Patents

Literature

319 results about "2-Methyl propane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Firstly it is 2-methyl propane and not 2,2 dimethyl ethane. Secondly, yes the two are structural isomers since both have the formula C4H10 and different in structure and properties.

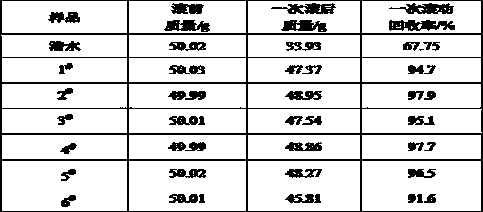

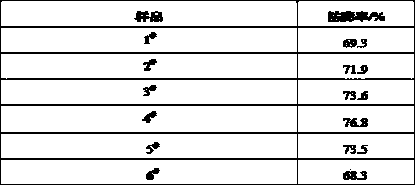

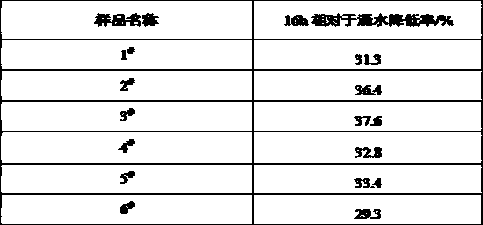

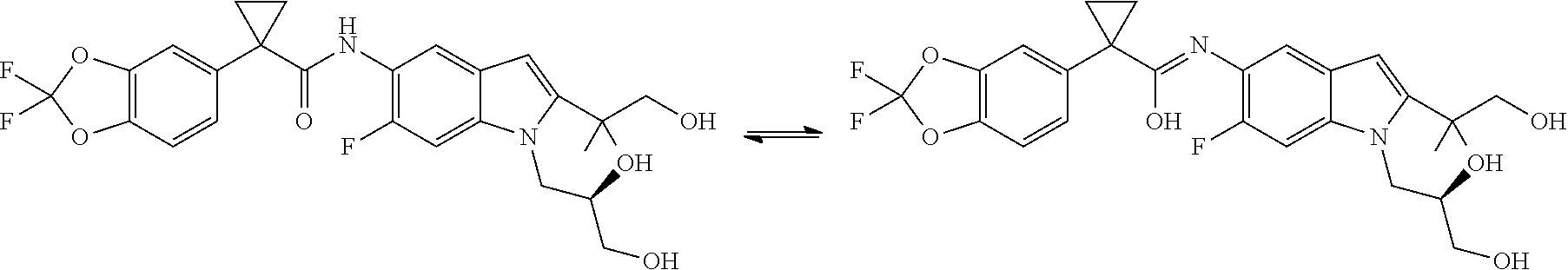

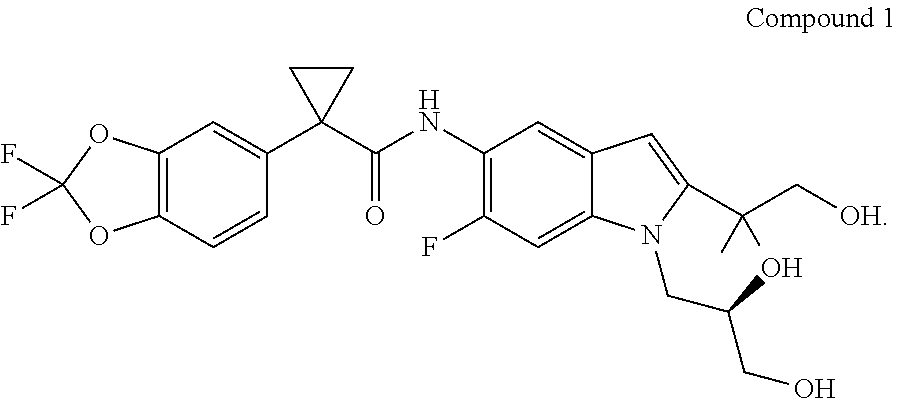

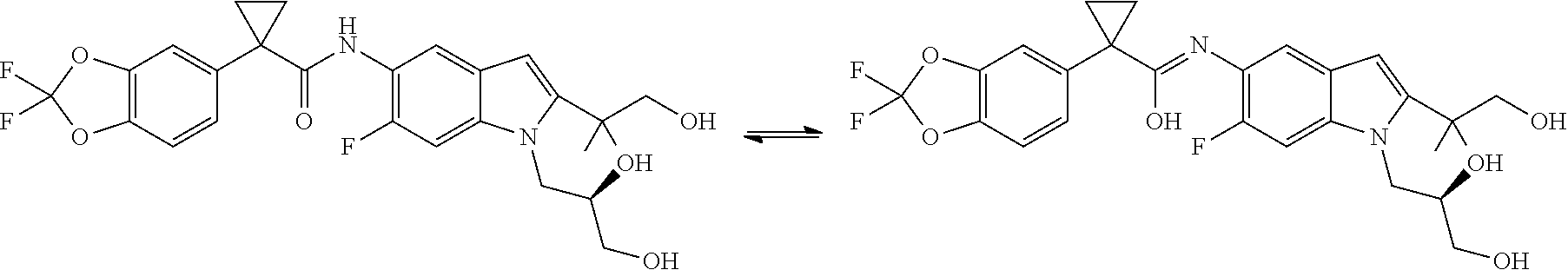

Pharmaceutical compositions of (r)-1-(2,2-difluorobenzo[d] [1,3]dioxol-5-yl)-n-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1h-indol-5-yl) cyclopropanecarboxamide and administration thereof

A pharmaceutical composition comprising Compound 1, (R)-1-(2,2-difluorobenzo[d][1,3]dioxol-5-yl)-N-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1H-indol-5-yl)cyclopropanecarboxamide, and at least one excipient selected from: a filler, a diluent, a disintegrant, a surfactant, a glidant and a lubricant, the composition being suitable for oral administration to a patient in need thereof to treat a CFTR mediated disease such as Cystic Fibrosis. Methods for treating a patient in need thereof include administering the pharmaceutical composition of Compound 1 are also disclosed.

Owner:VERTEX PHARMA INC

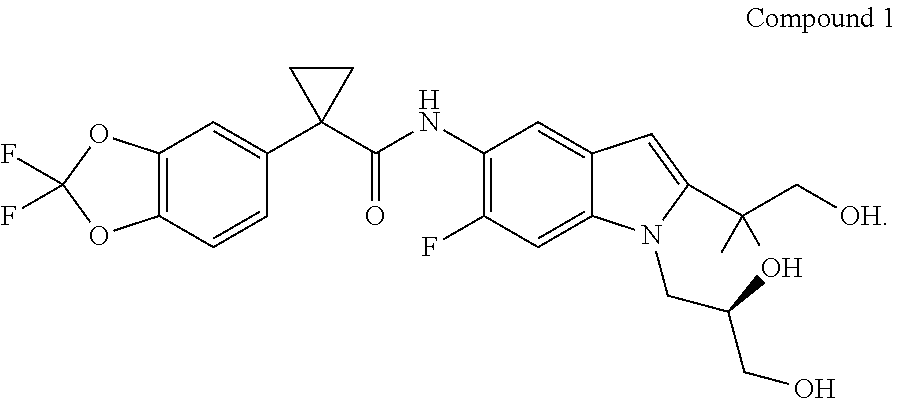

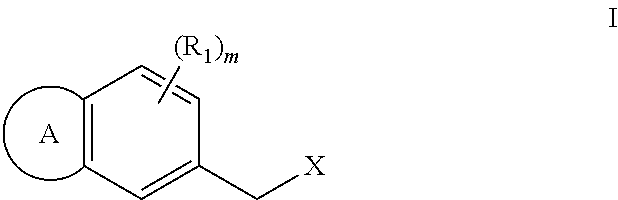

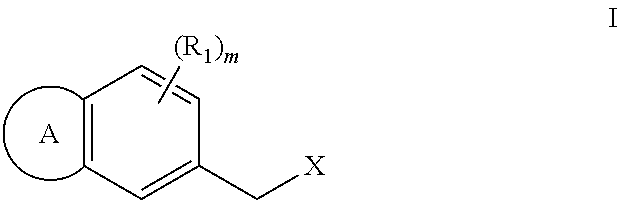

Formulations of (r)-1-(2,2-difluorobenzo[d] [1,3] dioxol-5-yl)-n-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1h-indol-5-yl)cyclopropanecarboxamide

ActiveUS20120015999A1Treating and lessening severityBiocideSenses disorderPharmacology2-Methyl propane

Owner:VERTEX PHARMA INC

Formulations of (R)-1-(2,2-difluorobenzo[D] [1,3] dioxol-5-yl)-N-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1H-indol-5-yl)cyclopropanecarboxamide

