Patents

Literature

49results about How to "Stop the collapse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

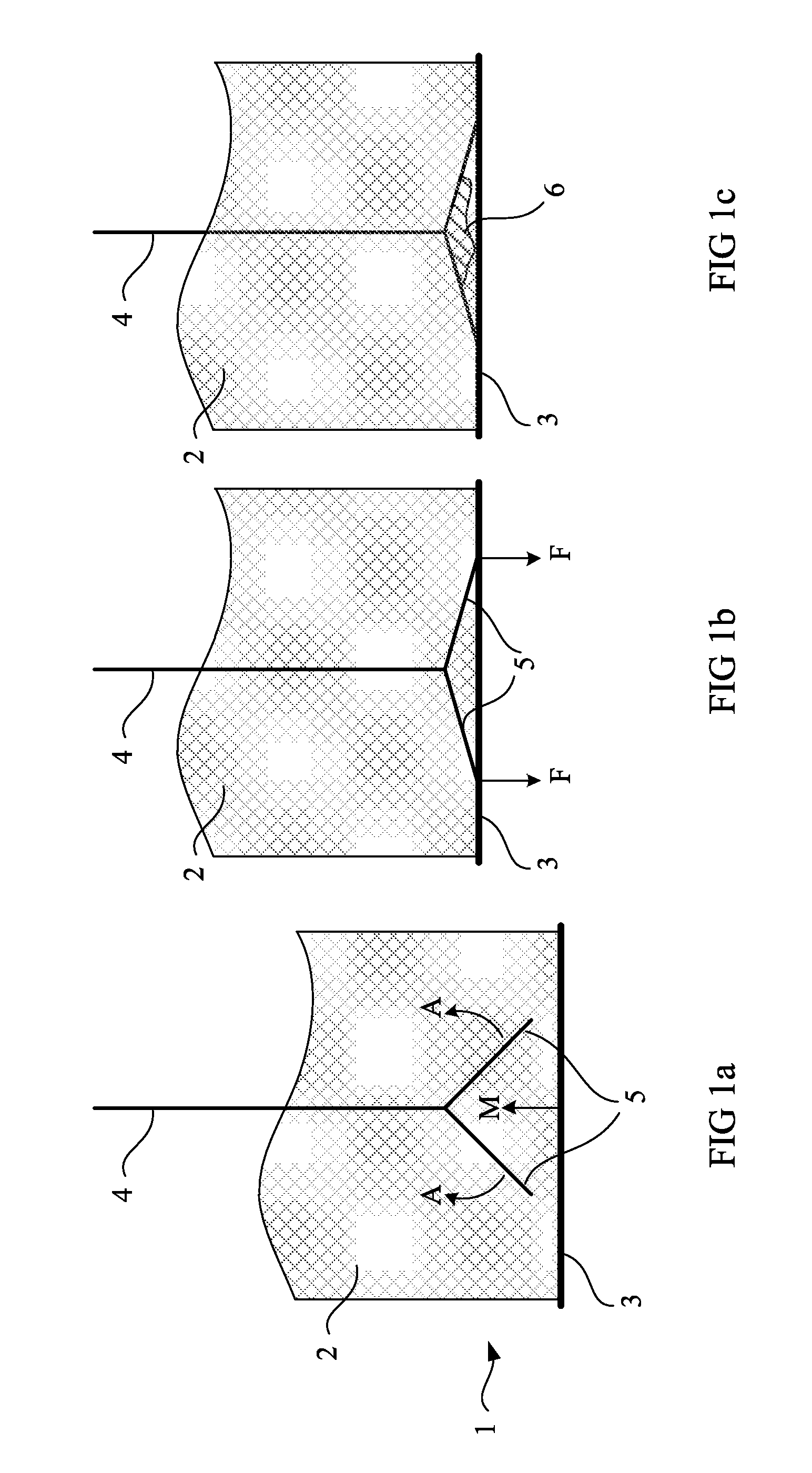

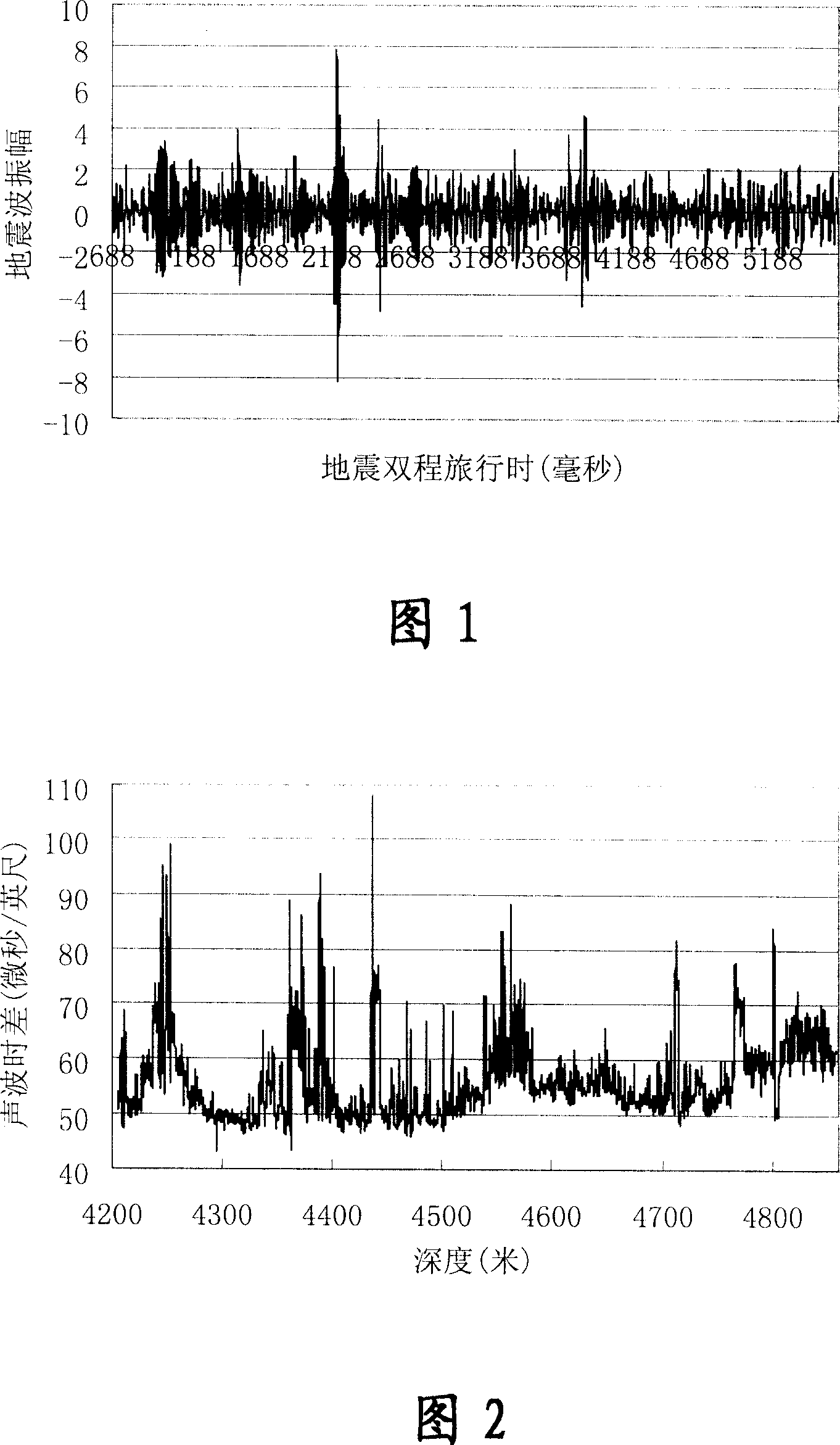

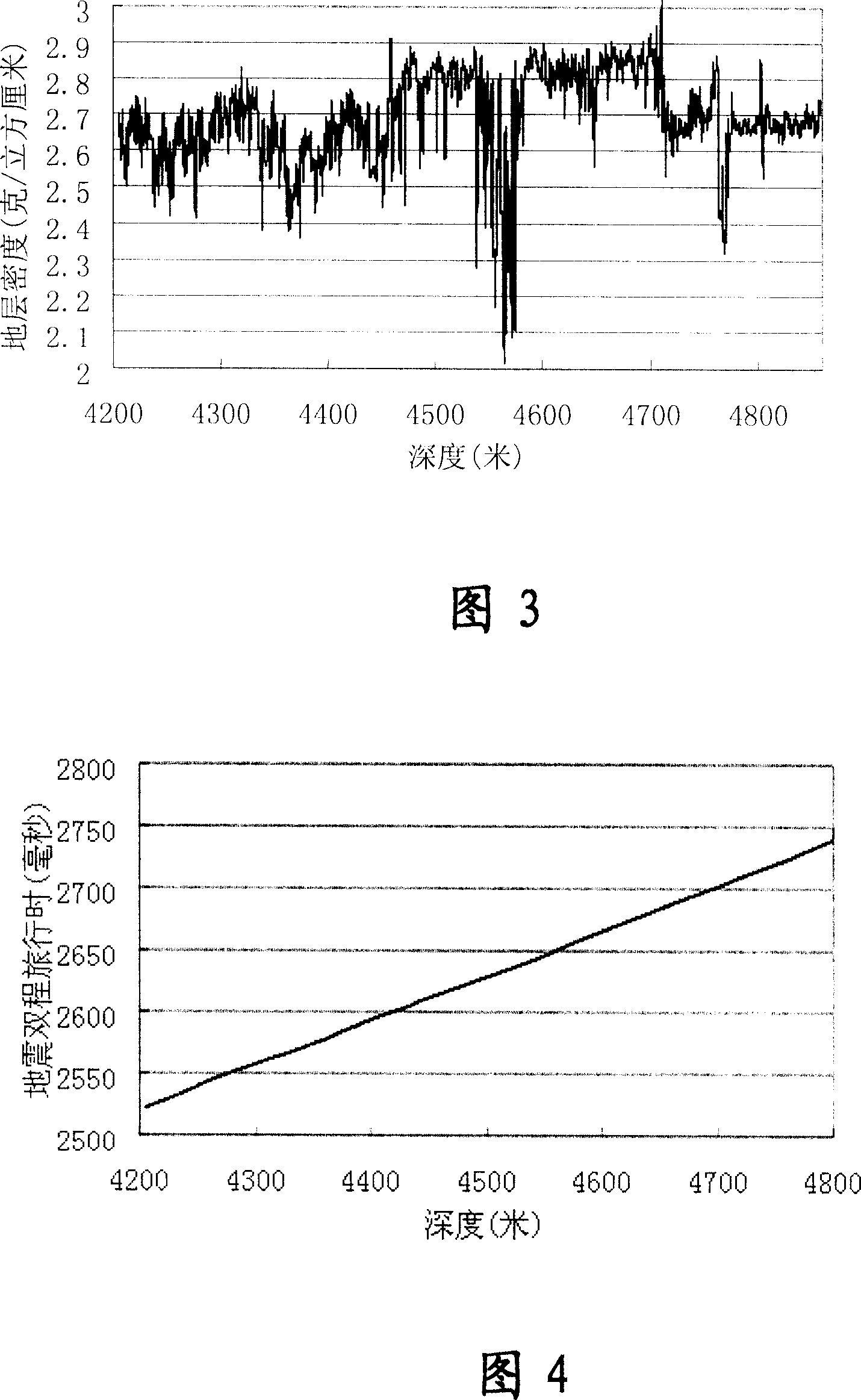

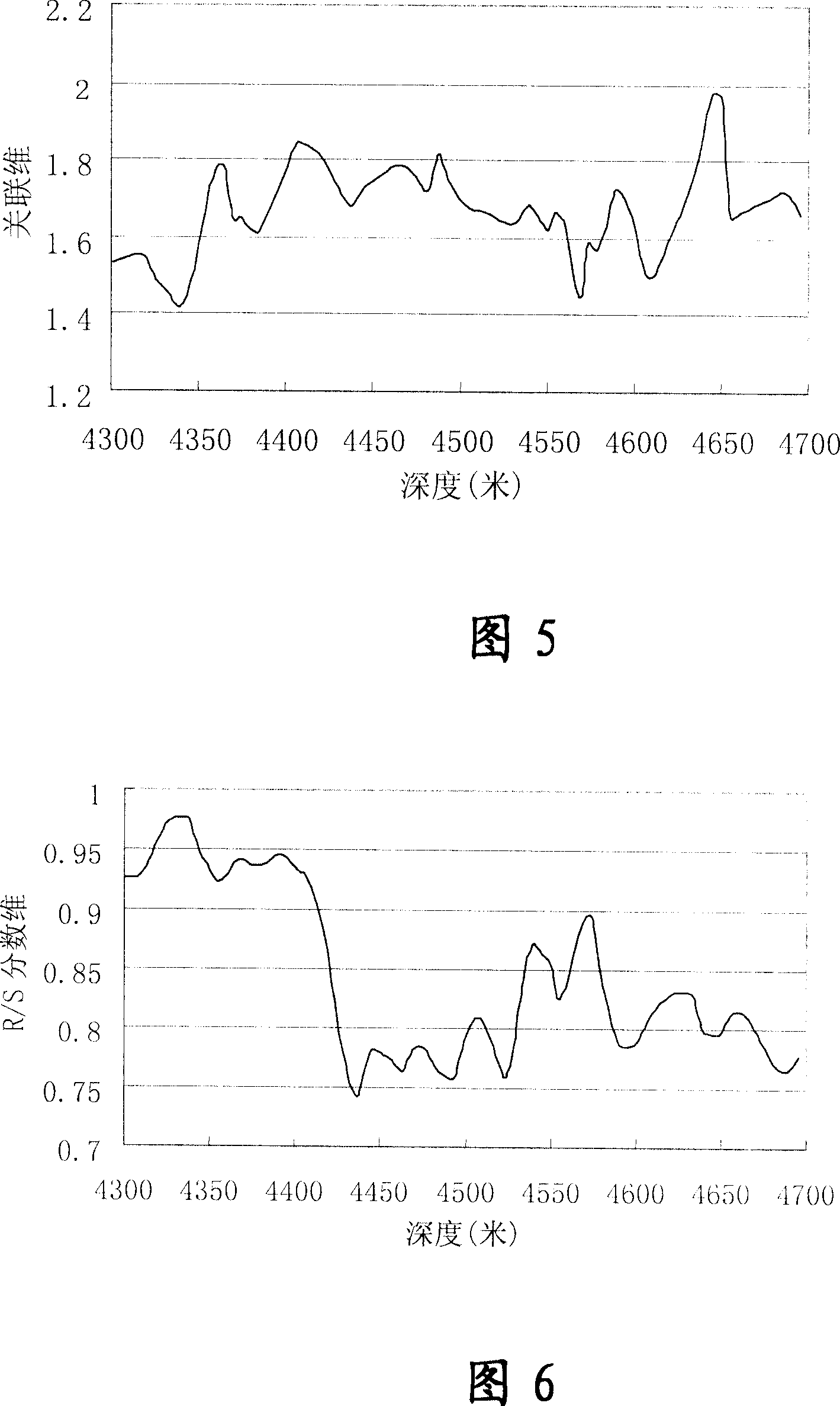

Method for prediction of collapse pressure and fracture pressure of stratum under drill bit while drilling

