Patents

Literature

39results about How to "Inhibition of hydration dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

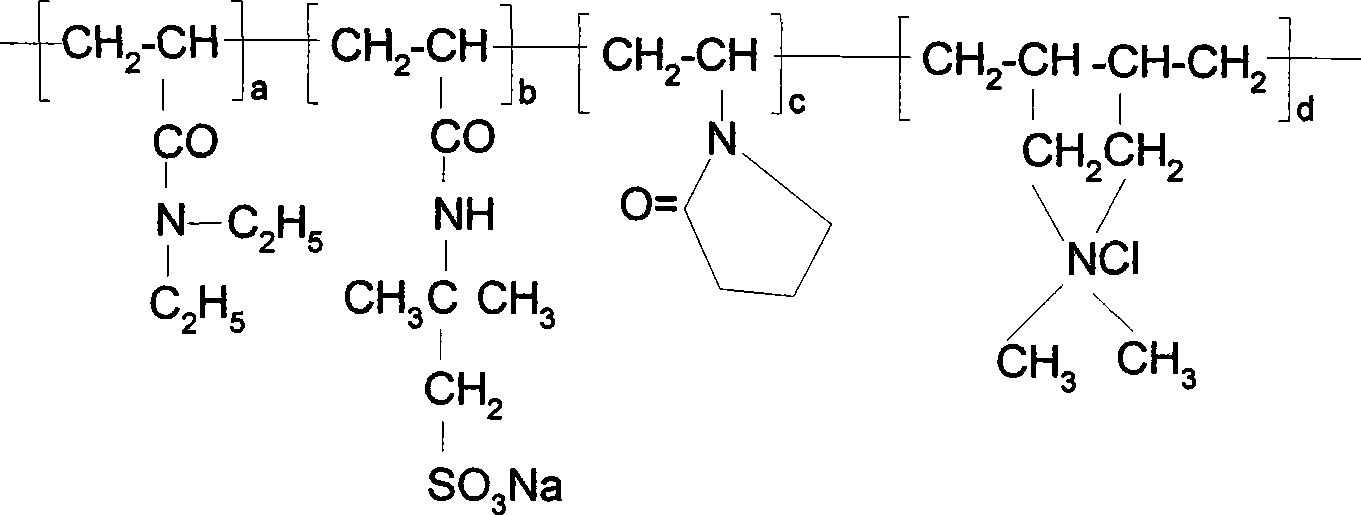

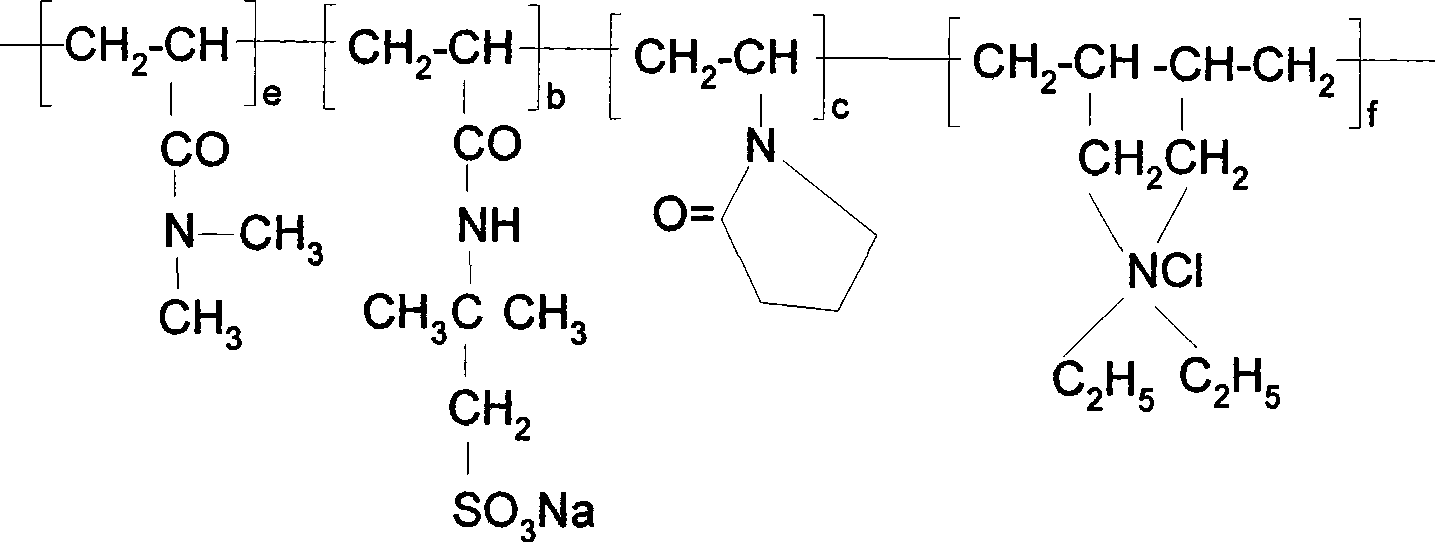

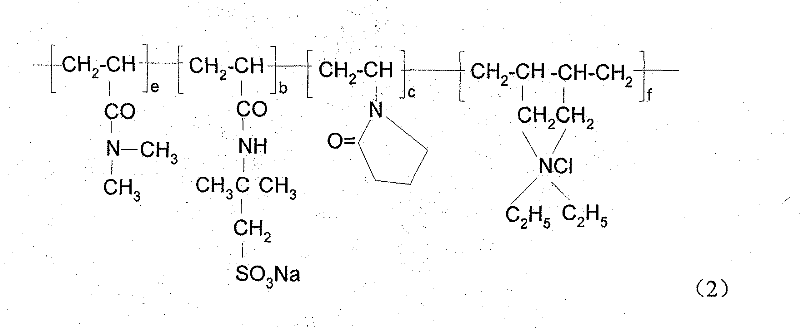

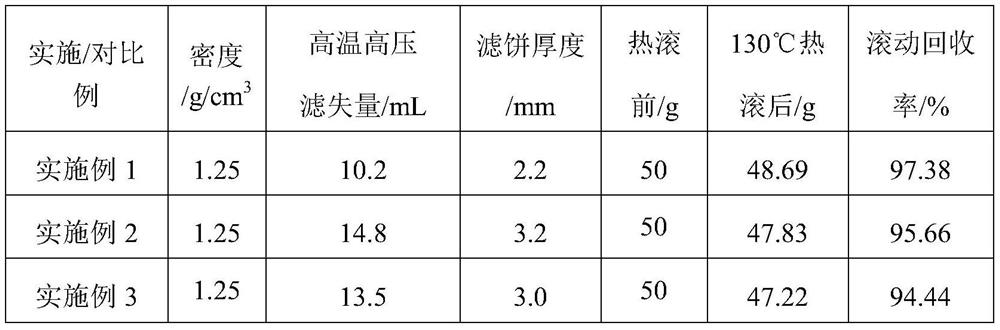

High-temperature resistant polymer fluid loss agent for drilling fluid and preparation method thereof

InactiveCN101531887AGood filter loss reduction effectInhibition of hydration dispersionDrilling compositionStructural unitSalt water