Owner:VERTEX PHARMA INC

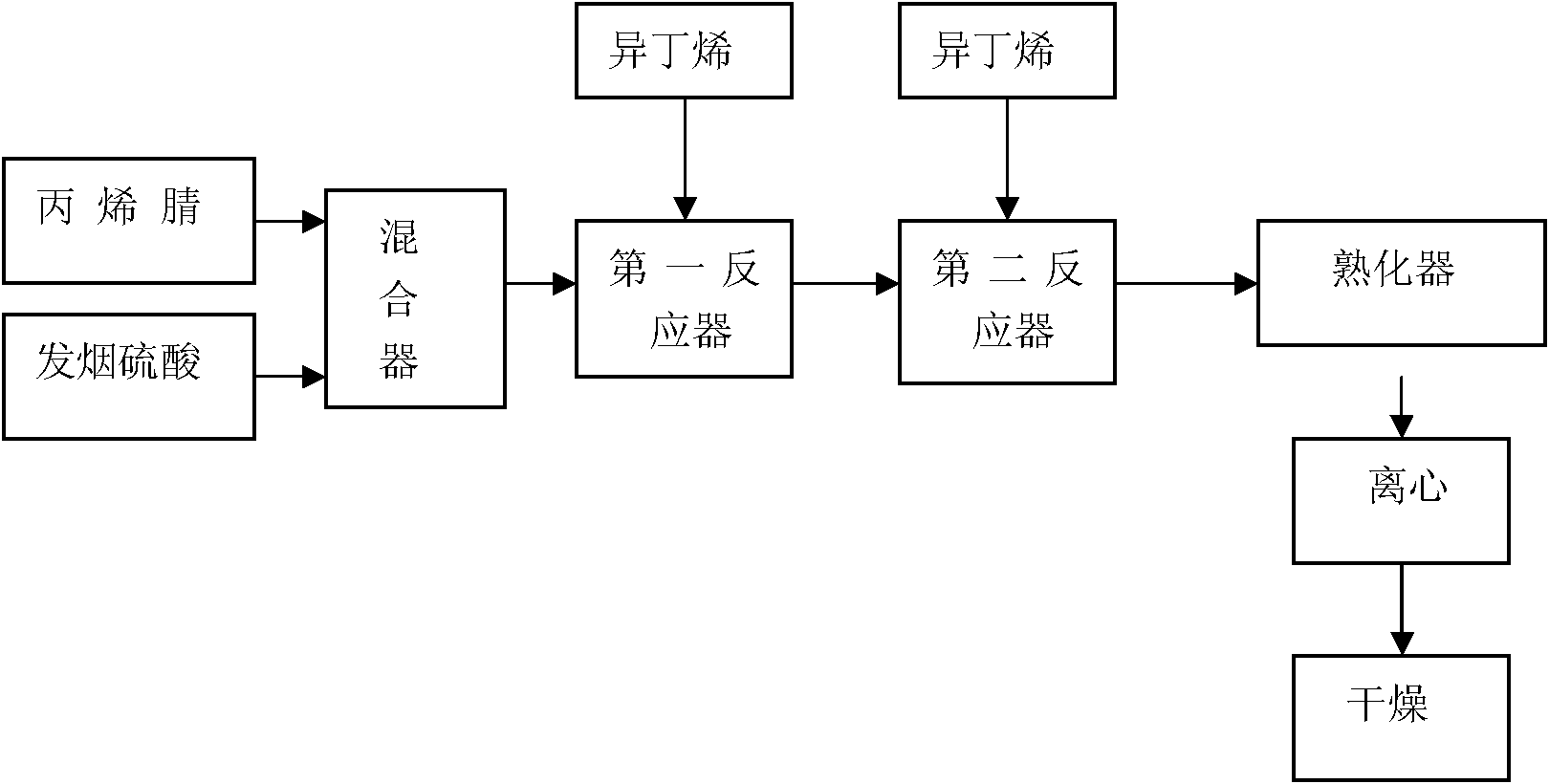

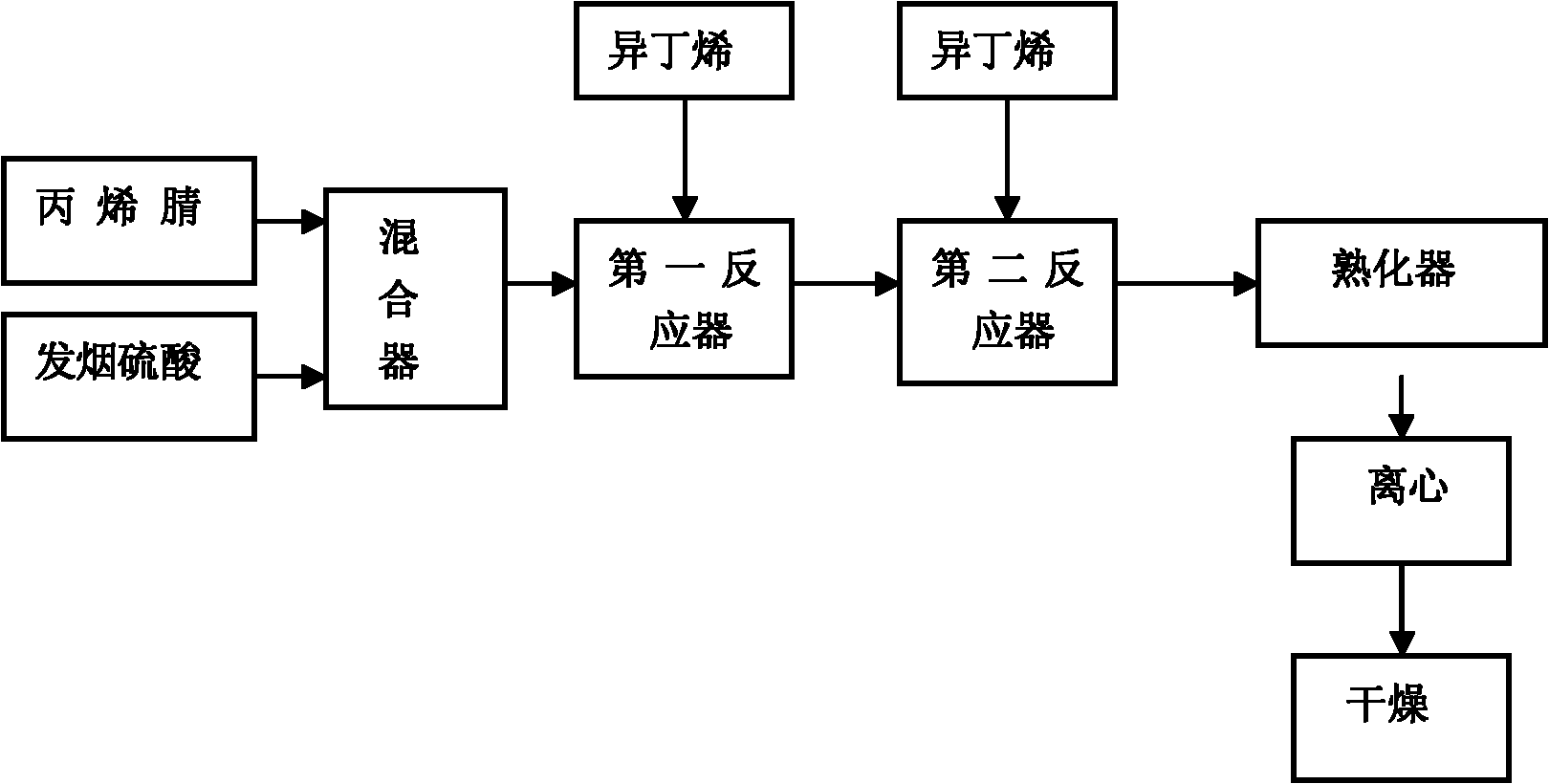

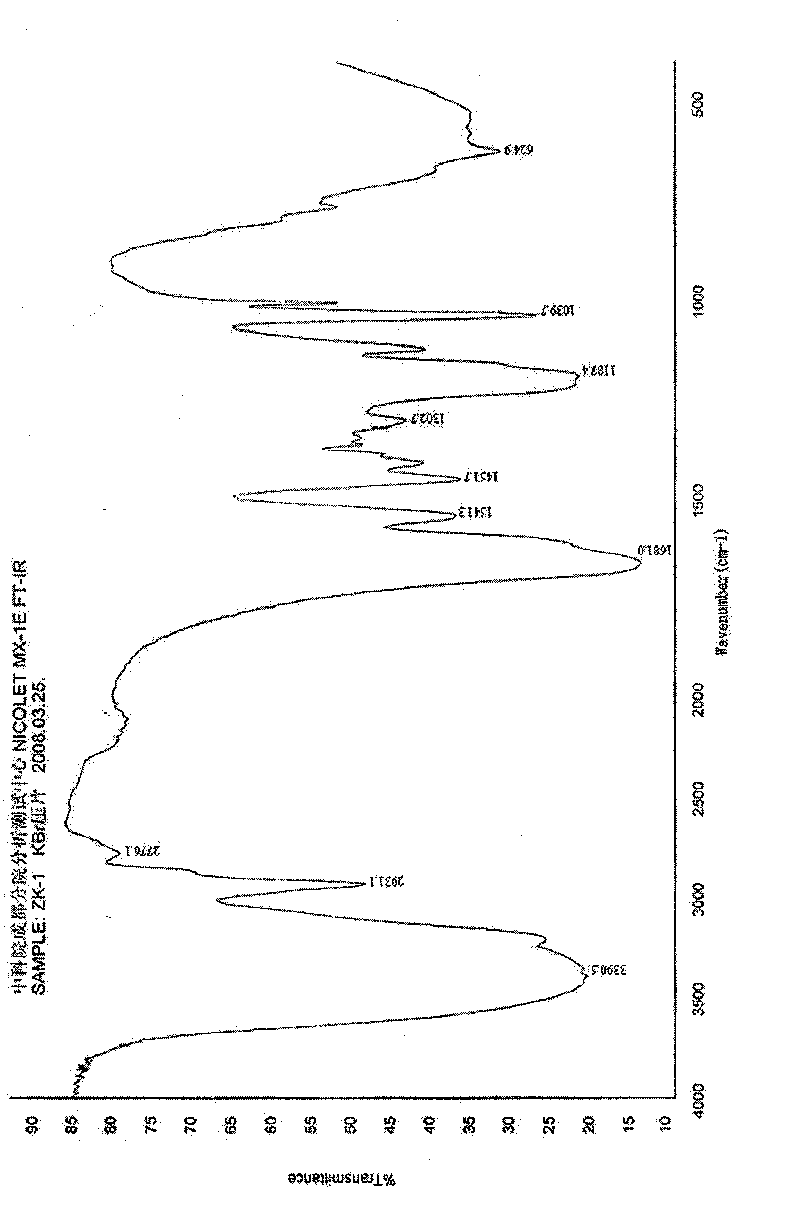

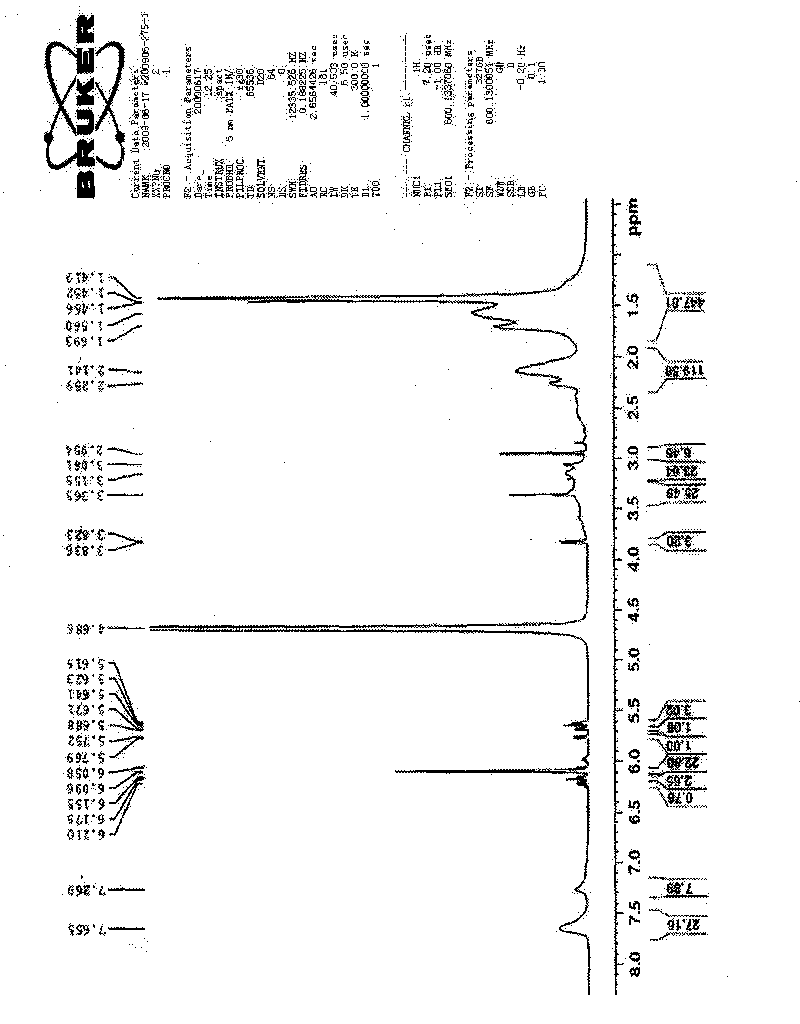

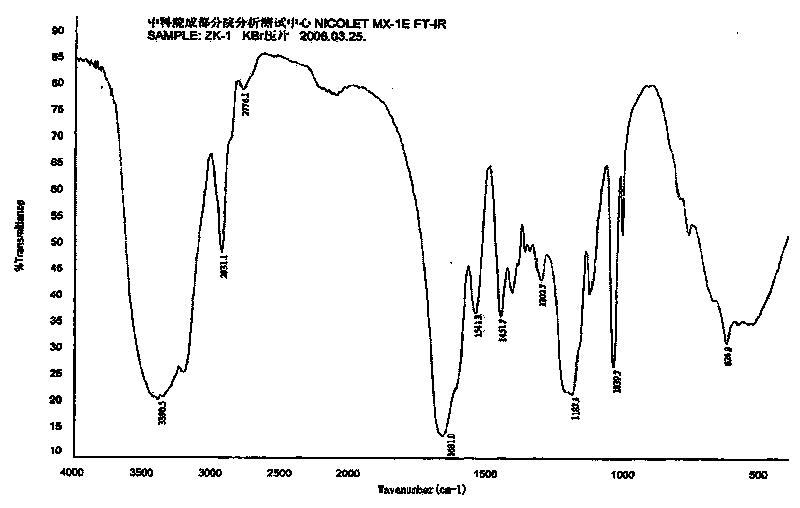

Synthesis process for 2-acrylamido-2-methyl propane sulfonic acid through continuous method

InactiveCN102351744AStable ratioStrong reaction stabilitySulfonic acid preparationFirst-order reactionAcrylonitrile

The invention discloses a synthesis process for 2-acrylamido-2-methyl propane sulfonic acid through a continuous method. The synthesis process comprises the following steps of: continuously and uniformly mixing acrylonitrile and fuming sulfuric acid at the temperature of 10-12 DEG C; performing first order reaction and second order reaction at the temperature of 20-45 DEG C under a condition of introducing vaporized isobutene; and slaking, centrifuging and drying to continuously produce the 2-acrylamido-2-methyl propane sulfonic acid product. By designing unique first order reaction, second order reaction and slaking flow, completeness degree of reaction of the material is guaranteed, the product yield and the quality stability are improved, and the reaction period is greatly shortened. The synthesis process has the advantages of scientific and rational flow design, practicability, product yield of over 96 percent and liquid phase detection purity of over 96 percent.

Owner:WEIFANG QUANXIN CHEM

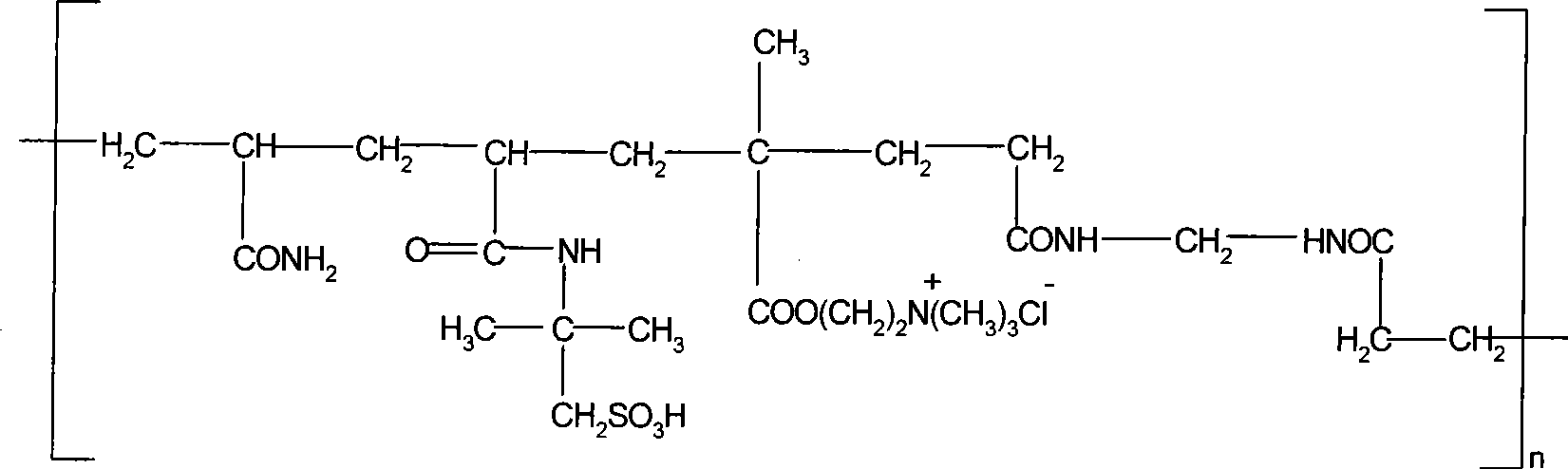

High temperature resistant amphoteric ion polymer fluid loss agent used for drilling fluid and preparation method thereof

The invention relates to high temperature resistant amphoteric ion polymer fluid loss agent used for drilling fluid of a high temperature and high pressure drilling and a preparation method thereof. Four monomers, namely, acrylamide (AM), 2-acrylamide-2-methyl propane sulfonic acid (AMPS), dimethyl diallylammonium chloride (DMDAAC) and styrenesulfonate (SSS) are used as raw materials, wherein the mole ratio of AM:AMPS:DMDAAC:SSS is (9-11):(3-4):(0.5-1.5):(1.0-1.5); ammoniumpersulfate-sodium bisulfite as an initiator is added and solution is copolymerized through a polymerization method to compose the fluid loss agent. The fluid loss agent provided by the invention has the advantages of ideal high temperature resistant (more than 220 DEG C) reducing filtrate performance, shale inhibition performance and stable fluid rheology performance and simple preparation method, convenient operation and higher yield.

Owner:SOUTHWEST PETROLEUM UNIV

2-acrylamide-2-methylpropanesulfonic acid and process for producing the same

ActiveUS20100274048A1Large molecular weightHigh purityOrganic compound preparationSulfonic acid preparationSulfur trioxideMethyl group