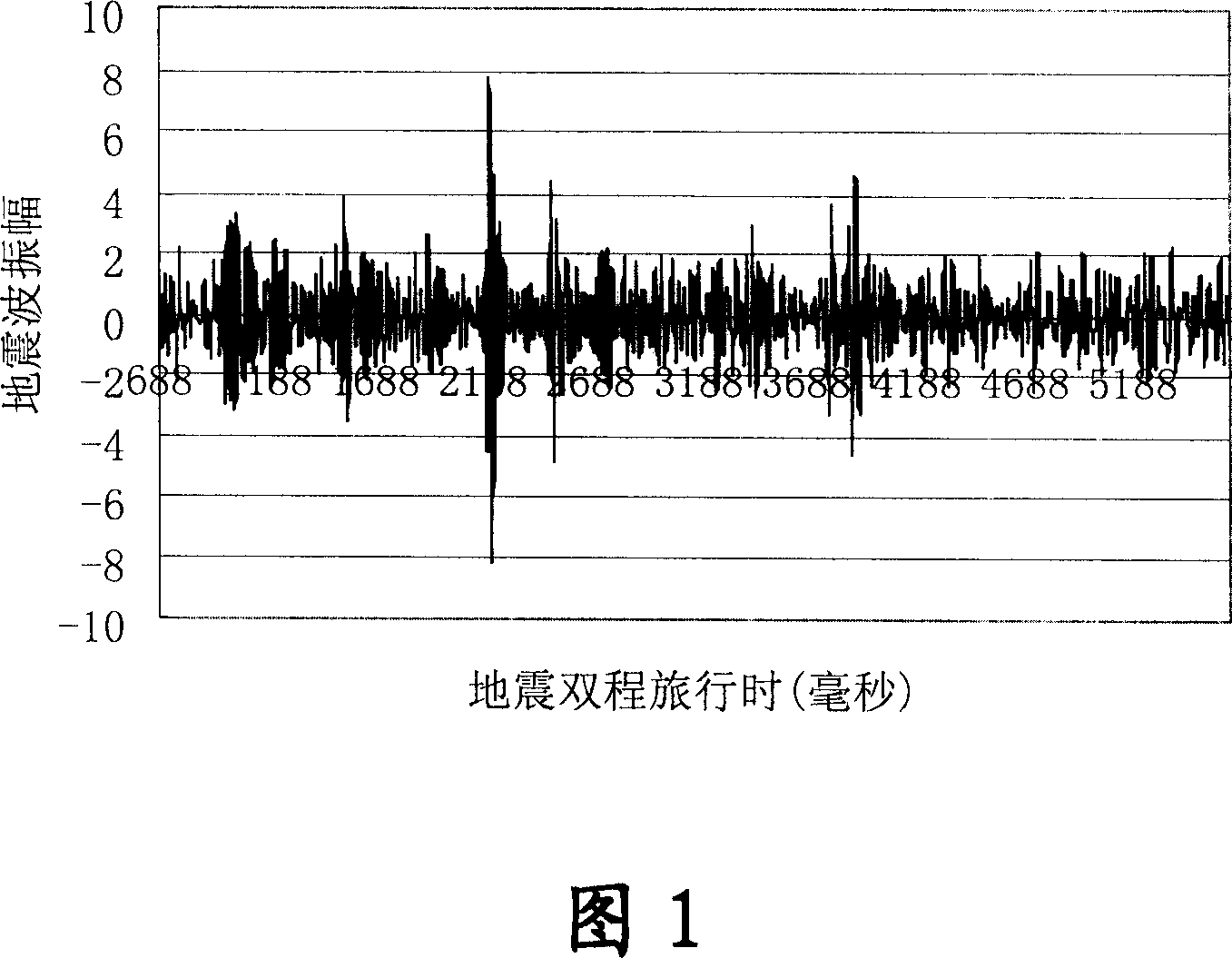

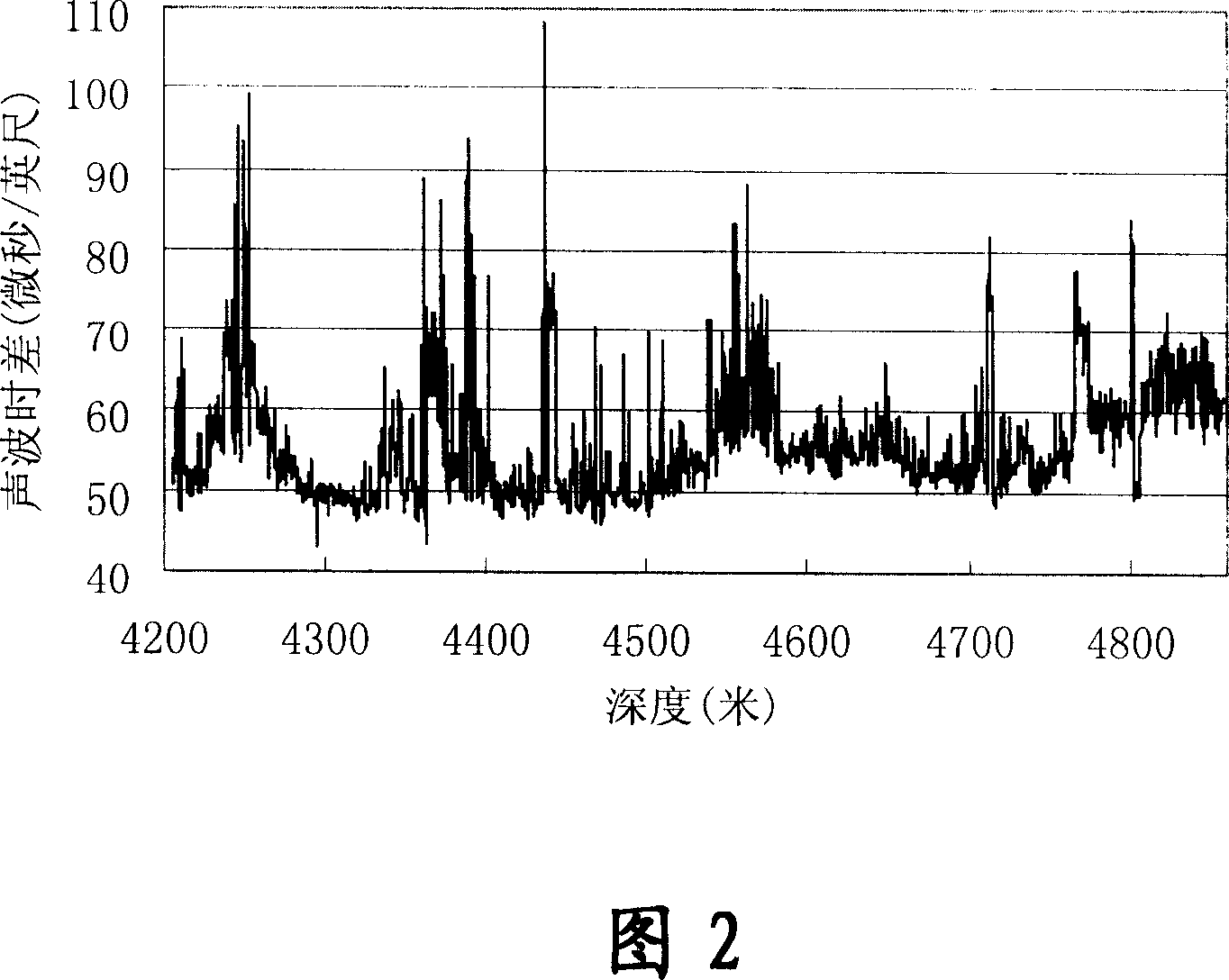

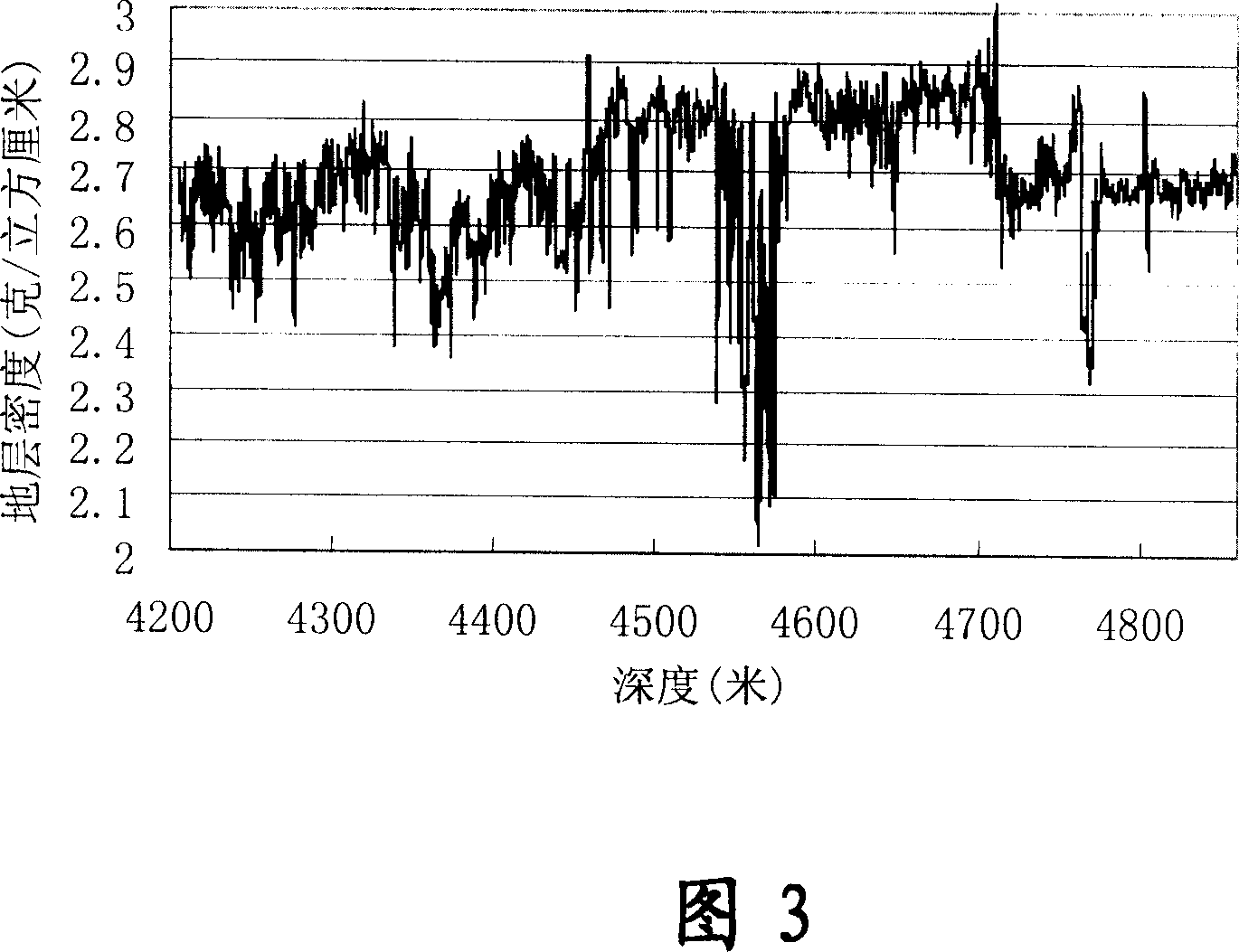

It relates to a method of predicting the collapse and crack pressure underground with the drilling head. Recording the earthquake status of a well to be drilled and several other adjacent drills that have already been drilled, getting the earthquake record of the well to be drill and already drilled through weighting, through sound wave echoing difference and density measuring for the already drilled wells to get the log data of different strata, a hierarchical model can be established to predict the sound wave speed and wave resistance of each strata based on the earthquake record. Through the log curve predicted of the strata of the well to be drilled, the collapse and crack pressure of the strata can be predicted combined with the interpretative model of the well wall stability mechanics logging. It can effectively prevent the collapse of the well wall and accidents occurrence underground.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

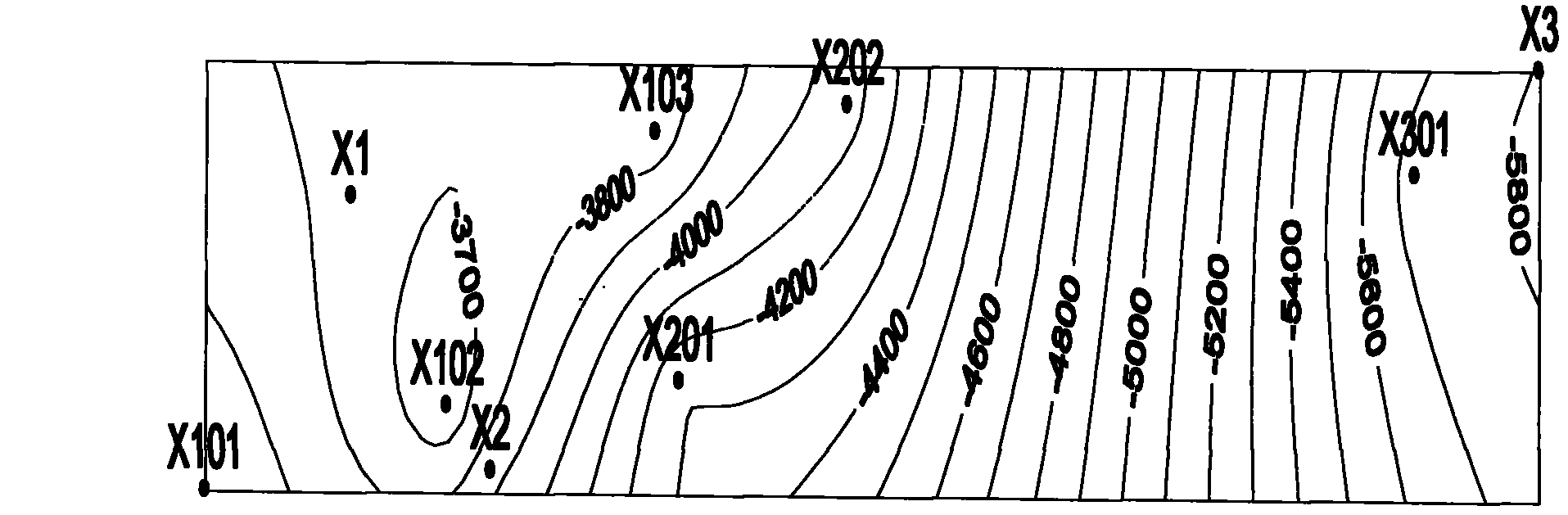

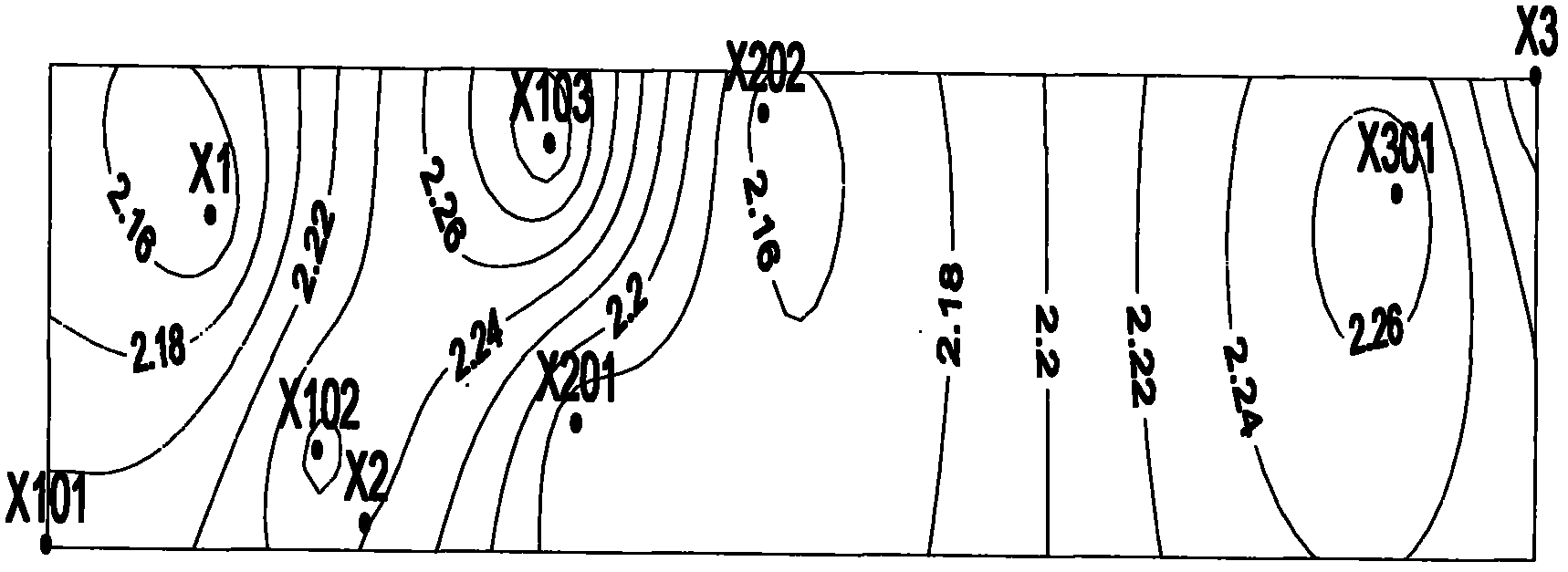

Method for predicting pore pressure of regional high-pressure saltwater layer by utilizing curvature of face of geologic structure

InactiveCN101942992AStop the well wall from collapsingPrevent downhole complicationsBorehole/well accessoriesGypsumGeomorphology

The invention discloses a method for predicting pore pressure of a regional high-pressure saltwater layer by utilizing a curvature of face of geologic structure. The method comprises the following steps of: determining a regional distribution regularity of salt and gypsum layers by utilizing seismic data and actual drilling logging data and constructing a contour map, constructing a regional height equation on the contour map by a harmonic trend surface method and determining the main curvature of any point constructing the region, calculating the main stress of any point, establishing a pore pressure prediction model of any point, and determining the pore pressure of the high-pressure saltwater layer. By the method, the scientific evidence for determining the safe density of drilling liquid is provided in field construction of drilling design so as to effectively prevent collapse of the well walls and avoid underground accidents.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Nanometer drilling fluid

InactiveCN101538456AReduce the pore radiusReduce porosityDrilling compositionSodium BentoniteEmulsion

The invention relates to nanometer drilling fluid. The concentration of the nanometer drilling fluid comprises 900kg / m<3> of water, 40-50kg / m<3> of bentonite, 25-30kg / m<3> of nanometer emulsion JDL-3, 2-3kg / m<3> of cationic gel MMH, 3-5kg / m<3> of high molecular polymer PAM, 10-15kg / m<3> of sulfonated gilsonite FT-1, 15-20kg / m<3> of sulfonated phenolic resin SMP, 15-20kg / m<3> of salt and temperature resistant fluid loss agent LS-1, 10-15kg / m<3> of flow type regulating agent DS-2 and 8-10kg / m<3> of sodium hydroxide (NaOH). The nanometer drilling fluid has good colloid dispersivity and high heat stability, improves the rheology of the drilling fluid, increases the compactness of mud cakes, improves the thickness of the mud cakes, quickly forms a layer of nanometer film on a well wall, prevents the drilling fluid from invading stratums near the well wall and pressure from being transmitted and has good anti-caving performance and good storage layer protection performance.