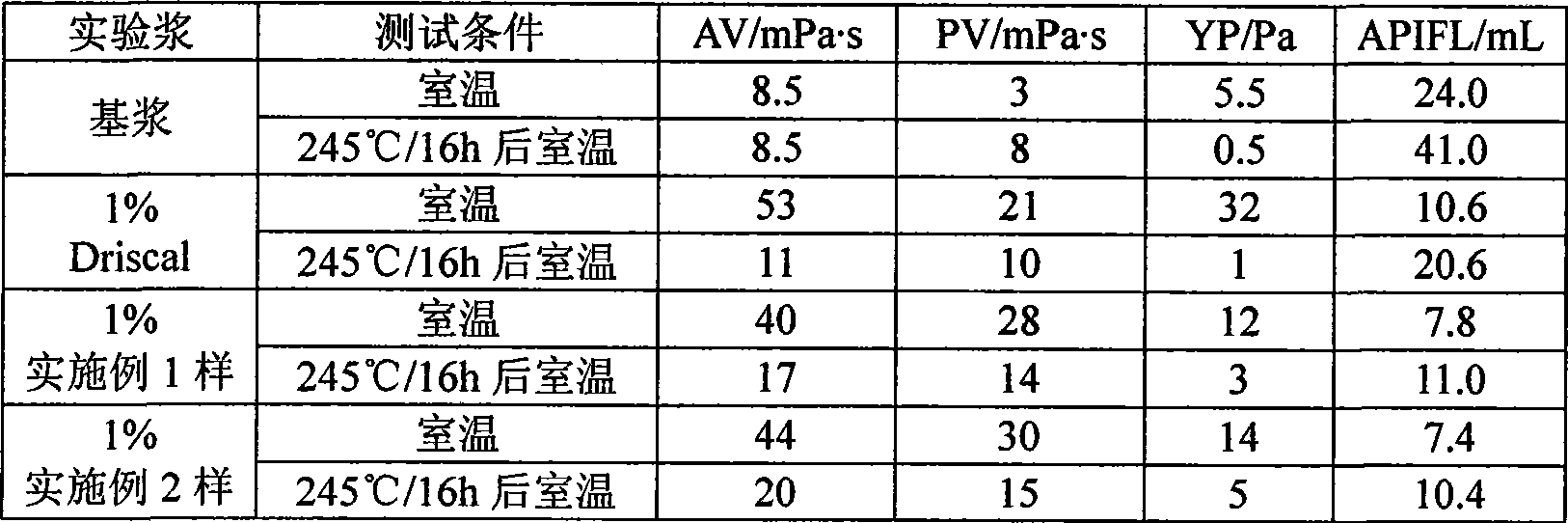

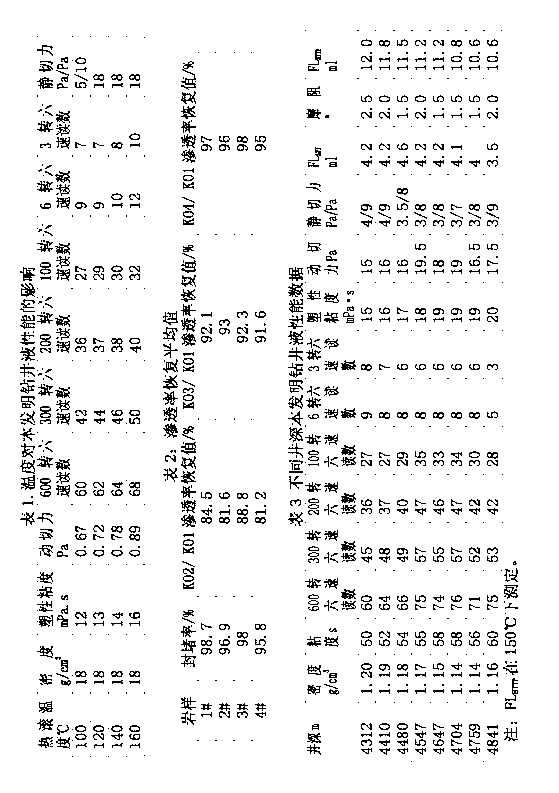

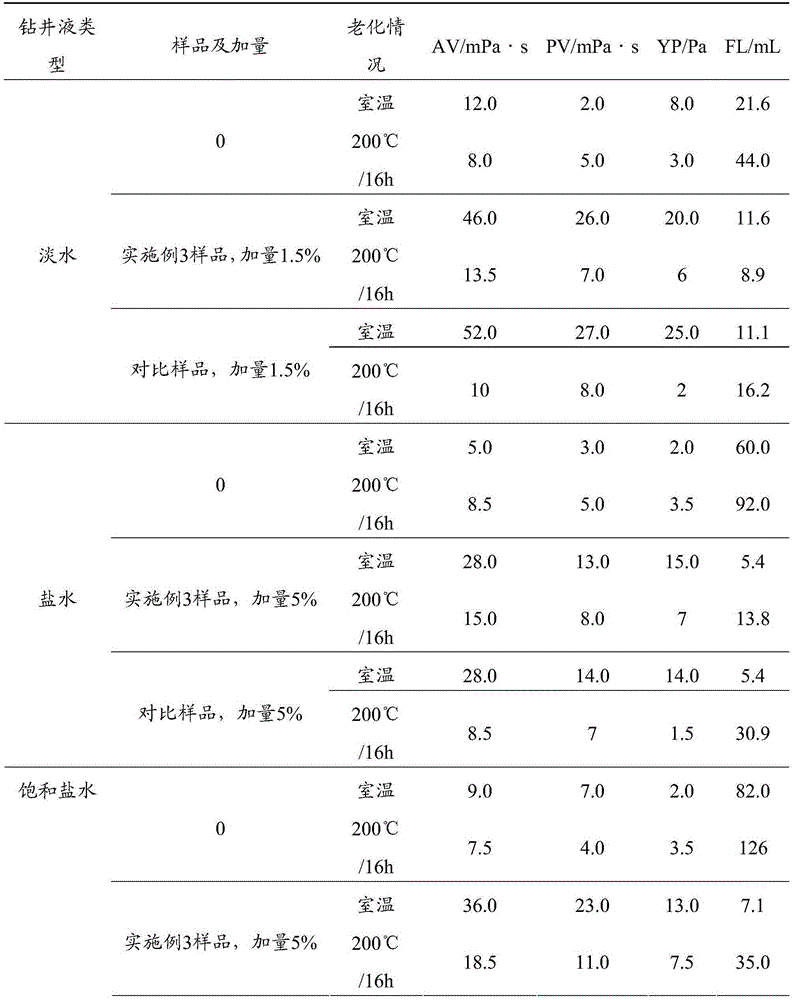

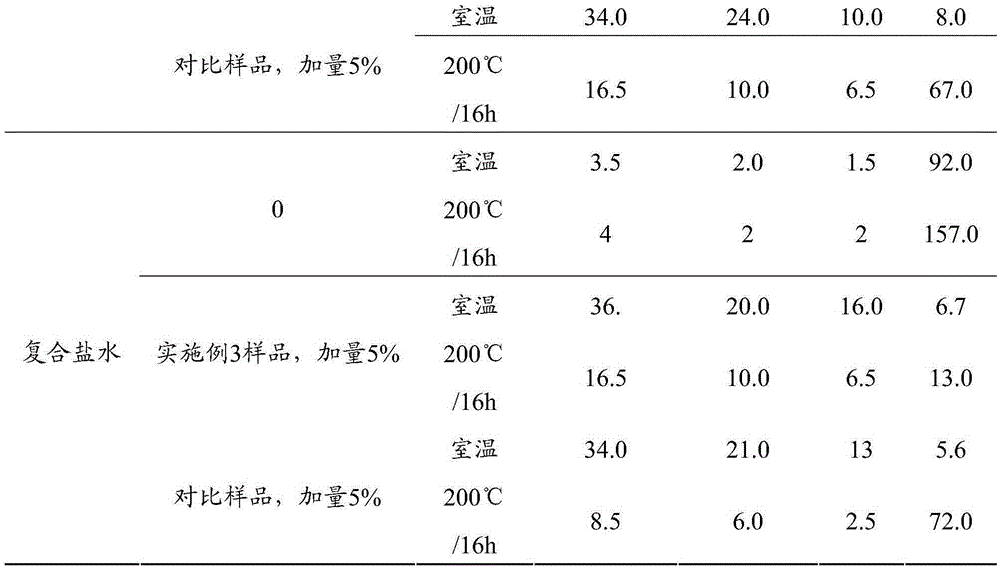

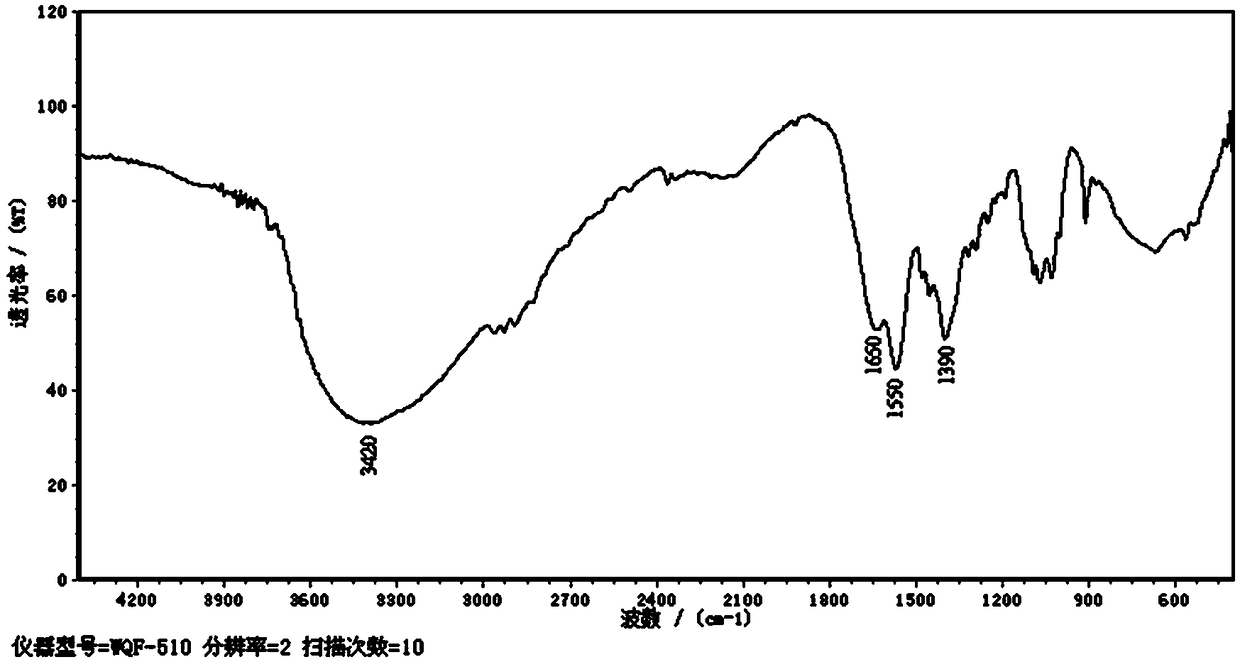

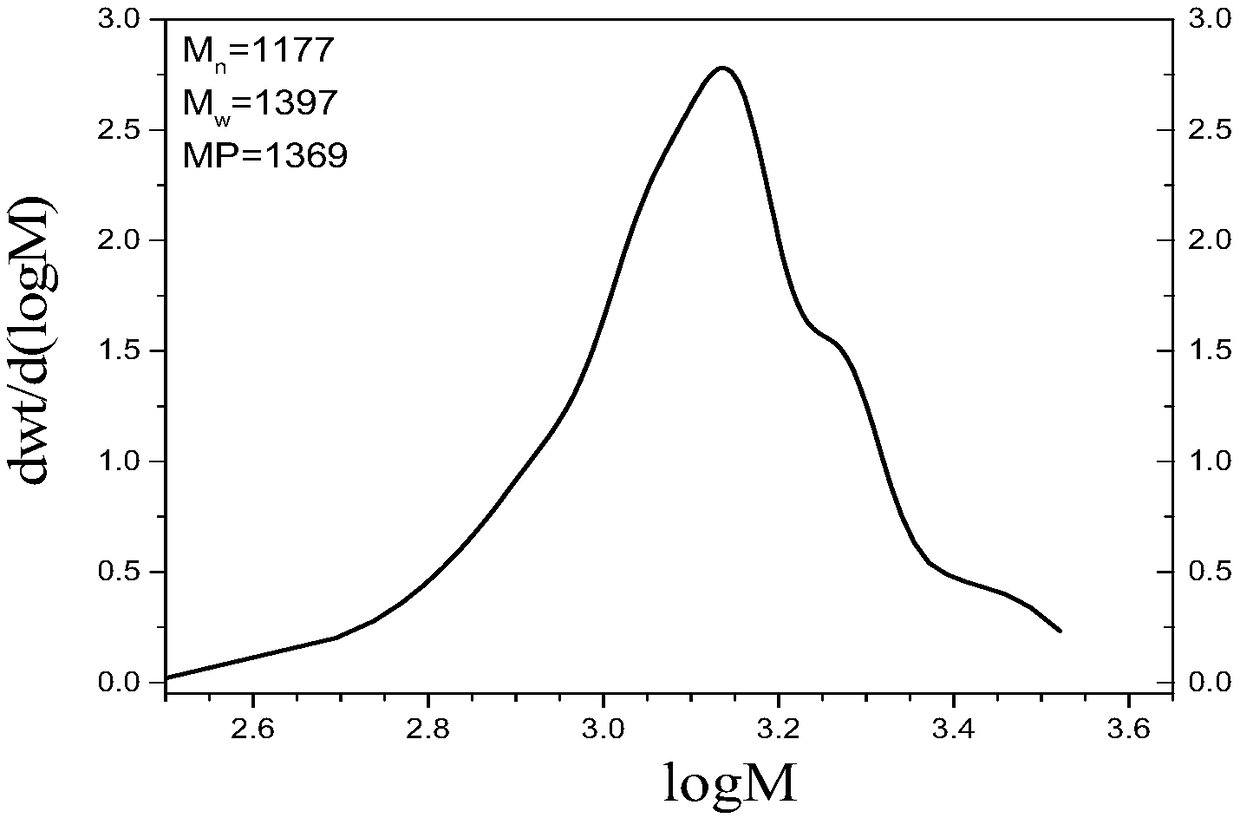

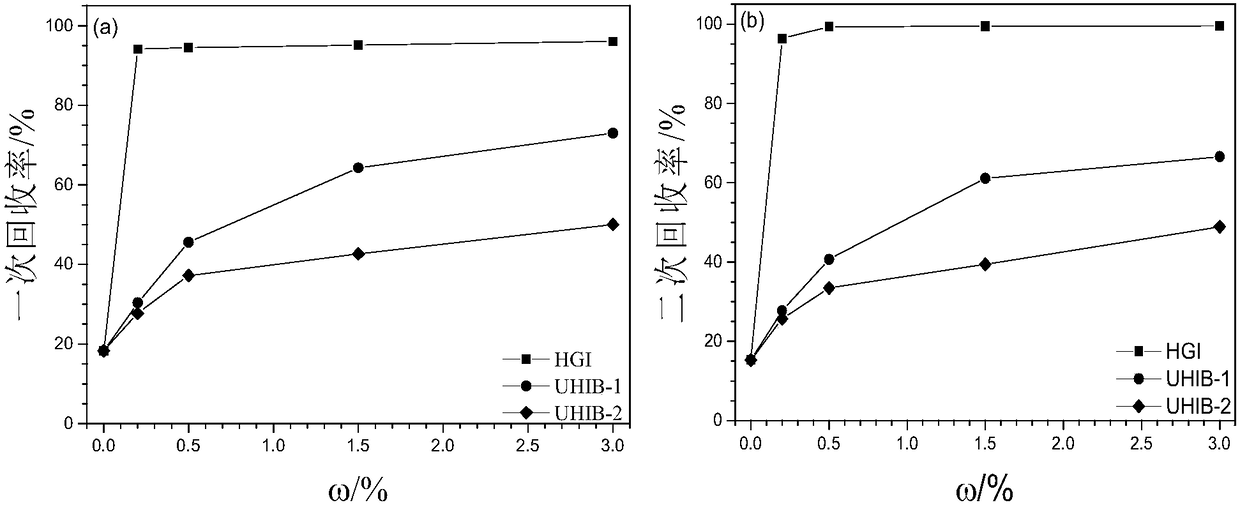

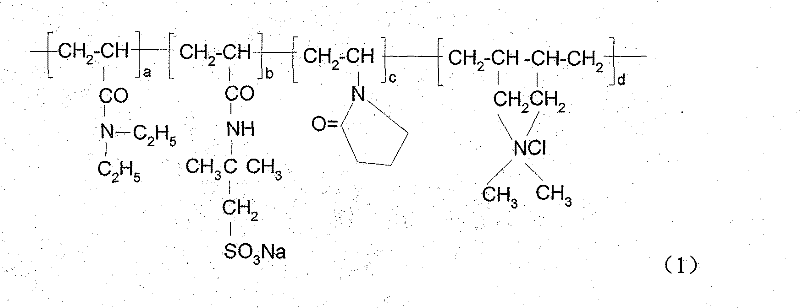

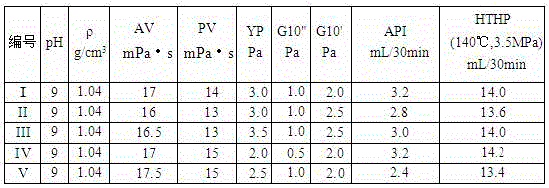

The invention discloses a high-temperature resistant polymer fluid loss agent for drilling fluid and a preparation method thereof. The polymer fluid loss agent is characterized in that the polymer fluid loss agent is a copolymer generated by olefine acid, alkenyl amide, alkenyl azululanone and alkenyl quaternary ammonium through reaction, molecules of the copolymer contain 800 to 1,800 structural units, and viscosity average molecular weight is 500,000 to 1,200,000. The polymer fluid loss agent can resist temperature of more than 245 DEG C in the drilling liquid, has good protective colloid performance to the drilling liquid, improves the quality of a filter cake, has good fluid loss reduction effect in fresh water, aggravated fresh water, salt water and the like, can simultaneously inhibit hydration and dispersion of clay and has good rheology.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Preparation method of starch grafted copolymer inverse emulsion for drilling fluid

ActiveCN103113524AImprove the lubrication effectGood anti-collapse abilityDrilling compositionWater basedPotassium hydroxide

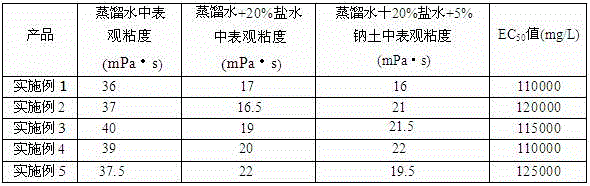

The invention relates to a preparation method of a starch grafted copolymer inverse emulsion for a drilling fluid. The method comprises the following steps of: adding an emulsifier sorbitan monooleate into white oil, and stirring, dissolving and introducing nitrogen to obtain an oil phase; dissolving potassium hydroxide in water, adding 2-acrylamidyl-2-methyl propanesulfonic acid, acrylamide, a vinyl monomer, a cationic monomer, polyoxyethylene sorbitan monooleate, ethylene diamine tetraacetic acid disodium salt and starch, and stirring to obtain an aqueous phase; adding the aqueous phase into the oil phase, adequately emulsifying, adjusting the pH value, introducing nitrogen, adding an initiator and a reducing agent; and stirring, heating, insulating heat, cooling, discharging and filtering under nitrogen protection to obtain the starch grafted copolymer inverse emulsion for the drilling fluid. The product serving as a drilling fluid treatment agent has good de-filtration effect, good thickening effect, a flow type regulating effect and good inhibition effect for dehydrating dispersion of clay and drillings, so that the quality of filter cakes is improved, the lubricity of the drilling liquid is improved and the processing cost of the drilling liquid is lowered, and the preparation method is suitable for various types of water-based drilling fluids.

Owner:CHINA PETROLEUM & CHEM CORP +1

No-clay low-solid phase horizontal well section drilling fluid and preparation method thereof

The invention relates to the technical field of drilling fluid used for the field of petroleum drilling engineering, and in particular relates to a no-clay low-solid phase horizontal well section drilling fluid and a preparation method of the drilling fluid. The no-clay low-solid phase horizontal well section drilling fluid is prepared by adding an alkalinity regulator, a filtrate reducer, an extracting agent, calcium carbonate superfine powder, a liquid lubricant and potassium chloride into water, and evenly mixing. The no-clay low-solid phase horizontal well section drilling fluid and the preparation method of the drilling fluid are simple, convenient and easy in technology, low in cost, beneficial to carrying rock debris in the horizontal section drilling process, good in temporary blockage capability and thorough in blockage removal, guarantee a wellbore to be clean, avoid the damage of highly-dispersed clay particles to the reservoir stratum, effectively prevent solid phase and liquid phase from invading the stratum, inhibit the hydration dispersing of the clay of the stratum, can effectively control the depth of a pollution zone, can well protect the reservoir stratum even if the well depth is increased and the work period is prolonged, are used for an underbalanced well, are good in temperature resistance, have the highest temperature resistance reaching up to 140 DEG C, and are suitable for all horizontal well reservoir stratum sections with the inclined depths not exceeding 5000m.

Owner:克拉玛依市金鑫科技有限公司

Glucoheptonate restraining agent for drilling fluid and method for preparing same

InactiveCN101311240AMeet or exceed suppressive capacityMeet the requirements of on-site drilling operationsDrilling compositionHydrolysisGluconates

The invention relates to a gluconate inhibitor used by drilling fluid in petroleum drilling and a preparation method thereof. Water and starch is mixed according to the weight ratio of 1: 0.01-2, proper amount of catalyst is added to carry out hydrolysis, and then an oxidizer is added to oxidize the solution and an alkaline finishing agent is used for adjusting to obtain the product. The inhibitor uses metal cations such as K<+>, Ca<2+>, and the like as the inhibiting ions to inhibit the hydration expansion and hydration dispersion of the clay shale; the glucose acid radical anions form protection film on the clay surface through the absorption function between hydroxide radical and the clay surface to prevent the hydration of the clay. The gluconate inhibitor provides for the inhibitive drilling fluid a safe and environment-friendly finishing agent with strong inhibition, lubrication action, no side effects to the performance of the drilling fluid, no negative impacts on the other drilling operation procedures.

