Concrete self-parting composite shear wall with built-in UHPC (Ultra High Performance Concrete)

A technology for combining shear walls and concrete walls, applied to walls, structural elements, building components, etc., can solve problems such as poor seismic performance, improve bearing capacity and ductility, increase seismic resistance, and improve bonding performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

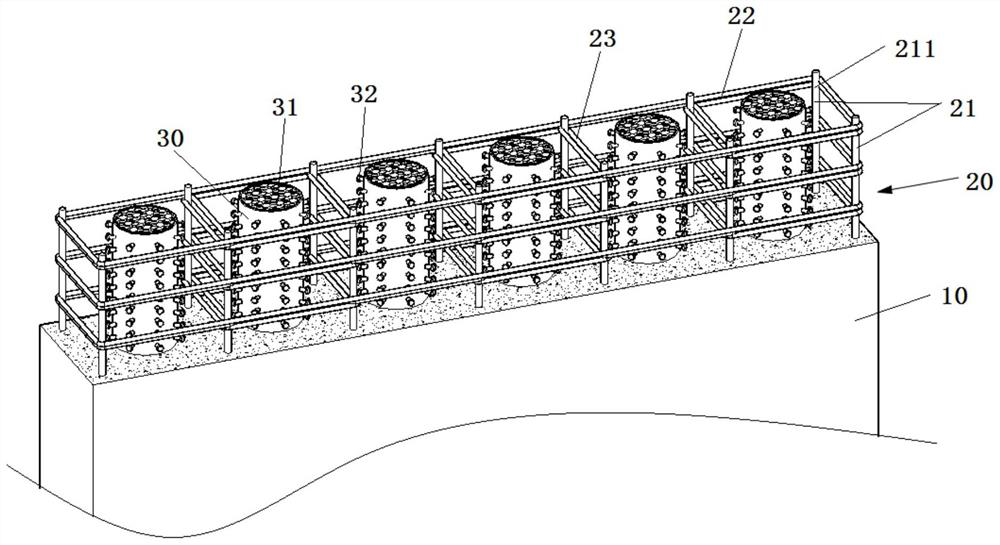

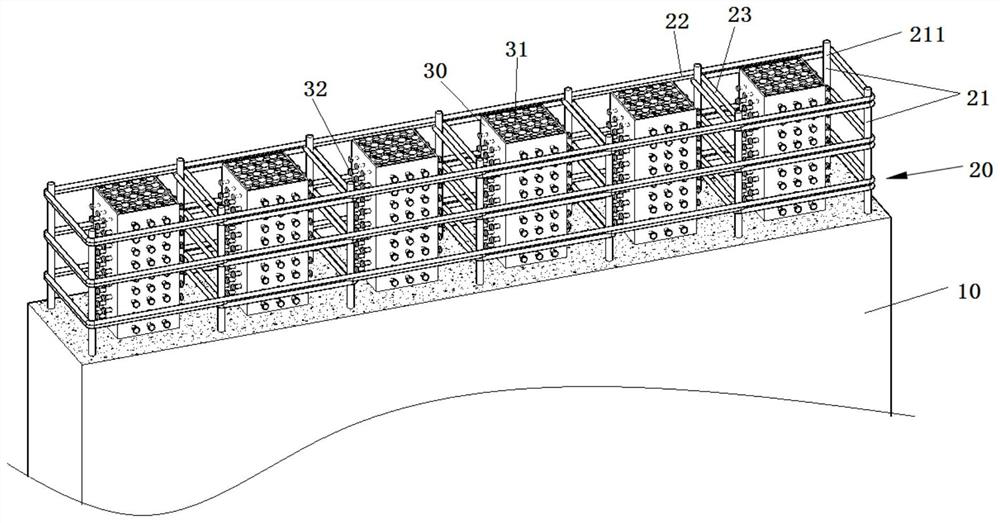

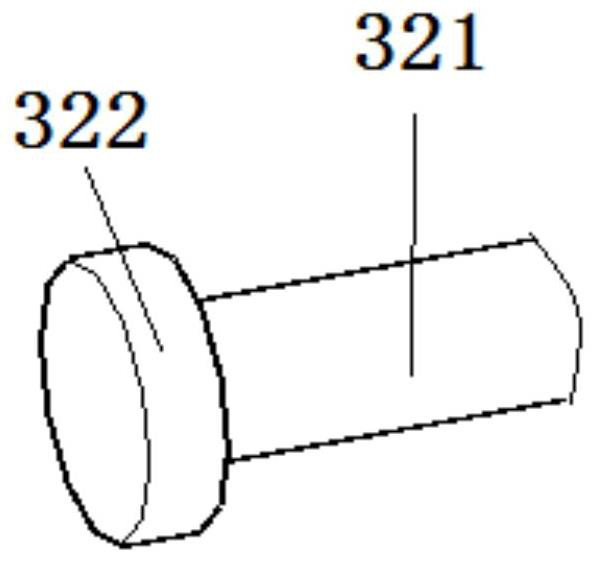

[0026] Such as Figure 1-3 As shown, the concrete self-partitioning composite shear wall with built-in UHPC in this embodiment includes a concrete wall 10, and a reinforcement cage 20 and a plurality of steel pipes 30 are buried inside the concrete wall 10, and a plurality of steel pipes 30 are arranged inside the reinforcement cage 20 , the steel pipes 30 are vertically arranged, and a plurality of steel pipes 30 are arranged at intervals along the length direction of the concrete wall 10, and the steel pipes 30 are filled with high-strength concrete 31, and the steel pipes 30 are built into the concrete wall 10 to improve the ductility of the wall, and also to The high-strength concrete 31 in the steel pipe 30 provides constraints and improves the load-bearing capacity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com