Preparation method of epoxysuccinate /acrylic acid/2-acrylamido-2-methyl propane sulfonic acid copolymer

A technology based on epoxy succinic acid and acrylamide, which is applied in chemical instruments and methods, water/sludge/sewage treatment, descaling and water softening, etc. It can solve the problem of poor zinc stabilization ability and unsatisfactory calcium phosphate scale inhibition rate and other problems, to achieve the effect of excellent scale inhibition performance and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

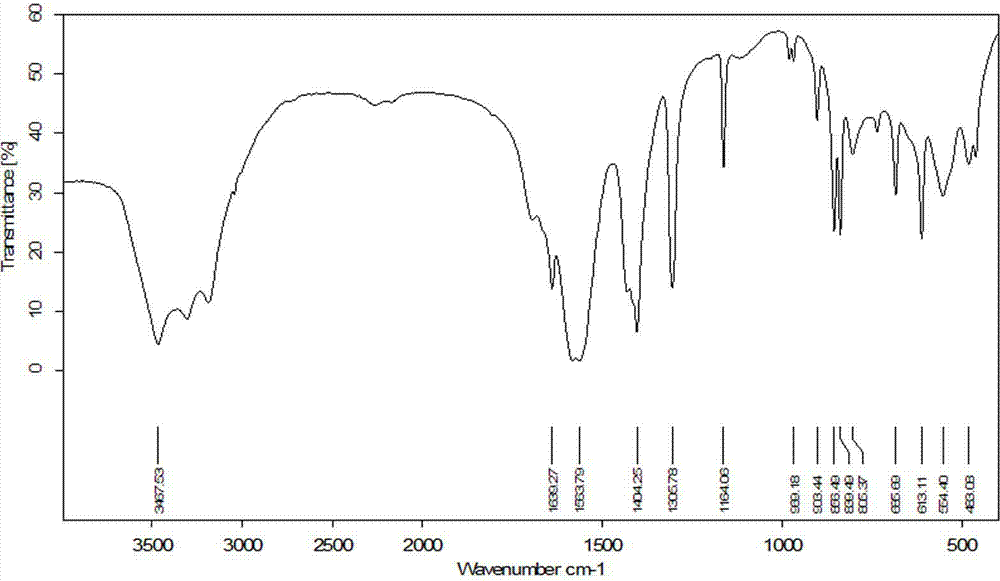

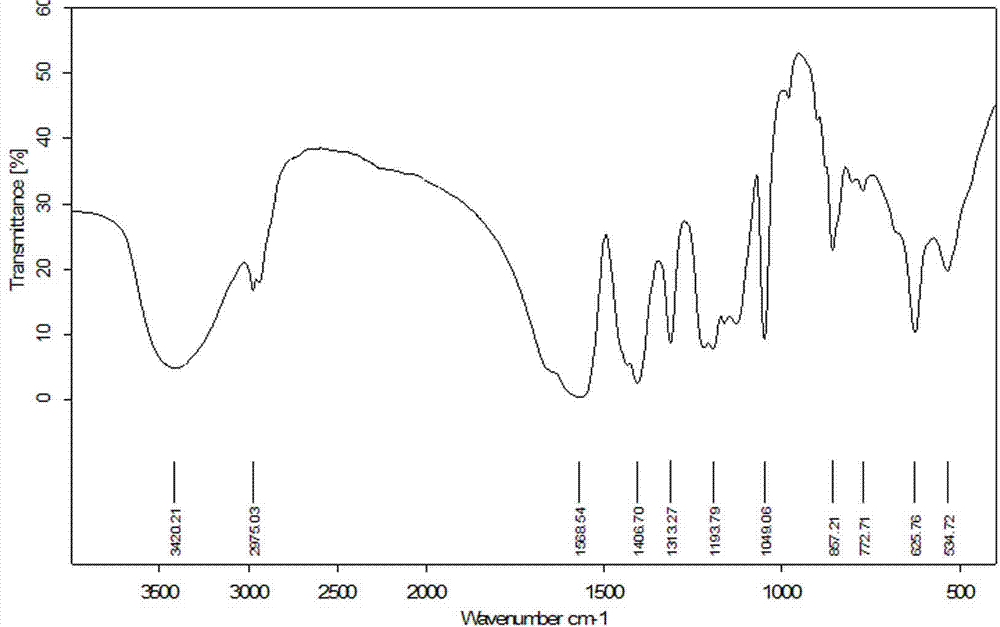

Image

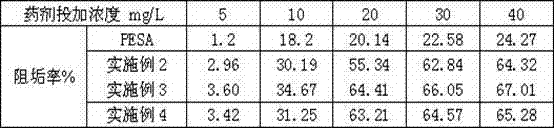

Examples

Embodiment 1

[0021] Embodiment 1: preparation epoxy succinic acid

[0022] (1) Weigh 0.2mol of maleic anhydride, put it into a four-neck flask equipped with a condenser, thermometer, stirrer and dropping funnel, add 40mL of deionized water to dissolve the maleic anhydride;

[0023] (2) When the maleic anhydride is completely dissolved, add 10 mL of 50% sodium hydroxide solution through the dropping funnel to the maleic anhydride aqueous solution under cooling and stirring at a constant speed for 40 minutes;

[0024] (3) After dropping the sodium hydroxide solution, raise the system temperature to 50-70°C, add a sodium tungstate catalyst with a mass of 1.5% maleic anhydride, and drop 40mL of a hydrogen peroxide solution with a mass concentration of 30% within 20 minutes at a constant speed At the same time, use 50% sodium hydroxide to adjust the pH value of the reaction system between 12~14. After the pH is stable, raise the temperature of the reaction system to 50~70°C, react at this tempe...

Embodiment 2

[0025] Embodiment 2: the preparation of epoxy succinic acid / acrylic acid / 2-acrylamido-2-methylpropanesulfonic acid copolymer