Owner:WESTERN DRILLING KELAMAYI DRILLING TECH INST

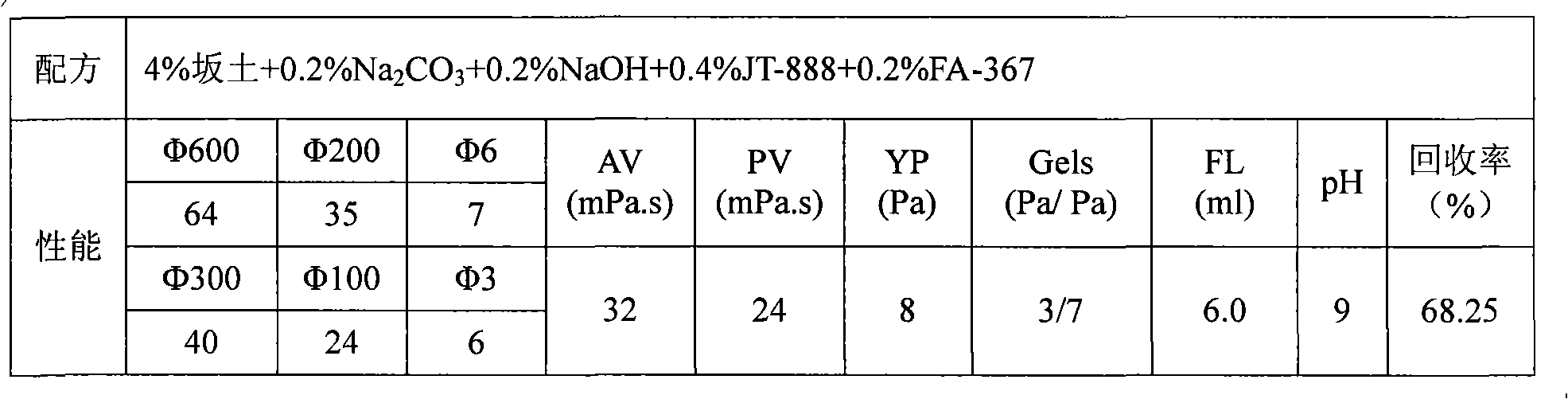

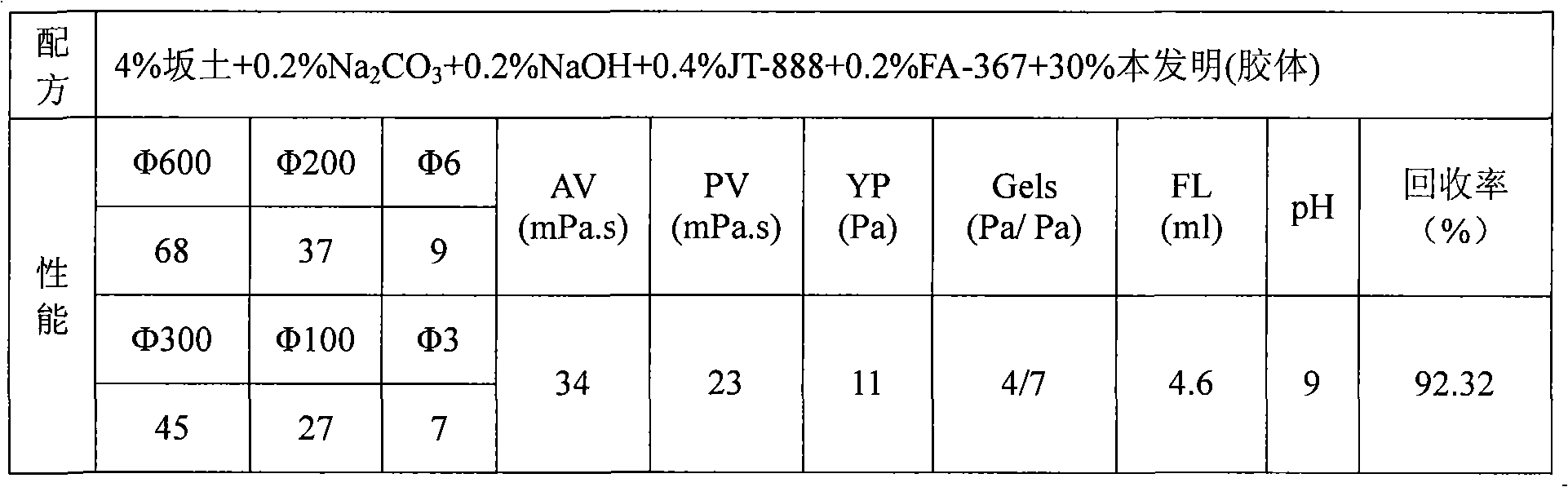

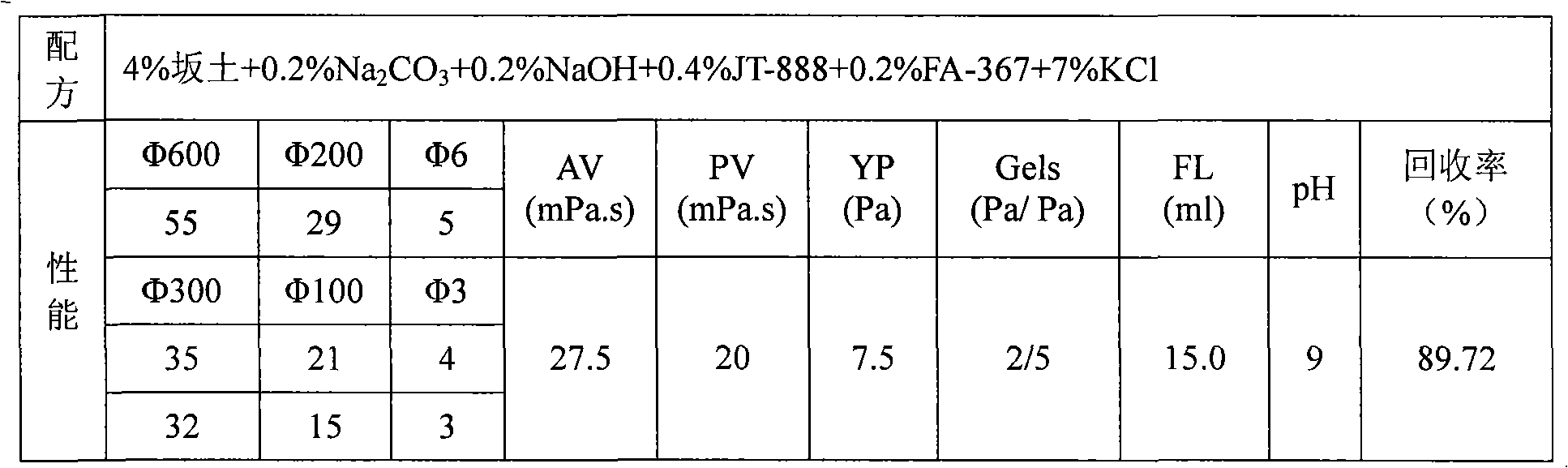

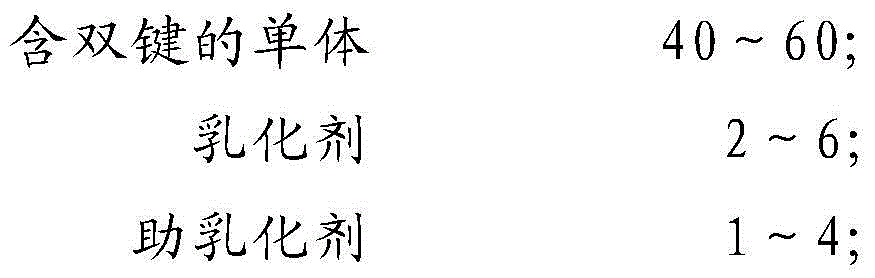

Nanometer emulsion blocking agent used for drilling fluid, and preparation method and application thereof

InactiveCN104927802AReduce fluid lossImprove the blocking effectDrilling compositionPressure transmissionDifferential pressure