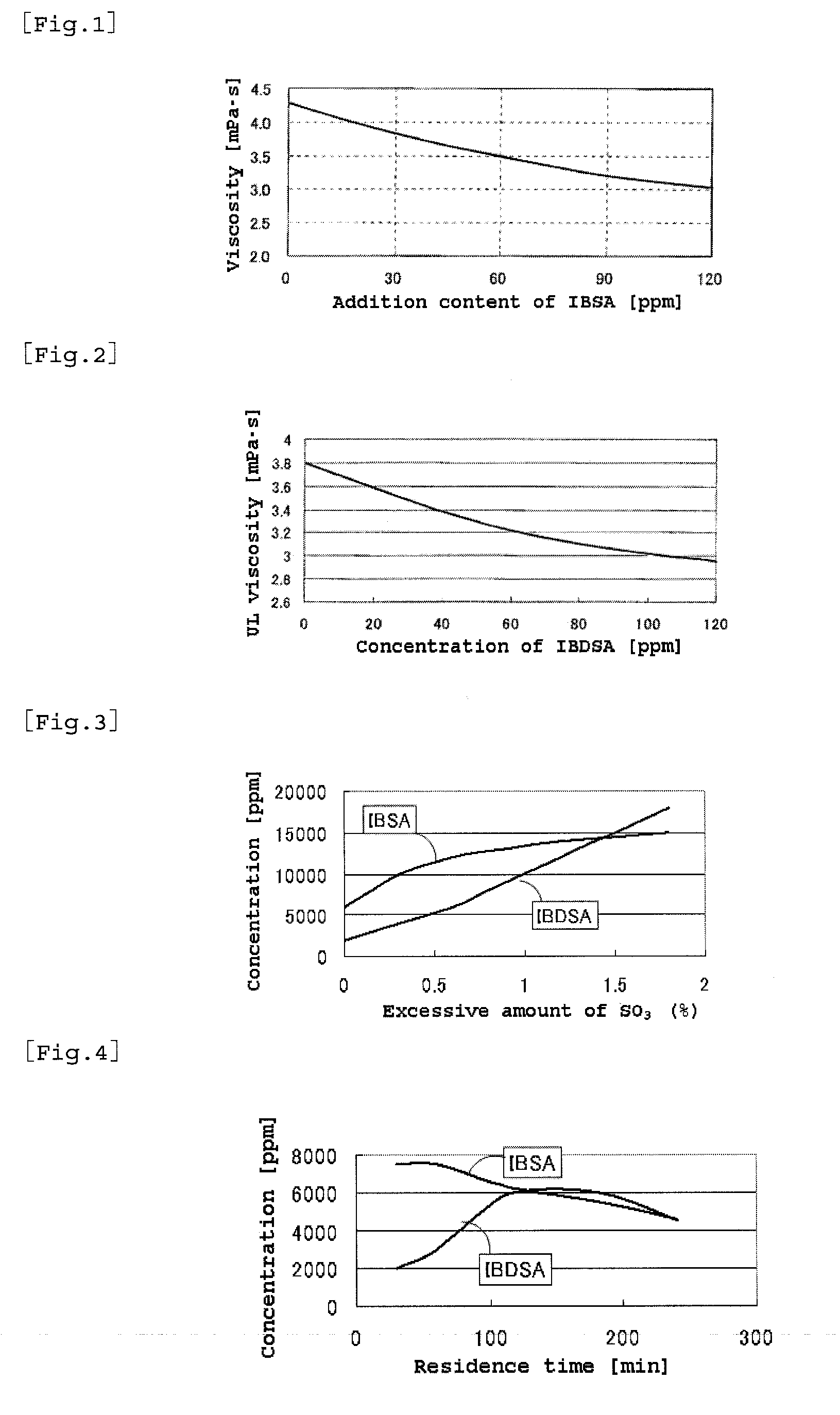

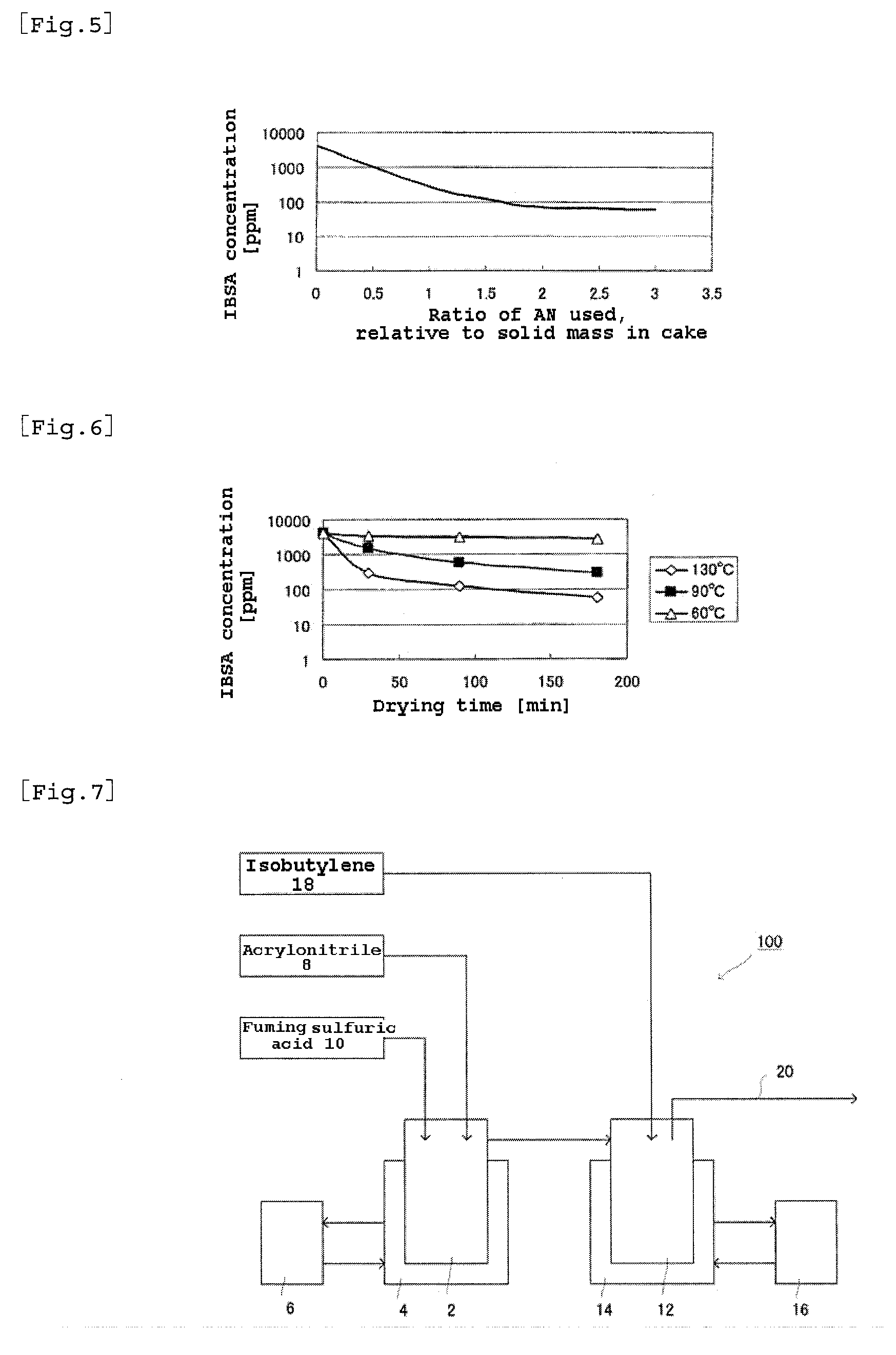

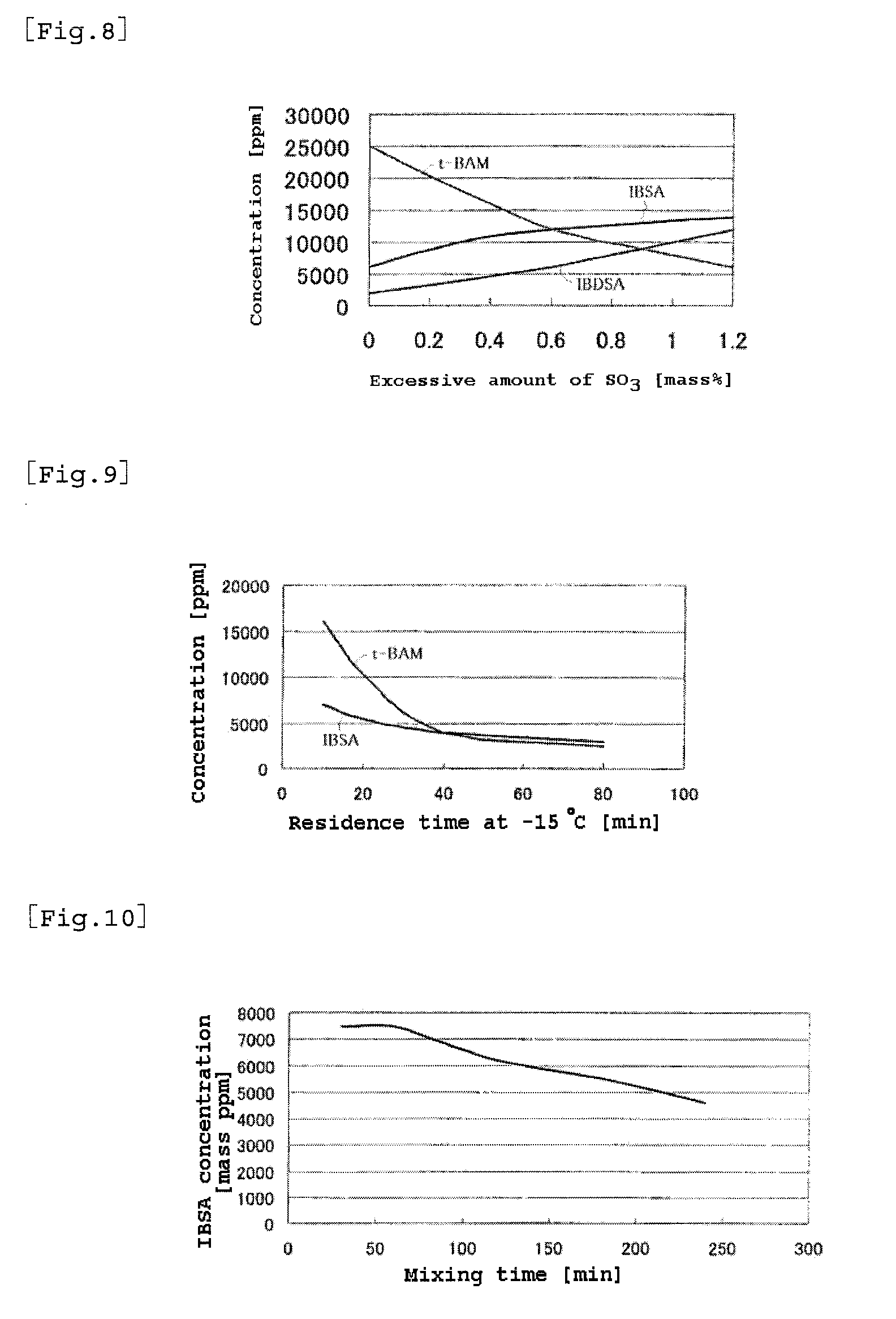

A process for producing 2-acrylamide-2-methyl propane sulfonic acid (ATBS) which comprises reacting acrylonitrile, fuming sulfuric acid, and isobutylene. During the reaction, the concentration of 2-methyl-2-propenyl-1-sulfonic acid (IBSA) and / or that of 2-methylidene-1,3-propylenedisulfonic acid (IBDSA) in the reaction system are determined. When the IBSA concentration exceeds 12,000 mass ppm and / or the IBDSA concentration exceeds 6,000 mass ppm, then the concentration of sulfur trioxide in the reaction system is reduced. Thus, ATBS having an IBSA content of 100 mass ppm or lower and an IBDSA content of 100 mass ppm or lower is produced.

Owner:TOAGOSEI CO LTD

Shale gas acid fracturing drag reducer and reparation method thereof

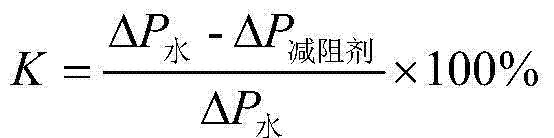

InactiveCN103694984AImprove acid resistanceImprove stabilityDrilling compositionEthylenediamineOil phase

The invention discloses a shale gas acid fracturing drag reducer and a reparation method of the shale gas acid fracturing drag reducer. The preparation method comprises the following steps: mixing monomer acrylic acid and 2-acrylamide-2 methyl propane sulfonic acid, dissolving in water, subsequently adding acrylamide, and finally adding ethylenediamine tetraacetic acid disodium to prepare into a water phase; mixing and dissolving a compounded surfactant with base oil to form an oil phase; performing inverse emulsion polymerization on the oil phase and the water phase to prepare the shale gas acid fracturing drag reducer. As a great amount of acid resistance monomers are introduced into the drag reducer, the acid resistance of the dreg reducer is greatly improved; the dreg reducer is milk white emulsion in appearance, is high in stability, non-ignitable, non-explosive, safe to transport and store, rapid to dissolve in water and free of fisheye; the requirements of continuous blending in shale gas acid fracturing can be met; the resistance reduction rate of a dreg reducer solution with the mass percentage of 0.2% can be greater than 70%.

Owner:SOUTHWEST PETROLEUM UNIV

Pharmaceutical compositions of (R)-1-(2,2-difluorobenzo[D][1,3]dioxol-5-yl)-N-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1H-indol-5-yl)cyclopropanecarboxamide and administration thereof

A pharmaceutical composition comprising Compound 1, (R)-1-(2,2-difluorobenzo[d][1,3]dioxo-5-yl)-N-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1H-indol-5-yl)cyclopropanecarboxamide, and at least one excipient selected from: a filler, a disintegrant, a surfactant, a glidant and a lubricant, the composition being suitable for oral administration to a patient in need thereof to treat a CFTR mediated disease such as Cystic Fibrosis. Methods for treating a patient in need thereof include administering the pharmaceutical composition of Compound 1 are also disclosed.

Owner:VERTEX PHARMA INC

Process of producing cycloalkylcarboxamido-indole compounds

The present invention features processes for preparing compounds, such as (R)-1-(2,2-difluorobenzo[d][1,3]dioxol-5-yl)-N-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1H-indol-5-yl)cyclopropanecarboxamide (Compound 1), useful for treating CFTR mediated diseases such as cystic fibrosis.

Owner:VERTEX PHARMA INC

Method for preparing high-temperature resistant and salt resistant tackifier for drilling fluid

ActiveCN101955564ASolve the problem of viscosity reductionInhibition of hydration dispersionDrilling compositionGramTackifier

The invention relates to a method for preparing high-temperature resistant and salt resistant tackifier for drilling fluid, which comprises the following: (1) a step of preparing raw materials, in which 56 to 60 grams of 2-acrylamido-2-methyl propane sulfonic acid, 20 to 30 grams of acrylamide, 15 to 25 grams of acrylic acid and 0.1 to 0.2 grams of initiator are prepared according to the additionamount in each 100 milliliters of water; (2) a step of preparing mother solution, in which the 2-acrylamido-2-methyl propane sulfonic acid, the acrylamide and the acrylic acid are added into water toprepare initial mother solution, the pH value of the initial solution is regulated to 6 to 7 with sodium hydroxide solution at a mass percentage concentration of 20 to 30 percent to prepare the mother solution; (3) a step of polymerization, in which the mother solution obtained by the step (2) to 60 to 80 DEG C, the initiator is added, and a reaction is performed for 2 to 4 hours; and (4) a step of drying, in which the mixture formed after the reaction in the step (3) is dried at 95 to 105 DEG C and crushed, and thus the high-temperature resistant and salt resistant tackifier for drilling fluid is prepared. When added in high-temperature and high-salt drilling fluid, the high-temperature resistant and salt resistant tackifier for drilling fluid can regulate flow type, flocculate and coat drillings and inhibit shale hydrous disintegration.

Owner:北京奥凯立科技发展股份有限公司

Acid fracturing thickening agent and preparation thereof

InactiveCN101412906AHigh viscosityImprove high temperature resistanceDrilling compositionTemperature resistancePetroleum

The invention discloses a novel acidified fractured thickening agent and a preparation method thereof, and belongs to the field of macromolecular synthesis. The thickening agent is prepared by the method comprising the following steps: adopting a water solution polymerizing method, oxidizing and reducing an evocating agent, adding proper amount of chain extender into a sealed system, and copolymerizing the mixture by the reaction of methacryloyloxy trimethyl-ammonium chloride (DMC), acrylamide (AM) and 2-acrylamido-2-methyl propane sulfonic acid (AMPS). The thickening agent has the advantages of acid resistance and high temperature resistance, has favorable thickening effect, and is applied to the fields of acidified fracturing construction, strengthening oil extraction work and the like in petroleum extraction.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