[0026] (1) In a four-necked flask equipped with a dropping funnel, a condenser, a thermometer and a stirrer, add epoxysuccinic acid and dissolve it with deionized water to a mass concentration of 20%;

[0027] (2) Heat the temperature of the reaction system to 80-90°C, use two dropping funnels to drop the mixture of acrylic acid, 2-acrylamido-2-methylpropanesulfonic acid aqueous solution and 10% mass concentration of Catalyst aqueous solution, the mass concentration of acrylic acid in the mixed solution is 20%, and the mass concentration of 2-acrylamido-2-methylpropanesulfonic acid is 25%, dripping simultaneously within 2h, described epoxy succinic acid, acrylic acid and The mass ratio of 2-acrylamido-2-methylpropanesulfonic acid is 1:0.5:0.5, the catalyst is ammonium persulfate, and the dosage is 4% of the total amount of monomers;

[0028] (3) After...

Embodiment 3

[0029] Embodiment 3: the preparation of epoxy succinic acid / acrylic acid / 2-acrylamido-2-methylpropanesulfonic acid copolymer

[0030] (1) In a four-necked flask equipped with a dropping funnel, condenser, thermometer and stirrer, add epoxysuccinic acid and dissolve it with deionized water to a mass concentration of 30%;

[0031] (2) Heat the temperature of the reaction system to 80-90°C, use two dropping funnels to drop the mixture of acrylic acid, 2-acrylamido-2-methylpropanesulfonic acid aqueous solution and 10% mass concentration of Catalyst aqueous solution, the mass concentration of acrylic acid in the mixed solution is 25%, and the mass concentration of 2-acrylamido-2-methylpropanesulfonic acid is 15%, dripping simultaneously within 2h, described epoxy succinic acid, acrylic acid and The mass ratio of 2-acrylamido-2-methylpropanesulfonic acid is 1:1:0.6, the catalyst is ammonium persulfate, and the dosage is 7% of the total amount of monomers;

[0032] (3) After all the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com