Owner:XI'AN PETROLEUM UNIVERSITY

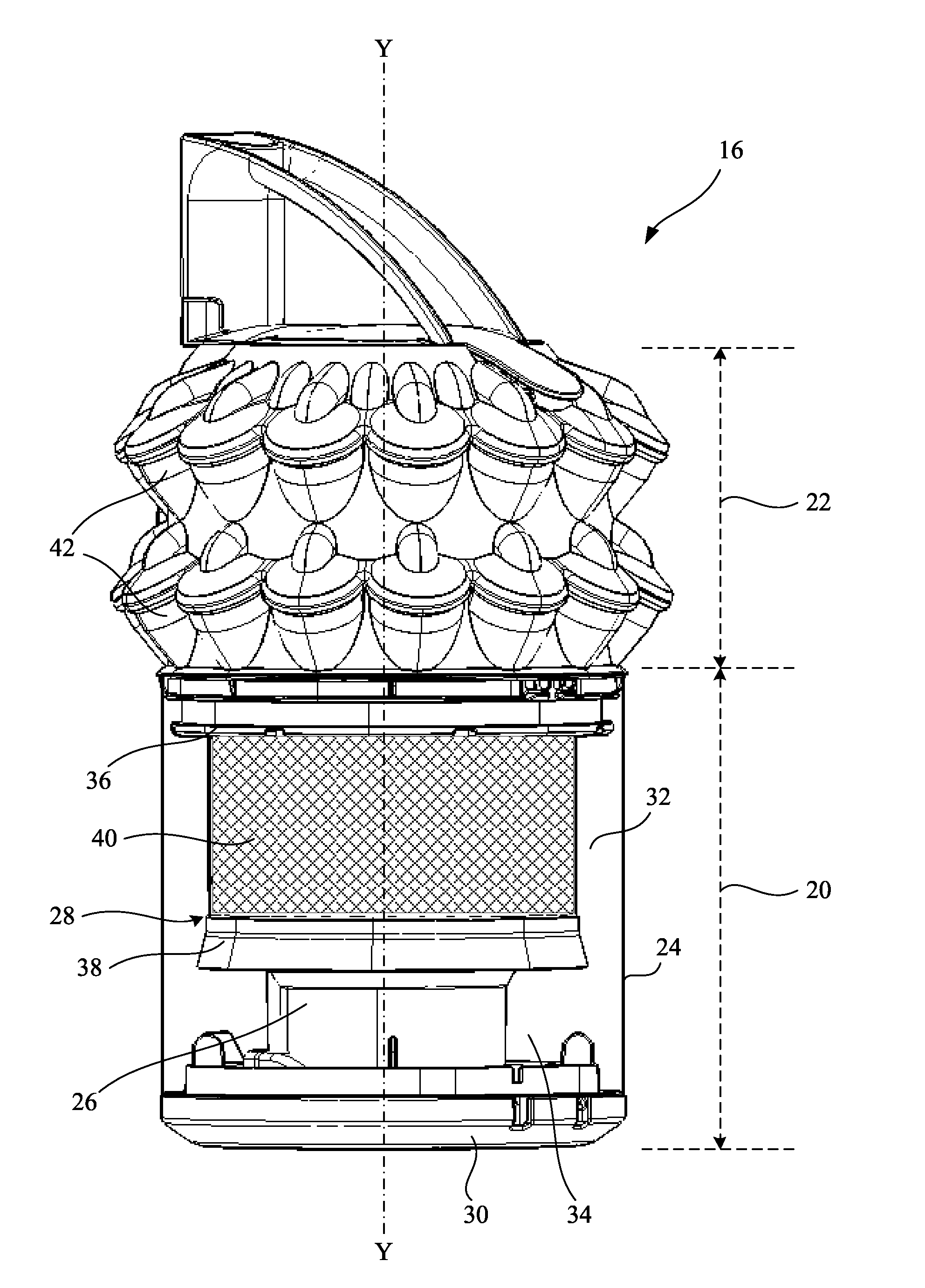

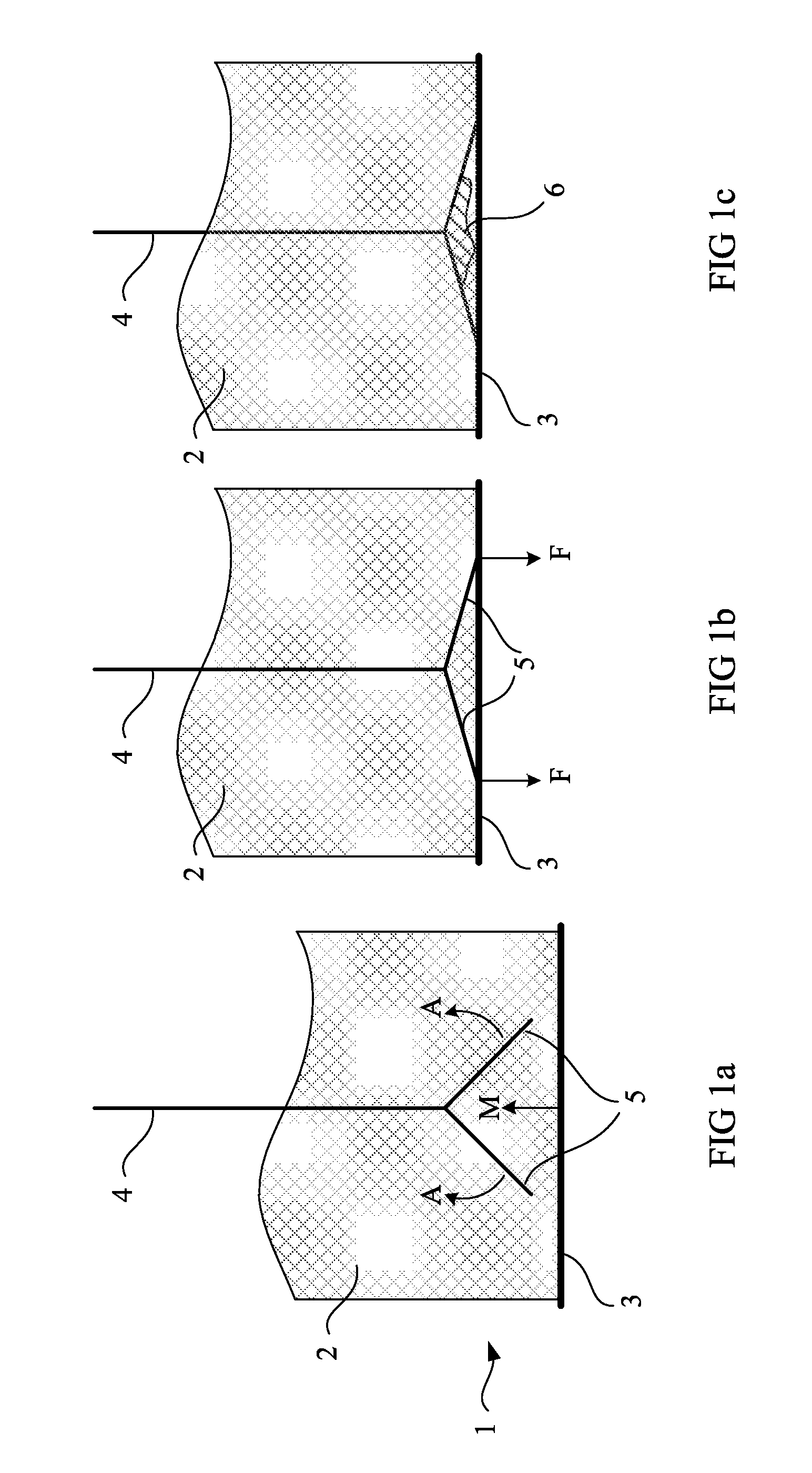

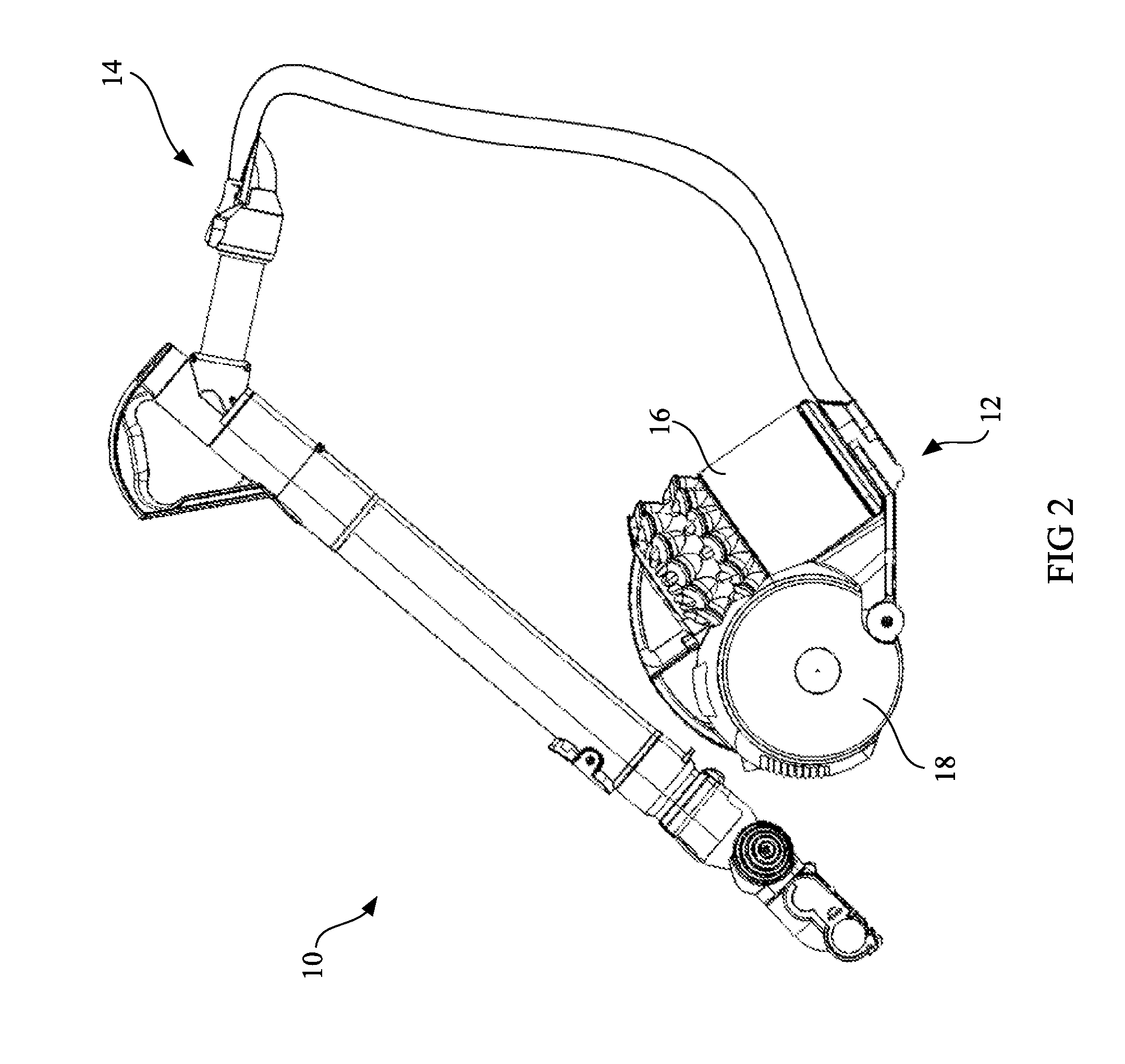

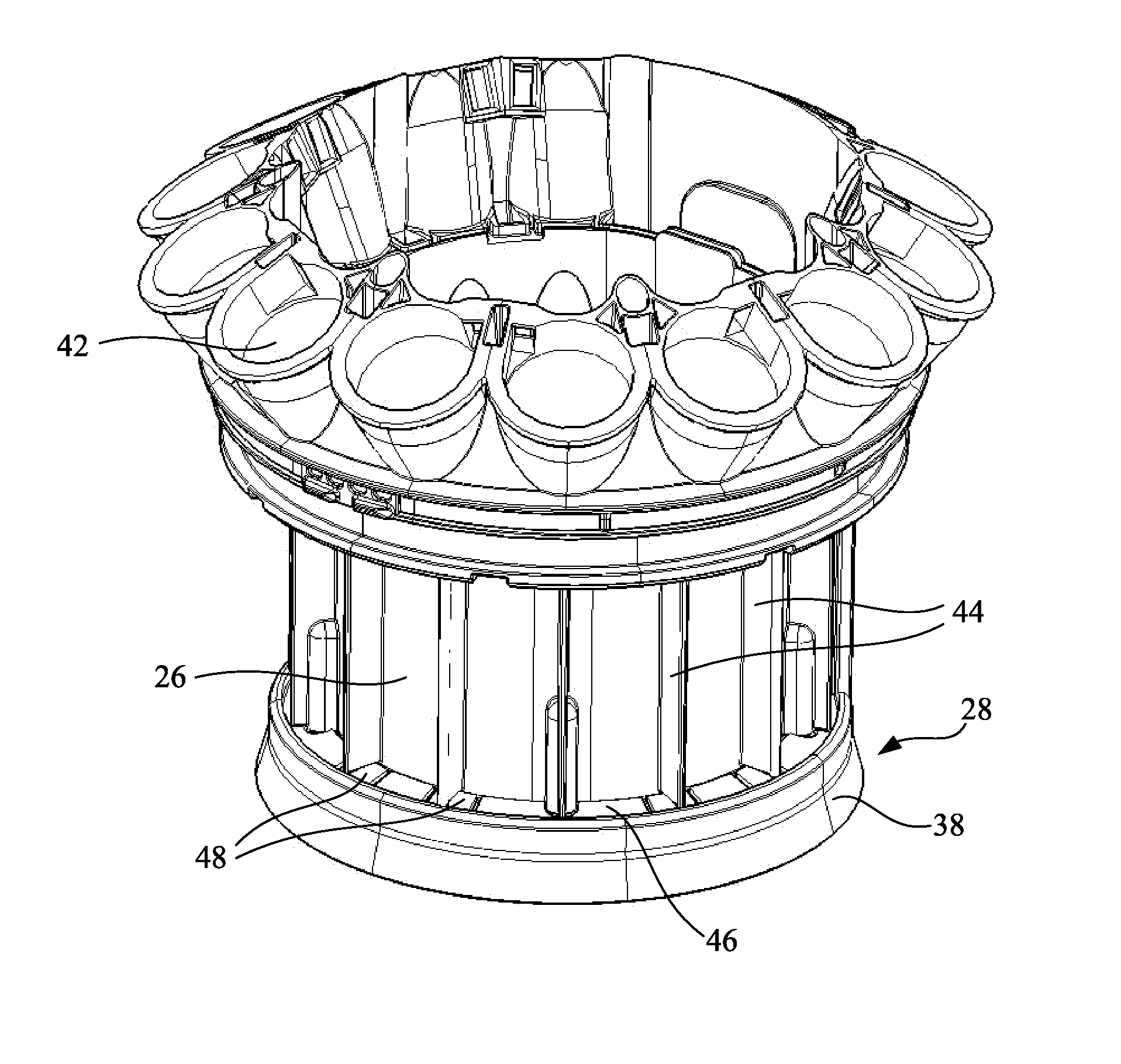

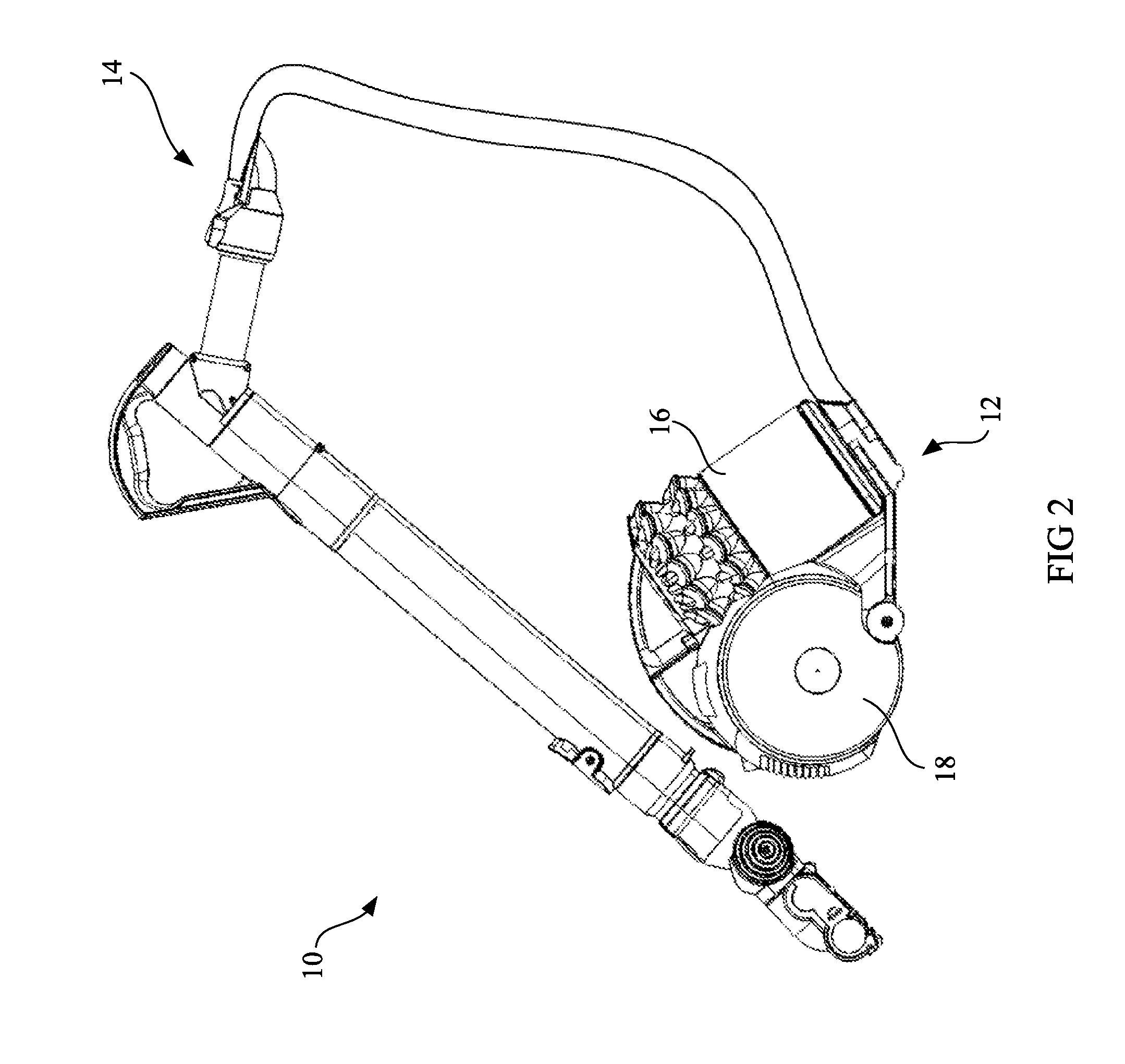

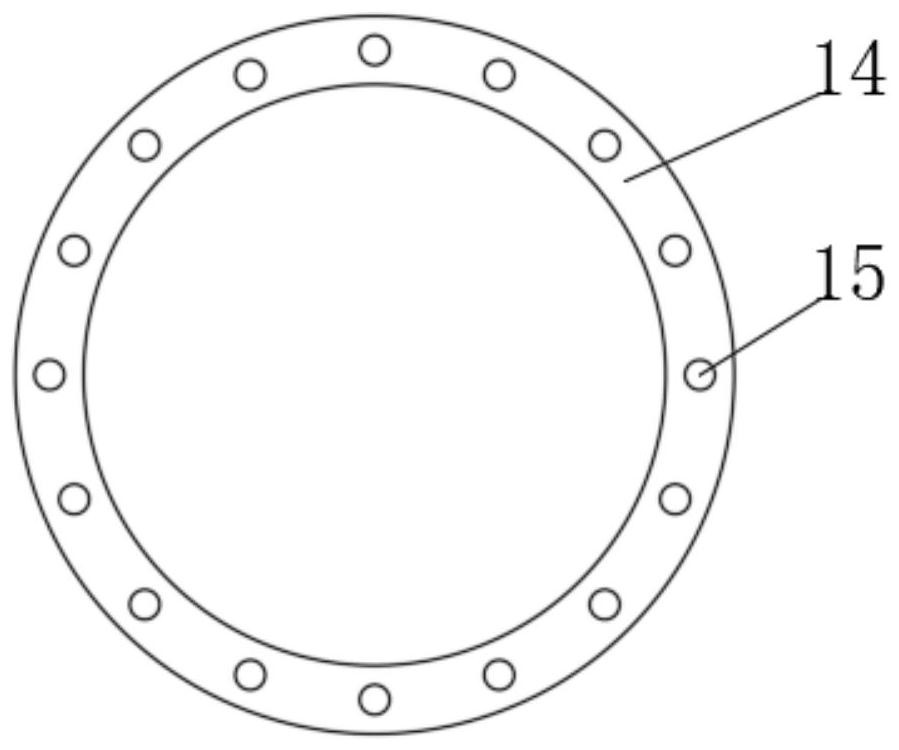

Cyclonic separator having a shroud

InactiveUS20150107048A1Easy maintenanceYield point is highCleaning filter meansCombination devicesEngineeringFlange

A cyclonic separator having an outer wall and an inner wall, and a shroud disposed between the outer wall and the inner wall, the inner wall having one or more outwardly projecting members, the shroud having upper and lower portions, and a mesh secured between the upper and lower portions, the lower portion having a flange that extends radially inward towards the inner wall, wherein the flange has one or more flexible portions, and the outwardly projecting members abut the flexible portions so as to bias the lower portion away from the upper portion to thus tension the mesh.

Owner:DYSON TECH LTD

Method for preparing TiO2-C composite carrier for p-carboxybenzaldehyde hydrogenation process

ActiveCN102139230ASmall specific surface areaStop the collapseCatalyst carriersOrganic compound preparationOrganic solventCrystal structure

The invention discloses a method for preparing a TiO2-C composite carrier for a p-carboxybenzaldehyde hydrogenation process. The preparation method sequentially comprises the following steps of: (1) adding a macromolecular compound into an organic solvent to obtain clarified solution containing the macromolecular compound; (2) adding a part of TiO2 powder; and (3) mixing the macromolecular compound modified TiO2 powder obtained in the step (2), the reset TiO2 powder and gel uniformly, kneading the mixture uniformly, and performing extrusion molding. The obtained formed product is thermally solidified and roasted in nitrogen atmosphere to form the TiO2-C composite carrier. The TiO2-C composite carrier has high specific surface area and pore volume and stable crystal structure, a Pd / TiO2-C catalyst prepared by using the carrier has high activity, and the conversion rate of the p-carboxybenzaldehyde can reach 99.5 percent. The preparation method is simple in process and is suitable for industrialized production.

Owner:CHINA PETROLEUM & CHEM CORP +1

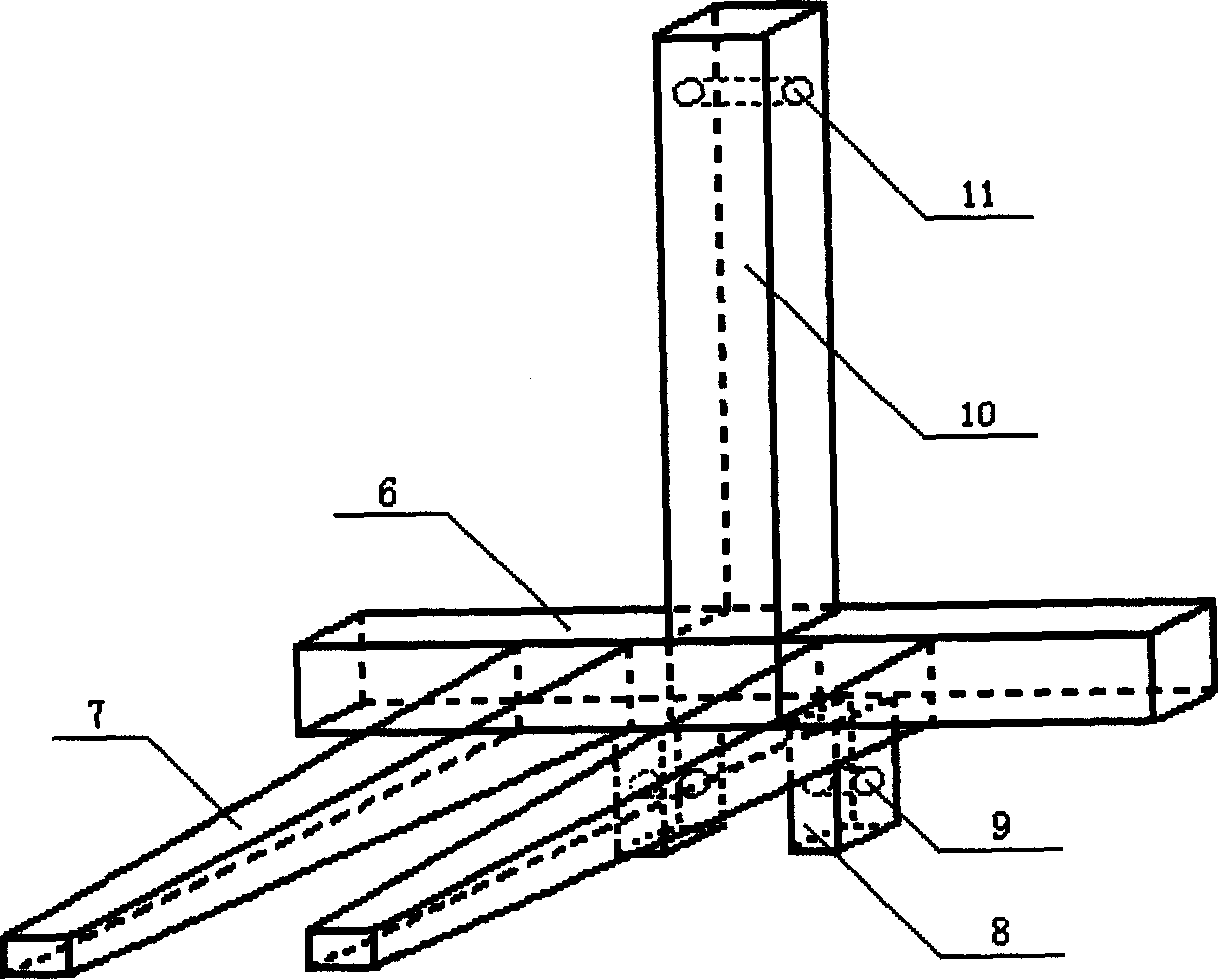

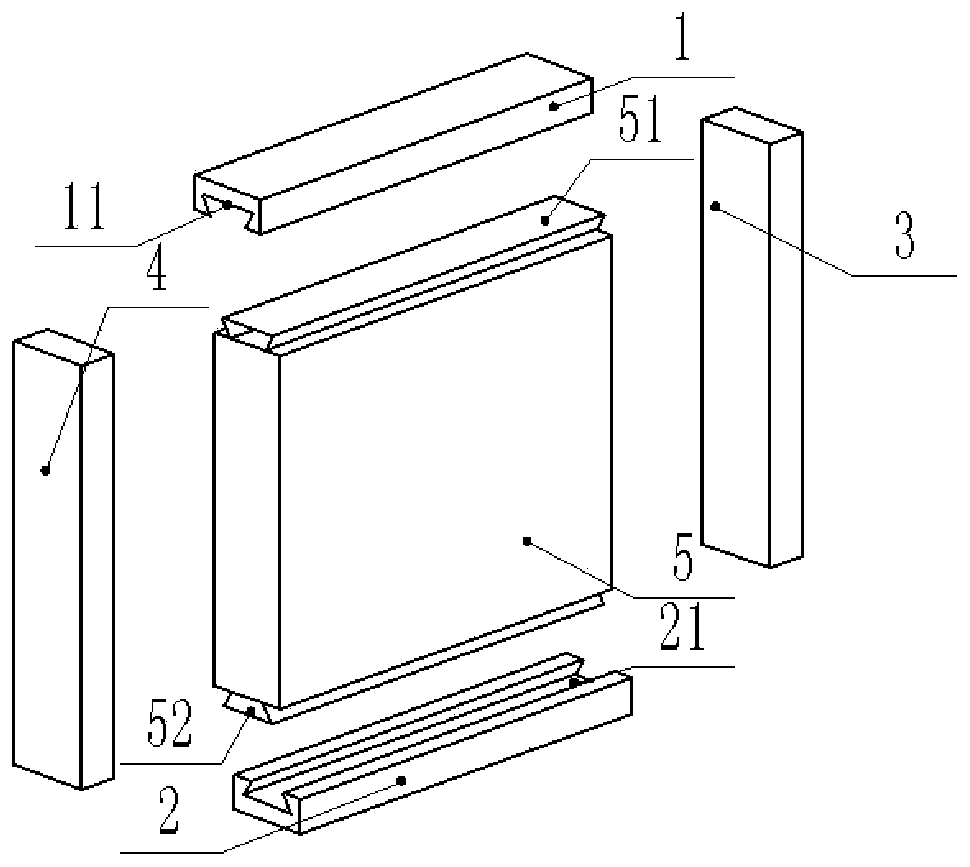

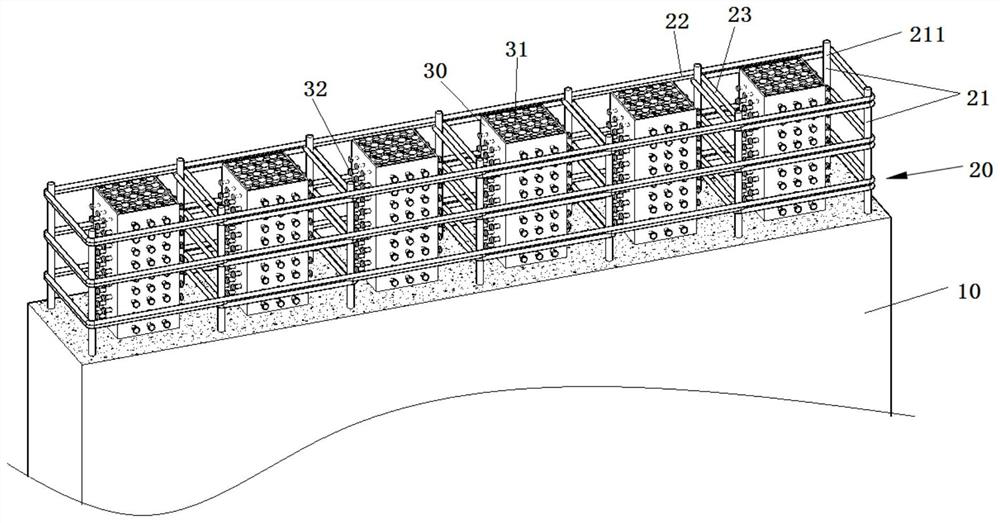

Construction method for supports of box iron supporting rack of small foundation pit

The invention belongs to the technical field of building construction, and particularly relates to a construction method for supports of a box iron supporting rack of a small foundation pit. Supporting of the small foundation pit can be implemented. The construction method for the supports of the box iron supporting rack of the small foundation pit comprises the following steps of machining the box iron supporting rack of the foundation pit in advance according to the size of the foundation pit; timely hoisting the supporting rack into the foundation pit after the foundation pit is excavated; hoisting the rack out of the foundation pit by using a crane after foundation construction is finished; performing construction of a next foundation; and detaching and recycling box iron and steel plates after overall construction is finished. The construction method for the supports of the box iron supporting rack of the small foundation pit has the advantages of convenience in construction, easiness in machining and manufacturing and high recyclability. Engineering construction cost can be saved effectively, and construction progress is accelerated. The construction method for the supports of the box iron supporting rack of the small foundation pit is environment-friendly and has wide application prospects and wide application markets.

