Foamy carbon doped ZIF-67 pyrolysis derived carbon material and preparation method thereof

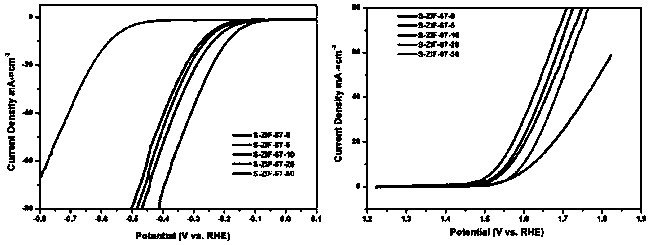

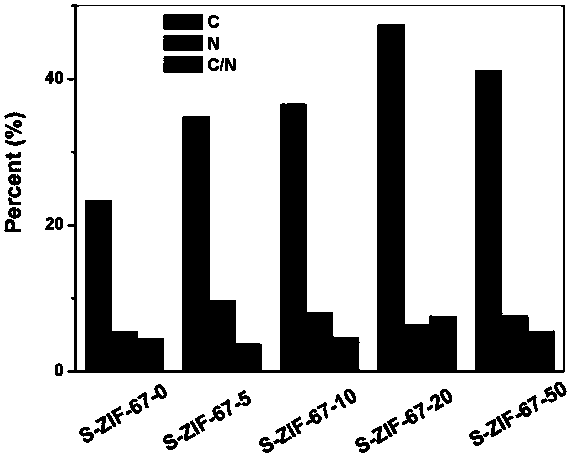

A ZIF-67, carbon foam technology, applied in the field of composite materials, can solve the problems of unsatisfactory performance of bifunctional catalysts, and achieve the effects of excellent oxygen evolution/hydrogen reaction durability, good catalytic performance, and enhanced electron transport ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

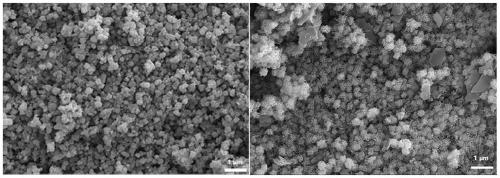

[0045] A kind of carbon foam mixed with ZIF-67 pyrolysis derivative carbon material, the specific preparation method is as follows:

[0046] 1) Put 2g of zinc nitrate hexahydrate and 1g of sucrose in a beaker and mix them uniformly. After obtaining a liquid mixture of sucrose and zinc nitrate in an oil bath at 110°C for 10 minutes, quickly place it in a blast drying oven at 120°C. Place 30min to obtain dark brown zinc-doped carbon foam;

[0047] 2) Dissolve 0.291g of cobalt nitrate hexahydrate and 0.66g of 2-methylimidazole in 15mL of methanol respectively to form a transparent cobalt nitrate solution and 2-methylimidazole solution. After ultrasonication for 10min, mix the two solutions to form a purple solution. Magnetically stir at room temperature for 24 hours, centrifuge the mixed solution and wash several times with methanol alcohol until the supernatant is colorless and transparent, place the purple precipitate after alcohol washing in a vacuum drying oven at 80°C for 12...

Embodiment 2

[0050] A kind of carbon foam mixed with ZIF-67 pyrolysis derivative carbon material, the specific preparation method is as follows:

[0051] 1) Put 2g of zinc nitrate hexahydrate and 1g of sucrose in a beaker and mix them uniformly. After obtaining a liquid mixture of sucrose and zinc nitrate in an oil bath at 120°C for 10 minutes, quickly place it in a blast drying oven at 120°C. Place 30min to obtain dark brown zinc-doped carbon foam;

[0052] 2) Dissolve 0.291g of cobalt nitrate hexahydrate and 0.66g of 2-methylimidazole in 15mL of methanol respectively to form a transparent cobalt nitrate solution and 2-methylimidazole solution. After ultrasonication for 10min, mix the two solutions to form a purple solution. Magnetically stir at room temperature for 24 hours, centrifuge the mixed solution and wash several times with methanol alcohol until the supernatant is colorless and transparent, place the purple precipitate after alcohol washing in a vacuum drying oven at 80°C for 12...

Embodiment 3

[0060] A kind of carbon foam mixed with ZIF-67 pyrolysis derivative carbon material, the specific preparation method is as follows:

[0061] 1) Put 2g of zinc nitrate hexahydrate and 1g of sucrose in a beaker and mix them uniformly. After obtaining a liquid mixture of sucrose and zinc nitrate in an oil bath at 110°C for 10 minutes, quickly place it in a blast drying oven at 120°C. Place 30min to obtain dark brown zinc-doped carbon foam;

[0062] 2) Dissolve 0.291g of cobalt nitrate hexahydrate and 0.66g of 2-methylimidazole in 15mL of methanol respectively to form a transparent cobalt nitrate solution and 2-methylimidazole solution. After ultrasonication for 10min, mix the two solutions to form a purple solution. Magnetically stir at room temperature for 24 hours, centrifuge the mixed solution and wash several times with methanol alcohol until the supernatant is colorless and transparent, place the purple precipitate after alcohol washing in a vacuum drying oven at 80°C for 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com