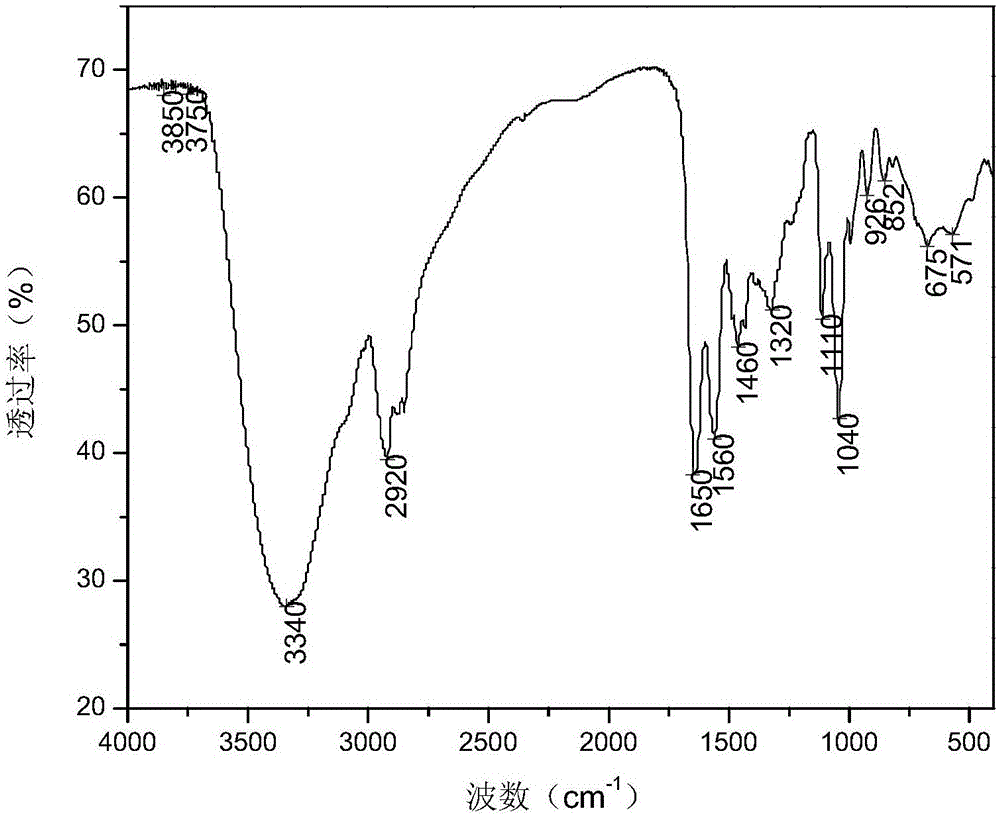

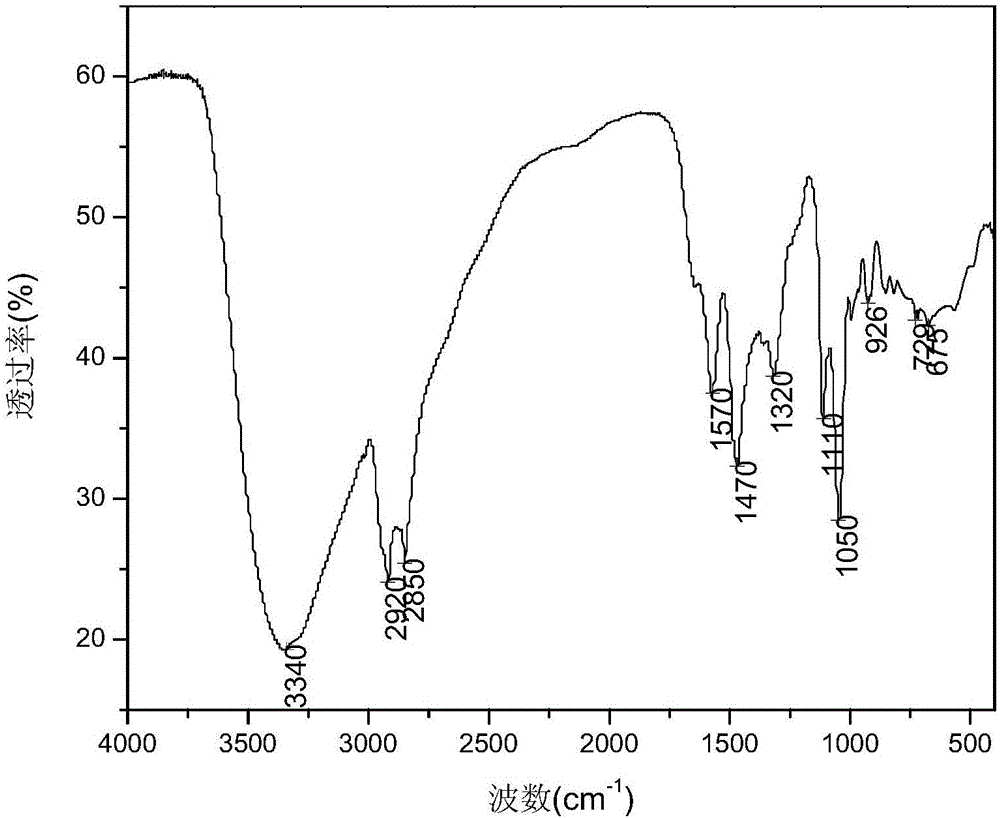

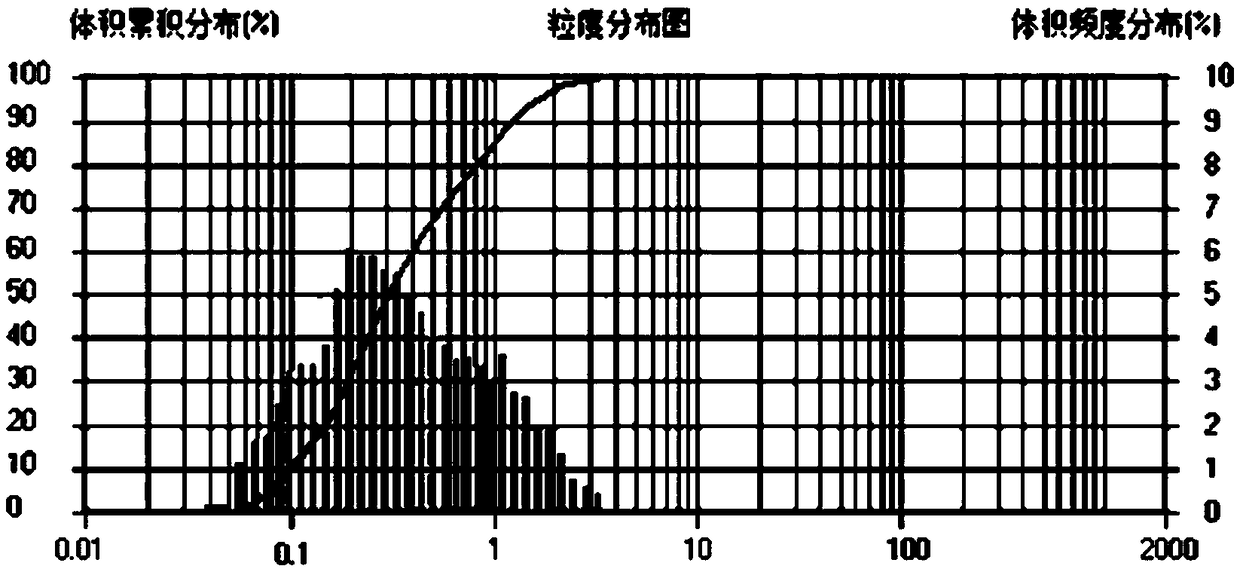

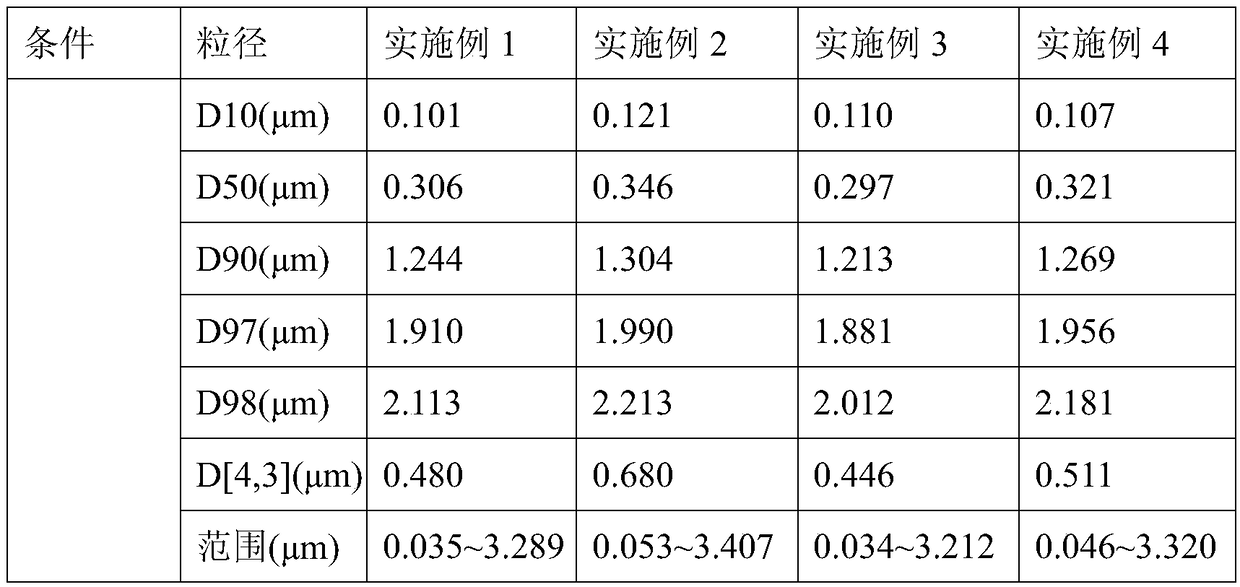

The invention relates to a nanometer emulsion blocking agent used for drilling fluid, and a preparation method and application thereof. The nanometer emulsion blocking agent is prepared through polymerization by dispersing at least two double-bond-contained monomers into water containing an emulsifier and a co-emulsifier in an weak alkali environment under the action of a catalyst; and raw materials participating in reaction comprise, by weight, 40 to 60 parts of the double-bond-contained monomers, 2 to 6 parts of the emulsifier, 1 to 4 parts of the co-emulsifier, 0.1 to 0.5 part of the catalyst and 30 to 50 parts of the water. Accordingn to the invention, a particle size of a dispersed particle in the nanometer emulsion blocking agent is distributed in a nanoscale and is less than 500 nm, so the nanometer emulsion blocking agent has good blocking effect, cen block micropores and be casted into microcracks, and is capable of reducing pore pressure transmission, maximumly reducing differential pressure sticking and effectively inhibiting hydration dispersion of clay; the nanometer emulsion blocking agent is stable in high salinity and has the advantages of convenient use, no toxicity, no pollution and easy degradation; and the preparation method of the nanometer emulsion blocking agent has the advantages of reasonable process, mild and controllable conditions, no post treatment, low cost and benefit ratio, and facilitation to industrial production.

Owner:北京中科日升科技有限公司

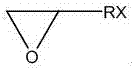

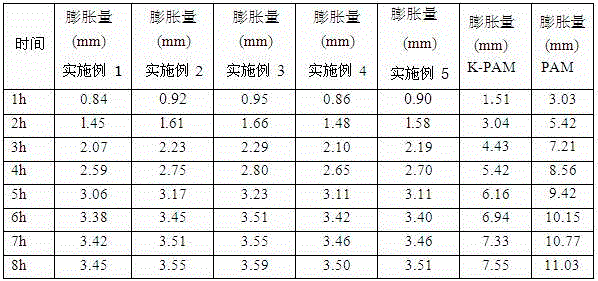

Dendritic quaternary ammonium salt shale inhibitor as well as preparation method and application thereof

ActiveCN106519254AInhibits hydration swellingReduce hydration repulsionDrilling compositionCyclic etherEvaporation

The invention relates to a dendritic quaternary ammonium salt shale inhibitor as well as a preparation method and application thereof. The dendritic quaternary ammonium salt shale inhibitor is a modified product obtained by quaterisation reaction of terminal amino dendritic polymer, cyclic ether and tertiary amine. The preparation method comprises the following steps: dissolving the terminal amine dendritic polymer into a dissolving solvent, then slowly dropwise adding the tertiary amine, stirring for 0.5 to 3 hours at a room temperature, and then slowly dropwise adding the cyclic ether; raising the temperature to be 40 to 90 degree centigrade after dropwise adding is finished, and reacting for 2 to 12 hours; removing the dissolving solvent through evaporation, adding a deposition solvent to deposit out a solid body, and vacuum-drying the solid body, thereby obtaining the dendritic quaternary ammonium salt shale inhibitor. The dendritic quaternary ammonium salt shale inhibitor provided by the invention has excellent inhibition performance, can effectively inhibit hydration dispersion of active clay shale (high montmorillonite content), and can effectively perform an inhibition effect under a low concentration.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Composite metal zwitterion polymer and its prepn and use

InactiveCN1388141AStrong anti-high temperature and high pressure anti-pollution abilityStrong apparent viscosityDrilling accessoriesFiltrationFresh water

The present invention relates to composite metal zwitterions polymer and its preparation. They are used as treating agent for drilling fluid and well completion fluid. The composite metal zwitterions polymer is prepared through re-compounding cationic, anionic and non-ionic monomer and metal hydroxide in certain proportion and vaporizing and desolvating flash polymerization. The composite metal zwirrerions polymer has excellent filtration property, clay hydration dispersion inhibiting property, rheological property and pollution and temperature resistance in fresh water, salty water and saturated mud.

Owner:中国石油天然气股份有限公司勘探开发研究院

Harm-free core-drilling fluid, and its preparing method and use

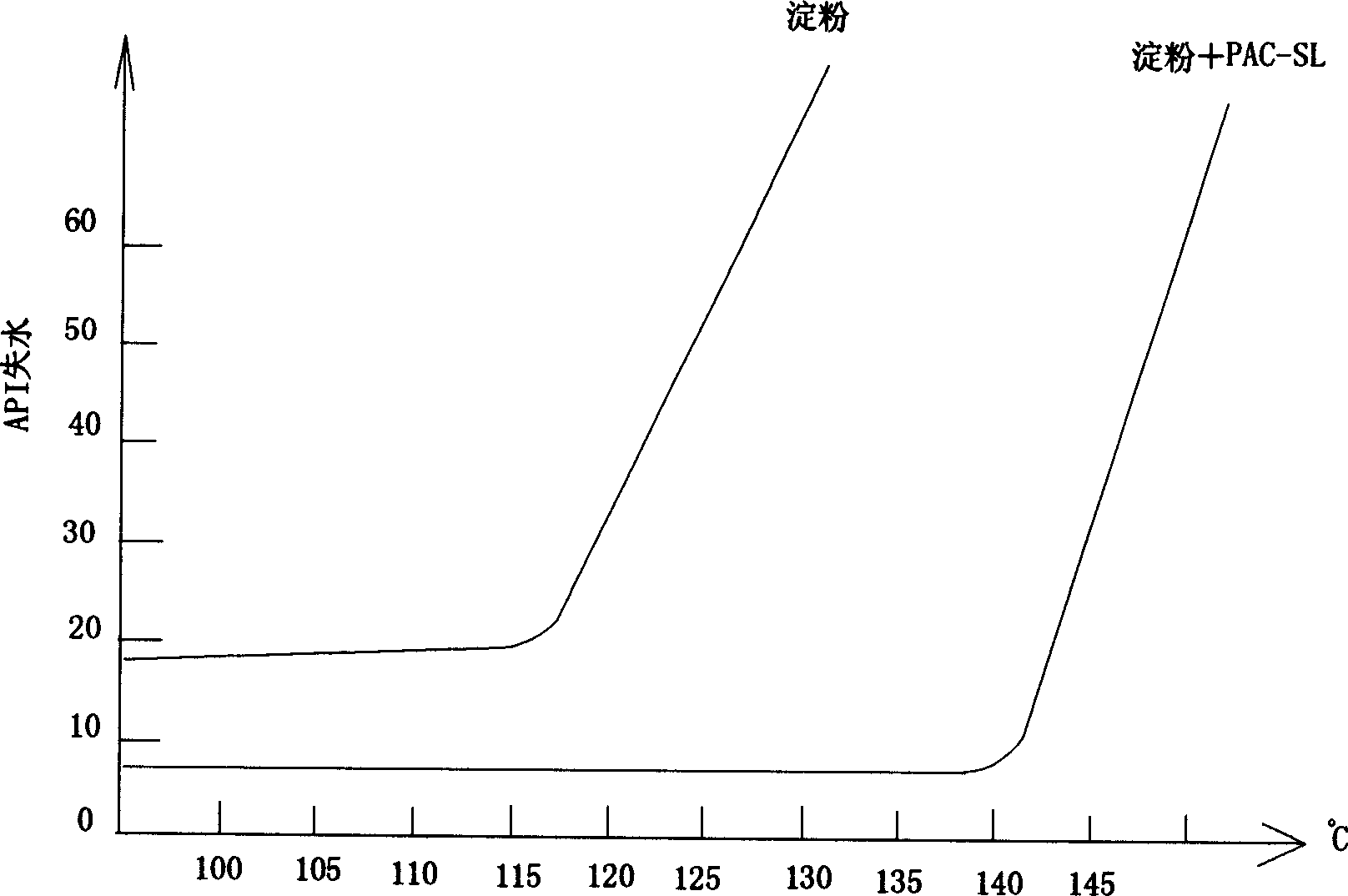

InactiveCN1978584AImprove the lubrication effectInhibition of hydration dispersionDrilling compositionWell drillingPetroleum

This invention discloses a kind of no damage fetching core borehole liquid and its preparation method. It is made up of the water 100000- 160000, NaCl 15000-19000, Na2CO3 200-400, NaOH 50-150, PAC-SL 150-550, FLOWZAN 200-600, Starch 1200-1800, the modified SOLTEX 1200-1800, Baracarb(5) CaCO3 a 2000-4000, Baracarb(50) CaCO3 b 2000-4000, Baracarb(600) CaCO3 c 2000-4000. The character of the no damage fetching core borehole liduid is in that: it has no damage to the core and the stratum; it has the good lubricating ability and has the good capability in cleaning well and inhibiting the drill chip disperses; the additive such as the FLOWZAN, the starch and the PAC-SL are all degraded by the organism. The Baracarb crushed by the marble is the inorganic additive and has no pollution to the environment; also it can not change the wetting property of the petrosal.

Owner:中国石油大学(华东)石油工程学院

Inverse emulsion polymer and preparation method and application thereof in preparation of water-based drilling fluid

The invention provides an inverse emulsion polymer and a preparation method and application thereof, the method is as follows: first, emulsification of an oil phase material and a water phase material which includes monomers A, B and C, a first emulsifier and water to obtain monomer emulsion; and polymerization of the monomer emulsion in the presence of an initiator to obtain the inverse emulsion polymer, wherein the monomer A is selected from water soluble allyl sulfonate; the monomer B is selected from one or more of acryloyl morpholine, vinyl caprolactam and vinyl morpholine, and the monomer C is selected from acrylate compounds comprising polyoxyethylene and alkyl. The temperature and salt resistance, calcium resistance and inhibiting capability of the inverse emulsion polymer are further enhanced, during application of the inverse emulsion polymer as a drilling fluid treatment agent, the inverse emulsion polymer not only has the effect of good filtrate loss reduction, viscosity increase, flow type adjustment, inhibition of hydration dispersion of clay and drilling cuttings at high temperature, can improve the quality of filter cake, improves drilling liquid lubrication, and is applicable to all types of water-based drilling fluids.

Owner:中石化石油工程技术服务有限公司 +1

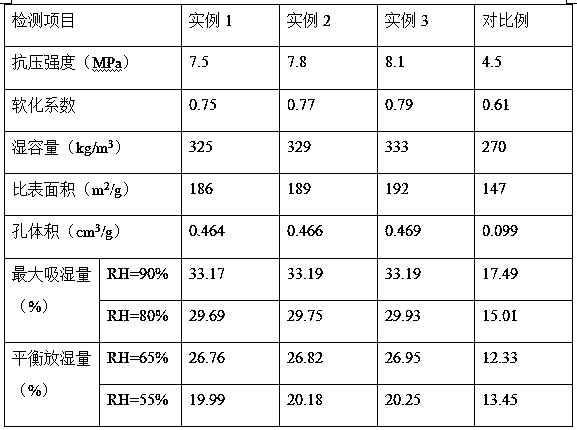

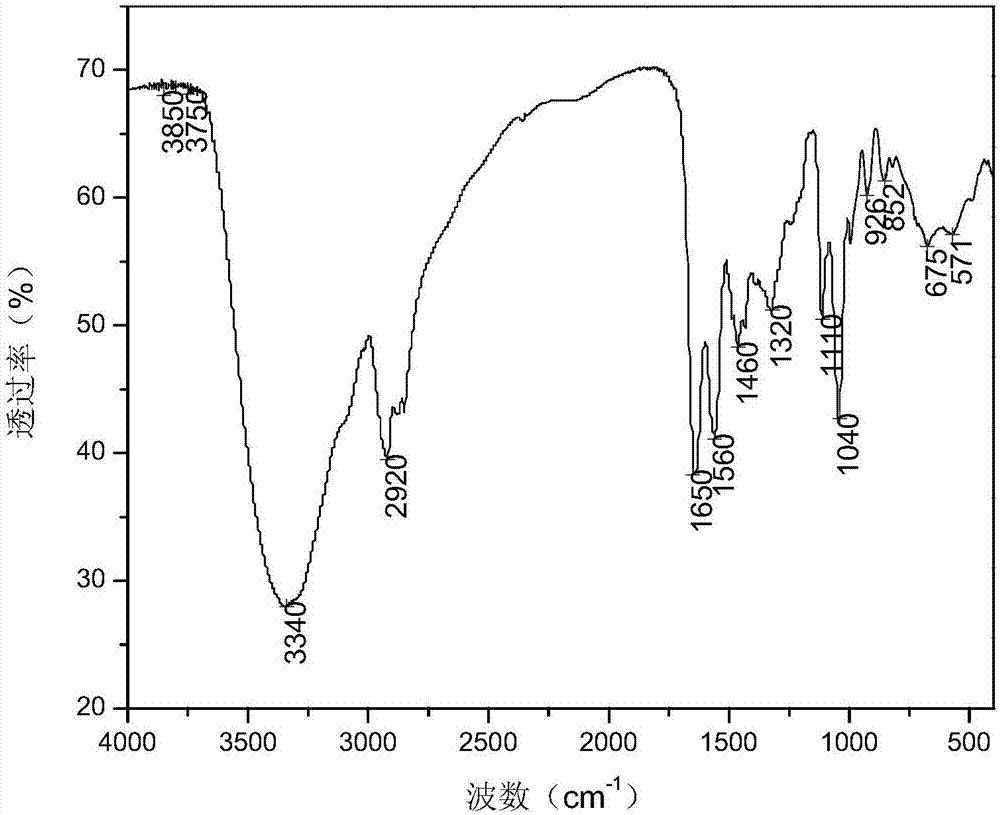

Preparation method of high-temperature resistant composite humidity-controlling material

The present invention relates to the technical field of preparation of humidity-controlling materials, and more particularly to a preparation method of a high-temperature resistant composite humidity-controlling material. When indoor humidity is high, capillary condensation may occur in the internal pores of diatomite, so that the humidity is reduced. When the humidity is low, the moisture storedin the pores of the diatomite can be released through the pores, so that the environmental humidity is improved. Calcium lignosulphonate is grafted with acrylamide to obtain a graft copolymer, and thelignosulfonate is adsorbed to various organic or inorganic particles, so that the hydration of free water molecules on the diatomite crystal layer is effectively weakened and blocked. Meanwhile, thecoalescence stability of the system is improved by a large number of anionic groups and non-ionic polar groups. N-vinyl pyrrolidone has the capability of resisting high-temperature degradation and metal salt ion invasion, and meanwhile, the nitrogen atoms and oxygen atoms in the N-vinyl pyrrolidone interact with the oxygen atoms or ammonia atoms in the acrylamide molecules, so that the hydrolysisof the acrylamide can be inhibited. The preparation method has an extensive application prospect.