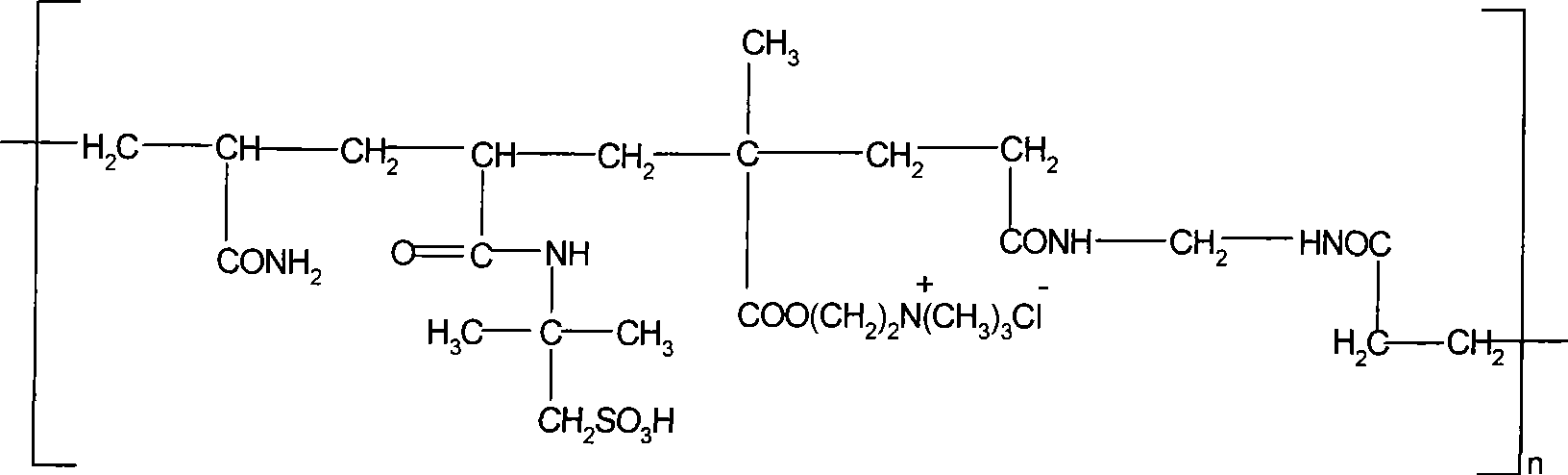

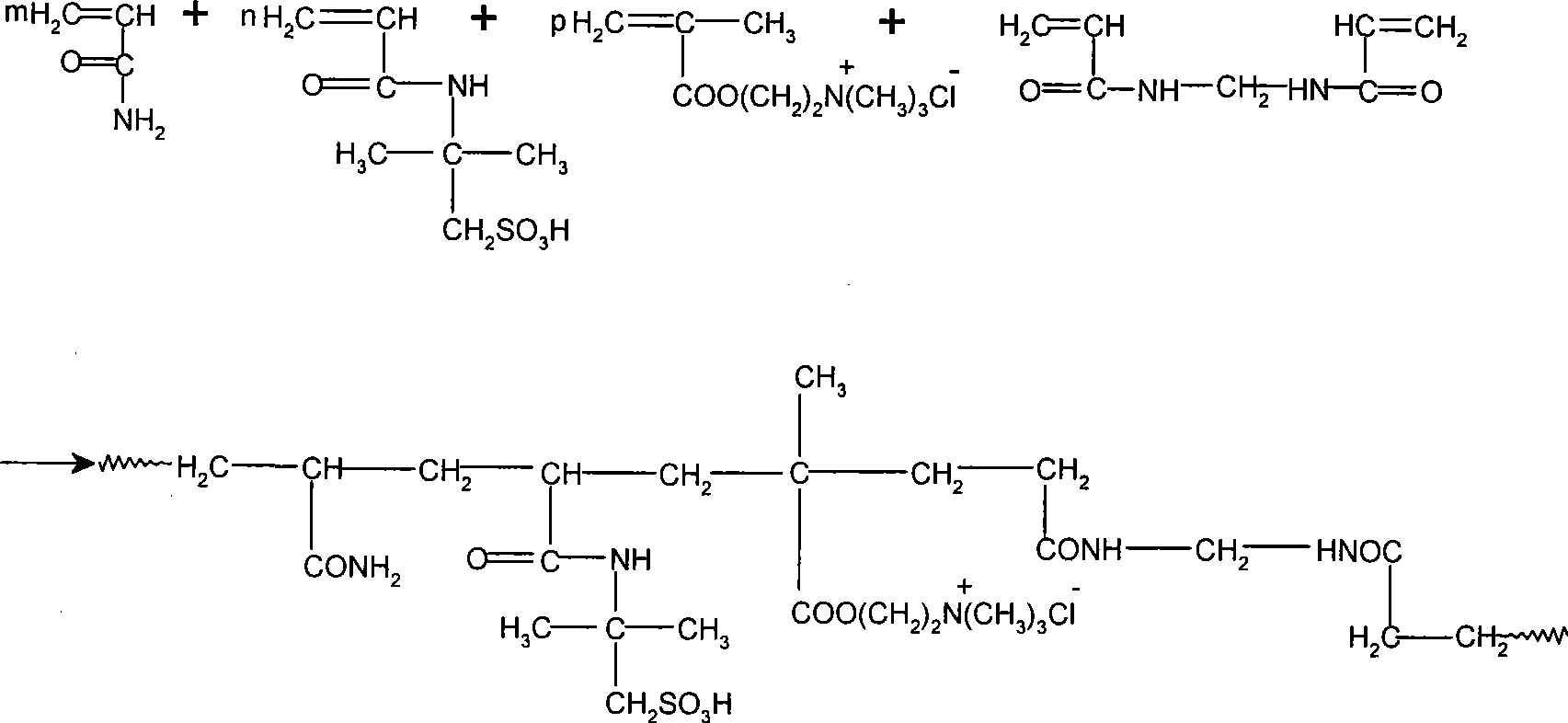

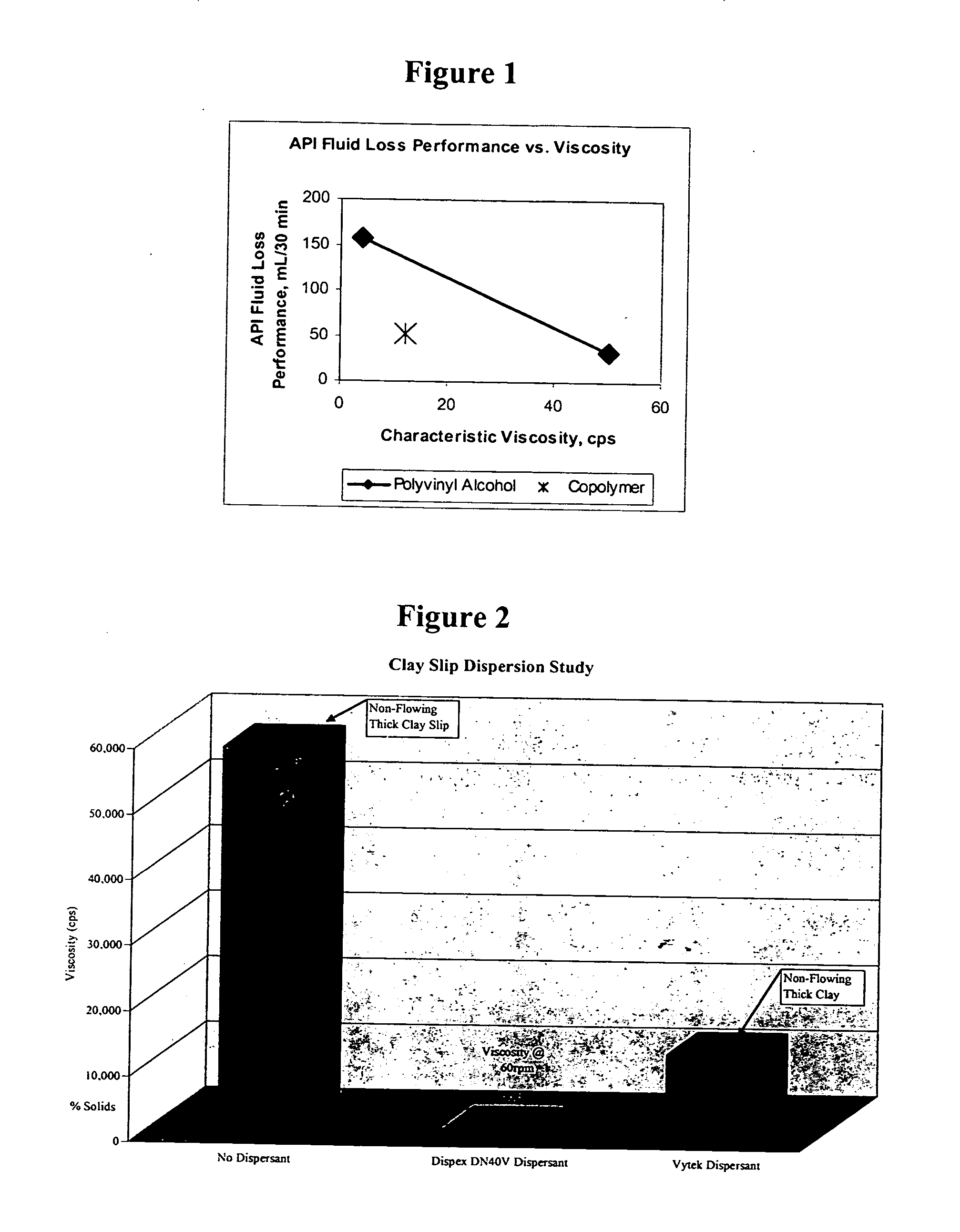

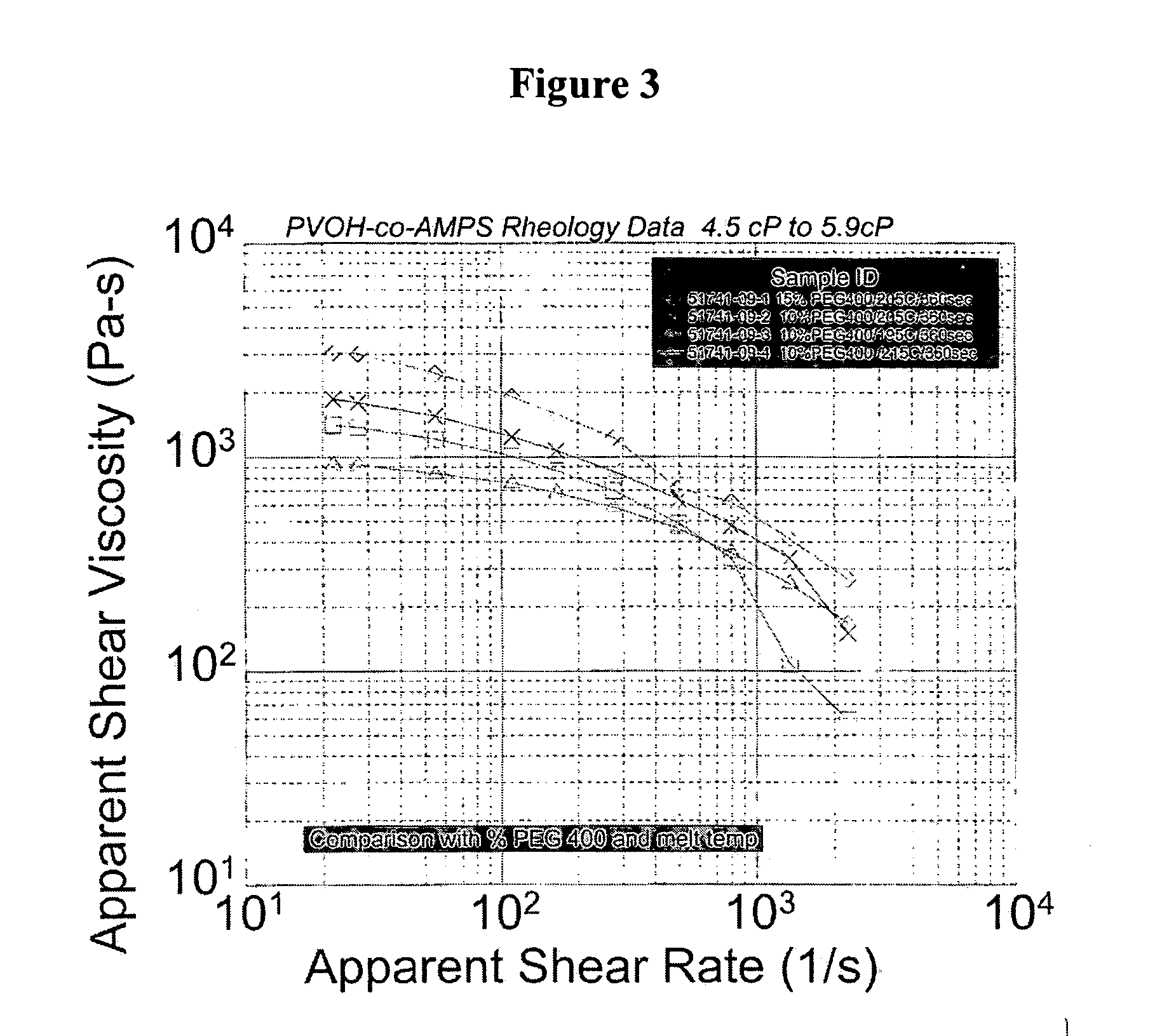

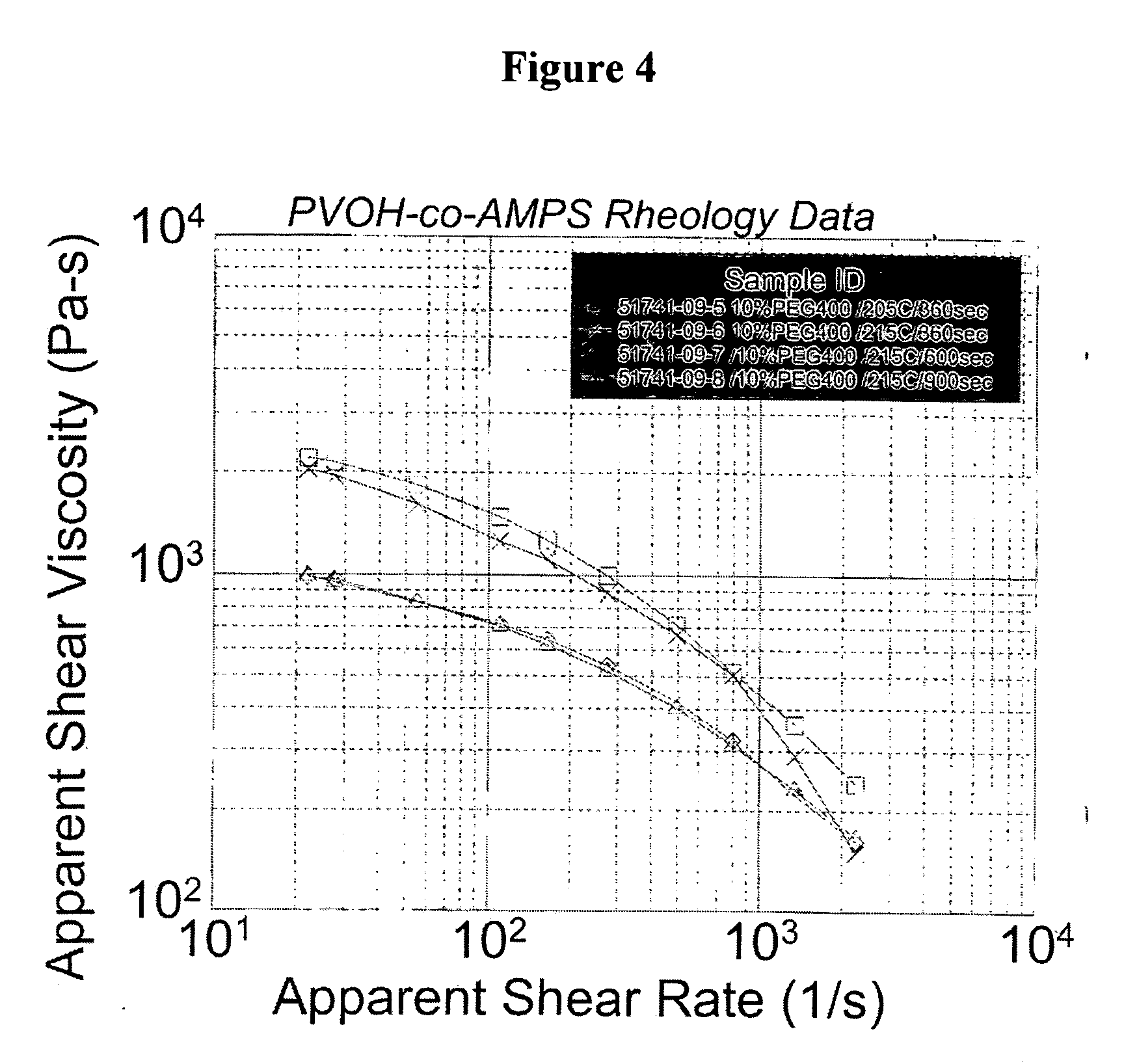

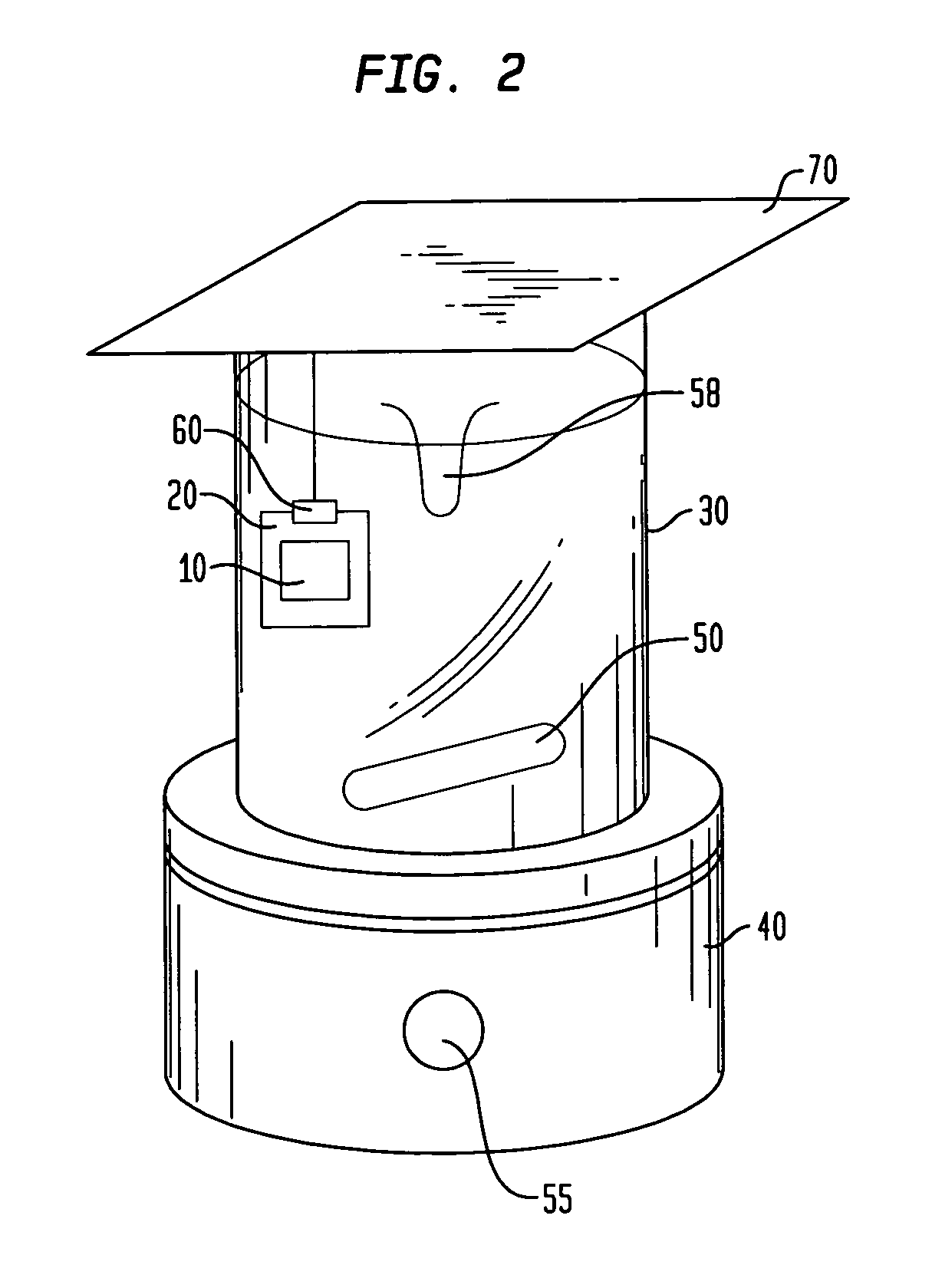

Vinyl alcohol copolymers for use in aqueous dispersions and melt extruded articles

In a method of preparing an aqueous dispersion selected from drilling fluids, hydraulic cement compositions, mineral pigment containing coatings, and papermaking furnishes or in a method of preparing a melt extrudate, the improvement comprising: a) producing a copolymer of vinyl alcohol (VOH) and 2-acrylamido-2-methyl propane sulfonic acid or a salt of such acid (AMPS) by steps including continuously feeding with agitation, vinyl acetate (VAM) and AMPS as comonomers, a free radical yielding polymerization initiator, and a solvent for said comonomers, initiator, and copolymer resulting from the copolymerization of said comonomers, maintaining the resulting reaction mass in said first reaction zone under polymerization conditions for a residence time sufficient for a major proportion of AMPS fed to said first reaction zone to polymerize, continuously feeding reaction mass from said first reaction zone with an additional supply of AMPS to a second reaction zone, maintaining the reaction mass in the second reaction zone for a residence time sufficient to polymerize a major proportion of the AMPS added to the second reaction zone, continuously withdrawing reaction mass from the second reaction zone, separating copolymer of VAM and AMPS from the latter reaction mass, and saponifying by hydrolysis and / or alcoholysis a major proportion of the acetate groups in said copolymer to form a copolymer of VOH and AMPS; and b) incorporating the saponified copolymer into the aqueous dispersion or melt extrudate.