Owner:CHINA SHANXI SIJIAN GRP

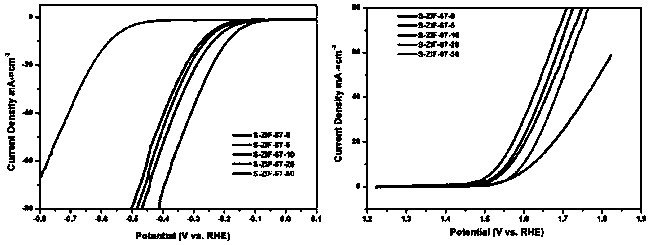

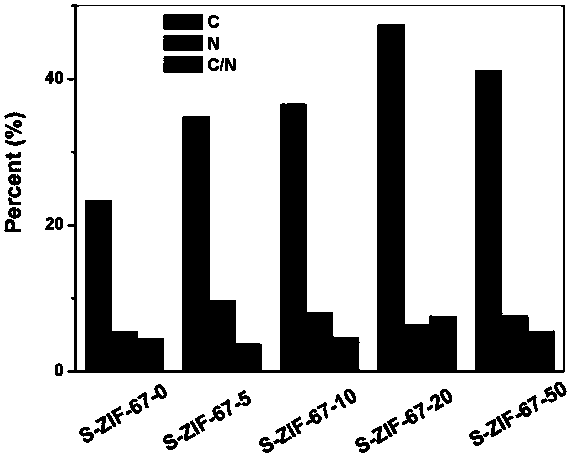

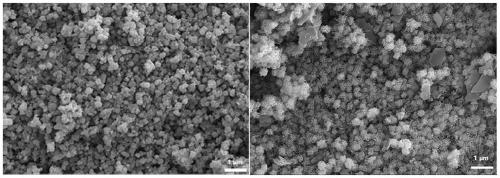

Foamy carbon doped ZIF-67 pyrolysis derived carbon material and preparation method thereof

ActiveCN111036219AStop the collapseImprove transmission performanceCarbon preparation/purificationMetal/metal-oxides/metal-hydroxide catalystsTube furnaceCarbon nanotube

The invention relates to a foamy carbon doped ZIF-67 pyrolysis derived carbon material and a preparation method thereof. The preparation method for the foamy carbon doped ZIF-67 pyrolysis derived carbon material comprises the following method: 1) synthesis of zinc doped foamy carbon; (2) synthesis of ZIF-67; and 3) synthesis of the foamy carbon doped ZIF-67 pyrolysis derived carbon material: uniformly mixing the zinc doped foamy carbon with ZIF-67 powder, then putting the formed mixture into a tubular furnace, carrying out pyrolysis treatment in an inert atmosphere, and carrying out cooling toroom temperature to obtain the foamy carbon doped ZIF-67 pyrolysis derived carbon material. The zinc-doped carbon precursor and the ZIF-67 are mixed and are then pyrolyzed in an inert atmosphere, sothe prepared material has a relatively large specific surface area; in addition, a large number of carbon nanotubes appear in the composite material, so the electron transmission capacity during electrochemical oxygen / hydrogen evolution is enhanced; and the provided zinc-doped ZIF-67 pyrolysis derived carbon material has efficient electro-catalytic performance, high stability and excellent oxygen / hydrogen evolution reaction durability in an alkaline medium.

Owner:WUHAN UNIV OF TECH

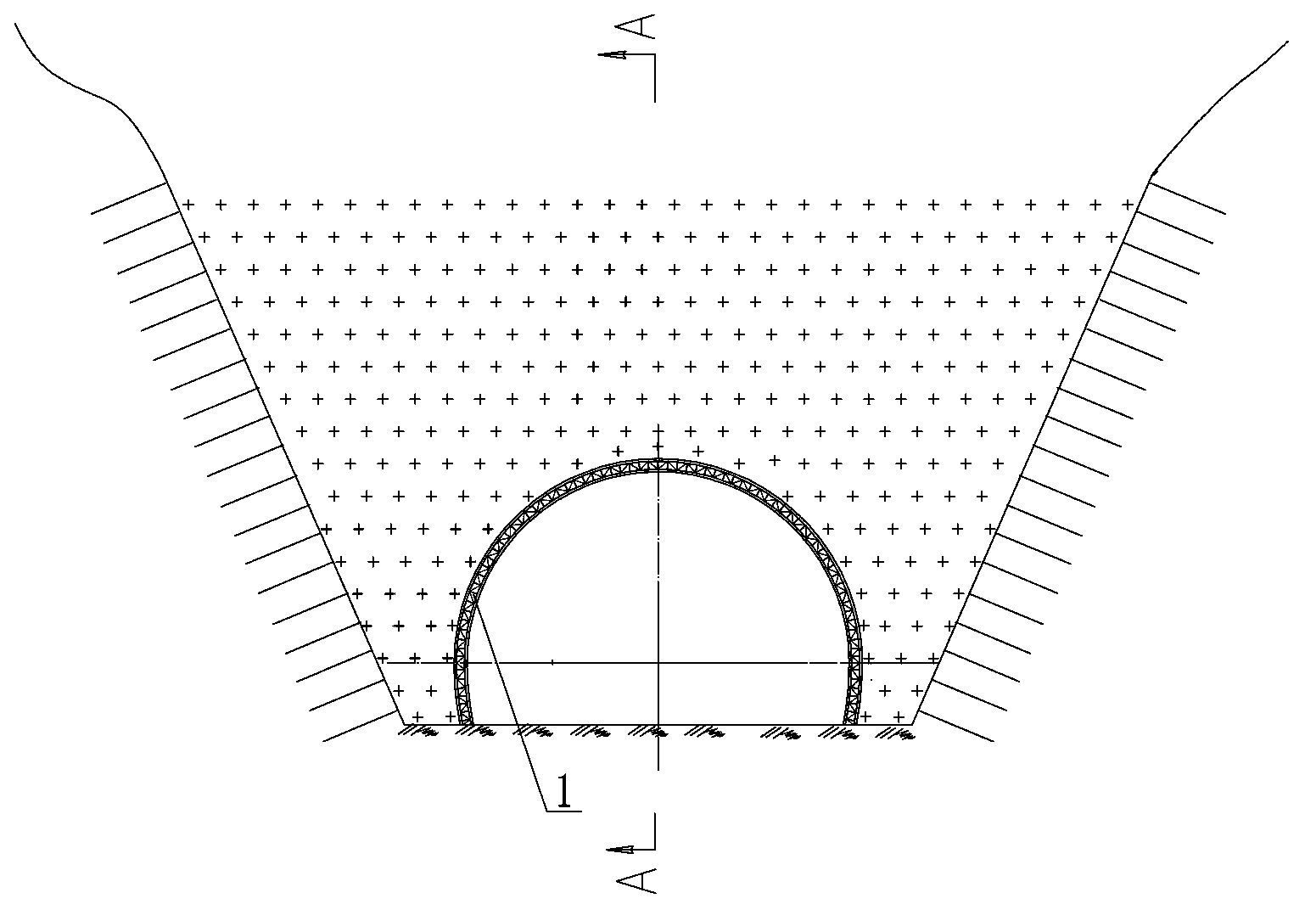

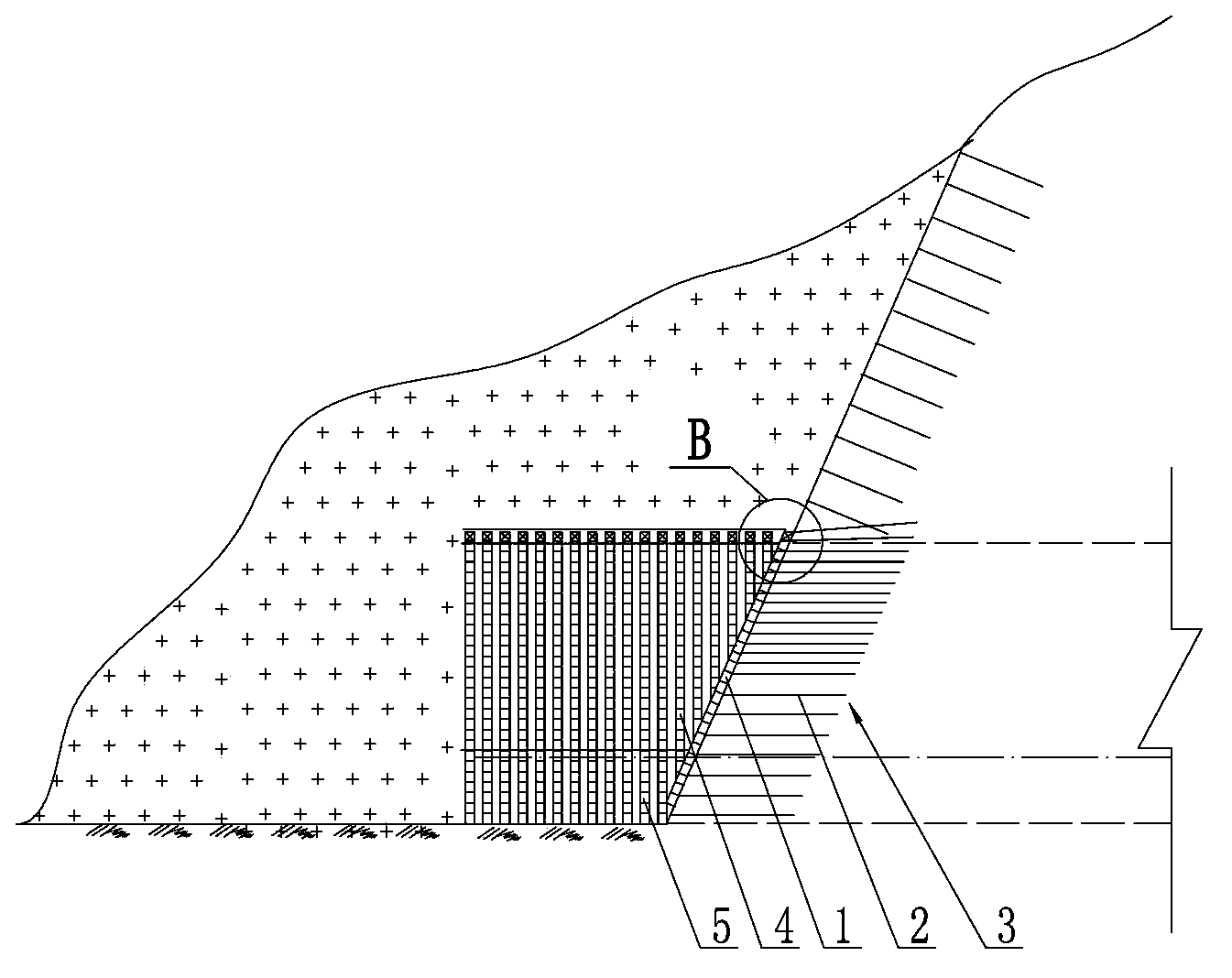

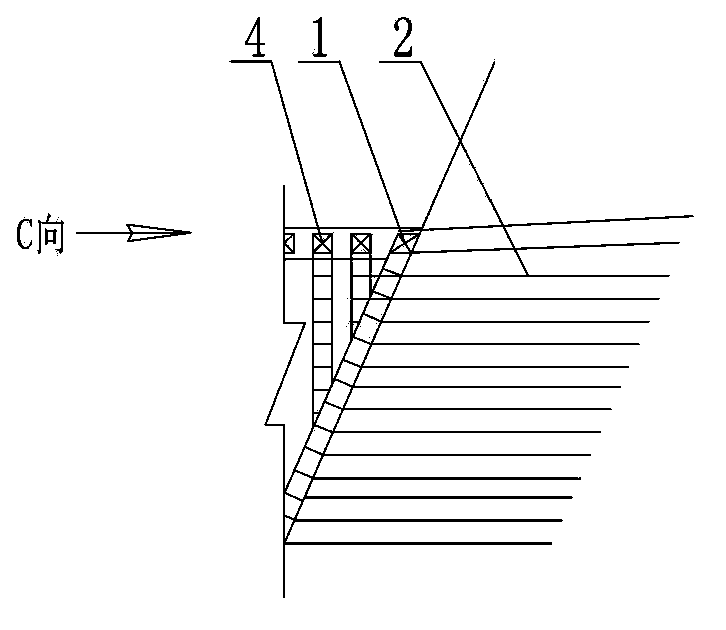

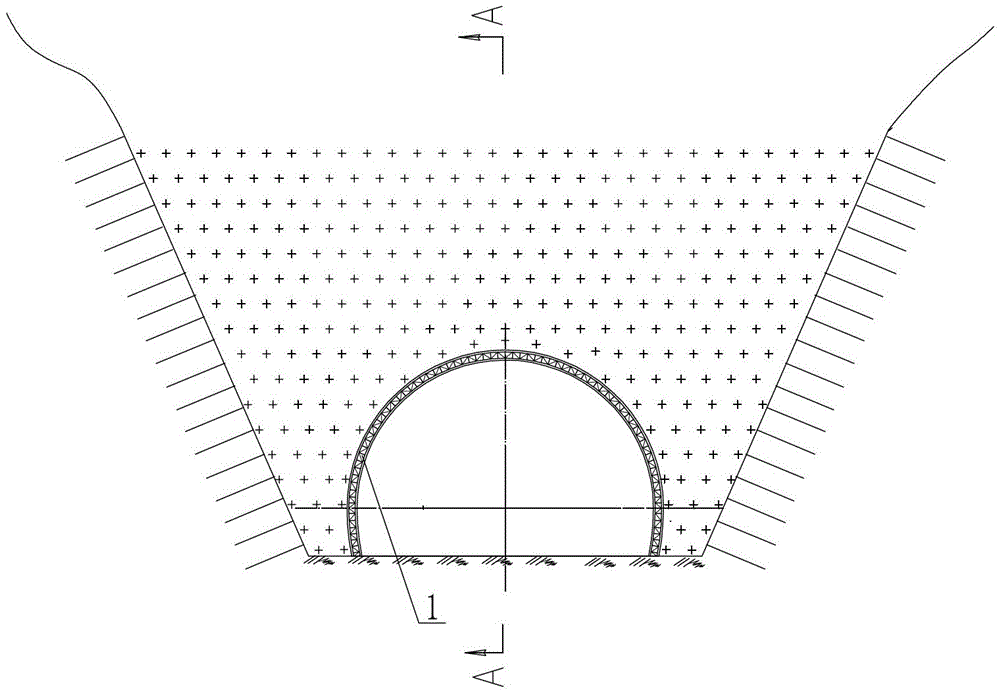

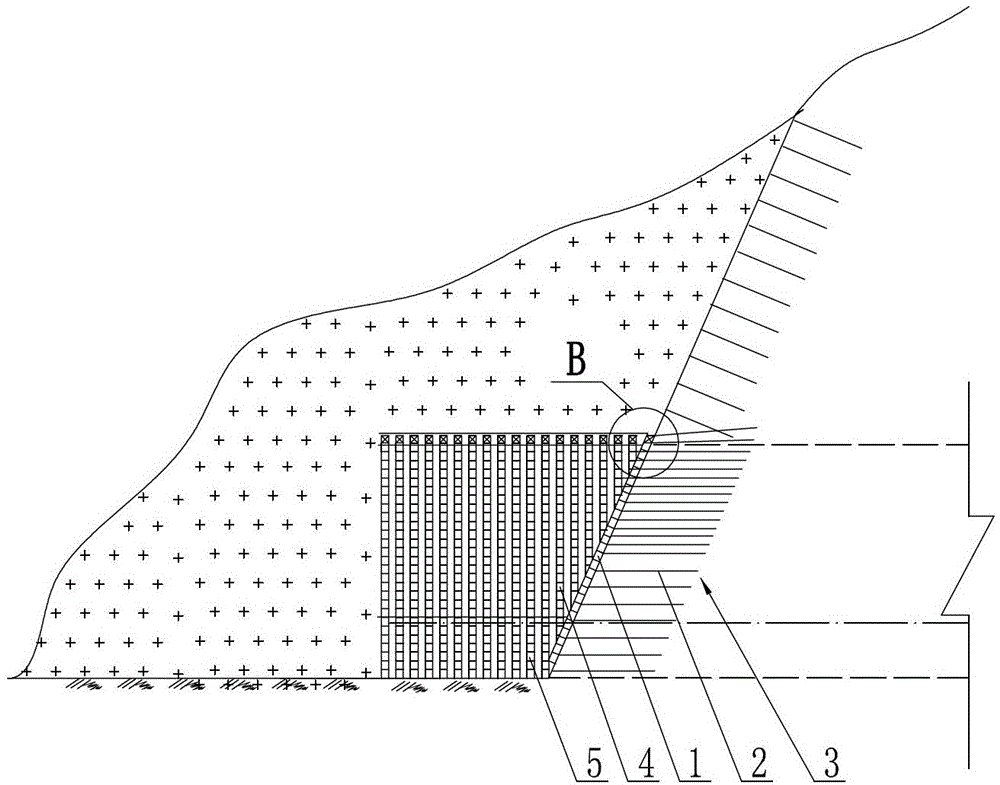

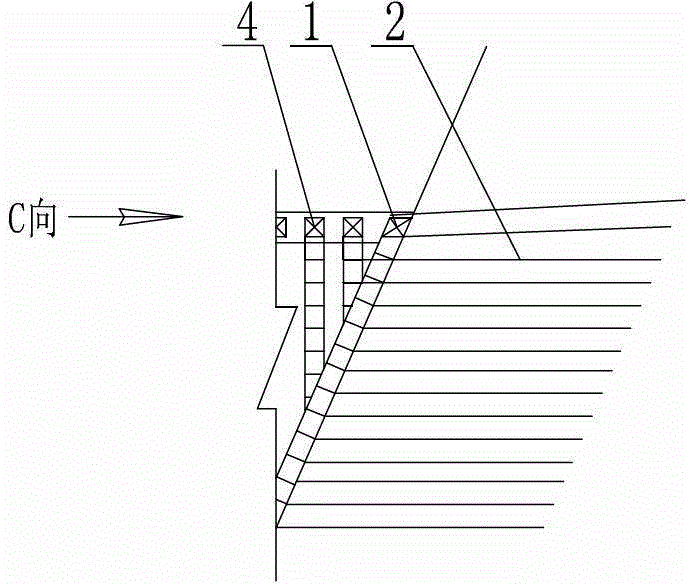

Suspended formwork lining method for cover arch outside tunnel portal with weak surrounding rocks

ActiveCN103362523AEnsuring a safe entryAvoid displacementUnderground chambersTunnel liningSupporting systemReinforced concrete

The invention discloses a suspended formwork lining method for a cover arch outside a tunnel portal with weak surrounding rocks. The method comprises the following steps of mounting a first cover arch grid steel frame and a small advanced pipe shed to form a tunnel locking port; mounting second and third groups of cover arch grid steel frames to form an integral steel frame; arranging longitudinal steel pipes, laying bamboo plywood, and connecting the longitudinal steel pipes and the integral steel frame to form a formwork support system by using iron wires; pouring concrete to finish the construction of a reinforced concrete cover arch, and the like. According to the method, a framework is arranged in reinforced concrete to serve as a support system for a concrete formwork, and a suspended formwork construction technology is adopted for pouring the concrete, so that support to the front slope of the tunnel portal with the weak surrounding rocks is formed within an extremely short time, the displacement and the glide of the open channel front slope and the open channel side slope of the portal are effectively prevented, the large-area collapse of an open channel mountain body is prevented, and the safety holing of a tunnel is ensured; and the method is applied to temporary projects under the emergency conditions of lack of external support components for concrete-poured formworks, irregular poured concrete structures, high requirements on construction time and high speed.