Owner:邹峰

Environment-friendly type drilling fluid anti-wear agent with high temperature resistance and preparation method of environment-friendly type drilling fluid anti-wear agent

InactiveCN105505338AHigh temperature resistanceLow biological toxicityDrilling compositionZinc compoundsPhosphorus pentasulfide

The invention relates to the technical field of drilling fluid auxiliaries, and provides an environment-friendly type drilling fluid anti-wear agent with high temperature resistance and a preparation method of the environment-friendly type drilling fluid anti-wear agent. The environment-friendly type drilling fluid anti-wear agent with the high temperature resistance comprises raw materials as follows: phosphorus pentasulfide, isooctyl alcohol, oleic acid, diethyl ammonium phosphate, potassium hydroxide, a molybdenum di-zinc compound, dimethyl silicon oil, zinc carbonate, aluminum distearate and water. The environment-friendly type drilling fluid anti-wear agent with the high temperature resistance is prepared from a natural polymer material, biomass oil and lipid through modified synthesis and esterification reaction, is not only an environment-friendly type drilling fluid auxiliary, but also can reduce wear, decrease frictional resistance and torque, increase the drilling rate and reduce drilling cost effectively and has higher tolerable temperature and higher salt intrusion resistance, thereby having more popularization value and further having better rock fragment hydrated dispersion inhibition capacity and better shale expansion inhibition function, and accordingly, the environment-friendly type drilling fluid anti-wear agent with the high temperature resistance is the environment-friendly drilling fluid auxiliary with the high temperature resistance and has the characteristics of advancement, maturity and economic efficiency.

Owner:XINJIANG DEBANG PETROLEUM TECH CO LTD

Environment-friendly pseudo oil-based drilling fluid and preparation method thereof

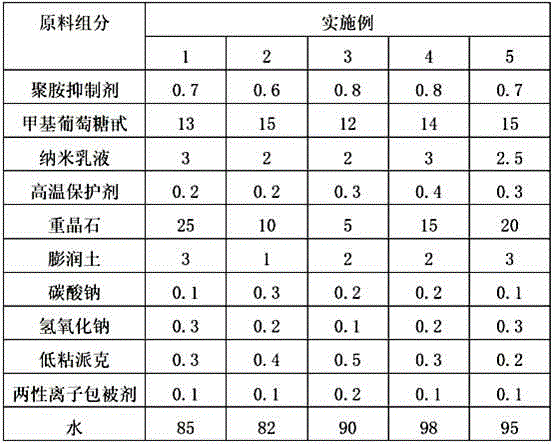

InactiveCN103555303AInhibit swellingInhibition of hydration dispersionDrilling compositionIonEnvironmental resistance

The invention discloses an environment-friendly pseudo oil-based drilling fluid and a preparation method thereof. The drilling fluid comprises the following raw materials in ratio: 0.6-0.8 part of polyamine inhibitor, 12-15 parts of methyl glucoside, 2-3 parts of nano-emulsion, 0.2-0.4 part of high temperature protective agent, 0-30 parts of barite, 1-3 parts of bentonite, 0.1-0.3 part of sodium carbonate, 0.1-0.3 part of sodium hydroxide, 0.2-0.5 part of low viscosity parker, 0.1-0.2 part of zwitter-ion coating agent, and 80-100 parts of water. The preparation method comprises the following steps: 1) respectively adding sodium hydroxide and sodium carbonate in water, and stirring; 2) adding the bentonite in the water, stirring at high speed, and standing at normal temperature; 3) stirring the solution of the step 2), adding methyl glucoside in the stirring process, and continuously stirring; 4) orderly adding the zwitter-ion coating agent, the low viscosity parker, the high temperature protective agent, the polyamine inhibitor and the nano-emulsion in the solution in the step 3) at intervals of stirring; and 5) regulating the density of the drilling fluid.

Owner:CHINA PETROCHEMICAL CORP +1

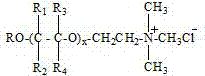

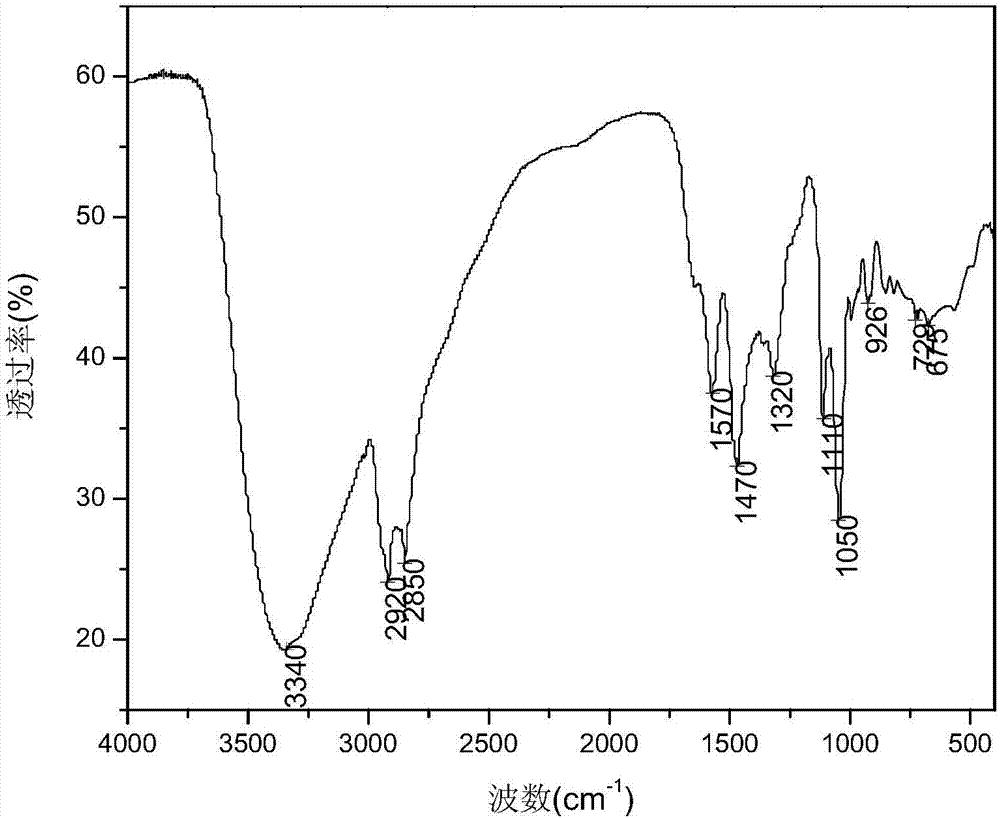

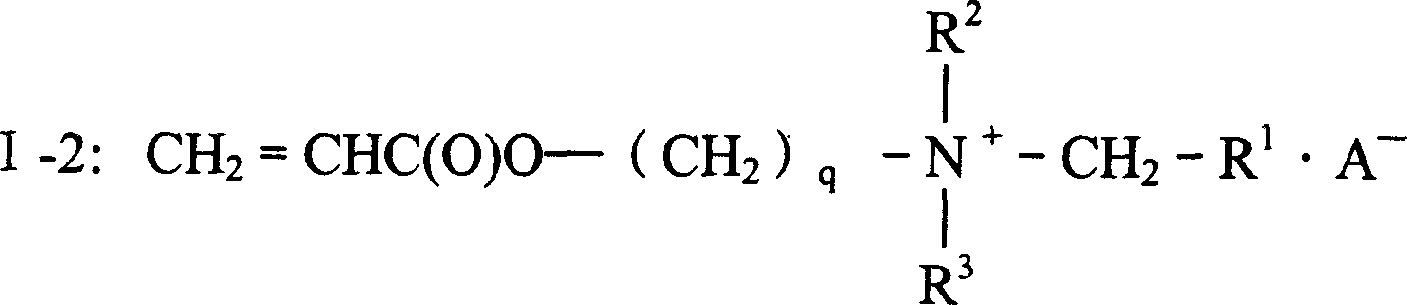

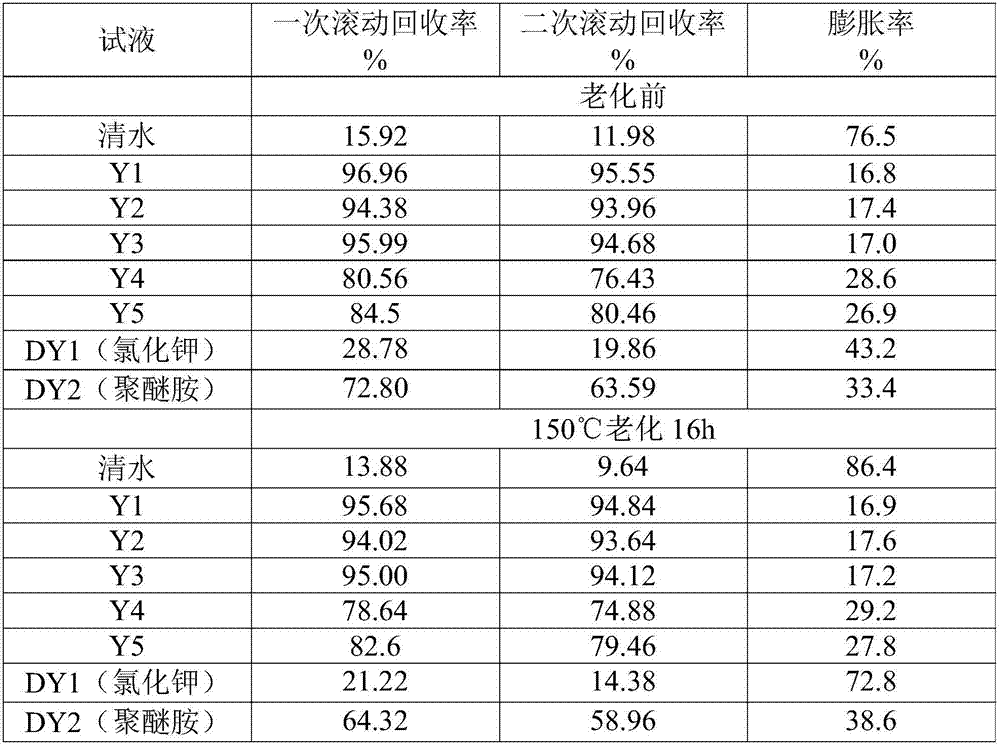

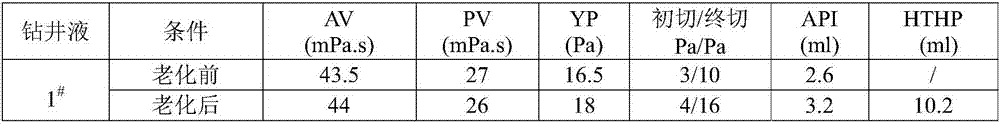

Polyamine inhibitor for water-based drilling fluid and preparation method of polyamine inhibitor

InactiveCN108148564AEnhanced inhibitory effectInhibition of hydration dispersionOrganic compound preparationDrilling compositionWater basedAcetic acid

The invention discloses a polyamine inhibitor for a water-based drilling fluid and a preparation method of the polyamine inhibitor. The structural formula of the polyamine inhibitor is as shown in thespecification. The preparation method includes the steps of firstly, weighing, by weight, 75-80 parts of maleic anhydride, 210-215 parts of triethanolamine, 8-12 parts of glacial acetic acid and 348-352 parts of tap water; secondly, placing the weighed maleic anhydride and triethanolamine in a reaction kettle under normal temperature; thirdly, rising the temperature in the reaction kettle to 80-90 DEG C in 4 minutes, and keeping the temperature for 30 minutes; fourthly, rising the temperature to 180 DEG C after the heat preservation, and using a vacuum pump to keep pressure in the reaction kettle in a 20mm mercury column state to perform reaction for 4 hours; fifthly, after the reaction, cooling and performing pressure relief, and cooling to 90 DEG C; sixthly, adding the glacial acetic acid and the tap water when required temperature is reached, and performing reaction for 2 hours to obtain the polyamine inhibitor. The polyamine inhibitor is applicable to a shale gas water-based drilling fluid system.