Owner:SEKISUI SPECIALTY CHEM AMERICA

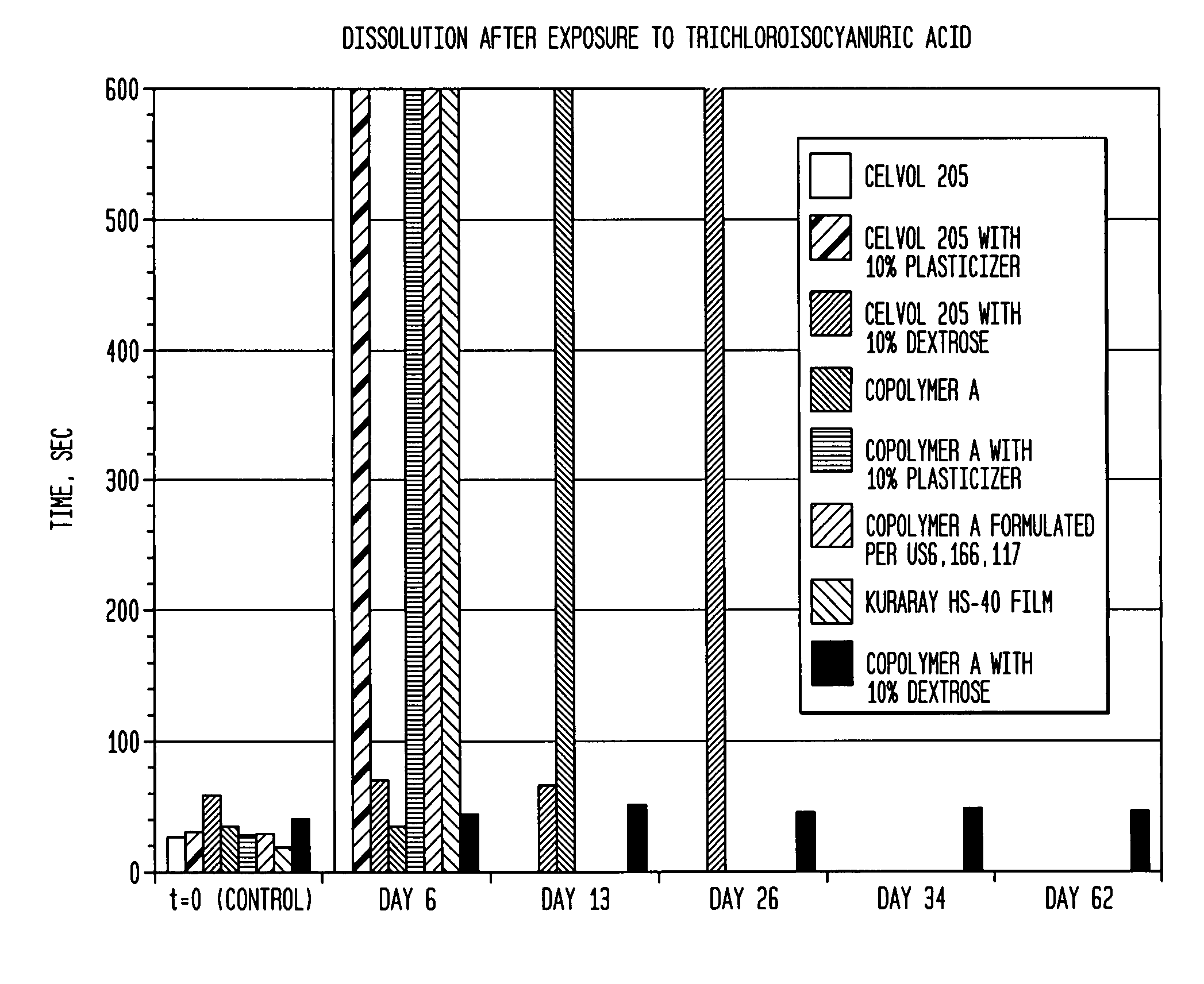

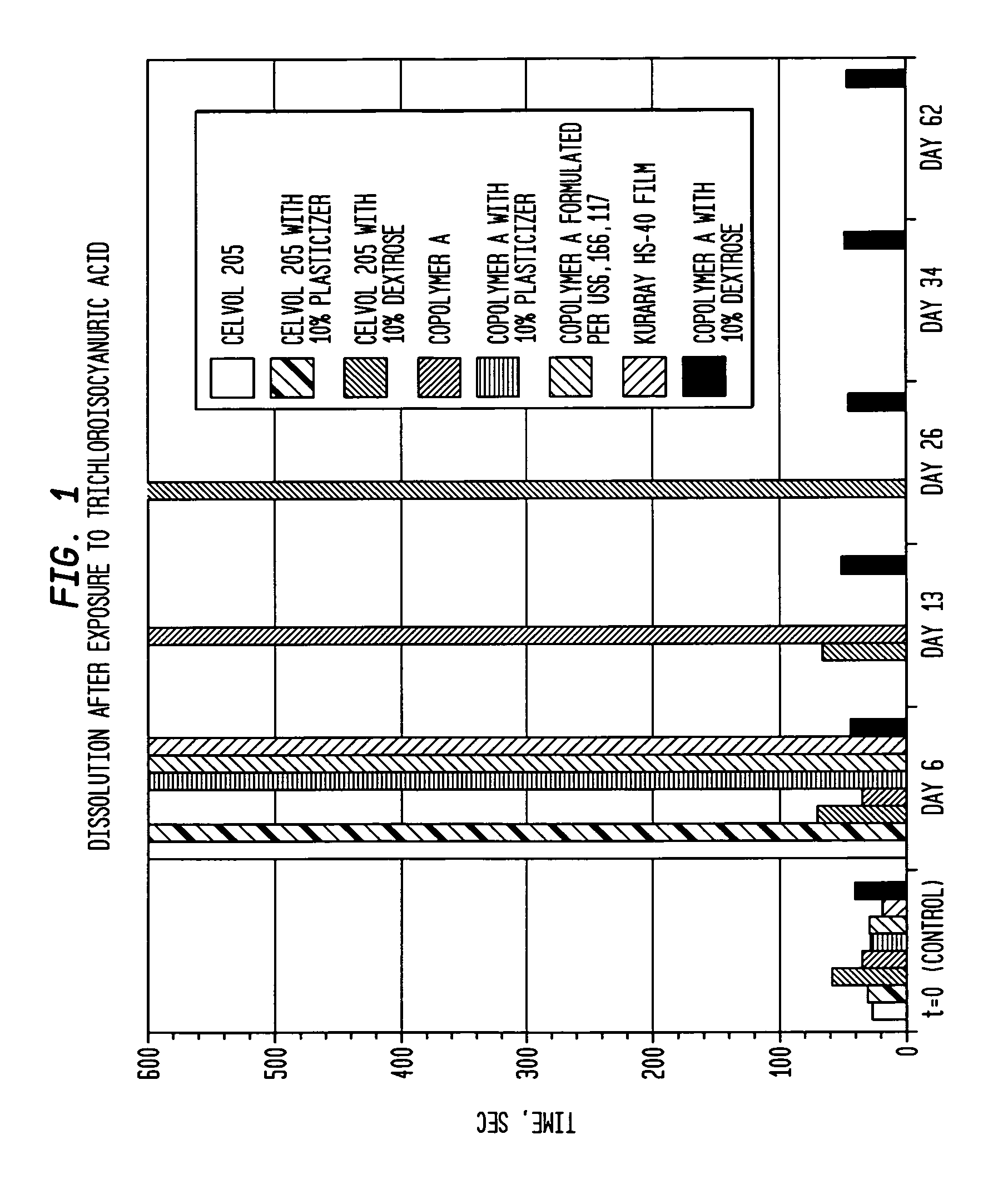

Polyvinyl alcohol films with improved resistance to oxidizing chemicals

ActiveUS7745517B2Good water solubilityExtended shelf lifeOrganic detergent compounding agentsSpecific water treatment objectivesVinyl alcoholCharacteristic viscosity

Owner:SEKISUI SPECIALTY CHEM AMERICA

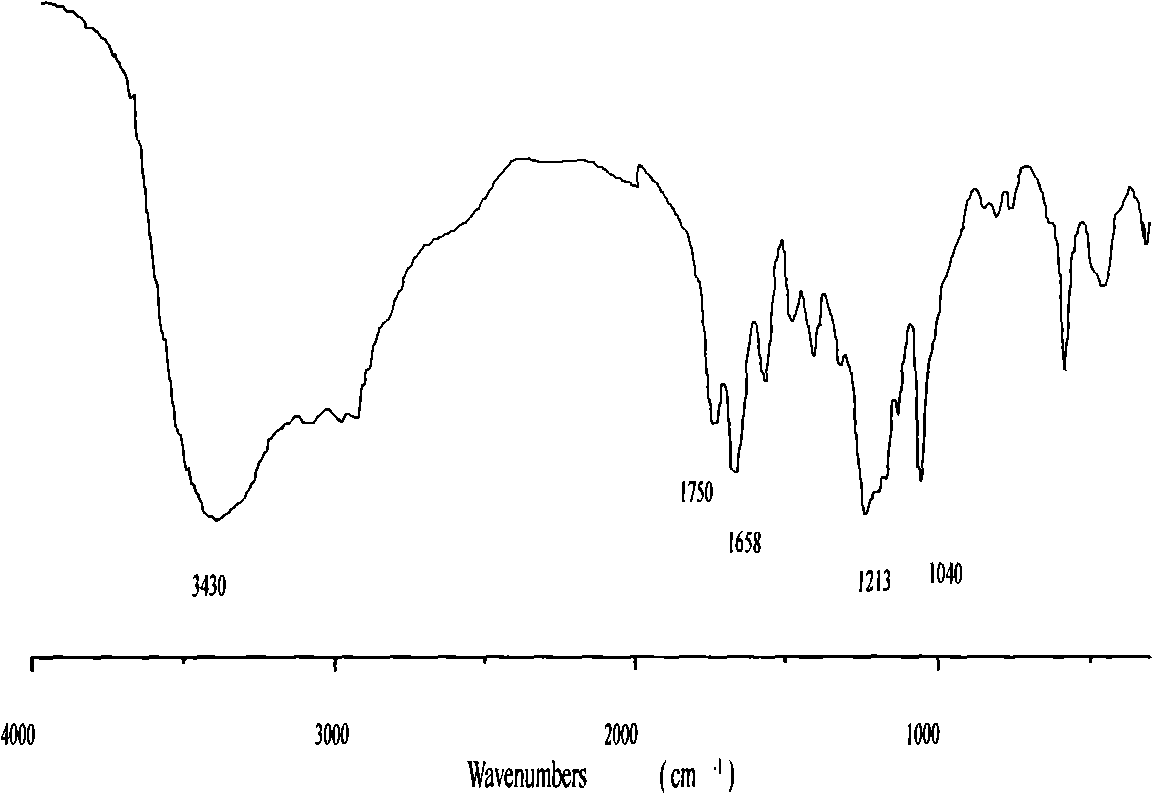

High temperature-resistance salt-resistance oil well cement filtrate reducer

The invention discloses a high temperature-resistance salt-resistance oil well cement filtrate reducer. The raw materials used in the production of the reducer comprise AMPS(2-acrylamido-2-methyl propane sulfonic acid), acrylic acid, acrylamide, sodium hydroxide, potassium persulfate and water in a mass part ratio of 32-36:2.5-3:12-15:4-6:0.3-0.5:120. The high temperature-resistance oil well cement filtrate reducer prepared according to the formula is applicable to all-grade cement in accordance with API standards; the additive amount of the reducer in a slurry system at a high temperature of 210 DEG C is 5 to 8 percent of the total volume of slurry; and the water loss rate in well cementation can be effectively controlled within 50ml.

Owner:山东胜油固井工程技术有限公司

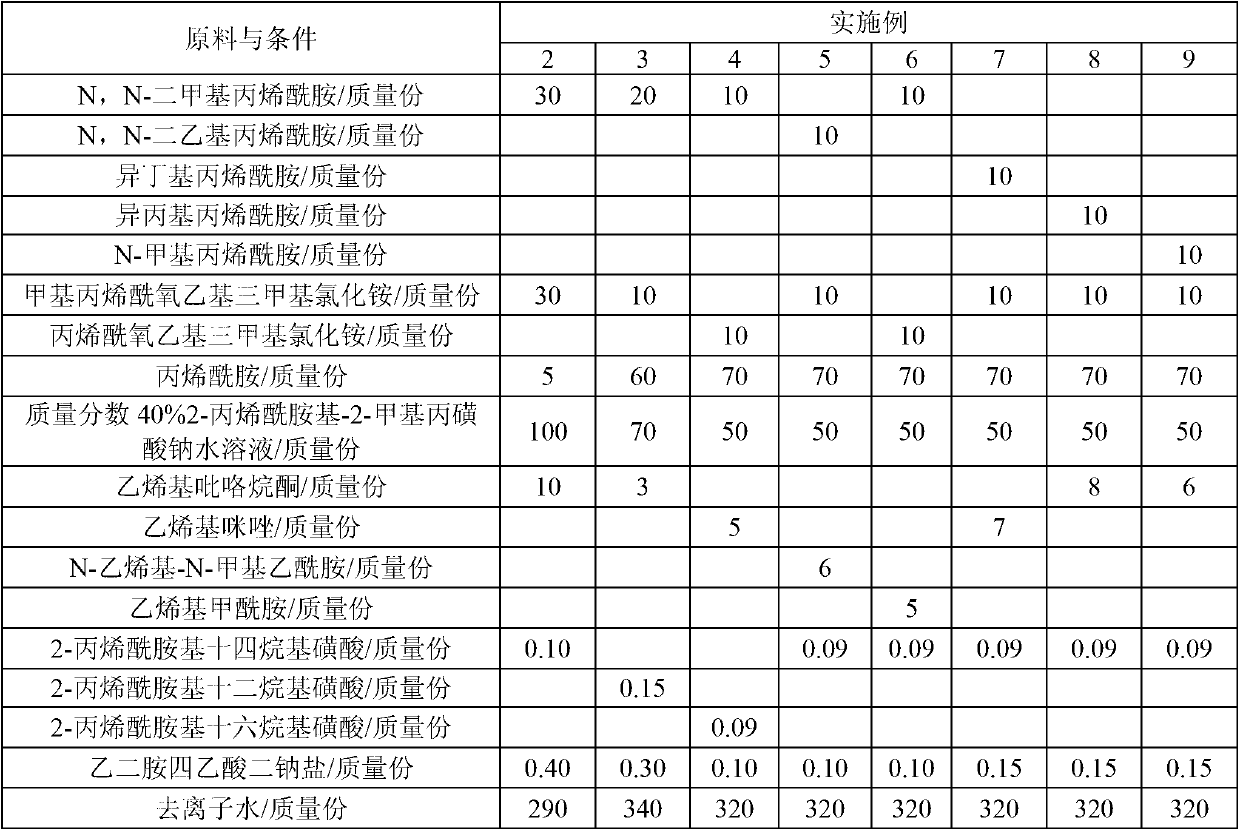

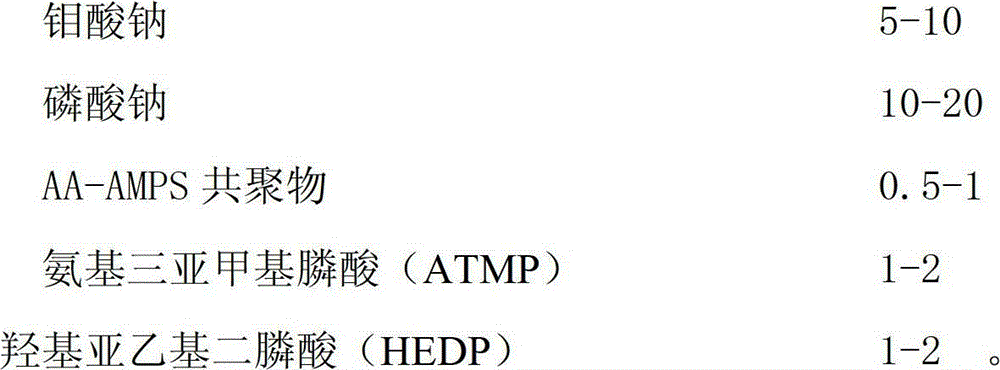

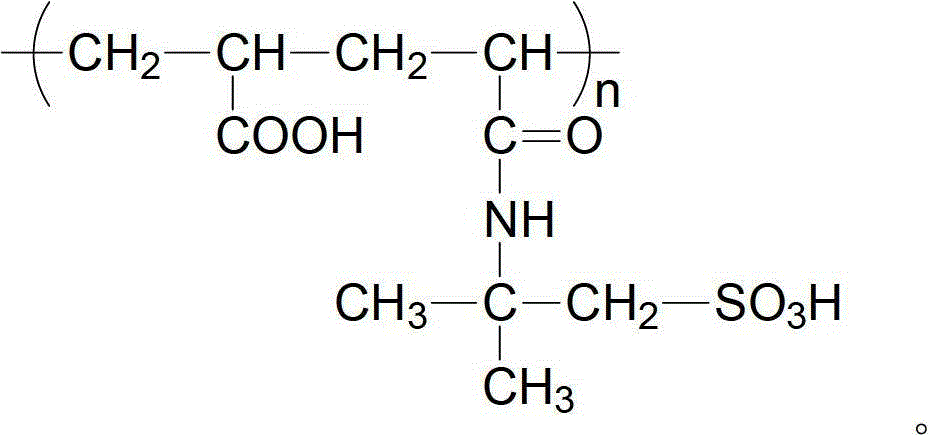

Amphoteric ionic polymer water base fracturing fluid thickening agent and preparation method thereof