Owner:CHONGQING JUNENG CONSTR GRP +1

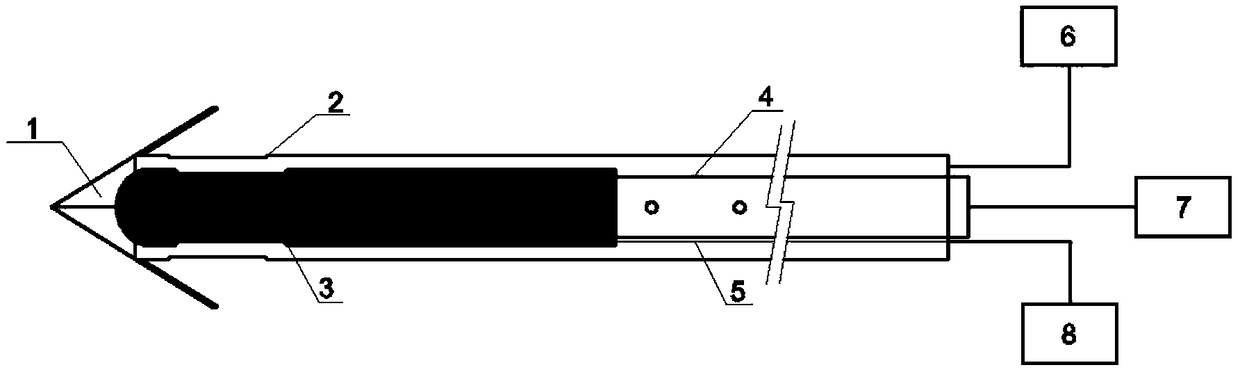

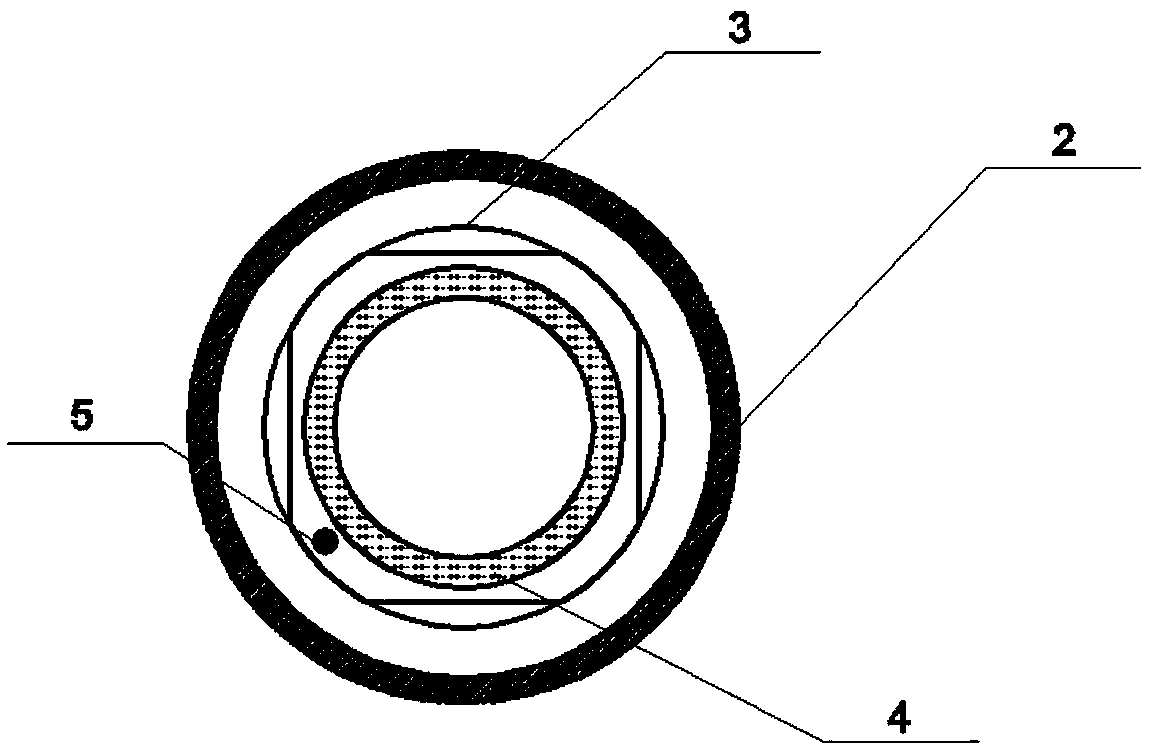

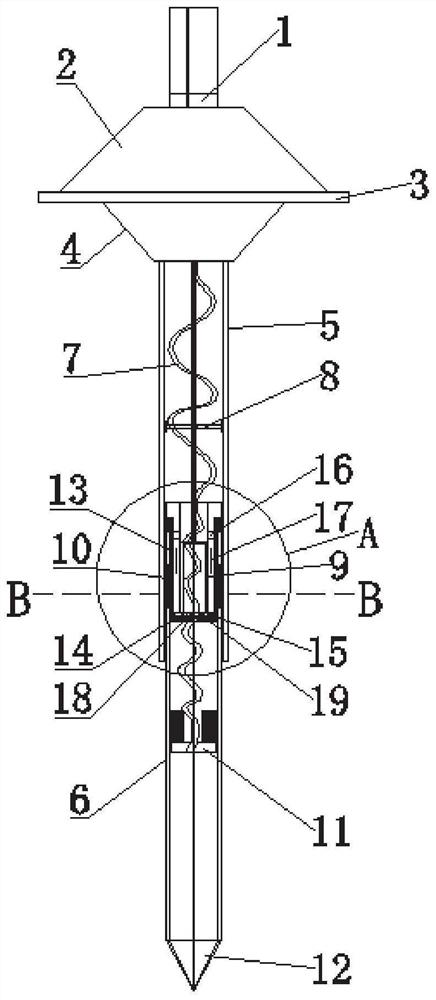

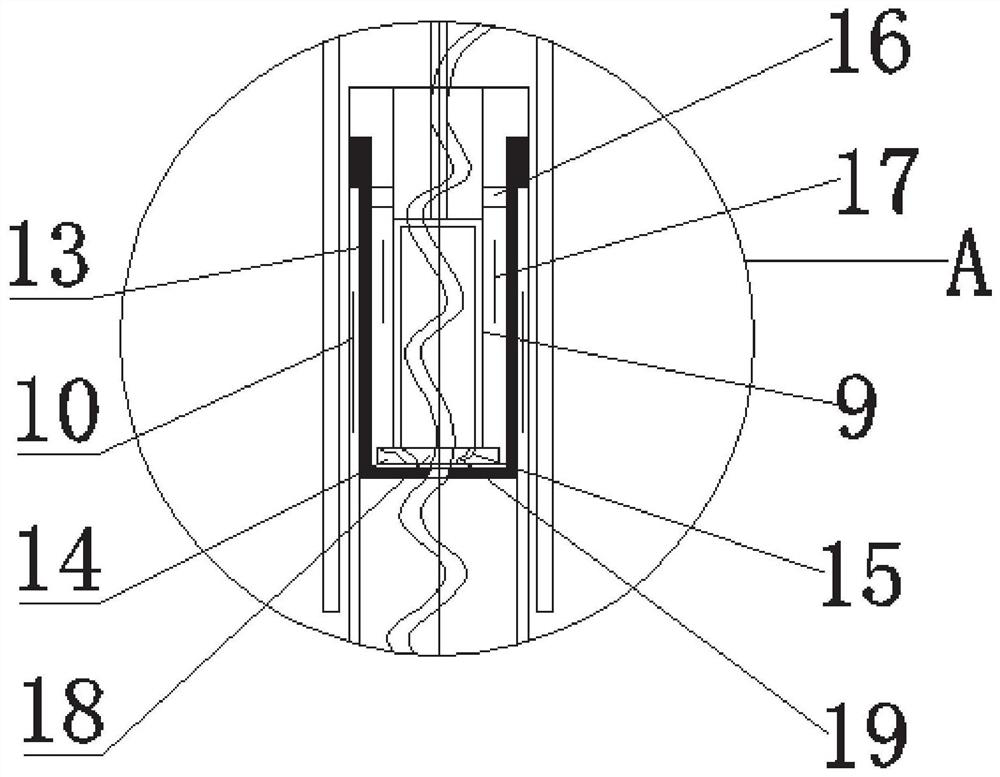

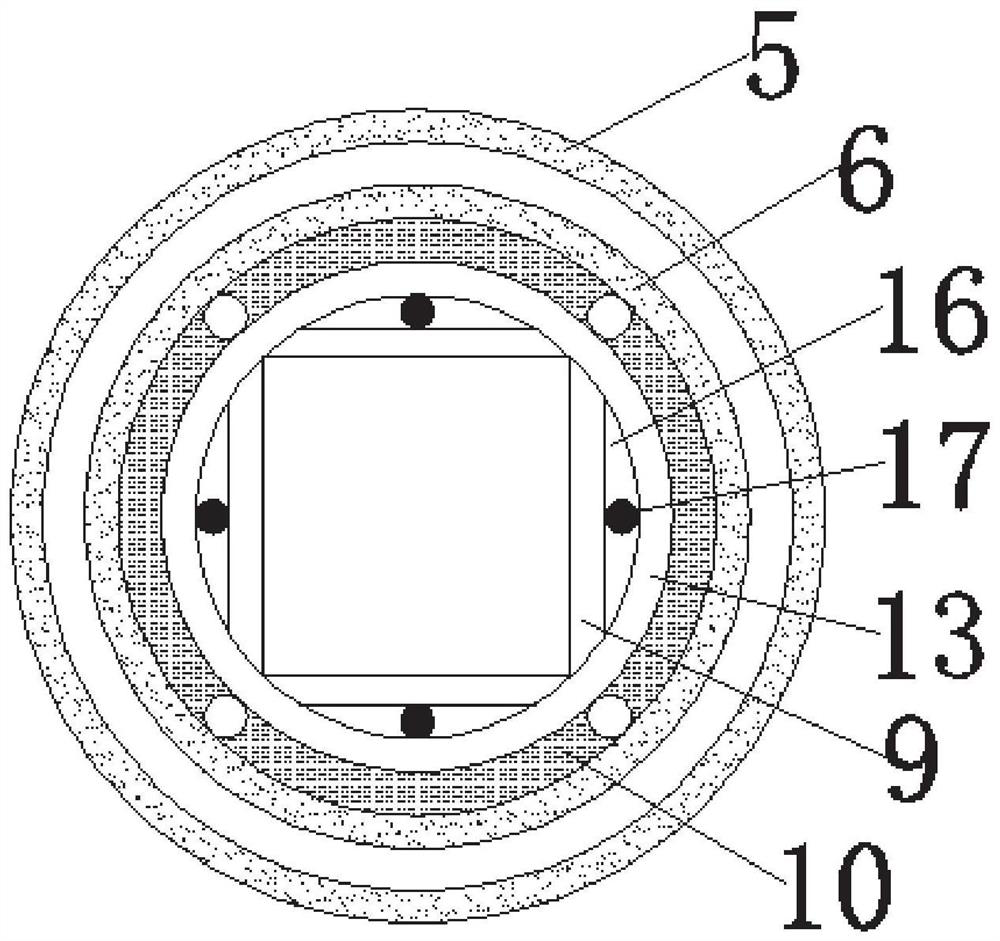

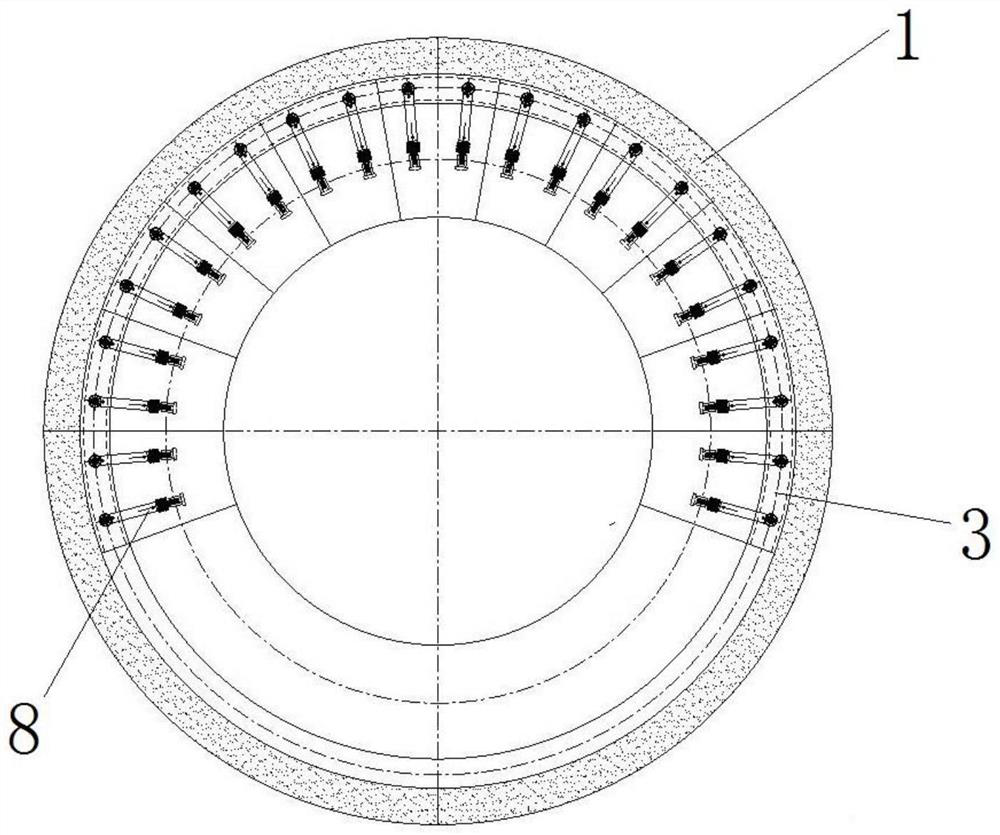

Drilling stress directional monitoring device and method

PendingCN109441426AOvercome the disadvantages of being unable to control the direction of stress testingEffective guidanceSurveyMining devicesProtractorEngineering

The invention provides a drilling stress directional monitoring device and method. The drilling stress directional monitoring device is constituted by a stress data collecting instrument, a wire, a stress sensor and a direction control device; the direction control device is jointly composed of a separable conical drilling bit, an air-blowing dust clearing casing, a directional propulsion groutingpipe, a gradienter, and an open-hole protractor; and the stress testing direction is determined through the gradienter and the open-hole protractor, the direction of the stress sensor is kept unchanged through the direction control device in the process of being propelled into a drilled hole, and thus the direction and magnitude of drilling stress in a coal roadway are accurately measured. The structure and method are easy, on-site operation is easy, the dynamic change of the drilling stress magnitude can be monitored in real time, and thus the drilling stress is tested and evaluated in realtime.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Cyclonic separator having a shroud

InactiveUS9339749B2Easy to solveEasy maintenanceSuction filtersReversed direction vortexEngineeringFlange

A cyclonic separator having an outer wall and an inner wall, and a shroud disposed between the outer wall and the inner wall, the inner wall having one or more outwardly projecting members, the shroud having upper and lower portions, and a mesh secured between the upper and lower portions, the lower portion having a flange that extends radially inward towards the inner wall, wherein the flange has one or more flexible portions, and the outwardly projecting members abut the flexible portions so as to bias the lower portion away from the upper portion to thus tension the mesh.

Owner:DYSON TECH LTD

Anti-collapse plugging agent for drilling fluid and preparation method and application thereof

ActiveCN105505345ADecreased fluorescence intensityGood sealingDrilling compositionSealing/packingPolymer scienceSulfite

The invention provides an anti-collapse plugging agent for drilling fluid and a preparation method and application thereof. The preparation method of the plugging agent includes the following steps that a, sulfite and / or hydrosulfite are / is added into water to be completely dissolved, a solution A is obtained, dimethylamine and aldehydes substances are added into the solution A, reaction is achieved through heating, and additive products are obtained; b, phenolic substances and aldehydes substances are mixed and heated to react, and a solution B is obtained; c, an alkali catalyst is added into the solution B, and a solution C is obtained; d, the additive products obtained in step a are added into the solution C obtained in the step c and made to react, and the anti-collapse plugging agent is obtained through drying after the reaction ends. The anti-collapse plugging agent is a novel anti-collapse plugging agent and has the advantages that fluorescent strength is low, the plugging performance at high temperature is good, viscosity and denseness are not increased, compatibility performance between the anti-collapse plugging agent and drilling fluid is good, and the reservoir protective effect is good.

Owner:SONGYUAN MARINE PETROLEUM TECH CO LTD

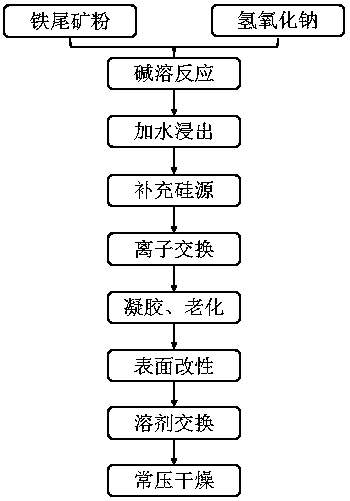

Method for preparing composite silicon-based aerogel by using iron tailings as raw material

ActiveCN109012517AImprove recycling ratesReduce the impactAerogel preparationColloidal chemistry detailsPorosityIon exchange

The invention discloses a method for preparing a composite silicon-based aerogel by using iron tailings as a raw material. The method comprises the following steps: mixing iron tailing powder with sodium hydroxide particles and performing an alkali dissolution reaction at a high temperature; after cooling, mixing a reaction product with water, and carrying out heating and stirring; then carrying out filtering, and uniformly mixing a filtrate with a water glass solution; performing ion exchange via a strong-acid cation exchange resin; dropwise adding an ammonia-water solution into a mixed liquid obtained after ion exchange so as to adjust a pH value; after a block gel is formed, immersing the block gel in a gel aging solution for standing and aged, and then taking out a formed wet sol; andsuccessively subjecting the obtained wet sol to surface modification by a modification liquid and solvent exchange with n-hexane, and then carrying out normal-pressure drying so as to obtain the composite silicon-based aerogel. According to the invention, solid wastes such as iron tailings are used as raw materials, so the aerogel has low price; preparation conditions are mild; requirements on equipment are low; industrialization can be easily implemented; and the prepared composite silicon-based aerogel has a tap density of 0.175 g / cm<3> or less, an average pore size of no more than 40 nm anda porosity of 93% or more.

