Multi-component vinyl polymer emulsion film-forming plugging agent for drilling fluid and preparation method thereof

A film-forming plugging agent, based polymer technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of exploration and development work loss, prolonged drilling construction period, high illite content, and achieve significant flexibility Blocking effect, good compatibility, inhibition of hydration and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

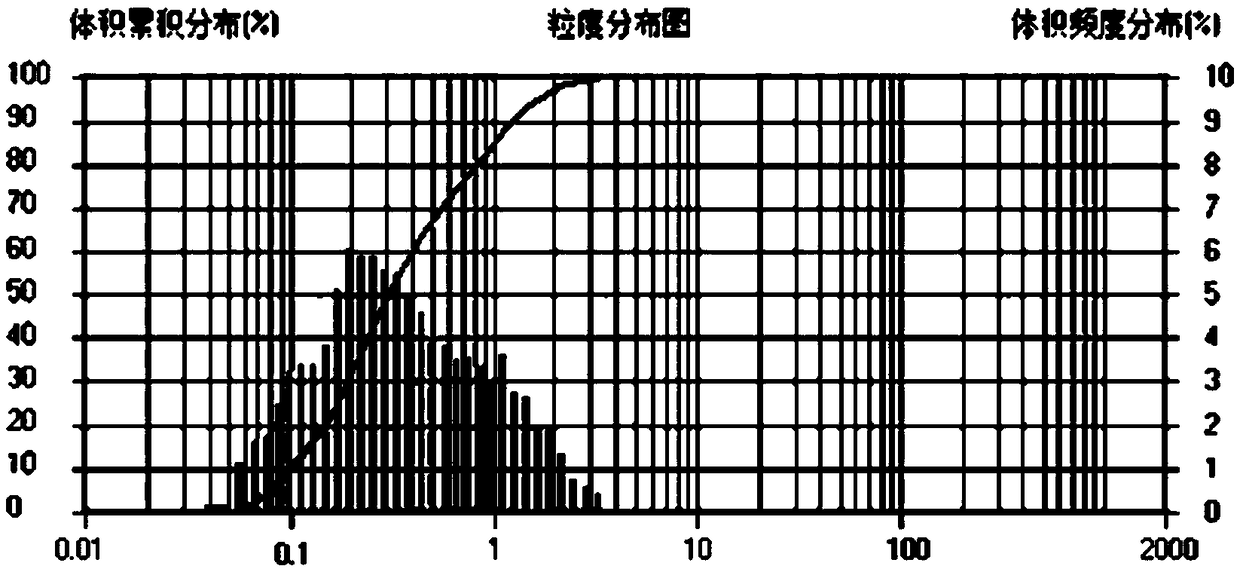

Image

Examples

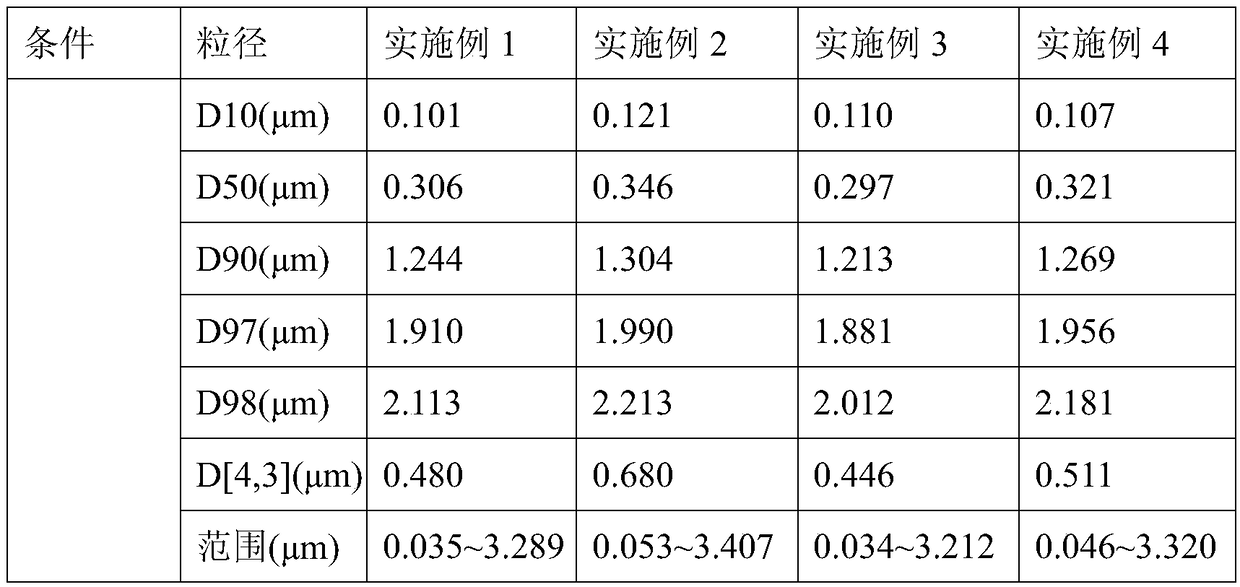

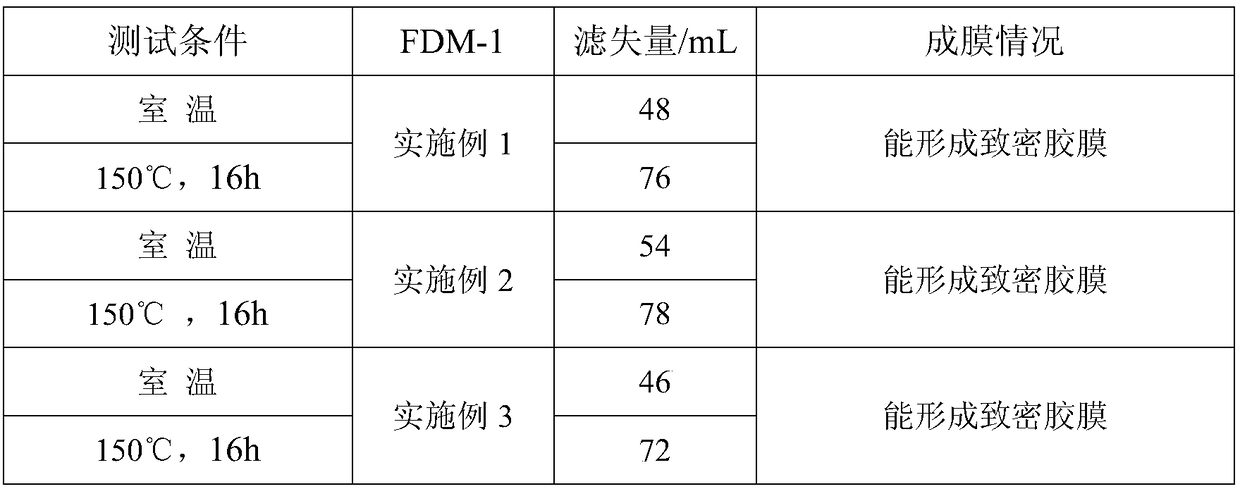

Embodiment 1

[0035] Embodiment 1: prepare raw materials according to quality and 100%, adopt industrial grade raw materials: styrene 18%, maleic anhydride 14.2%, acrylate 7.5%, benzoyl hydroperoxide 0.5%, tertiary dodecyl mercaptan 1%, Potassium rosinate soap 6%, sodium alginate 8%, modified nano-calcium carbonate 1%, sodium dithionite 2%, polydimethylsiloxane 2%, and the balance is ionized water. In the No. 1 reaction kettle, add the formula amount of ionized water 4 / 5 and potassium rosinate soap in sequence, raise the temperature to 50-70°C, and stir for 20 minutes; then add styrene, maleic anhydride, acrylate, and benzoyl hydroperoxide in sequence , tert-dodecyl mercaptan, raise the temperature to 70°C, start timing the reaction, stop heating after 1h, and lower the temperature; add 1 / 5 of the formula amount of ionized water, sodium alginate, sodium dithionite, Polydimethylsiloxane and modified nano-calcium carbonate were stirred at room temperature for 30 minutes; the mixture obtained ...

Embodiment 2