Owner:SOUTHWEST PETROLEUM UNIV

High-temperature resistant polymer fluid loss agent for drilling fluid and preparation method thereof

InactiveCN101531887BGood filter loss reduction effectInhibition of hydration dispersionDrilling compositionPolymer scienceSalt water

The invention discloses a high-temperature resistant polymer fluid loss agent for drilling fluid and a preparation method thereof. The polymer fluid loss agent is characterized in that the polymer fluid loss agent is a copolymer generated by olefine acid, alkenyl amide, alkenyl azululanone and alkenyl quaternary ammonium through reaction, molecules of the copolymer contain 800 to 1,800 structuralunits, and viscosity average molecular weight is 500,000 to 1,200,000. The polymer fluid loss agent can resist temperature of more than 245 DEG C in the drilling liquid, has good protective colloid performance to the drilling liquid, improves the quality of a filter cake, has good fluid loss reduction effect in fresh water, aggravated fresh water, salt water and the like, can simultaneously inhibit hydration and dispersion of clay and has good rheology.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

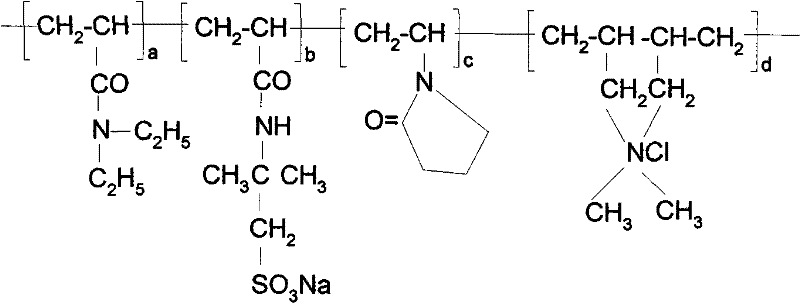

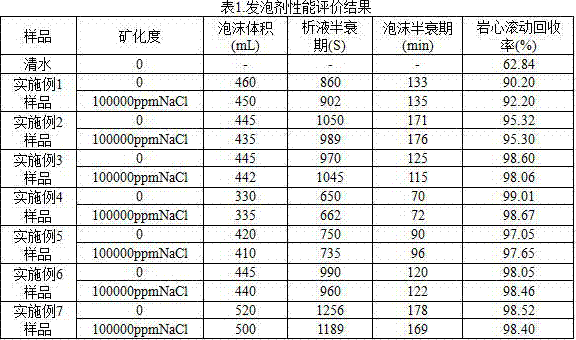

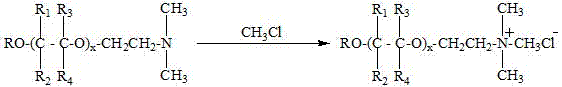

Salt-tolerant highly-inhibitive foaming agent for foam drilling of shale formation

ActiveCN107201217APromote adsorptionInhibition of hydration dispersionOrganic compound preparationDrilling compositionEtherCarbon chain

The invention belongs to the field of surfactants and particularly relates to a highly-inhibitive foaming agent for foam drilling of shale formation and a preparation method of the foaming agent. The foaming agent which is a surfactant is structurally characterized in that a quaternary ammonium salt and polyoxyalkyl ether structure in strong electric charge interaction with shale is introduced while an appropriate hydrophobic carbon chain length is kept. The preparation method includes that alkyl polyoxyalkyl ether dimethyl tertiary amine and methane chloride are subjected to quaternary amination to obtain a surfactant sample. When the foaming agent is applied to the shale formation, remarkable inhibition performance and salt tolerance are provided wile great foaming performance is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

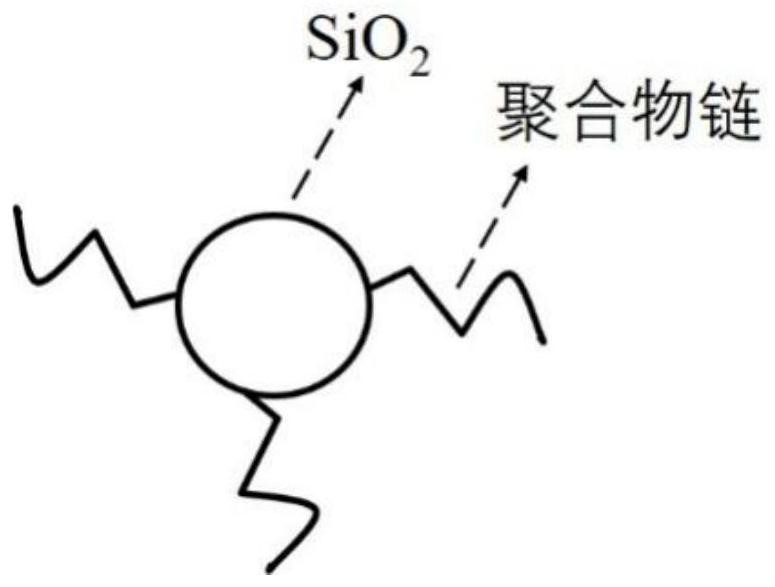

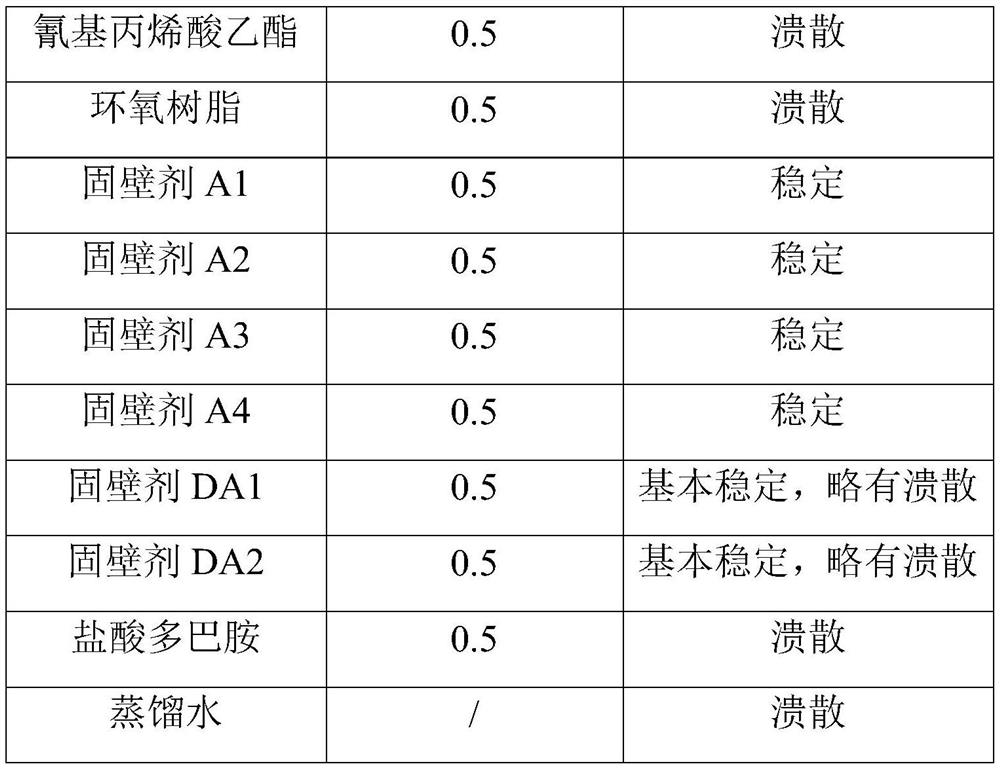

Cementing and blocking type wall fixing agent for water-based drilling fluid as well as preparation method and application of cementing and blocking type wall fixing agent

ActiveCN114716984AGood sealingStrong cementing functionOther chemical processesDrilling compositionMeth-Ethyl group

The invention relates to the technical field of well drilling, and discloses a cementing plugging type wall fixing agent as well as a preparation method and application thereof. The method comprises the following steps: (1) preparing a dispersion system A from nano silicon dioxide, preparing a dispersion system B from gamma-(methacryloyloxy) propyltrimethoxysilane, mixing the dispersion system A and the dispersion system B, adjusting the pH value to 8-9, adding phenothiazine for reaction, filtering after the reaction is finished, and washing and drying a product; (2) mixing the modified silicon dioxide prepared in the step (1), acrylamide, acrylic acid, sodium p-styrenesulfonate, dimethyl diallyl ammonium chloride, 1-ethyl-(3-dimethylaminopropyl) carbodiimide, dopamine hydrochloride and water, introducing protective gas to remove oxygen, and adding an initiator to react; and (3) washing, drying and crushing the product obtained in the step (2) to obtain the wall fixing agent. The wall fixing agent disclosed by the invention is beneficial to maintaining and even enhancing rock strength, so that an effect of stabilizing a fractured formation well wall is achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A dendritic quaternary ammonium salt shale inhibitor and its preparation method and application

ActiveCN106519254BEnhanced inhibitory effectInhibition of hydration dispersionDrilling compositionCyclic etherRoom temperature

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Coated inhibitor for drilling fluid and its preparation method and application

ActiveCN104449601BInhibition of hydration dispersionPrevent collapseDrilling compositionSynthesis methodsGlycerol

The invention provides a coating inhibitor for a drilling fluid as well as a preparation method and application thereof. The preparation method of the coating inhibitor comprises the following steps of: mixing a vegetable gelatin, anhydrous sodium carbonate, ethanol, water, glycerol, trimethylamine and epoxy chloropropane at a weight ratio of (240-260):(2.4-2.6):(750-1,000):(200-500):(5-10):(80-100):(400-440), and enabling the mixed system to react for 4.5-5 hours under the reflux condition to obtain the coating inhibitor. The coating inhibitor provided by the invention is a natural polymer strong coating inhibitor and has the advantages of strong coating inhibiting performance, strong salt and calcium resisting capacity, no biotoxicity and low cost, and in addition, the coating inhibitor can be biodegraded easily, is simple in synthesis method and is favorable for protecting the oil-gas layer.

Owner:北京培康佳业技术发展有限公司

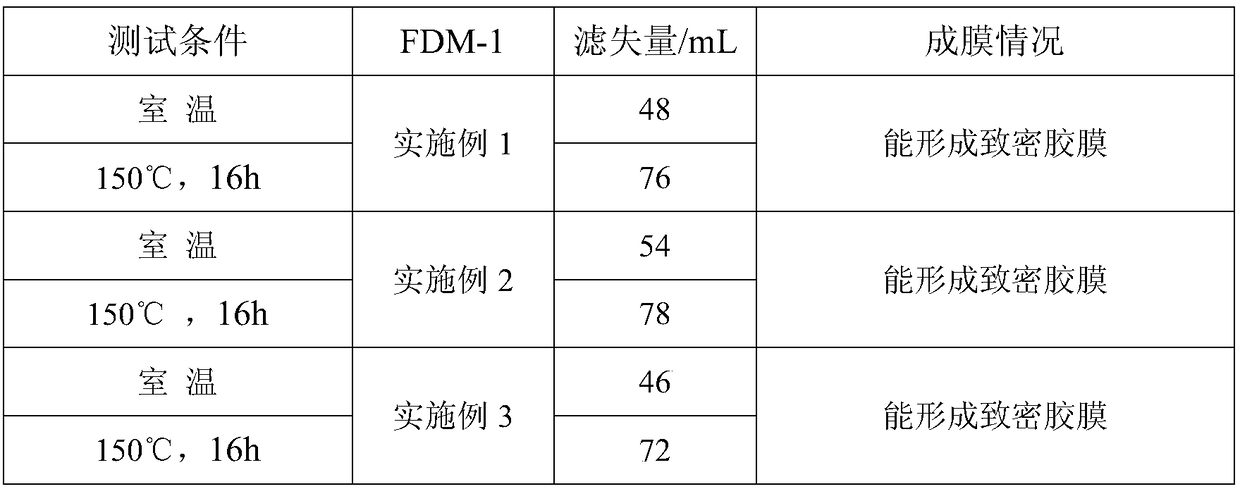

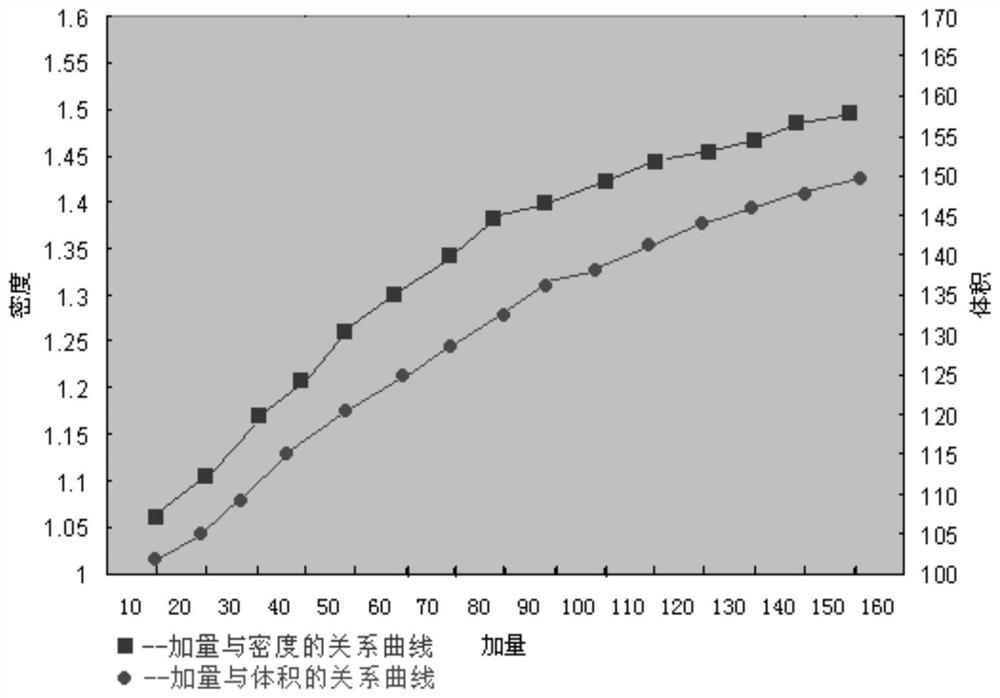

Multi-component vinyl polymer emulsion film-forming plugging agent for drilling fluid and preparation method thereof

ActiveCN106479456BImproved particle size distributionImprove toughnessDrilling compositionPolymer scienceSolvent

The invention provides a preparation method of a multielement vinyl polymer emulsion film forming blocking agent for a drilling fluid. The preparation method comprises the steps as follows: raw materials are prepared according to the component ratio; a solvent accounting for 4 / 5 of the formula quantity and an emulsifier are added to a No. 1 reactor in sequence, heated to 50-70 DEG C and stirred for 20-30min; then, styrene, maleic anhydride, acrylate, an initiator and a molecular weight regulator are added in sequence, the mixture is heated to 70-80 DEG C, timing for a reaction is started, and the mixture is stopped from being heated after 1 h and cooled; the solvent accounting for 1 / 5 of the formula quantity, a stabilizer, a deoxidant, a defoamer and modified nano-calcium carbonate are added to a No. 2 reactor in sequence and are stirred at the room temperature for 30-40 min; the mixture obtained in the previous step is added to the No. 1 reactor slowly and reacts at 40-50 DEG C for 2-3 h, and the multielement vinyl polymer emulsion film forming blocking agent is obtained. In combination with micro-scale deformable and cementing film forming particles, the blocking and collapse preventing capacity of the drilling fluid is improved, the mud cake quality is improved, the filter loss is reduced, the compatibility is good, and the temperature of 130 DEG C can be resisted.

Owner:成都西油华巍科技有限公司

Composite metal zwitterion polymer and its prepn and use

InactiveCN1181114CGood filter loss reduction effectInhibition of hydration dispersionDrilling accessoriesFiltrationFresh water

The present invention relates to composite metal zwitterions polymer and its preparation. They are used as treating agent for drilling fluid and well completion fluid. The composite metal zwitterions polymer is prepared through re-compounding cationic, anionic and non-ionic monomer and metal hydroxide in certain proportion and vaporizing and desolvating flash polymerization. The composite metal zwirrerions polymer has excellent filtration property, clay hydration dispersion inhibiting property, rheological property and pollution and temperature resistance in fresh water, salty water and saturated mud.