ActiveCN103131404AWith hydrophobic associationStrong shear stabilityDrilling compositionWater basedPolymer science

The invention relates to an amphoteric ionic polymer water base fracturing fluid thickening agent and a preparation method of the amphoteric ionic polymer water base fracturing fluid thickening agent, and belongs to the technical field of propping agent fracturing fluid used for oil and gas reservoir volume increase and injection increasing measures. The amphoteric ionic polymer water base fracturing fluid thickening agent is prepared through copolymerization of alkyl group acrylic amide, acrylic amide, 2-acrylic amide group-2-methyl propane sulfonic acid sodium aqueous solution, cationic monomers, vinyl monomers and polymerizable surface active agent monomers. The amphoteric ionic polymer water base fracturing fluid thickening agent and the preparation method of the amphoteric ionic polymer water base fracturing fluid thickening agent have the advantages that raw materials used for the amphoteric ionic polymer water base fracturing fluid thickening agent are all industrial products, purification treatment is not needed before a reaction, a complexing agent is added so that polymerization of the complexing agent and an initiating agent can be initiated at an appropriate temperature, and the preparation technology is simple; due to the fact that the surface active agent monomers are added, an obtained polymer has a hydrophobic association function and is higher in shearing stability, easy to dissolve, free of pollution and harm and good in sand carrying performance; and the amphoteric ionic polymer water base fracturing fluid thickening agent can be resistant to the high temperature of 180 DEG C, is suitable for fracturing of high temperature strata, has high shearing-resistant performance to meet the requirement of high-flow fracturing construction, has high sand carrying performance and no-residue performance, and causes no harm to reservoir strata.

Owner:CHINA PETROLEUM & CHEM CORP +3

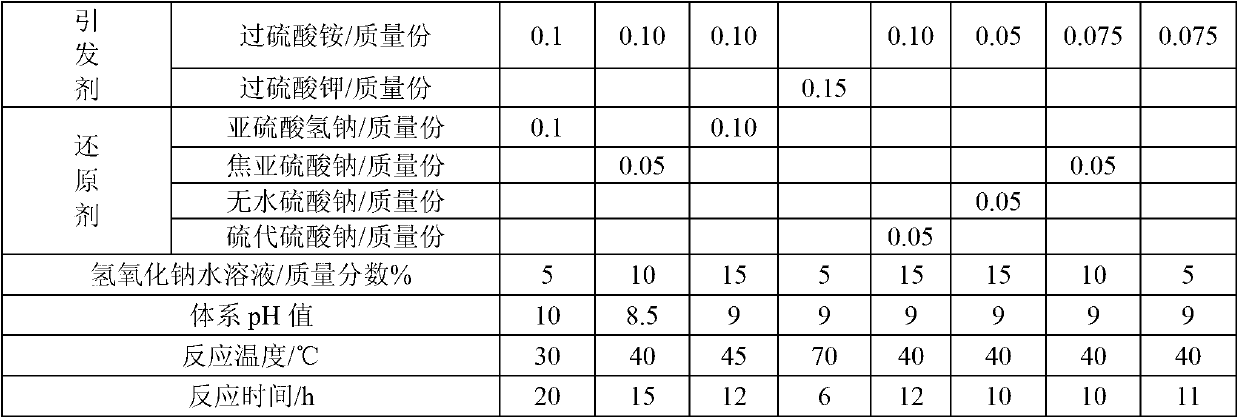

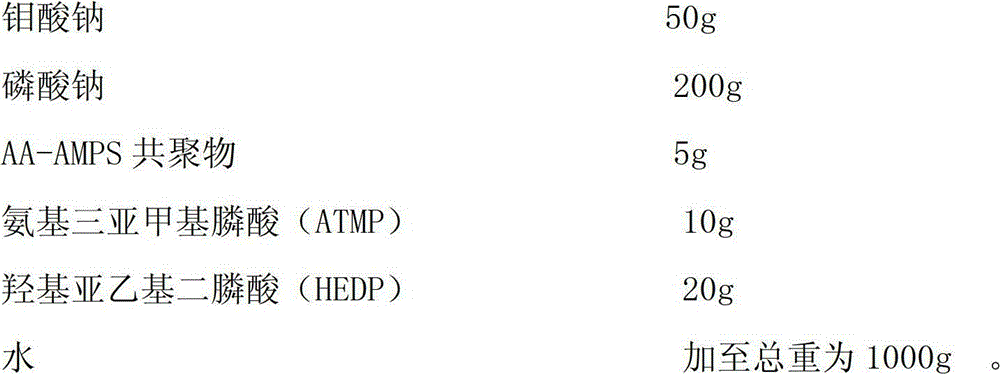

Oil field compound type anti-scale corrosion inhibitor and preparation method thereof

InactiveCN102911651AGood synergyGood scale and corrosion inhibitionBorehole/well accessoriesSodium phosphatesSimple component

The invention relates to an oil field compound type anti-scale corrosion inhibitor and a preparation method thereof, belonging to the technical field of corrosion inhibitor. The oil field compound type anti-scale corrosion inhibitor is characterized by comprising the components by mass percent: 5-10% of sodium molybdate, 10-20% of sodium phosphate, 0.5-1% of acrylic acid-2-acrylamido-2-methyl propane sulfonic acid (AA-AMPS) copolymer, 1-2% of amino trimethylene phosphonic acid and 1-2% of hydroxyl ethylidene diphosphonic acid (HEDP). The preparation method comprises the steps of: firstly, completely dissolving sodium molybdate and sodium phosphate by using water; then, adding the AA-AMPS copolymer under the condition of stirring until the copolymer is completely dissolved; subsequently, adding ATMP and the HEDP, and further stirring for dissolving; and finally, adding water until the concentration of the mixed solution is in accordance with the requirement, so as to obtain the oil field compound type anti-scale corrosion inhibitor. The inhibitor disclosed by the invention has the advantages of simple components, available raw materials, simple technology, high efficiency, low cost, low dosage, good scale inhibition, descaling and corrosion inhibition effects and the like, and is convenient to prepare, rapid.

Owner:E TECH ENERGY TECH DEV CORP

Vinyl alcohol copolymers for use in aqueous dispersions and melt extruded articles

A product comprising a cold water soluble film wherein: a) the film comprises a copolymer of vinyl alcohol (VOH) with a minor amount of 2-acrylamido-2-methyl propane sulfonic acid in free acid form or as a salt of the free acid (AMPS); and b) the film has a harsh chemical dissolution time of less than about 80 seconds measured by the harsh chemical dissolution test method after 8 weeks.

Owner:SEKISUI SPECIALTY CHEM AMERICA

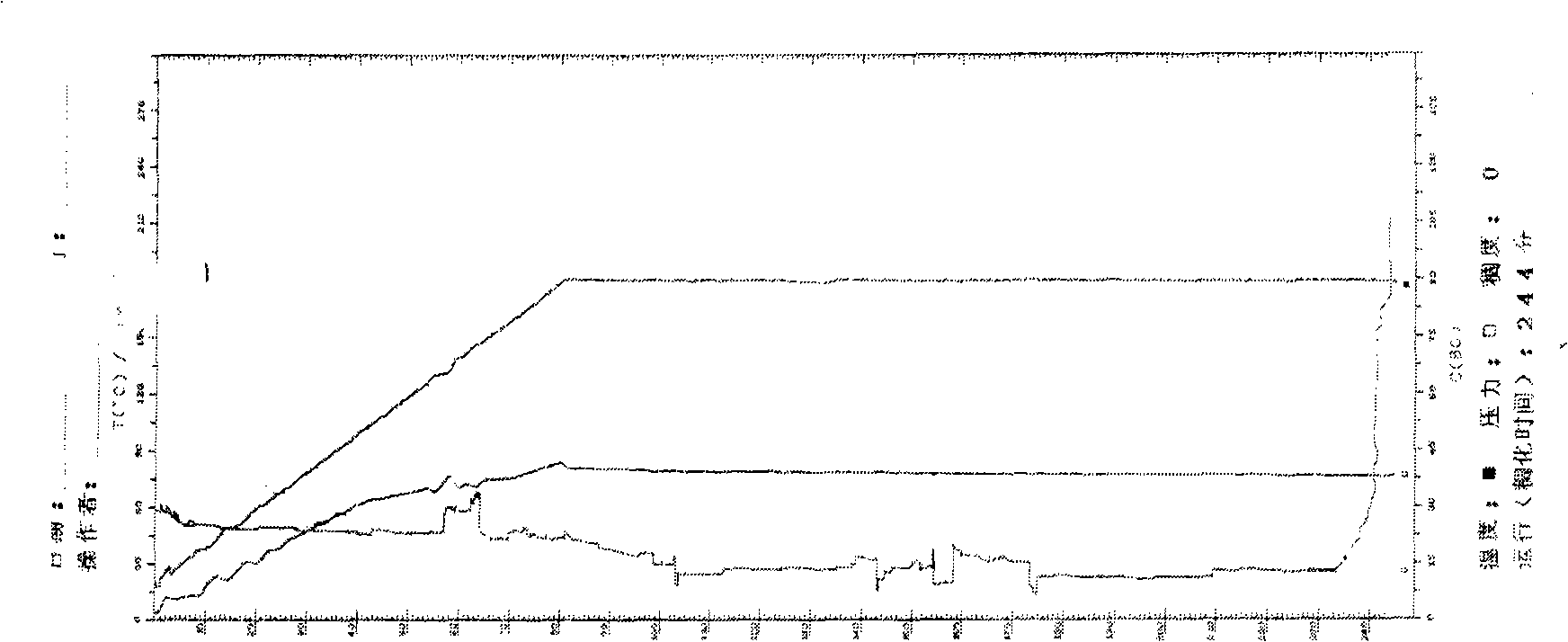

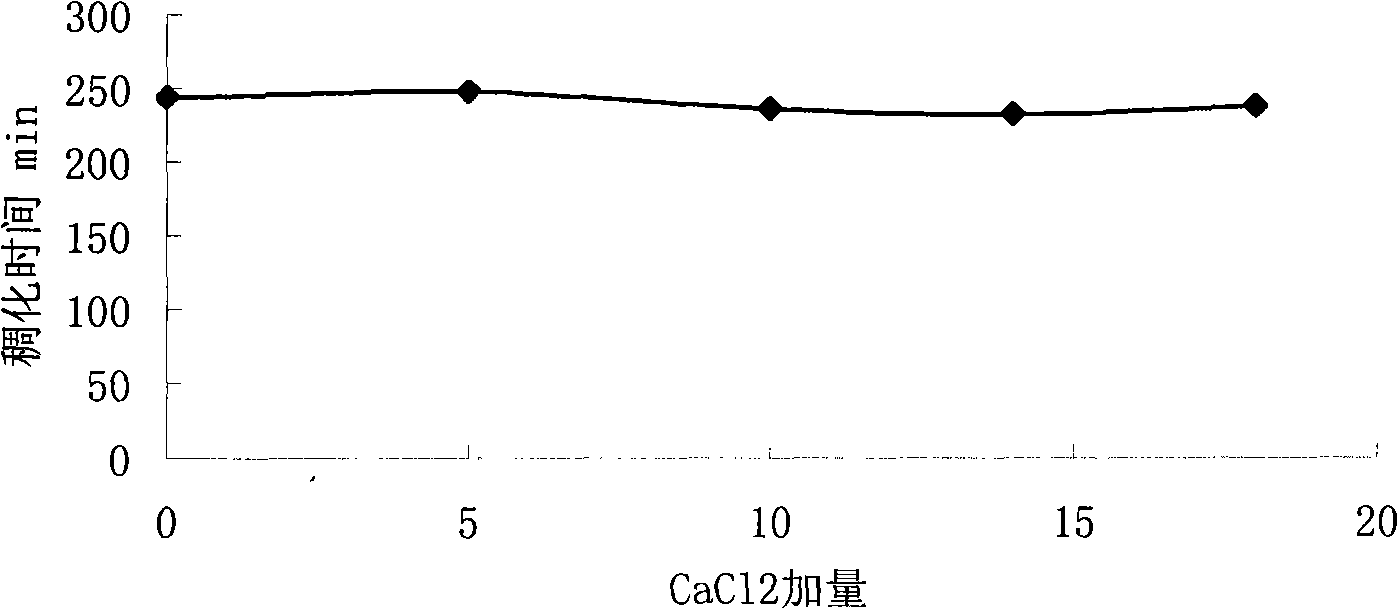

Well cementing high-temperature inhibiting agent for oil gas well and preparation method

InactiveCN101402849AMeet the needs of safe constructionThickening time adjustableDrilling compositionItaconic acidWell cementing

The invention discloses a novel cement high temperature retarder used for cementing an oil (gas) well as well as a preparing method thereof. The invention relates to a macromolecular polymer which has high temperature resistance and is prepared by using an acetone liquid to deposit and wash an itaconic acid, 2-acrylamide-2-methyl propane sulfonic acid (AMPS), benzoperoxide and the like which are taken as materials. The novel cement high temperature retarder added into a cement pulp has the characteristics of good retardation effect, good fluidity as well as salt and calcium resistance under high temperature and the like. The invention can meet the demands of safe construction on cementing depth wells and ultra-deep wells.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

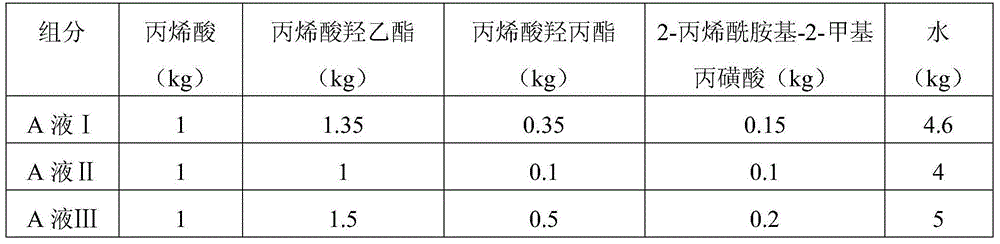

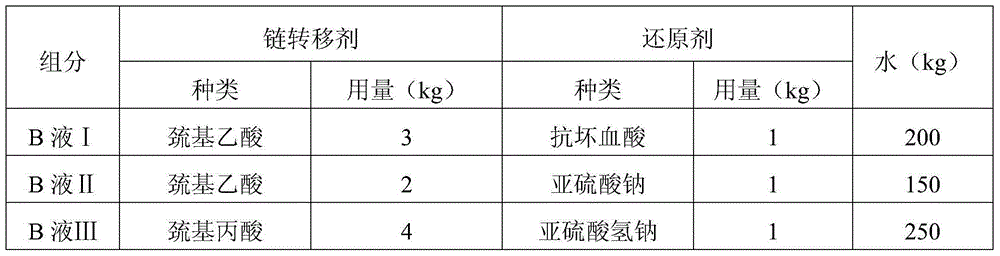

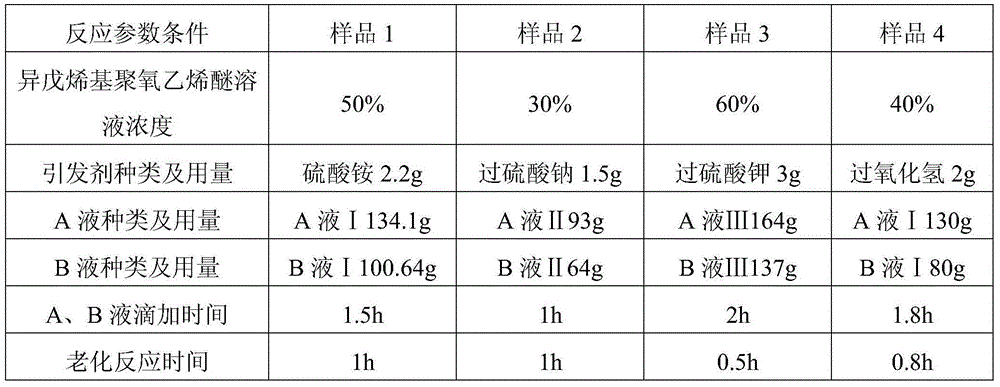

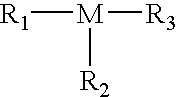

Slow-release slump-retaining type polycarboxylic acid high-performance water reducing agent and preparation method thereof