[0036] Embodiment 2: prepare raw materials according to quality and 100%, adopt industrial grade raw materials: styrene 20%, maleic anhydride 16%, acrylate 5%, benzoyl hydroperoxide 0.2%, tertiary dodecyl mercaptan 0.5%, Potassium rosinate soap 3%, sodium alginate 5%, modified nano-calcium carbonate 1%, sodium dithionite 0.5%, polydimethylsiloxane 0.5%, and the balance is ionized water. In the No. 1 reaction kettle, add the formula amount of ionized water 4 / 5, potassium abietate soap successively, raise the temperature to 70°C, and stir for 30 minutes; then add styrene, maleic anhydride, acrylate, benzoyl hydroperoxide, tert- For dodecyl mercaptan, raise the temperature to 80°C, start timing the reaction, stop heating after 1 hour, and lower the temperature; add 1 / 5 of the formula amount of ionized water, sodium alginate, sodium dithionite, and Methyl siloxane, modified nano-calcium carbonate, stirred at room temperature for 40 minutes; the mixture obtained in No. 2 reactor wa...

Embodiment 3

[0037] Embodiment 3: prepare raw materials according to quality and 100%, adopt industrial grade raw materials: styrene 19%, maleic anhydride 15%, acrylate 6%, benzoyl hydroperoxide 0.4%, tertiary dodecyl mercaptan 0.8%, Potassium rosinate soap 5%, sodium alginate 6%, modified nano-calcium carbonate 1%, sodium dithionite 1%, polydimethylsiloxane 01%, and the balance is ionized water. In the No. 1 reaction kettle, add the formula amount of ionized water 4 / 5, potassium abietate soap successively, raise the temperature to 60°C, and stir for 25 minutes; then add styrene, maleic anhydride, acrylate, benzoyl hydroperoxide, tert- For dodecyl mercaptan, raise the temperature to 75°C, start timing the reaction, stop heating after 1 hour, and lower the temperature; add 1 / 5 of the formula amount of ionized water, sodium alginate, sodium dithionite, poly di Methyl siloxane, modified nano-calcium carbonate, stirred at room temperature for 35 minutes; slowly add the mixture obtained from No...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com