Modified copolyester, thermal shrinkage polyester film produced thereby and method for preparing same

A technology of copolyester and polyester film, which is applied in the field of heat-shrinkable polyester film preparation, can solve the problems of not being able to meet the processing conditions of secondary blown film, low melting strength, and not particularly high molecular weight, and achieve excellent heat shrinkage effect , Improve melting strength, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] I. Preparation of Modified Copolyester with Addition of First Modifier and Branching Agent

[0079] Pour terephthalic acid, ethylene glycol, 1,3-dihydroxy-2-methylpropane, and 1,1,1-tris(hydroxymethyl)propane in a molar ratio of 1:0.998:0.249:0.003 and stir Stir in the tank to form a paste, and add 75ppm of heat stabilizer (phosphoric acid), then pour the paste into the esterification tank, heat up and stir, and carry out the esterification reaction at the same time, which lasts 6 to 7 hours. Control it within 3kg / cm2, while allowing the water generated by the reaction to distill out and collect through the rectifying tube. The final temperature of the esterification end is 250°C, and then the esterified product in the reaction tank is transferred to the condensation reaction tank, and 300ppm of antimony trioxide and 50ppm of cobalt acetate are added as catalysts, and the temperature is gradually raised to 285°C, and within 2 hours Vacuum to about 1torr. Until the int...

Embodiment 2

[0093] I. Preparation of Modified Copolyesters

[0094] The copolyester of this embodiment is prepared in the same manner as in Example 1, except that isophthalic acid is further added as a second modifier, and terephthalic acid, isophthalic acid, ethylene glycol, 1 , the molar ratio of 3-dihydroxy-2-methylpropane to 1,1,1-tris(hydroxymethyl)propane is 1:0.053:1.118:0.197:0.003, and the measured Tg value is 74°C.

Embodiment 3

[0096] I. Second blown film to make heat-shrinkable polyester film

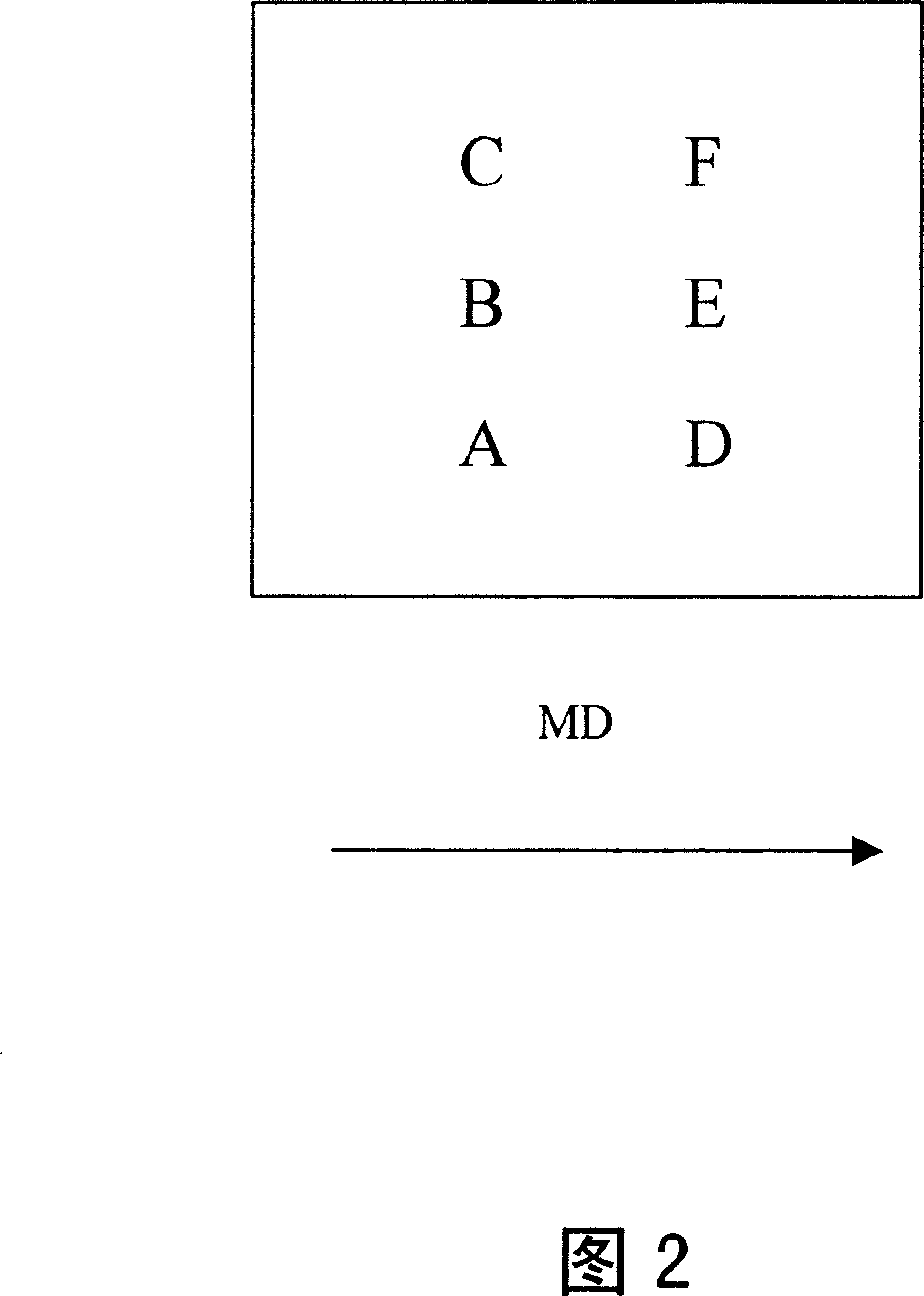

[0097]The PET copolyester obtained in Experimental Example 1 was dried at low temperature (60° C.) for more than 12 hours, and then added into an extruder (L / D=25, φ=65) (setting temperatures were 185° C., 190° C. ℃, 195℃; Die 1 temperature 180℃, Die 2 temperature 190℃), film blowing is carried out with two continuous film blowing machines, that is to say, it is carried out by dry stretching and cooling on the upper blowing ring, and then the film is wound up to the top Then it goes down and then stretched through an electric oven, and finally the stretched film is rewound. Among them, the extension temperature is set to three sections, respectively 110°C, 100°C, and 90°C. The width of the air ring (bubble 1) of the first blown film is 200mm, and the width of the air ring (bubble 2) of the second blown film is 400mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com