The invention relates to a slow-release slump-retaining type polycarboxylic acid high-performance water reducing agent and a preparation method of the slow-release slump-retaining type polycarboxylic acid high-performance water reducing agent, and belongs to the technical field of concrete admixtures. The reducing agent is characterized in that a polycarboxylate-type water reducing agent is provided and the polycarboxylate-type water reducing agent comprises the following components in parts by weight: 300 parts of isoamyl alkenyl polyoxyethylene ether, 1.5-3 parts of initiating agents, 93-164 parts of liquid A, and 64-137 parts of liquid B, wherein the liquid A is prepared from acrylic acid, hydroxyethyl acrylate, hydroxy-propyl acrylate, 2-acrylamido-2-methyl propane sulfonic acid (AMPS) and water; and the liquid B is prepared from a chain transfer agent and water. The water reducing agent is the slow-release slump-retaining type polycarboxylic acid high-performance water reducing agent; the slow-release slump-retaining type polycarboxylic acid high-performance water reducing agent is high in adaptability, and high in slump-retaining performance; moreover, the production process is a constant-temperature process, the heating is not needed so that the energy sources are saved; and compared with the prior art, the slow-release slump-retaining type polycarboxylic acid high-performance water reducing agent has the advantages that the production period is greatly shortened, and the production efficiency is improved.

Owner:四川恒泽建材有限公司

Process for synthesis of polyalphaolefin and removal of residual catalyst components

InactiveUS20100069687A1Reduce residue levelsHydrocarbon purification/separationHydrocarbons from unsaturated hydrocarbon additionPolyolefinMetal catalyst

A process for reducing the level of residual catalyst comprising one or more 1-halo-2-methylpropanes and a Group 13 metal catalyst from a crude polyolefins product, the process comprising contacting the crude organic product with a solid adsorbent in an adsorbent system. Also provided is a co-catalyst system for polymerizing alpha olefins.

Owner:CHEMTURA CORP

Method for synthesizing base underground crosslinked thickening agent

The invention relates to a base underground crosslinked thickening agent, in particular to a polyacrylamide thickening agent for further revamping of oilfield stimulation after alkaline / surfactant / polymer (ASP) flooding. The thickening agent is especially suitable for profile control and water shutoff of high-water-cut and strong basic oil reservoirs with vast surfactants. The base underground crosslinked thickening agent is synthesized by four monomers including acrylamide (AM), acrylic acid (AA), 2-acrylamide-2-methyl propane sulfonate (AMPS) and vinyl pyrrolidone (NVP) by aqueous solution copolymerization. The base underground crosslinked thickening agent has the characteristics of wide applicable scope (applicable to various water-base controlling, shutoff and flooding), quick dissolution in the presence of base and surfactants, high anti-shearing capability, environment friendliness, etc.

Owner:NANTONG KEYI CHEM

Oilwell cement filtrate loss reduction additive

The invention provides a filtration-reducing agent for oil well cement, which is used in well drilling and well cementing processes of petroleum and natural gas to reduce filtration of cementing paste. The filtration-reducing agent is a penta-copolymer, and a copolymerized monometer is 2-acrylamide-2-methyl propane sulfonic acid (AMPS), N, N'-dimethyl acrylamide (DMAA), unsaturated monocarboxylic acid, unsaturated dicarboxylic acid, and N, N'-methane biacrylamide (MBA). The filtration-reducing agent has favorable filtration reducing performance and rheological performance, and wide applicable temperature range, and is suitable for fresh-water and salt-water cementing paste.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

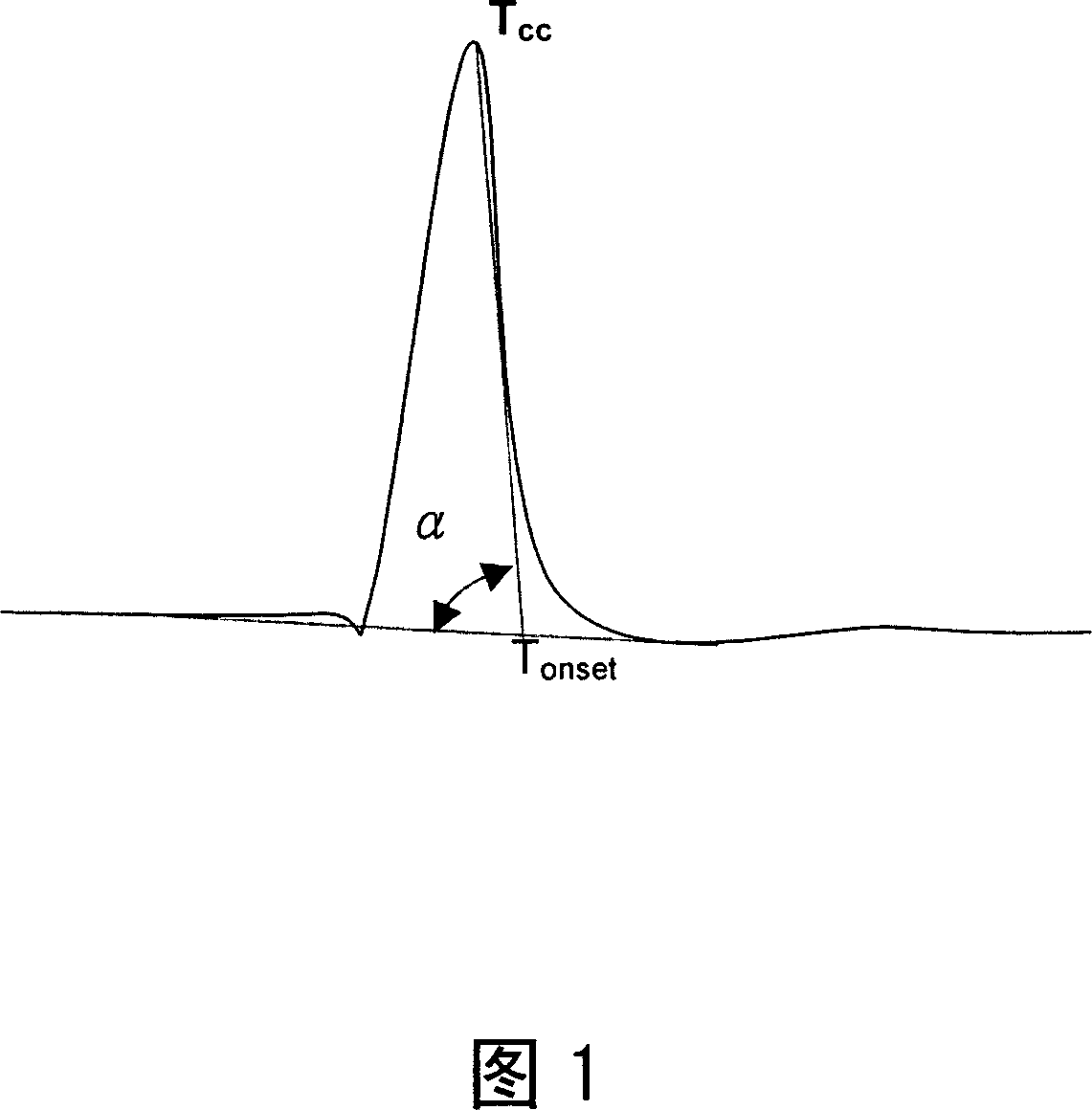

Solid Forms of (R)-1(2,2-Difluorobenzo[D][1,3]Dioxol-5-yl)-N-(1-(2,3-Dihydroxypropyl-6-Fluoro-2-(1-Hydroxy-2-Methylpropan-2-yl)-1H-Indol-5-yl)-Cyclopropanecarboxamide

ActiveUS20130143918A1Treating and lessening severityBiocideOrganic chemistry methodsMedicine2-Methyl propane

The present invention relates to solid forms of (R)-1-(2,2-difluorobenzo[d][1,3]dioxol-5-yl)-N-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1H-indol-5-yl)cyclopropanecarboxamide (Compound 1) in substantially crystalline form (Form A) or amorphous form, pharmaceutical compositions thereof, and methods of treatment therewith.

Owner:VERTEX PHARMA INC

Preparation method of low molecular weight clay stabilizer

The invention belongs to the technical field of oil production engineering, and provides a preparation method of a low molecular weight polymer clay stabilizer. The clay stabilizer is prepared from raw materials of carbon-containing ammonium salt and 2-acrylamido-2-methyl propane sulfonic acid (AMPS) in the presence of an initiator in an aqueous solution through polymerization. The number average molecular weight of the polymer is less than 50000. The sulfonic acid group is introduced into the polymer stabilizer, so as to increase the water solubility and high temperature performance of the polymer. The stabilizer can form multiple point adsorption with a plurality of clay particles in the water; after adsorption, a layer of protective film is formed on the surface of clay particles to prevent expansion and migration of clay particles; and the stabilizer has the high temperature resistance performance reaching more than 120 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process of producing cycloalkylcarboxamido-indole compounds

ActiveUS20130324743A1Reduce severityOrganic active ingredientsSenses disorderCystic fibrosis lungsMedicinal chemistry

The present invention features processes for preparing compounds, such as (R)-1-(2,2-difluorobenzo[d][1,3]dioxol-5-yl)-N-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1H-indol-5-yl)cyclopropanecarboxamide (Compound 1), useful for treating CFTR mediated diseases such as cystic fibrosis.

Owner:VERTEX PHARMA INC

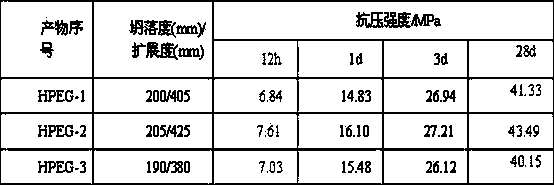

High-early-strength polycarboxylate water reducer as well as synthesis method and application method of polycarboxylate water reducer

The invention belongs to the technical field of building materials, and in particular relates to a polycarboxylate water reducer with high water-reducing rate and good early-strength effect as well as a synthesis method and an application method of the polycarboxylate water reducer. The synthetic raw materials for the water reducer comprise isobutylene alcohol polyoxyethylene ether (HPEG), acrylic acid (AA), 2-acrylamide-2-methyl propane sulfonic acid (AMPS), hydrogen peroxide (H2O2), vitamin C (VC), thioglycollic acid (TGA), a base and water. The synthesis method comprises the following steps of mixing AA and AMPS with water to prepare a 45%-65% of solution compound A; then, mixing TGA and VC with water to prepare a 2%-5% of solution B material; mixing HPEG with water to prepare a 45%-65% of HPEG aqueous solution, adding the HPEG aqueous solution to a reaction kettle and heating under stirring so that complete dissolution is achieved, adding H2O2 when the temperature is raised to (40-45) DEG C, and dropwise adding the solution A material and the solution B material, wherein the adding time of the solution A material is controlled at 2-3 hours and the adding time of the solution B material A is controlled at 2-3 hours; after the dropwise addition is completed, maintaining the temperature for 1-2 hours and adjusting pH to be 6-8 after the reactant is cooled to obtain the desired product. According to the invention, the process is simple, the product has stable performance and good market prospects.

Owner:TONGJI UNIV

Modified copolyester, thermal shrinkage polyester film produced thereby and method for preparing same

ActiveCN101134810ALow costSolve the problem of not being suitable for secondary blown film processingEpoxyCopolyester

The present invention reveals one kind of modified copolyester, which is polymer of one composition comprising terephthalic acid, ethylene glycol, one first modifier for destroying crystallinity and one branch chain agent for strength melt strength. The modified copolyester has glass transition temperature within 40-85 deg.c. The first modifier is 1, 3-dihydroxy-2-methyl propane, 1, 3- dihydroxy-2- methyl propane alkoxy ester and / or 2, 5-dimethyl-2, 5-hexadiol; and the branch chain agent is compound with at least three reactive radicals selected from OH, COOH, NCO, NH2, epoxy group and COOR, where, R is C1-C18 alkyl radical. The present invention also reveals process of preparing heat shrinking polyester film with sheet or film of the modified copolyester and through stretching, cooling and curing.