Owner:中国石油天然气股份有限公司勘探开发研究院

Clay-free low-solid horizontal drilling fluid and preparation method thereof

The invention relates to the technical field of drilling fluid used in the field of petroleum drilling engineering, and relates to a clay-free low-solid horizontal well section drilling fluid and a preparation method thereof. The clay-free low-solid horizontal well section drilling fluid is obtained by adding an alkalinity regulator to water , fluid loss reducer, cutting agent, superfine calcium carbonate, liquid lubricant and potassium chloride, and mixed to obtain. The process of the invention is simple and easy, low in cost, beneficial to cuttings carrying in the drilling process of the horizontal section, has good temporary plugging ability, complete plugging removal, ensures wellbore cleanliness, and avoids damage to reservoirs caused by highly dispersed clay particles , effectively prevent the solid and liquid phases from invading the formation, inhibit the hydration and dispersion of formation clay, and effectively control the depth of the pollution zone. In the well, it has good temperature resistance, and the highest temperature resistance can reach 140°C, which can be applied to all horizontal well reservoir sections with an inclined depth of no more than 5000m.

Owner:克拉玛依市金鑫科技有限公司

High-temperature water-based drilling fluid and preparation method thereof

ActiveCN110846004BGood resistance to salt and pollutionAppropriate viscosityDrilling compositionPolyethylene glycolPhysical chemistry

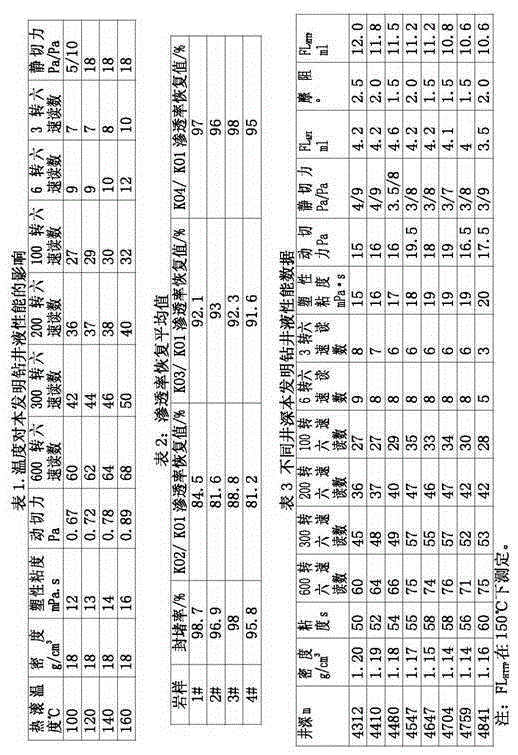

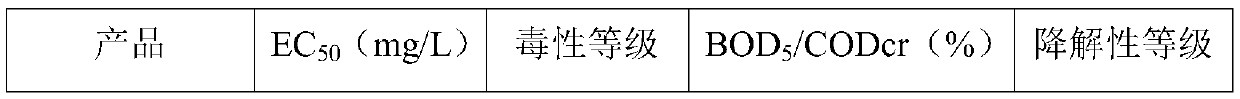

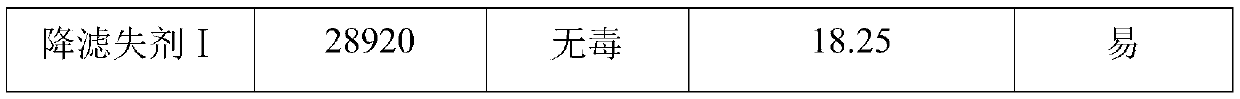

The invention discloses a high-temperature water-based drilling fluid. The high-temperature water-based drilling fluid comprises, by weight, 103 to 104 parts of base slurry, 1 to 1.5 parts of a filtrate reducer I, 1.5 to 2 parts of a filtrate reducer II, 2 to 2.5 parts of a filtrate reducer III, 2 parts of polyethylene glycol, 1 to 1.5 parts of aminosilanol, 3 to 5 parts of potassium chloride, 2 to 2.5 parts of a lubricant, 0.6 to 1 part of calcium carbonate powder with a size of 600 to 800 meshes, 1.2 to 1.5 parts of modified diatomite with a size of 400 to 500 meshes and barite with an addition amount that allows the high-temperature water-based drilling fluid to be weighted to 1.4-1.7 g / cm<3>. The invention also discloses a preparation method of the high-temperature water-based drillingfluid. The drilling fluid has the beneficial effects of resisting high temperature and reducing the permeability and the filter loss of the drilling fluid.

Owner:BEIJING DADE GUANGYUAN PETROLEUM TECH SERVICE

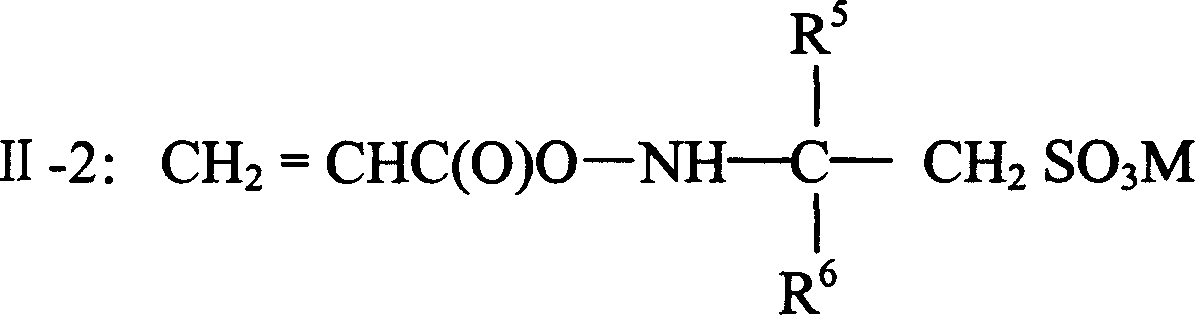

Salt-resistant filtrate-loss reducer for drilling fluid and preparation method of salt-resistant filtrate-loss reducer

InactiveCN104531099AMild molecular strengthChange molecular strengthDrilling compositionSolubilityFresh water organism

The invention discloses a salt-resistant filtrate-loss reducer for a drilling fluid. The salt-resistant filtrate-loss reducer comprises the following raw materials: 2400-3600kg of acrylamide, 180-350kg of sodium carbonate, 0-200kg of 2-acrylamide-2-methyl propane sulfonic acid, 100-300kg of hydroxide calcium and 5-10kg of N,N-methylenebisacrylamide. The preparation method of the salt-resistant filtrate-loss reducer comprises the steps of polymerizing the raw materials, modifying and the like. The salt-resistant filtrate-loss reducer has the advantages of proper viscosity, very strong water solubility, good compatibility, low filtrate loss and strong salt resistance and can be used in combination with different drilling fluids, also can be used in various freshwater and saltwater drilling fluids and can inhibit the hydration dispersion of shale; the addition amount of the salt-resistant filtrate-loss reducer in freshwater is 0.2%-0.5% and the addition amount of the salt-resistant filtrate-loss reducer in saltwater is 1.0%-2.0%.

Owner:HEBEI GUANGDA PETROCHEM

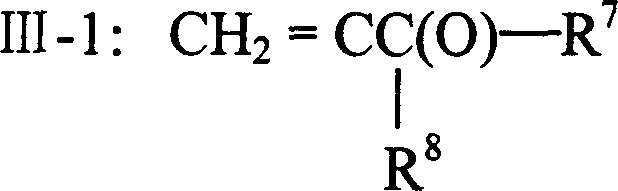

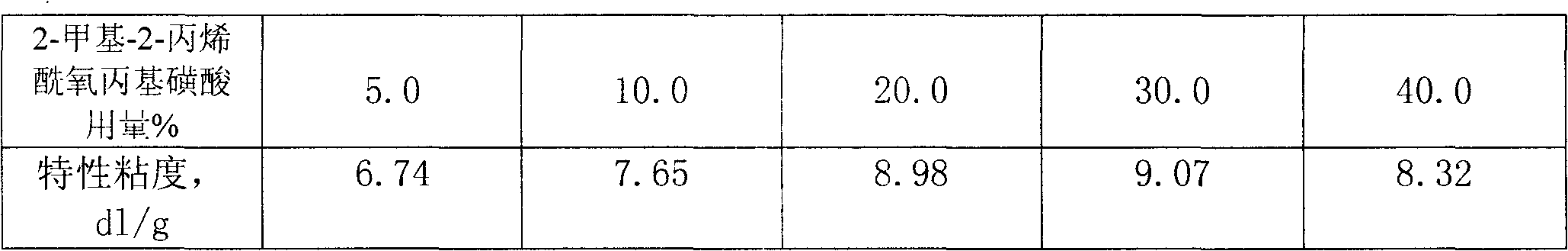

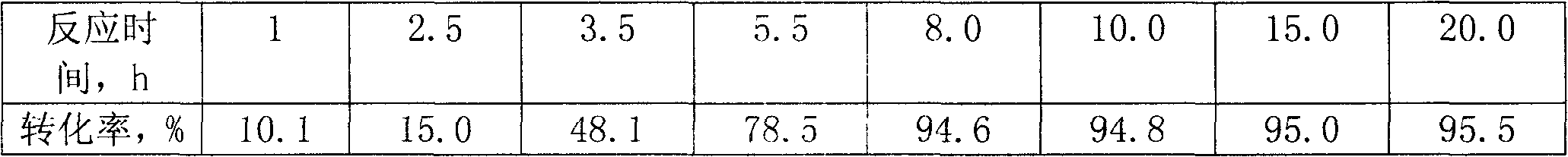

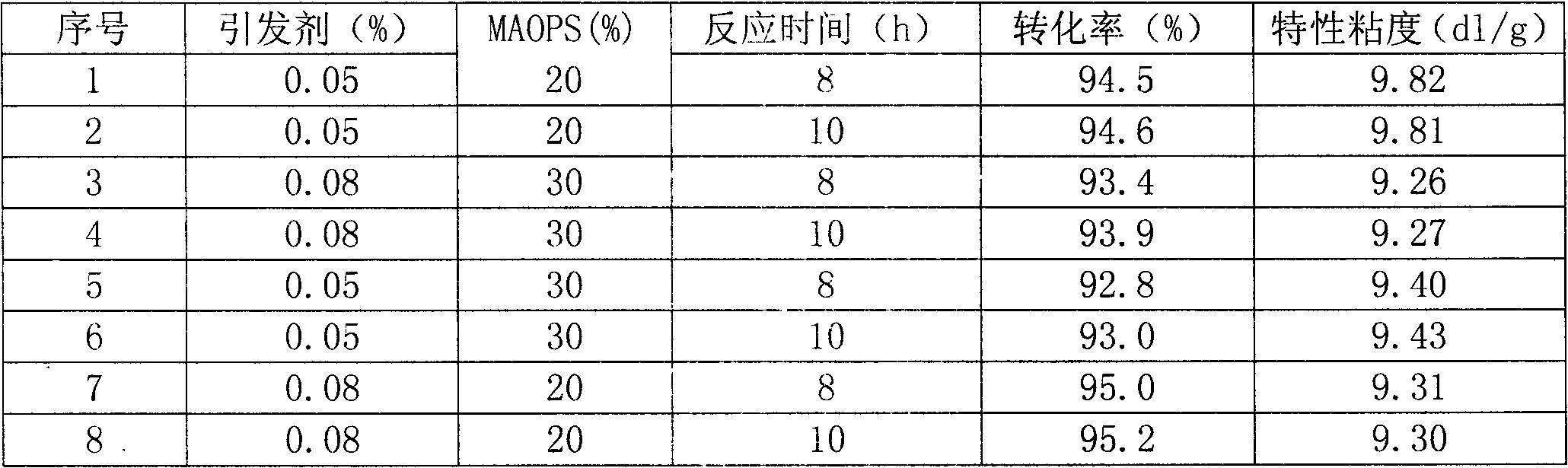

Production method of polymer for drilling fluid

The invention discloses a production method of a polymer for a drilling fluid, comprising the following steps: dissolving 2-methyl-2- acyloxy propyl sulfonate in water, then adding water in equimolar sodium hydroxide, stirring for dissolving and cooling, mixing the two mixtures and then adding a proper amount of acrylamide and acrylic acid, stirring for dissolving, heating up the mixed liquid to 35 DEG C with introducing nitrogen, then adding an initiating agent having an amount accounting for 0.05-0.08 % of the total weight of acrylamide and acrylic acid, uniformly stirring, then introducing nitrogen for a certain time, reacting for 8-10 h at a constant temperature of 35 DEG C to obtain a gel product, cutting and pelleting the gel product, and drying to obtain the polymer for the drilling fluid. The polymer produced by the invention has strong salt resistance and calcium pollution resistance, strong ability to inhibit clay hydrating and dispersing, and strong flocculation and coating capacities, can be applied in fresh water drilling fluid, salt-water drilling fluid, saturated salt-water drilling fluid, seawater drilling fluid and other drilling fluids, and has good compatibility with other treating agents to drilling fluid.

Owner:HUIXIAN AEROSPACE CHEM NO 1 FACTORY

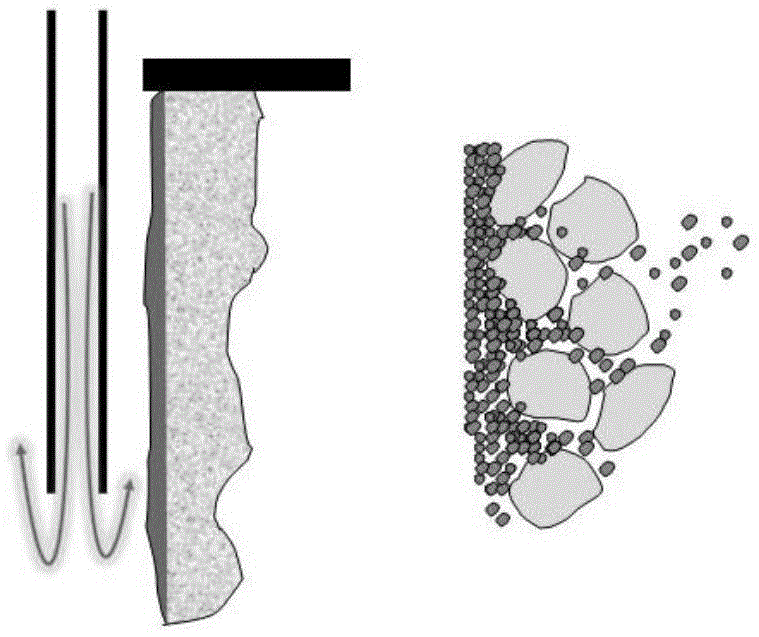

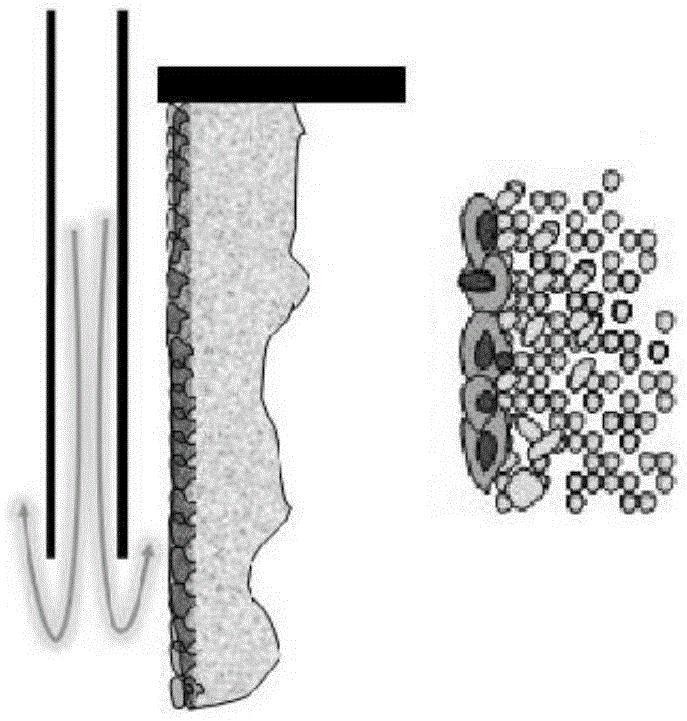

Mosaic shielding drilling fluid

The invention relates to mosaic shielding drilling fluid, which comprises the following components by weight content: 0.2-8.5% of mosaic shielding agent, 0-5% of adhesion agent, 0-8% of weighting agent and the balance of base liquid, the mosaic shielding agent is added in water with a monomer, an initiator, a dispersant and rigid core, the components are uniformly stirred and heated to a reaction, and then dried to obtain the drilling fluid. The drilling fluid has unidirectional plugging effect due to usage of the mosaic shielding agent, and has good adaptability for inlet apertures with different shapes due to elastic variability characteristic, and the oil well production power can not be influenced.

