Full-section hard rock tunnel boring machine

A tunnel boring machine, full-section technology, used in tunnels, mining equipment, earth-moving drilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

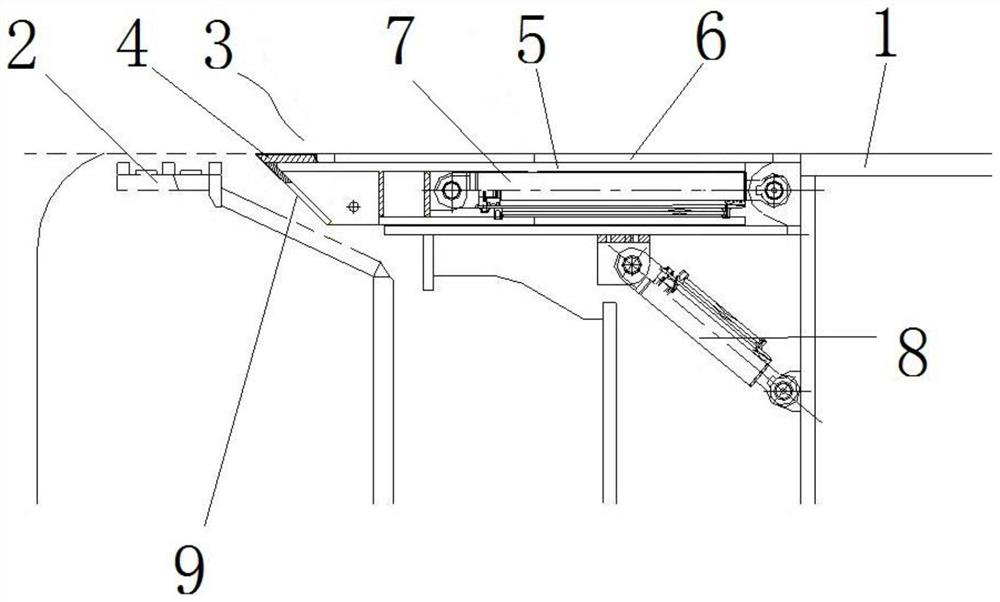

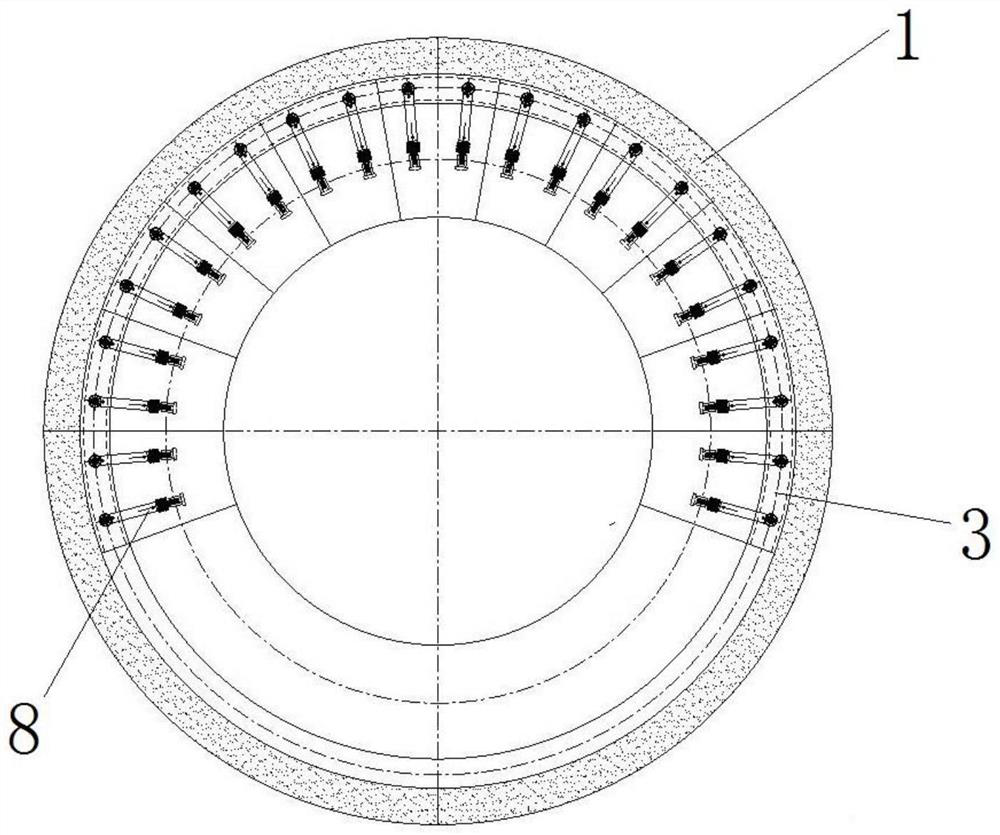

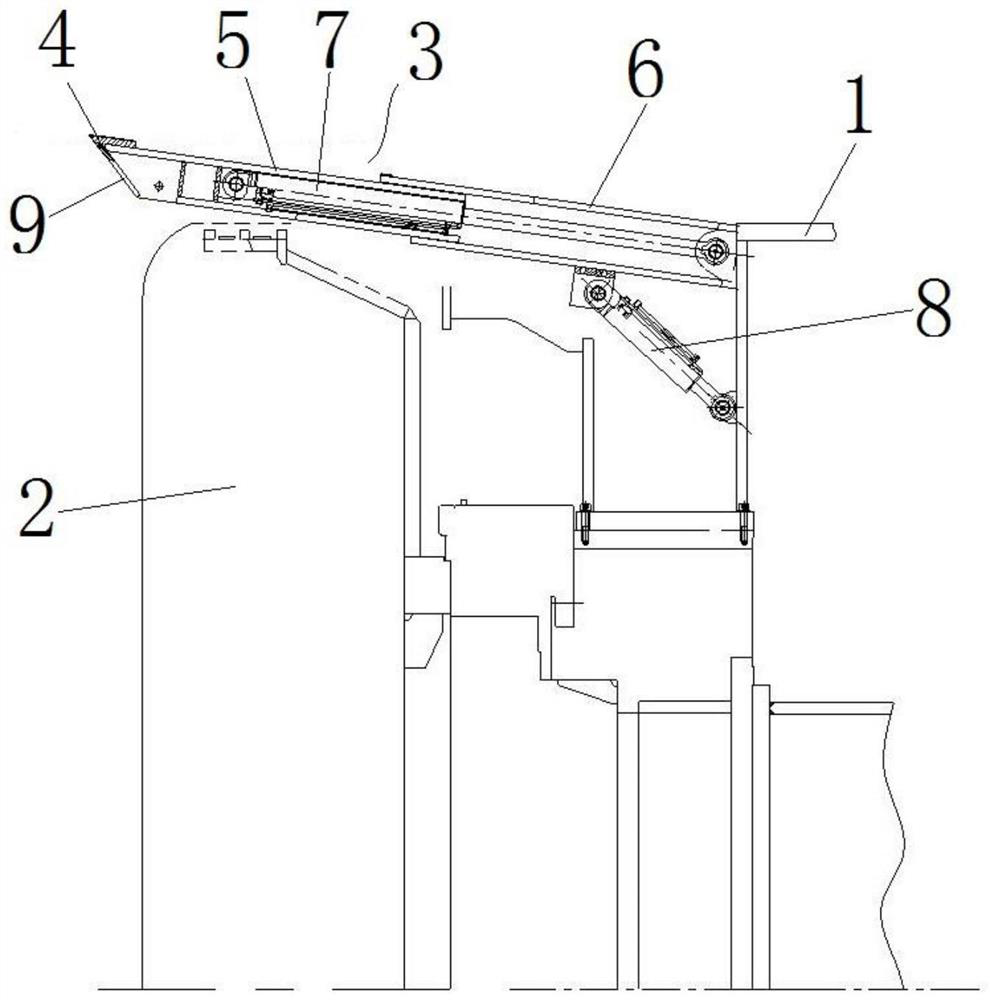

[0035] as Figures 1 through 4 As shown, the full-section hard rock tunnel boring machine comprises cutterhead 2 and a shield located behind cutterhead 2, the shield comprises shield 1, and in shield 1 there is a main drive that drives the cutterhead 2 to rotate. Among them, there is a knife insertion protection mechanism in the shield behind cutterhead 2, and the knife insertion protection mechanism is supported in the extension direction parallel to the shield when the full-section hard rock tunnel boring machine is in a normal boring state, so as to be used as a shield 1 shell on the back side of cutterhead 2, at this time the insertion knife drive mechanism is in a horizontal protection state. When the full-section hard rock tunnel TBM is in the tunneling condition of the falling rock crushing zone, the control knife insertion protection mechanism is expanded outwards, thereby forming a circular support on the outward side of the cutterhead for 2 weeks to prevent the cutterhead...

specific Embodiment 2

[0045]The difference from Example 1 is that, in Example 1, one end of the insert knife 3 is in the pendulum arm 6 and the lumen of the swing arm 6 is coordinated with the anterior and posterior guides. In the present embodiment, both ends of the insertion knife are within the swing arm, i.e., when the insertion knife protection mechanism is located in a horizontal protection state, the insertion knife as a whole is submerged into the inner cavity of the swing arm.

specific Embodiment 3

[0047] The difference from Example 1 is that, in Example 1, one end of the swing arm drive cylinder 8 is hinged on the side of the swing arm 6 towards the inside of the shield 1, the other end is hinged on the shield 1, the swing arm drive cylinder 8 is arranged obliquely in the shield 1 so that the swing arm drive cylinder 8 can be directly ejected out of the shield 1 when extended. In the present embodiment, in order to ensure the swing arm driving cylinder under conventional working conditions on the swing arm support effect, and further protect the swing arm drive cylinder, the swing arm drive cylinder and the swing arm between the additional leverage mechanism, through the transfer of the upper force of the lever mechanism will be the swing arm up, the lever mechanism can greatly reduce the pressure of the swing arm, thereby protecting the swing arm drive cylinder, while reducing the top thrust of the cylinder, increasing the service life, the lever mechanism can be a small c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com