Owner:FAR EASTERN NEW CENTURY COPRRATION

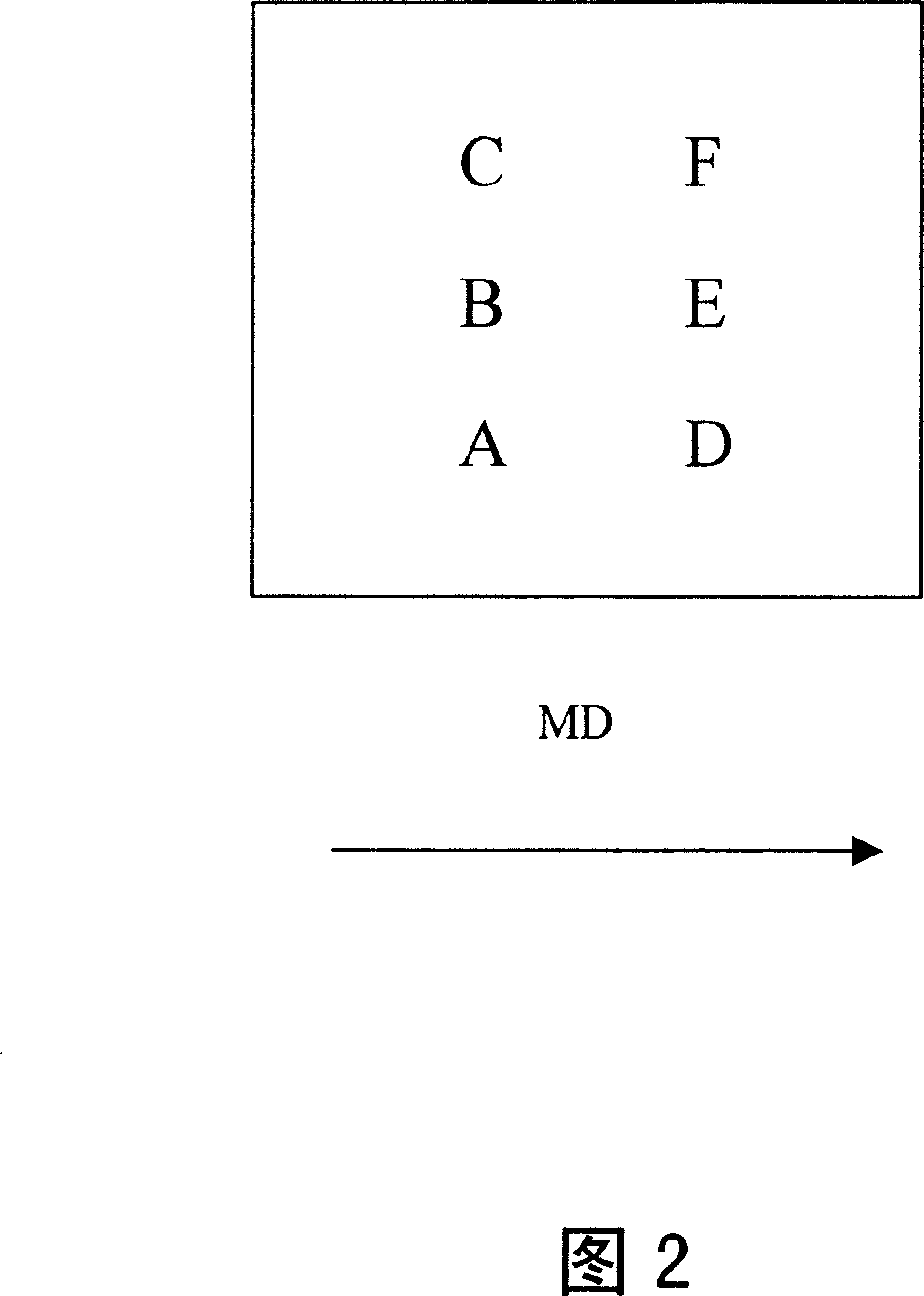

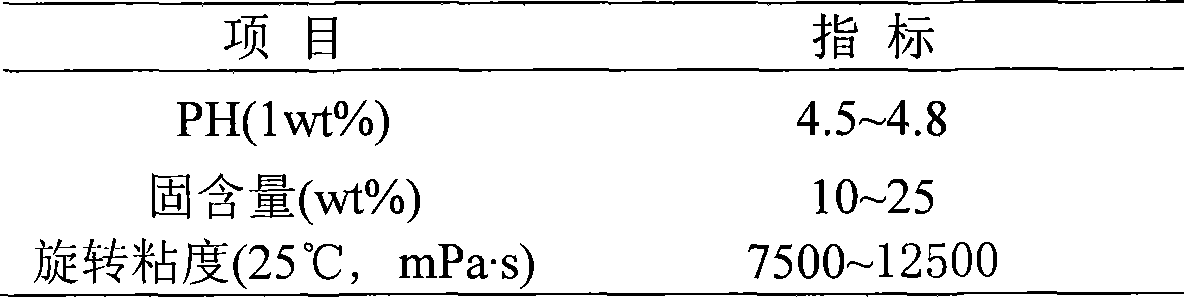

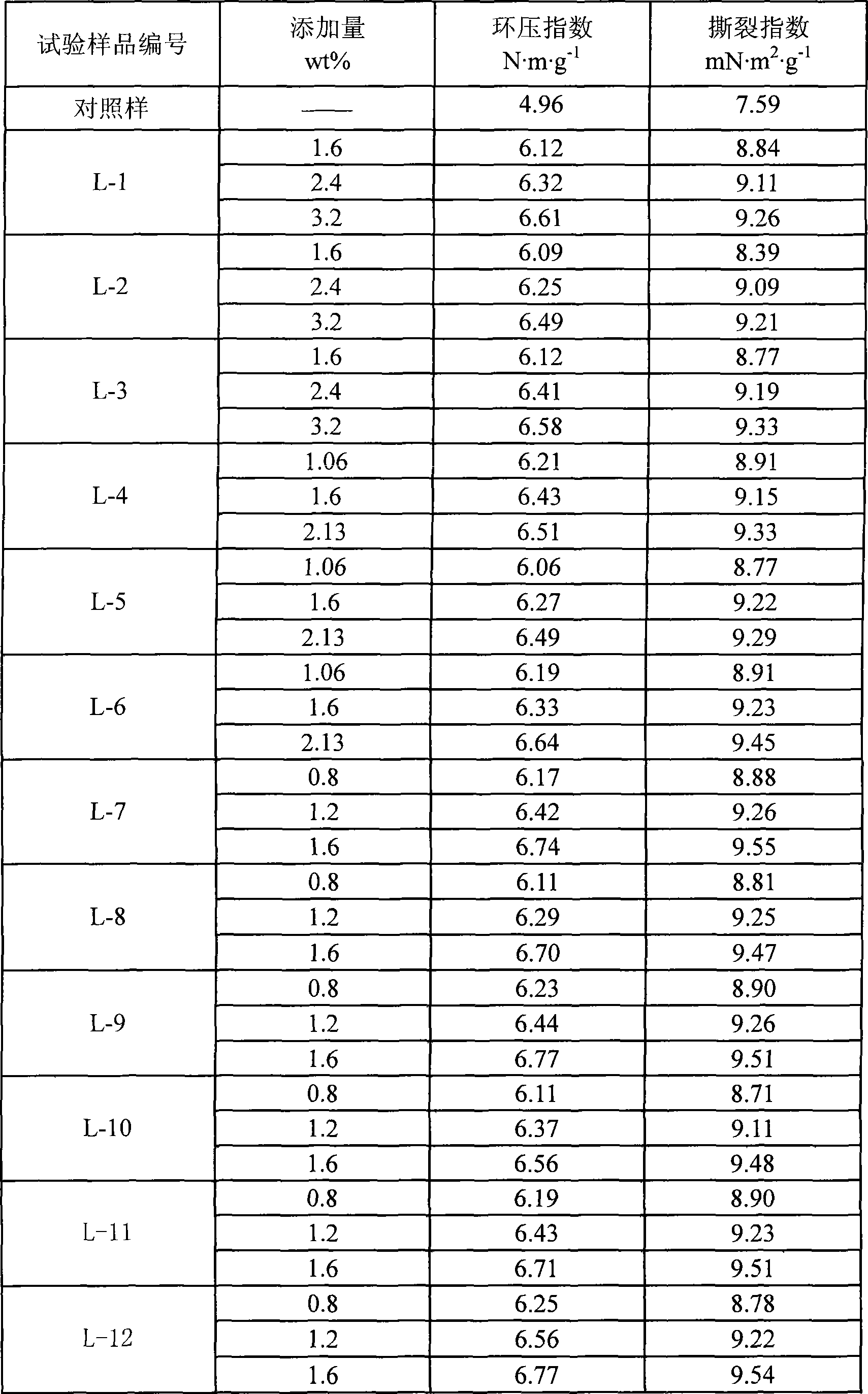

Production method of anti-interference paper intensifier

ActiveCN101487207AEvenly distributedComplete copolymerizationReinforcing agents additionDouble bondCarboxylic acid

The invention provides a method for preparing anti-interference paper reinforcing agent, comprising the steps as follows: (1) according to molar percentage, 80-96% of acrylamide monomer, 1-10% of double-bonded carboxylic acid monomer, 1-15% of water-soluble cation monomer and 1-5% of 2-acrylamide-2-methyl propane sulfonate monomer are taken and added in water while stirring to prepare a mixed water solution; (2) the pH value of the water solution is adjusted to 4.0-5.0; under the protection of nitrogen, the temperature is increased to 50-70 DEG C; subsequently, crosslinking agent, molecular weight regulator and prophase initiator are added so that the polymerization reaction is carried out for 20-35min; and (3) later initiator is added in the outcome in step (2), with the temperature kept within 80-100 DEG C for 30-60min; subsequently, termination agent is added so that the polymerization reaction is stopped. The method is stable and controllable, and can obtain the product which has strong anti-interference capability, high crosslinking degree, good flowability, complete copolymerization, low residue, uniform distribution of cations, and stable and controllable viscosity during the polymerization process.

Owner:广州星业科技股份有限公司

Formulations And Method For Post-CMP Cleaning

ActiveUS20110136717A1Organic detergent compounding agentsNon-surface-active detergent compositionsSulfonateAmmonium hydroxide

The present invention is a method of cleaning to removal residue in semiconductor manufacturing processing, comprising contacting a surface to be cleaned with an aqueous formulation having a polymer selected from the group consisting of acrylamido-methyl-propane sulfonate) polymers, acrylic acid-2-acrylamido-2-methylpropane sulfonic acid copolymer and mixtures thereof and a quaternary ammonium hydroxide having greater than 4 carbon atoms or choline hydroxide with a non-acetylinic surfactant.The present invention is also a post-CMP cleaning formulation having the components set forth in the method above.

Owner:VERSUM MATERIALS US LLC

Method of manufacturing the super-absorbent polymer (SAP) which is powdery, insoluble in water, and able to absorb water, blood and urine and has slight soluble things

ActiveUS20080081848A1Moderate heat of reactionThe polymerization process is stableOther chemical processesPhotomechanical apparatusEpoxyCross-link

Owner:FORMOSA PLASTICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Pharmaceutical compositions of (r)-1-(2,2-difluorobenzo[d] [1,3]dioxol-5-yl)-n-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1h-indol-5-yl) cyclopropanecarboxamide and administration thereof Pharmaceutical compositions of (r)-1-(2,2-difluorobenzo[d] [1,3]dioxol-5-yl)-n-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1h-indol-5-yl) cyclopropanecarboxamide and administration thereof](https://images-eureka.patsnap.com/patent_img/9bf554c5-b898-43aa-b4e5-83e553189b5a/US20120046330A1-20120223-D00001.png)

![Pharmaceutical compositions of (r)-1-(2,2-difluorobenzo[d] [1,3]dioxol-5-yl)-n-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1h-indol-5-yl) cyclopropanecarboxamide and administration thereof Pharmaceutical compositions of (r)-1-(2,2-difluorobenzo[d] [1,3]dioxol-5-yl)-n-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1h-indol-5-yl) cyclopropanecarboxamide and administration thereof](https://images-eureka.patsnap.com/patent_img/9bf554c5-b898-43aa-b4e5-83e553189b5a/US20120046330A1-20120223-D00002.png)

![Pharmaceutical compositions of (r)-1-(2,2-difluorobenzo[d] [1,3]dioxol-5-yl)-n-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1h-indol-5-yl) cyclopropanecarboxamide and administration thereof Pharmaceutical compositions of (r)-1-(2,2-difluorobenzo[d] [1,3]dioxol-5-yl)-n-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1h-indol-5-yl) cyclopropanecarboxamide and administration thereof](https://images-eureka.patsnap.com/patent_img/9bf554c5-b898-43aa-b4e5-83e553189b5a/US20120046330A1-20120223-D00003.png)

![Formulations of (r)-1-(2,2-difluorobenzo[d] [1,3] dioxol-5-yl)-n-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1h-indol-5-yl)cyclopropanecarboxamide Formulations of (r)-1-(2,2-difluorobenzo[d] [1,3] dioxol-5-yl)-n-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1h-indol-5-yl)cyclopropanecarboxamide](https://images-eureka.patsnap.com/patent_img/4db0eab5-a537-41dd-b28d-8b418940b79d/US20120015999A1-20120119-C00001.png)

![Formulations of (r)-1-(2,2-difluorobenzo[d] [1,3] dioxol-5-yl)-n-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1h-indol-5-yl)cyclopropanecarboxamide Formulations of (r)-1-(2,2-difluorobenzo[d] [1,3] dioxol-5-yl)-n-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1h-indol-5-yl)cyclopropanecarboxamide](https://images-eureka.patsnap.com/patent_img/4db0eab5-a537-41dd-b28d-8b418940b79d/US20120015999A1-20120119-C00002.png)

![Formulations of (r)-1-(2,2-difluorobenzo[d] [1,3] dioxol-5-yl)-n-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1h-indol-5-yl)cyclopropanecarboxamide Formulations of (r)-1-(2,2-difluorobenzo[d] [1,3] dioxol-5-yl)-n-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1h-indol-5-yl)cyclopropanecarboxamide](https://images-eureka.patsnap.com/patent_img/4db0eab5-a537-41dd-b28d-8b418940b79d/US20120015999A1-20120119-C00003.png)

![Formulations of (R)-1-(2,2-difluorobenzo[D] [1,3] dioxol-5-yl)-N-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1H-indol-5-yl)cyclopropanecarboxamide Formulations of (R)-1-(2,2-difluorobenzo[D] [1,3] dioxol-5-yl)-N-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1H-indol-5-yl)cyclopropanecarboxamide](https://images-eureka.patsnap.com/patent_img/17ba3e4f-b9f7-4e5c-8d63-daf8b9f03c18/US08563593-20131022-C00001.png)

![Formulations of (R)-1-(2,2-difluorobenzo[D] [1,3] dioxol-5-yl)-N-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1H-indol-5-yl)cyclopropanecarboxamide Formulations of (R)-1-(2,2-difluorobenzo[D] [1,3] dioxol-5-yl)-N-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1H-indol-5-yl)cyclopropanecarboxamide](https://images-eureka.patsnap.com/patent_img/17ba3e4f-b9f7-4e5c-8d63-daf8b9f03c18/US08563593-20131022-C00002.png)

![Formulations of (R)-1-(2,2-difluorobenzo[D] [1,3] dioxol-5-yl)-N-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1H-indol-5-yl)cyclopropanecarboxamide Formulations of (R)-1-(2,2-difluorobenzo[D] [1,3] dioxol-5-yl)-N-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1H-indol-5-yl)cyclopropanecarboxamide](https://images-eureka.patsnap.com/patent_img/17ba3e4f-b9f7-4e5c-8d63-daf8b9f03c18/US08563593-20131022-C00003.png)

![Pharmaceutical compositions of (R)-1-(2,2-difluorobenzo[D][1,3]dioxol-5-yl)-N-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1H-indol-5-yl)cyclopropanecarboxamide and administration thereof Pharmaceutical compositions of (R)-1-(2,2-difluorobenzo[D][1,3]dioxol-5-yl)-N-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1H-indol-5-yl)cyclopropanecarboxamide and administration thereof](https://images-eureka.patsnap.com/patent_img/035f9415-566e-4b07-8bb0-7cbc2e5f286b/US09012496-20150421-D00001.PNG)

![Pharmaceutical compositions of (R)-1-(2,2-difluorobenzo[D][1,3]dioxol-5-yl)-N-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1H-indol-5-yl)cyclopropanecarboxamide and administration thereof Pharmaceutical compositions of (R)-1-(2,2-difluorobenzo[D][1,3]dioxol-5-yl)-N-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1H-indol-5-yl)cyclopropanecarboxamide and administration thereof](https://images-eureka.patsnap.com/patent_img/035f9415-566e-4b07-8bb0-7cbc2e5f286b/US09012496-20150421-D00002.PNG)

![Pharmaceutical compositions of (R)-1-(2,2-difluorobenzo[D][1,3]dioxol-5-yl)-N-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1H-indol-5-yl)cyclopropanecarboxamide and administration thereof Pharmaceutical compositions of (R)-1-(2,2-difluorobenzo[D][1,3]dioxol-5-yl)-N-(1-(2,3-dihydroxypropyl)-6-fluoro-2-(1-hydroxy-2-methylpropan-2-yl)-1H-indol-5-yl)cyclopropanecarboxamide and administration thereof](https://images-eureka.patsnap.com/patent_img/035f9415-566e-4b07-8bb0-7cbc2e5f286b/US09012496-20150421-D00003.PNG)

![Solid Forms of (R)-1(2,2-Difluorobenzo[D][1,3]Dioxol-5-yl)-N-(1-(2,3-Dihydroxypropyl-6-Fluoro-2-(1-Hydroxy-2-Methylpropan-2-yl)-1H-Indol-5-yl)-Cyclopropanecarboxamide Solid Forms of (R)-1(2,2-Difluorobenzo[D][1,3]Dioxol-5-yl)-N-(1-(2,3-Dihydroxypropyl-6-Fluoro-2-(1-Hydroxy-2-Methylpropan-2-yl)-1H-Indol-5-yl)-Cyclopropanecarboxamide](https://images-eureka.patsnap.com/patent_img/957bed38-02dd-42d7-9e72-b2b9ddd04297/US20130143918A1-20130606-D00001.png)

![Solid Forms of (R)-1(2,2-Difluorobenzo[D][1,3]Dioxol-5-yl)-N-(1-(2,3-Dihydroxypropyl-6-Fluoro-2-(1-Hydroxy-2-Methylpropan-2-yl)-1H-Indol-5-yl)-Cyclopropanecarboxamide Solid Forms of (R)-1(2,2-Difluorobenzo[D][1,3]Dioxol-5-yl)-N-(1-(2,3-Dihydroxypropyl-6-Fluoro-2-(1-Hydroxy-2-Methylpropan-2-yl)-1H-Indol-5-yl)-Cyclopropanecarboxamide](https://images-eureka.patsnap.com/patent_img/957bed38-02dd-42d7-9e72-b2b9ddd04297/US20130143918A1-20130606-D00002.png)

![Solid Forms of (R)-1(2,2-Difluorobenzo[D][1,3]Dioxol-5-yl)-N-(1-(2,3-Dihydroxypropyl-6-Fluoro-2-(1-Hydroxy-2-Methylpropan-2-yl)-1H-Indol-5-yl)-Cyclopropanecarboxamide Solid Forms of (R)-1(2,2-Difluorobenzo[D][1,3]Dioxol-5-yl)-N-(1-(2,3-Dihydroxypropyl-6-Fluoro-2-(1-Hydroxy-2-Methylpropan-2-yl)-1H-Indol-5-yl)-Cyclopropanecarboxamide](https://images-eureka.patsnap.com/patent_img/957bed38-02dd-42d7-9e72-b2b9ddd04297/US20130143918A1-20130606-D00003.png)