Owner:ZHEJIANG UNIV OF TECH

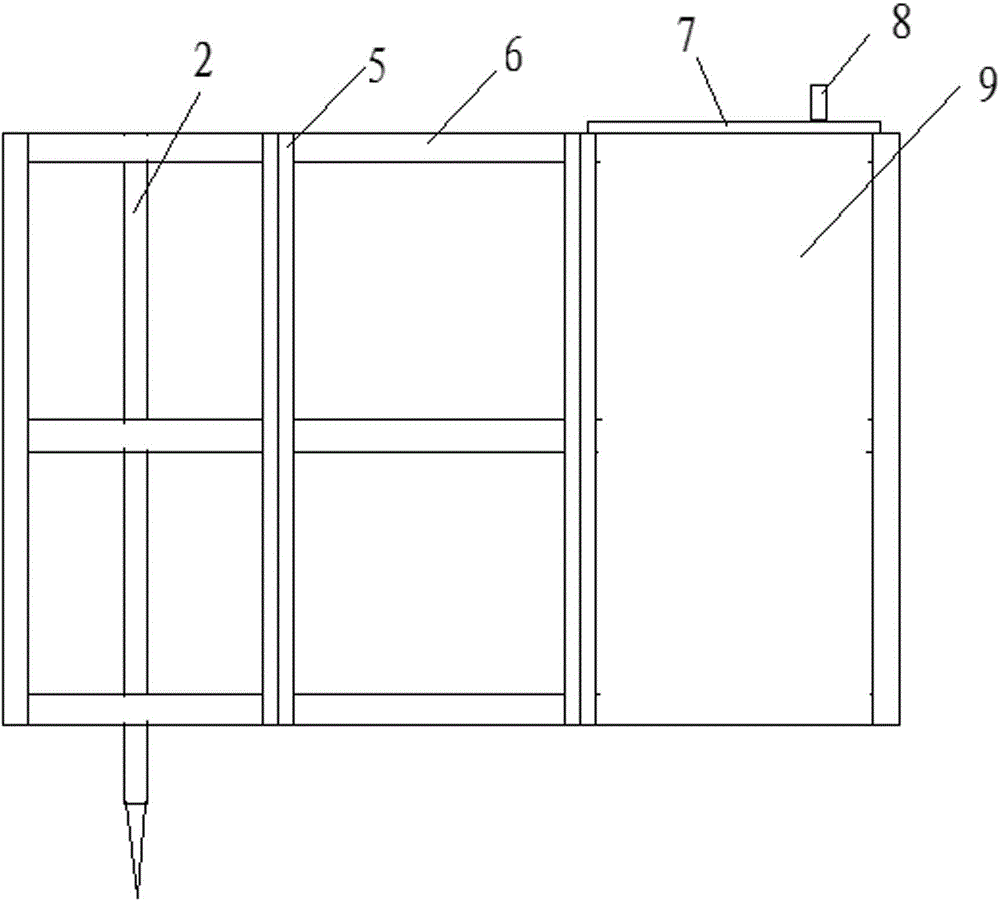

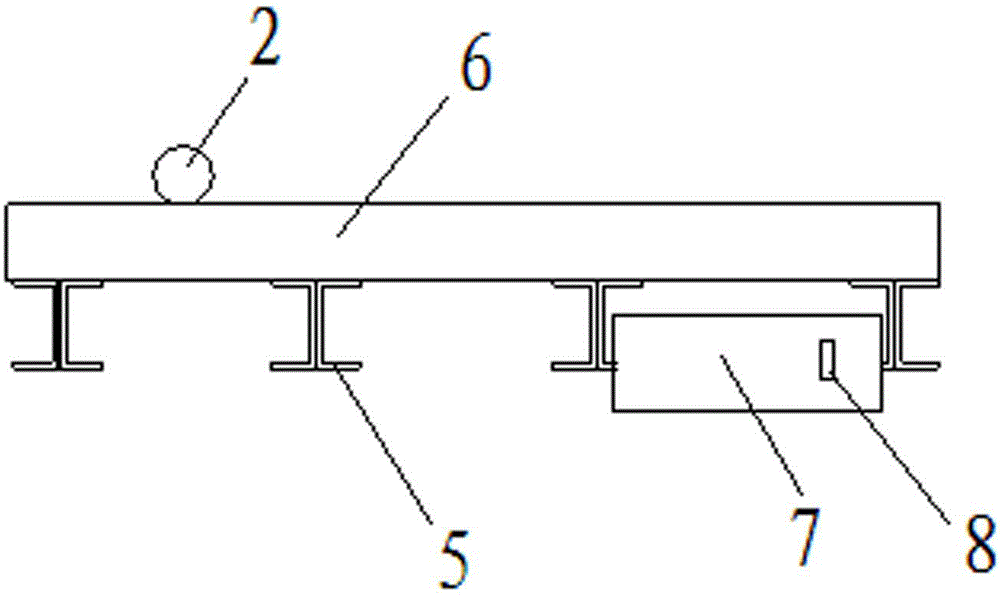

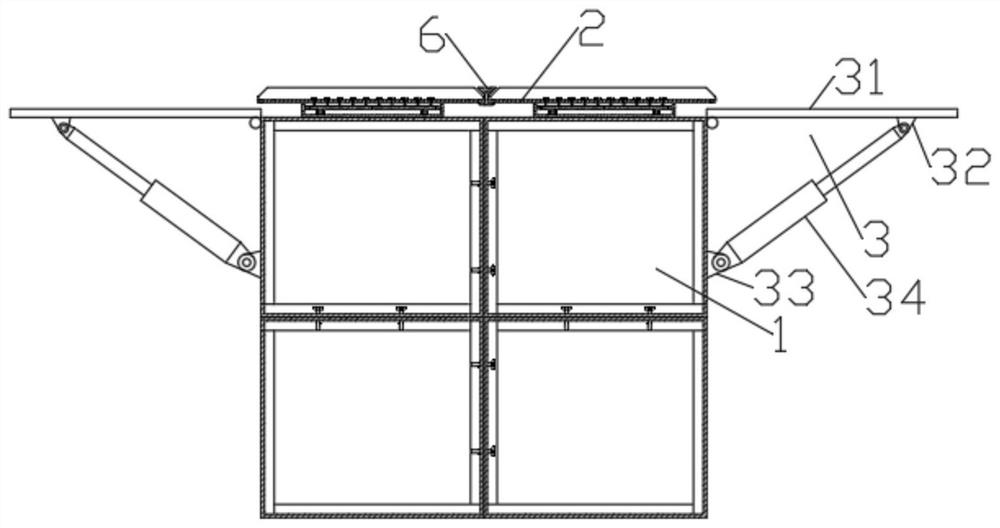

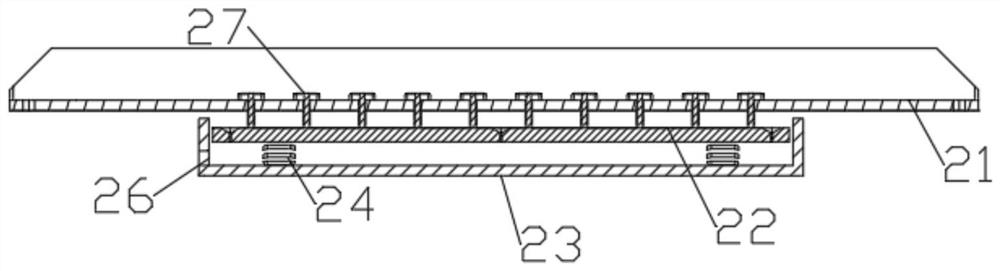

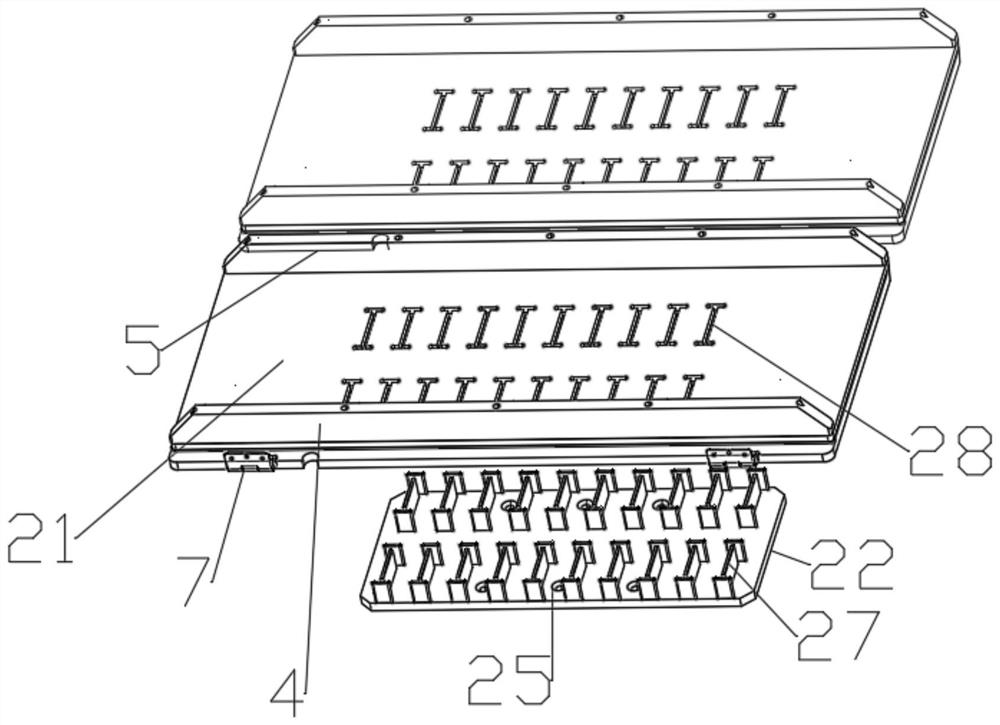

Assembled temporary supporting device for pavement collapse

The invention discloses an assembled temporary supporting device for pavement collapse, and belongs to the technical field of road construction. The assembled temporary supporting device for pavementcollapse comprises a lower supporting structure, an upper supporting structure fixedly arranged on the upper side of the lower supporting structure, and auxiliary supporting structures arranged at twosides of the upper supporting structure, wherein the upper supporting structure comprises a faceplate, a compression plate, a dirt collecting groove and an elastic supporting device; the faceplate and the compression plate are both rectangular plates; the compression plate is arranged in the dirt collecting groove in way of being capable of vertically sliding; the outer side of the compression plate cooperates with the inner wall of the dirt collecting groove; and the elastic supporting device is arranged in the dirt collecting groove, and is used for elastically supporting the compression plate. The assembled temporary supporting device for pavement collapse provided by the invention can be used for temporarily supporting a collapsed road section before the road is repaired, so that thepurpose of dredging the traffic is achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

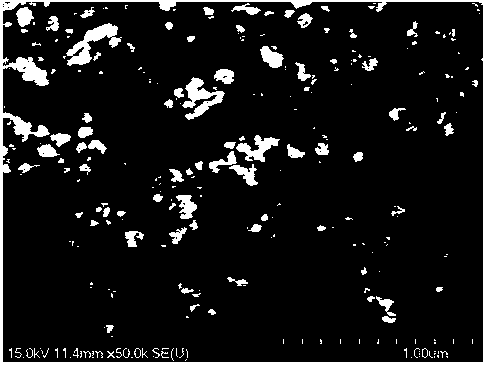

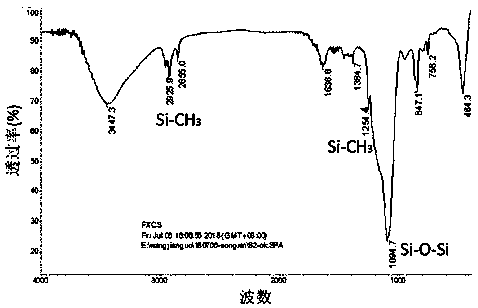

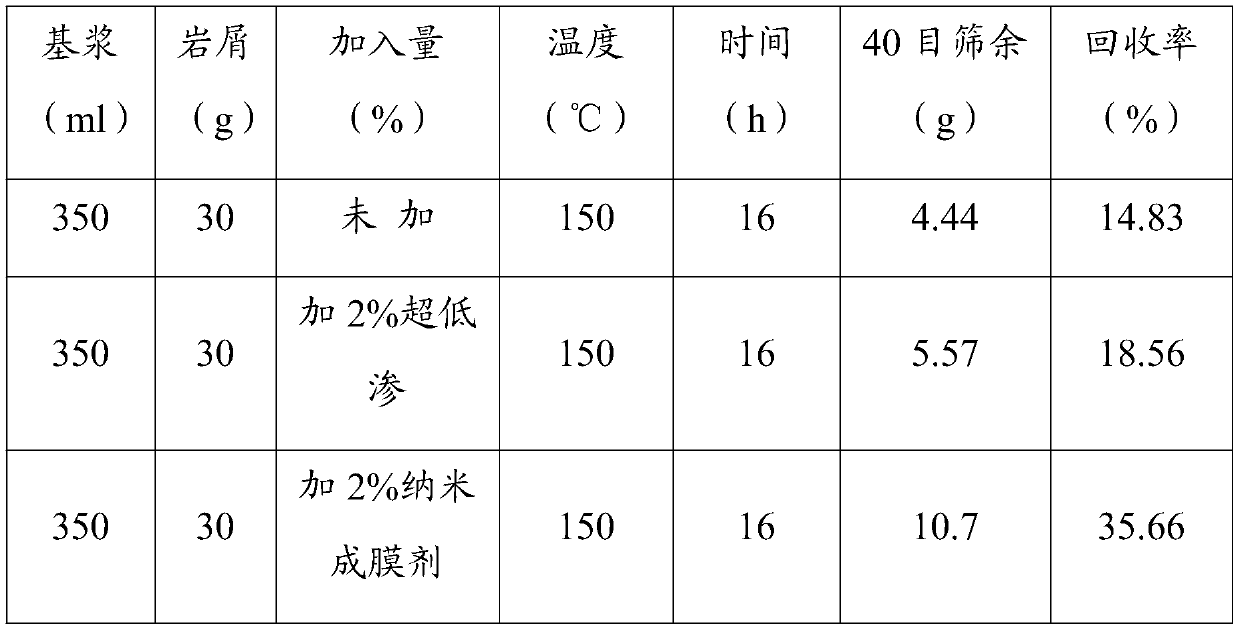

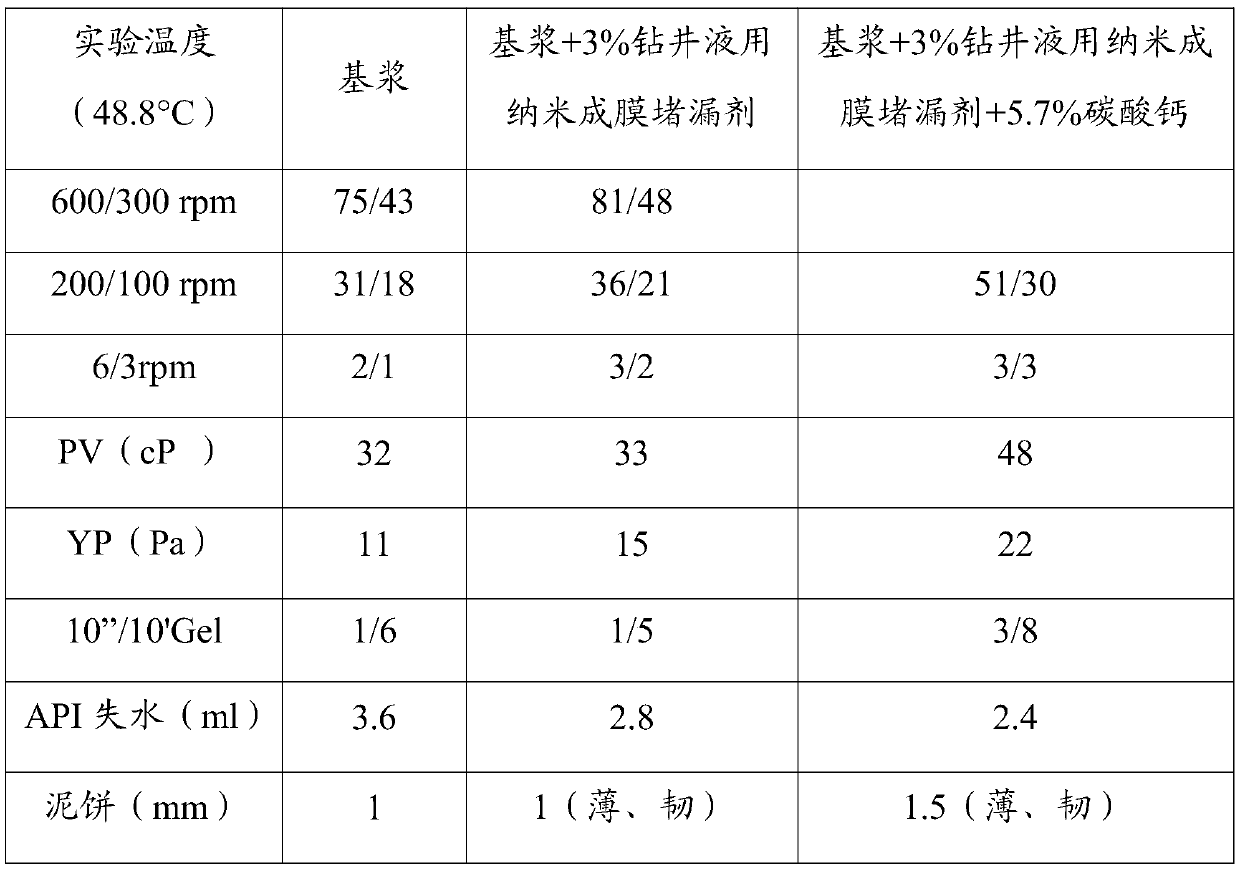

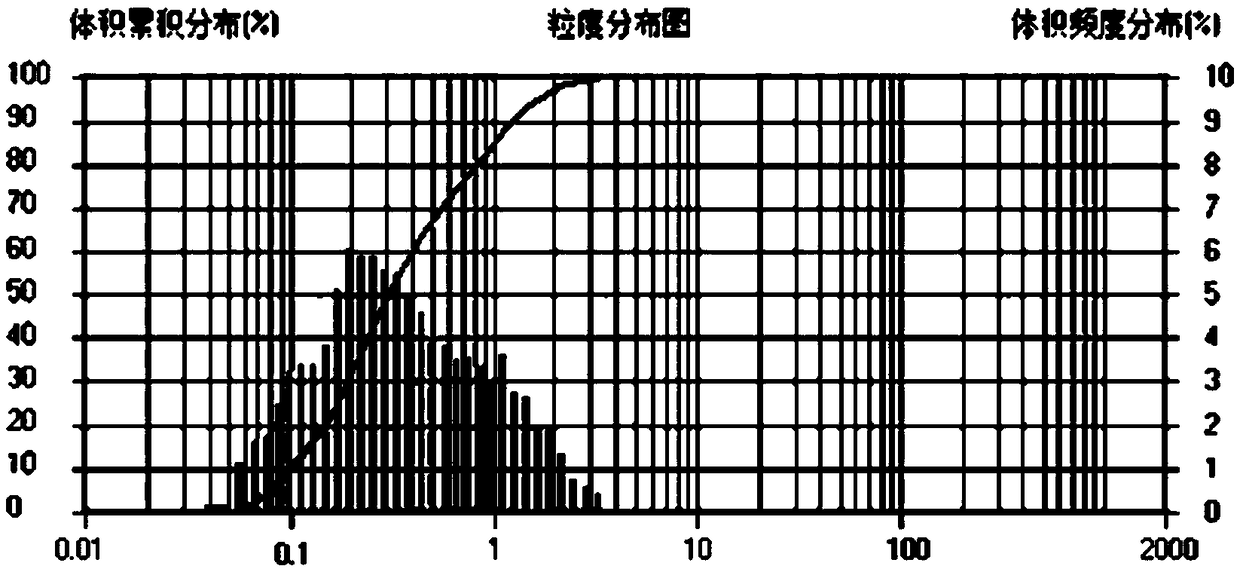

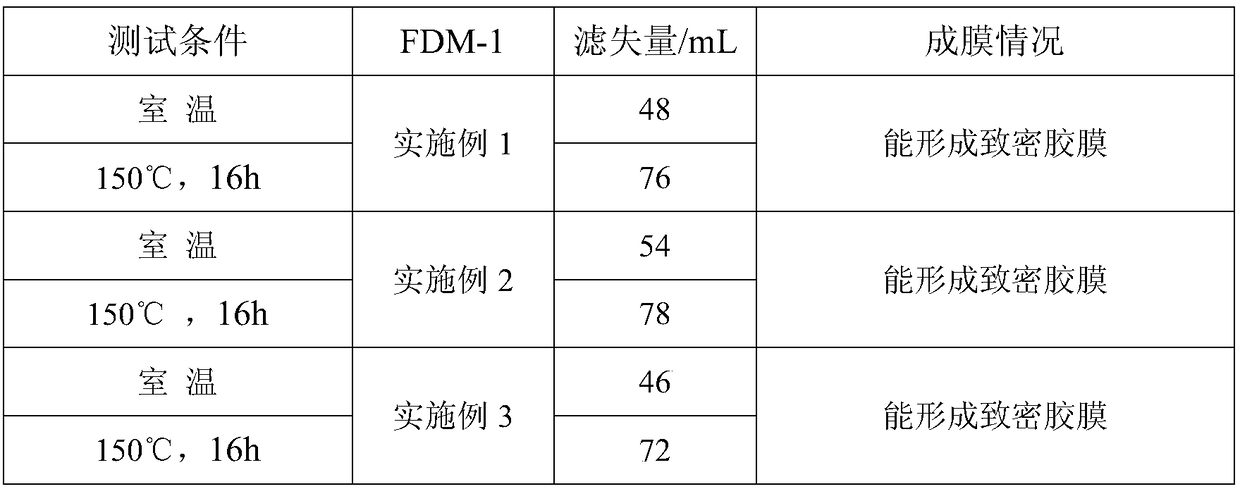

Nano filming plugging agent for drilling fluid and preparation method and application of nano filming plugging agent

InactiveCN110157397AImprove the blocking effectReduce high temperature and high pressure filtration lossDrilling compositionPolymer scienceEngineering

The invention provides a nano filming plugging agent for a drilling fluid. The nano filming plugging agent comprises the following components: silicon oxide, polyurethane granules, a dispersant and analcohol. By controlling proportions and preparation processes of raw materials, the prepared nano filming plugging agent for the drilling fluid is an odorless white liquid, the density is 1.05g / cm<3>, the granularity of solid particles is 50-400nm, the nano filming plugging agent for the drilling fluid is compressed in the surface of a wall well or microcracks of mud shale to form a semi-permeable isolation film, that is, a complete protection layer is formed on the wall well, fluids can be prevented from entering a stratum, effective pressure can be increased, ineffective pressure can be reduced, a wall well stabilizing function can be effectively brought into play, the drilling fluid blocking capability can be improved, the filter loss of the drilling fluid can be reduced, the quality and plugging performance of mud cakes can be improved, the inhibition of the drilling fluid can be improved, a liquid in a shaft can be prevented from entering stratum pores and cracks, the probabilityof differential pressure adhesion and tool jamming can be reduced, and in addition, the nano filming plugging agent is simple, convenient and easy in control of preparation processes, convenient andrapid to use, and high in popularization and application value.

Owner:XINJIANG GRAND OILFIELD TECH

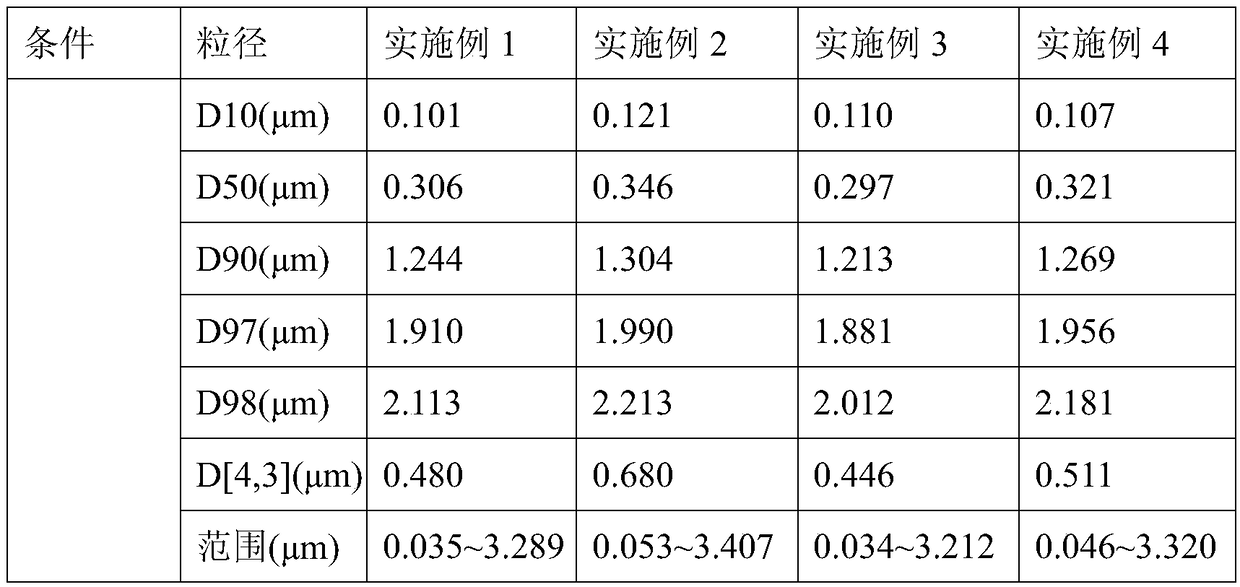

Multi-component vinyl polymer emulsion film-forming plugging agent for drilling fluid and preparation method thereof

ActiveCN106479456BImproved particle size distributionImprove toughnessDrilling compositionPolymer scienceSolvent

The invention provides a preparation method of a multielement vinyl polymer emulsion film forming blocking agent for a drilling fluid. The preparation method comprises the steps as follows: raw materials are prepared according to the component ratio; a solvent accounting for 4 / 5 of the formula quantity and an emulsifier are added to a No. 1 reactor in sequence, heated to 50-70 DEG C and stirred for 20-30min; then, styrene, maleic anhydride, acrylate, an initiator and a molecular weight regulator are added in sequence, the mixture is heated to 70-80 DEG C, timing for a reaction is started, and the mixture is stopped from being heated after 1 h and cooled; the solvent accounting for 1 / 5 of the formula quantity, a stabilizer, a deoxidant, a defoamer and modified nano-calcium carbonate are added to a No. 2 reactor in sequence and are stirred at the room temperature for 30-40 min; the mixture obtained in the previous step is added to the No. 1 reactor slowly and reacts at 40-50 DEG C for 2-3 h, and the multielement vinyl polymer emulsion film forming blocking agent is obtained. In combination with micro-scale deformable and cementing film forming particles, the blocking and collapse preventing capacity of the drilling fluid is improved, the mud cake quality is improved, the filter loss is reduced, the compatibility is good, and the temperature of 130 DEG C can be resisted.

