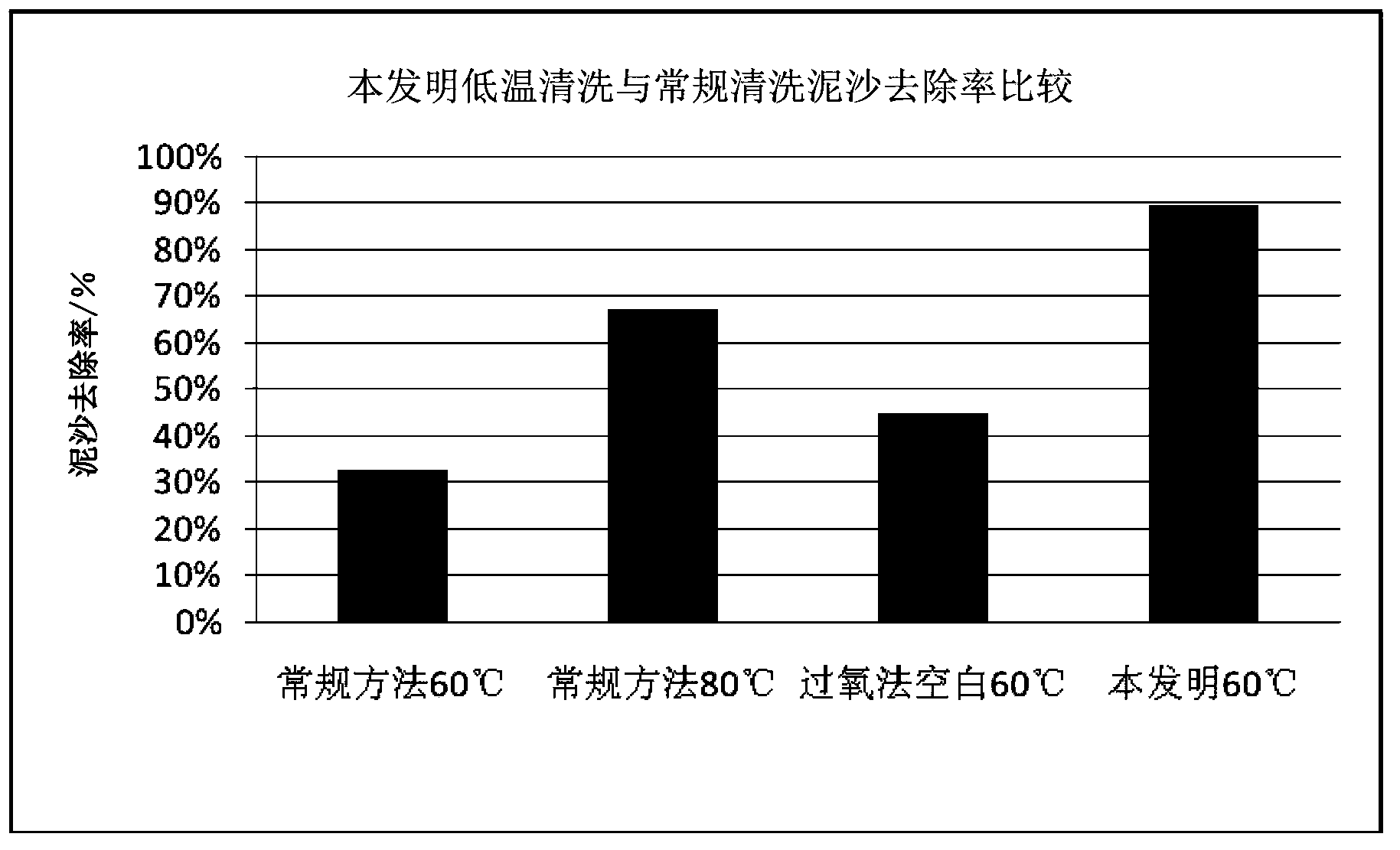

Cleaning additive and cleaning method adopting the cleaning additive

InactiveCN103849498AImprove solubilityLess corrosiveNon-ionic surface-active compoundsNon-surface-active detergent compositionsOrganic phosphorusBottle

The invention discloses a cleaning additive for glass bottles and a cleaning method of the glass bottles. The cleaning method and the cleaning additive are used for glass bottle cleaning by a primary alkaline bath and a secondary alkaline bath. The cleaning additive comprises a component A, a component B and a component C, wherein the component A comprises an organic phosphorus chelating agent, the component B comprises peroxide, the component C comprises a defoaming agent, the component A is added into the primary alkaline bath, the component B is selectively added into the primary alkaline bath, the component A and the component B are added into the secondary alkaline bath, and the component C is selectively added into the primary alkaline bath or the secondary alkaline bath. Based on the weight of alkaline solution in the primary alkaline bath or the secondary alkaline bath where the component is added, the adding amount of the component A is 0.05-5%, the adding amount of the component B is 0.1-0.5%, and the adding amount of the component C is 0-0.5%. The alkaline solution in the primary alkaline bath and the secondary alkaline bath is sodium hydroxide solution having a concentration of 1.5-3%. The cleaning additive and the cleaning method can achieve stable and good cleaning effects at a relatively low temperature that is usually 50-70 DEG C.