Owner:东营市大用石油助剂有限责任公司

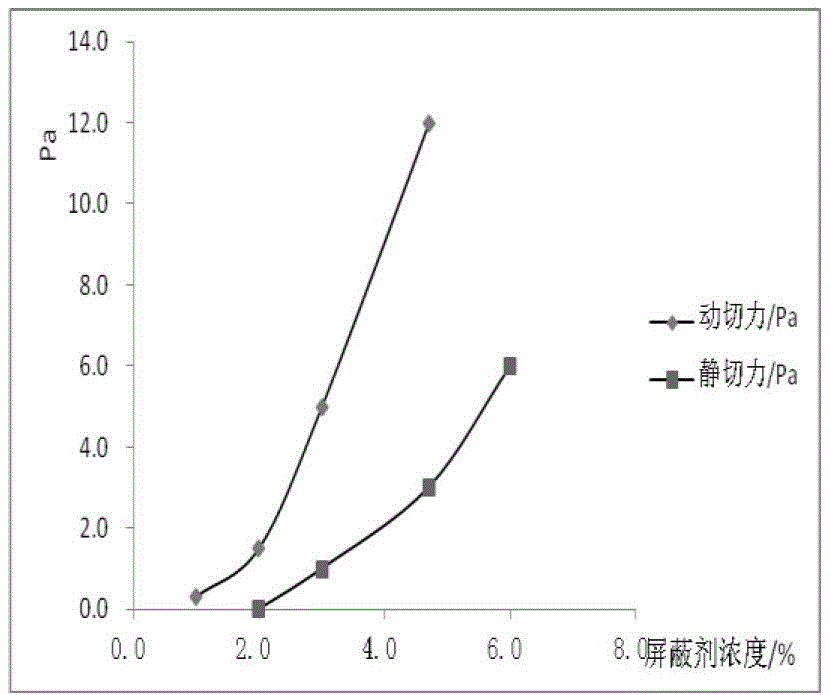

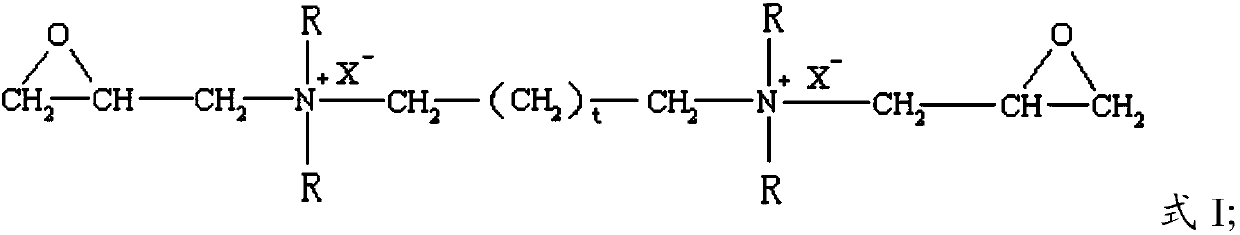

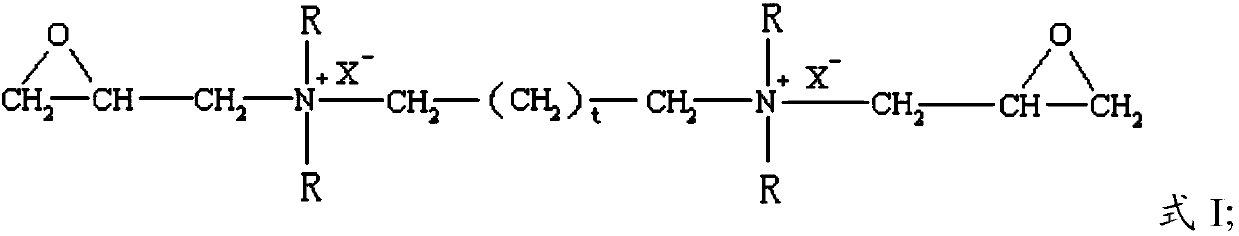

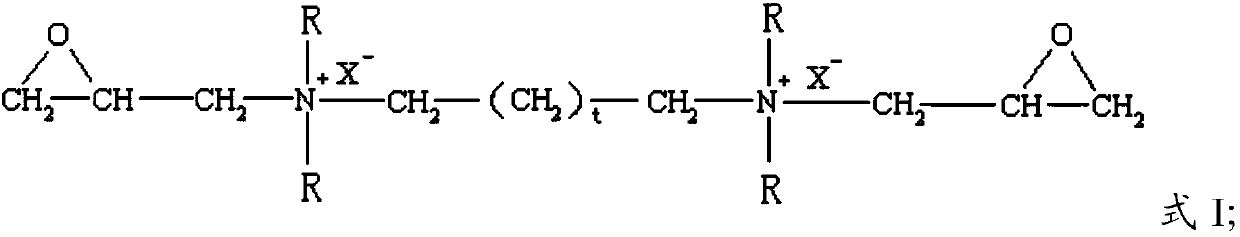

Modified cationic compound and preparation method thereof, and solid phase chemical cleaning agent for drilling fluids

ActiveCN109912545AInhibition of hydration dispersionGuaranteed cleanlinessOrganic chemistryDrilling compositionSolid phasesHalogen

The invention belongs to the technical field of water-soluble cationic compounds in petroleum drilling oilfield chemistry, and provides a modified cationic compound and a preparation method thereof, and a solid phase chemical cleaning agent for drilling fluids, wherein the modified cationic compound has a structure represented by a formula I, R is C1-C5 alkyl, X is halogen, t is an arbitrary integer selected from 0-6, and the solid phase chemical cleaning agent comprises an iron salt, an ammonium salt, a silicate and the modified cationic compound. According to the present invention, the solidphase chemical cleaning agent for drilling fluids is obtained by using the modified cationic compound, wherein the modified cationic compound has the structure represented by the formula I, and has double effects of flocculation and inhibition, such that the inhibition ability of drilling fluids and the drilling fluid solid phase removal efficiency can be improved so as to achieve low solid phaserapid drilling. The formula I is defined in the specification.

Owner:SINOPEC SSC +1

Application of modified chitosan as shale inhibitor and application of temperature-resistant and environmentally friendly water-based drilling fluid

ActiveCN106367042BImprove temperature resistanceBiodegradableDrilling compositionWater basedWell drilling

The invention relates to the field of well drilling in petroleum industry, and particularly relates to an application of modified chitosan as a shale inhibitor and an application of an anti-temperature and environment-friendly water-based drilling fluid. The modified chitosan has a modifying group represented as the formula (1). The modified chitosan is applied in oil and gas drilling as the shale inhibitor, especially, shale gas well drilling, thereby achieving excellent inhibition effects. The modified chitosan has excellent temperature resistance, so that a high inhibition effect can be maintained even at a high temperature for a long time. The modified chitosan also has the biodegradability of chitosan and belongs to environment-friendly shale inhibitors.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Water-based drilling fluid composition and water-based drilling fluid

PendingCN114836178AInhibition of hydration dispersionPromotes wellbore stabilityDrilling compositionDrill cuttingsPetrology

The invention provides a water-based drilling fluid composition and a water-based drilling fluid. The water-based drilling fluid composition comprises the following components in parts by weight: 100 parts of water, 4-10 parts of a filtrate reducer, 2-7 parts of a cationic polyacrylamide polymer inhibitor and 2-9 parts of a nano silicon dioxide blocking agent. On one hand, positive charges carried by the electropositive drilling fluid system containing the cationic polyacrylamide polymer inhibitor can reduce negative potentials of clay minerals and drilling cuttings, and well wall stability is promoted. And on the other hand, the nano-sized silicon dioxide blocking agent can reduce filtrate invasion and pressure transfer effect, so that the water-based drilling fluid can effectively solve the problem of borehole wall instability in the shale formation drilling process based on the two effects. Meanwhile, the electropositive drilling fluid system containing the cationic polyacrylamide polymer inhibitor can inhibit dispersion of drilling cuttings, so that the drilling speed is increased, and the raw materials are wide in source and low in cost.

Owner:PETROCHINA CO LTD

A kind of preparation method of starch graft copolymer inverse emulsion for drilling fluid

ActiveCN103113524BImprove the lubrication effectGood anti-collapse abilityDrilling compositionWater basedPotassium hydroxide

The invention relates to a method for preparing a starch graft copolymer inverse emulsion for drilling fluid, which comprises the following steps: adding an emulsifier sorbitan oleate into white oil, stirring and dissolving, and passing nitrogen to obtain an oil phase; Dissolve potassium oxide in water, add 2‑acrylamido‑2‑methylpropanesulfonic acid, acrylamide, vinyl monomer, cationic monomer, polyoxyethylene sorbitan fatty acid ester, ethylenediaminetetraacetic acid di Sodium salt, starch, stir to obtain water phase; add water phase to oil phase, fully emulsify, adjust pH value, pass nitrogen, add initiator and reducing agent, under nitrogen protection, stir to heat up, keep warm, cool down, discharge, filter The starch graft copolymer inverse emulsion for drilling fluid was obtained. As a drilling fluid treatment agent, this product has good fluid loss reduction, viscosity increase, flow regulation, and the ability to inhibit the hydration and dispersion of clay and cuttings. It can improve the quality of filter cake, improve the lubricity of drilling fluid, and reduce the cost of drilling fluid treatment. , suitable for various types of water-based drilling fluids.

Owner:CHINA PETROLEUM & CHEM CORP +1

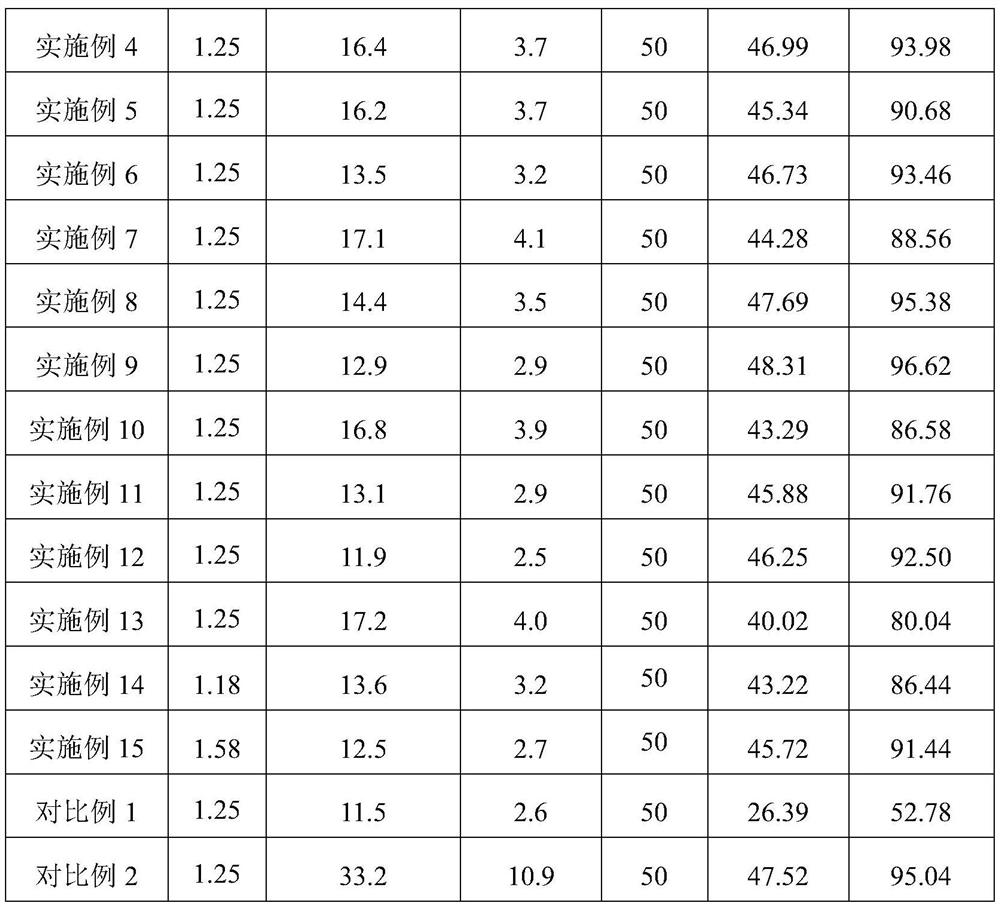

Organic salt weighting agent

PendingCN112760085AInhibition of wellbore fracturesIncrease ROPDrilling compositionCarboxylateOrganic acid

The invention discloses an organic salt weighting agent which comprises an organic salt, the molecular formula of the organic salt is AR(COO)nMn, wherein A is a heteroatom or a group with a heteroatom, R is an organic carbon chain with a carbon number of 1-6, COO<-> is an organic carboxylate radical, and M is a metal cation or an ammonium ion. The organic salt weighting agent disclosed by the invention has the chemical molecular structure characteristics of formate, namely contains organic acid radicals such as COO <-> and cations such as low-valence alkali metal ions, shows relatively high density and relatively good temperature-resistant stability and inhibitive ability, can resist various types of pollution, and is beneficial to protecting an oil and gas reservoir. The drilling speed can be increased by using the drilling fluid, and production verifies that the drilling fluid is very suitable for drilling operation of complex wells in the Duha oil field.

Owner:KARAMAY CITY YIEN TECHN SERVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com