Owner:成都西油华巍科技有限公司

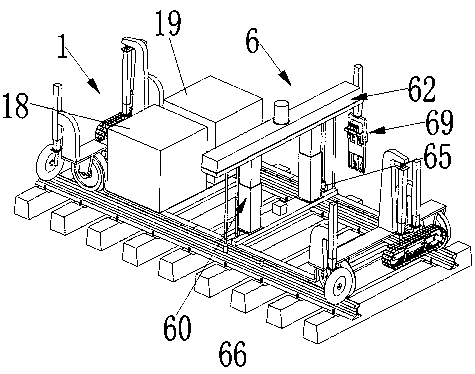

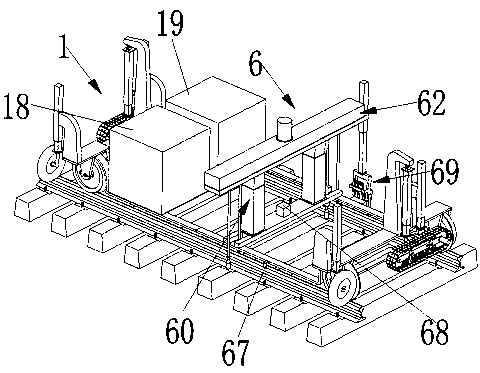

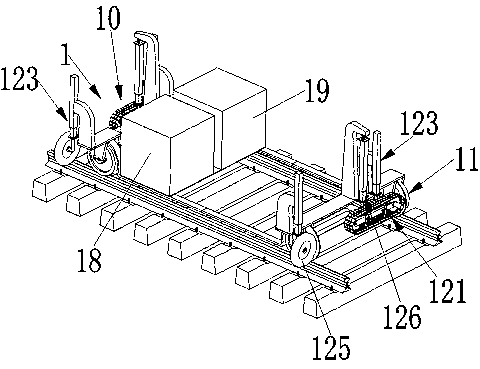

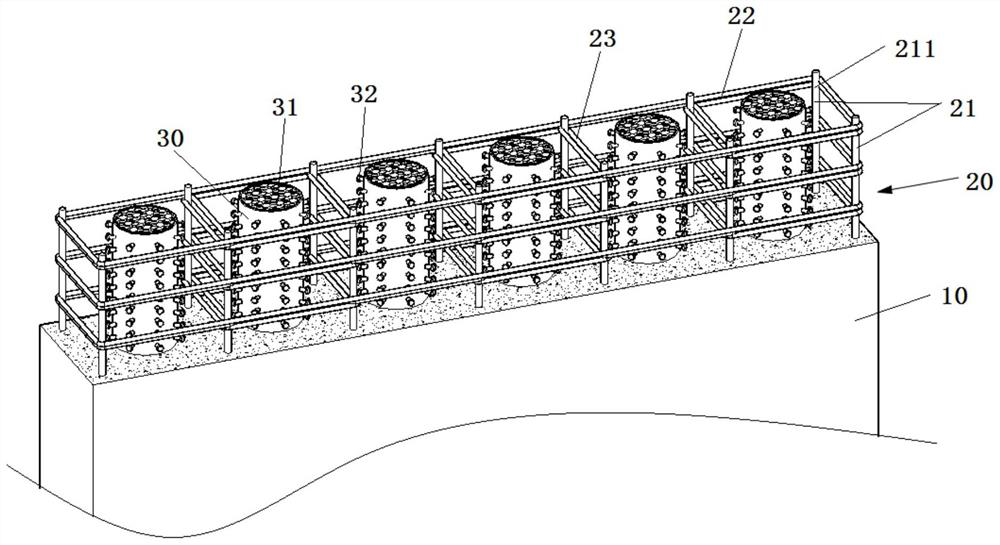

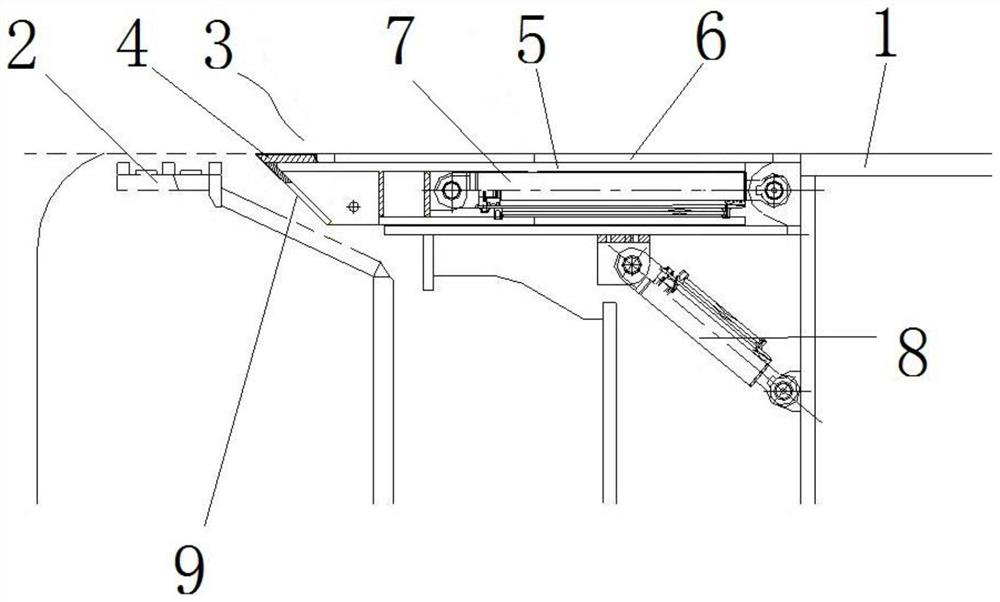

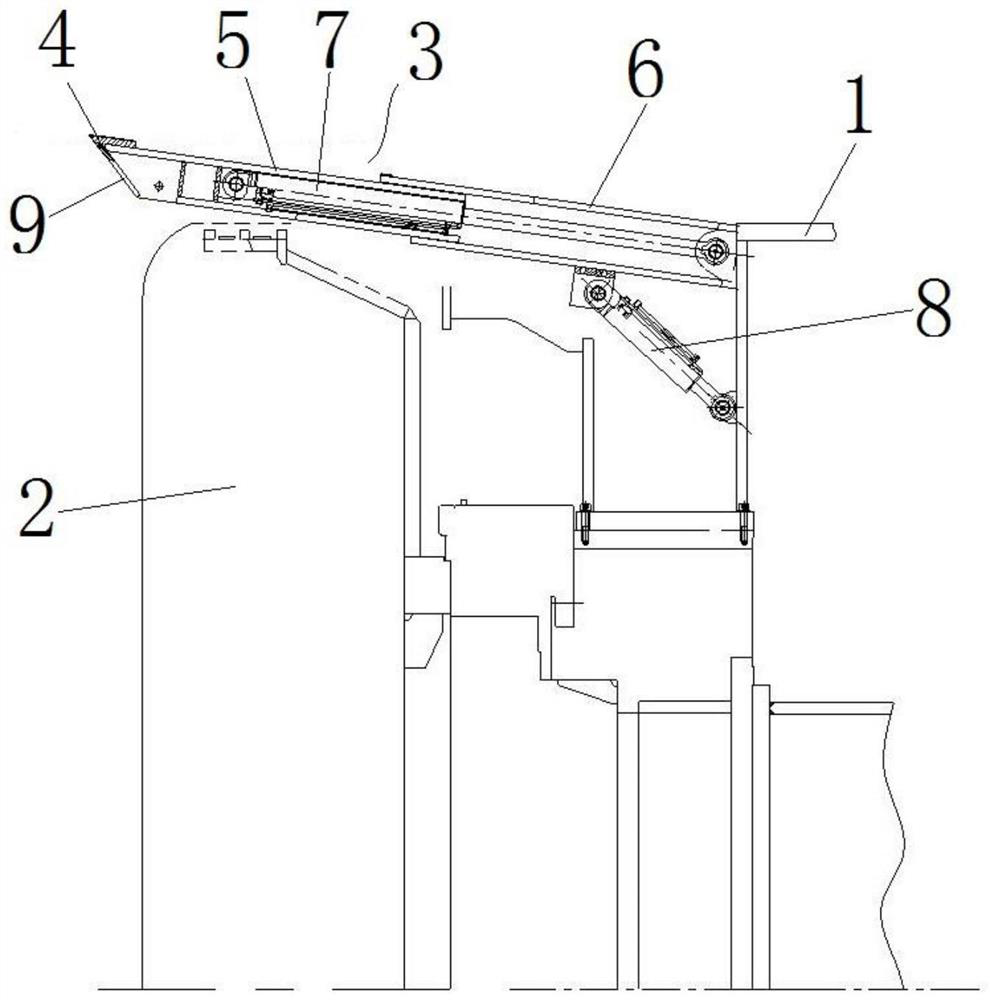

Pre-tightening force adjustable nut assembling and disassembling intelligent device

InactiveCN110144781AAutomatic Quick AlignmentAdapt to installationRailway track constructionAutomatic controlControl system

The invention discloses a pre-tightening force adjustable nut assembling and disassembling intelligent device. The pre-tightening force adjustable nut assembling and disassembling intelligent device comprises a self-propelled rail vehicle, a four-nut assembling and disassembling multifunctional device, a rechargeable battery pack and inverter and a hydraulic system and control system box; the rechargeable battery pack and inverter provides power for an oil pump and a control system; an oil tank, the oil pump, a hydraulic control system and an automatic control system are arranged in the hydraulic system and control system box; the vehicle rail bears the four-nut assembling and disassembling multifunctional device to rapidly arrive and depart a sleeper changing site; the four-nut assemblingand disassembling multifunctional device is automatically and rapidly aligned with a working position; pre-tightening forces of four nuts are consistent so that the four-nut assembling and disassembling multifunctional device can adapt to mounting of the nuts with different pre-tightening force requirements; collapsing of stone ballasts at the end of a sleeper can be effectively stopped to provide guarantee for rapidly changing a new sleeper; the rail vehicle can self-move on a railway track in a round trip so as to avoid influence on the running of a train; when the rail vehicle gets on andoff a track, the gravity center of the rail vehicle does not rise and the rail vehicle does not bump; the operation is convenient; intelligent control is easy to realize; and the working efficiency inassembling and disassembling the nuts and stopping collapsing of the stone ballasts at the end of the sleeper is high.

Owner:KUNMING UNIV

Drilling powder for geological prospecting and preparation method thereof

The invention belongs to the field of drilling of geological prospecting, and relates to drilling powder for geological prospecting and a preparation method thereof. The drilling powder is characterized by comprising the following raw materials in parts by weight: 700-750 parts of bentonite, 40-60 parts of emulsion polymer, 70-100 parts of sulfonated lignite, 40-70 parts of hydrolyzed polyacrylonitrile ammonium salt, 20-100 parts of lubricant, and 40-60 parts of barite. The drilling powder has multiple effects and strong applicability, is environment-friendly, has low preparation cost, and has the preparation method which is simple and easy to operate.

Owner:濮阳市诚信钻采助剂有限公司

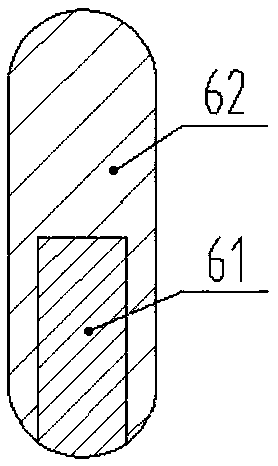

Telescopic anchor rod and construction method thereof

ActiveCN113294187AAdjustable lengthPlay a good role in self-supportClimate change adaptationAnchoring boltsEngineeringStructural engineering

The invention discloses a telescopic anchor rod. The telescopic anchor rod comprises a first anchor rod and a second anchor rod which are rotationally connected through threads; a grout stop plug, a pressure bearing gasket and a grouting head are sequentially arranged at the top end of the first anchor rod from bottom to top and fixedly connected through a nut at the top; the bottom end of the second anchor rod is connected with a drill bit; a spiral rod piece, a drive mechanism, a first blocking piece and a second blocking piece are arranged in a cavity of the first anchor rod and a cavity of the second anchor rod; the drive mechanism is arranged between the first anchor rod and the second anchor rod and connected with the first anchor rod and the second anchor rod through the spiral rod piece; the first blocking piece and the second blocking piece are arranged in the first anchor rod and the second anchor rod correspondingly; on the two sides of the drive mechanism, the top end of the spiral rod piece is connected with the pressure bearing gasket, and the bottom end of the spiral rod piece is connected with the second blocking piece; and the drive mechanism is provided with an open hole for containing the spiral rod piece. The telescopic anchor rod is simple in structure, firm, reliable, convenient and fast to operate, adjustable in length, good in adjusting stability, high in tensile strength, wide in application range and low in cost.

Owner:SHANGHAI INST OF TECH

A method for predicting formation collapse pressure and fracture pressure under the drill bit while drilling

InactiveCN1966934BStop the collapsePrevent downhole complicationsSurveySeismology for water-loggingGeomorphologyWell drilling

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

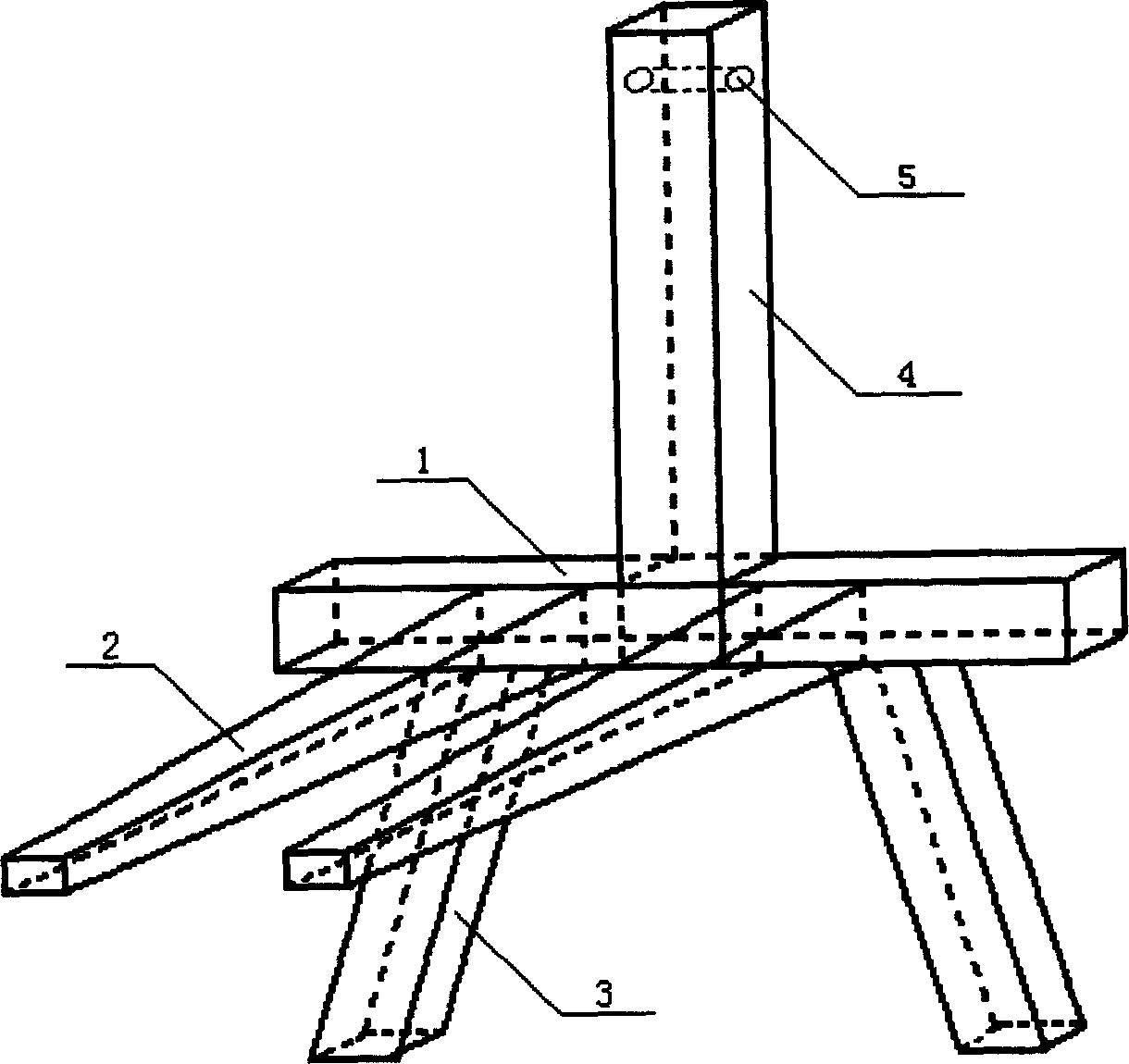

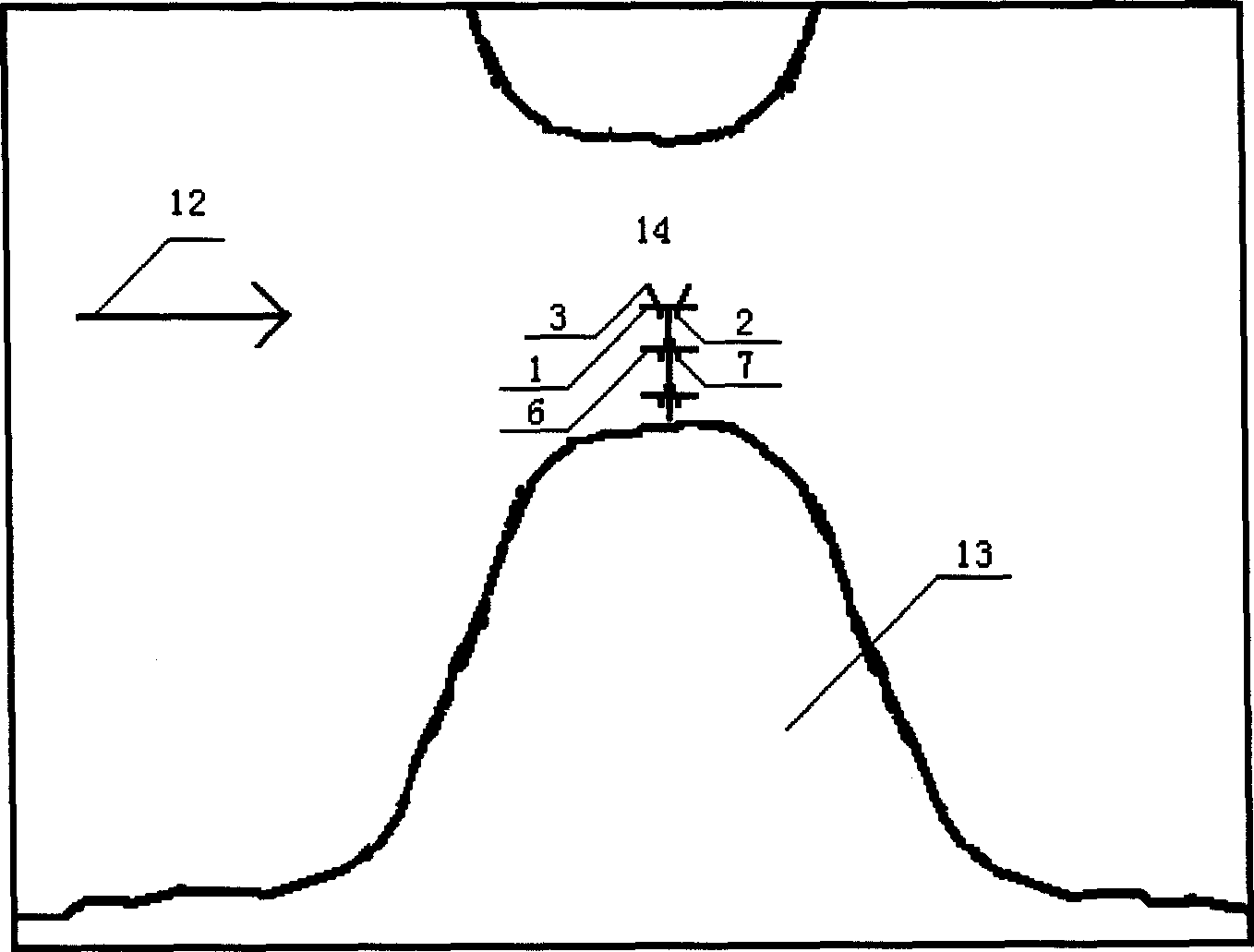

Method for preventing cave-in collapse of cut-off hip dike

A method for preventing collapse of cut-off dyke is characterized by that several shaped reinforced concrete frames, which has one interception arm and more than two supporting legs, are interconnected and arranged on the front slope of said dyke in such manner that their legs are inserted in river bed, and the cut-off material is arranged in the water around said frames.