Owner:ECOLAB USA INC

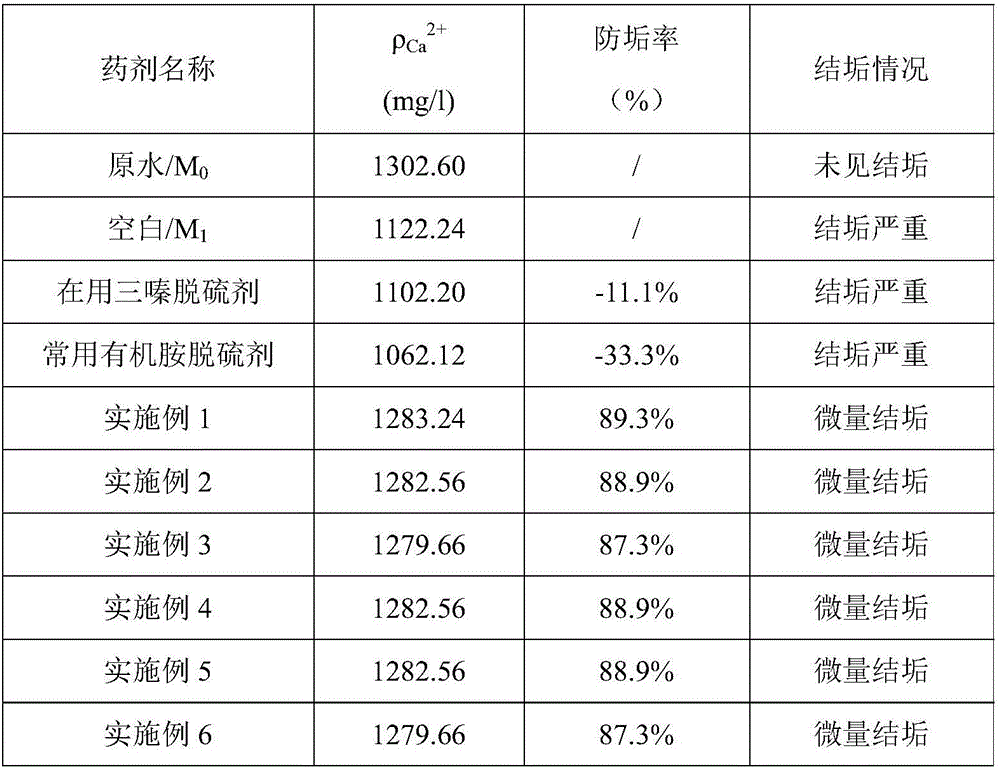

Oil field scale prevention desulfurizing agent and preparing method thereof

ActiveCN106554804AImprove desulfurizationGood antifouling effectHydrocarbon oils refiningTreatment apparatus corrosion/fouling inhibitionTemperature controlPhosphate

The invention relates to the field of chemical desulphuration, and discloses an oil field scale prevention desulfurizing agent and a preparing method thereof. The oil field scale prevention desulfurizing agent is prepared in the manner that a modifying agent, a synergist and a dispersing agent are added in a main agent, and the main agent is obtained in the manner that organic amine and a formaldehyde solution serve as raw materials and are subjected to polymerization, dehydration and refining. The preparing method comprises the steps that the organic amine is stirred under a certain temperature condition, the formaldehyde solution is dripped, the temperature control reaction is conducted after dripping is finished, and the main agent is obtained after decompression dehydration under a certain vacuum degree and temperature condition; then the reaction temperature is controlled, and a modifying agent is dripped in the main agent, and the reaction is conducted; and finally, the synergist and the dispersing agent are sequentially added in a reaction product, and stirring is conducted till uniform mixing. The oil field scale prevention desulfurizing agent has a nitrogen-containing triazine structure, the efficient desulfuration effect can be guaranteed, the phosphate functional group is introduced in molecules, and meanwhile excellent scale prevention performance is achieved. Thus, the oil field scale prevention desulfurizing agent has good desulfuration and scale prevention performance at the same time, and the oil field scale prevention desulfurizing agent is suitable for the desulfuration process of oil field fluid production.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Phosphorus-free composite water treatment agent

InactiveCN101746903ANot prone to eutrophicationPrevention of "red tide" public hazardScale removal and water softeningWater/sewage treatment using germicide/oligodynamic-processEcological environmentEutrophication

The invention belongs to a novel environment friendly water treatment agent, in particular to a phosphorus-free composite water treatment agent, comprising the following components in parts by weight: 1-7 parts of polyaspartic acid, 0.5-5 parts of molybdate, 1-10 parts of polyacrylic acid, 1-10 parts of terpolymer and 2-100 parts of bactericide. The water treatment agent does not contain phosphorus and other hazardous substance which are harmful to the environment, can not easily cause eutrophication, can prevent the pollution of the 'red tide' from being generated in the peripheral water area, has good corrosion inhibition and scale inhibition effects and takes the common surface water as make-up water, when the cycle of concentration is 2-6, the annual corrosion inhibition of carbon steel reaches lower than 0.02mm / a, and the scale inhibition of the calcium carbonate in the water can reach more than 90 percent. The invention is used for the water treatment of industrial recirculating water cooling systems and boiler water systems.

Owner:NANJING TECH UNIV

Dirt dispersion agent containing sulfonic acid copolymer

InactiveCN1837103AGood anti-scaling effectGood dispersionScale removal and water softeningPhosphateSodium lignosulfonate

The invention provides an anti-scaling disperser, which comprises 2-acrylamide-2-methyl propanesulfonic acid copolymer, sodium lignosulfonate, tannic acid, sodium humate and water. 78{>The invention also provides a method for using the anti-scaling disperser by compounding with organic phosphate and zinc salts, or compounding with zinc chloride to 8-12%.

Owner:SHANGHAI WANSEN WATER TREATMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com