Owner:WUHAN UNIV

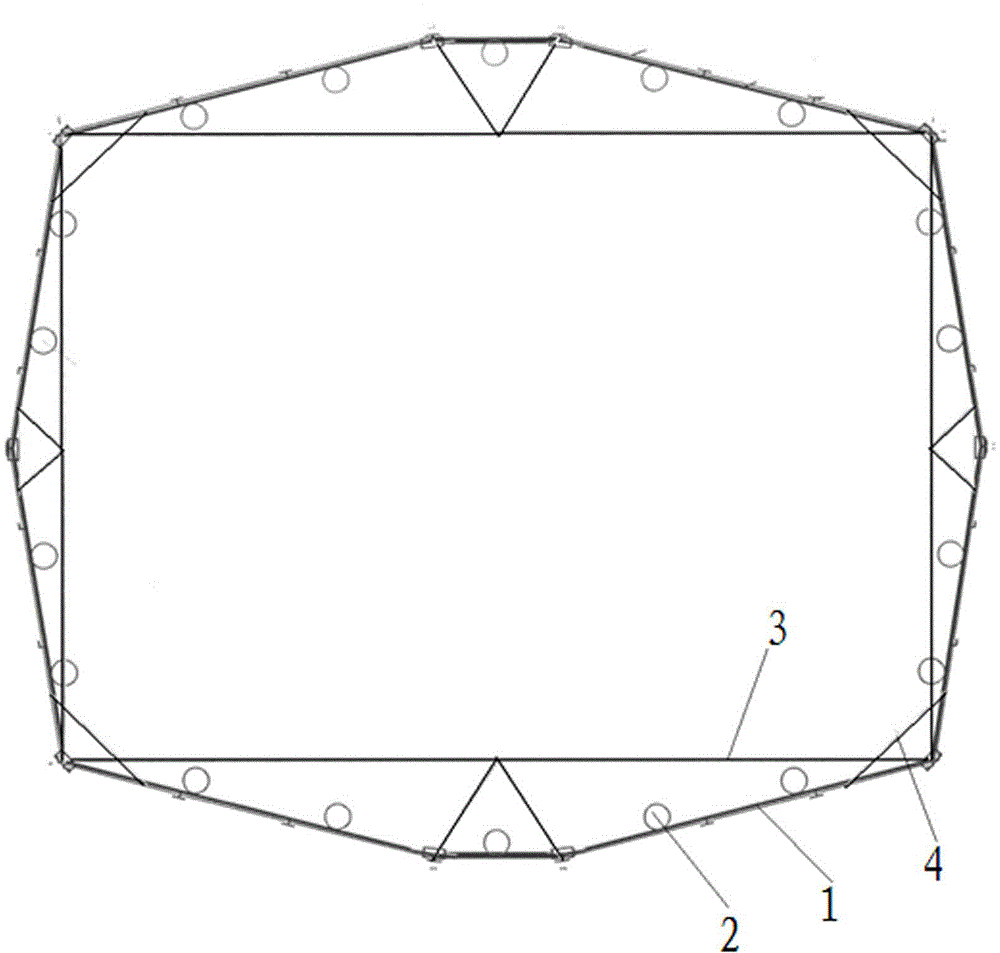

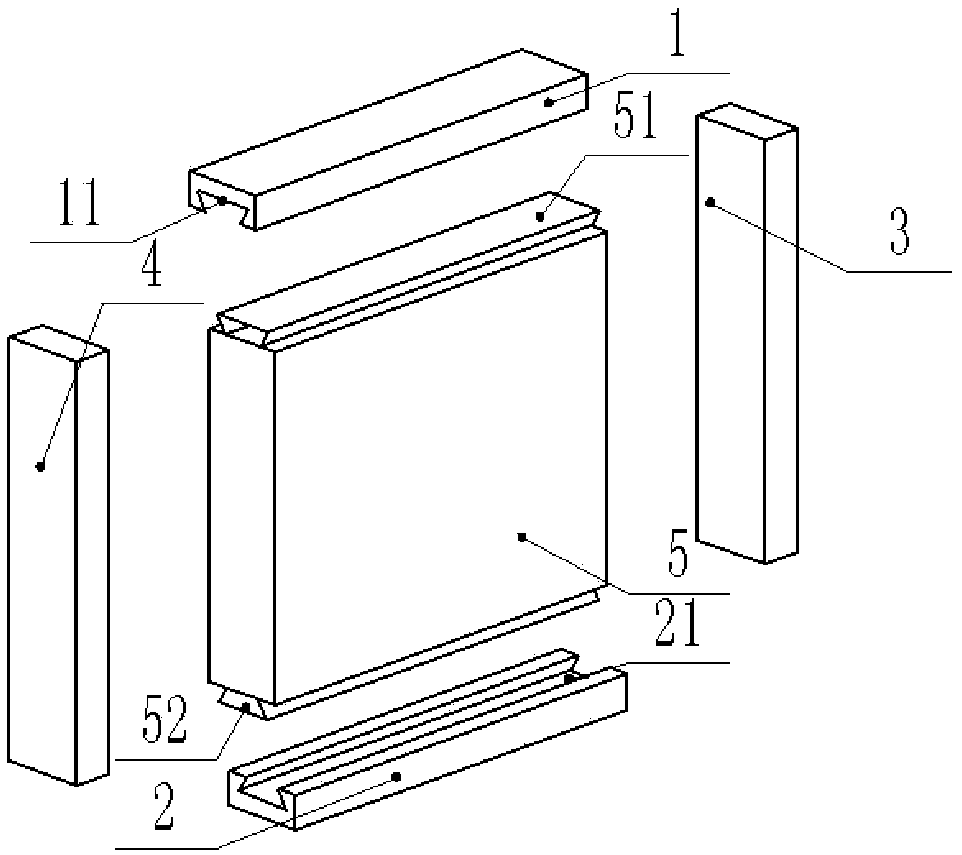

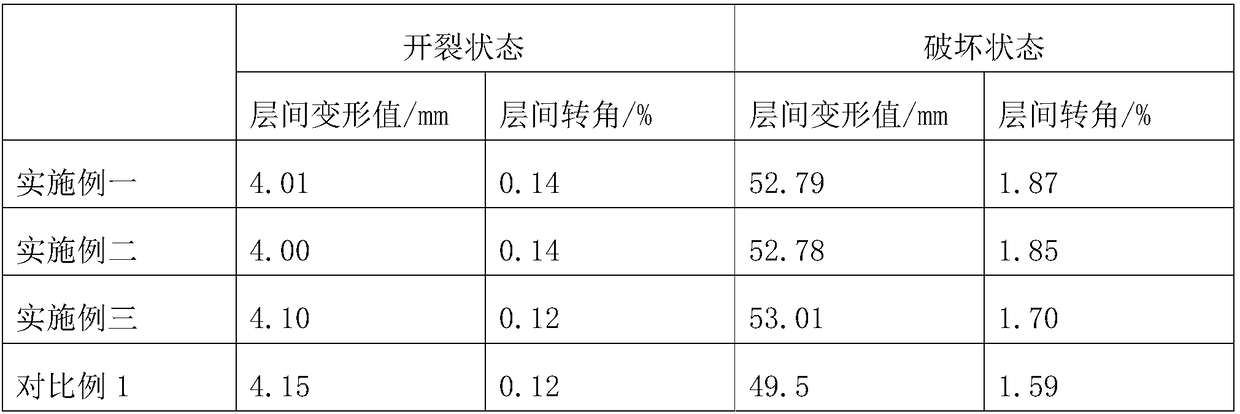

Manufacturing method for seismic lightweight wallboard

ActiveCN109397475ASuitable for a wide range of environmentsWide range of applicationsCeramic shaping apparatusHydroxypropylmethyl cellulosePolystyrene particle

The invention relates to the field of construction wallboards, in particular to a manufacturing method for a seismic lightweight wallboard. The manufacturing method comprises the step of die making: making a seismic frame die and a cushioning interlayer die which are used for pouring a seismic frame and a cushioning interlayer separately; the step of preparation of pouring materials: selecting ceramisite, high impact resistance polystyrene particles, polypropylene fiber and hydroxypropyl methyl cellulose, and preparing the pouring materials; the step of pouring: putting the pouring materials into the seismic frame die, and forming an upper cross beam, a lower cross beam, a left side beam and a right side beam by pouring; putting the pouring materials into the cushioning interlayer die, andforming the cushioning interlayer by pouring; and the step of wallboard making: connecting the cushioning interlayer with tongue-and-groove of the upper cross beam and the lower cross beam through tenon, and fixedly connecting the left side beam and the right side beam with the upper cross beam and the lower cross beam. According to the manufacturing method, the problems of low rigidity and poorseismic performance of an existing wallboard are solved.

Owner:重庆成维轻质墙板有限公司

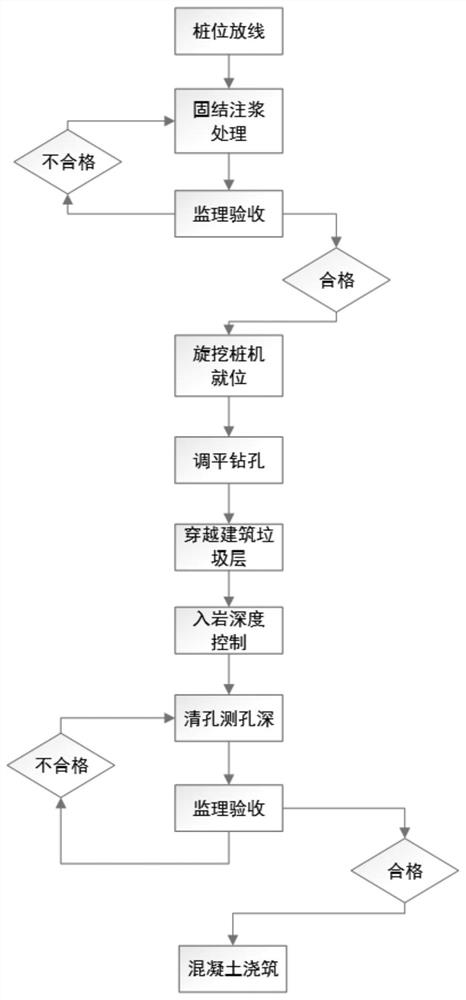

Construction method for crossing construction waste rotary excavating pile

InactiveCN112726565AStop the collapseSolve the situation of collapsed holesBulkheads/pilesSoil preservationArchitectural engineeringStructural engineering

The invention provides a construction method of a crossing construction waste rotary excavating pile. The construction method includes the steps of S1, paying off at a pile position; S2, carrying out consolidation grouting treatment; S3, carrying out supervision and acceptance; S4, placing a rotary drilling rig; S5, carrying out leveling and drilling; S6, crossing a construction waste layer; S7, controlling rock entering depth; S8, cleaning a hole and measuring the depth of the hole; S9, carrying out supervision and acceptance; and S10, carrying out concrete pouring. According to the construction method of the crossing construction waste rotary excavating pile, the construction quality of penetrating through the construction waste rotary excavating pile can be improved, the working efficiency is improved, and the construction period is shortened.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU

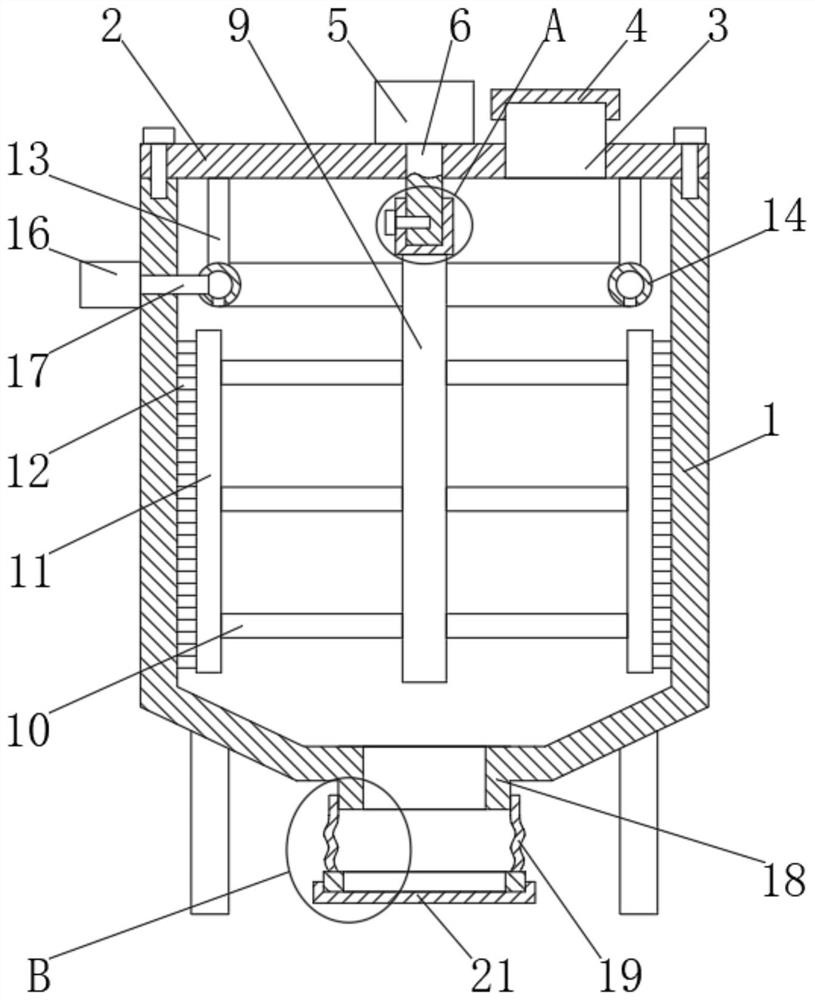

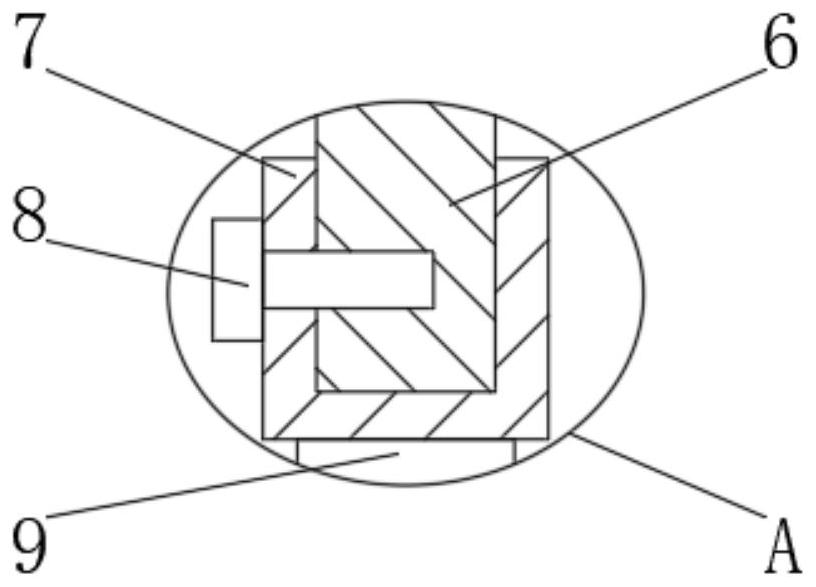

Artificial well wall sand control based on CMAS technologyand water control construction process thereof

The invention belongs to the technical field of artificial well wall sand control, and particularly relates to an artificial well wall sand control based on a CMAS technology, a water control construction process thereof and a stirring device. The sand control is prepared from the following raw materials in parts by weight: 10-20 parts of calcium oxide, 20-30 parts of magnesium oxide, 8-10 parts of aluminum oxide, 30-40 parts of silicon dioxide, 5-7 parts of copper peroxide, 6-8 parts of borax powder, 4-6 parts of furnace slag, and 8-10 parts of fly ash. According to the technology, clean water or reinjection sewage is used for carrying a CMAS sand control agent to a well bottom oil layer deficit position, the CMAS sand control agent and a rock stratum are self-cemented and solidified to form a high-strength and high-permeability artificial rock stratum, sand migration is prevented, and oil layer collapse is prevented.

Owner:孙波 +1

Artificial borehole wall sand prevention and water control construction process based on CMAS technology

InactiveCN112811878AStop the collapseInhibit migrationFlexible article cleaningDrilling compositionMagnesiumSewage

The invention belongs to the technical field of artificial borehole wall sand prevention, and particularly relates to an artificial borehole wall sand prevention based on a CMAS technology, which is prepared from the following raw materials in parts by weight: 10-20 parts of calcium oxide, 20-30 parts of magnesium oxide, 8-10 parts of aluminum oxide, 30-40 parts of silicon dioxide, 5-7 parts of copper peroxide, 6-8 parts of borax powder, 4-6 parts of furnace slag and 8-10 parts of fly ash. According to the technology, clean water or reinjection sewage is used for carrying the CMAS sand control agent to a well bottom oil layer deficit position, the CMAS sand control agent and a rock stratum are self-cemented and solidified to form a high-strength and high-permeability artificial rock stratum, sand migration is prevented, and oil layer collapse is prevented.

Owner:孙波

Method for preparing noble metal/TiO2-C catalyst for hydrofining of crude terephthalic acid

ActiveCN102139211BSmall specific surface areaStop the collapseCatalyst carriersOrganic compound preparationHydrogenOrganic solvent

The invention discloses a method for preparing a noble metal / TiO2-C catalyst for hydrofining of crude terephthalic acid. The method sequentially comprises the following steps of: (1) adding a macromolecular compound into an organic solvent to obtain clarified solution containing the macromolecular compound; (2) adding TiO2 powder; (3) adding TiO2 powder and gel, and performing extrusion molding; and (4) soaking the TiO2-C composite carrier obtained in the step (3) into solution containing a noble metal compound, and performing calcination and hydrogen reduction to obtain the noble metal / TiO2-C catalyst for hydrofining of the crude terephthalic acid. The Pd / TiO2-C catalyst has high specific surface area and pore volume, stable crystal structure and high activity; and the terephthalic acid after hydrofining has low impurity content. The preparation method is simple in process, does not produce any adverse influence on the catalyst, and is suitable for industrialized production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing TiO2-C composite carrier for p-carboxybenzaldehyde hydrogenation process

ActiveCN102139230BSmall specific surface areaStop the collapseCatalyst carriersOrganic compound preparationOrganic solventCrystal structure

The invention discloses a method for preparing a TiO2-C composite carrier for a p-carboxybenzaldehyde hydrogenation process. The preparation method sequentially comprises the following steps of: (1) adding a macromolecular compound into an organic solvent to obtain clarified solution containing the macromolecular compound; (2) adding a part of TiO2 powder; and (3) mixing the macromolecular compound modified TiO2 powder obtained in the step (2), the reset TiO2 powder and gel uniformly, kneading the mixture uniformly, and performing extrusion molding. The obtained formed product is thermally solidified and roasted in nitrogen atmosphere to form the TiO2-C composite carrier. The TiO2-C composite carrier has high specific surface area and pore volume and stable crystal structure, a Pd / TiO2-C catalyst prepared by using the carrier has high activity, and the conversion rate of the p-carboxybenzaldehyde can reach 99.5 percent. The preparation method is simple in process and is suitable for industrialized production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Suspended formwork lining method for cover arch outside tunnel portal with weak surrounding rocks

ActiveCN103362523BEnsuring a safe entryAvoid displacementUnderground chambersTunnel liningSupporting systemReinforced concrete

The invention discloses a suspended formwork lining method for a cover arch outside a tunnel portal with weak surrounding rocks. The method comprises the following steps of mounting a first cover arch grid steel frame and a small advanced pipe shed to form a tunnel locking port; mounting second and third groups of cover arch grid steel frames to form an integral steel frame; arranging longitudinal steel pipes, laying bamboo plywood, and connecting the longitudinal steel pipes and the integral steel frame to form a formwork support system by using iron wires; pouring concrete to finish the construction of a reinforced concrete cover arch, and the like. According to the method, a framework is arranged in reinforced concrete to serve as a support system for a concrete formwork, and a suspended formwork construction technology is adopted for pouring the concrete, so that support to the front slope of the tunnel portal with the weak surrounding rocks is formed within an extremely short time, the displacement and the glide of the open channel front slope and the open channel side slope of the portal are effectively prevented, the large-area collapse of an open channel mountain body is prevented, and the safety holing of a tunnel is ensured; and the method is applied to temporary projects under the emergency conditions of lack of external support components for concrete-poured formworks, irregular poured concrete structures, high requirements on construction time and high speed.

Owner:CHONGQING JUNENG CONSTR GRP +1

A kind of anti-seismic lightweight wall panel manufacturing method

The invention relates to the field of construction wallboards, in particular to a manufacturing method for a seismic lightweight wallboard. The manufacturing method comprises the step of die making: making a seismic frame die and a cushioning interlayer die which are used for pouring a seismic frame and a cushioning interlayer separately; the step of preparation of pouring materials: selecting ceramisite, high impact resistance polystyrene particles, polypropylene fiber and hydroxypropyl methyl cellulose, and preparing the pouring materials; the step of pouring: putting the pouring materials into the seismic frame die, and forming an upper cross beam, a lower cross beam, a left side beam and a right side beam by pouring; putting the pouring materials into the cushioning interlayer die, andforming the cushioning interlayer by pouring; and the step of wallboard making: connecting the cushioning interlayer with tongue-and-groove of the upper cross beam and the lower cross beam through tenon, and fixedly connecting the left side beam and the right side beam with the upper cross beam and the lower cross beam. According to the manufacturing method, the problems of low rigidity and poorseismic performance of an existing wallboard are solved.

Owner:重庆成维轻质墙板有限公司

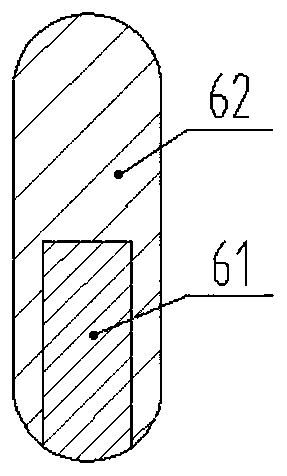

Concrete self-parting composite shear wall with built-in UHPC (Ultra High Performance Concrete)

PendingCN114319649AImprove ductilityImprove carrying capacityWallsProtective buildings/sheltersHigh strength concreteEarthquake resistance

The invention relates to a concrete self-parting composite shear wall with built-in UHPC (Ultra High Performance Concrete), and belongs to the technical field of building structures. Comprising a concrete wall body, a reinforcement cage and a plurality of steel pipes are embedded in the concrete wall body, the steel pipes are arranged on the inner side of the reinforcement cage, the steel pipes are vertically arranged, the steel pipes are arranged at intervals in the length direction of the concrete wall body, and the steel pipes are filled with high-strength concrete. The problems that a concrete shear wall in the prior art is poor in anti-seismic property and the like are solved.

Owner:CSCEC STRAIT CONSTR & DEV

Full-section hard rock tunnel boring machine

PendingCN114508359ASolve the technical problem of the broken stone that is easy to be collapsedAvoid enteringTunnelsRock tunnelTunnel boring machine

The invention aims to provide a full-section hard rock tunnel boring machine to solve the technical problem that a cutter head is easily blocked by collapsed broken stones when a TBM (Tunnel Boring Machine) is used for tunneling in a hard rock crushing area in the prior art. The full-section hard rock tunnel boring machine comprises a cutterhead and a shield, the shield comprises a shield body, a main drive and slotting tool protection mechanisms are arranged in the shield body, the slotting tool protection mechanisms are arranged at intervals in the circumferential direction of the shield body, each slotting tool protection mechanism comprises a swing arm hinged to the shield body, and a swing arm driving mechanism for driving the swing arm to swing in a pitching mode is connected to the swing arm. A slotting tool is movably installed on the swing arm in the length direction of the swing arm. The swing arm is further provided with a slotting tool driving mechanism for driving the slotting tool to reciprocate in the length direction of the swing arm, and after the swing arm driving mechanism drives the swing arm to swing towards the outside of the shield body, the slotting tool driving mechanism can drive the slotting tool to move forwards to be inserted into surrounding rock on the front side of the swing arm from the radial outer side of the cutter head.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com